Top 5 Wire Edm Parts Suppliers (And How to Choose)

Introduction: Navigating the Global Market for wire edm parts

In the complex landscape of manufacturing, sourcing high-quality wire EDM parts can pose significant challenges for international B2B buyers. As industries increasingly rely on electrical discharge machining for precision fabrication, understanding the diverse range of components—from wire guides and power feed contacts to flush nozzles and isolator plates—becomes essential. This guide serves as a comprehensive resource, equipping you with insights into the types of wire EDM parts available, their applications across various sectors, and the intricacies of supplier vetting.

Navigating the global market requires a strategic approach, especially for buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide empowers you to make informed purchasing decisions by providing actionable insights into cost considerations, quality standards, and best practices for sourcing. By leveraging this knowledge, you can enhance operational efficiency and ensure that your machinery operates at peak performance.

Whether you are a seasoned procurement specialist or new to the wire EDM landscape, this guide will help demystify the complexities of sourcing EDM components, ultimately leading to a more streamlined and effective procurement process.

Understanding wire edm parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Power Feed Contacts | Conduct electricity between the machine and wire; available in various materials like tungsten carbide. | Metal fabrication, aerospace, automotive. | Pros: High durability, excellent conductivity. Cons: Can be costly; requires careful selection based on machine compatibility. |

| Wire Guides | Direct the wire during the EDM process; made from materials like diamond or ceramic for wear resistance. | Precision machining, mold making, tool making. | Pros: Enhance cutting accuracy, reduce wire breakage. Cons: Material choice impacts performance; specific to machine type. |

| Flush Nozzles | Facilitate coolant flow to improve machining efficiency; available in various sizes and configurations. | High-precision applications, intricate designs. | Pros: Improve flushing efficiency, reduce thermal distortion. Cons: Incorrect sizing can lead to inefficiencies. |

| EDM Filters | Remove contaminants from the dielectric fluid; essential for maintaining machine performance. | General EDM operations, maintenance. | Pros: Extend machine life, improve part quality. Cons: Regular replacement needed, adding to maintenance costs. |

| Tension Rollers | Maintain wire tension; critical for consistent cutting performance; often made of durable materials. | High-speed wire cutting operations. | Pros: Consistent wire tension improves machining accuracy. Cons: Installation and maintenance can be complex. |

What Are Power Feed Contacts and Why Are They Important for B2B Buyers?

Power feed contacts are essential components in wire EDM machines that facilitate the transmission of electrical energy to the wire electrode. Typically made from high-conductivity materials such as tungsten carbide, these contacts play a crucial role in ensuring efficient machining processes. B2B buyers must consider the compatibility of these contacts with their specific machine models, as well as the operational costs associated with their replacement. Investing in high-quality power feed contacts can lead to improved performance and reduced downtime.

How Do Wire Guides Enhance EDM Performance?

Wire guides are integral to the wire EDM process, directing the wire electrode accurately during operation. Made from materials like diamond or ceramic, these guides are designed to withstand wear and tear, thus ensuring longevity and reliability. For businesses engaged in precision machining, selecting the right type of wire guide can significantly reduce wire breakage and enhance cutting accuracy. Buyers should evaluate the specifications of wire guides to ensure they match their machine’s requirements and operational needs.

What Role Do Flush Nozzles Play in EDM Applications?

Flush nozzles are critical components that help deliver dielectric fluid to the cutting zone, thereby improving cooling and flushing efficiency during the EDM process. They come in various sizes and configurations, allowing for tailored applications depending on the intricacy of the design being machined. Businesses must assess the compatibility of flush nozzles with their existing systems, as improper sizing can lead to inefficiencies. Regular maintenance and replacement of nozzles are necessary to maintain optimal machining conditions.

Why Are EDM Filters Essential for Maintaining Machine Performance?

EDM filters are vital for ensuring the cleanliness of dielectric fluids used in wire EDM machines. By removing contaminants, these filters help maintain the quality of the machining process and extend the life of the machine. For B2B buyers, investing in high-quality filters can lead to better part quality and reduced maintenance issues. However, it is important to factor in the ongoing costs associated with regular filter replacements as part of a comprehensive maintenance strategy.

How Do Tension Rollers Affect Cutting Precision in EDM Processes?

Tension rollers are designed to maintain consistent wire tension during the cutting process, which is crucial for achieving high precision in wire EDM operations. These components are typically made from durable materials to withstand the rigors of high-speed cutting. B2B buyers should consider the installation and maintenance requirements of tension rollers, as improper handling can lead to reduced performance. Choosing the right tension roller can significantly enhance machining accuracy and overall efficiency.

Key Industrial Applications of wire edm parts

| Industry/Sector | Specific Application of wire edm parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft and satellite systems | High accuracy and reliability in critical applications | Certifications (e.g., AS9100), material specifications |

| Automotive | Manufacturing of intricate parts like gears and molds | Enhanced performance and durability of vehicle components | OEM compatibility, lead times, and quality assurance |

| Medical Devices | Production of surgical instruments and implants | Compliance with stringent regulatory standards | Biocompatibility, precision tolerances, and sterilization |

| Electronics | Fabrication of connectors and circuit boards | Improved functionality and efficiency in electronic devices | Supply chain reliability, rapid prototyping capabilities |

| Tool and Die | Creation of complex dies and molds for manufacturing | Cost savings through reduced waste and faster production | Material selection, customization options, and lifecycle support |

How Are Wire EDM Parts Utilized in the Aerospace Sector?

In the aerospace industry, wire EDM parts are crucial for producing precision components used in aircraft and satellite systems. These parts must meet stringent tolerances and quality standards to ensure safety and reliability in flight. Wire EDM enables manufacturers to create complex shapes and intricate designs that are often impossible with traditional machining methods. For international buyers, particularly from Europe and the Middle East, sourcing wire EDM parts requires attention to certifications like AS9100 and strict adherence to material specifications to ensure compliance with regulatory requirements.

