Top 6 9V Ac Power Supply Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 9v ac power supply

In today’s interconnected global economy, sourcing a reliable 9V AC power supply can be a significant challenge for businesses operating in diverse regions, including Africa, South America, the Middle East, and Europe. With varying quality standards, compliance regulations, and logistical considerations, international B2B buyers must navigate a complex landscape to ensure they select the right power solutions for their operational needs. This guide serves as a comprehensive resource, detailing the various types of 9V AC power supplies, their applications across different industries, and essential factors to consider when vetting suppliers.

From understanding the technical specifications and safety features to evaluating cost considerations and shipping logistics, this guide empowers buyers to make informed purchasing decisions. It also highlights best practices for supplier selection, ensuring that businesses can find partners who not only meet their quality requirements but also align with their operational goals. Whether you are based in Brazil, Saudi Arabia, or any other part of the globe, this guide aims to simplify the sourcing process, ultimately helping you secure the most effective and efficient power solutions for your needs. By leveraging this knowledge, international buyers can mitigate risks, reduce costs, and enhance their overall supply chain efficiency.

Understanding 9v ac power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall Adapter | Compact design, typically 100-240V input, 9V output | Electronics, labeling machines, toys | Pros: Easy to use, widely available. Cons: Limited output current. |

| AC-AC Power Supply | Direct AC output, often with higher current ratings | Industrial equipment, medical devices | Pros: Higher power capacity, reliable for continuous use. Cons: Bulkier design. |

| Universal Power Adapter | Adjustable voltage settings, multiple output types | Versatile applications across devices | Pros: Flexibility for various devices. Cons: May be more expensive. |

| Custom Power Supply | Tailored specifications for unique applications | Specialized machinery, custom electronics | Pros: Optimized performance for specific needs. Cons: Longer lead times. |

| Multi-Voltage Adapter | Supports multiple voltage outputs including 9V AC | Consumer electronics, gadgets | Pros: Versatile for different devices. Cons: Complexity in usage. |

What Are the Key Characteristics of Wall Adapters for 9V AC Power Supply?

Wall adapters are among the most common types of 9V AC power supplies. They are designed for ease of use, connecting directly to wall sockets and providing 9V output for various devices. Typically, they support a wide input voltage range of 100-240V, making them suitable for international use. B2B buyers often prefer wall adapters for applications in electronics, labeling machines, and toys due to their compact design and availability. However, they may have limitations in output current, which could restrict their use in high-power applications.

How Do AC-AC Power Supplies Differ in Functionality and Application?

AC-AC power supplies provide direct AC output at specified voltage levels, such as 9V. These units often feature higher current ratings, making them ideal for industrial equipment and medical devices that require reliable power for continuous operation. B2B buyers value these power supplies for their robustness and ability to handle significant loads. However, their bulkier design can be a drawback for applications where space is a concern, and they may require more careful installation.

Why Consider a Universal Power Adapter for 9V AC Applications?

Universal power adapters are designed to accommodate various voltage settings, making them a versatile choice for businesses with diverse equipment needs. These adapters can provide 9V AC output along with other voltage options, allowing for flexibility across multiple devices. B2B applications often include consumer electronics and gadgets, where the ability to switch voltage settings is beneficial. While they offer great adaptability, universal adapters may come at a higher price point compared to standard wall adapters.

What Advantages Do Custom Power Supplies Offer for Specific Needs?

Custom power supplies are tailored to meet the unique specifications of specific applications, making them a valuable choice for businesses with specialized machinery or custom electronics. These power supplies ensure optimized performance and reliability, critical in sectors like manufacturing and medical technology. However, B2B buyers should consider the longer lead times associated with custom orders and the potential for higher costs compared to off-the-shelf solutions.

How Do Multi-Voltage Adapters Enhance Device Compatibility?

Multi-voltage adapters provide the ability to output various voltage levels, including 9V AC, making them suitable for a wide range of consumer electronics. Their versatility allows businesses to streamline their inventory by using a single adapter type for multiple devices. However, the complexity of operation and potential confusion among users can be a disadvantage. B2B buyers should weigh the benefits of compatibility against the learning curve for staff in using these adapters effectively.

Key Industrial Applications of 9v ac power supply

| Industry/Sector | Specific Application of 9v ac power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Powering Label Makers | Cost savings by reducing battery replacement needs | Compatibility with various devices, safety certifications |

| Telecommunications | Supporting Network Equipment | Ensures reliable operation of critical communication devices | Voltage stability, durability, and environmental ratings |

| Medical Equipment | Operating Diagnostic Devices | Enhances patient safety and device reliability | Compliance with medical standards, low electromagnetic interference |

| Industrial Automation | Driving Sensors and Controllers | Increases efficiency and reduces downtime | Robustness, ease of integration, and technical support |

| Retail Solutions | Powering Point of Sale (POS) Systems | Streamlines transactions and improves customer experience | Availability of adapters, warranty, and after-sales service |

How is the 9V AC Power Supply Used in Consumer Electronics?

