Top 5 Weld Wire Suppliers (And How to Choose)

Introduction: Navigating the Global Market for weld wire

The global market for weld wire presents a myriad of challenges for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality weld wire that meets specific industry standards can be daunting, especially with varying regulations and material specifications across countries. This comprehensive guide aims to equip buyers with the essential knowledge needed to navigate these complexities.

Within these pages, you will find detailed insights into the diverse types of weld wire available—including MIG, TIG, and flux-cored options—as well as their specific applications across industries such as construction, automotive, and oil and gas. We delve into critical considerations for supplier vetting to ensure that your selected partner adheres to quality standards and can meet your logistical needs. Additionally, we explore cost factors that influence purchasing decisions, helping you understand market dynamics and enabling you to negotiate effectively.

By leveraging the information provided in this guide, B2B buyers will be empowered to make informed purchasing decisions, enhancing their procurement strategy while minimizing risks associated with sourcing weld wire. This knowledge is vital for companies in regions like Nigeria and Vietnam, where understanding local market conditions and supplier capabilities can significantly impact project success and operational efficiency.

Understanding weld wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MIG Wire | Solid wire fed through a welding gun, typically requires gas. | Automotive, construction, manufacturing | Pros: Versatile, fast, and clean welds. Cons: Requires gas shielding, not ideal for outdoor use. |

| TIG Wire | Filler rod used with a non-consumable tungsten electrode. | Aerospace, precision fabrication, art welding | Pros: High-quality welds, good for thin materials. Cons: Slower process, requires skilled operators. |

| Flux-Cored Wire | Contains flux within the wire, can be used without gas. | Heavy equipment, shipbuilding, construction | Pros: Excellent penetration, good for outdoor use. Cons: Produces more slag, may require post-weld cleanup. |

| Aluminum Wire | Specifically designed for welding aluminum alloys. | Marine, automotive, aerospace | Pros: Lightweight, corrosion-resistant welds. Cons: Requires careful handling, more expensive than steel wires. |

| Stainless Steel Wire | Designed for corrosion resistance and durability. | Food processing, chemical industries, construction | Pros: Strong, durable, and rust-resistant. Cons: Higher cost, requires specific techniques for effective welding. |

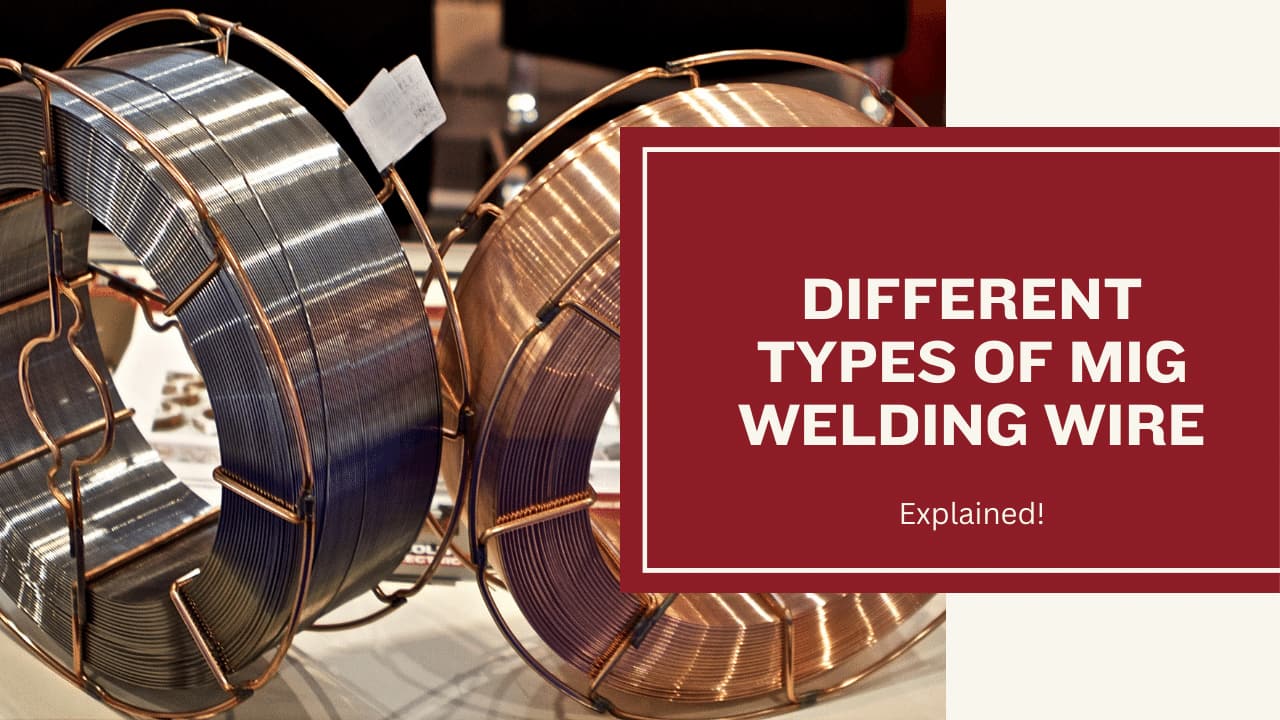

What Are the Key Characteristics of MIG Wire?

