Top 6 Diy Polyurethane Bushings Suppliers (And How to Choose)

Introduction: Navigating the Global Market for diy polyurethane bushings

In today’s competitive landscape, sourcing high-quality DIY polyurethane bushings can present significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a growing demand for custom automotive solutions, understanding the nuances of material selection, manufacturing processes, and supplier reliability is paramount. This guide serves as a comprehensive resource, addressing the various types of polyurethane bushings available, their diverse applications, and the critical factors for vetting suppliers.

By exploring the intricacies of DIY polyurethane bushings, this guide empowers buyers to make informed purchasing decisions. It delves into essential topics such as cost analysis, quality assurance, and the importance of matching specific bushing characteristics to operational needs. Additionally, it highlights best practices for negotiating with suppliers and ensuring compliance with local regulations, which is particularly relevant for markets in Brazil and Nigeria, where import standards may differ significantly.

As you navigate the global market for DIY polyurethane bushings, this guide is designed to equip you with the insights necessary to streamline your procurement process. By leveraging the information within, you can enhance your supply chain efficiency, reduce operational costs, and ultimately drive your business success in an increasingly interconnected world.

Understanding diy polyurethane bushings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Molded Polyurethane Bushings | Custom molded shapes, various hardness options | Automotive suspension, machinery parts | Pros: High durability, customizable; Cons: Higher initial tooling costs. |

| Machined Polyurethane Bushings | Precision machined from solid polyurethane blocks | Aerospace components, high-performance vehicles | Pros: Tight tolerances, excellent performance; Cons: Requires specialized machining equipment. |

| Hybrid Urethane Bushings | Combination of urethane and metal for added strength | Heavy machinery, off-road applications | Pros: Enhanced strength, reduced wear; Cons: More complex manufacturing process. |

| Reinforced Polyurethane Bushings | Incorporation of fibers for increased strength | Industrial machinery, automotive applications | Pros: High load-bearing capacity; Cons: Potentially higher costs due to materials. |

| DIY Urethane Pour Bushings | Made using DIY molding techniques, cost-effective | Custom applications, hobbyist projects | Pros: Low cost, flexibility in design; Cons: Inconsistency in quality without proper techniques. |

What Are Molded Polyurethane Bushings and Their Applications?

Molded polyurethane bushings are produced by pouring liquid polyurethane into a mold, allowing for intricate shapes and varying hardness levels. These bushings are commonly used in automotive suspension systems and machinery parts, where durability and resilience are essential. B2B buyers should consider the initial investment in molds, which can be offset by the long-term benefits of tailored solutions that meet specific load requirements.

How Do Machined Polyurethane Bushings Stand Out?

Machined polyurethane bushings are crafted from solid polyurethane blocks using precision machining techniques. This type is ideal for applications requiring tight tolerances, such as aerospace components and high-performance vehicles. When purchasing, B2B buyers should assess the availability of machining resources and the costs associated with precision manufacturing, as these factors can impact overall project budgets.

What Benefits Do Hybrid Urethane Bushings Provide?

Hybrid urethane bushings combine urethane with metal reinforcements, offering enhanced strength and durability. These bushings are particularly suited for heavy machinery and off-road applications, where extreme conditions are prevalent. Buyers should weigh the complexity of the manufacturing process against the potential performance benefits, particularly in demanding environments.

Why Choose Reinforced Polyurethane Bushings?

Reinforced polyurethane bushings incorporate additional fibers to increase their strength and load-bearing capacity. Commonly used in industrial machinery and automotive applications, these bushings provide a balance of flexibility and resilience. B2B buyers must consider the cost implications of using advanced materials, but the long-term savings from reduced wear and maintenance can justify the investment.

What Are the Advantages of DIY Urethane Pour Bushings?

DIY urethane pour bushings are made using simple molding techniques, making them an affordable option for custom applications and hobbyist projects. This type allows for flexibility in design and is ideal for those looking to experiment with bushing specifications. However, B2B buyers should be aware of the potential for quality inconsistency due to varying levels of skill and technique in the molding process.

Key Industrial Applications of diy polyurethane bushings

| Industry/Sector | Specific Application of diy polyurethane bushings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom suspension components for vehicles | Enhanced durability and performance | Material hardness, compliance with automotive standards |

| Industrial Machinery | Vibration dampening in heavy machinery | Reduced wear and tear, increased lifespan | Load capacity, chemical resistance, and temperature tolerance |

| Construction Equipment | Bushings for excavators and cranes | Improved stability and operational efficiency | Custom sizing, environmental resistance, and durability |

| Aerospace | Lightweight bushings in aircraft systems | Weight reduction, improved fuel efficiency | Compliance with aerospace regulations, material integrity |

| Marine | Bushings for boat trailers and marine engines | Enhanced performance in harsh environments | Corrosion resistance, UV stability, and water exposure tolerance |

How Are diy Polyurethane Bushings Used in Automotive Manufacturing?

In the automotive manufacturing sector, diy polyurethane bushings are often used to create custom suspension components. These bushings replace traditional rubber ones, offering superior durability and performance under high-stress conditions. For international buyers, particularly in regions like Africa and Brazil, the ability to fabricate bushings locally can significantly reduce lead times and costs. Buyers must ensure that the materials used comply with industry standards and can withstand the specific load and environmental conditions of their vehicles.

Illustrative image related to diy polyurethane bushings

What Role Do diy Polyurethane Bushings Play in Industrial Machinery?

In industrial machinery, diy polyurethane bushings serve as effective vibration dampeners. They are essential in heavy machinery, where reducing wear and tear can lead to significant cost savings over time. For businesses in South America and the Middle East, sourcing locally manufactured bushings can enhance operational efficiency while ensuring that the products meet local industrial standards. Buyers should focus on the load capacity and chemical resistance of the bushings to ensure they can withstand the demands of their specific applications.

How Can diy Polyurethane Bushings Improve Construction Equipment?

In the construction industry, diy polyurethane bushings are utilized in equipment such as excavators and cranes. These bushings improve stability and operational efficiency by providing better shock absorption and reducing maintenance needs. For B2B buyers in Europe, the ability to customize bushings to fit specific machinery models can lead to enhanced performance. It’s crucial for buyers to consider custom sizing and environmental resistance, particularly in regions with extreme weather conditions.