In the consumer electronics sector, 9V AC power supplies are commonly used to power devices such as label makers. These devices often require consistent voltage to maintain functionality without the hassle of frequent battery changes. For international buyers, especially in regions like Africa and South America, sourcing adapters that are compatible with various label makers is crucial. Additionally, businesses should prioritize products with safety certifications to ensure compliance with local regulations.

Illustrative image related to 9v ac power supply

Why is 9V AC Power Supply Important for Telecommunications?

Telecommunications equipment, including routers and network switches, often relies on 9V AC power supplies for stable operation. A reliable power source is essential to maintain connectivity and performance, especially in regions with fluctuating power quality, such as the Middle East. When sourcing these power supplies, businesses should consider factors like voltage stability and the ability to withstand environmental conditions to ensure uninterrupted service.

What Role Does 9V AC Power Supply Play in Medical Equipment?

In the medical field, 9V AC power supplies are vital for powering diagnostic devices such as ultrasound machines and portable monitors. These devices must operate reliably to ensure patient safety and accurate diagnostics. Buyers in Europe and other regions must ensure that the power supplies meet stringent medical standards and exhibit low electromagnetic interference. This compliance is crucial for maintaining the integrity of sensitive medical equipment.

How is 9V AC Power Supply Utilized in Industrial Automation?

Industrial automation systems often use 9V AC power supplies to drive sensors and control systems. These power supplies contribute to increased efficiency and reduced operational downtime. For businesses in sectors like manufacturing, sourcing robust and durable power supplies is critical. They should also seek suppliers who offer technical support and integration assistance to ensure smooth operation within their existing systems.

What is the Significance of 9V AC Power Supply in Retail Solutions?

In retail environments, 9V AC power supplies are essential for powering Point of Sale (POS) systems, which streamline transactions and enhance customer service. A reliable power source ensures that these systems remain operational during peak hours. International buyers should focus on the availability of adapters that fit their local standards and inquire about warranty and after-sales support to mitigate future operational risks.

3 Common User Pain Points for ‘9v ac power supply’ & Their Solutions

Scenario 1: Inconsistent Voltage Output Leading to Equipment Failure

The Problem: Many businesses rely on 9V AC power supplies to operate sensitive electronic devices such as label printers, security systems, and other equipment. A common challenge arises when the voltage output fluctuates, causing devices to malfunction or even sustain damage. This inconsistency can lead to costly downtimes and repairs, disrupting operations and affecting productivity. For buyers in regions with unstable power grids, such as parts of Africa or South America, the risk of voltage irregularities is even higher, making it crucial to find reliable solutions.

Illustrative image related to 9v ac power supply

The Solution: To mitigate voltage inconsistency, B2B buyers should prioritize sourcing power supplies from reputable manufacturers that offer multi-protect features, including overvoltage and overcurrent protection. When evaluating potential suppliers, request detailed specifications and certifications that indicate compliance with international quality standards. Additionally, consider investing in voltage regulation devices or uninterruptible power supplies (UPS) that can stabilize output voltage before it reaches your equipment. Regular maintenance checks on the power supply units can also identify any signs of wear or malfunction before they lead to significant operational disruptions.

Scenario 2: Compatibility Issues with Existing Equipment

The Problem: Another significant pain point for B2B buyers is ensuring compatibility between new 9V AC power supplies and existing equipment. Many businesses have a mix of devices from different manufacturers, each requiring specific power adapter configurations. This lack of standardization can lead to frustration when new adapters do not fit or function as expected, resulting in wasted time and resources in the procurement process.

The Solution: To avoid compatibility issues, it’s essential to conduct thorough assessments of your current equipment’s power requirements, including output voltage, amperage, and connector types. When sourcing new power supplies, look for adapters that provide detailed compatibility lists with the devices you own. Additionally, consider purchasing universal power adapters with adjustable voltage settings and interchangeable connectors. This flexibility can streamline the procurement process and reduce the need for multiple specific adapters, ultimately saving costs and simplifying inventory management.

Scenario 3: Supply Chain Delays and Unreliable Shipping

The Problem: For international B2B buyers, especially in emerging markets, supply chain delays can pose a significant challenge when sourcing 9V AC power supplies. Factors such as customs clearance, logistical inefficiencies, and regional shipping constraints can lead to prolonged lead times, risking project timelines and customer satisfaction. These delays can be particularly detrimental for businesses that require immediate replacements for critical equipment.

The Solution: To navigate supply chain challenges, it’s advisable for B2B buyers to establish relationships with multiple suppliers, including local distributors and manufacturers. This diversification can provide backup options in case of delays with one vendor. Additionally, engaging suppliers who offer reliable shipping options, such as expedited services or guaranteed delivery times, can enhance predictability. When negotiating with suppliers, inquire about their shipping policies, average delivery times, and any potential customs duties that may apply. Creating a robust inventory management system that anticipates demand and allows for proactive ordering can also help mitigate the impact of supply chain disruptions, ensuring your operations run smoothly without interruption.

Strategic Material Selection Guide for 9v ac power supply

What Are the Key Materials Used in 9V AC Power Supplies?

