Top 6 Conical Gears Suppliers (And How to Choose)

Introduction: Navigating the Global Market for conical gears

Navigating the complexities of sourcing conical gears can pose significant challenges for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With a myriad of options available, from straight to spiral bevel gears, understanding the nuances of these components is crucial for efficient power transmission in machinery. This guide serves as a comprehensive resource, addressing essential aspects such as the various types of conical gears, their diverse applications across industries, supplier vetting processes, and cost considerations.

As you delve into this guide, you will gain insights into the critical factors that influence purchasing decisions, enabling you to make informed choices that align with your operational needs. Whether you are involved in robotics, medical devices, or food processing equipment, having a clear understanding of conical gear specifications and applications will empower you to select the right components for your projects.

Furthermore, this guide emphasizes the importance of evaluating suppliers based on quality, reliability, and technological capabilities, ensuring that you partner with manufacturers who meet international standards. By equipping yourself with this knowledge, you not only enhance your purchasing strategy but also improve your overall operational efficiency, driving better outcomes for your business in the global market.

Understanding conical gears Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Teeth are straight and point towards the apex of the cone. | Machine tools, printing machines, differentials | Pros: Simpler manufacturing; no inward thrust. Cons: Limited strength; no post-heat treatment grinding. |

| Spiral Bevel Gears | Teeth are curved, allowing for smoother meshing. | Automotive, aerospace, robotics | Pros: Higher load capacity; quieter operation. Cons: More complex to manufacture; higher cost. |

| Miter Gears | A special type of bevel gear with a pitch angle of 45°. | Robotics, conveyors, compact transmissions | Pros: Compact design; efficient for 90° direction changes. Cons: Limited to specific angles; lower torque capacity. |

| Hypoid Gears | Similar to spiral gears but with an offset between shafts. | Automotive differentials, heavy machinery | Pros: High torque transmission; smooth operation. Cons: Higher manufacturing complexity; requires precise alignment. |

| Face Gears | Feature a flat surface and can engage with other gears at angles. | Robotics, specialized machinery | Pros: Versatile engagement; allows for unique designs. Cons: Limited availability; specialized applications may increase costs. |

What Are the Key Characteristics of Straight Bevel Gears?

Straight bevel gears are the simplest form of conical gears, characterized by their straight teeth that converge at the apex of the cone. They are primarily used in applications where space is limited and speed is low, such as machine tools and printing machines. When considering purchasing straight bevel gears, buyers should note their ease of manufacturing and lower costs, but also their limitations in strength and inability to undergo post-heat treatment grinding, which can affect performance in high-torque applications.

How Do Spiral Bevel Gears Compare to Other Types?

Spiral bevel gears feature teeth that are curved, allowing for gradual engagement and smoother operation. This design makes them suitable for applications requiring high load capacity and quieter performance, such as in the automotive and aerospace industries. While they provide significant advantages over straight bevel gears, including better efficiency and strength, buyers should be aware of the increased manufacturing complexity and costs associated with spiral bevel gears.

What Are Miter Gears and Their Advantages?

Miter gears are a specific subset of bevel gears with a pitch angle of 45°, designed to transmit motion between shafts that intersect at right angles. Their compact design makes them ideal for applications such as conveyors and robotics where space is at a premium. Buyers should consider the efficiency of miter gears in direction changes, but also be mindful of their limited torque capacity and specific angle constraints that may not suit all applications.

Why Choose Hypoid Gears for Heavy Machinery?

Hypoid gears are a variation of spiral bevel gears with an offset between the input and output shafts, allowing for high torque transmission. They are commonly used in automotive differentials and heavy machinery due to their ability to handle significant loads while maintaining smooth operation. However, the complexity of their manufacturing and the need for precise alignment can lead to higher costs, making them a consideration for buyers looking for durability and performance in demanding applications.

What Are Face Gears and Their Applications?

Face gears are distinguished by their flat surfaces, allowing them to engage with other gears at various angles. This versatility makes them suitable for specialized machinery and robotics applications. While they offer unique design opportunities, buyers should note their limited availability and potentially higher costs due to their specialized nature. Understanding the specific requirements of the intended application is crucial when considering face gears for procurement.

