Top 5 What Are Rubber Sheets Suppliers (And How to Choose)

Introduction: Navigating the Global Market for what are rubber sheets

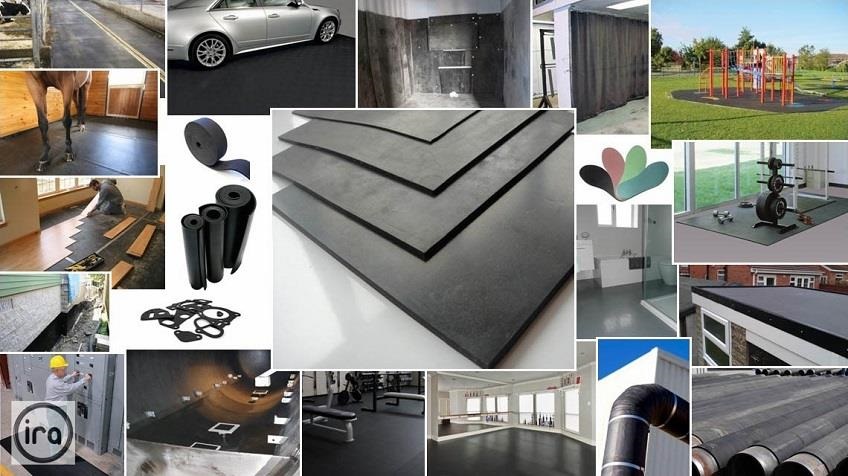

In the ever-evolving landscape of global commerce, sourcing high-quality rubber sheets can pose a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. As industries increasingly rely on rubber sheets for applications ranging from construction safety to industrial gaskets, understanding the nuances of this material becomes essential. This comprehensive guide will delve into the various types of rubber sheets, including natural, synthetic, recycled, and reclaimed options, and their specific applications in different sectors.

Moreover, we will provide actionable insights into the supplier vetting process, enabling buyers to discern quality and reliability in potential partners. Key considerations such as cost factors, custom fabrication options, and the environmental implications of different rubber types will also be explored. By equipping international B2B buyers with the knowledge needed to make informed purchasing decisions, this guide aims to streamline the sourcing process, reduce operational risks, and ultimately enhance product performance. Whether you’re a buyer from Nigeria seeking eco-friendly solutions or a distributor in Vietnam looking for durable materials, this resource will serve as a valuable tool in navigating the complexities of the rubber sheet market.

Understanding what are rubber sheets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Rubber | Derived from latex of rubber trees; excellent elasticity and resilience. | Automotive, manufacturing, and consumer goods. | Pros: High tensile strength, eco-friendly. Cons: Vulnerable to UV and ozone degradation. |

| Synthetic Rubber | Man-made, customizable properties; includes various types such as SBR and EPDM. | Industrial applications, automotive, and construction. | Pros: Tailored properties, resistant to chemicals. Cons: Can be less durable than natural rubber in some conditions. |

| Recycled Rubber | Made from reclaimed tire materials; eco-conscious option. | Flooring, mats, and padding in gyms or playgrounds. | Pros: Cost-effective, sustainable. Cons: May have variations in quality and performance. |

| EPDM Rubber | High resistance to heat, weather, and ozone; ideal for outdoor use. | Roofing, automotive seals, and gaskets. | Pros: Long-lasting, versatile. Cons: Higher initial cost compared to other types. |

| Nitrile Rubber | Excellent oil and fuel resistance; suitable for harsh environments. | Gaskets, seals, and automotive parts. | Pros: Durable in extreme conditions, great chemical resistance. Cons: Limited temperature range compared to other types. |

What Are the Characteristics of Natural Rubber Sheets?

Natural rubber sheets are sourced from the latex of rubber trees, primarily found in tropical regions. They are known for their exceptional elasticity, tensile strength, and resilience, making them suitable for various applications, including automotive parts, manufacturing, and consumer goods. When considering natural rubber, buyers should note that while it is eco-friendly and offers high performance, it can degrade under UV exposure and ozone, necessitating proper storage and handling to prolong its lifespan.

Why Choose Synthetic Rubber Sheets for Your Business Needs?

Synthetic rubber sheets are engineered from petroleum byproducts, allowing for a wide range of customizable properties tailored to specific applications. Common types include Styrene Butadiene Rubber (SBR) and Ethylene Propylene Diene Monomer (EPDM). These sheets are widely used in industrial settings, automotive manufacturing, and construction due to their chemical resistance and durability. Buyers should evaluate the specific properties required for their applications, as synthetic rubbers may not always match the performance of natural rubber in certain conditions.

What Advantages Do Recycled Rubber Sheets Offer?

Recycled rubber sheets are produced from reclaimed tire materials, making them an eco-conscious choice for various applications. They are commonly utilized in flooring, gym mats, and playground padding. The primary advantages of recycled rubber include cost-effectiveness and sustainability, appealing to businesses focused on reducing their environmental footprint. However, buyers must be aware that the quality and performance of recycled rubber can vary, so sourcing from reputable suppliers is crucial to ensure consistent product standards.

When Should You Consider EPDM Rubber Sheets?

EPDM rubber sheets are renowned for their superior resistance to heat, weather, and ozone, making them ideal for outdoor applications such as roofing and automotive seals. Their longevity and versatility make them a preferred choice in many industries. While the initial investment for EPDM may be higher than other rubber types, the long-term durability can lead to significant cost savings in maintenance and replacements. Businesses should assess their specific environmental conditions to determine if EPDM is the right fit.

How Does Nitrile Rubber Meet Harsh Environment Requirements?

Nitrile rubber sheets are specifically designed to withstand oil, fuel, and extreme environmental conditions, making them suitable for gaskets, seals, and automotive components. Their excellent chemical resistance ensures reliability in demanding applications. However, buyers should consider the limitations in temperature ranges compared to other rubber types, as this can impact their effectiveness in certain scenarios. Proper selection based on the intended use is essential to maximize the benefits of nitrile rubber.