When selecting materials for 9V AC power supplies, it is essential to consider their properties, advantages, limitations, and suitability for various applications. Below is an analysis of four common materials used in the manufacturing of these power supplies: plastic, aluminum, copper, and silicone.

How Does Plastic Impact the Performance of 9V AC Power Supplies?

Key Properties: Plastic is lightweight and offers good insulation properties, making it ideal for housing electronic components. It typically has a temperature rating ranging from -20°C to 85°C, depending on the specific type used.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for mass production of power supply casings. However, it may not withstand high temperatures or harsh environmental conditions, leading to potential degradation over time.

Impact on Application: Plastic is suitable for indoor applications where environmental exposure is limited. However, it may not be compatible with high-temperature or high-humidity environments, which are common in some regions.

Considerations for International Buyers: Compliance with international standards such as UL and CE is crucial. Buyers in Africa and South America should be aware of local regulations regarding plastic materials, especially concerning environmental impact.

What Role Does Aluminum Play in 9V AC Power Supply Manufacturing?

Key Properties: Aluminum is known for its excellent thermal conductivity and lightweight nature. It can withstand temperatures up to 150°C and is resistant to corrosion when anodized.

Illustrative image related to 9v ac power supply

Pros & Cons: The major advantage of aluminum is its durability and ability to dissipate heat effectively, which is critical for power supply performance. However, it is more expensive than plastic and may require more complex manufacturing processes.

Impact on Application: Aluminum is suitable for applications requiring efficient heat management, making it ideal for high-performance power supplies. It is often used in outdoor applications due to its corrosion resistance.

Considerations for International Buyers: Compliance with ASTM standards is essential for aluminum components. Buyers from Europe and the Middle East should also consider the availability of anodizing services to enhance corrosion resistance.

How Does Copper Contribute to the Functionality of 9V AC Power Supplies?

Key Properties: Copper has the highest electrical conductivity of all metals and excellent thermal conductivity. It can operate effectively at temperatures up to 200°C.

Pros & Cons: The primary advantage of copper is its efficiency in conducting electricity, which reduces energy loss. However, it is relatively expensive compared to other materials and can be prone to corrosion if not properly treated.

Impact on Application: Copper is essential for internal wiring and connections in power supplies, ensuring optimal performance. Its high conductivity makes it suitable for applications with high current demands.

Illustrative image related to 9v ac power supply

Considerations for International Buyers: Compliance with JIS standards is important for copper components. Buyers in regions like Brazil and Saudi Arabia should ensure that copper products are sourced from reputable suppliers to avoid issues with quality and reliability.

What Advantages Does Silicone Offer for 9V AC Power Supplies?

Key Properties: Silicone is a flexible material with a temperature rating that can range from -60°C to 200°C. It is also resistant to UV light and ozone.

Pros & Cons: The flexibility and resistance to extreme temperatures make silicone an excellent choice for insulation and sealing applications. However, it can be more expensive than traditional insulating materials and may require specialized manufacturing techniques.

Impact on Application: Silicone is particularly useful in environments with temperature fluctuations and exposure to moisture, making it ideal for outdoor power supplies.

Considerations for International Buyers: Buyers should consider compliance with international safety standards for silicone materials. In regions like the Middle East, where high temperatures are common, silicone’s properties can be particularly advantageous.

Summary Table of Material Selection for 9V AC Power Supply

| Material | Typical Use Case for 9V AC Power Supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing for electronic components | Low cost and lightweight | Limited temperature resistance | Low |

| Aluminum | Heat sinks and casings | Excellent heat dissipation | Higher cost and manufacturing complexity | Medium |

| Copper | Internal wiring and connectors | High electrical conductivity | Expensive and corrosion-prone | High |

| Silicone | Insulation and sealing | Flexibility and temperature resistance | Higher cost and specialized manufacturing | Medium |

This strategic material selection guide provides B2B buyers with valuable insights into the materials used in 9V AC power supplies, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 9v ac power supply

What Are the Key Stages in the Manufacturing Process of 9V AC Power Supplies?

The manufacturing process of 9V AC power supplies involves several critical stages that ensure the final product meets both performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to 9v ac power supply

Material Preparation: The first step involves sourcing high-quality raw materials, such as transformers, circuit boards, capacitors, and housing materials. Suppliers must adhere to stringent specifications to guarantee that components meet the required electrical and thermal properties.

Forming: During this stage, the components are shaped and configured. Techniques such as molding and die-cutting are commonly used to create the necessary shapes for the transformer and housing. The design must allow for adequate heat dissipation and protection against environmental factors.

Assembly: The assembly phase is where various components are integrated. This typically involves soldering circuit boards, attaching connectors, and securing the transformer within the housing. Automated assembly lines are often employed to enhance efficiency and ensure precision.

Finishing: The final stage includes testing and quality assurance checks before the product is packaged. This may involve applying protective coatings, labeling, and ensuring compliance with international standards. Proper finishing not only enhances the aesthetic appeal but also contributes to the longevity and reliability of the power supply.