Why Are diy Polyurethane Bushings Important in Aerospace Applications?

In aerospace, lightweight diy polyurethane bushings are critical components used in various systems to reduce weight and improve fuel efficiency. Given the stringent regulations in the aerospace industry, international buyers must ensure that the bushings comply with all relevant safety and performance standards. Buyers should prioritize material integrity and durability, as these factors significantly impact aircraft performance and safety.

How Do diy Polyurethane Bushings Enhance Marine Applications?

In the marine industry, diy polyurethane bushings are often applied in boat trailers and marine engines. They provide enhanced performance in harsh environments, including resistance to saltwater and UV exposure. For businesses operating in coastal regions, sourcing durable bushings can improve the longevity of their equipment. When purchasing, it’s essential to consider corrosion resistance and the bushings’ ability to withstand prolonged water exposure, ensuring reliable performance in maritime conditions.

Illustrative image related to diy polyurethane bushings

3 Common User Pain Points for ‘diy polyurethane bushings’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Materials for DIY Polyurethane Bushings

The Problem:

Many B2B buyers, particularly those operating in regions like Africa and South America, often face challenges when sourcing high-quality materials for DIY polyurethane bushings. Local suppliers may offer limited options or subpar products that don’t meet the required specifications for durability and performance. This can lead to increased costs and project delays, especially when trying to adhere to international standards or specific industry regulations.

The Solution:

To mitigate sourcing challenges, buyers should establish relationships with reputable suppliers who specialize in polyurethane materials. Conduct thorough research to identify manufacturers or distributors with a proven track record in the industry. Utilize platforms such as Alibaba or local trade fairs to connect with suppliers and request samples to test for quality. Additionally, consider forming strategic partnerships with international suppliers who can provide bulk purchasing options, reducing costs and ensuring consistent supply. By creating a well-defined specification for the bushings, including hardness, flexibility, and resistance to environmental factors, buyers can better communicate their needs and avoid substandard materials.

Scenario 2: Complex Manufacturing Processes Leading to High Production Costs

The Problem:

B2B buyers often encounter high production costs due to the complexity of manufacturing DIY polyurethane bushings. The processes involved in molding and machining these components can be labor-intensive, requiring specialized equipment and skilled labor. For many businesses, especially smaller manufacturers, this translates to significant overhead costs that can hinder profitability and competitiveness in the market.

The Solution:

To optimize the manufacturing process and reduce costs, buyers should invest in training for their workforce to enhance skills in molding techniques and machining practices specific to polyurethane materials. Implementing lean manufacturing principles can also streamline operations, minimizing waste and improving efficiency. Additionally, consider using automated equipment for repetitive tasks, which can lower labor costs and increase production speed. Exploring alternative manufacturing methods, such as 3D printing for prototypes or small runs, can also provide cost-effective solutions while maintaining quality standards.

Scenario 3: Inconsistent Performance and Quality Control Issues

The Problem:

Another common pain point for B2B buyers is the inconsistent performance of DIY polyurethane bushings, which can arise from variations in material properties or manufacturing processes. Without stringent quality control measures in place, the resulting bushings may not perform as expected, leading to equipment failures, increased maintenance costs, and potential safety risks in applications ranging from automotive to industrial machinery.

The Solution:

To ensure consistent quality and performance, buyers should implement a robust quality assurance program that includes regular testing of materials and finished products. Establish clear performance metrics based on industry standards and conduct routine inspections throughout the production process. Investing in advanced testing equipment to measure properties such as hardness, tensile strength, and wear resistance will provide valuable insights into the quality of the bushings being produced. Additionally, fostering a culture of continuous improvement within the manufacturing team can lead to innovations in production techniques and materials, ultimately enhancing product reliability and customer satisfaction.