Key Industrial Applications of what are rubber sheets

| Industry/Sector | Specific Application of what are rubber sheets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and safety mats in commercial buildings | Enhances safety and durability in high-traffic areas | Material thickness, slip resistance, and custom sizing |

| Automotive | Gaskets and seals for engines and machinery | Ensures leak prevention and operational efficiency | Temperature tolerance, chemical resistance, and compliance with automotive standards |

| Manufacturing | Vibration dampening pads and protective coverings | Reduces wear and tear on machinery, prolonging lifespan | Hardness ratings, custom fabrication options, and availability of various rubber types |

| Agriculture | Protective liners for silos and storage facilities | Minimizes contamination and product loss | Resistance to moisture, UV stability, and ease of installation |

| Food Processing | Food-grade rubber sheets for conveyor belts | Ensures hygiene and compliance with safety regulations | Certification for food safety, durability, and ease of cleaning |

How Are Rubber Sheets Used in Construction and What Problems Do They Solve?

In the construction industry, rubber sheets are frequently utilized for flooring and safety mats, particularly in commercial buildings. These mats provide excellent slip resistance, crucial for ensuring safety in high-traffic areas such as entryways and staircases. They also contribute to sound dampening and impact absorption, enhancing the overall user experience. Buyers from regions like Africa and South America should prioritize sourcing materials that meet local safety standards and consider custom sizing to fit specific project dimensions.

What Role Do Rubber Sheets Play in the Automotive Sector?

Rubber sheets find vital applications in the automotive sector, particularly as gaskets and seals. These components are essential for preventing leaks in engines and machinery, thereby ensuring operational efficiency. The choice of rubber type is critical, as it must withstand high temperatures and resist various chemicals. B2B buyers must ensure that the rubber sheets sourced comply with automotive industry standards to guarantee performance and longevity, especially in regions with extreme climates like the Middle East.

How Do Manufacturing Industries Benefit from Rubber Sheets?

In manufacturing, rubber sheets are widely used as vibration dampening pads and protective coverings for machinery. These applications help reduce wear and tear, prolonging the lifespan of expensive equipment and minimizing maintenance costs. Buyers should consider the hardness ratings and custom fabrication options available to meet their specific machinery requirements. Additionally, sourcing from reliable suppliers who can provide various rubber types will ensure that the materials used are suitable for the intended applications.

Why Are Rubber Sheets Important in Agriculture?

Rubber sheets serve as protective liners in agricultural settings, particularly for silos and storage facilities. These liners help minimize contamination and product loss, ensuring that stored materials remain safe and untainted. When sourcing rubber sheets for agricultural use, buyers should focus on materials that offer resistance to moisture and UV stability, as these factors significantly impact the longevity and effectiveness of the liners. This is particularly important for buyers in tropical regions where exposure to the elements is a constant challenge.

How Are Rubber Sheets Used in Food Processing and What Are the Key Considerations?

In the food processing industry, rubber sheets are often employed as food-grade conveyor belts. These sheets must adhere to strict hygiene standards and be easy to clean to ensure compliance with safety regulations. B2B buyers should prioritize sourcing rubber sheets that are certified for food safety and are durable enough to withstand continuous use. Additionally, ease of cleaning and maintenance should be a key consideration, particularly for businesses operating in regions with stringent food safety laws, such as Europe.

3 Common User Pain Points for ‘what are rubber sheets’ & Their Solutions

Scenario 1: Sourcing the Right Rubber Sheet for Specific Applications

The Problem: B2B buyers often struggle to identify the most suitable type of rubber sheet for their specific applications. With various options like EPDM, SBR, and natural rubber available, determining which material will provide the necessary durability, chemical resistance, or temperature tolerance can be overwhelming. This challenge is exacerbated in regions where access to detailed product information is limited, leading to potential project delays and increased costs due to unsuitable purchases.

The Solution: To effectively source the right rubber sheet, buyers should first conduct a thorough needs assessment. This includes understanding the environmental conditions (e.g., exposure to chemicals, temperature extremes) and the mechanical requirements (e.g., tensile strength, abrasion resistance) of their application. Once these factors are clear, buyers can consult with reputable suppliers who specialize in rubber products. Engaging in direct communication with suppliers allows buyers to ask specific questions and request samples for testing. Furthermore, leveraging online resources, including product datasheets and technical specifications, can help buyers compare different rubber types more efficiently. By taking these steps, B2B buyers can ensure they select a rubber sheet that meets their unique requirements, reducing the risk of project setbacks.

Scenario 2: Managing Inventory of Rubber Sheets for Diverse Needs

The Problem: Companies often find themselves with an excessive inventory of rubber sheets that do not match their current project requirements, leading to wasted resources and increased storage costs. This is particularly common in businesses that require multiple types of rubber sheets for various applications but lack a streamlined inventory management system. The inability to forecast demand accurately results in either surplus stock or shortages, affecting production timelines and profitability.

The Solution: Implementing a just-in-time (JIT) inventory management system can significantly improve the efficiency of rubber sheet procurement. This approach involves closely monitoring usage patterns and aligning orders with current and projected needs. Buyers should analyze historical data on rubber sheet consumption and collaborate with suppliers to set up flexible ordering options. Establishing a minimum order quantity with suppliers can ensure that necessary materials are always available without overstocking. Additionally, leveraging inventory management software can provide real-time insights into stock levels, helping businesses make informed decisions on when to reorder. This proactive strategy minimizes waste and keeps costs in check, ultimately enhancing operational efficiency.

Scenario 3: Ensuring Quality and Compliance of Rubber Sheets

The Problem: B2B buyers frequently face challenges in ensuring that the rubber sheets they procure meet industry standards and regulatory compliance, particularly in sectors such as food processing, pharmaceuticals, or automotive manufacturing. The risk of sourcing subpar or non-compliant materials can lead to serious repercussions, including safety hazards, product recalls, and damage to brand reputation.