How Do International Standards Influence Quality Control in 9V AC Power Supply Manufacturing?

Quality control (QC) is a crucial aspect of manufacturing 9V AC power supplies, especially for international B2B buyers. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system. ISO 9001 focuses on customer satisfaction and the continual improvement of processes.

Industry-Specific Standards: In addition to ISO, products may need to comply with other certifications like CE (Conformité Européenne) for European markets or UL (Underwriters Laboratories) for North American safety standards. These certifications assure buyers that the products meet strict safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with standards.

Illustrative image related to 9v ac power supply

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival. Suppliers must provide certificates of compliance to verify that materials meet specified standards.

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves real-time monitoring and testing. This may include functional tests on circuit boards or thermal imaging to detect overheating components. Continuous monitoring helps identify and rectify issues before the final assembly.

Final Quality Control (FQC): Once assembly is complete, FQC is performed to validate the performance of the finished product. This may involve electrical testing, safety assessments, and durability tests. Products are often subjected to stress tests to ensure they can handle expected operational conditions.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for 9V AC power supplies can vary based on the intended application and market requirements. Common testing methods include:

- Electrical Testing: Ensures that the output voltage and current meet specified standards. This is typically done using multimeters and oscilloscopes.

- Thermal Testing: Evaluates the device’s performance under various temperature conditions. Thermal imaging cameras can detect hotspots that may indicate potential failures.

- Load Testing: Simulates real-world usage by applying various loads to the power supply to ensure it can handle operational demands without overheating or failing.

- EMI/EMC Testing: Ensures that the power supply does not emit excessive electromagnetic interference and complies with electromagnetic compatibility regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers, which is particularly important when sourcing from international markets.

Supplier Audits: Conducting supplier audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can be done through on-site visits or third-party audit services.

Quality Reports: Requesting detailed quality reports, including IQC, IPQC, and FQC data, can provide insights into the supplier’s consistency and reliability. These reports should demonstrate adherence to international standards.

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These inspectors can verify that products meet the agreed-upon specifications and standards before shipment.

Illustrative image related to 9v ac power supply

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their procurement decisions.

Customs and Import Regulations: Understanding the customs and import regulations of the destination country is essential. Buyers should be aware of potential duties and compliance requirements that could affect the product’s marketability.

Cultural and Regional Standards: Different regions may have varying quality expectations and standards. It is crucial for buyers to ensure that suppliers can meet local compliance requirements, such as certifications specific to the region.

Communication and Responsiveness: Establishing clear communication channels with suppliers is vital. Buyers should evaluate how responsive suppliers are to inquiries and their willingness to accommodate specific quality requests.

Conclusion

The manufacturing and quality assurance processes for 9V AC power supplies are intricate and critical for ensuring product reliability and safety. By understanding these processes, international B2B buyers can make informed decisions, ensuring that they partner with suppliers who prioritize quality and compliance. Implementing thorough verification methods will further enhance buyer confidence in their sourcing strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘9v ac power supply’

To assist international B2B buyers in procuring a reliable 9V AC power supply, this guide offers a step-by-step checklist. Each step is designed to help you navigate the complexities of sourcing, ensuring you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to outline your technical requirements. Consider factors like output voltage, current rating, and plug type, as these will determine compatibility with your devices. A clear specification will streamline your sourcing process and help avoid costly mistakes later.

Illustrative image related to 9v ac power supply

- Output Voltage: Ensure it meets the 9V requirement.

- Current Rating: Common ratings are 1A, 1.5A, or 2A; select based on device needs.

- Plug Type: Verify the connector size, such as 2.5mm x 5.5mm, to avoid mismatches.

Step 2: Research and Identify Reputable Suppliers

Once specifications are set, research potential suppliers. Look for established companies with a track record of providing quality power supplies. Websites, industry reviews, and networking can help you find trustworthy sources.

- Online Marketplaces: Platforms like Alibaba or local distributors can offer a range of options.

- Industry Associations: Membership in relevant organizations can indicate credibility.

Step 3: Evaluate Supplier Certifications

Supplier certifications are crucial for ensuring product safety and quality. Check for compliance with international standards like CE, RoHS, or UL. These certifications indicate that the products have undergone rigorous testing and meet safety guidelines.

- Quality Assurance: Certifications help mitigate risks associated with defective products.

- Regulatory Compliance: Ensure that the products meet the import standards for your region.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the 9V AC power supply. Testing the product firsthand helps validate its performance and compatibility with your devices. It also allows you to assess the supplier’s reliability.

- Performance Testing: Check for stability, overheating, and noise levels.

- Compatibility Checks: Ensure the adapter works seamlessly with your equipment.

Step 5: Negotiate Terms and Pricing

Once satisfied with the supplier and product quality, initiate negotiations. Discuss pricing, payment terms, and minimum order quantities (MOQs). Aim for favorable conditions that align with your budget and project timelines.

Illustrative image related to 9v ac power supply

- Bulk Discounts: Inquire about pricing breaks for larger orders.