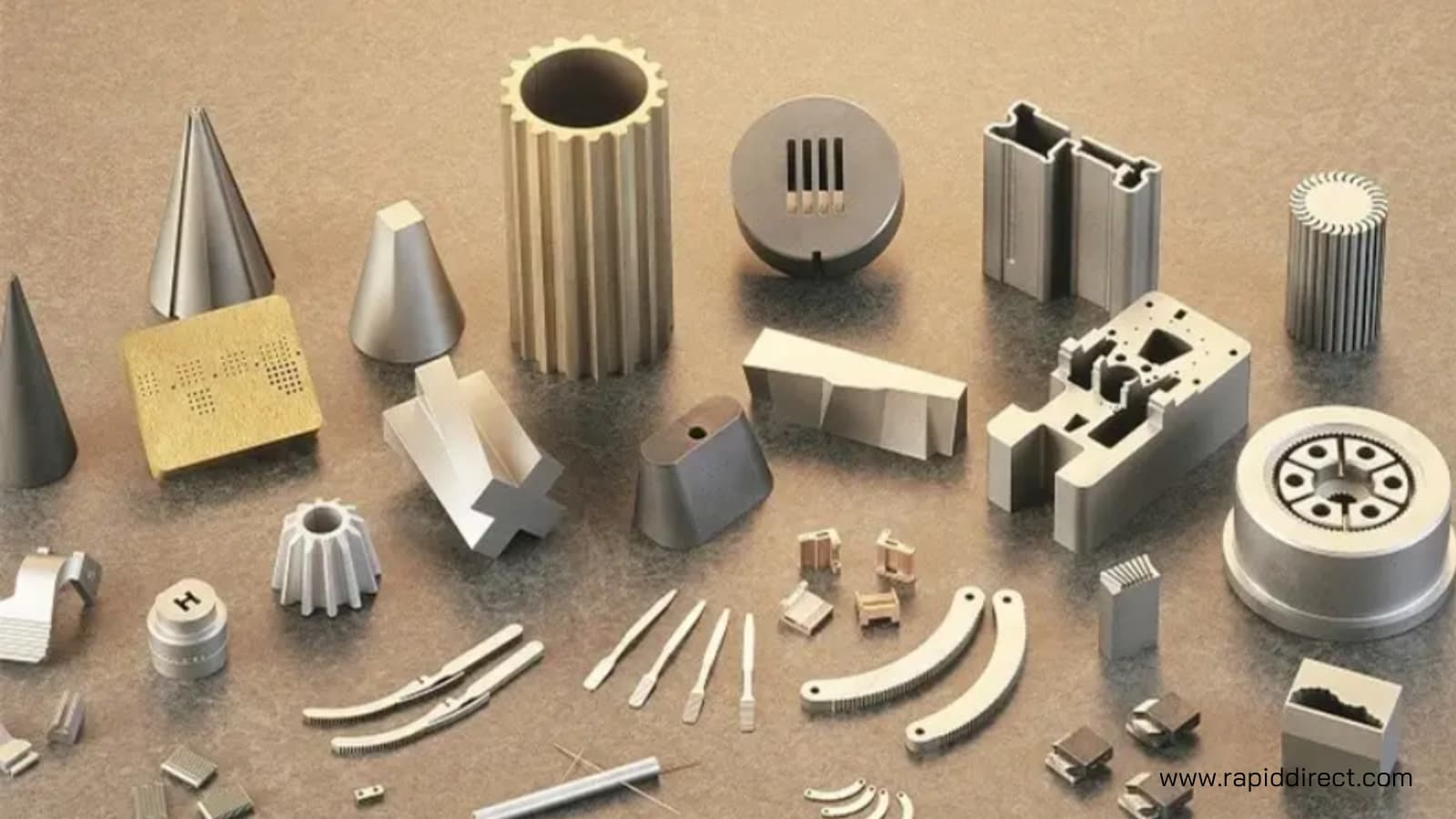

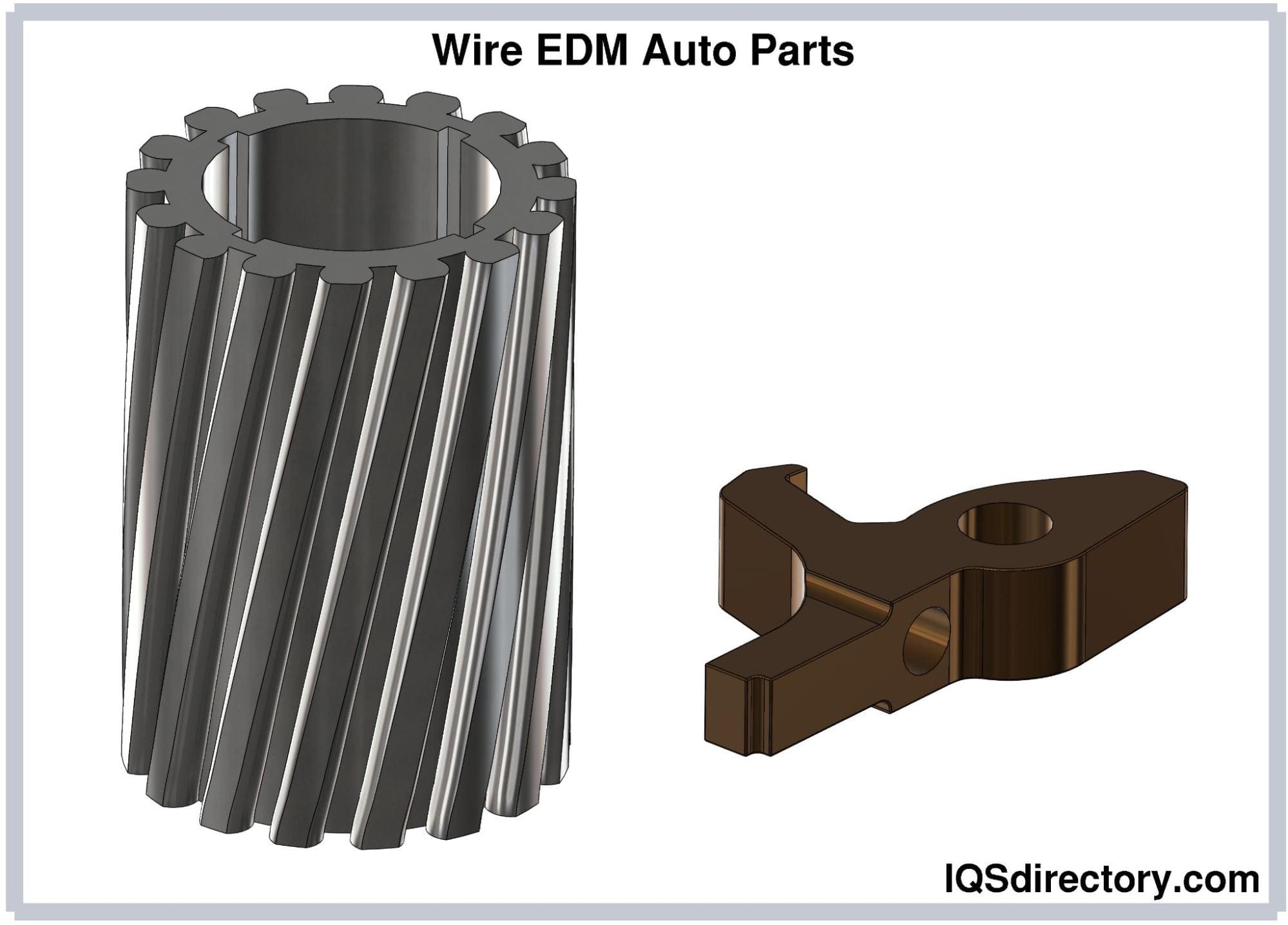

Illustrative image related to wire edm parts

What Role Do Wire EDM Parts Play in Automotive Manufacturing?

In automotive manufacturing, wire EDM parts are employed to fabricate intricate components such as gears, molds, and fixtures. The precision offered by wire EDM allows for the production of high-performance parts that contribute to the overall durability and efficiency of vehicles. Buyers from South America and Africa should prioritize suppliers who can guarantee OEM compatibility and provide robust quality assurance processes, as these factors are critical in maintaining operational efficiency and reducing downtime.

How Are Wire EDM Parts Essential in the Medical Device Sector?

Wire EDM parts are indispensable in the medical device sector, where they are used to manufacture surgical instruments and implants that meet high biocompatibility and precision standards. The ability to produce complex geometries with tight tolerances ensures that these devices function correctly and safely in medical applications. International buyers, particularly from regions with stringent regulatory environments, need to ensure that suppliers can provide documentation of biocompatibility and compliance with medical device regulations.

In What Ways Are Wire EDM Parts Applied in Electronics Manufacturing?

In the electronics sector, wire EDM is utilized for fabricating connectors, circuit boards, and other intricate electronic components. This method allows for high levels of precision, which is essential for the performance and reliability of electronic devices. Buyers from Africa and Europe should focus on sourcing suppliers who offer rapid prototyping capabilities and reliable supply chains to meet the fast-paced demands of the electronics market.

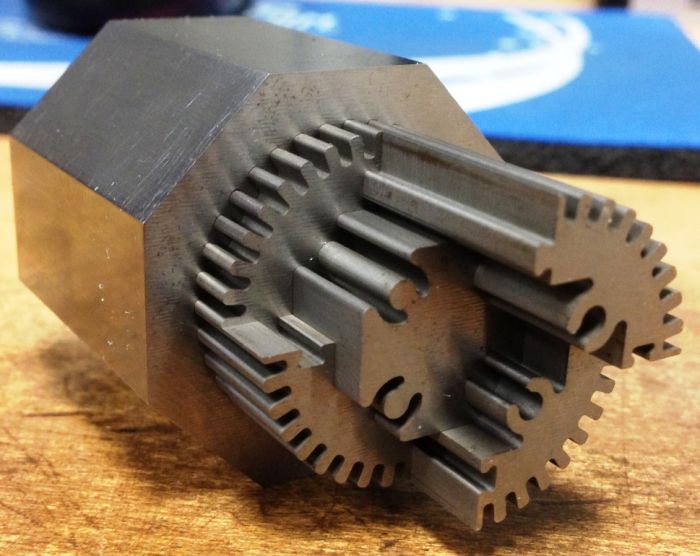

How Do Wire EDM Parts Benefit Tool and Die Creation?

Wire EDM parts are critical in the tool and die industry, where they are used to create complex dies and molds for various manufacturing processes. The precision of wire EDM reduces material waste and enhances production efficiency, leading to significant cost savings. B2B buyers should consider the material selection and customization options offered by suppliers, as these factors can greatly influence the performance and lifecycle of the tooling solutions provided.

3 Common User Pain Points for ‘wire edm parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Parts for Diverse EDM Machines