The Solution: To mitigate these risks, buyers should prioritize sourcing rubber sheets from certified manufacturers who adhere to international quality standards such as ISO or ASTM. Requesting certificates of compliance and detailed product specifications is crucial in verifying that materials meet the required industry benchmarks. Additionally, conducting audits or site visits to manufacturers can provide deeper insight into their production processes and quality control measures. Buyers should also stay informed about relevant regulations in their industry and ensure that their suppliers can demonstrate compliance. By establishing strong relationships with reputable suppliers and maintaining a rigorous vetting process, B2B buyers can confidently procure rubber sheets that meet both quality and compliance standards, safeguarding their operations and reputation.

Strategic Material Selection Guide for what are rubber sheets

What are the Key Properties of Common Rubber Sheet Materials?

When selecting rubber sheets for various applications, understanding the distinct properties of different materials is crucial for B2B buyers. Here, we analyze four common types of rubber sheets: Natural Rubber, EPDM, Neoprene, and Nitrile. Each material has unique characteristics that influence their performance and suitability for specific applications.

What are the Key Properties of Natural Rubber Sheets?

Natural rubber, derived from the latex of rubber trees, is known for its excellent elasticity and resilience. It performs well in a wide temperature range, typically from -40°F to 175°F (-40°C to 80°C), making it suitable for various environments. However, it is not resistant to oil and solvents, which can degrade its performance.

Pros: Natural rubber sheets offer superior tensile strength and tear resistance, making them ideal for applications requiring durability. They are also cost-effective compared to synthetic alternatives.

Cons: The primary limitation is their susceptibility to degradation from oils and UV exposure, which can limit their application in industrial settings.

Impact on Application: Natural rubber is best suited for applications involving water and moderate temperatures but should be avoided in oil-rich environments.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding natural rubber sourcing, as well as international standards such as ASTM D2000.

How Does EPDM Rubber Compare for Sheet Applications?

Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic material known for its outstanding resistance to UV radiation, ozone, and extreme temperatures (from -60°F to 300°F or -51°C to 149°C). This makes it an excellent choice for outdoor applications and environments where weathering is a concern.

Pros: EPDM sheets are durable, resistant to aging, and maintain flexibility in cold temperatures. They are also non-toxic and environmentally friendly.

Cons: While EPDM is versatile, it has lower tensile strength compared to natural rubber and may not be suitable for high-impact applications.

Impact on Application: EPDM is commonly used in roofing, automotive weather seals, and gaskets, particularly in climates with significant temperature fluctuations.

International Considerations: Buyers in Europe and the Middle East should check for compliance with environmental standards, as EPDM is often preferred for sustainable building practices.

What are the Advantages of Neoprene Rubber Sheets?

Neoprene rubber is a synthetic rubber that offers excellent chemical resistance, making it suitable for applications involving oils, fuels, and solvents. It typically performs well in temperatures ranging from -40°F to 212°F (-40°C to 100°C).

Pros: Neoprene sheets are durable, resistant to weathering, and provide good thermal insulation. They are also available in various thicknesses and can be customized for specific applications.

Cons: The main drawback is the higher cost compared to other rubber types, which may impact budget-sensitive projects.

Impact on Application: Neoprene is ideal for automotive, marine, and industrial applications where exposure to chemicals is a concern.

International Considerations: Buyers should ensure that Neoprene products meet relevant chemical resistance standards, especially in regions with stringent regulations like Europe.

How Does Nitrile Rubber Stand Out for Sheet Usage?

Nitrile rubber (NBR) is particularly known for its excellent oil and fuel resistance, making it a preferred choice in industries such as automotive and aerospace. It can withstand temperatures from -40°F to 212°F (-40°C to 100°C).

Pros: Nitrile sheets are highly durable and provide excellent resistance to abrasion and wear, making them suitable for high-stress applications.

Cons: However, Nitrile rubber is less effective in extreme temperatures and has limited ozone resistance compared to other rubber types.

Impact on Application: Nitrile is commonly used in gaskets, seals, and hoses in environments where oil exposure is prevalent.

International Considerations: B2B buyers should verify compliance with ASTM and ISO standards related to oil resistance, especially in industrial applications across Africa and the Middle East.

Summary Table of Rubber Sheet Materials

| Material | Typical Use Case for what are rubber sheets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | General-purpose applications, flooring | High elasticity and cost-effective | Poor oil and UV resistance | Low |

| EPDM | Outdoor seals, roofing, gaskets | Excellent UV and ozone resistance | Lower tensile strength than natural rubber | Medium |

| Neoprene | Automotive, marine applications | Great chemical resistance | Higher cost compared to other rubbers | High |

| Nitrile | Gaskets, seals in oil-rich environments | Excellent oil and fuel resistance | Limited ozone resistance | Medium |

This strategic material selection guide provides essential insights for B2B buyers seeking to optimize their rubber sheet choices based on specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what are rubber sheets

What Are the Key Stages in the Manufacturing Process of Rubber Sheets?

The manufacturing process of rubber sheets is intricate and involves several critical stages. Understanding these stages can help B2B buyers assess the quality and suitability of rubber products for their applications.

How is Material Prepared for Rubber Sheet Production?

The first step in rubber sheet manufacturing is material preparation. This phase involves selecting the appropriate type of rubber, which can be natural, synthetic, recycled, or reclaimed. The raw materials are then processed to achieve the desired consistency and properties. For synthetic rubbers, this includes combining various polymers, such as styrene-butadiene or neoprene, along with additives like fillers and accelerators to enhance performance characteristics.

