Top 6 Bevel Side Gear Suppliers (And How to Choose)

Introduction: Navigating the Global Market for bevel side gear

In an increasingly interconnected global market, sourcing the right bevel side gear can present unique challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The diversity of applications and varying quality standards can complicate the purchasing process, making it essential to understand not only the types of bevel gears available but also their specific applications, materials, and manufacturing processes. This guide aims to demystify the complexities of bevel side gear procurement, providing a comprehensive overview of the different gear types, including straight and spiral bevel gears, as well as their respective advantages and disadvantages.

Furthermore, we delve into critical aspects such as supplier vetting, cost considerations, and the latest industry trends that impact pricing and availability. By equipping international B2B buyers with actionable insights and practical knowledge, this guide empowers you to make informed purchasing decisions that align with your operational needs and budget constraints. Whether you’re looking to enhance machinery efficiency in Brazil or ensure precision engineering in Germany, understanding the nuances of bevel side gears will enable you to select the right products that drive your business success. As you navigate this dynamic marketplace, let this guide serve as your trusted resource for informed decision-making in your bevel gear sourcing journey.

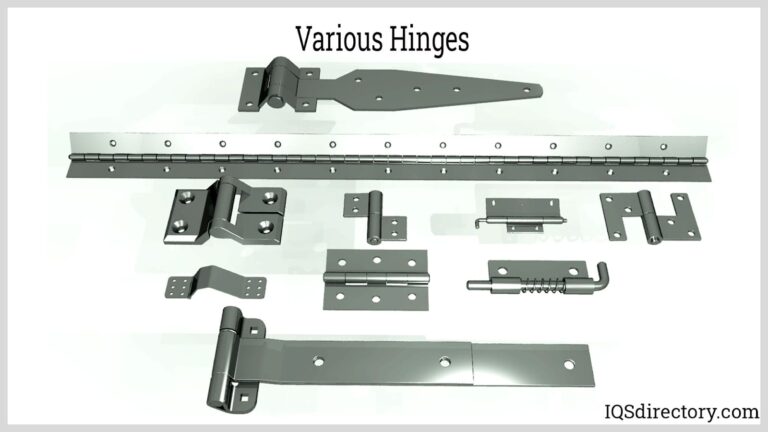

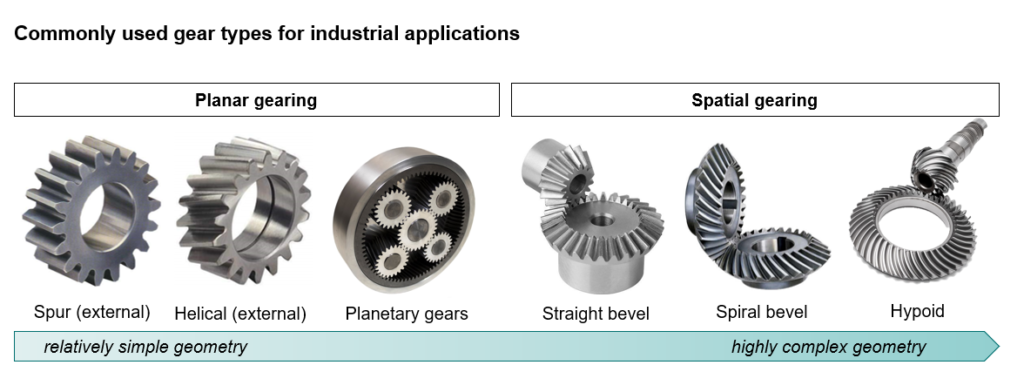

Understanding bevel side gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Teeth are straight and aligned towards the apex of the cone. | Machine tools, printing machines, differentials | Pros: Simpler manufacturing, no inward thrust. Cons: Limited to lower speed applications, cannot be ground post-heat treatment. |

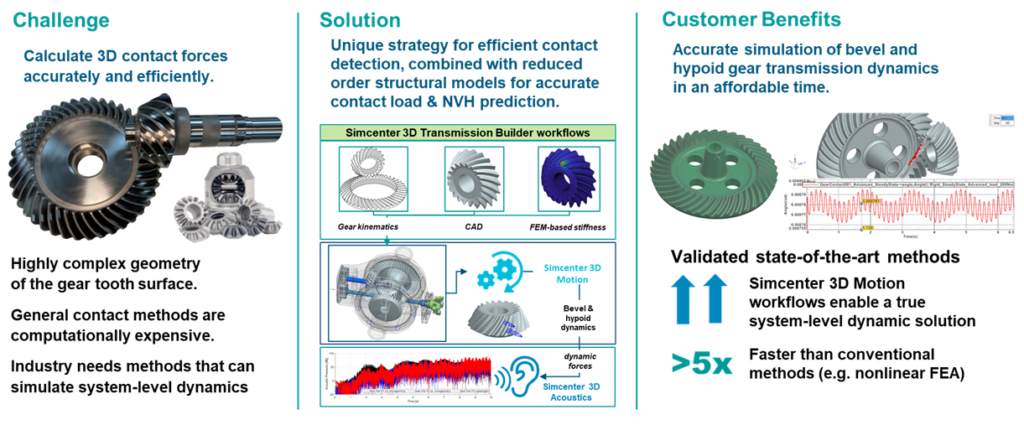

| Spiral Bevel Gears | Curved teeth that provide gradual engagement and smooth operation. | Automotive, aerospace, and high-speed machinery | Pros: High precision due to post-heat treatment grinding. Cons: More complex to manufacture and higher costs. |

| Hypoid Gears | Offset design allows for greater load capacity and efficiency. | Heavy machinery, automotive differentials | Pros: High torque transmission, smooth operation. Cons: More expensive and requires precise alignment. |

| Miter Gears | Special type of bevel gear with a 1:1 gear ratio. | Robotics, conveyor systems | Pros: Simple design, easy to install. Cons: Limited to applications requiring equal speed ratios. |

| Crown Gears | Feature a pitch angle of 90°, can engage with racks. | Elevators, winches, and lifting equipment | Pros: Versatile in applications, high efficiency. Cons: Requires precise manufacturing, can be costly. |

What Are the Key Characteristics of Straight Bevel Gears?