The Problem: B2B buyers often face challenges when sourcing wire EDM parts compatible with a variety of machine brands and models. This is particularly true for international buyers who may not have immediate access to local suppliers. The intricacies of different OEM specifications can lead to confusion, resulting in the procurement of incorrect or substandard components. For instance, a manufacturer in South Africa might need parts for both Fanuc and Mitsubishi machines, but struggles to find a single supplier that offers reliable options for both brands.

Illustrative image related to wire edm parts

The Solution: To overcome this issue, buyers should partner with suppliers that specialize in a broad range of EDM machine parts and have a proven track record of quality assurance. It’s essential to confirm that the supplier maintains a comprehensive inventory of OEM parts for multiple manufacturers, including detailed product specifications and compatibility charts. Leveraging technology, such as part number cross-referencing tools, can also facilitate accurate sourcing. Additionally, establishing a strong communication line with suppliers can provide access to expert advice on selecting the right parts, ensuring compatibility and reliability, and ultimately reducing downtime.

Scenario 2: High Costs Due to Frequent Breakdowns and Downtime

The Problem: Frequent breakdowns of wire EDM machines can be a significant pain point for manufacturers, leading to costly downtime and lost productivity. This scenario is often exacerbated when buyers opt for lower-quality, cheaper parts that do not withstand operational demands. For example, a company in Brazil might replace wear parts with non-OEM alternatives, only to find that these components fail prematurely, incurring additional repair costs and prolonging machine inoperability.

The Solution: Investing in high-quality OEM parts is essential for maintaining machine performance and longevity. Buyers should conduct a thorough cost-benefit analysis when considering parts for wire EDM machines. While the initial investment in quality components may be higher, the reduction in frequent breakdowns and maintenance costs will ultimately save money in the long run. Collaborating with suppliers who offer warranties on their products can also provide peace of mind. Moreover, implementing a preventive maintenance schedule that includes regular inspections and timely replacement of wear parts can help identify potential issues before they escalate, thereby minimizing downtime.