Strategic Material Selection Guide for diy polyurethane bushings

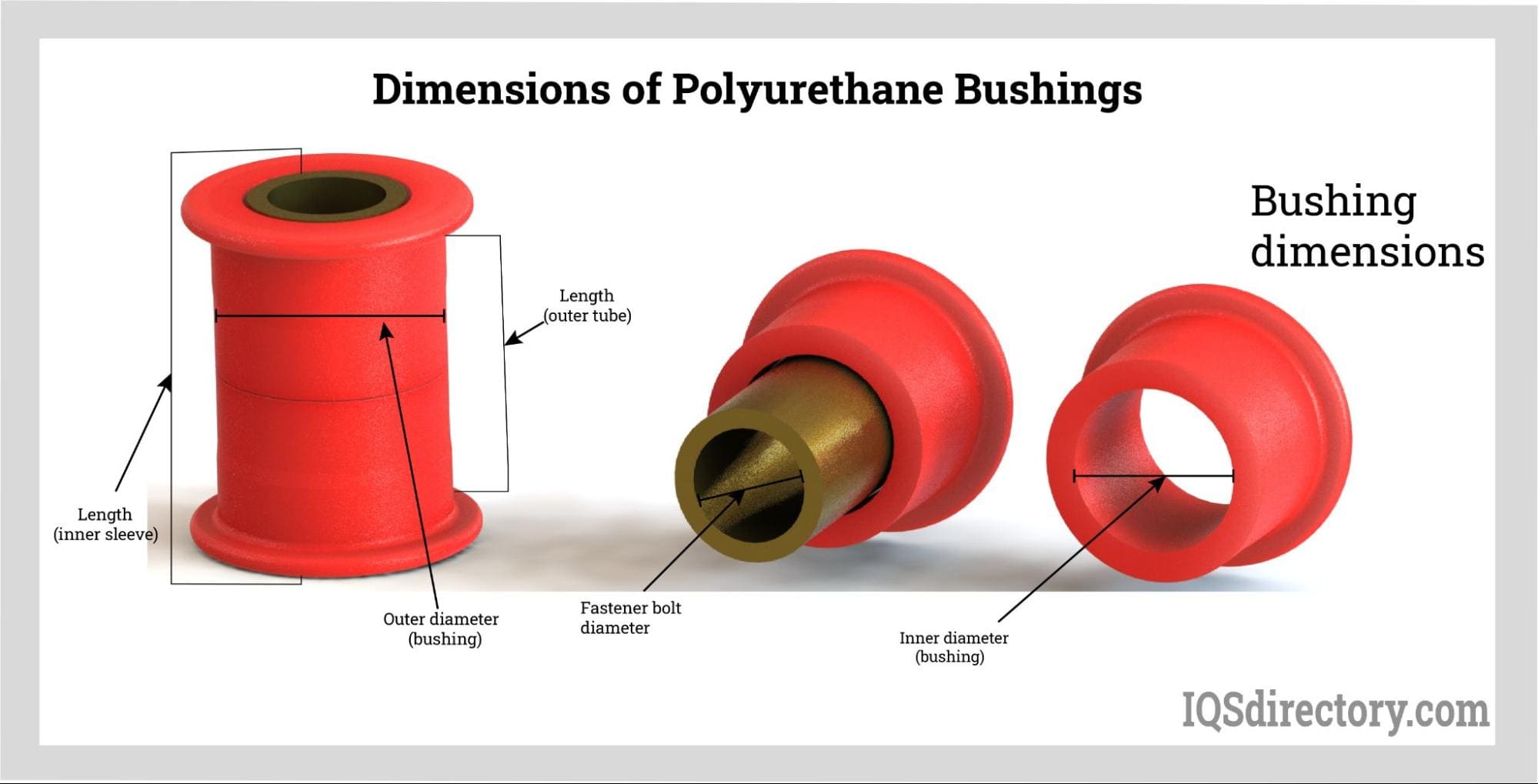

What Are the Key Properties of Common Materials for DIY Polyurethane Bushings?

When selecting materials for DIY polyurethane bushings, various options are available, each with distinct properties and implications for performance. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Urethane?

Urethane, specifically formulated for bushing applications, is a versatile thermosetting polymer. It exhibits excellent resistance to wear, abrasion, and a broad range of temperatures, typically from -30°C to 80°C. Urethane also has good chemical resistance, making it suitable for automotive and industrial applications.

Illustrative image related to diy polyurethane bushings

Pros: Urethane bushings are known for their durability and ability to withstand significant stress, making them ideal for performance applications. They also provide better vibration dampening compared to traditional rubber bushings.

Cons: The manufacturing complexity can be higher, especially when creating custom molds. Additionally, urethane can be more expensive than conventional rubber, which may impact budget-sensitive projects.

Impact on Application: Urethane is compatible with various automotive fluids, including oils and greases, which is critical for applications in harsh environments.

Considerations for International Buyers: Compliance with international standards such as ASTM D2000 and DIN 53505 is essential. Buyers should also consider local availability and sourcing options to ensure timely production.

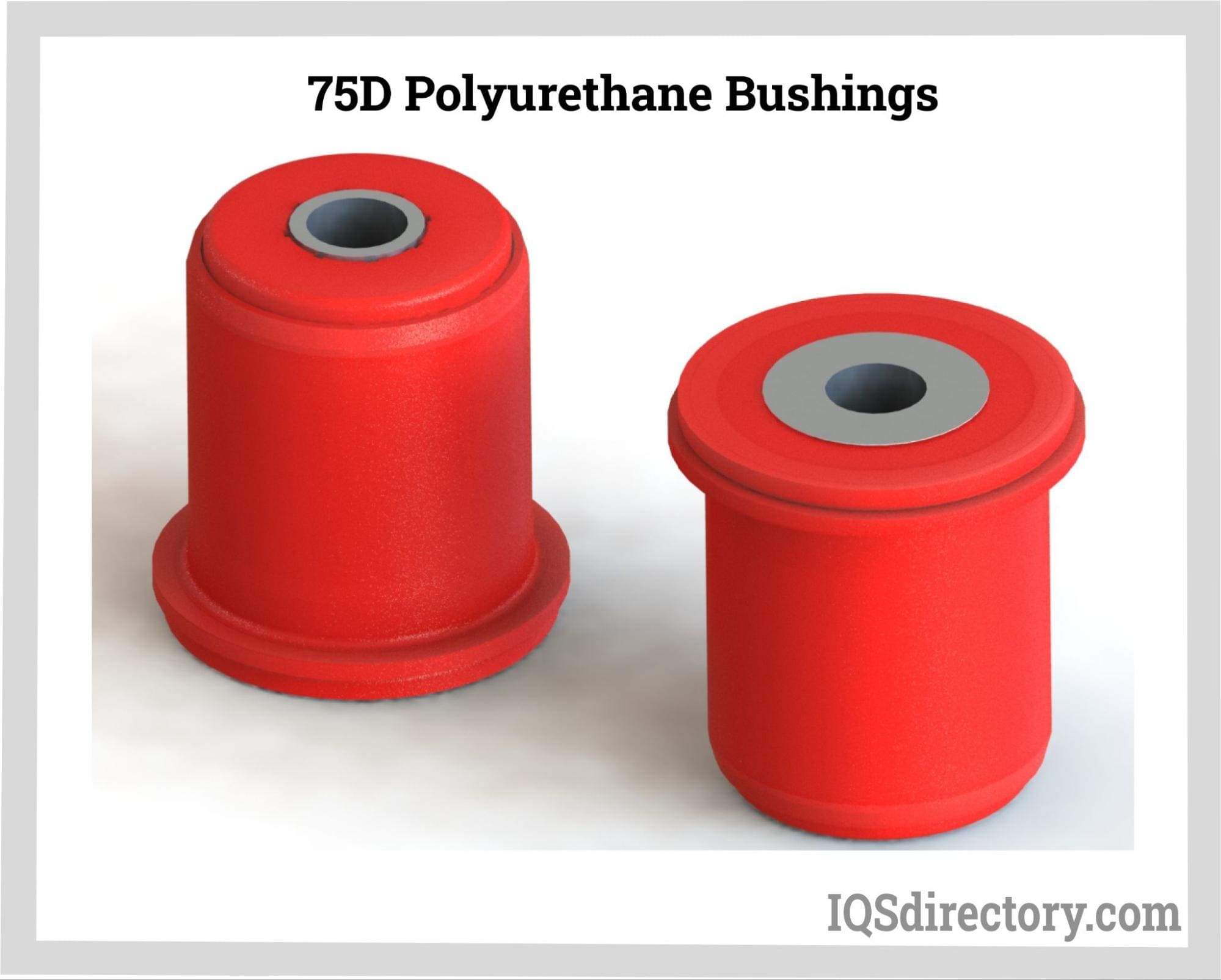

How Does Delrin Compare as a Material for Bushings?