- Payment Options: Discuss flexible payment methods that suit your financial planning.

Step 6: Understand Shipping and Delivery Logistics

Logistics can significantly impact your project timelines. Clarify shipping methods, costs, and estimated delivery times with your supplier. Be aware of customs duties and import regulations in your country to avoid unexpected delays.

- Shipping Methods: Explore options like express or standard shipping based on urgency.

- Customs Considerations: Research potential import fees to budget accurately.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your supplier. Regular updates on order status, shipping, and potential issues will facilitate a smooth procurement process. This step is crucial for building a long-term relationship.

- Contact Points: Identify primary contacts for quick resolutions.

- Regular Check-ins: Schedule updates to stay informed about production and delivery.

Following this checklist will empower you to make informed decisions while sourcing a 9V AC power supply, ensuring that your procurement process is efficient and effective.

Illustrative image related to 9v ac power supply

Comprehensive Cost and Pricing Analysis for 9v ac power supply Sourcing

Understanding the cost structure and pricing dynamics of sourcing 9V AC power supplies is crucial for international B2B buyers. This analysis will delve into the essential components that influence costs, pricing strategies, and tips for effective negotiation, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Cost Components of 9V AC Power Supplies?

Materials: The primary materials used in manufacturing 9V AC power supplies include copper for wiring, plastic for casings, and various electronic components such as capacitors and transformers. The quality and source of these materials can significantly affect the overall cost.

Labor: Labor costs vary widely based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality. It’s essential to assess the skill level of the workforce when considering labor as a cost component.

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, rent, and equipment maintenance. Overhead can fluctuate based on the efficiency of the manufacturing processes employed by the supplier.

Tooling: For custom specifications or high-volume orders, tooling costs can be substantial. These expenses cover the creation of specialized molds or machinery needed to produce the power supplies to specific designs.

Illustrative image related to 9v ac power supply

Quality Control (QC): Implementing robust QC measures is vital to ensure product reliability and safety. The costs associated with QC can vary depending on the standards required (e.g., ISO certifications), which can be a crucial factor for buyers in regulated markets.

Logistics: Shipping and handling costs are significant, particularly for international transactions. Factors such as distance, shipping method, and customs duties can influence logistics costs. Buyers should be aware of the Incoterms agreed upon, as they determine who bears these costs.

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on market competition and the supplier’s position in the supply chain.

How Do Price Influencers Affect the Cost of 9V AC Power Supplies?

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Higher volumes often lead to reduced unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities to optimize cost efficiency.

Specifications and Customization: Custom specifications can lead to increased costs due to the additional materials and tooling required. However, tailored solutions that meet specific application needs can provide greater value in the long term.

Illustrative image related to 9v ac power supply

Material Quality and Certifications: Higher quality materials and certifications (such as CE, UL, or RoHS compliance) can raise the initial cost of the power supply. However, investing in certified products can reduce the Total Cost of Ownership (TCO) by minimizing failures and warranty claims.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to attract business. Conducting due diligence on suppliers is essential to ensure reliability.

Incoterms: Understanding shipping terms is critical. Different Incoterms (like FOB, CIF, or DDP) determine who is responsible for shipping costs and risks, which can affect the overall price.

What Are the Best Practices for Buyers in Negotiating Costs?

Negotiation: Buyers should leverage their purchasing volume to negotiate better pricing. Building a long-term relationship with suppliers can also lead to favorable terms and pricing adjustments.

Illustrative image related to 9v ac power supply

Cost-Efficiency: Consider the TCO rather than just the initial purchase price. Assess factors such as durability, energy efficiency, and warranty terms to determine the true cost impact over the product lifecycle.

Pricing Nuances for International Buyers: International buyers should be mindful of currency fluctuations, import duties, and local regulations that can impact pricing. It’s advisable to consult local experts or freight forwarders to navigate these complexities effectively.

Conclusion

Sourcing 9V AC power supplies involves understanding a multifaceted cost structure influenced by various factors, including material quality, labor costs, and logistics. By employing strategic negotiation techniques and considering the TCO, international B2B buyers can optimize their sourcing decisions, ensuring both cost-effectiveness and product reliability. It is important to remain aware that prices can fluctuate based on market conditions and supplier capabilities, necessitating ongoing market research and supplier engagement.

Alternatives Analysis: Comparing 9v ac power supply With Other Solutions

Introduction to Alternative Power Supply Solutions

In the quest for reliable power solutions, businesses often explore various alternatives to the traditional 9V AC power supply. Understanding the strengths and weaknesses of different options allows B2B buyers to make informed decisions that align with their operational requirements and budget constraints. This analysis compares the 9V AC power supply with two viable alternatives: a 9V DC power supply and a universal power adapter.