Scenario 3: Lack of Technical Expertise for Proper Installation and Use

The Problem: Many B2B buyers struggle with the technical complexities of installing and using wire EDM parts correctly. This can lead to improper setup, inefficient operation, and even damage to the EDM machine. For example, a manufacturer in Germany might receive new wire guides but lacks the expertise to install them correctly, resulting in misalignment and compromised cutting performance.

The Solution: To address this challenge, buyers should seek suppliers who not only provide parts but also offer comprehensive technical support and installation guidance. Detailed installation manuals, video tutorials, and access to customer service representatives can significantly ease the installation process. Additionally, training sessions or workshops conducted by the supplier can enhance the technical know-how of the workforce. Encouraging an ongoing relationship with the supplier for future training opportunities can foster a culture of continuous improvement within the organization, ensuring that the team is well-equipped to handle new technologies and components as they emerge in the industry.

Strategic Material Selection Guide for wire edm parts

What Are the Key Materials Used in Wire EDM Parts?

Wire EDM (Electrical Discharge Machining) parts require materials that can withstand the rigors of high precision machining processes. The selection of materials is critical for ensuring optimal performance, longevity, and cost-effectiveness. Below, we analyze four common materials used in wire EDM parts, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Steel Alloys Perform in Wire EDM Applications?

Key Properties: Steel alloys, particularly tool steels like D2 and A2, offer high hardness and wear resistance, making them ideal for EDM applications. They can withstand high temperatures and pressures, which is essential during machining.

Pros & Cons: The durability of steel alloys is a significant advantage; they can endure repeated use without significant wear. However, they are susceptible to corrosion if not properly treated or coated, which can impact their longevity. Additionally, the manufacturing complexity can be higher due to the need for heat treatment processes.

Impact on Application: Steel alloys are compatible with various media, including water-based and oil-based coolants, which are often used in EDM processes. However, their corrosion susceptibility can limit their use in environments with high humidity or corrosive substances.

International Considerations: Buyers from regions such as Europe and the Middle East should ensure compliance with standards like DIN and ASTM, which dictate material properties and performance.

What Role Does Copper Play in Wire EDM Parts?

Key Properties: Copper is known for its excellent electrical conductivity and thermal properties, making it suitable for certain EDM applications, especially in electrodes.

Pros & Cons: The primary advantage of copper is its ability to efficiently transfer heat and electricity, enhancing machining precision. However, copper is softer than steel, which can lead to faster wear rates and reduced durability. Its cost can also be higher compared to other materials, impacting overall project budgets.

Impact on Application: Copper is particularly effective in applications requiring high-speed machining, but its lower hardness means it may not be suitable for all EDM environments, especially where abrasive materials are present.

Illustrative image related to wire edm parts

International Considerations: For buyers in South America and Africa, understanding local regulations regarding copper sourcing and recycling is vital, as these can affect availability and costs.

Why Is Tungsten a Preferred Material for Wire EDM Parts?

Key Properties: Tungsten is characterized by its high melting point and exceptional hardness, making it highly resistant to wear and deformation under high temperatures.

Pros & Cons: The durability of tungsten is unmatched, making it ideal for high-performance applications. However, its high cost and difficulty in machining can be significant drawbacks, often requiring specialized equipment and processes.

Illustrative image related to wire edm parts

Impact on Application: Tungsten is compatible with high-temperature environments, making it suitable for applications involving extreme conditions. However, its brittleness can limit its use in applications requiring flexibility.

International Considerations: Buyers from Germany and other European countries should be aware of the stringent regulations regarding tungsten sourcing, as well as compliance with environmental standards.

How Does Ceramic Material Enhance Wire EDM Parts?

Key Properties: Ceramics provide excellent hardness and wear resistance, along with good thermal stability, making them suitable for high-precision applications.

Pros & Cons: The primary advantage of ceramics is their superior wear resistance, which leads to longer tool life. However, they are brittle and can fracture under impact, which limits their application in high-stress environments. Their cost is generally higher than metals, which can affect project budgets.

Impact on Application: Ceramics are compatible with non-corrosive media and are ideal for applications requiring high precision and minimal thermal expansion. However, their brittleness can pose challenges in dynamic applications.

International Considerations: Buyers from the Middle East and Africa should consider local availability and sourcing of ceramic materials, as well as compliance with international standards for quality assurance.

Summary of Material Selection for Wire EDM Parts

| Material | Typical Use Case for wire edm parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Tooling and structural components | High durability and wear resistance | Corrosion susceptibility | Medium |

| Copper | Electrodes and high-speed machining | Excellent electrical and thermal conductivity | Softer, leading to faster wear | High |

| Tungsten | High-performance applications | Unmatched hardness and durability | High cost and machining difficulty | High |

| Ceramic | Precision components | Superior wear resistance | Brittle and prone to fracture | High |

In conclusion, selecting the right material for wire EDM parts is crucial for optimizing performance and cost-effectiveness. International buyers must consider local regulations, material properties, and application-specific requirements to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for wire edm parts

What Are the Key Manufacturing Processes for Wire EDM Parts?

Manufacturing wire EDM (Electrical Discharge Machining) parts involves several critical stages that ensure precision, efficiency, and quality. The main stages of the manufacturing process typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Wire EDM Parts?

Material preparation is the first step in the manufacturing process. It involves selecting high-quality raw materials, often metals such as stainless steel, titanium, and aluminum, which are suitable for EDM processes. The material is cut to the desired size and cleaned to remove any contaminants that might affect the machining process.

In this stage, manufacturers may also perform heat treatments to enhance the material’s properties, such as hardness and tensile strength. Proper material preparation is essential as it directly influences the performance and longevity of the finished parts.

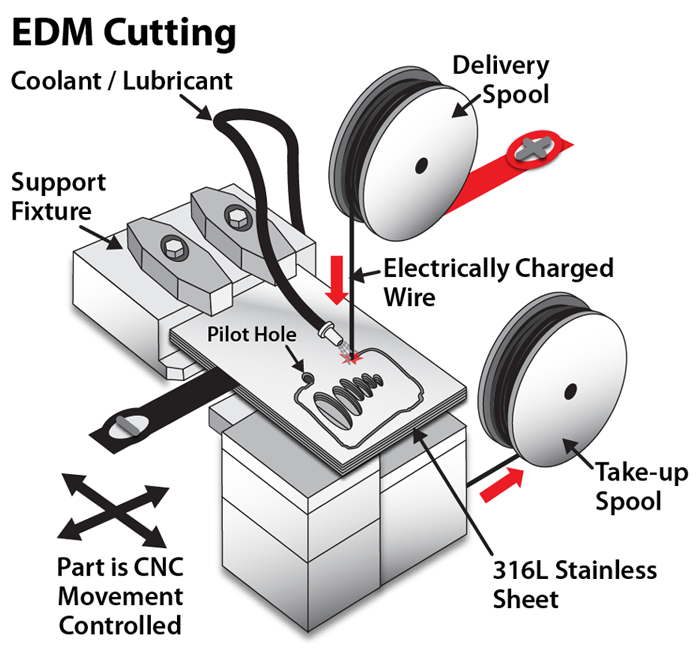

What Forming Techniques Are Used in Wire EDM Manufacturing?