Once the materials are mixed, they are often subjected to a milling process where they are blended and refined. This ensures a homogeneous mixture that will yield uniform properties across the final product. Proper formulation during this stage is crucial, as it directly impacts the physical and chemical characteristics of the rubber sheets.

What Techniques are Used in Forming Rubber Sheets?

After material preparation, the next stage is forming the rubber sheets. This can be achieved through several techniques, with the most common being calendering and extrusion.

-

Calendering: In this method, the prepared rubber is fed through a series of rollers, which flatten and shape it into sheets of uniform thickness. This technique is particularly effective for producing large volumes of rubber sheets quickly and consistently.

-

Extrusion: Another popular technique involves forcing the rubber through a die to create sheets of specific dimensions. Extrusion is beneficial for creating rubber profiles and custom shapes that may be required for specialized applications.

Both techniques require precise control of temperature and pressure to ensure optimal curing and material properties.

What Happens During the Assembly and Finishing Stages?

The assembly stage may involve cutting the sheets into specific dimensions or shapes based on customer requirements. This customization is crucial for B2B buyers who need tailored solutions for their applications.

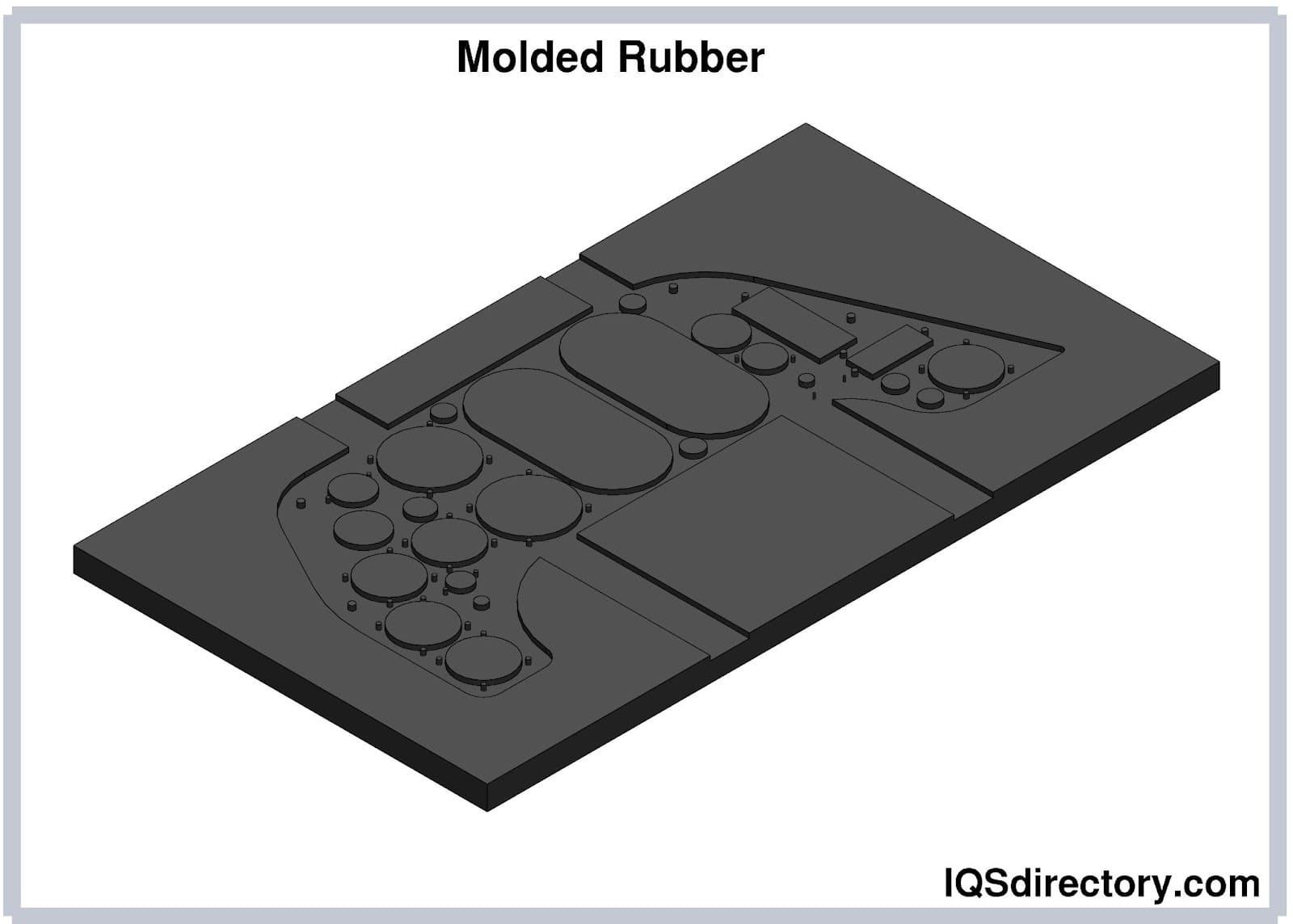

Illustrative image related to what are rubber sheets

Following assembly, the finishing stage enhances the aesthetic and functional properties of the rubber sheets. This may include processes such as surface treatment to improve adhesion, coloring for visual appeal, or additional vulcanization to enhance durability. The finishing touches not only improve the product’s performance but also its marketability.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the rubber sheet manufacturing process. B2B buyers should familiarize themselves with relevant international and industry-specific standards that govern product quality.

Which International Standards Are Relevant for Rubber Sheets?

The most widely recognized international standard is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with this standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking and API specifications may also apply, depending on the intended application of the rubber sheets.

What Are the Key Quality Control Checkpoints in Rubber Sheet Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints typically include:

Illustrative image related to what are rubber sheets

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. Poor-quality raw materials can lead to defects in the final product.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and material consistency are monitored to maintain quality. This stage ensures that any deviations from specifications are addressed immediately.