Comparison Table

| Comparison Aspect | 9V AC Power Supply | 9V DC Power Supply | Universal Power Adapter |

|---|---|---|---|

| Performance | Provides consistent AC output for devices needing alternating current | Delivers stable DC output, suitable for devices requiring direct current | Versatile, supports multiple voltages and currents; adaptable to various devices |

| Cost | Moderate, typically ranging from $10-$30 | Usually lower cost, around $5-$20 | Higher upfront cost, typically $20-$50 due to multi-functionality |

| Ease of Implementation | Simple installation with standard connectors | Direct plug-and-play with compatible devices | Requires careful selection of voltage and current settings for devices |

| Maintenance | Low maintenance; occasional checks for wear | Very low maintenance; long lifespan | Moderate maintenance; may require recalibration for specific outputs |

| Best Use Case | Ideal for appliances and equipment specifically designed for AC use | Best for electronics like sensors, LED strips, and battery chargers that require DC | Suitable for diverse applications, especially in environments with varied device power needs |

Detailed Breakdown of Alternatives

9V DC Power Supply

A 9V DC power supply is a great alternative for devices that operate on direct current. This solution provides a stable output, making it ideal for electronics that require a consistent voltage. The primary advantages include lower costs and minimal maintenance, as these units often have a longer lifespan compared to AC power supplies. However, it is crucial to ensure that the device in use is compatible with DC power, as using the wrong type can lead to malfunctions.

Illustrative image related to 9v ac power supply

Universal Power Adapter

Universal power adapters are designed to cater to a variety of devices, providing multiple voltage and current options. This flexibility makes them an excellent choice for businesses with a diverse range of electronic equipment. While they tend to be more expensive upfront, their ability to replace several adapters can lead to cost savings in the long run. The primary drawback is that they may require more careful setup and adjustment to ensure compatibility with specific devices, which can complicate implementation in some cases.

Conclusion: Choosing the Right Power Supply Solution

When selecting a power supply solution, B2B buyers must consider specific operational needs, including device compatibility, budget constraints, and the variety of applications within their organization. The 9V AC power supply is best suited for appliances designed for AC use, while the 9V DC power supply offers a cost-effective and reliable alternative for direct current needs. For businesses requiring versatility across multiple devices, a universal power adapter may provide the best long-term solution despite its higher initial cost. Assessing these factors will help ensure the right choice is made, optimizing both performance and cost-effectiveness in power supply solutions.

Essential Technical Properties and Trade Terminology for 9v ac power supply

What Are the Key Technical Properties of a 9V AC Power Supply?

Understanding the technical properties of a 9V AC power supply is crucial for international B2B buyers, especially when considering compatibility and reliability for various applications. Here are some essential specifications:

1. Input Voltage Range

The input voltage range typically specified for a 9V AC power supply is between 100-240V. This wide range allows for global compatibility, making it suitable for use in diverse regions, including Africa, South America, and Europe. For businesses, this flexibility reduces the need for multiple product variants tailored to specific regional voltages.

2. Output Voltage and Current Rating

The output voltage is fixed at 9V AC, with current ratings often ranging from 1A to 2A or more. This specification is critical for ensuring that the power supply can adequately meet the power demands of devices such as label makers and other electronic equipment. Buyers must consider the current rating to avoid underpowering or damaging their devices.

3. Connector Type

The connector type, often standardized as 2.5 x 5.5mm for many 9V AC power supplies, is essential for ensuring compatibility with the intended equipment. Understanding the connector specifications helps buyers avoid compatibility issues and ensures that the power supply integrates seamlessly with their devices.

4. Safety Certifications

Safety certifications, such as CE, UL, or FCC, indicate that the power supply complies with international safety standards. For B2B buyers, ensuring that products have these certifications not only guarantees the safety of their operations but also enhances marketability by instilling confidence in end-users.

5. Operating Temperature Range

The operating temperature range specifies the conditions under which the power supply can function optimally, typically from -10°C to +50°C. This property is vital for buyers who operate in environments with extreme temperatures, ensuring that their power supplies remain reliable under varying conditions.

6. Energy Efficiency Rating

An energy efficiency rating, such as Energy Star, indicates how efficiently the power supply converts electrical energy into usable power. Higher efficiency ratings can lead to cost savings in energy bills and are increasingly important for businesses aiming to reduce their carbon footprint.

What Are Common Trade Terms in the 9V AC Power Supply Industry?

Familiarizing oneself with industry jargon can significantly ease communication and negotiation in B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company. In the context of 9V AC power supplies, an OEM may produce adapters for brands that require tailored solutions for their devices. Understanding OEM relationships can help buyers identify reliable partners for custom products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects inventory management and overall costs. Knowing the MOQ helps in budgeting and determining the feasibility of bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products or services. For 9V AC power supplies, issuing an RFQ can help buyers compare prices and terms from multiple suppliers, leading to better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as delivery, risk transfer, and cost allocation. Understanding these terms is vital for international B2B transactions to ensure clarity and avoid disputes.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. For B2B buyers, understanding lead times for 9V AC power supplies is essential for effective project planning and inventory management.