The forming stage is where the actual machining takes place. In wire EDM, a thin wire electrode is fed through the material, creating a precise cut using electrical discharges. The wire is typically made of copper or brass and is carefully selected based on the specific application and material being machined.

Key techniques during the forming stage include:

- Wire Feeding: The wire is continuously fed through the workpiece while maintaining the correct tension and alignment.

- Spark Generation: Electrical discharges occur between the wire and the workpiece, vaporizing material and creating the desired shape.

- Control Systems: Advanced CNC (Computer Numerical Control) systems monitor and adjust parameters like voltage, current, and feed rate to ensure optimal cutting performance.

How Are Wire EDM Parts Assembled and Finished?

Following the forming process, assembly may be necessary if the parts consist of multiple components. This stage involves precise fitting and fastening, often using screws, bolts, or adhesives, depending on the design specifications.

Finishing is the final stage in the manufacturing process. It encompasses various activities aimed at improving the surface finish and overall quality of the parts. Common finishing techniques include:

- Deburring: Removing sharp edges and burrs formed during machining.

- Polishing: Enhancing the surface finish to meet aesthetic or functional requirements.

- Coating: Applying protective coatings to enhance corrosion resistance or reduce friction.

What Are the Quality Assurance Protocols for Wire EDM Parts?

Quality assurance (QA) is vital in wire EDM manufacturing to ensure that parts meet international standards and customer specifications. B2B buyers must understand the QA protocols to verify the reliability of their suppliers.

Illustrative image related to wire edm parts

Which International Standards Apply to Wire EDM Manufacturing?

Manufacturers often adhere to various international standards to ensure quality. The ISO 9001 standard is a widely recognized framework for quality management systems, emphasizing customer satisfaction and continuous improvement. Other industry-specific certifications may include CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for parts used in the oil and gas sector.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify defects early and minimize waste. The main checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): Conducting comprehensive inspections of the finished products before they are shipped to customers.

What Common Testing Methods Are Used in QC?

To ensure quality, various testing methods are employed, including:

- Dimensional Inspection: Using tools like calipers and micrometers to verify the dimensions of the parts.

- Surface Roughness Testing: Measuring surface finish to ensure it meets specified tolerances.

- Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle inspection to detect internal flaws without damaging the parts.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should consider several strategies to verify the quality control measures of their suppliers:

- Conduct Audits: Regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality control systems. Buyers can assess compliance with international standards and the effectiveness of QC measures.

- Request Quality Reports: Suppliers should be able to provide documentation detailing their quality control procedures and results from various inspections and tests.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an impartial evaluation of the manufacturing processes and product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate certain nuances when it comes to quality control. Understanding local regulations, compliance requirements, and cultural differences in manufacturing practices is essential. For instance, European buyers might prioritize CE certification, while Middle Eastern buyers may focus on compliance with regional standards.

Additionally, communication is key. Buyers should establish clear expectations regarding quality standards and ensure that suppliers are capable of meeting those requirements consistently. Building strong relationships with suppliers can also facilitate better quality assurance practices and prompt resolution of any issues that arise.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for wire EDM parts is crucial for B2B buyers. By focusing on quality control measures and verifying supplier capabilities, businesses can ensure they receive reliable, high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire edm parts’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring wire EDM parts. By following this checklist, you can ensure that your sourcing process is methodical, reducing risks and enhancing the quality of your procurement decisions.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical specifications required for your wire EDM parts. This includes dimensions, material types, and compatibility with existing machines. Ensuring that you have a precise understanding of what you need will facilitate better communication with suppliers and help avoid costly mistakes.

- Considerations:

- Review your machine’s manual for part specifications.

- Consult with your engineering team to confirm requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in wire EDM parts. Look for companies that have a proven track record in the industry, particularly those with experience serving clients in your region. Supplier credibility can significantly impact the quality and reliability of the parts you receive.

- Sources to Explore:

- Industry forums and trade shows.

- Online reviews and testimonials from previous clients.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or equivalent quality management standards. These certifications indicate that the supplier adheres to rigorous quality control processes, ensuring the parts meet industry standards.

- Why It Matters:

- Certified suppliers are more likely to deliver consistent quality.

- Reduces the risk of receiving defective or incompatible parts.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, lead times, and terms of sale. Comparing these factors can help you identify the best value for your investment. However, remember that the cheapest option isn’t always the best; consider quality and service as well.

- What to Look For:

- Hidden costs such as shipping and handling.

- Terms regarding returns and warranties.

Step 5: Assess Customer Support and Communication

Evaluate the level of customer support offered by suppliers. Effective communication is essential for resolving issues that may arise during the procurement process. A responsive supplier can greatly ease the procurement journey, ensuring that you receive timely updates and assistance.

- Key Indicators:

- Responsiveness to inquiries during the initial contact.

- Availability of technical support for product-related questions.

Step 6: Check References and Case Studies

Before finalizing your decision, ask suppliers for references or case studies from similar industries or regions. Engaging with previous clients can provide insights into the supplier’s reliability and service quality.

- Questions to Ask References:

- How satisfied were you with the part quality and performance?

- Were there any issues with the delivery or support?

Step 7: Finalize the Order and Establish a Relationship

Once you have selected a supplier, finalize your order and establish a working relationship. Open communication about future needs can lead to better service and pricing in the long run. Cultivating a strong partnership can also facilitate smoother transactions in future orders.

Illustrative image related to wire edm parts

- Strategies for Relationship Building:

- Regularly communicate your needs and feedback.

- Consider setting up a long-term agreement for consistent supply.