-

Final Quality Control (FQC): After production, the rubber sheets undergo thorough testing to verify that they meet quality standards. This may include physical tests for tensile strength, elongation, and hardness, as well as chemical tests for resistance to oils and other substances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s QC processes is crucial to ensure product reliability. Here are some actionable steps:

-

Conduct Audits: Buyers can perform on-site audits to assess the manufacturer’s QMS and QC practices. This provides firsthand insight into their operational capabilities and commitment to quality.

-

Request QC Reports: Suppliers should be able to provide documentation of their QC processes, including testing methods and results. Reviewing these reports can help buyers gauge the consistency and reliability of the products.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and the final product. This is particularly useful for international transactions, where direct oversight may not be feasible.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is essential. Different regions may have specific standards that affect the suitability of rubber sheets for certain applications.

Additionally, logistics and transportation considerations should not be overlooked. Quality can be compromised during shipping, so it’s important to ensure that suppliers use appropriate packaging and handling procedures. B2B buyers should also consider the potential for customs regulations to impact product acceptance, requiring additional documentation or certifications.

Conclusion

In summary, the manufacturing processes and quality assurance practices for rubber sheets are multifaceted and critical to ensuring product quality and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers and products that meet their specific needs. Emphasizing quality control standards and verification methods will help establish a reliable supply chain that meets international expectations.

Illustrative image related to what are rubber sheets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what are rubber sheets’

Introduction

When sourcing rubber sheets for industrial applications, a systematic approach ensures that you meet both your technical requirements and budget constraints. This checklist provides actionable steps for B2B buyers to streamline the procurement process, ensuring that you select the right type of rubber sheets for your specific needs.

Step 1: Define Your Technical Specifications

Before you start contacting suppliers, it’s essential to outline your technical requirements. Consider factors such as thickness, type of rubber (natural, synthetic, recycled), and physical properties like chemical resistance or temperature tolerance.

- Identify Applications: Specify how and where the rubber sheets will be used (e.g., flooring, gaskets, protective covers).

- Understand Standards: Familiarize yourself with any industry-specific standards that the rubber sheets must meet.

Step 2: Research Different Types of Rubber Sheets

Understanding the various types of rubber sheets available can significantly impact your selection process. Each type—natural rubber, synthetic rubber, EPDM, and others—has unique properties suited for different applications.

- Know the Benefits: For instance, EPDM is excellent for outdoor use due to its UV resistance, while nitrile rubber excels in fuel and oil applications.

- Evaluate Costs: Different types of rubber come with varying price points; understanding these can help you stay within budget.

Step 3: Evaluate Potential Suppliers

Choosing the right supplier is critical to ensuring quality and reliability. Conduct thorough evaluations of potential suppliers to gauge their credibility and expertise.

- Request Documentation: Ask for certifications, quality assurance processes, and product samples to verify their capabilities.

- Check References: Look for testimonials or case studies from other businesses in your industry to assess supplier performance.

Step 4: Verify Supplier Certifications

Before finalizing any orders, ensure that your chosen supplier meets relevant industry certifications. This step is vital for maintaining quality and compliance with regulations.

- Look for ISO Certifications: ISO 9001 is a common quality management standard that indicates a commitment to quality.

- Check for Material Safety Data Sheets (MSDS): These documents provide critical information on the safety and handling of the rubber materials.

Step 5: Assess Customization Options

Depending on your project requirements, you may need custom-sized rubber sheets. Assess the supplier’s ability to provide tailored solutions that meet your specifications.

- Inquire About Custom Cuts: Determine if the supplier can accommodate specific dimensions and shapes.

- Evaluate Flexibility: A supplier that offers small batch orders can be beneficial for testing new applications without significant financial risk.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful procurement process. Ensure that your supplier is responsive and open to discussions about your needs.

- Set Up Regular Updates: Establish a schedule for updates on order status and any potential issues.

- Encourage Feedback: Be open to providing feedback throughout the process to foster a collaborative relationship.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in receiving your rubber sheets. Understanding shipping times, costs, and import regulations can prevent unexpected delays.

- Confirm Shipping Methods: Ensure the supplier can meet your delivery timelines and has reliable shipping options.

- Understand Customs Regulations: For international orders, familiarize yourself with any import duties or compliance requirements specific to your region.

By following this practical checklist, B2B buyers can confidently navigate the procurement process for rubber sheets, ensuring they find the right products for their specific applications.

Comprehensive Cost and Pricing Analysis for what are rubber sheets Sourcing

Understanding the cost structure and pricing for rubber sheets is crucial for international B2B buyers, especially when sourcing from regions like Africa, South America, the Middle East, and Europe. This analysis will break down the primary cost components, explore factors influencing pricing, and offer actionable tips for effective negotiation and procurement.

What Are the Key Cost Components in Rubber Sheets Sourcing?

The cost structure of rubber sheets can be broadly categorized into several components:

-

Materials: The type of rubber—natural, synthetic, recycled, or reclaimed—significantly influences material costs. For instance, natural rubber sourced from the Hevea brasiliensis tree is often more expensive due to its harvesting process. In contrast, recycled rubber can be more cost-effective but may vary in quality.

-

Labor: Labor costs include wages for skilled workers involved in manufacturing and processing rubber sheets. Regions with lower labor costs can provide a competitive edge, but quality assurance must not be compromised.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and administrative expenses. Efficient production processes can help minimize these overheads, contributing to lower prices.

-

Tooling: The cost of molds and machinery required to manufacture specific rubber sheet designs impacts initial investment and, subsequently, pricing. Custom tooling can increase costs, especially for unique specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. However, these measures can add to the overall cost, especially if certifications (e.g., ISO, ASTM) are required.

-

Logistics: Shipping and handling costs can vary based on distance, weight, and shipping method. For international buyers, understanding Incoterms is essential to ascertain who bears these costs during the shipping process.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on supplier reputation, market demand, and competition.

What Factors Influence Pricing for Rubber Sheets?