MIG (Metal Inert Gas) wire is a solid wire that is continuously fed through a welding gun, making it a popular choice for high-speed production environments. It typically requires a shielding gas to protect the weld pool from contamination. MIG wire is highly versatile, suitable for a wide range of materials, including mild steel and aluminum, making it ideal for industries like automotive and construction. Buyers should consider factors such as wire diameter and gas type to ensure compatibility with their specific welding equipment.

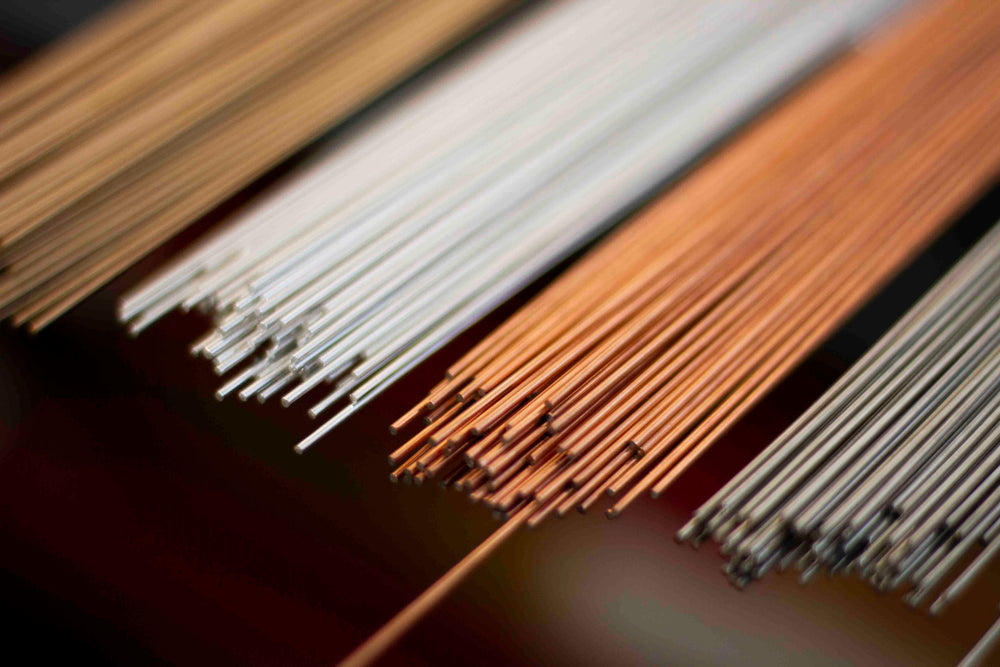

How Does TIG Wire Stand Out in Precision Welding?

TIG (Tungsten Inert Gas) wire is used in conjunction with a non-consumable tungsten electrode, making it ideal for applications that require high precision and clean welds. This type of welding is commonly employed in industries like aerospace and high-end fabrication, where the quality of the weld is paramount. While TIG welding offers superior control, it is a slower process and requires skilled operators. Buyers should evaluate the skill level of their workforce and the specific requirements of their projects when considering TIG wire.

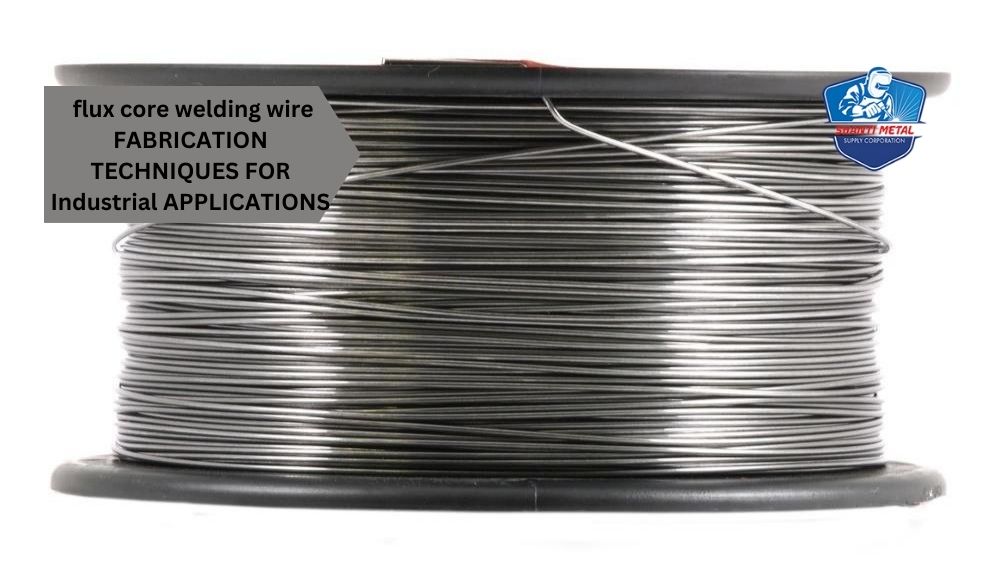

What Are the Advantages of Using Flux-Cored Wire?

Flux-cored wire is unique in that it contains a flux core, allowing it to be used without a separate shielding gas. This feature makes it particularly advantageous for outdoor welding applications, such as in construction and shipbuilding, where wind can disperse shielding gases. Flux-cored wires provide excellent penetration and are suitable for thicker materials. However, they produce more slag, which may necessitate additional cleanup efforts post-weld. Buyers should weigh the benefits of ease of use against the potential for increased post-weld work.