By following these steps, you can streamline your sourcing process for wire EDM parts, ensuring you find reliable suppliers that meet your technical and budgetary needs.

Comprehensive Cost and Pricing Analysis for wire edm parts Sourcing

What Are the Key Cost Components in Wire EDM Parts Sourcing?

When sourcing wire EDM parts, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The type of materials used in wire EDM parts significantly affects costs. Common materials include tungsten carbide and high-grade steel, which may vary in price depending on their sourcing and market demand.

-

Labor: Labor costs encompass the wages of skilled technicians and engineers involved in the manufacturing process. In regions with high labor costs, such as Western Europe, this can be a substantial portion of the overall price.

-

Manufacturing Overhead: This includes costs associated with the operation of machinery, utilities, and facility maintenance. Efficient manufacturing processes can help reduce these overhead costs, which is a critical consideration for buyers.

-

Tooling: Specialized tooling for wire EDM operations can be expensive, especially if custom designs are required. The investment in tooling can impact the initial pricing of parts but may lead to cost savings in the long run through improved efficiency.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet specifications and standards. This can add to the overall cost but is essential for maintaining quality and reducing the risk of defects.

-

Logistics: Shipping and handling costs vary based on the origin of the parts and destination. Factors such as packaging, freight methods, and customs duties must be considered, particularly for international shipments.

-

Margin: Suppliers typically build in a profit margin, which can vary based on market competition and perceived value of the parts.

How Do Price Influencers Affect Wire EDM Parts Costs?

Several factors influence the pricing of wire EDM parts:

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also facilitate better pricing negotiations.

-

Specifications and Customization: Custom parts tailored to specific machine models or unique applications typically carry higher prices. Standardized parts usually offer better pricing due to lower manufacturing complexity.

-

Materials: The choice of materials can significantly impact pricing. High-performance materials may enhance durability but come at a premium.

-

Quality and Certifications: Parts that meet international quality standards or have specific certifications (such as ISO) may command higher prices due to the assurance of reliability and performance.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence prices. Established suppliers with a history of quality may charge more but provide peace of mind.

-

Incoterms: The terms of shipping (such as FOB, CIF) affect the total landed cost. Understanding these terms can help buyers avoid unexpected charges and negotiate better shipping arrangements.

What Are Some Essential Buyer Tips for Cost Efficiency in Wire EDM Parts Sourcing?

To maximize cost efficiency, buyers should consider the following strategies:

-

Negotiation: Engage in proactive discussions with suppliers to explore volume discounts, flexible payment terms, and potential cost reductions. Building long-term relationships can lead to better pricing over time.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with parts, including maintenance, operational efficiency, and potential downtime. A lower upfront cost may not always equate to better value.

-

Pricing Nuances for International Buyers: Understand currency fluctuations, tariffs, and local regulations that can impact overall costs. Buyers from Africa, South America, the Middle East, and Europe should consider these elements when calculating budgets.

-

Supplier Diversity: Engage multiple suppliers to compare prices and ensure competitive offers. This can also provide leverage in negotiations.

-

Market Research: Stay informed about industry trends and pricing fluctuations in the wire EDM parts market. This knowledge can help buyers make informed decisions and time their purchases effectively.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing wire edm parts With Other Solutions

Introduction to Alternative Solutions for Wire EDM Parts

In the realm of precision machining, wire EDM (Electrical Discharge Machining) parts stand out for their ability to create intricate shapes with high accuracy. However, there are alternative technologies and methods that can be considered depending on specific project requirements, budget constraints, and desired outcomes. Understanding these alternatives can help international B2B buyers make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Wire EDM Parts | Laser Cutting | Waterjet Cutting |

|---|---|---|---|

| Performance | High precision and detail; effective for hard materials | Excellent for thin materials; less precision on thicker substrates | Good for a variety of materials; precision depends on thickness |

| Cost | Moderate initial investment; ongoing maintenance costs | Generally lower costs for setup but varies with material | Higher operational costs due to water and abrasive materials |

| Ease of Implementation | Requires skilled operators and setup | Relatively easier to set up; less technical training needed | Moderate complexity; requires water source and disposal solutions |

| Maintenance | Regular maintenance of parts; specialized knowledge required | Low maintenance; regular lens cleaning | Regular maintenance of pumps and disposal of abrasives |

| Best Use Case | Complex geometries and hard materials | Quick cuts for thin metals and plastics | Versatile applications including metals, glass, and ceramics |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Laser Cutting?

Laser cutting is renowned for its speed and versatility, particularly when working with thin materials like plastics and metals. The technology provides a clean cut and can be more cost-effective for production runs of less intricate designs. However, it may not achieve the same level of precision as wire EDM, especially on thicker materials. Additionally, laser cutting can struggle with reflective materials and requires a different skill set from operators, focusing more on programming and material handling than on intricate part design.

How Does Waterjet Cutting Compare to Wire EDM Parts?

Waterjet cutting utilizes high-pressure water mixed with abrasives to cut through various materials, making it an excellent choice for applications requiring no heat-affected zones. This method is particularly beneficial for materials sensitive to heat, such as plastics and composites. While waterjet cutting can be more versatile in terms of material compatibility, it often incurs higher operational costs due to the need for water and abrasives. Furthermore, the precision can vary significantly based on the thickness of the material being cut.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate machining solution ultimately hinges on the specific requirements of your project. For intricate designs and hard materials, wire EDM parts remain unparalleled in precision and detail. However, if your operations prioritize speed and cost-effectiveness, laser cutting may be the better option for simpler geometries. Alternatively, if you need versatility across various materials and want to avoid heat-related issues, consider waterjet cutting. Evaluate these alternatives against your operational capabilities and project specifications to make a well-informed decision that enhances productivity and cost-efficiency in your business.

Essential Technical Properties and Trade Terminology for wire edm parts

What Are the Essential Technical Properties of Wire EDM Parts?