Straight bevel gears are characterized by their simple design, with teeth that are straight and directed towards the gear’s apex. This design makes them easier to manufacture and typically results in lower costs. They are primarily used in applications where lower speeds are sufficient, such as machine tools and printing machines. However, they cannot be ground after heat treatment, which may limit their use in high-precision applications. Buyers should consider the operational speed and load requirements before selecting this type.

Why Choose Spiral Bevel Gears for High-Speed Applications?

Spiral bevel gears are identified by their curved teeth, which allow for smooth and gradual engagement. This feature enhances operational efficiency and noise reduction, making them ideal for high-speed applications in sectors like automotive and aerospace. Their ability to be ground post-heat treatment means they can achieve high precision, a crucial factor for buyers seeking reliability in demanding environments. However, the complexity of their manufacturing process can lead to higher costs, which should be factored into purchasing decisions.

What Advantages Do Hypoid Gears Offer for Heavy Machinery?

Hypoid gears feature an offset design that allows for greater load capacities and smooth operation, making them suitable for heavy machinery and automotive differentials. Their unique construction enables efficient torque transmission, which is essential for applications requiring high power. Buyers should be aware that while hypoid gears offer significant advantages in performance, they also come with increased costs and the necessity for precise alignment during installation.

How Do Miter Gears Simplify Applications?

Miter gears are a specialized form of bevel gear that operates with a 1:1 gear ratio, making them particularly useful in applications where speed ratios need to be equal. Their straightforward design facilitates easy installation and integration into various systems, such as robotics and conveyor systems. However, their application is limited to scenarios where this specific speed ratio is required, which may restrict their versatility for some buyers.

In What Situations Are Crown Gears Most Effective?

Crown gears are distinguished by their unique pitch angle of 90 degrees, allowing them to engage with racks, making them suitable for applications like elevators and winches. Their versatility and high efficiency make them a popular choice in various mechanical systems. However, the requirement for precise manufacturing can lead to higher costs, which buyers should consider alongside the gear’s intended application and operational demands.

Key Industrial Applications of bevel side gear

| Industry/Sector | Specific Application of bevel side gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machine Tools | Enhanced precision and efficiency in machining | Material quality, gear type (spiral vs. straight), and customization options |

| Automotive | Differential Gear Systems | Improved power transmission and vehicle handling | Load capacity, noise reduction, and compatibility with existing systems |

| Mining and Construction | Heavy Equipment Gearboxes | Reliable performance under extreme conditions | Durability, resistance to wear, and availability of spare parts |

| Food and Beverage Processing | Conveyor Systems | Efficient transport of goods with minimal downtime | Hygiene standards, material suitability, and maintenance requirements |

| Renewable Energy | Wind Turbine Gearboxes | Increased energy efficiency and reliability | Gear ratio options, material for corrosion resistance, and sourcing lead times |

How is bevel side gear utilized in the manufacturing sector?

In manufacturing, bevel side gears are integral to CNC machine tools, where they facilitate precise movements and adjustments. These gears allow for the effective transfer of rotational motion between intersecting shafts, enhancing machining efficiency and accuracy. Buyers in this sector should prioritize high-quality materials and precise manufacturing methods, as these factors directly influence performance and longevity. Customization options may also be necessary to meet specific machine configurations and operational conditions.

What role do bevel side gears play in automotive applications?

In the automotive industry, bevel side gears are commonly used in differential gear systems, which are essential for distributing power to the wheels while allowing for differences in wheel speed during turns. This application significantly enhances vehicle handling and performance. B2B buyers must consider factors like load capacity and noise reduction, as well as compatibility with existing systems. Selecting gears that minimize wear and ensure smooth operation is crucial for maintaining vehicle reliability.

How do bevel side gears support mining and construction equipment?

Bevel side gears are critical in heavy equipment gearboxes within the mining and construction sectors, where they help transmit power efficiently under extreme load conditions. These gears must withstand harsh environments, making durability and wear resistance key considerations for procurement. Buyers should focus on sourcing gears that meet stringent quality standards and are readily available for maintenance and replacement, ensuring minimal downtime for machinery.

What benefits do bevel side gears offer in food and beverage processing?

In food and beverage processing, bevel side gears are utilized in conveyor systems to facilitate the smooth transport of goods. Their design helps maintain operational efficiency and minimizes downtime, which is vital in high-volume production environments. Buyers should consider hygiene standards and material suitability, as food safety is paramount. Additionally, understanding maintenance requirements can help prevent costly interruptions in production.

How are bevel side gears utilized in renewable energy applications?