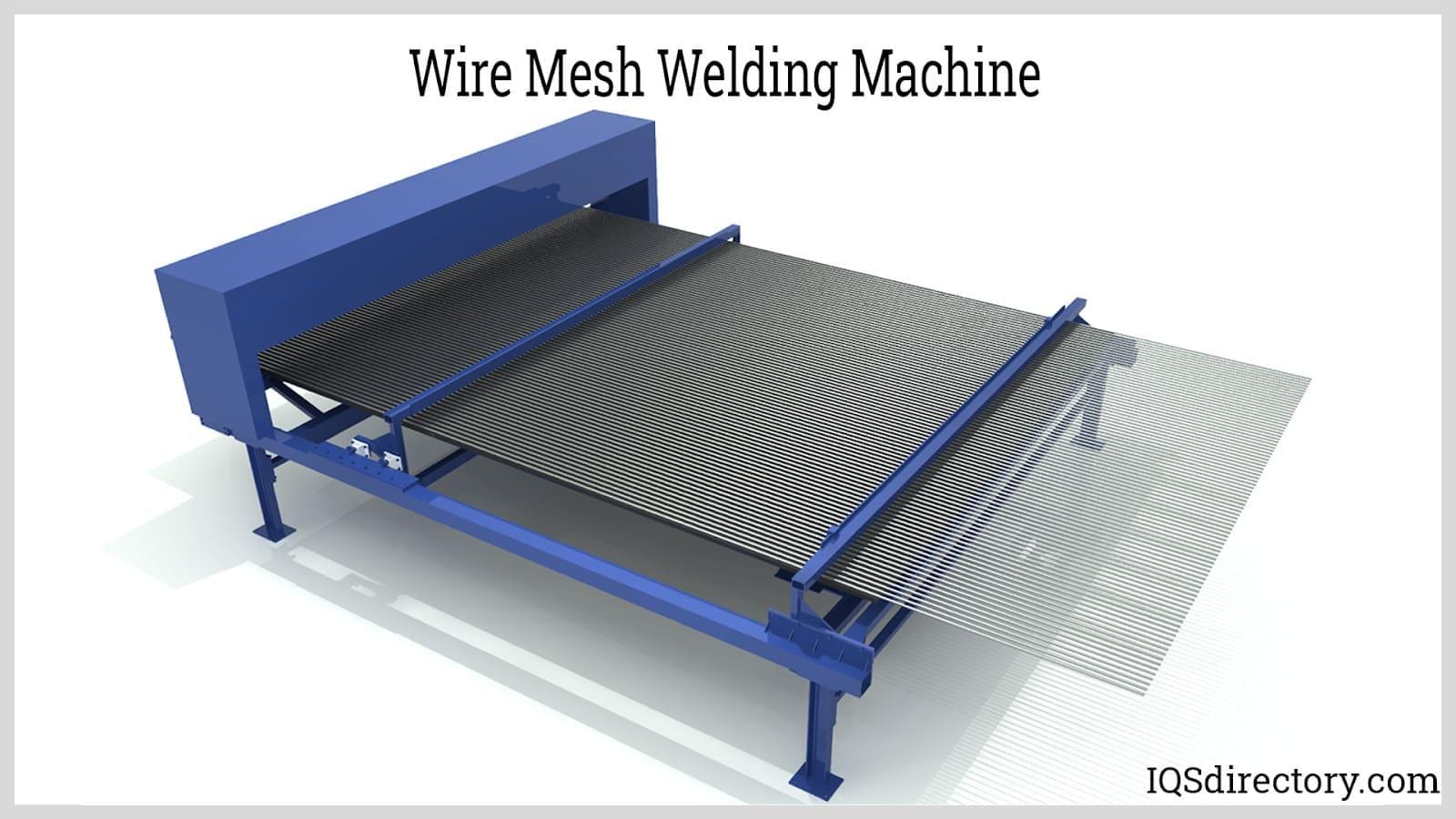

Illustrative image related to weld wire

Why Choose Aluminum Wire for Specialized Applications?

Aluminum wire is specifically formulated for welding aluminum alloys, which are commonly found in marine and automotive applications. This wire is lightweight and offers excellent corrosion resistance, making it suitable for environments where weight savings are critical. However, aluminum welding requires careful handling and specific techniques to avoid issues like porosity. Buyers should consider the specific requirements of their projects and the potential for higher costs compared to traditional steel wires when opting for aluminum wire.

What Makes Stainless Steel Wire Essential in Industry?

Stainless steel wire is designed for applications where corrosion resistance and durability are critical, such as in the food processing and chemical industries. This type of wire allows for strong and resilient welds that can withstand harsh environments. However, stainless steel wire tends to be more expensive than other types, and welding it requires specialized techniques to achieve the best results. Buyers should assess their application needs, budget constraints, and the required welding expertise when considering stainless steel wire for their projects.

Key Industrial Applications of weld wire

| Industry/Sector | Specific Application of weld wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Pipe welding for drilling and refining | Ensures durability and leak-free operation in harsh environments | Compliance with international standards and certifications (e.g., API, ASME) |

| Construction | Structural steel fabrication | Provides strength and stability to buildings and infrastructure | Availability of high-quality materials and timely delivery for project deadlines |

| Automotive | Manufacturing of vehicle components | Enhances safety and performance through reliable joint integrity | Need for specialized alloys and consistent quality control measures |

| Marine | Hull and structural welding | Protects against corrosion and extends the lifespan of vessels | Sourcing from suppliers with marine-grade certifications and corrosion resistance |

| Food & Beverage | Equipment fabrication for processing plants | Ensures hygiene and compliance with safety regulations | Requirement for food-grade materials and certifications (e.g., FDA compliance) |

How is Weld Wire Used in the Oil & Gas Industry?