Understanding the technical specifications of wire EDM (Electrical Discharge Machining) parts is crucial for B2B buyers, especially when ensuring compatibility, performance, and longevity in manufacturing processes. Here are several key specifications to consider:

Illustrative image related to wire edm parts

-

Material Grade

– Wire EDM parts are typically manufactured from materials like tungsten carbide, copper, and high-speed steel. The material grade directly influences the part’s durability, conductivity, and wear resistance. For instance, tungsten carbide is preferred for its strength and resistance to wear, making it suitable for high-precision applications. Selecting the right material ensures that parts can withstand the operational demands of specific machining tasks. -

Tolerance

– Tolerance refers to the permissible limit of variation in a physical dimension. In wire EDM, tight tolerances (often within ±0.001 mm) are critical for achieving high precision in machining operations. This specification is essential for industries like aerospace and automotive, where even minor deviations can lead to significant failures. Understanding tolerance levels helps buyers ensure that parts will meet their specific machining requirements. -

Wire Diameter

– The diameter of the wire used in EDM significantly affects the machining capabilities. Common wire diameters range from 0.1 mm to 0.3 mm. A smaller diameter allows for finer cuts and intricate designs, while a larger diameter can improve cutting speed and efficiency. Buyers should match the wire diameter to their specific machining needs to optimize performance. -

Power Feed Contacts

– Power feed contacts are essential components that transfer electrical energy to the wire. They can be made from various materials, including copper and tungsten carbide, depending on the required electrical conductivity and wear resistance. Selecting the right power feed contacts is vital for ensuring consistent performance and minimizing downtime due to wear. -

Cooling and Flushing Systems

– Effective cooling and flushing systems are vital for maintaining optimal machining conditions. These systems help remove debris and cool the workpiece during the machining process, preventing overheating and ensuring precision. B2B buyers should consider the compatibility of cooling systems with specific EDM machines to enhance operational efficiency. -

Finish Quality

– The finish quality of wire EDM parts is critical for many applications, influencing both aesthetic and functional properties. Common finishes include standard, fine, and ultra-fine, each suited for different applications. Understanding the required finish quality helps buyers ensure that parts will meet industry standards and customer expectations.

What Are Common Trade Terms in Wire EDM Parts Procurement?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are several common trade terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For wire EDM parts, knowing the OEM ensures compatibility with specific machines. Buyers often seek OEM parts for their reliability and performance assurance. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to plan their purchasing strategies effectively, ensuring they meet production demands without overstocking. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process helps buyers compare offers and negotiate better terms, making it a fundamental aspect of procurement. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for B2B transactions, as they affect shipping costs, risk, and liability. -

Lead Time

– Lead time refers to the amount of time from placing an order to the delivery of goods. Understanding lead times is vital for production planning and inventory management, allowing buyers to align their supply chain effectively. -

Certification Standards

– Certification standards, such as ISO and ASTM, define the quality and safety benchmarks for manufacturing processes. Compliance with these standards assures buyers of the quality and reliability of wire EDM parts, which is particularly important in regulated industries.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right wire EDM parts for their specific manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the wire edm parts Sector

What Are the Key Market Dynamics and Trends Affecting Wire EDM Parts?

The global wire EDM (Electrical Discharge Machining) parts market is experiencing significant growth driven by the increasing demand for precision machining across various industries, including aerospace, automotive, and electronics. Key factors propelling this trend include the rise of automation in manufacturing processes and advancements in EDM technology, which allow for more intricate designs and improved efficiency. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly leveraging digital platforms to source high-quality EDM parts, enhancing their supply chain management.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are reshaping the sourcing landscape, enabling real-time inventory management and predictive maintenance solutions. These innovations help companies optimize their operations and minimize downtime, making it imperative for buyers to stay updated on technological advancements. Moreover, the growing trend of customization in manufacturing is pushing suppliers to offer tailored EDM parts that meet specific customer requirements, further driving the competitive landscape.

How Are Sustainability and Ethical Sourcing Addressed in the Wire EDM Parts Sector?

Sustainability has become a cornerstone of modern manufacturing practices, and the wire EDM parts sector is no exception. The environmental impact of production processes, including waste generation and energy consumption, is prompting businesses to seek suppliers who prioritize sustainable practices. Ethical sourcing is increasingly important for B2B buyers, particularly those looking to establish a positive brand reputation and comply with stringent regulations regarding environmental responsibility.

Buyers are encouraged to evaluate suppliers based on their commitment to sustainable practices, such as the use of eco-friendly materials and energy-efficient manufacturing processes. Certifications like ISO 14001 (Environmental Management) and adherence to green standards can serve as indicators of a supplier’s dedication to sustainability. Additionally, the integration of recycled materials in the production of EDM parts not only reduces environmental impact but also aligns with the growing consumer preference for sustainable products.

What Is the Historical Context Behind the Development of Wire EDM Parts?

The evolution of wire EDM technology dates back to the late 1950s, when it was first introduced as a method for machining hard materials that were otherwise difficult to cut. Initially used in specialized applications, wire EDM has gained traction over the decades, evolving into a mainstream manufacturing process due to its precision and versatility. As technological advancements progressed, wire EDM machines became more sophisticated, allowing for complex geometries and tight tolerances.

This historical context is crucial for international B2B buyers, as it highlights the industry’s journey towards innovation and efficiency. Understanding the development of wire EDM parts can inform purchasing decisions, enabling buyers to appreciate the technological capabilities of modern suppliers and the importance of sourcing high-quality components for optimal performance. As the market continues to evolve, staying informed about historical trends can provide valuable insights into future directions and opportunities in the wire EDM parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wire edm parts

-

How do I solve issues with sourcing high-quality wire EDM parts?

To ensure you source high-quality wire EDM parts, start by identifying reputable suppliers with strong industry experience. Look for companies that provide detailed product specifications, certifications, and customer reviews. Request samples before placing a bulk order to assess the quality firsthand. Additionally, consider suppliers who offer a comprehensive warranty or guarantee, which indicates confidence in their product reliability. -

What is the best wire EDM part for precision machining?

The best wire EDM parts for precision machining often include diamond or ceramic wire guides and carbide power feed contacts. These components are designed to enhance the accuracy and efficiency of the machining process. When selecting parts, ensure they are compatible with your specific EDM machine model to achieve optimal performance and minimize downtime. -

How can I ensure the supplier I choose is reliable?

To verify a supplier’s reliability, check their industry reputation through reviews and testimonials. Request references from past clients, and assess their communication responsiveness. It’s beneficial to review their certifications and compliance with international standards, such as ISO. Finally, consider conducting a site visit or virtual meeting to discuss your needs and evaluate their operations. -

What customization options are available for wire EDM parts?