6. Warranty and Return Policy

A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of the product. A clear return policy outlines the conditions under which products can be returned. Both are crucial for B2B buyers to mitigate risk and ensure product quality.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing 9V AC power supplies, ultimately leading to better operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the 9v ac power supply Sector

Market Overview & Key Trends in the 9V AC Power Supply Sector

The 9V AC power supply market is experiencing notable growth driven by several global factors. The increasing demand for electronic devices across various sectors, including consumer electronics, industrial applications, and telecommunications, is a primary driver. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable power solutions, suppliers are adapting to meet specific regional needs, including voltage requirements and compliance with local regulations.

Emerging trends in sourcing indicate a shift towards more adaptable power supply solutions. Manufacturers are increasingly offering multi-voltage adapters and customized power supplies that cater to diverse applications, such as smart home devices and IoT products. The rise of smart technologies and automation in various industries is pushing for more sophisticated power solutions that not only provide energy but also ensure efficiency and safety.

Additionally, the rise of e-commerce platforms has transformed procurement processes. B2B buyers now have access to a broader range of suppliers globally, enabling them to compare products and prices more effectively. This competitive landscape encourages manufacturers to innovate while also focusing on cost-effectiveness to attract buyers from price-sensitive markets like Brazil and Saudi Arabia.

How Are Sustainability & Ethical Sourcing Impacting the 9V AC Power Supply Sector?

Sustainability and ethical sourcing have become paramount in the B2B landscape, particularly for the 9V AC power supply sector. As international buyers increasingly prioritize environmental responsibility, suppliers are compelled to adopt sustainable practices throughout their supply chains. This includes utilizing eco-friendly materials, implementing energy-efficient manufacturing processes, and ensuring proper disposal and recycling methods for electronic waste.

Moreover, the demand for certifications that validate sustainability claims is on the rise. Buyers are looking for products that comply with green certifications, such as Energy Star and RoHS, which signify reduced environmental impact. This trend not only enhances the marketability of products but also aligns with the values of socially conscious consumers and businesses.

Ethical sourcing also plays a crucial role in building trust with clients. Suppliers that transparently communicate their sourcing practices and labor standards can differentiate themselves in a competitive market. This is particularly significant for buyers in regions with strict regulations regarding labor practices, such as Europe, where compliance with ethical standards is not just a preference but often a requirement.

Brief Evolution of the 9V AC Power Supply Sector

The evolution of the 9V AC power supply sector can be traced back to the proliferation of electronic devices in the late 20th century. Initially, power supplies were bulky and inefficient, often lacking the safety features that are standard today. As technology advanced, the demand for smaller, more efficient power supplies grew, leading to innovations in compact designs and integrated circuits.

In the 2000s, the advent of digital electronics and the rise of consumer electronics saw an explosion in the demand for versatile power supplies, including the 9V AC variant. Manufacturers began focusing on producing power supplies that not only met electrical specifications but also adhered to safety and regulatory standards.

Today, with the integration of smart technology and the Internet of Things, the 9V AC power supply market continues to evolve, offering solutions that cater to an increasingly tech-savvy consumer base. This ongoing innovation reflects the sector’s adaptability to changing market dynamics and consumer needs, positioning it well for future growth.

Frequently Asked Questions (FAQs) for B2B Buyers of 9v ac power supply

-

How do I ensure the 9V AC power supply meets my specifications?

To ensure the 9V AC power supply meets your specifications, you should start by defining your requirements clearly, including voltage, current, and connector type. Always request technical datasheets from suppliers that detail the product specifications. Additionally, consider requesting samples for testing to verify compatibility with your devices. It’s also beneficial to communicate directly with manufacturers to address any specific compliance or certification needs relevant to your market. -

What is the best way to vet suppliers for 9V AC power supplies?

The best way to vet suppliers is to conduct thorough research, including checking for industry certifications and customer reviews. Look for suppliers with a solid track record in manufacturing power supplies and ensure they comply with international quality standards, such as ISO. Engaging in direct communication can provide insights into their customer service and responsiveness. Additionally, consider visiting their facilities or asking for references from other B2B clients to gauge their reliability. -

Are there customization options available for 9V AC power supplies?

Yes, many manufacturers offer customization options for 9V AC power supplies, including tailored voltage outputs, current ratings, connector types, and even branding on the units. When discussing customization, be clear about your specifications and the intended application of the power supply. Some suppliers may have minimum order quantities (MOQs) for custom products, so it’s crucial to confirm these details upfront. -

What are the common minimum order quantities (MOQs) for 9V AC power supplies?

MOQs for 9V AC power supplies can vary significantly between manufacturers, often ranging from 100 to 1000 units. Factors influencing MOQs include production capabilities, customization requirements, and supplier policies. When negotiating with suppliers, it’s important to discuss your order needs and see if they can accommodate smaller quantities, especially for initial orders or pilot projects. -

What payment terms should I expect when sourcing 9V AC power supplies?

Payment terms can vary by supplier and region but typically include options like upfront payment, partial payment upon order confirmation, and balance before shipping. International buyers may also encounter payment methods such as letters of credit or escrow services for higher-value transactions. Always clarify payment terms before placing an order to avoid misunderstandings and ensure a smooth transaction process. -

How can I handle customs and import fees for 9V AC power supplies?