Several factors can significantly affect the pricing of rubber sheets:

-

Volume/MOQ: Larger orders usually lead to better pricing due to economies of scale. Suppliers are often willing to negotiate better rates for high-volume purchases.

-

Specifications and Customization: Custom rubber sheets tailored to specific applications or industries will typically incur higher costs due to unique material requirements and manufacturing processes.

-

Material Quality and Certifications: Higher quality materials or those with certifications will command premium prices. Buyers should assess whether the additional cost is justified by the application requirements.

-

Supplier Factors: The supplier’s experience, reputation, and location can impact pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: Understanding the agreed shipping terms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can affect the total landed cost.

What Are Effective Tips for Negotiating Rubber Sheet Prices?

For international buyers, especially from developing regions, navigating the cost landscape requires strategic planning:

-

Leverage Volume Discounts: If possible, consolidate orders to meet minimum order quantities (MOQs) that qualify for bulk pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and maintenance.

-

Negotiate Based on Specifications: Clearly communicate your needs and explore alternative materials or specifications that may reduce costs without sacrificing quality.

-

Research Market Trends: Stay informed about market fluctuations and trends in rubber pricing. This knowledge can provide leverage during negotiations.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insider knowledge on upcoming deals.

Conclusion

Sourcing rubber sheets involves a complex interplay of cost components and price influencers. By understanding these dynamics and employing strategic negotiation tactics, international B2B buyers can optimize their procurement processes, ensuring they receive quality products at competitive prices. Always remember that prices can fluctuate based on market conditions, so it’s advisable to approach negotiations with flexibility and preparedness.

Alternatives Analysis: Comparing what are rubber sheets With Other Solutions

Introduction to Alternatives for Rubber Sheets

In various industrial applications, the choice of materials can significantly impact performance, cost-effectiveness, and overall functionality. Rubber sheets are a popular choice due to their versatility and durability, but other materials and technologies can also fulfill similar roles. This section explores viable alternatives to rubber sheets, providing a detailed comparison to aid B2B buyers in making informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | What Are Rubber Sheets | Alternative 1 Name: PVC Sheets | Alternative 2 Name: Foam Sheets |

|---|---|---|---|

| Performance | Excellent for impact absorption, slip resistance, and weather resistance. | Good chemical resistance, moderate durability. | Lightweight, good shock absorption but less durable. |

| Cost | Moderate to high, depending on type. | Generally lower cost, affordable for many applications. | Low cost, economical for bulk purchasing. |

| Ease of Implementation | Customizable; can be cut to size. | Easy to handle and install, often available in large rolls. | Simple to cut and shape, lightweight for easy installation. |

| Maintenance | Low maintenance, resistant to wear and tear. | Requires regular cleaning to maintain appearance. | Generally low, but can degrade over time with exposure to moisture. |

| Best Use Case | Industrial flooring, gaskets, seals, and protective mats. | Chemical containment, flooring, and wall coverings. | Packaging, cushioning, and insulation applications. |

Detailed Breakdown of Alternatives

Alternative 1: PVC Sheets

PVC (Polyvinyl Chloride) sheets are a common alternative to rubber sheets, particularly in environments where chemical resistance is essential. They offer good durability and are often less expensive than rubber sheets. However, while PVC is resistant to moisture and certain chemicals, it lacks the same level of impact absorption and flexibility that rubber sheets provide. Additionally, PVC can be less effective in extreme temperatures, making it less versatile in outdoor applications.

Alternative 2: Foam Sheets

Foam sheets, made from various materials such as polyethylene or polyurethane, are lightweight and offer excellent cushioning properties. They are particularly suitable for applications requiring shock absorption, such as packaging and insulation. While foam sheets are generally more cost-effective, their durability is inferior to rubber sheets, especially in high-traffic or industrial settings. Over time, foam can compress and degrade, necessitating more frequent replacements.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right material for your application, it’s essential to weigh the specific requirements against the characteristics of each alternative. Rubber sheets excel in environments requiring durability and impact resistance, making them ideal for industrial applications. PVC sheets offer a cost-effective solution for chemical resistance, while foam sheets are suitable for lightweight cushioning needs. By carefully assessing the performance requirements, budget constraints, and intended use, B2B buyers can make informed decisions that align with their operational goals and enhance overall efficiency.

Essential Technical Properties and Trade Terminology for what are rubber sheets

What Are the Key Technical Properties of Rubber Sheets in B2B Applications?

When selecting rubber sheets for industrial applications, several critical technical properties must be considered to ensure they meet specific requirements. Here are some essential specifications that B2B buyers should focus on:

1. Material Grade

Rubber sheets are classified into different material grades, including natural rubber, synthetic rubber (such as SBR, EPDM, and NBR), recycled rubber, and reclaimed rubber. Each type has unique properties that affect durability, flexibility, and chemical resistance. For instance, EPDM rubber is ideal for outdoor applications due to its resistance to UV rays and ozone, while NBR is suitable for environments involving oils and fuels. Understanding material grade helps businesses choose the right rubber sheet for their specific needs, optimizing performance and lifespan.

2. Durometer Hardness

Durometer hardness measures a rubber material’s resistance to indentation, typically expressed on a scale of Shore A. A higher durometer indicates a harder rubber, while a lower number signifies a softer material. For example, a durometer of 60A is commonly used for general-purpose applications, while a 70A may be better suited for gaskets or seals. Selecting the appropriate hardness is crucial, as it affects not only the application but also the sheet’s longevity and performance under stress.

3. Thickness Tolerance

Thickness tolerance refers to the permissible variation in the thickness of rubber sheets, which can significantly impact their performance in specific applications. For example, certain industrial uses may require rubber sheets with a thickness of 1/4 inch ± 0.015 inches. Tighter tolerances ensure better fit and function, reducing the risk of failure in critical applications. Buyers should verify the thickness tolerance to ensure compatibility with their machinery or installations.