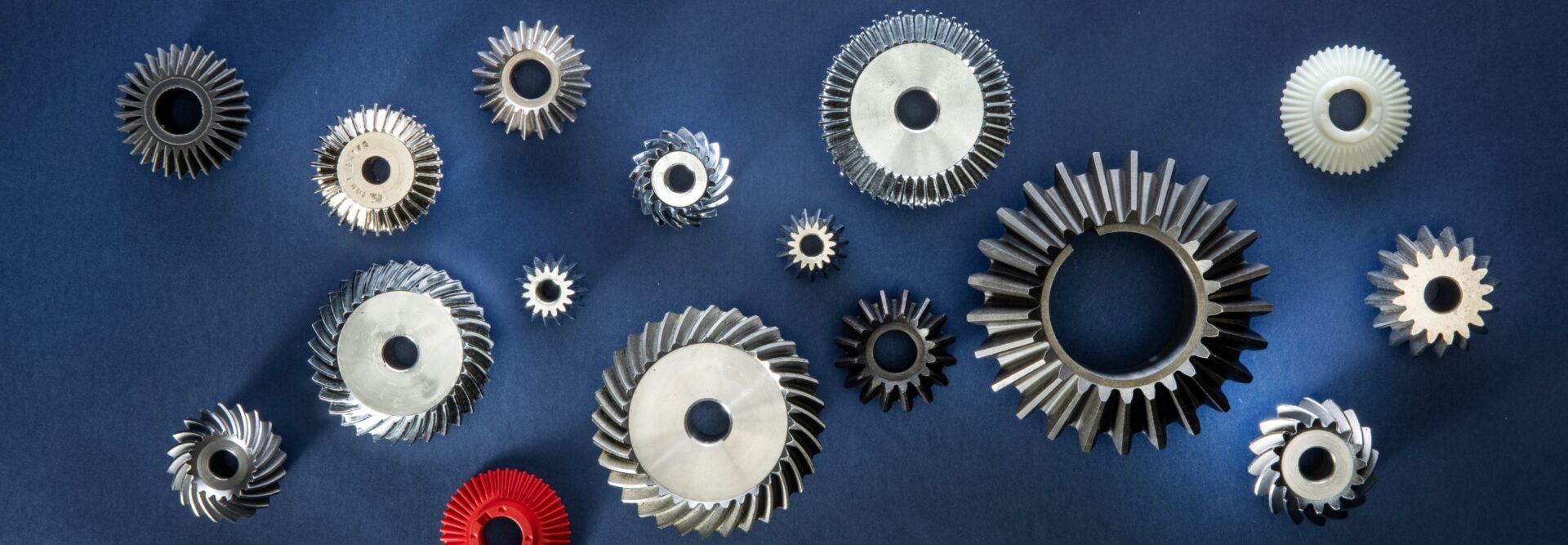

Illustrative image related to conical gears

Key Industrial Applications of conical gears

| Industry/Sector | Specific Application of conical gears | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Robotics | Motion transmission in robotic arms | Enhances precision in movement and reduces noise levels | Consider gear material for durability and weight |

| Semiconductor Equipment | Wafer handling systems | Ensures smooth operation and high reliability | Focus on precision manufacturing and heat resistance |

| Medical Devices | Surgical instruments and imaging equipment | Provides reliability and accuracy in critical applications | Look for biocompatibility and ease of cleaning |

| Food Processing Equipment | Conveyor systems and packaging machinery | Improves efficiency and hygiene in production processes | Emphasize corrosion resistance and easy maintenance |

| Machine Tools | CNC machines and lathes | Increases machining precision and reduces downtime | Evaluate gear tolerances and compatibility with existing systems |

What Are the Key Applications of Conical Gears in Robotics?

In the robotics sector, conical gears are crucial for motion transmission within robotic arms and joints. These gears facilitate the precise movement required for tasks ranging from assembly to intricate surgical procedures. By providing smooth and efficient power transfer, they minimize noise and vibration, enhancing the overall performance of robotic systems. For international buyers, sourcing high-quality conical gears that meet specific load and speed requirements is essential, particularly in regions like Europe and the Middle East, where automation is rapidly advancing.

How Do Conical Gears Benefit Semiconductor Equipment Manufacturing?

Conical gears play a vital role in semiconductor equipment, particularly in wafer handling systems. Their ability to ensure smooth operation is critical in environments where precision is paramount. These gears help maintain the integrity of delicate semiconductor wafers during processing, thus minimizing the risk of damage. Buyers in this sector should prioritize sourcing gears with high manufacturing precision and heat resistance to withstand the demanding conditions typical in semiconductor fabrication.

What Role Do Conical Gears Play in Medical Devices?

In the medical device industry, conical gears are integral to the functionality of surgical instruments and imaging equipment. They provide the necessary precision and reliability required in critical medical applications, where failure is not an option. Buyers should consider materials that are biocompatible and easy to clean, as hygiene is a top priority in medical applications. Ensuring that sourced gears meet stringent regulatory standards is crucial, especially for manufacturers targeting markets in Europe and North America.

Why Are Conical Gears Important in Food Processing Equipment?

Conical gears are widely used in food processing equipment, particularly in conveyor systems and packaging machinery. They enhance operational efficiency while ensuring hygiene, which is essential in food production. The use of corrosion-resistant materials is a key consideration for buyers in this sector, as it directly impacts the durability and safety of the equipment. Sourcing gears that comply with food safety regulations is crucial for businesses aiming to maintain high standards in food processing.

How Do Conical Gears Enhance Machine Tool Performance?

In machine tools, conical gears are pivotal for CNC machines and lathes, where they help increase machining precision and reduce downtime. Their design allows for efficient power transmission, which is essential for high-speed operations. Buyers should evaluate gear tolerances and compatibility with existing systems to ensure seamless integration. Additionally, sourcing gears that can withstand high operational stresses is vital for maintaining productivity in competitive manufacturing environments.

Illustrative image related to conical gears

3 Common User Pain Points for ‘conical gears’ & Their Solutions

Scenario 1: Inconsistent Quality in Conical Gear Manufacturing

The Problem:

B2B buyers often face challenges related to the inconsistency in quality of conical gears from different suppliers. This inconsistency can lead to misalignment issues, increased wear and tear, and ultimately, equipment failure. Buyers may find it difficult to ensure that the gears meet specific tolerances and performance standards, especially when sourcing from multiple regions like Africa, South America, or the Middle East, where manufacturing standards may vary significantly.