In the renewable energy sector, particularly in wind turbine gearboxes, bevel side gears play a crucial role in optimizing energy efficiency. They enable the effective conversion of rotational energy from the turbine blades into usable power. For international buyers, sourcing gears that offer corrosion resistance and the appropriate gear ratio options is essential to ensure long-term reliability. Additionally, understanding sourcing lead times can help align with project timelines and operational demands.

3 Common User Pain Points for ‘bevel side gear’ & Their Solutions

Scenario 1: Sourcing High-Quality Bevel Side Gears for Precision Engineering Applications

The Problem: Many B2B buyers struggle with sourcing bevel side gears that meet stringent quality standards for precision engineering applications. In industries like aerospace or automotive, even the slightest deviation in gear specifications can lead to performance issues, safety hazards, or costly downtime. Buyers often face challenges verifying the reliability of suppliers, especially when dealing with international vendors. This lack of transparency can create anxiety about whether the sourced parts will deliver the required performance and durability.

The Solution: To mitigate these concerns, buyers should prioritize suppliers that offer comprehensive quality assurance processes, such as ISO certification. Conducting thorough due diligence on potential suppliers, including requesting samples and detailed specifications, can help ensure the gear meets specific engineering requirements. Additionally, utilizing CAD software to simulate the gear’s performance in the intended application can provide insights into its suitability before finalizing the purchase. Building long-term relationships with reputable manufacturers can also offer the added benefit of consistent quality and service.

Scenario 2: Overcoming Installation Challenges with Bevel Side Gears

The Problem: Installation difficulties can be a significant pain point for B2B buyers, particularly when bevel side gears are part of complex machinery setups. Misalignment during installation can lead to premature wear or failure, resulting in costly repairs and operational delays. Buyers often lack the expertise or technical support needed to ensure precise installation, leading to frustration and potential financial losses.

The Solution: To address installation challenges, buyers should invest in training programs for their technical staff or seek assistance from the gear manufacturer. Many suppliers offer installation guides, technical support, or even on-site assistance. It’s crucial to follow the manufacturer’s installation guidelines meticulously and use appropriate tools and fixtures to maintain alignment. Implementing a pre-installation checklist can also help ensure that all components are correctly positioned and secured, reducing the risk of future issues.

Scenario 3: Managing Costs While Ensuring Performance with Bevel Side Gears

The Problem: Cost management is a persistent issue for B2B buyers of bevel side gears, especially in competitive markets where margins are tight. Buyers often find themselves torn between selecting lower-cost options that may compromise performance and durability or investing in higher-quality products that fit their budget constraints. This dilemma can lead to uncertainty and hesitation in the procurement process.

The Solution: Buyers can effectively manage costs by conducting a total cost of ownership (TCO) analysis. This involves evaluating not just the initial purchase price but also factors such as lifespan, maintenance needs, and energy efficiency. Engaging in discussions with suppliers about bulk purchasing options or long-term contracts can also yield cost savings. Additionally, considering alternative materials or gear types—such as plastic bevel gears for lighter applications—may provide a balance between cost and performance. By fostering open communication with suppliers, buyers can negotiate better terms and identify innovative solutions that meet both budgetary and operational needs.

Strategic Material Selection Guide for bevel side gear

What are the Key Properties of Common Materials for Bevel Side Gears?

When selecting materials for bevel side gears, it’s crucial to consider their mechanical properties, which directly influence performance and longevity. Here, we analyze four common materials used in the manufacturing of bevel side gears: carbon steel, alloy steel, stainless steel, and engineering plastics.

How Does Carbon Steel Perform in Bevel Side Gear Applications?

Carbon steel, specifically grades like S45C, is widely used in bevel gear applications due to its favorable mechanical properties. It offers good tensile strength and hardness, making it suitable for moderate load applications. Carbon steel typically has a temperature rating of around 300°C and can withstand moderate pressure levels.

Illustrative image related to bevel side gear

Pros: Carbon steel is relatively inexpensive and easy to machine, which lowers manufacturing complexity. It also provides good wear resistance when properly heat-treated.

Cons: However, carbon steel is prone to corrosion if not properly coated or treated, which can limit its use in humid or corrosive environments.

Impact on Application: Carbon steel bevel gears are ideal for applications in dry environments or where lubrication is sufficient to mitigate wear.

Illustrative image related to bevel side gear

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or JIS, particularly for corrosion resistance if the gears will be exposed to harsh conditions.

What Advantages Does Alloy Steel Offer for Bevel Side Gears?

Alloy steels, such as SCM415, are engineered for enhanced strength and toughness. These materials can withstand higher loads and provide better fatigue resistance compared to standard carbon steels. Alloy steels typically have a temperature tolerance of up to 400°C and can handle higher pressure applications.

Pros: The primary advantage of alloy steel is its superior mechanical properties, which make it suitable for heavy-duty applications. It can also be treated to improve wear resistance.

Cons: The cost of alloy steel is higher than that of carbon steel, and the manufacturing process can be more complex due to the need for specialized heat treatments.

Impact on Application: Alloy steel bevel gears are well-suited for applications in industrial machinery, automotive differentials, and high-load environments.

Considerations for International Buyers: Compliance with standards like DIN and ASTM is critical, especially in European markets like Germany, where quality assurance is paramount.

How Does Stainless Steel Compare in Bevel Side Gear Manufacturing?

Stainless steel, particularly grades like SUS303, is favored for its excellent corrosion resistance and aesthetic appeal. It can operate effectively at temperatures up to 500°C and is suitable for environments where exposure to moisture or chemicals is a concern.