Delrin, or polyoxymethylene (POM), is a high-performance thermoplastic known for its stiffness and low friction properties. It operates effectively in temperatures up to 90°C and offers excellent dimensional stability.

Illustrative image related to diy polyurethane bushings

Pros: Delrin bushings provide superior strength and rigidity, making them suitable for high-load applications. They are also resistant to moisture and many chemicals, enhancing their longevity.

Cons: The primary drawback is the higher cost and the need for precision machining, which can complicate the manufacturing process. Additionally, Delrin lacks the flexibility of urethane, which may limit its application in dynamic environments.

Impact on Application: Delrin’s low friction characteristics make it ideal for applications where movement is frequent, such as in suspension systems.

Considerations for International Buyers: Buyers should ensure that suppliers can meet machining specifications and that the material complies with relevant standards such as ISO 9001 for quality management.

Illustrative image related to diy polyurethane bushings

What Advantages Do Rubber Materials Offer for DIY Bushings?

Traditional rubber materials, such as natural rubber or synthetic variants, have been used for bushings for decades. They offer good elasticity and can withstand a wide range of temperatures.

Pros: Rubber is cost-effective and provides excellent vibration dampening, making it suitable for everyday applications.

Cons: However, rubber is less durable than urethane and Delrin, particularly in high-stress environments. It can degrade over time due to exposure to oils and UV light.

Impact on Application: Rubber is compatible with various automotive fluids but may not perform well under extreme conditions.

Considerations for International Buyers: Buyers should be aware of the specific rubber grades and their compliance with standards like ASTM D2000, especially in regions with stringent automotive regulations.

What Role Does Metal Play in Bushings?

Metal bushings, often made from aluminum or steel, provide exceptional strength and durability. They can operate effectively in high-temperature and high-load applications.

Pros: Metal bushings are highly durable and can withstand significant wear and tear, making them suitable for heavy-duty applications.

Cons: The primary limitation is their weight and potential for corrosion, particularly in humid or saline environments. Additionally, they may not provide the same level of vibration dampening as polymer-based bushings.

Impact on Application: Metal bushings are often used in applications where strength is prioritized over flexibility, such as in industrial machinery.

Considerations for International Buyers: Buyers should consider corrosion resistance and compliance with standards such as ASTM A536. They should also evaluate local sourcing options to mitigate shipping costs.

Illustrative image related to diy polyurethane bushings

Summary Table of Material Selection for DIY Polyurethane Bushings

| Material | Typical Use Case for DIY Polyurethane Bushings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Urethane | Automotive suspension and performance applications | Excellent wear resistance and vibration dampening | Higher manufacturing complexity | Medium |

| Delrin | High-load applications requiring low friction | Superior strength and rigidity | Requires precision machining | High |

| Rubber | General automotive applications | Cost-effective and good vibration dampening | Less durable under extreme conditions | Low |

| Metal | Heavy-duty industrial applications | Exceptional strength and durability | Heavier and prone to corrosion | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for diy polyurethane bushings

What Are the Key Stages in the Manufacturing Process of DIY Polyurethane Bushings?

The manufacturing process of DIY polyurethane bushings involves several critical stages that ensure the final product meets performance and durability standards. Understanding these stages is essential for B2B buyers looking to source quality bushings for automotive or industrial applications.

1. Material Preparation: What Materials Are Used for Polyurethane Bushings?

The primary material for manufacturing polyurethane bushings is urethane, a versatile polymer known for its resilience and flexibility. Depending on the application, the hardness of the urethane can be adjusted, typically measured on the Shore hardness scale.

Before production, raw urethane is prepared by mixing two components: a polyol and an isocyanate. This mixture must be handled with care, as the reaction between these components can release gases that need to be managed to ensure safety and quality. For DIY applications, suppliers often provide kits that contain pre-measured components to simplify the process.

Illustrative image related to diy polyurethane bushings

2. Forming: What Techniques Are Used to Shape Polyurethane Bushings?

The forming stage can vary depending on whether the bushings are being molded or machined.

- Molding: This is the most common method for producing polyurethane bushings. A mold is created, typically from a durable material such as aluminum or steel, which can withstand the pressure and heat generated during the curing process. The urethane mixture is poured into the mold, where it hardens over time.

- Machining: In some cases, particularly for high-precision applications, bushings may be machined from solid urethane blocks. This requires specialized equipment such as lathes and CNC machines, allowing for tight tolerances and specific dimensions.

3. Assembly: How Are Polyurethane Bushings Assembled?

After forming, bushings may require assembly with metal components, such as sleeves or inserts. This step ensures that the bushings fit correctly within their designated applications, whether in automotive control arms or industrial machinery.

Assembly may involve:

- Press-fitting metal sleeves into the polyurethane bushings to enhance structural integrity and load-bearing capacity.

- Bonding techniques, such as using adhesives to ensure a strong connection between polyurethane and metal parts.

4. Finishing: What Are the Final Steps in Producing Quality Bushings?

Finishing involves several processes to ensure that the bushings meet specific quality and aesthetic standards. This may include:

- Trimming excess material or flash that occurs during the molding process.

- Surface treatment, such as sanding or polishing, to enhance the finish and prevent wear.

- Coating with a protective layer to improve resistance to environmental factors such as moisture, chemicals, and UV light.

What Quality Assurance Measures Should B2B Buyers Expect for Polyurethane Bushings?

Quality assurance (QA) is crucial in ensuring that the final product adheres to industry standards and customer specifications. B2B buyers should be aware of various QA processes and international standards relevant to polyurethane bushings.

1. What International Standards Should Buyers Look for in Polyurethane Bushings?

Buyers should seek suppliers that adhere to recognized international standards, such as:

- ISO 9001: This standard outlines the criteria for a quality management system and emphasizes customer satisfaction and continuous improvement.