The Solution:

To mitigate quality inconsistencies, buyers should establish clear specifications that align with industry standards, such as ISO or AGMA. When sourcing conical gears, prioritize suppliers who provide comprehensive quality assurance documentation, including material certificates and inspection reports. Engaging in a supplier audit process can also help assess the manufacturing capabilities and quality control measures of potential vendors. Additionally, consider suppliers who utilize advanced manufacturing techniques like the Gleason method, known for producing high-precision bevel gears. This proactive approach will help ensure that the gears meet your operational requirements and reduce the risk of unexpected failures.

Scenario 2: Difficulty in Selecting the Right Type of Conical Gear

The Problem:

With various types of conical gears available, including straight and spiral bevel gears, B2B buyers often struggle to select the right type for their specific application. Misjudgment in gear selection can result in inefficient power transmission, increased noise, and even mechanical failures, which can be costly and time-consuming to rectify.

The Solution:

To address this selection challenge, buyers should conduct a thorough analysis of their application requirements, including load capacity, speed, and the angle of shaft intersection. Utilizing gear calculators or consulting with gear specialists can help clarify which gear type will best suit the application. Additionally, collaborating with a manufacturer who offers customizable options can be advantageous. This allows for the creation of a tailored solution that meets unique specifications, ensuring optimal performance. Furthermore, buyers should consider engaging in pilot testing with prototype gears to validate their selection before committing to larger orders.

Scenario 3: High Costs Due to Frequent Gear Failures

The Problem:

Frequent failures of conical gears can lead to significant downtime and high replacement costs for B2B buyers. Often, these failures result from inadequate lubrication, improper installation, or the use of subpar materials. This not only affects production schedules but also strains supplier relationships and erodes profit margins.

The Solution:

To combat high failure rates, buyers should implement a robust maintenance schedule that includes regular inspections and lubrication of conical gears. It is essential to specify the right lubrication type and quantity based on the gear’s operational environment. Additionally, buyers should invest in training for their staff on proper installation techniques to minimize human error during gear assembly. Engaging with suppliers who provide ongoing technical support and training can also be beneficial. Choosing high-quality materials—such as SCM415 alloy steel for its strength and wear resistance—will further enhance durability. By taking these proactive steps, buyers can significantly reduce the frequency of gear failures and associated costs.

Strategic Material Selection Guide for conical gears

What are the Key Properties of Common Materials for Conical Gears?

When selecting materials for conical gears, it is essential to consider properties such as strength, wear resistance, and corrosion resistance. The most common materials used in the manufacturing of conical gears include carbon steel, alloy steel, stainless steel, and engineering plastics. Each material offers unique advantages and limitations that affect performance, durability, and application suitability.

How Does Carbon Steel Perform in Conical Gear Applications?

Carbon steel, particularly grades like S45C, is widely used in conical gear manufacturing due to its excellent machinability and strength. It typically exhibits good wear resistance and can withstand moderate temperatures and pressures. However, its susceptibility to corrosion is a significant drawback, particularly in humid or corrosive environments.

Pros: Carbon steel is cost-effective and relatively easy to manufacture. It is suitable for applications where high strength is required but does not involve exposure to harsh environments.

Cons: Its corrosion vulnerability limits its use in applications where moisture or chemicals are present, necessitating protective coatings or treatments.

For international buyers, compliance with standards such as ASTM A36 or JIS G3101 is crucial. Markets in Africa and South America may favor lower-cost options, while European buyers might prefer higher-grade materials with better corrosion resistance.

What Advantages Do Alloy Steels Offer for Conical Gears?

Alloy steels, such as SCM415, are engineered to provide enhanced mechanical properties through the addition of elements like chromium and molybdenum. These materials are known for their superior strength, toughness, and fatigue resistance, making them ideal for high-load applications.

Pros: Alloy steels are highly durable and can be heat-treated to improve hardness and wear resistance. They are well-suited for applications in demanding environments, such as automotive and industrial machinery.

Cons: The manufacturing process for alloy steels can be more complex and costly compared to carbon steel. Additionally, they may require specific heat treatment processes to achieve optimal performance.

International buyers should consider compliance with standards like ASTM A514 or DIN 17100, as these materials are often used in heavy-duty applications across various industries.

Why Choose Stainless Steel for Conical Gears?

Stainless steel, particularly grades like SUS303, is favored for its excellent corrosion resistance and aesthetic appeal. This material is ideal for applications in food processing, medical devices, and environments where hygiene is paramount.

Pros: Stainless steel offers high durability and resistance to rust and corrosion. It is easy to clean, making it suitable for sanitary applications.

Cons: The primary drawback is its higher cost compared to carbon and alloy steels. Additionally, stainless steel may not have the same load-bearing capacity as alloy steels.

For buyers in the Middle East and Europe, compliance with international standards such as ASTM A240 or DIN 17440 is essential, particularly in industries that require stringent hygiene standards.

When are Engineering Plastics Suitable for Conical Gears?

Engineering plastics, such as MC901 and Duracon, are increasingly used in low-load applications where weight reduction and noise reduction are priorities. These materials are lightweight and can be molded into complex shapes.

Pros: Engineering plastics are resistant to corrosion and do not require lubrication, making them ideal for specific applications. They also tend to be quieter during operation.