Pros: The main advantage of stainless steel is its resistance to rust and corrosion, which extends the lifespan of bevel gears in challenging environments.

Cons: However, stainless steel is more expensive than carbon and alloy steels and can be more difficult to machine, leading to increased manufacturing costs.

Impact on Application: Stainless steel bevel gears are ideal for food processing, pharmaceutical, and marine applications where hygiene and corrosion resistance are critical.

Illustrative image related to bevel side gear

Considerations for International Buyers: Buyers should be aware of specific compliance requirements for food-grade materials, particularly in Europe, where standards are stringent.

What Role Do Engineering Plastics Play in Bevel Side Gear Applications?

Engineering plastics, such as MC901, are increasingly used for bevel gears in applications requiring lightweight and low-noise operation. These materials can operate effectively at temperatures up to 80°C and are suitable for low-load applications.

Pros: Engineering plastics are lightweight, resistant to corrosion, and can operate without lubrication, reducing maintenance costs.

Cons: The primary limitation is their lower load-bearing capacity compared to metals, making them unsuitable for high-stress applications.

Impact on Application: Plastic bevel gears are commonly used in consumer electronics, toys, and light machinery where noise reduction is essential.

Considerations for International Buyers: Buyers should ensure that the selected plastic grades meet local compliance standards, particularly in regions where environmental regulations are strict.

Summary Table of Material Selection for Bevel Side Gears

| Material | Typical Use Case for bevel side gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Moderate load applications | Cost-effective and easy to machine | Prone to corrosion without treatment | Low |

| Alloy Steel | Heavy-duty industrial machinery | Superior strength and fatigue resistance | Higher cost and complex manufacturing | Med |

| Stainless Steel | Food processing and marine applications | Excellent corrosion resistance | More expensive and difficult to machine | High |

| Engineering Plastics | Consumer electronics and light machinery | Lightweight and low-noise operation | Lower load capacity than metals | Med |

This guide provides a comprehensive overview of material selection for bevel side gears, offering B2B buyers critical insights to make informed decisions based on their specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bevel side gear

What Are the Main Stages in the Manufacturing Process of Bevel Side Gears?

The manufacturing process for bevel side gears involves several critical stages, each designed to ensure precision and quality. Understanding these stages can help B2B buyers assess the capabilities and reliability of potential suppliers.

Material Preparation: What Materials Are Commonly Used for Bevel Side Gears?

The first step in the manufacturing process is material preparation. Bevel gears are typically made from a variety of materials, including carbon steel (such as S45C and SCM415), alloy steel, and engineering plastics like MC901. The choice of material directly affects the gear’s performance, strength, and application suitability. For instance, carbon steels are common for their balance of cost and performance, while plastics may be used in applications requiring lower loads and noise reduction.

How Are Bevel Side Gears Formed?

Following material preparation, the next stage is forming the gear teeth. This process can be done through several techniques, including:

- Cutting: Traditional methods such as hobbing or shaping are used to create the tooth profile. This is often the initial step for straight bevel gears.

- Grinding: For higher precision, especially in spiral bevel gears, grinding is employed post-heat treatment to enhance accuracy and surface finish.

- Forging: This method is utilized for high-strength applications, where the gear is shaped under heat and pressure.

- Casting: In some cases, especially for complex shapes, casting methods may be employed.

Each of these techniques requires specific machinery and expertise, which can vary by manufacturer.

What Are the Key Finishing Steps in Bevel Side Gear Manufacturing?

After forming, bevel side gears undergo finishing processes to achieve the desired specifications. These may include:

- Heat Treatment: Gears are often subjected to processes like carburizing or induction hardening to improve wear resistance and strength.

- Surface Treatment: Techniques such as polishing or coating may be applied to reduce friction and enhance durability.

- Assembly: If the bevel gear is part of a larger assembly, such as a gearbox, precise assembly processes are vital to ensure proper meshing and function.

What Quality Assurance Standards Are Relevant for Bevel Side Gears?

Quality assurance is a critical component of the manufacturing process, particularly for international B2B transactions. Various standards and checkpoints ensure that bevel side gears meet the required specifications.

Which International Standards Should Buyers Look For?

International standards such as ISO 9001 are essential for ensuring consistent quality in manufacturing processes. This standard focuses on quality management systems and helps organizations enhance customer satisfaction through effective process management. In addition to ISO standards, industry-specific certifications, such as CE marking for safety and compliance in Europe or API standards for oil and gas applications, may also be relevant depending on the intended use of the bevel gears.

What Are the Key Quality Control Checkpoints in Bevel Gear Manufacturing?

Quality control (QC) processes are structured around several critical checkpoints:

- Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor dimensions, tolerances, and other critical parameters.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted to verify that the finished bevel gears meet all specifications and performance criteria.

What Testing Methods Are Commonly Used for Bevel Side Gears?

Various testing methods are employed to validate the quality of bevel side gears, including:

- Dimensional Inspection: Utilizing tools such as calipers and micrometers to verify the dimensions and tolerances of the gears.

- Functional Testing: This includes operational tests to assess performance under load conditions, ensuring that the gears operate smoothly and efficiently.

- Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing may be employed to detect internal flaws without damaging the gears.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Buyers can take several steps:

Illustrative image related to bevel side gear

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing and QC processes. This includes reviewing documentation, inspecting facilities, and assessing equipment.