Customs and import fees are typically the responsibility of the buyer. To manage these costs, check your country’s regulations regarding import duties and taxes for electronic goods. It’s advisable to consult with a customs broker to understand the potential fees and ensure compliance with local laws. Additionally, communicate with your supplier to determine if they can provide necessary documentation to facilitate the customs process. -

What logistics considerations should I keep in mind when importing 9V AC power supplies?

When importing 9V AC power supplies, consider shipping methods, delivery times, and reliability of logistics partners. Evaluate options like air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. It’s also important to account for lead times in production and shipping, and to verify that the supplier can meet your delivery schedule. Lastly, ensure that tracking information is provided for transparency throughout the shipping process. -

What quality assurance measures should I look for in a supplier of 9V AC power supplies?

Quality assurance measures can include certifications such as CE, UL, or RoHS compliance, which indicate adherence to safety and environmental standards. Inquire about the supplier’s quality control processes, including testing protocols for their products before shipment. Requesting samples or visiting their production facilities can also provide insight into their commitment to quality. Additionally, consider establishing a quality agreement that outlines expectations for performance and defect resolution.

Top 6 9V Ac Power Supply Manufacturers & Suppliers List

1. Jameco – 9V AC to AC Adapter

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: 9v ac to ac adapter available at Jameco Electronics, in-stock and ready to ship. Jameco has been in business for over 50 years and carries over 70,000 electronic components including power supplies and wall adapters.

2. Analog Man – 9V AC Power Supply

Domain: buyanalogman.com

Registered: 2006 (19 years)

Introduction: This company, Analog Man – 9V AC Power Supply, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

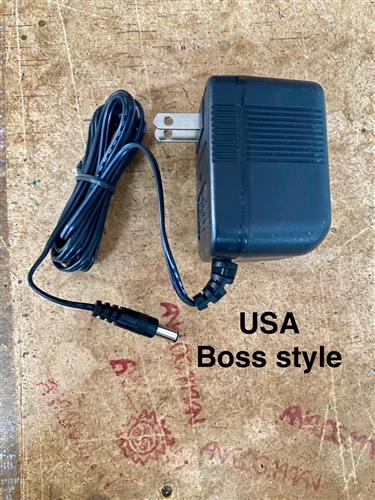

3. Alesis – HR-16 Drum Machine Power Supply

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Alesis HR-16 drum machine requires a 9V AC power supply. Using a 12V AC adapter may damage the device. 9V AC is different from 9V DC, and using the wrong type of power supply can result in malfunction or damage. A reverse polarity cable may be used to adapt power supplies, but it is crucial to adhere to the manufacturer’s specifications to avoid frying the gear.

4. ACDC Power Shack – AC-AC Power Supply

Domain: acdcpowershack.com

Registered: 2017 (8 years)

Introduction: {“Product Name”: “AC-AC Power Supply”, “Input Voltage”: “120VAC”, “Output Voltage”: “9VAC”, “Output Current”: “1110mA”, “Plug Size”: “2.5 x 5.5mm (RIGHT ANGLE)”, “Part Number”: “AC-091B”, “Price”: “$13.00”, “Reviews”: [{“Rating”: “5.0”, “Count”: “2”}] }

5. Power Adapter Solutions – 9V AC & 5V DC

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Power adapter requirements: 9V AC and 5V DC output, each needing around 9W. Suggested solutions include using a good USB charger for 5V and a 240V:9V transformer for 9V AC. Recommendations for components include a 240 VAC to 9 VAC 40 VA transformer and 5V regulators for DC output. Considerations for isolation and rectification are mentioned.

6. Instructables – 9VAC Power Supply Conversion

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: 9VAC Power Supply for X0xb0x; Conversion from 12VDC to 9VAC; Requires: 12VDC power supply, soldering iron, solder, 2 jumper wires; Process: Open power supply, remove components except transformer and output connections, replace 2 diodes with jumpers, close and test; Output voltage: 11VAC open circuit, drops to 8.5VAC under load; Compatible plug: 5.5mm x 2.1mm; Safety precautions emphasized.

Strategic Sourcing Conclusion and Outlook for 9v ac power supply

In summary, the strategic sourcing of 9V AC power supplies is paramount for international buyers seeking reliable and efficient solutions. Key takeaways include the importance of understanding regional voltage requirements, compatibility with various devices, and the necessity for suppliers to demonstrate robust safety features such as overcurrent and short-circuit protection. Additionally, effective logistics management—including shipping options and customs considerations—plays a critical role in ensuring timely delivery and cost-effectiveness.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality power solutions will only increase. Buyers are encouraged to leverage relationships with suppliers who can provide comprehensive product support and transparent communication. By prioritizing strategic sourcing, businesses can enhance their operational efficiency and secure a competitive edge in their respective markets.

Looking ahead, the landscape for 9V AC power supplies is ripe with opportunities. Companies that invest in understanding their sourcing options and forging strong partnerships will be well-positioned to meet the growing demands of their customers. Now is the time to explore diverse sourcing avenues and align with trusted suppliers to ensure a sustainable and successful future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.