Cons: Their load-bearing capacity is significantly lower than metals, limiting their use in high-stress applications. They may also have a lower temperature tolerance.

International buyers should consider the specific requirements for plastic materials, including compliance with standards like ASTM D638 or ISO 1043, particularly in industries such as consumer electronics and automotive.

Summary Table of Material Selection for Conical Gears

| Material | Typical Use Case for conical gears | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General machinery, low-stress applications | Cost-effective and easy to machine | Susceptible to corrosion | Low |

| Alloy Steel | Heavy-duty machinery, automotive applications | High strength and fatigue resistance | Higher manufacturing complexity and cost | Medium |

| Stainless Steel | Food processing, medical devices | Excellent corrosion resistance | Higher cost and lower load capacity | High |

| Engineering Plastics | Consumer electronics, low-load applications | Lightweight and noise-reducing | Limited load-bearing capacity | Medium |

This material selection guide provides B2B buyers with actionable insights into the properties, advantages, and considerations necessary for choosing the right conical gear materials for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for conical gears

What are the Main Stages of Conical Gear Manufacturing?

The manufacturing process for conical gears, such as bevel gears, involves several critical stages, each designed to ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Conical Gear Production?

Material selection is crucial for producing conical gears, as the choice affects performance, durability, and cost. Common materials include carbon steel, alloy steel, and engineering plastics. The preparation stage typically involves cutting the raw materials into manageable sizes, followed by heat treatment processes like carburizing or hardening to enhance strength and wear resistance.

What Techniques are Used in Forming Conical Gears?

The forming stage can employ various techniques, the most prevalent being the Gleason and Klingelnberg methods. These methods are instrumental in shaping the teeth of the gears. The Gleason method, known for its efficiency and precision, uses specialized machines to create helical tooth profiles. In contrast, the Klingelnberg method focuses on achieving equal depth for both toe and heel of the teeth, making it popular in certain regions.

How is Assembly Handled in Conical Gear Manufacturing?

Assembly for conical gears often involves pairing gears with their respective shafts. Precision in this stage is vital, as misalignments can lead to premature wear and failure. Manufacturers utilize jigs and fixtures to ensure accurate placement and secure fitting. Quality assurance measures during assembly include checks for backlash, alignment, and torque specifications.

What Finishing Techniques are Commonly Used for Conical Gears?

Finishing processes enhance the performance characteristics of conical gears. Common techniques include grinding, polishing, and coating. Grinding is critical for achieving the desired tooth profile and surface finish, significantly influencing noise reduction and efficiency. Polishing can further reduce friction, while coatings may be applied to improve corrosion resistance and durability.

What Quality Assurance Measures are Essential for Conical Gears?

Quality assurance (QA) is integral to the production of conical gears, ensuring that they meet industry standards and client specifications.

Illustrative image related to conical gears

Which International Standards Should B2B Buyers Look for?

International standards such as ISO 9001 provide a framework for quality management systems. For specific industries, certifications like CE and API are crucial, especially in sectors like automotive and aerospace, where safety and performance are paramount. These certifications indicate that the products have undergone rigorous testing and adhere to international safety and quality guidelines.

What are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints play a significant role throughout the manufacturing process.

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and components for conformity to specifications.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure that processes adhere to defined standards. This may involve dimensional checks and functional testing.

- Final Quality Control (FQC): Upon completion, finished gears undergo comprehensive testing, including dimensional accuracy, surface finish, and performance under load conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should implement several strategies to verify a supplier’s quality control processes:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and processes firsthand.

- Quality Reports: Requesting detailed quality reports, including test results and compliance certificates, provides insight into the supplier’s quality management practices.

- Third-Party Inspections: Engaging third-party inspection agencies can provide impartial verification of quality claims, further ensuring that products meet specified standards.

What Testing Methods are Commonly Used for Conical Gears?

Testing methods for conical gears are varied, focusing on different performance attributes. Common techniques include:

- Dimensional Inspection: Utilizing tools like calipers and micrometers to measure gear dimensions against specifications.

- Load Testing: Assessing the gear’s performance under simulated operational conditions to ensure it can handle the required torque and speed.

- Noise and Vibration Testing: Evaluating the gear’s operational noise levels and vibrations, which can indicate issues with alignment or surface finish.

How Do QC and Certification Nuances Affect International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various quality assurance and certification nuances. Different countries may have specific regulations and standards that must be adhered to, influencing both manufacturing processes and the final product.

Buyers should be aware of local market demands, which may require additional certifications or compliance with regional safety standards. Establishing strong communication with suppliers regarding these requirements is essential to ensure that products are not only compliant but also competitive in the target markets.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing conical gears, ultimately ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conical gears’

To ensure a successful procurement process for conical gears, it’s essential to follow a structured approach. This guide provides a practical checklist to streamline your sourcing efforts, ensuring you meet your technical requirements while establishing strong supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful sourcing process. Identify the specific type of conical gears you need, including dimensions, material specifications, and load capacity. Consider factors such as operating environment and compatibility with existing machinery to ensure optimal performance.

Step 2: Research Industry Standards and Regulations

Understanding the industry standards applicable to conical gears is crucial for compliance and quality assurance. Familiarize yourself with standards such as ISO or ANSI, which may govern gear manufacturing and testing processes. This knowledge will help you assess suppliers’ offerings and ensure that their products meet required benchmarks.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, including their experience in manufacturing conical gears, and gather references from other clients in similar industries. This vetting process helps identify reliable suppliers who can meet your quality and delivery expectations.