4. Chemical Resistance

Different rubber materials exhibit varying degrees of resistance to chemicals, oils, and solvents. For instance, nitrile rubber excels in environments where oil exposure is common, while silicone rubber is known for its resistance to high temperatures and certain chemicals. Understanding the chemical resistance properties of rubber sheets is essential for B2B buyers to ensure that the material will withstand the specific conditions of their operations without degrading.

5. Temperature Range

Rubber sheets have specific temperature ranges within which they can perform optimally. For example, neoprene rubber typically operates effectively between -20°F to 200°F, while silicone rubber can withstand temperatures up to 500°F. Knowing the operational temperature range helps buyers choose rubber sheets that will maintain their integrity and functionality, even under extreme conditions.

Illustrative image related to what are rubber sheets

What Common Trade Terms Should B2B Buyers Understand in the Rubber Sheet Market?

In addition to technical properties, familiarity with industry jargon is vital for effective communication and negotiation. Here are some common trade terms relevant to rubber sheets:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. In the rubber sheet industry, OEMs often produce custom rubber solutions tailored to the specifications of their clients. Understanding OEM relationships can help buyers ensure they are sourcing high-quality products that meet their needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. In the rubber sheet market, MOQs can vary significantly depending on the manufacturer and the type of rubber being ordered. Knowing the MOQ helps buyers plan their purchasing strategy and manage inventory costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products or services. In the rubber sheet industry, submitting an RFQ allows buyers to gather detailed information on product specifications, pricing, and lead times, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for B2B buyers engaged in cross-border rubber sheet procurement, as they clarify shipping costs, risks, and obligations.

5. Custom Fabrication

Custom fabrication involves the process of tailoring rubber sheets to meet specific dimensions or requirements. This service is essential for businesses needing specialized shapes or sizes for unique applications. Familiarity with custom fabrication options allows buyers to optimize their use of rubber sheets and minimize waste.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing rubber sheets for their industrial applications, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the what are rubber sheets Sector

What Are the Key Market Trends Influencing the Rubber Sheets Sector?

The global rubber sheets market is driven by several factors, including increasing industrialization, the demand for durable and versatile materials, and advancements in manufacturing technologies. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality rubber sheets for various applications, from construction and automotive to healthcare and consumer goods. Notably, the rise of e-commerce and digital supply chains has transformed sourcing methods, enabling buyers to access a wider range of products and suppliers with greater efficiency.

Emerging trends indicate a growing preference for specialized rubber types, such as EPDM and Nitrile, due to their unique properties like UV resistance and chemical stability. Additionally, the customization of rubber sheets is becoming a standard practice, allowing businesses to tailor products to specific operational needs. As the market evolves, buyers must remain vigilant about fluctuations in raw material prices, which can significantly impact the cost of rubber sheets.

Moreover, the integration of smart technologies in manufacturing processes, such as automation and data analytics, is enhancing product quality and operational efficiency. This shift toward Industry 4.0 not only reduces production costs but also improves the responsiveness of suppliers to market demands. For B2B buyers, understanding these dynamics is crucial for making informed purchasing decisions and maintaining a competitive edge.

How Are Sustainability and Ethical Sourcing Reshaping the Rubber Sheets Market?

The environmental impact of rubber production has prompted a significant shift towards sustainability in the rubber sheets sector. Buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices and demonstrate a commitment to reducing their carbon footprint. This includes sourcing natural rubber from certified plantations that practice responsible forestry and ensuring that synthetic rubber is produced using sustainable methods.

The importance of ethical supply chains cannot be overstated. Companies that embrace sustainability are not only contributing to environmental conservation but are also gaining a competitive advantage by appealing to eco-conscious consumers and businesses. Certifications such as Forest Stewardship Council (FSC) for natural rubber and ISO standards for manufacturing practices are becoming essential criteria for B2B buyers when evaluating suppliers.

Additionally, the use of recycled and reclaimed rubber is gaining traction as businesses seek to reduce waste and promote circular economy practices. By opting for products made from recycled materials, companies can significantly lower their environmental impact while often enjoying cost savings. As the demand for sustainable products continues to rise, B2B buyers must actively seek out suppliers that align with their environmental values.

What Is the Historical Context of Rubber Sheets in B2B Markets?

The use of rubber sheets dates back to the late 19th century when advancements in vulcanization processes allowed for the production of more durable and versatile rubber products. Initially utilized primarily in industrial applications, the versatility of rubber sheets quickly expanded to various sectors, including construction, automotive, and consumer goods.

Over the decades, the rubber sheets market has evolved significantly, driven by technological advancements and changing consumer demands. The introduction of synthetic rubber in the mid-20th century revolutionized the industry, providing alternatives that offered enhanced performance characteristics. Today, the rubber sheets market continues to grow, with an emphasis on innovation, sustainability, and customization, reflecting the needs of a diverse range of industries.

Understanding this historical context is essential for B2B buyers as it highlights the industry’s resilience and adaptability, providing insights into future trends and opportunities. As the market progresses, buyers can leverage this knowledge to make strategic sourcing decisions that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of what are rubber sheets

-

How do I choose the right type of rubber sheet for my application?

Selecting the appropriate rubber sheet depends on the specific requirements of your application. Consider factors such as the environment (indoor vs. outdoor), exposure to chemicals, temperature ranges, and mechanical stresses. For instance, EPDM rubber is ideal for outdoor use due to its UV and ozone resistance, while Nitrile rubber is better suited for applications involving oils and fuels. Consulting with suppliers about your needs can help you identify the best material type, thickness, and texture for optimal performance. -

What are the different types of rubber sheets available for industrial use?