- Requesting Quality Reports: Suppliers should provide documentation of their QC processes, including inspection records and compliance certifications.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of a supplier’s quality standards and practices.

What Are the QC Certification Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of certification nuances that can affect product quality and compliance. Different countries may have varying standards and regulations, making it essential for buyers to ensure that their suppliers meet both local and international requirements. For instance, understanding the implications of CE marking in Europe versus ANSI standards in the U.S. can significantly impact procurement decisions.

Conclusion

In summary, the manufacturing processes and quality assurance practices for bevel side gears are multifaceted and critical to ensuring product reliability and performance. By understanding the stages of manufacturing, relevant standards, QC checkpoints, and testing methods, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only aids in sourcing high-quality bevel gears but also helps build long-term partnerships based on trust and compliance in international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bevel side gear’

To successfully procure bevel side gears, a structured approach is essential. This guide provides a comprehensive checklist designed to assist B2B buyers in making informed decisions, ensuring that your sourcing process is efficient and effective.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify the technical specifications of the bevel side gear you require. This includes details such as gear type (straight or spiral), material (steel, stainless steel, or plastic), and dimensions (module size, tooth count, etc.). A clear understanding of these specifications not only helps in obtaining accurate quotes but also ensures compatibility with your machinery.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in bevel side gears. Look for manufacturers with a solid track record in your industry and positive reviews from other buyers. Utilize online directories, industry forums, and trade shows to gather a list of potential suppliers, focusing on those with global shipping capabilities, particularly in your target regions like Africa and South America.

Step 3: Evaluate Supplier Capabilities and Certifications

Before making any commitments, assess the capabilities of your shortlisted suppliers. Verify their certifications, such as ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about their manufacturing processes, technology used (e.g., Gleason or Klingelnberg methods), and their ability to customize products based on your specifications.

Step 4: Request Samples and Technical Documentation

To ensure that the bevel side gears meet your quality standards, request samples from your potential suppliers. Along with samples, ask for technical documentation, including CAD drawings and material specifications. This step is crucial for assessing the gear’s performance and compatibility with your existing systems.

Step 5: Compare Pricing and Terms of Sale

Once you have received quotes, compare pricing structures and terms of sale from different suppliers. Look beyond the initial cost; consider factors such as minimum order quantities, payment terms, lead times, and shipping costs. A supplier offering competitive pricing but lengthy lead times may not serve your needs effectively.

Step 6: Verify After-Sales Support and Warranty Policies

Investigate the after-sales support provided by your chosen supplier. A reliable supplier should offer robust customer service, including assistance with installation and troubleshooting. Additionally, review their warranty policies to ensure that you are covered in case of defects or performance issues.

Step 7: Finalize Your Purchase and Establish a Communication Plan

After selecting a supplier, finalize your purchase agreement, ensuring all terms are clearly documented. Establish a communication plan for ongoing interaction, including regular updates on production status and shipping. This proactive approach helps maintain a smooth relationship and ensures that any potential issues are addressed promptly.

By following these steps, B2B buyers can navigate the complexities of sourcing bevel side gears effectively, ensuring they choose the right products and suppliers for their operational needs.

Comprehensive Cost and Pricing Analysis for bevel side gear Sourcing

Understanding the cost structure and pricing dynamics for bevel side gears is essential for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the key components of costs and influential pricing factors, equipping buyers with actionable insights.

What Are the Key Cost Components in Bevel Side Gear Manufacturing?

The cost structure of bevel side gears typically includes several critical components:

-

Materials: The choice of materials significantly impacts costs. Common materials include S45C carbon steel, SCM415 alloy steel, and engineering plastics like MC901. The price varies based on material properties, such as strength and corrosion resistance. For example, stainless steel options generally come at a premium due to their durability.

-

Labor: Labor costs can fluctuate based on the region and the complexity of the gear manufacturing process. Highly skilled labor is required for precision machining, especially for spiral bevel gears that undergo additional grinding post-heat treatment.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs, making it crucial for suppliers to optimize their operations.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or high-precision gears. Tooling costs are amortized over production runs, affecting the overall price per unit.

-

Quality Control (QC): Ensuring high-quality standards through rigorous QC processes adds to the cost. Certifications such as ISO 9001 can enhance trust and potentially increase the price due to the associated quality assurance measures.

-

Logistics: Transportation and shipping costs play a vital role, especially for international transactions. Factors such as shipping methods, distance, and customs duties can significantly affect the total cost.

-

Margin: Suppliers typically add a margin to cover profit and risk. This margin can vary widely based on market conditions and the supplier’s position within the supply chain.

What Influences Pricing for Bevel Side Gears?

Several factors can influence the pricing of bevel side gears:

-

Volume/MOQ: Suppliers often provide discounts for larger orders, so understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom gear specifications can lead to increased costs due to unique tooling and material requirements. Buyers should assess whether standard options can meet their needs to reduce expenses.

-

Quality and Certifications: Higher quality gears that meet stringent specifications (like those used in critical applications) will command higher prices. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can all affect pricing. Established suppliers with proven track records may charge more but provide greater reliability.

-

Incoterms: Understanding the terms of trade can help buyers anticipate additional costs. Different Incoterms (like FOB or CIF) can shift responsibility for shipping and insurance, impacting the total cost.

How Can Buyers Optimize Costs and Negotiate Effectively?