- Considerations:

- Company reputation and history in the industry.

- Customer reviews and case studies showcasing their past work.

Step 4: Request Samples and Conduct Testing

It’s advisable to request samples of conical gears from shortlisted suppliers. Testing these samples allows you to assess their performance, durability, and compatibility with your systems. Pay attention to the gear’s finish, precision, and any signs of manufacturing defects.

Step 5: Negotiate Pricing and Terms

Once you have evaluated samples, initiate discussions on pricing and terms. Be transparent about your budget constraints while ensuring you receive value for your investment. Consider factors like bulk order discounts, payment terms, and warranty provisions.

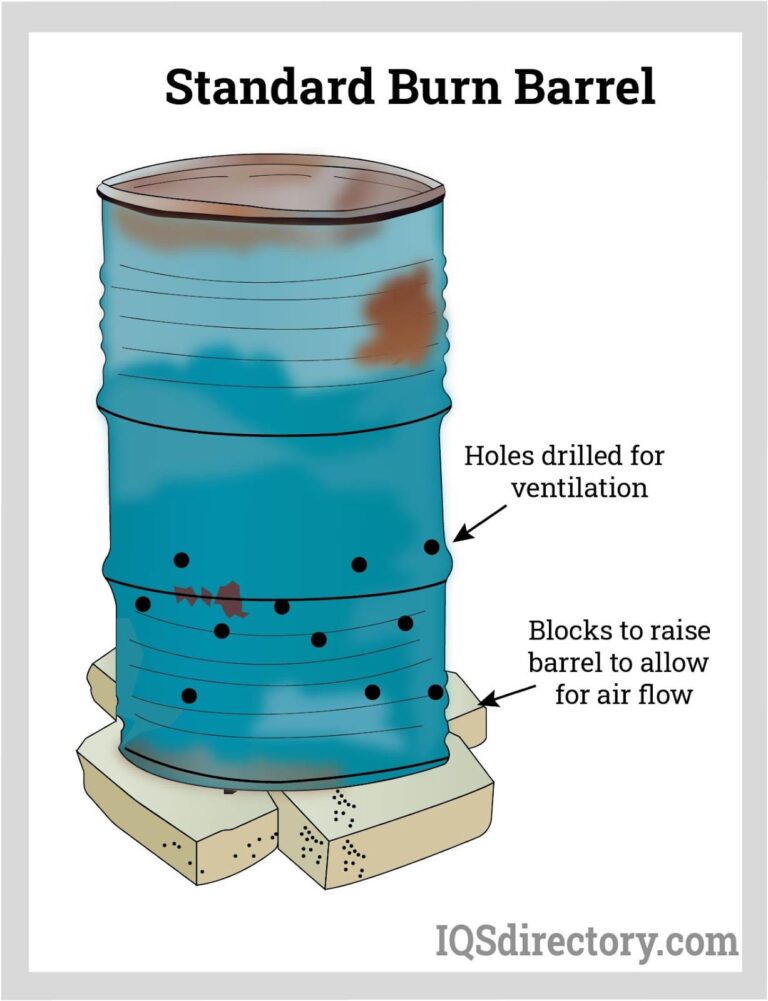

Illustrative image related to conical gears

- Tip: Compare offers from multiple suppliers to leverage better pricing and terms.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications, which may include quality management systems like ISO 9001. Certifications indicate a commitment to quality and adherence to industry standards, providing additional assurance of the supplier’s reliability.

Step 7: Establish Clear Communication Channels

Effective communication with your supplier is vital throughout the procurement process. Establish clear points of contact and preferred communication methods to facilitate timely updates and address any concerns. Regular communication can also help in managing expectations and ensuring smooth operations post-purchase.

By following this checklist, you can streamline your sourcing process for conical gears, ultimately leading to better procurement decisions and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for conical gears Sourcing

Analyzing the cost structure and pricing for conical gears is essential for international B2B buyers looking to optimize their sourcing strategies. This section delves into the key components of costs, pricing influencers, and strategic buyer tips to facilitate informed purchasing decisions.

What Are the Key Cost Components for Conical Gears?

When evaluating the overall cost of conical gears, several components come into play:

-

Materials: The choice of material significantly affects the price. Common materials include various grades of steel (e.g., S45C, SCM415), stainless steel, and engineering plastics. The material’s mechanical properties and performance characteristics directly correlate with its cost.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes. For instance, spiral bevel gears, which require more sophisticated machining techniques, tend to incur higher labor costs compared to straight bevel gears.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. High overhead can lead to increased pricing for buyers, particularly from regions where operational costs are elevated.

-

Tooling: The initial investment in tooling can be substantial, especially for custom gear designs. Buyers should consider whether the tooling costs are amortized over large production runs, which can affect per-unit pricing.

-

Quality Control (QC): Ensuring the gears meet specific quality standards adds to the overall cost. Rigorous QC processes can enhance product reliability but may also increase manufacturing expenses.

-

Logistics: Shipping and transportation costs can vary widely based on geographical location and chosen Incoterms. Buyers should account for these costs in their total procurement budget.