Weld wire plays a critical role in the oil and gas sector, particularly in the welding of pipes for drilling and refining processes. These applications require weld wires that can withstand extreme pressures and corrosive environments. By using high-quality weld wire, companies can ensure leak-free operations, which is crucial for safety and compliance. Buyers should consider sourcing from suppliers who adhere to international standards like API and ASME to guarantee product reliability.

What is the Importance of Weld Wire in Construction?

In the construction industry, weld wire is essential for structural steel fabrication. It is used to create strong, stable connections between steel components, ensuring the integrity of buildings and infrastructure. The choice of weld wire affects the overall strength and safety of the construction. B2B buyers must prioritize sourcing high-quality materials that meet project specifications and ensure timely delivery to avoid delays in construction timelines.

How Does Weld Wire Enhance Automotive Manufacturing?

In automotive manufacturing, weld wire is utilized for fabricating vehicle components, where joint integrity is paramount. High-performance weld wire enhances the safety and functionality of vehicles by providing robust connections that can endure stress. Buyers in this sector should look for specialized alloys that meet stringent quality control measures to ensure consistent performance across production runs.

Why is Weld Wire Critical in Marine Applications?

Weld wire is vital for welding hulls and structures in the marine industry, where corrosion resistance is a significant concern. Using the right type of weld wire can protect vessels from harsh marine environments, extending their lifespan and reducing maintenance costs. Buyers should focus on sourcing from suppliers that offer marine-grade certifications to ensure compliance with industry standards and regulations.

What Role Does Weld Wire Play in Food & Beverage Equipment Fabrication?

In the food and beverage sector, weld wire is crucial for fabricating equipment that meets hygiene and safety regulations. The use of food-grade weld wire ensures that products do not contaminate food and comply with safety standards. B2B buyers must prioritize sourcing materials that are certified for food contact, such as those compliant with FDA regulations, to maintain product safety and quality in processing plants.

3 Common User Pain Points for ‘weld wire’ & Their Solutions

Scenario 1: Sourcing the Right Weld Wire for Specific Applications

The Problem: B2B buyers often struggle with sourcing the appropriate weld wire for specialized applications, such as those found in the oil and gas industry, aerospace, or food processing. Different materials require specific welding wires that can withstand unique environmental challenges, such as high temperatures, corrosion, or pressure. Buyers may find themselves overwhelmed by the variety of options available, leading to potential project delays or subpar welding results.

The Solution: To effectively source the right weld wire, buyers should start by clearly defining their project requirements, including the base material and environmental conditions. Engaging with manufacturers or suppliers who specialize in the intended application is crucial. For instance, if you are working on a project that involves stainless steel in a high-corrosion environment, look for suppliers with a strong inventory of stainless steel MIG and TIG wires. Additionally, requesting technical data sheets can help verify the specifications and ensure that the chosen weld wire meets industry standards. Building a relationship with a trusted supplier can also provide ongoing support, including technical guidance and timely updates on new products that may better suit evolving project needs.

Scenario 2: Managing Inventory and Reducing Waste

The Problem: Inventory management is a significant pain point for many B2B buyers dealing with weld wire. Maintaining adequate stock levels without over-purchasing can be a delicate balance, particularly when project timelines are unpredictable. Excess inventory can lead to wasted resources, while insufficient stock can halt production and cause delays.

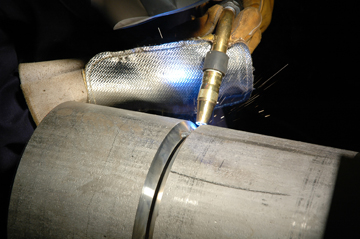

Illustrative image related to weld wire

The Solution: Implementing a just-in-time (JIT) inventory system can help mitigate this issue. By closely monitoring usage patterns and project timelines, businesses can better anticipate their weld wire needs. Establishing a reliable partnership with suppliers who offer flexible order quantities and rapid delivery options can also help. For example, consider suppliers who can provide same-day or next-day delivery services. Additionally, utilizing inventory management software can provide real-time insights into stock levels and help predict future needs based on historical data. This proactive approach not only minimizes waste but also ensures that the necessary materials are always on hand, reducing downtime in production.

Scenario 3: Training Staff on Proper Welding Techniques

The Problem: Many companies face the challenge of ensuring their staff are adequately trained in the correct use of weld wire and welding techniques. Inadequate training can lead to poor welding quality, increased defects, and safety hazards, ultimately impacting project outcomes and increasing costs.

The Solution: Investing in comprehensive training programs for staff is essential. Companies should consider partnering with organizations that specialize in welding education or utilizing in-house experts to conduct workshops. These training sessions should cover not only the technical aspects of welding but also the proper handling and storage of different types of weld wire. Practical, hands-on training can reinforce learning and ensure that employees understand how to select the right weld wire for specific tasks. Additionally, providing access to online resources, such as video tutorials and safety guidelines, can serve as ongoing education for staff. Encouraging a culture of continuous learning and improvement will foster a more skilled workforce capable of producing high-quality welds, thereby enhancing overall operational efficiency.