To achieve cost-efficiency in bevel side gear sourcing, buyers should consider the following tips:

-

Negotiate with Suppliers: Open discussions about pricing can lead to better deals, especially for bulk orders. Leverage relationships and long-term partnerships to negotiate favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as maintenance, longevity, and performance. Investing in higher-quality gears may yield savings over time.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local market conditions that can impact pricing. Staying informed can aid in making strategic purchasing decisions.

-

Assess Supplier Capabilities: Before committing, evaluate the supplier’s manufacturing capabilities and quality standards. This assessment can help avoid unforeseen costs related to defects or delays.

Conclusion

The cost and pricing structure for bevel side gear sourcing involves a complex interplay of materials, labor, logistics, and supplier dynamics. By understanding these components and factors, international B2B buyers can make informed decisions, ensuring they achieve both quality and cost-efficiency in their sourcing strategies. Always remember that indicative prices can vary significantly based on the specifics of each order, so detailed discussions with suppliers are crucial.

Alternatives Analysis: Comparing bevel side gear With Other Solutions

Exploring Alternatives to Bevel Side Gears

In the realm of mechanical engineering, selecting the right gear system is crucial for optimizing performance and efficiency. Bevel side gears are widely used for transmitting power between intersecting shafts; however, there are viable alternatives that may better suit specific applications. This section provides a comparative analysis of bevel side gears against alternative solutions, highlighting key factors that influence purchasing decisions.

| Comparison Aspect | Bevel Side Gear | Worm Gear | Helical Gear |

|---|---|---|---|

| Performance | High efficiency (98-99%) | Moderate efficiency (70-85%) | High efficiency (90-95%) |

| Cost | Moderate to high | Generally low | Moderate to high |

| Ease of Implementation | Requires precise alignment | Easier to install due to compact design | Complex installation |

| Maintenance | Moderate maintenance needs | Low maintenance | Moderate maintenance |

| Best Use Case | High-speed applications | Low-speed, high-torque applications | Versatile, medium-speed applications |

What Are the Key Advantages and Disadvantages of Worm Gears?

Worm gears are a popular alternative for power transmission, particularly in applications requiring high torque at low speeds. Their unique design allows for a compact setup, making them ideal for space-constrained environments. However, the trade-off is a lower efficiency compared to bevel gears, which can result in increased heat generation and energy loss. Additionally, while worm gears require less frequent maintenance, they can suffer from wear over time due to their sliding contact nature.

How Do Helical Gears Compare to Bevel Side Gears?

Helical gears are another alternative that offers high efficiency and smooth operation, making them suitable for various applications. They are designed with angled teeth, allowing for gradual engagement, which reduces noise and vibration. While they provide a higher efficiency than worm gears, they can be more complex to install and require precise alignment similar to bevel gears. Maintenance is generally moderate, as they may require periodic checks for wear but are less prone to wear compared to worm gears.

Which Gear Solution is Best for Your Application?

Choosing the right gear solution depends on several factors, including the specific application, performance requirements, and budget constraints. Bevel side gears are optimal for high-speed applications that demand high efficiency and power transmission. If space is a concern and the application involves low-speed, high-torque needs, worm gears may be more suitable. On the other hand, for versatile applications requiring smooth operation at medium speeds, helical gears can provide a balanced solution.

In conclusion, B2B buyers should carefully evaluate their operational needs, considering factors such as performance, cost, ease of implementation, and maintenance requirements when selecting between bevel side gears and their alternatives. Understanding these variables will empower buyers to make informed decisions that align with their business objectives and operational efficiency.

Essential Technical Properties and Trade Terminology for bevel side gear

What Are the Key Technical Properties of Bevel Side Gears?

Understanding the technical specifications of bevel side gears is essential for B2B buyers to ensure compatibility and performance in their applications. Here are some critical properties to consider:

1. Material Grade

Bevel side gears can be constructed from various materials, including carbon steel (e.g., S45C, SCM415) and engineering plastics (e.g., MC901). The choice of material affects the gear’s strength, wear resistance, and overall durability. For instance, SCM415 is an alloy steel known for its excellent mechanical properties, making it suitable for high-load applications. Selecting the right material is crucial for optimizing performance and longevity, particularly in harsh operating environments.

2. Tooth Finish

The tooth finish of bevel side gears can be categorized as cut (non-ground) or ground. Ground teeth provide superior accuracy and surface finish, which can lead to reduced noise and improved efficiency during operation. For B2B buyers, understanding the significance of tooth finish is vital for ensuring smooth operation and minimizing maintenance costs over time.

3. Module and Pitch

The module refers to the size of the teeth and is defined as the ratio of the pitch diameter to the number of teeth. It is a critical specification that influences the gear’s strength and load-bearing capacity. A higher module generally indicates a more robust gear, suitable for heavy-duty applications. Buyers should consider the module when selecting gears to ensure they meet the required torque and speed specifications.

4. Speed Ratio

Speed ratio defines the relationship between the input and output speeds of the gears. For bevel side gears, common speed ratios range from 1.5 to 60, depending on the type and application. A proper understanding of speed ratios helps buyers select gears that can achieve desired performance outcomes, especially in applications requiring specific speed adjustments.

5. Hardening Method

The hardening process, such as carburizing or induction hardening, enhances the material’s hardness and wear resistance. This is particularly important for gears subjected to high stress and friction. Buyers should inquire about the hardening methods used in the bevel side gears to ensure they are suitable for their application’s operational demands.