-

Margin: Suppliers often include a markup to cover risks and profit margins. This can vary based on market demand, competition, and the supplier’s positioning.

How Do Pricing Influencers Impact Conical Gear Costs?

Several factors influence the pricing structure of conical gears:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to optimize unit costs.

-

Specifications and Customization: Customized gears that require specific tolerances or unique designs typically incur higher costs. Buyers should evaluate the necessity of custom features against standard options.

-

Material Selection: The choice of material affects not only the initial price but also the durability and lifecycle cost of the gears. Higher-quality materials may have a higher upfront cost but could result in lower total ownership costs due to reduced maintenance and replacement frequency.

-

Quality Certifications: Gears that meet international quality standards or possess certifications may come at a premium price. However, these certifications often assure performance and reliability, which can justify the higher cost.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers may charge more due to their reliability and service, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms determine who bears the shipping and risk costs. Understanding these terms is crucial for calculating the total cost of ownership accurately.

What Tips Can Buyers Utilize for Cost-Efficiency in Sourcing Conical Gears?

International buyers should adopt strategic approaches to maximize cost efficiency:

-

Negotiate Wisely: Engage suppliers in discussions about pricing, especially regarding volume discounts and payment terms. Establishing a long-term relationship can lead to better terms over time.

-

Consider Total Cost of Ownership: Look beyond the initial purchase price to assess the total cost of ownership, including maintenance, downtime, and replacement costs. This perspective can reveal the true value of investing in higher-quality gears.

-

Understand Pricing Nuances: Be aware that pricing may vary significantly across different regions. Buyers from Africa, South America, the Middle East, and Europe should conduct market research to benchmark prices and identify competitive suppliers.

-

Explore Local Suppliers: For certain applications, sourcing locally may reduce logistics costs and lead times. Investigating regional suppliers could provide advantageous pricing structures.

Conclusion

In summary, understanding the intricate cost components and pricing influencers in conical gear sourcing is essential for international B2B buyers. By leveraging negotiation strategies and considering total cost implications, buyers can make informed decisions that align with their operational needs and budget constraints. Always consult with multiple suppliers to ensure competitive pricing and quality assurance.

Illustrative image related to conical gears

Alternatives Analysis: Comparing conical gears With Other Solutions

Understanding Alternatives to Conical Gears

In the realm of power transmission, selecting the right gear system is crucial for operational efficiency and cost-effectiveness. Conical gears, commonly known as bevel gears, are widely utilized for their ability to transmit torque between intersecting shafts. However, various alternative solutions exist, each with its own set of advantages and disadvantages. This section will explore these alternatives in detail, enabling B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Conical Gears | Worm Gears | Planetary Gears |

|---|---|---|---|

| Performance | High efficiency (98-99%) | Moderate efficiency (60-90%) | Very high efficiency (up to 97%) |

| Cost | Moderate to high | Generally low to moderate | Higher initial cost |

| Ease of Implementation | Requires precise alignment | Easier to install | Complex installation |

| Maintenance | Moderate; depends on application | Low maintenance | Moderate; can be more complex |

| Best Use Case | High-speed applications, robotics | Low-speed, high torque applications | Compact systems needing high torque |

Detailed Breakdown of Alternatives

Worm Gears

Worm gears are a popular alternative for applications requiring high torque at low speeds. They consist of a worm (a screw-like gear) that meshes with a worm wheel. One of their primary advantages is their ability to provide a high gear reduction ratio in a compact design. Additionally, they exhibit self-locking capabilities, preventing back-driving, which is beneficial in applications where safety is a concern. However, the efficiency of worm gears can be lower due to sliding friction, typically ranging from 60% to 90%. This makes them less suitable for high-speed applications where energy loss is a critical factor.

Planetary Gears

Planetary gears are another effective alternative, particularly for applications that require high torque and compact designs. They consist of a central sun gear, planet gears that rotate around it, and a ring gear encasing the planets. Their major advantage is the distribution of load across multiple gears, which enhances durability and efficiency, often achieving up to 97% efficiency. This makes them ideal for high-performance applications such as automotive transmissions and aerospace systems. However, the complexity of their design can lead to higher manufacturing costs and more intricate installation processes, which may not be suitable for all B2B buyers.

Conclusion: Choosing the Right Gear Solution

When selecting a gear solution, B2B buyers must consider various factors, including performance requirements, cost constraints, and the specific operational environment. Conical gears are excellent for high-speed applications requiring efficient torque transmission, while worm gears offer compact designs ideal for low-speed, high-torque scenarios. Planetary gears stand out for their robustness and efficiency but come with increased complexity and cost. By carefully evaluating these aspects and aligning them with operational needs, buyers can make informed decisions that optimize performance and reduce costs in their applications.

Essential Technical Properties and Trade Terminology for conical gears

What Are the Key Technical Properties of Conical Gears?

When evaluating conical gears, particularly for international B2B applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several essential properties that buyers should consider:

-

Material Grade: The choice of material directly impacts the performance and durability of conical gears. Common materials include carbon steel (e.g., S45C), alloy steel (e.g., SCM415), and engineering plastics (e.g., MC901). Each material has specific properties suited for different applications—steel gears offer high strength and wear resistance, while plastic gears are lighter and suitable for low-load applications.