- CE Marking: Essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

- API Certification: For bushings used in the oil and gas industry, API standards ensure that products meet specific operational and safety requirements.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical in identifying defects and ensuring that products meet specifications. Common checkpoints include:

Illustrative image related to diy polyurethane bushings

- Incoming Quality Control (IQC): Assessing raw materials before production to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process through periodic inspections and testing to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections and tests on the finished product to ensure it meets all specifications before shipment.

3. What Testing Methods Are Commonly Used for Polyurethane Bushings?

Several testing methods can be employed to verify the quality of polyurethane bushings:

- Mechanical Testing: Assessing tensile strength, hardness (using the Shore scale), and fatigue resistance to ensure the bushings can withstand operational stresses.

- Environmental Testing: Evaluating the material’s resistance to chemicals, moisture, and temperature fluctuations.

- Dimensional Testing: Using calipers and gauges to ensure that the bushings meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should implement several verification strategies:

1. Conduct Supplier Audits

Regular audits of suppliers’ manufacturing processes and quality control systems provide insights into their operations. This can include reviewing their compliance with ISO 9001 and other relevant certifications.

2. Request Quality Reports

Buyers should ask for documentation of quality control processes, including test results and inspection reports. This transparency helps in assessing the reliability of the supplier.

3. Use Third-Party Inspection Services

Engaging third-party inspection services can add an extra layer of assurance. These services can conduct independent inspections and testing, providing unbiased reports on product quality.

Illustrative image related to diy polyurethane bushings

What Are the Unique QC Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider additional QC nuances:

- Local Regulations: Different countries may have specific regulations regarding materials and product safety. Buyers should ensure that suppliers are compliant with local standards.

- Cultural Differences: Understanding the cultural context can help in navigating negotiations and expectations regarding quality and service levels.

- Logistics and Supply Chain: Buyers should assess the supplier’s capabilities in terms of logistics and the ability to deliver products on time, which can impact quality and performance.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing DIY polyurethane bushings, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diy polyurethane bushings’

To assist B2B buyers in procuring DIY polyurethane bushings effectively, this guide provides a clear checklist of actionable steps. These steps will help ensure that you source high-quality materials and products that meet your specific needs.

Illustrative image related to diy polyurethane bushings

Step 1: Define Your Technical Specifications

Before initiating any sourcing activities, clearly outline the technical specifications required for your polyurethane bushings. Consider factors such as hardness (measured on the Shore scale), dimensions, and material compatibility with existing components. Defining these specifications helps prevent costly mistakes and ensures that the bushings will perform as intended in your applications.

Step 2: Research Material Options

Investigate the various types of polyurethane available on the market. Different formulations can offer varying levels of durability, flexibility, and resistance to chemicals. Focus on sourcing high-quality materials that meet industry standards and are suitable for the specific environmental conditions they will encounter.

- Consider Hardness Levels: Identify the hardness level that best suits your application needs.

- Evaluate Environmental Resistance: Look for materials that can withstand specific temperatures and exposure to chemicals relevant to your industry.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, case studies, and references from buyers in similar industries or regions. A reliable supplier should have a proven track record in delivering quality products and excellent customer service.

- Request Samples: Always ask for product samples to evaluate the quality firsthand.

- Check Certifications: Ensure that suppliers have relevant certifications (e.g., ISO) that demonstrate adherence to quality standards.

Step 4: Assess Manufacturing Capabilities

Understand the manufacturing processes employed by your suppliers to produce polyurethane bushings. This includes their capabilities in molding, machining, and any other relevant manufacturing techniques. Knowing their processes helps you gauge whether they can meet your production needs and timelines.

- Inquire About Production Capacity: Confirm that the supplier can handle your order volume.

- Discuss Customization Options: Determine if they offer customization services to meet your specific requirements.

Step 5: Verify Compliance with Industry Standards

Ensure that the bushings comply with relevant industry standards and regulations. This is especially critical in sectors like automotive or aerospace, where safety and performance are paramount. Compliance not only helps avoid legal issues but also enhances the reliability of your products.

- Request Documentation: Suppliers should provide documentation proving compliance with applicable standards.

- Stay Informed on Regulations: Keep abreast of any changes in regulations that may affect your sourcing decisions.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to secure favorable pricing and terms. Consider aspects such as payment schedules, delivery timelines, and warranty provisions. Clear agreements can help mitigate risks and foster a long-term relationship.

- Explore Bulk Discounts: Discuss the potential for discounts on larger orders.

- Clarify Return Policies: Understand the supplier’s return and refund policies in case the products do not meet your expectations.

Step 7: Establish a Quality Control Process

Implement a robust quality control process to monitor the quality of the polyurethane bushings upon receipt. This step is crucial to ensure that the products meet your specifications and perform reliably in your applications.

- Conduct Incoming Inspections: Regularly inspect the quality of materials upon delivery.

- Maintain Communication with Suppliers: Establish open lines of communication to address any quality issues promptly.

By following this comprehensive checklist, B2B buyers can successfully navigate the sourcing process for DIY polyurethane bushings, ensuring they procure high-quality products that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for diy polyurethane bushings Sourcing

Analyzing the cost structure and pricing for DIY polyurethane bushings is essential for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. Understanding the components of cost and the factors influencing pricing can help businesses make informed sourcing decisions.

Illustrative image related to diy polyurethane bushings

What Are the Key Cost Components in DIY Polyurethane Bushings?

-

Materials: The primary cost driver in sourcing DIY polyurethane bushings is the raw materials. Polyurethane, known for its durability and versatility, is available in various grades and formulations, which can significantly impact pricing. For instance, a standard two-part urethane kit may range from $15 to $30, depending on the supplier and quality. Additionally, if custom formulations are required, the costs can increase substantially.

-

Labor: Labor costs can vary based on the complexity of the manufacturing process. If a company opts to manufacture bushings in-house, skilled labor is necessary for tasks such as machining or molding. In regions with lower labor costs, like parts of Africa or South America, this can be a cost-saving measure. However, businesses must weigh these savings against potential quality control issues.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. For businesses sourcing in developed regions, these overheads can be significantly higher, impacting the final pricing of bushings.