Strategic Material Selection Guide for weld wire

When selecting weld wire, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. This guide analyzes four common materials used in weld wire: Mild Steel, Stainless Steel, Aluminum, and Nickel Alloys. Each material presents unique characteristics that influence performance, cost, and suitability for specific applications.

Illustrative image related to weld wire

What Are the Key Properties of Mild Steel Weld Wire?

Mild Steel weld wire is known for its excellent weldability and strength. It typically has a tensile strength of around 60,000 psi and is suitable for high-temperature applications. Mild Steel exhibits good ductility and can withstand moderate pressure and stress, making it ideal for structural applications. However, it has limited corrosion resistance, which can be a drawback in harsh environments.

Pros and Cons: The primary advantage of Mild Steel is its cost-effectiveness and availability. It is relatively easy to manufacture, making it a popular choice for general construction and fabrication. However, its susceptibility to rust and corrosion limits its use in applications exposed to moisture or chemicals.

How Does Stainless Steel Weld Wire Perform in Different Environments?

Stainless Steel weld wire is renowned for its corrosion resistance and durability, making it suitable for industries such as food processing, marine applications, and chemical manufacturing. It typically features a tensile strength of 70,000 psi or higher and can withstand extreme temperatures and pressures. The addition of chromium and nickel enhances its resistance to oxidation and pitting.

Pros and Cons: The key advantage of Stainless Steel is its longevity and ability to maintain structural integrity in corrosive environments. However, it is generally more expensive than Mild Steel and can be more challenging to weld due to its thermal conductivity. This complexity may require specialized training or equipment for effective application.

Illustrative image related to weld wire

What Advantages Does Aluminum Weld Wire Offer for Specific Applications?

Aluminum weld wire is lightweight and has excellent corrosion resistance, making it ideal for applications in the aerospace, automotive, and marine industries. It typically has a tensile strength between 40,000 to 80,000 psi, depending on the alloy. Aluminum is also known for its thermal conductivity, which can be beneficial in applications requiring heat dissipation.

Pros and Cons: The primary advantage of Aluminum weld wire is its weight, which contributes to fuel efficiency in transportation applications. However, it is generally more expensive than Mild Steel and can be more difficult to weld due to its oxide layer. This requires pre-weld cleaning and specific welding techniques to ensure a strong joint.

Why Are Nickel Alloys Important in High-Temperature Applications?

Nickel Alloys are critical for applications that involve extreme temperatures and corrosive environments, such as in power plants and chemical processing facilities. They can withstand temperatures above 1,000°F and offer high tensile strength, often exceeding 100,000 psi. Nickel Alloys also exhibit excellent resistance to oxidation and sulfidation.

Pros and Cons: The main advantage of Nickel Alloys is their ability to perform reliably in challenging conditions, making them ideal for high-performance applications. However, they are among the most expensive welding materials and can be complex to work with, requiring specialized equipment and techniques.

Summary Table of Material Selection for Weld Wire

| Material | Typical Use Case for weld wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General construction and fabrication | Cost-effective and widely available | Limited corrosion resistance | Low |

| Stainless Steel | Food processing and marine applications | Excellent corrosion resistance | Higher cost and welding complexity | High |

| Aluminum | Aerospace and automotive industries | Lightweight and corrosion-resistant | More expensive and difficult to weld | Medium |

| Nickel Alloys | Power plants and chemical processing | High performance in extreme conditions | Very high cost and complex welding | High |

This strategic material selection guide provides valuable insights for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Understanding the properties and applications of these materials can help in making informed decisions that align with industry standards and project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for weld wire

What Are the Key Stages in the Manufacturing Process of Weld Wire?

The manufacturing process of weld wire is intricate and involves several critical stages to ensure the final product meets industry standards and customer expectations. Here’s a breakdown of the main stages:

1. Material Preparation: Sourcing and Quality of Raw Materials

The first step in manufacturing weld wire is sourcing high-quality raw materials, which often include various metals such as steel, stainless steel, aluminum, nickel, and copper alloys. Suppliers must ensure that these materials meet specific chemical and mechanical properties required for welding applications.

Once the materials are sourced, they undergo a thorough inspection, often referred to as Incoming Quality Control (IQC). This includes checking for surface defects, chemical composition, and other attributes. The materials are then cut to size and prepared for the next stage.

2. Forming: Shaping the Wire

The forming stage involves several techniques to create the desired wire diameter and shape. This typically includes drawing, where the metal is pulled through a series of dies to reduce its diameter and increase its length.

During this process, temperature control is crucial, as it affects the wire’s mechanical properties. Manufacturers often employ cold drawing for materials that require high strength and precision.

3. Assembly: Coiling and Packaging

After the wire is formed, it is coiled into spools or drums for ease of handling and transportation. This stage may also involve the application of protective coatings or lubricants to prevent oxidation and facilitate smoother feeding during the welding process.

Quality checks are also conducted at this stage to ensure that the wire meets specified tolerances and surface quality.

Illustrative image related to weld wire

4. Finishing: Final Treatments

The finishing stage includes several processes such as annealing, where the wire is heated and then cooled to relieve internal stresses. Depending on the type of weld wire, additional treatments may be applied to enhance properties like corrosion resistance or electrical conductivity.

Final packaging also takes place in this stage, ensuring the product is protected during transportation and storage.

How Is Quality Assurance Integrated Throughout the Weld Wire Manufacturing Process?

Quality assurance (QA) is vital in the manufacturing of weld wire, ensuring that the final product is reliable and meets international standards.