-

Tooth Finish and Hardening: The manufacturing process determines the tooth finish and hardening of the gear, which affects its performance. Gears can be non-ground, ground, or induction-hardened. For instance, ground spiral bevel gears are known for their precision and low noise, making them ideal for high-speed applications. Understanding the differences can help buyers select gears that meet their operational requirements.

-

Module and Pitch: The module (or pitch) of a gear is a critical specification that defines the size of the teeth. It is calculated as the ratio of the pitch diameter to the number of teeth. A correct module ensures proper meshing with other gears and affects the load-carrying capacity. Buyers need to choose the appropriate module to match existing gear systems.

-

Speed Ratio: This indicates the relationship between the input and output speeds of the gear system. Conical gears typically operate at various speed ratios, impacting the overall efficiency of the machinery. Understanding the required speed ratio is vital for optimizing system performance and preventing mechanical failures.

-

Grade and Tolerance: The JIS (Japanese Industrial Standards) grade indicates the manufacturing quality and precision of the gears. Tolerances define the allowable deviation from specified dimensions. High-grade gears with tight tolerances are essential for applications requiring high reliability and performance, such as robotics and medical devices.

What Are Common Trade Terms Related to Conical Gears?

In the world of B2B transactions for conical gears, familiarity with specific trade terminology can facilitate smoother negotiations and transactions. Here are key terms to understand:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. Buyers often engage with OEMs to ensure that they receive high-quality, compatible parts tailored to their specifications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, especially for international buyers who may face different sourcing constraints.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and availability for specific products. Submitting an RFQ is a critical step for buyers to compare offers and negotiate terms, ensuring they secure the best deal for their needs.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for understanding shipping costs, risks, and delivery obligations, which can significantly affect the total cost of procurement.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead time helps buyers plan their production schedules and inventory levels, minimizing downtime and ensuring timely project completion.

-

KPI (Key Performance Indicator): In the context of B2B transactions, KPIs are measurable values that demonstrate how effectively a company is achieving its key business objectives. Buyers may use KPIs to evaluate supplier performance, ensuring they meet quality and delivery standards.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of procuring conical gears more effectively, ensuring that their machinery operates efficiently and reliably.

Navigating Market Dynamics and Sourcing Trends in the conical gears Sector

What Are the Key Market Dynamics and Trends in the Conical Gears Sector?

The conical gears market is experiencing robust growth driven by several global factors. The increasing demand for automation across various industries, including robotics, automotive, and manufacturing, is propelling the need for efficient power transmission solutions. Additionally, the rise of electric vehicles and renewable energy technologies has led to a surge in applications for conical gears, particularly in gearboxes and powertrains. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly focusing on suppliers who can provide innovative and cost-effective solutions.

Emerging technologies, such as additive manufacturing, are also reshaping sourcing strategies. B2B buyers are leveraging 3D printing for rapid prototyping and low-volume production, which offers flexibility in design and manufacturing processes. Furthermore, the trend towards digitalization in supply chain management, including the use of AI and IoT for predictive analytics, is allowing buyers to make more informed sourcing decisions.

As competition intensifies, companies that can offer customized solutions, quick turnaround times, and superior customer service will gain a competitive edge. Global supply chain disruptions have emphasized the need for resilient sourcing strategies, prompting buyers to diversify their supplier base and consider local manufacturers to mitigate risks.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy in the Conical Gears Sector?

Sustainability is becoming a critical consideration in the procurement of conical gears. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of eco-friendly materials and energy-efficient manufacturing processes.

Ethical sourcing is also paramount in today’s market. Buyers are expected to ensure that their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential benchmarks for buyers seeking to partner with ethically responsible suppliers.

Moreover, the demand for ‘green’ materials, such as recycled metals or bio-based plastics, is on the rise. Suppliers who can offer products that align with these sustainability goals not only enhance their marketability but also foster long-term relationships with environmentally conscious clients. By integrating sustainability into sourcing strategies, businesses can improve their brand reputation and appeal to a broader customer base.

What Is the Evolution of Conical Gears and Its Relevance to Today’s B2B Landscape?

The evolution of conical gears can be traced back to their fundamental design, which allows for power transmission between intersecting shafts. Initially, these gears were primarily made of metal, limiting their applications and increasing costs. However, advancements in materials science and manufacturing techniques, including the Gleason and Klingelnberg methods, have revolutionized the industry.

Today, conical gears are available in various materials, including high-strength alloys and engineering plastics, which cater to diverse applications from automotive to aerospace. The development of computer-aided design (CAD) has further streamlined the design process, allowing for greater precision and customization.

This historical progression underscores the importance of innovation in the conical gears sector. B2B buyers must remain cognizant of these advancements to leverage the most efficient and effective solutions for their operational needs. As the market continues to evolve, staying updated on technological advancements and material options will be crucial for maintaining a competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of conical gears

-

How do I choose the right conical gear for my application?

Selecting the appropriate conical gear requires assessing several factors including torque requirements, speed ratios, and the angles of intersection between shafts. Consider the type of bevel gear—straight or spiral—based on your noise reduction needs and load characteristics. Additionally, evaluate the material options, such as carbon steel or plastic, which can influence durability and performance. Collaborating with a knowledgeable supplier can help you navigate these choices to find a gear that meets your specific application needs. -

What is the best material for conical gears in harsh environments?