-

Tooling: Custom tooling for manufacturing specific bushing designs can be a significant initial investment. This cost is often amortized over large production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring the quality of the bushings is critical, especially for automotive applications where safety is paramount. Implementing rigorous QC processes can incur additional costs but is essential for maintaining product integrity.

-

Logistics: Shipping costs play a crucial role, particularly for international buyers. Factors such as distance, shipping method, and customs duties can add to the overall cost. Businesses should consider Incoterms that best suit their logistical capabilities to mitigate these expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. The margin can vary significantly based on the supplier’s market position and the perceived value of the bushings.

What Influences Pricing for DIY Polyurethane Bushings?

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders due to economies of scale. Buyers should negotiate MOQs that align with their production needs while ensuring cost-effectiveness.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should clarify their requirements upfront to avoid unexpected charges during the sourcing process.

-

Material Quality and Certifications: Higher quality materials that meet specific industry standards will typically come at a premium. Buyers should assess whether the certifications (e.g., ISO, ASTM) are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the implications of Incoterms on shipping responsibilities and costs can help buyers minimize risks and optimize their total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices?

-

Leverage Volume Discounts: Consider consolidating orders to meet higher volume thresholds, which can unlock bulk pricing.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with quality, durability, and maintenance.

-

Negotiate Terms Upfront: Discuss payment terms, shipping costs, and warranties before finalizing agreements to avoid surprises later on.

-

Understand Local Market Dynamics: Buyers in regions like Brazil or Nigeria should be aware of local economic conditions, which can affect pricing and supplier negotiations.

-

Be Open to Alternative Materials: If specifications allow, consider alternative materials that may offer similar performance at a lower cost.

Disclaimer

Prices mentioned are indicative and can vary significantly based on market conditions, supplier negotiations, and specific order requirements. Always consult with multiple suppliers to obtain the most accurate and competitive pricing for your specific needs.

Alternatives Analysis: Comparing diy polyurethane bushings With Other Solutions

Exploring Alternatives to DIY Polyurethane Bushings

In the realm of automotive suspension solutions, DIY polyurethane bushings present an appealing option for enthusiasts and professionals alike. However, several alternatives exist that offer unique benefits and drawbacks. This analysis compares DIY polyurethane bushings to two viable alternatives: pre-manufactured rubber bushings and Delrin bushings. Each option has its own set of characteristics that cater to different requirements and preferences, making it essential for B2B buyers to evaluate their specific needs.

| Comparison Aspect | DIY Polyurethane Bushings | Pre-Manufactured Rubber Bushings | Delrin Bushings |

|---|---|---|---|

| Performance | Excellent durability and stiffness; customizable hardness | Good flexibility and comfort; less durable under extreme conditions | High stiffness and precision; low friction |

| Cost | Low initial cost, depending on materials and tools | Moderate cost; may vary by manufacturer | Higher cost due to machining and materials |

| Ease of Implementation | Requires skills in molding and machining; time-consuming | Quick installation; ready-to-use | Requires machining skills; can be complex |

| Maintenance | Minimal maintenance required; longevity if done correctly | Moderate; may need replacement sooner than alternatives | Low; very durable and long-lasting |

| Best Use Case | Custom applications and enthusiasts seeking performance tuning | General-purpose applications; comfortable rides | Performance-focused setups; precision applications |

What Are the Pros and Cons of Pre-Manufactured Rubber Bushings?

Pre-manufactured rubber bushings are a traditional choice in automotive applications, offering a balance of comfort and performance. They provide good flexibility, which enhances ride quality, making them suitable for everyday driving conditions. However, their durability is often questioned, especially under high-stress situations such as racing or off-road use. They tend to wear out faster than polyurethane options, leading to more frequent replacements. For businesses focusing on standard vehicles without extreme performance needs, rubber bushings remain a viable option.

How Do Delrin Bushings Compare to DIY Polyurethane Options?

Delrin bushings are made from acetal resin, which offers high stiffness and low friction, making them ideal for precision applications. They provide a rigid response that can enhance handling performance, especially in racing scenarios. However, the cost of Delrin bushings is generally higher due to the machining process required to create them. Additionally, while they excel in performance, they may not provide the same level of comfort as rubber or polyurethane options. Businesses that prioritize precision and performance may find Delrin bushings to be a superior choice, despite the increased investment.

Conclusion: How to Choose the Right Bushing Solution for Your Needs

When selecting the right bushing solution, B2B buyers must consider their specific application requirements. DIY polyurethane bushings offer a customizable and cost-effective option for those with the skills and tools to create them, making them ideal for enthusiasts and specialized applications. In contrast, pre-manufactured rubber bushings provide ease of use and comfort for everyday vehicles, while Delrin bushings cater to high-performance needs with their precision engineering. By assessing performance requirements, budget constraints, and installation capabilities, businesses can make an informed decision that best aligns with their operational goals.

Essential Technical Properties and Trade Terminology for diy polyurethane bushings

What Are the Key Technical Properties of DIY Polyurethane Bushings?

When engaging in the production of DIY polyurethane bushings, understanding critical specifications is essential for ensuring quality and performance. Here are several important technical properties to consider:

1. Material Grade

Polyurethane bushings can be made from various grades of urethane, which affects their hardness, durability, and flexibility. The hardness is typically measured on the Shore scale, with common grades ranging from Shore A 70 (soft) to Shore D 90 (hard). Selecting the appropriate grade is crucial, as it influences the bushing’s performance under load, its resistance to wear, and its overall lifespan. For applications requiring more rigidity, a higher Shore hardness is preferable, while softer grades are better suited for absorbing vibrations.

2. Tolerance

Tolerance refers to the acceptable range of variation in the dimensions of the bushings. Tight tolerances are essential in applications where precise fitting is necessary, such as in control arms or suspension systems. A tolerance of ±0.01 inches is often considered standard for high-performance bushings. Inaccurate tolerances can lead to misalignment, increased wear, and potential failure of the components, making this specification critical for durability and performance.