What Are Common Trade Terms Related to Bevel Side Gears?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B space. Here are several common terms related to bevel side gears:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is important for buyers to ensure compatibility with existing systems and machinery.

Illustrative image related to bevel side gear

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers to understand their purchasing power and inventory management, especially when dealing with specialized components like bevel side gears.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. For B2B buyers, crafting an effective RFQ can facilitate better negotiations and ensure that all necessary specifications are communicated clearly to potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in international trade, as it helps clarify logistics and cost responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the context of bevel side gears, understanding lead times is crucial for project planning and inventory management, especially in industries where timely delivery is critical to operations.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their selection of bevel side gears meets their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the bevel side gear Sector

What Are the Key Trends Shaping the Global Bevel Side Gear Market?

The bevel side gear market is witnessing a transformation driven by several global factors. One of the primary drivers is the surge in automation across various industries, including automotive, aerospace, and manufacturing. This trend is propelling the demand for precision-engineered components, such as bevel gears, which are essential for efficient power transmission between intersecting shafts. Additionally, the growing emphasis on lightweight and compact machinery is leading to an increased adoption of spiral bevel gears, known for their high efficiency and smooth operation.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are also influencing sourcing trends. Manufacturers are increasingly integrating smart technologies into their production processes, enhancing the accuracy and reliability of bevel gears. As a result, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must stay updated on technological advancements to make informed purchasing decisions.

Furthermore, the market dynamics are shifting towards a preference for customized solutions. Buyers are increasingly seeking suppliers who can provide tailored bevel gear solutions that meet specific operational requirements, including unique sizes, materials, and performance specifications. This customization trend underscores the importance of strong supplier relationships and effective communication in the sourcing process.

How Does Sustainability Influence Sourcing Decisions in the Bevel Side Gear Sector?

Sustainability is becoming a significant consideration in the sourcing of bevel side gears, with businesses increasingly aware of their environmental impact. The manufacturing of bevel gears often involves processes that can generate substantial waste and emissions. Consequently, buyers are prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint through efficient manufacturing practices and waste management.

Ethical sourcing is equally important. Companies are scrutinizing their supply chains to ensure compliance with labor standards and environmental regulations. This scrutiny extends to the materials used in bevel gear production. The use of sustainable materials, such as recycled metals or eco-friendly plastics, is gaining traction among buyers looking to enhance their sustainability profile.

Furthermore, certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are increasingly sought after by B2B buyers. These certifications serve as indicators of a supplier’s commitment to sustainable practices, providing buyers with confidence in their sourcing decisions. By aligning procurement strategies with sustainability goals, businesses can not only mitigate risks but also enhance their brand reputation in a competitive market.

What Is the Historical Context of Bevel Side Gears in B2B Sourcing?

The evolution of bevel side gears can be traced back to the industrial revolution, where the need for efficient power transmission in machinery became paramount. Initially, straight bevel gears were the standard due to their simpler manufacturing processes. However, as industries advanced, the demand for higher efficiency and smoother operation led to the development of spiral bevel gears.

The introduction of advanced manufacturing techniques, such as the Gleason method, revolutionized bevel gear production, enabling the creation of high-precision gears that could withstand greater loads. This historical progression highlights the importance of innovation in the bevel gear sector and its impact on sourcing strategies. Today, B2B buyers must consider not only the technical specifications of bevel gears but also the historical context that informs current manufacturing practices and market dynamics.

In conclusion, navigating the bevel side gear market requires a keen understanding of emerging trends, sustainability considerations, and the historical evolution of the product. By leveraging this knowledge, international B2B buyers can make informed sourcing decisions that align with their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of bevel side gear

-

1. How do I select the right bevel side gear for my application?

To select the appropriate bevel side gear, consider factors such as the required torque, speed, and the angle between shafts. Evaluate the gear type—straight or spiral—based on your application needs. Spiral bevel gears provide smoother operation and reduced noise, making them suitable for high-performance applications. Additionally, assess the materials used, as they impact durability and performance. Consulting with suppliers for technical specifications and possibly utilizing CAD software for design integration can help ensure compatibility with your machinery. -

2. What are the key factors to consider when sourcing bevel side gears internationally?

When sourcing bevel side gears internationally, prioritize supplier credibility and reliability. Look for manufacturers with a proven track record, quality certifications (like ISO), and positive customer reviews. Consider the supplier’s production capabilities, lead times, and their ability to meet your customization needs. It’s also essential to understand the import regulations and tariffs in your region, as these can significantly affect overall costs and delivery timelines. -

3. What customization options are available for bevel side gears?

Many manufacturers offer customization options for bevel side gears, including modifications in size, material, tooth design, and finishing processes. Customization is particularly useful for specific applications that require unique specifications. Discuss your precise requirements with potential suppliers to determine the feasibility and cost implications of custom designs. Additionally, inquire about the supplier’s experience with custom projects to ensure they can meet your expectations. -

4. What is the minimum order quantity (MOQ) for bevel side gears?

Minimum order quantities for bevel side gears can vary widely depending on the manufacturer and the complexity of the gear. Typically, MOQs may range from a few dozen to several hundred units. When negotiating with suppliers, clarify your needs and express any concerns about inventory management. Some manufacturers might offer flexibility in MOQs for first-time orders or trial runs, especially if you are testing new designs or materials. -