Many suppliers offer customization options for wire EDM parts to meet specific operational needs. This can include modifications in size, materials, or configurations. When discussing customization, provide clear specifications and requirements to the supplier. Ensure they have the capabilities to deliver tailored solutions without compromising on quality or lead times. -

What are the typical minimum order quantities (MOQs) for wire EDM parts?

Minimum order quantities for wire EDM parts can vary significantly among suppliers. Generally, MOQs may range from a few pieces to several dozen, depending on the part type and supplier policy. It’s advisable to inquire about MOQs upfront and discuss flexibility, especially if you are a small or medium-sized business looking to test the market before committing to larger orders. -

What payment terms should I expect when purchasing wire EDM parts internationally?

Payment terms for international purchases of wire EDM parts typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may offer net payment terms (e.g., net 30 days) for established customers. Always clarify payment terms in advance and consider using secure payment methods to protect your transaction. -

How can I manage logistics effectively when importing wire EDM parts?

Effective logistics management when importing wire EDM parts involves selecting reliable shipping partners and understanding local customs regulations. Consider using freight forwarders who specialize in industrial parts to streamline the process. Ensure all necessary documentation, such as invoices and packing lists, is accurate to avoid delays. Track shipments regularly to anticipate any potential issues. -

What quality assurance measures should I look for in wire EDM parts?

When sourcing wire EDM parts, look for suppliers who implement robust quality assurance measures. This includes routine inspections, adherence to international quality standards (such as ISO 9001), and the availability of certification documents. Ask about their testing procedures for parts, including performance under operational conditions, to ensure they meet your quality expectations before shipment.

Top 5 Wire Edm Parts Manufacturers & Suppliers List

1. Reddit – Wire EDM Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Wire EDM (Electrical Discharge Machining) is used to create ‘zero tolerance’ or ‘perfect fit’ parts in a punch/die configuration. The process involves workholding techniques to prevent the punch from sagging or falling through after the cut is complete. Common methods include leaving a tab that is ground off later or using hot glue and magnets to secure the workpiece during machining.

2. Novotec – EDM Wear Parts

Domain: us.novotec-edm.com

Registered: 1998 (27 years)

Introduction: Novotec offers an extensive range of EDM wear parts that are fully compliant with OEM specifications. Key features include: in-house design and production facilities, an extensive database of technical data for optimal advice, and rigorous quality control procedures ensuring high-quality products. The product range includes nozzles, wire guides, motors, and cables, compatible with major machine ma…

3. Alternative Machine Tool – EDM Supplies & Accessories

Domain: alternativemachinetool.com

Registered: 2001 (24 years)

Introduction: EDM supplies for sale: Consumables, accessories & machine components. Popular items include: 3.4 X 400MM BRASS, 3.5 X 400MM BRASS, O-RING Rubber Grommet for EDM Hole Driller, 3.6 X 400MM BRASS FLANGE BEARING, 6-PIN WIRE ALIGNMENT CABLE, CARBIDE for MITSUBISHI, RECTIFIER RING DBJ1900. Product categories include EDM Wire, EDM Hole Driller, Tool Room Machinery, and various brands like Fanuc, Agie-Cha…

4. eMachineShop – Wire EDM Services

Domain: emachineshop.com

Registered: 1999 (26 years)

Introduction: Wire EDM Services: eMachineShop offers electrical discharge machining (EDM) services including sinker and wire EDM for single parts, prototypes, or production orders. Key features include: 50+ materials available, free shipping in the USA, and a 100% quality guarantee. Advantages of Wire EDM include the ability to produce sharp inside corners, ideal for parts with thin walls, and no burring. Desig…

5. Taguti – Sodick EDM Drilling & Fanuc Wire EDM Power Supply

Domain: taguti.net

Registered: 2018 (7 years)

Introduction: Key Products: 1. Sodick EDM Drilling TS Guide for Agie Charmilles & Sodick S140D Wire Guide – Features high accuracy, long service life, easy wire feeding. Price: from $18.00. 2. Fanuc Wire EDM Power Supply F006 A290-8110-X750 – High density raw materials, good conductivity, suitable for high current cutting. Price: $7.50. 3. Fanuc EDM Wire Guide F113 A290-8110-X715 – High accuracy, long service l…

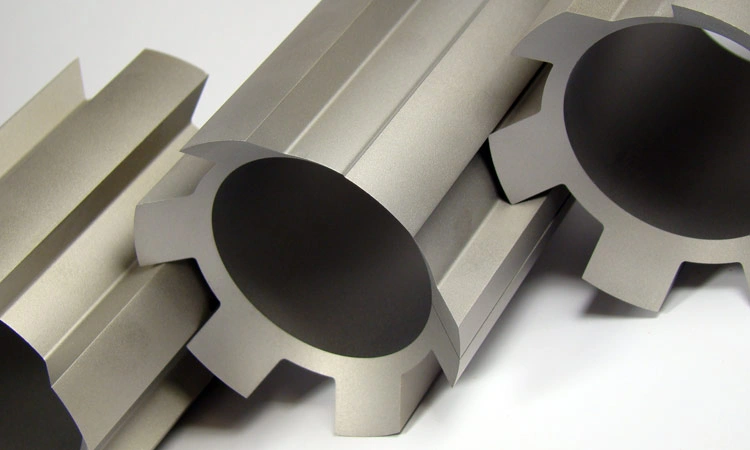

Strategic Sourcing Conclusion and Outlook for wire edm parts

As the global market for wire EDM parts continues to evolve, strategic sourcing remains a pivotal element for B2B buyers aiming to enhance their operational efficiency and competitiveness. By understanding the diverse range of spare parts and consumables available, businesses can optimize their procurement strategies, ensuring they maintain high-performance standards while minimizing downtime.

The availability of OEM and aftermarket parts for leading wire EDM manufacturers—such as Fanuc, Mitsubishi, and Sodick—provides flexibility in sourcing. Buyers are encouraged to leverage established networks and inventories, ensuring timely access to critical components. This proactive approach not only supports uninterrupted production but also fosters long-term partnerships with suppliers who can provide expert guidance and tailored solutions.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should prioritize establishing robust sourcing strategies that encompass both quality and cost-effectiveness. As market demands shift, investing in reliable suppliers will be crucial to staying ahead in a competitive landscape. Engage with your suppliers today to explore innovative solutions that will drive your business forward.

Illustrative image related to wire edm parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.