International Standards and Certifications

For B2B buyers, understanding the relevant certifications is crucial. ISO 9001:2015 is one of the most recognized quality management standards, ensuring that manufacturers maintain consistent quality in their processes. Other industry-specific standards may include CE marking for products sold in Europe and API standards for products used in the petroleum industry.

What Are the Key Quality Control Checkpoints?

Quality control is integrated throughout the manufacturing process with several checkpoints, including:

Illustrative image related to weld wire

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducting inspections during the manufacturing process, including monitoring the forming and finishing stages.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications before shipment.

Each of these checkpoints involves specific testing methods, including tensile tests, bend tests, and metallographic examinations to assess the wire’s properties.

What Common Testing Methods Are Employed in Weld Wire Quality Assurance?

Various testing methods are employed to ensure the quality of weld wire, including:

- Tensile Testing: Measures the strength and ductility of the wire.

- Bend Testing: Assesses the wire’s flexibility and ability to withstand deformation.

- Chemical Composition Analysis: Confirms that the material meets specified alloy requirements.

- Surface Quality Inspection: Examines the wire for defects, such as cracks or inconsistencies.

These tests are often conducted in-house, but reputable manufacturers may also engage third-party testing laboratories to provide unbiased results.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some actionable steps:

1. Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

2. Request Quality Assurance Documentation

Buyers should request documentation such as ISO certificates, quality control reports, and test results for products. These documents provide assurance that the supplier adheres to quality standards.

Illustrative image related to weld wire

3. Engage Third-Party Inspectors

Hiring third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality control systems.

4. Understand Regional Regulations

Different regions may have specific regulations concerning welding products. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential legal issues.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers must navigate various nuances when dealing with quality control in weld wire manufacturing:

Illustrative image related to weld wire

- Cultural Differences: Understanding cultural attitudes towards quality and compliance can significantly affect business relationships.

- Logistics and Supply Chain Considerations: Delays in shipping or customs can impact the availability of quality assurance documentation. It is crucial to plan for these factors.

- Market-Specific Requirements: Different markets may have unique requirements for certifications and quality standards. Buyers should ensure that their suppliers can meet these needs.

Conclusion

Manufacturing weld wire involves a complex interplay of processes and stringent quality assurance measures. For B2B buyers, understanding these elements is crucial to ensure they are sourcing high-quality products that meet their specific needs. By leveraging audits, documentation, and third-party inspections, buyers can confidently navigate the international landscape of weld wire procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘weld wire’

Introduction

Sourcing weld wire for industrial applications requires careful consideration to ensure quality, compliance, and suitability for specific projects. This guide provides a step-by-step checklist to aid international B2B buyers in navigating the procurement process effectively. By following these steps, you can streamline your sourcing efforts and secure the best products for your welding needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before starting the sourcing process. Identify the type of weld wire required based on the materials being joined, such as mild steel, stainless steel, or aluminum. Consider factors like wire diameter, melting point, and the specific welding technique (MIG, TIG, or flux-cored) that will be employed.

Illustrative image related to weld wire

- Material Requirements: Determine the alloy compositions and grades necessary for your projects to ensure compatibility and performance.

- Industry Standards: Reference relevant industry standards or certifications that your weld wire must meet, such as AWS (American Welding Society) classifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in weld wire products. Look for companies with a strong reputation and experience in your specific industry segment.

- Supplier Reviews: Check customer testimonials and online reviews to gauge the reliability and service quality of potential suppliers.

- Market Presence: Evaluate their geographical reach, especially if you are sourcing from regions like Africa, South America, or Europe, to ensure they can meet your logistics needs.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that suppliers hold the necessary certifications, such as ISO 9001:2015. Certifications indicate a commitment to quality and adherence to international standards.

- Compliance Verification: Request documentation proving their compliance with industry standards relevant to your application.

- Quality Assurance Processes: Inquire about their quality assurance processes to ensure consistent product quality.

Step 4: Request Product Samples

Obtaining product samples is essential for assessing the quality and performance of the weld wire. This step allows you to test the wire in real-world applications before committing to a bulk purchase.

- Testing Compatibility: Use samples to evaluate how well the wire performs with your equipment and meets project requirements.

- Performance Metrics: Analyze key performance metrics such as weld strength, ease of use, and any specific characteristics relevant to your welding processes.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing structures and payment terms. A competitive price is essential, but it should not compromise quality.

Illustrative image related to weld wire

- Transparent Pricing Models: Look for suppliers that provide clear and transparent pricing without hidden fees.

- Flexible Payment Options: Evaluate payment terms that suit your cash flow needs, such as net terms or installment payments.

Step 6: Consider Logistics and Delivery Options

Assess the logistical capabilities of your chosen suppliers, including shipping times and costs. Reliable delivery is critical to maintaining your production schedule.

- Lead Times: Understand the lead times for orders and whether the supplier can accommodate urgent requests.

- Shipping Partnerships: Inquire about their shipping methods and partnerships to ensure timely delivery to your location.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement with clear terms regarding pricing, delivery schedules, and quality expectations. This document should protect both parties and outline all relevant details.

- Contract Review: Ensure the agreement includes clauses for quality assurance, returns, and dispute resolution.

- Communication Channels: Establish clear communication channels for ongoing support and inquiries during the fulfillment process.

By following this checklist, B2B buyers can make informed decisions when sourcing weld wire, ensuring they meet their project requirements while fostering strong supplier relationships.