5. What payment terms should I expect when purchasing bevel side gears?

Payment terms can differ significantly among suppliers. Common options include upfront payments, deposits, or net payment terms (such as 30 or 60 days after delivery). It’s crucial to discuss and agree upon payment terms before finalizing any order. Ensure that you understand any applicable fees, currency exchange rates, and the implications of international transactions, such as letter of credit requirements, to avoid unexpected costs. -

6. How can I ensure the quality of bevel side gears I purchase?

To ensure quality, request samples from potential suppliers before placing large orders. Inquire about their quality assurance processes and standards, such as ISO certification, and ask for detailed inspection reports. Engaging third-party inspection services can also provide an unbiased evaluation of the gear’s performance and adherence to specifications. Establishing a clear communication channel with the supplier regarding quality expectations will help mitigate risks associated with subpar products. -

7. What logistics considerations should I be aware of when importing bevel side gears?

Logistics is a critical aspect of importing bevel side gears. Consider shipping methods (air, sea, or land) based on your budget and urgency. Factor in customs clearance processes, duties, and taxes that may apply upon arrival in your country. Collaborating with a reliable logistics provider can streamline the process and ensure timely delivery. Additionally, maintaining open lines of communication with your supplier regarding shipping schedules and tracking can help manage expectations. -

8. How do I handle warranty and after-sales service for bevel side gears?

When purchasing bevel side gears, clarify the warranty terms with your supplier, including the duration and coverage details. Most reputable manufacturers offer warranties that cover defects in materials and workmanship. Understanding the claims process is essential; ensure you know how to report issues and what documentation is required. Additionally, inquire about after-sales support, such as replacement parts availability and technical assistance, to ensure smooth operation and maintenance of your equipment.

Top 6 Bevel Side Gear Manufacturers & Suppliers List

1. KHK – Bevel Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Bevel Gears are cone-shaped gears that transmit power between two intersecting axles. They are classified into straight bevel gears (no helix angles) and spiral bevel gears (with helix angles). KHK manufactures bevel gears using the Gleason method, which is preferred for its superior noise reduction capabilities. Key specifications include:

1. **MHP High-Ratio Hypoid Gears**: Module: 1 – 1.5, Spe…

2. Servocity – MOD 1.5 Bevel Gears (2:1 Ratio)

Domain: servocity.com

Registered: 2000 (25 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning. Compatible miter gears can be mixed and matched within the same series. Key products include:

– MOD 1.5 Bevel Gears (2:1 Ratio): Requires specific tooth profile, only compatible with pinion gear.

– MOD 1 Miter Gears (1:1 Ratio): Two-piece steel construction, pin…

3. Reddit – Artistic Bevel Gears

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bevel gears designed for a 90-degree shift in angle of rotation; unique profile required (4″ diameter, .2″ thickness); intended for artistic rather than practical use; no significant load or forces involved; interest in understanding gear design math (tooth ratio, cone angle, addendum/dedendum measure, pitch); desire to learn for future projects with tighter tolerances.

4. Solink Motor – Helical Bevel Gear

Domain: solinkmotor.com

Registered: 2023 (2 years)

Introduction: {“name”: “Helical bevel gear with 10 straight teeth on the upper side”, “price”: “€19.99”, “SKU”: “SL-001-New-D”, “description”: “This helical bevel gear, featuring 10 straight teeth on the upper side, is designed for maximum compatibility with mainstream standard spur and sector gears. However, this helical bevel does not work with G&G M14 gearbox and TM AK Gearbox.”, “package_includes”: [“Helica…

5. ScienceDirect – Bevel Gears

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Bevel gears are conical-shaped gears used to transmit rotational power between shafts typically oriented at an angle of 90 degrees. They are commonly applied in devices such as cordless hand-tools and automotive transmissions. Bevel gears can be designed for various angles, although they are most frequently used for 90° drives. They differ from spur gears in shape and shaft orientation, with bevel…

6. Engineering Stack Exchange – Bevel Gear Design Insights

Domain: engineering.stackexchange.com

Registered: 2009 (16 years)

Introduction: The user is designing a mechanism with two parallel shafts rotating in the same direction, using bevel gears to connect a third shaft at 90 degrees. The user is considering 3D printing the gears and is interested in the impact of gear size and the number of teeth on operation. They are looking for advice on gear types (straight, spiral) and the effect of tooth geometry on rotation direction. The d…

Strategic Sourcing Conclusion and Outlook for bevel side gear

In the ever-evolving landscape of industrial machinery, strategic sourcing of bevel side gears is paramount for optimizing operational efficiency and ensuring competitive advantage. The insights gained from the differentiation between straight and spiral bevel gears highlight the importance of selecting the appropriate gear type based on application requirements, such as load capacity, noise reduction, and manufacturing method. For international B2B buyers, especially in Africa, South America, the Middle East, and Europe, leveraging these insights can lead to significant cost savings and enhanced product performance.

Understanding the nuances of material selection, gear manufacturing processes, and the latest technological advancements enables companies to make informed decisions that align with their operational goals. As the demand for high-precision and durable gear solutions continues to grow, fostering partnerships with reliable suppliers will be crucial.

Looking ahead, businesses are encouraged to embrace strategic sourcing practices that prioritize quality, efficiency, and innovation. This proactive approach will not only enhance your supply chain resilience but also position your organization for future growth in an increasingly competitive market. Explore partnerships today that will propel your operations forward and meet the challenges of tomorrow.

Illustrative image related to bevel side gear

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.