There are several types of rubber sheets, including natural rubber, synthetic rubber (like Neoprene and EPDM), reclaimed rubber, and recycled rubber. Each type has unique properties tailored to specific applications. For example, Neoprene offers excellent chemical resistance, while recycled rubber is eco-friendly and cost-effective for flooring solutions. Understanding these types can guide you in selecting the right material based on performance criteria and sustainability goals. -

What customization options are available for rubber sheets?

Most suppliers offer customization options to meet specific requirements, including size, thickness, color, and surface texture. Custom-cut rubber sheets can be tailored to fit unique dimensions, reducing waste and enhancing efficiency. Additionally, some manufacturers can produce rubber sheets with specific chemical or thermal properties suited for particular applications. Communicating your precise specifications to the supplier will help ensure the final product meets your needs. -

What is the minimum order quantity (MOQ) for rubber sheets?

The minimum order quantity for rubber sheets can vary significantly between suppliers. Some manufacturers may offer small quantities for prototyping or testing, while others may have higher MOQs due to production costs. It’s essential to discuss your needs with potential suppliers to find a balance between your budget and the quantities required for your project. Additionally, consider the benefits of bulk ordering, such as lower per-unit costs and improved supply chain efficiency. -

What payment terms should I expect when sourcing rubber sheets internationally?

Payment terms can vary by supplier and region. Common terms include upfront payment, partial payments, or payment upon delivery. It’s crucial to clarify these terms before finalizing your order. International buyers may also encounter letters of credit or escrow services for added security. Understanding the payment expectations will help you manage cash flow effectively and minimize risks associated with international transactions. -

How can I ensure quality assurance (QA) for rubber sheets?

To guarantee quality assurance, request product specifications, certifications, and test results from your supplier. Many manufacturers will conduct quality control tests to ensure their rubber sheets meet industry standards. Consider asking for samples before placing a large order to evaluate the material’s performance. Establishing a clear QA process with your supplier can help mitigate risks and ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing rubber sheets?

When importing rubber sheets, consider factors like shipping methods, customs duties, and delivery timelines. Choose a logistics provider experienced in handling rubber products to ensure safe transport and compliance with international regulations. Additionally, understanding the lead times for production and shipping will help you plan your inventory and avoid delays in your supply chain. Communicating with your supplier about logistics can streamline the import process. -

How can I vet suppliers of rubber sheets to ensure reliability?

To vet suppliers, conduct thorough research on their reputation, production capabilities, and customer reviews. Look for certifications that demonstrate compliance with international standards, such as ISO or ASTM. Engaging in direct communication with potential suppliers to discuss your needs and their experience can also provide insight into their reliability. Consider visiting their facilities if possible, or requesting references from other international buyers to assess their credibility.

Top 5 What Are Rubber Sheets Manufacturers & Suppliers List

1. RubberCal – Versatile Rubber Sheets

Domain: rubbercal.com

Registered: 1999 (26 years)

Introduction: Rubber sheets are versatile materials used in various applications, including home renovations and construction safety. They are classified into four main types: recycled rubber, reclaimed rubber, synthetic rubber, and natural rubber. Recycled rubber is made from re-bonded tire crumb, while reclaimed rubber is de-vulcanized and re-vulcanized, resulting in a seamless product. Natural rubber is harv…

2. SealFast – Sheet Rubber Solutions

Domain: sealfast.com

Registered: 1998 (27 years)

Introduction: Sheet rubber is an elastomeric material available in rolls or sheets, used in various applications including work surface protection, cushioning, gasket removal, seal creation, and scraper applications. It is commonly used in automotive and aerospace industries for seals, gaskets, vibration isolation, and soundproofing. Types of sheet rubber include: 1. Neoprene Rubber Sheets – oil-resistant and w…

3. ElastoStar – Rubber Sheets & Specialty Solutions

Domain: elastostar.com

Registered: 2013 (12 years)

Introduction: Rubber Sheets Types: Natural Rubber Sheets, Synthetic Rubber Sheets (EPDM, Neoprene, Silicone, Nitrile), Specialty Rubber Sheets (Viton, Butyl). Uses: Sealing, insulation, vibration damping in automotive, construction, manufacturing, commercial flooring, DIY projects, specialized applications (gaskets, protective pads). Features: Durability, flexibility, resistance to chemicals, UV rays, extreme t…

4. Merriam-Webster – Rubber Sheet Definition

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: This company, Merriam-Webster – Rubber Sheet Definition, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Aquaseal – Rubber Sheeting

Domain: aquasealrubber.co.uk

Registered: 2001 (24 years)

Introduction: Rubber sheeting is a versatile material made from natural or synthetic rubber, offering durability, flexibility, and resistance to environmental factors. It is available in various thicknesses, textures, and colors. Common applications include flooring in industrial and commercial settings, sports facilities, manufacturing gaskets and seals, soundproofing, and vibration reduction. Types of rubber …

Strategic Sourcing Conclusion and Outlook for what are rubber sheets

In the dynamic landscape of industrial materials, rubber sheets stand out for their versatility and wide-ranging applications. From construction to manufacturing, understanding the various types of rubber—natural, synthetic, recycled, and reclaimed—enables B2B buyers to make informed purchasing decisions tailored to their specific needs. Strategic sourcing of rubber sheets not only enhances operational efficiency but also fosters sustainable practices by integrating recycled materials into projects.

For international buyers, particularly in Africa, South America, the Middle East, and Europe, the importance of partnering with reliable suppliers cannot be overstated. Quality rubber sheets can significantly impact product performance and longevity, making it imperative to evaluate suppliers based on their materials, manufacturing processes, and customization capabilities.

As the demand for eco-friendly and durable materials continues to grow, now is the time to explore innovative rubber sheet solutions. By leveraging strategic sourcing, businesses can optimize their supply chains while contributing to environmental sustainability. Start your journey today by connecting with reputable suppliers who can meet your unique requirements and help you stay ahead in a competitive marketplace.

Illustrative image related to what are rubber sheets

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.