Illustrative image related to weld wire

Comprehensive Cost and Pricing Analysis for weld wire Sourcing

What Are the Key Cost Components in Weld Wire Sourcing?

When sourcing weld wire, understanding the cost structure is crucial for B2B buyers. The main components include:

-

Materials: The primary cost driver, materials can vary significantly based on type (e.g., stainless steel, aluminum, nickel alloys) and market fluctuations. Prices can also be influenced by global supply chain dynamics and the availability of raw materials.

-

Labor: Labor costs encompass the wages for skilled workers involved in manufacturing and quality control. In regions with higher labor costs, these expenses can significantly impact the overall pricing of weld wire.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Effective overhead management can help suppliers offer more competitive pricing.

-

Tooling: The costs associated with specialized tools and equipment necessary for producing various types of weld wire. Tooling costs can be amortized over larger production volumes, which is why minimum order quantities (MOQs) play a crucial role in pricing.

-

Quality Control (QC): Ensuring that products meet required specifications incurs costs related to testing and compliance. Certification processes, such as ISO or AWS standards, can add to these expenses but are essential for maintaining product integrity.

-

Logistics: This covers shipping, handling, and storage costs. For international buyers, logistics costs can vary widely based on location, shipping methods, and chosen Incoterms.

-

Margin: Suppliers will typically add a profit margin on top of their costs, which can vary based on market conditions and competition.

How Do Price Influencers Impact Weld Wire Costs?

Several factors can influence the pricing of weld wire beyond the basic cost components:

-

Volume/MOQ: Larger orders often result in lower per-unit prices due to economies of scale. Buyers should negotiate MOQs that align with their needs to achieve better pricing.

-

Specifications and Customization: Custom specifications may lead to higher costs due to unique tooling or material requirements. Buyers should balance the need for customization with budget constraints.

-

Materials: The choice of materials significantly affects pricing. For example, high-performance alloys may command a premium price compared to standard options.

-

Quality and Certifications: Products that meet stringent quality standards or have specific certifications will typically be priced higher. Buyers must assess whether the additional costs align with their project requirements.

-

Supplier Factors: Supplier reputation, reliability, and location can also influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: The terms of shipping and delivery can drastically affect the total cost. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost Insurance and Freight) is vital for accurate cost estimation.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can benefit from several strategies when sourcing weld wire:

-

Effective Negotiation: Building strong relationships with suppliers can lead to better pricing and terms. Consider negotiating on volume, payment terms, and delivery schedules.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, downtime, and quality issues. Opt for suppliers who provide value through reliable products and services.

-

Understand Pricing Nuances: Different regions may have unique pricing structures influenced by local regulations, tariffs, and market conditions. Conduct thorough research to understand these factors before finalizing purchases.

-

Request Multiple Quotes: Engaging with several suppliers can provide insights into market pricing and help buyers identify the best deals.

-

Leverage Local Expertise: Partnering with local agents or consultants familiar with the welding industry in target regions can provide valuable insights and facilitate smoother transactions.

Disclaimer on Indicative Prices

Prices for weld wire can fluctuate based on various market conditions and specific buyer requirements. It’s advisable for buyers to obtain updated quotes and conduct market comparisons to ensure they are getting the best possible deal.

Illustrative image related to weld wire

Alternatives Analysis: Comparing weld wire With Other Solutions

Exploring Alternatives to Weld Wire: A Comparative Analysis

In the competitive landscape of industrial applications, choosing the right welding solution is crucial for operational efficiency and cost-effectiveness. While weld wire is a popular choice for various welding applications, it’s essential to evaluate other alternatives that may better suit specific project requirements. This analysis compares weld wire with two viable alternatives: Laser Welding and Plasma Arc Welding.

Comparison Table

| Comparison Aspect | Weld Wire | Laser Welding | Plasma Arc Welding |

|---|---|---|---|

| Performance | High-quality welds, versatile for various materials | Exceptional precision and speed, minimal heat-affected zone | Good penetration and control, suitable for thick materials |

| Cost | Generally lower initial costs, variable based on material type | Higher initial setup costs, lower operational costs for large volumes | Moderate costs, depends on equipment and consumables |

| Ease of Implementation | Relatively simple setup and operation, requires skilled labor | Requires specialized training and equipment | More complex than weld wire, requires skilled operators |

| Maintenance | Low maintenance, regular checks needed for wire feed | Moderate maintenance, focus on optics and laser source | Higher maintenance due to consumable parts and equipment |

| Best Use Case | General fabrication, automotive, and construction | High-precision applications, electronics, and aerospace | Heavy-duty welding, shipbuilding, and pipe fabrication |

Detailed Breakdown of Alternatives

Laser Welding

Laser welding utilizes focused laser beams to join materials, providing high precision and minimal thermal distortion. Its advantages include fast processing speeds and the ability to weld complex geometries without the need for additional filler materials. However, the initial investment in laser equipment can be significant, making it less accessible for smaller operations. Furthermore, the need for skilled technicians to operate laser systems can limit its practicality in some environments. Laser welding is best suited for industries requiring high-quality, intricate welds, such as aerospace and electronics.

Plasma Arc Welding

Plasma arc welding employs a plasma torch to produce a high-temperature arc that melts the base material and filler. This method is known for its deep penetration and ability to weld thicker materials. It is particularly effective in heavy industries like shipbuilding and oil and gas. While plasma arc welding offers robust performance, it also comes with moderate initial costs and requires a higher level of operator skill compared to traditional weld wire methods. Additionally, the equipment demands more maintenance due to its consumable components, which can impact long-term operational efficiency.