For applications in harsh environments, such as those involving high temperatures or corrosive substances, stainless steel or specially coated materials are optimal. Stainless steel offers excellent corrosion resistance, while alloy steels can provide enhanced strength and durability. It’s essential to match the material to the environmental conditions and mechanical loads. Discussing your specific requirements with potential suppliers can yield valuable insights into the best material choices for your conical gears. -

What customization options are available for conical gears?

Most manufacturers offer customization options for conical gears, including modifications in tooth design, size, and material. Customization can also include specific heat treatment processes or surface finishes to enhance performance characteristics like wear resistance. When considering custom solutions, provide detailed specifications to your supplier. This ensures that the gears will meet your operational requirements and fit seamlessly into your machinery. -

What are the minimum order quantities (MOQs) for conical gears?

Minimum order quantities can vary significantly between suppliers and can depend on factors such as the complexity of the gear design and production capabilities. Generally, standard products may have lower MOQs, while custom gears may require larger orders to justify production costs. It is advisable to discuss your needs directly with suppliers to find flexible options that accommodate your budget and project timelines. -

How can I vet potential suppliers for conical gears?

To effectively vet suppliers, evaluate their industry experience, certifications, and customer reviews. Request samples to assess quality and compliance with specifications. Additionally, inquire about their manufacturing processes, quality assurance measures, and lead times. Engaging in direct communication can also provide insights into their responsiveness and willingness to collaborate on custom projects, which is crucial for long-term partnerships. -

What payment terms should I expect when purchasing conical gears internationally?

Payment terms can vary by supplier and region, but common practices include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Ensure to clarify these terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new or unverified suppliers. -

What quality assurance measures should be in place for conical gears?

Quality assurance for conical gears should include rigorous testing procedures such as dimensional inspections, load tests, and material verification. Suppliers should ideally be certified by relevant quality standards, such as ISO 9001. Request documentation of quality checks and test results with your orders to ensure that the gears meet required specifications and performance standards. -

What logistics considerations should I keep in mind when sourcing conical gears?

When sourcing conical gears, logistics considerations include shipping methods, lead times, and customs regulations. Ensure that the supplier can provide reliable shipping options and timely delivery to meet your production schedules. Additionally, be aware of import duties and taxes in your country, as these can affect overall costs. Establishing a clear logistics plan with your supplier can help mitigate potential delays and ensure smooth operations.

Top 6 Conical Gears Manufacturers & Suppliers List

1. KHK – Bevel Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Bevel Gears are cone-shaped gears that transmit power between two intersecting axles. They are classified into straight bevel gears (no helix angles) and spiral bevel gears (with helix angles). KHK primarily uses the Gleason manufacturing method for bevel gears. Key specifications include:

1. **MHP High-Ratio Hypoid Gears**: Module: 1 – 1.5, Speed ratio: 15 – 60, Material: SCM415, Hardening: Carb…

2. igus – Bevel Gears

Domain: igus.com

Registered: 1995 (30 years)

Introduction: Bevel gears are conically shaped gears used to transmit power between two shafts at a 90-degree angle. They mesh their teeth together to transfer torque and rotational motion between non-parallel shafts. The gear ratio, determined by the number of teeth on each gear, is crucial for mechanical advantage, affecting speed and torque output. Bevel gears with a 1:1 ratio are known as miter gears. igus …

3. Maedler North America – Fast Delivery & Easy Returns

Domain: maedlernorthamerica.com

Registered: 2020 (5 years)

Introduction: This company, Maedler North America – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. McMaster – Miter Gears & Bevel Gears

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Miter Gears & Bevel Gears, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. ScienceDirect – Conical Gears

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Conical gears are gears with teeth cut onto a frustum of a conical blank, characterized by complex geometry that distinguishes their manufacturing from cylindrical gears. They are typically machined from a gear blank with a continuously varying diameter along its axis, making their fabrication challenging and limiting manufacturing processes to a few specialized methods. Conical gears require high…

6. GoBilda – Bevel Gears

Domain: gobilda.com

Registered: 2015 (10 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning.

1. **MOD 1.5 Bevel Gears (2:1 Ratio)**: Creates a 2:1 reduction; requires a specific tooth profile for compatibility.

2. **MOD 1 Miter Gears (1:1 Ratio)**: Two-piece steel construction with pinch bolts for secure locking; titanium nitride finish for durability….

Strategic Sourcing Conclusion and Outlook for conical gears

In the evolving landscape of industrial applications, conical gears present a unique opportunity for businesses looking to enhance efficiency and reliability. The shift towards spiral bevel gears, driven by their superior performance in noise reduction and load management, underscores the importance of strategic sourcing. By understanding the nuances of gear types—ranging from straight to spiral and hypoid—buyers can make informed decisions that align with their operational needs and budget constraints.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the ability to source high-quality conical gears is pivotal. Partnering with reputable manufacturers who utilize advanced methods like the Gleason technique ensures that businesses receive products that meet rigorous standards for durability and precision. As industries continue to innovate, the demand for specialized gear solutions will only grow.

Looking ahead, organizations should prioritize building strong supplier relationships and staying abreast of technological advancements in gear manufacturing. This proactive approach not only secures a competitive advantage but also positions businesses to thrive in the global marketplace. Engage with trusted suppliers today to explore how conical gears can transform your operations for a more efficient tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to conical gears

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.