3. Load Capacity

This property indicates the maximum load a bushing can sustain without deformation or failure. Load capacity is particularly important in automotive applications, where bushings are subjected to dynamic forces during operation. Buyers should assess the anticipated loads in their specific applications to select bushings that meet or exceed these requirements, ensuring safety and functionality.

Illustrative image related to diy polyurethane bushings

4. Compression Set

Compression set measures the permanent deformation of a bushing after it has been subjected to a compressive load. A low compression set indicates better resilience and longevity, as the bushing will return to its original shape after the load is removed. This property is vital for maintaining performance over time, especially in high-stress environments.

5. Chemical Resistance

Polyurethane bushings are often exposed to various chemicals, including oils, fuels, and solvents. Assessing chemical resistance is essential to ensure that the bushings do not degrade over time, which could compromise their integrity and performance. Selecting a urethane formulation that offers high chemical resistance can enhance the lifespan of the bushings, especially in automotive applications.

What Are Common Trade Terms Related to DIY Polyurethane Bushings?

Familiarity with industry jargon can facilitate smoother transactions and communication between buyers and suppliers. Here are several common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bushings, buyers may seek OEM parts for guaranteed compatibility and quality assurance. Understanding this term helps buyers recognize the importance of sourcing components from reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for businesses looking to manage inventory costs effectively. Understanding MOQ helps buyers negotiate better terms and plan their purchasing strategies, particularly when dealing with custom or specialized bushings.

Illustrative image related to diy polyurethane bushings

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This process is essential for comparing costs and specifications among different vendors, enabling informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding Incoterms is crucial for B2B buyers involved in global trade, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the context of DIY polyurethane bushings, understanding lead times helps businesses plan their projects effectively, ensuring that they have the necessary components on hand when needed.

Illustrative image related to diy polyurethane bushings

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing DIY polyurethane bushings, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the diy polyurethane bushings Sector

What are the Global Drivers and Key Trends Influencing the DIY Polyurethane Bushings Market?

The DIY polyurethane bushings market is experiencing significant growth driven by several global factors. First, the increasing popularity of automotive customization and performance enhancement in regions like Africa, South America, and Europe is propelling demand. Enthusiasts are turning to DIY solutions to achieve superior performance, leading to a surge in the availability of materials and components. Additionally, the rise of e-commerce platforms has made sourcing polyurethane bushings and associated materials easier for international buyers, streamlining the purchasing process.

Emerging technologies, such as 3D printing and advanced molding techniques, are reshaping the landscape of DIY bushings production. These technologies allow for greater customization and rapid prototyping, enabling businesses to meet specific customer needs efficiently. Furthermore, the trend towards modularity in automotive design is encouraging DIY enthusiasts to explore custom bushing solutions that enhance vehicle handling and longevity.

Market dynamics are also influenced by varying regulatory standards across regions, with buyers needing to stay informed about compliance requirements. For example, the automotive aftermarket in Brazil and Nigeria faces unique challenges related to material sourcing and quality assurance, which can impact production timelines and costs. Understanding these dynamics is crucial for international B2B buyers to navigate the complexities of the DIY polyurethane bushings market effectively.

How is Sustainability and Ethical Sourcing Shaping the DIY Polyurethane Bushings Industry?

Sustainability is becoming a critical consideration for businesses involved in the DIY polyurethane bushings sector. The environmental impact of manufacturing and sourcing materials is prompting buyers to prioritize ethical supply chains. Buyers are increasingly seeking suppliers who can demonstrate a commitment to sustainable practices, such as using recycled materials or eco-friendly production methods.

Ethical sourcing also extends to the use of certified materials. Certifications such as ISO 14001 for environmental management or those focusing on sustainable materials can enhance a supplier’s reputation and appeal to environmentally conscious buyers. Furthermore, as the global market shifts towards greener alternatives, the demand for bio-based polyurethanes is on the rise. These materials not only reduce carbon footprints but also offer comparable performance characteristics to traditional polyurethane.

For B2B buyers, investing in sustainable practices can yield long-term benefits, including improved brand loyalty and customer satisfaction. Engaging with suppliers who prioritize sustainability can also mitigate risks associated with regulatory changes and consumer preferences, positioning businesses for future growth in a competitive market.

What is the Historical Context of DIY Polyurethane Bushings?

The evolution of DIY polyurethane bushings can be traced back to the automotive industry’s need for enhanced performance and durability. Originally, bushings were predominantly made from rubber, but as the demand for high-performance vehicles grew, alternatives like polyurethane emerged due to their superior resilience and vibration-dampening properties.

In the late 20th century, the DIY culture gained momentum, particularly among automotive enthusiasts who sought to improve their vehicles’ performance through customization. This shift was fueled by the rise of online forums and communities where knowledge and techniques for DIY bushing production were shared. The introduction of user-friendly materials and tools has further democratized the process, enabling a broader audience to engage in DIY projects.

Today, the DIY polyurethane bushings market reflects a blend of traditional craftsmanship and modern technology, making it an attractive option for both hobbyists and professional builders looking to optimize vehicle performance. Understanding this historical context can provide valuable insights for B2B buyers aiming to capitalize on current market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of diy polyurethane bushings

-

How do I solve issues with existing polyurethane bushings?

If you’re experiencing problems with existing polyurethane bushings, consider inspecting them for wear, cracks, or improper fit. Replacement may be necessary if damage is found. Alternatively, you can enhance performance by switching to a different hardness grade or material, such as Delrin, which can provide better durability. If you’re interested in DIY solutions, you can create your own bushings using molds made from existing ones, allowing you to customize the dimensions and hardness to suit your specific application. -

What is the best method for sourcing high-quality DIY polyurethane bushings?

To source high-quality DIY polyurethane bushings, start by identifying reputable suppliers with a track record in manufacturing and distributing bushings. Look for suppliers who offer detailed product specifications, including material composition and hardness ratings. Request samples to evaluate quality before placing larger orders. Additionally, consider suppliers with experience in international trade to ensure they understand the regulations and logistics involved in shipping to your region. -

How can I customize polyurethane bushings for my specific application?

Customization of polyurethane bushings can be achieved through various methods, including adjusting the hardness level, dimensions, and design. Many suppliers offer options for custom orders, allowing you to specify exact measurements and material properties. When creating your own bushings, use molds that reflect your desired specifications. Collaborating with a manufacturer experienced in custom fabrication can ensure that the final product meets your precise requirements. -

What are the minimum order quantities (MOQ) for DIY polyurethane bushings?

Minimum order quantities (MOQ) for DIY polyurethane bushings vary by supplier and can range from as low as 50 units to several hundred. When sourcing, inquire about the MOQ to ensure it aligns with your business needs. Smaller quantities may be available for custom orders, but keep in mind that pricing per unit may increase. If you’re testing a new design or material, some suppliers may offer flexible options to accommodate initial orders. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms when sourcing from international suppliers typically vary but often include options like advance payment, letters of credit, or net 30/60/90 days. It’s crucial to negotiate terms that protect your interests, especially in international transactions. Ensure that you have clear agreements regarding payment methods, currency, and any applicable fees. Building a trustworthy relationship with your supplier can also lead to more favorable payment terms over time. -

How can I ensure quality assurance (QA) for my polyurethane bushings?

To ensure quality assurance (QA) for your polyurethane bushings, establish clear specifications and standards with your supplier before production begins. Request certifications or test results that verify material properties and performance metrics. Consider implementing a third-party inspection process to evaluate product quality upon receipt. Regular communication with your supplier throughout the manufacturing process can help address any potential issues proactively. -

What logistics considerations should I keep in mind when importing bushings?

When importing polyurethane bushings, consider logistics factors such as shipping costs, transit times, and customs regulations. Work with a logistics provider experienced in international shipping to navigate potential challenges. Ensure all documentation is in order, including invoices, packing lists, and customs declarations, to prevent delays. Additionally, be aware of any tariffs or duties that may apply to your order based on the destination country. -

How do I vet potential suppliers for polyurethane bushings?

To vet potential suppliers for polyurethane bushings, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Request references and reach out to them to gauge satisfaction with the supplier’s products and services. Assess the supplier’s production capabilities, quality control processes, and compliance with international standards. A reliable supplier should be transparent and responsive, facilitating a strong business relationship.

Top 6 Diy Polyurethane Bushings Manufacturers & Suppliers List

1. Reddit – DIY Polyurethane Bushings for MX5 NC

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DIY Polyurethane bushings for car applications, specifically for MX5 NC. Normal rubber bushings resist rotation, while polyurethane bushings allow some movement but not side-to-side. Concerns about casting bushings in place as they may not be free to rotate, which could cause issues. Discussion includes experiences with metal sleeves, the importance of applying grease, and the impact of polyuretha…

2. DuPont – Delrin and Urethane Kits

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Delrin (polyoxymethylene) – thermoplastic sold by DuPont; 4-foot stick purchased for less than $50; used for making bushings. Urethane – two-part mixture; 16-ounce kit purchased for under $20; hardness of Shore 80, similar to tire rubber; takes about 10 minutes to start thickening and 24 hours to cure. Bronze-coated steel sleeves – used in conjunction with Delrin bushings, same dimensions and wall…

3. Driftworks – EasyFlo 60 Liquid Plastic Polyurethane Casting Resin

Domain: driftworks.com

Registered: 2002 (23 years)

Introduction: EasyFlo 60 Liquid Plastic Polyurethane Casting RESIN, 1kg, super low viscosity, 1:1 by volume, 2 min. working time, 15-30 min. demould, cured product is white or can be filled with dry fillers such as bronze powder, ideal for decorative objects, prototype or production parts, tools, models, duplicate masters.

4. Barnes 4WD – Poly Bushing

Domain: barnes4wd.com

Registered: 2006 (19 years)

Introduction: Collection: Poly Bushings and Bushing Kits

Total Products: 25

Availability: 24 In stock, 1 Out of stock

Price Range: From $2.35 to $48.24

Key Products:

1. Poly Bushing – $2.83 USD

2. Small Poly Bushing – $2.35 USD (5.0 / 5.0 rating)

3. Crossmember Mounting Set – $48.24 USD (5.0 / 5.0 rating)

4. DOM Sleeve & Poly Bushing 2 Inch Mounting Width 1/2″ Bolt Hole – $9.50 USD

5. DOM Sleeve & Poly Bushing…

5. Sika – DIY Poly Bushings

Domain: vwvortex.com

Registered: 1997 (28 years)

Introduction: DIY poly bushings made from windshield glue, specifically Sika track drive, which is identified as polyurethane. Concerns include the thickness of the glue for proper application and bonding with OEM rubber. Users have discussed the hardness of polyurethane and alternatives like 3M brand adhesives. Some have attempted to use black adhesion primer with mixed results, indicating that the glue may se…

6. MGEXP – Customizable Urethane Bushings for MGB and GT Vehicles

Domain: mgexp.com

Registered: 2011 (14 years)

Introduction: DIY urethane bushings for MGB and GT vehicles, customizable shore hardness between regular rubber and commonly available polyurethane bushings. Materials can include polyurethane sealants from home improvement stores. Molding requires suitable molds, which can be made using a lathe, and a non-stick coating for easy removal. Polyurethane rubber is available in different hardness levels, typically r…

Strategic Sourcing Conclusion and Outlook for diy polyurethane bushings

In the realm of DIY polyurethane bushings, strategic sourcing emerges as a crucial factor for international B2B buyers aiming to enhance their automotive projects. By leveraging local suppliers and materials, businesses can significantly reduce costs while ensuring high-quality production. The ability to create custom bushings using readily available materials not only meets specific project requirements but also fosters innovation in design and functionality.

Key takeaways for buyers include the importance of understanding the properties of different polyurethane materials, the benefits of local sourcing, and the potential for collaboration with machine shops for precision work. As markets in Africa, South America, the Middle East, and Europe continue to evolve, embracing DIY solutions can provide a competitive edge in the automotive industry.

Looking ahead, B2B buyers are encouraged to explore partnerships with suppliers who can offer both materials and technical support. By investing in DIY polyurethane bushing production, companies can not only enhance their product offerings but also drive sustainability through localized manufacturing. Take the initiative now to transform your sourcing strategy and capitalize on the growing demand for custom automotive solutions.

Illustrative image related to diy polyurethane bushings

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.