How to Choose the Right Welding Solution for Your Needs

When selecting a welding solution, B2B buyers should consider their specific project requirements, including material types, thickness, and desired weld quality. Weld wire remains a versatile and cost-effective option for many applications, especially in general fabrication and construction. However, for projects that demand precision and minimal distortion, laser welding may be the better choice, despite its higher initial costs. Conversely, for heavy-duty applications requiring deep penetration, plasma arc welding could provide the necessary performance.

Illustrative image related to weld wire

Ultimately, the decision should weigh the balance between initial investment, operational costs, and the skill level available within the workforce. Each alternative has its strengths and weaknesses, and understanding these can lead to more informed purchasing decisions that align with business goals.

Essential Technical Properties and Trade Terminology for weld wire

What Are the Key Technical Properties of Weld Wire That B2B Buyers Should Know?

Understanding the essential technical properties of weld wire is critical for B2B buyers to ensure they select the right product for their specific applications. Here are some key specifications:

-

Material Grade: The material grade of weld wire indicates its chemical composition and mechanical properties. Common grades include ER70S-6 for mild steel and ER4047 for aluminum. Selecting the correct material grade is vital as it affects weld strength, corrosion resistance, and compatibility with base materials.

-

Wire Diameter: The diameter of the weld wire influences the heat input and deposition rate during the welding process. For instance, a .030 inch diameter wire is often used for thin materials, while larger diameters, like .045 inches, are suited for thicker materials. Understanding the appropriate diameter helps ensure optimal performance and weld quality.

-

Tensile Strength: This property measures the maximum amount of tensile (pulling) stress a material can withstand before failure. Weld wires are often categorized based on their tensile strength, which is crucial for applications that demand high durability, such as in construction or heavy machinery manufacturing.

-

Welding Process Compatibility: Different types of weld wire are designed for specific welding processes such as MIG, TIG, or flux-cored welding. Knowing the compatibility helps buyers choose the right wire that matches their equipment and operational needs, ensuring effective and efficient welding.

-

Coating Type: Some weld wires come with coatings that enhance performance by improving arc stability and reducing spatter. For example, flux-cored wires have a core material that produces a shielding gas during the welding process. Understanding coating types helps buyers achieve better results based on their welding environment and requirements.

-

Melting Point: The melting point of weld wire determines the appropriate temperature settings during the welding process. Different materials have varying melting points, and knowing this helps in selecting the right wire for specific applications to avoid overheating or underheating.

What Are Common Trade Terms in the Weld Wire Industry?

Familiarity with trade terminology can help B2B buyers navigate purchasing decisions more effectively. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking for high-quality and compatible weld wire for their specific machinery.

-

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory and budget constraints effectively, particularly in regions with varying demand, such as Africa and South America.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This process is essential for comparing different suppliers and ensuring competitive pricing, especially for bulk purchases.

-

Incoterms: Short for International Commercial Terms, these are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance, and risk management during the purchase of weld wire.

-

Welding Classification: This refers to the standardized categorization of weld wires based on their intended use and performance characteristics. Understanding these classifications helps buyers select the right type of wire for their specific welding applications.

-

Flux-Cored Wire: A type of welding wire that has a core filled with flux material. This type of wire is essential for certain welding applications, providing benefits like better penetration and reduced spatter. Knowledge of this term aids buyers in selecting the appropriate wire for challenging environments.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their welding projects.

Illustrative image related to weld wire

Navigating Market Dynamics and Sourcing Trends in the weld wire Sector

What Are the Key Market Dynamics and Trends Influencing the Weld Wire Sector?

The global weld wire market is being shaped by several critical drivers, including increasing industrialization, the growth of the construction and manufacturing sectors, and the rising demand for high-quality welding solutions. Notably, regions such as Africa, South America, the Middle East, and Europe are experiencing a surge in infrastructure projects, which directly boosts the demand for various types of weld wire, including MIG, TIG, and flux-cored options. Emerging technologies like automation and advanced welding techniques are also influencing sourcing trends, as businesses seek to enhance efficiency and reduce labor costs.

B2B buyers are increasingly leveraging digital platforms to streamline their procurement processes, allowing for quicker access to a wider range of suppliers and products. The rise of e-commerce in industrial sectors enables international buyers to compare prices, quality, and delivery times, facilitating informed decision-making. Additionally, the advent of Industry 4.0 is leading to increased integration of IoT and AI technologies in welding operations, which optimize inventory management and predict maintenance needs, further influencing sourcing strategies.

In terms of market dynamics, fluctuating raw material prices and supply chain disruptions remain significant challenges for international buyers. Factors such as geopolitical tensions, environmental regulations, and the ongoing impacts of the COVID-19 pandemic have created a complex landscape. Consequently, buyers must remain agile, adapting their sourcing strategies to navigate these challenges while ensuring they can meet their operational demands.

How Is Sustainability Reshaping Sourcing Practices in the Weld Wire Industry?

Sustainability and ethical sourcing are becoming increasingly important considerations for B2B buyers in the weld wire sector. Environmental impacts associated with welding processes, including emissions and waste production, are prompting companies to seek out ‘green’ certifications and materials. Many manufacturers are now focusing on producing weld wires from recycled materials or implementing environmentally friendly production methods, aligning with global sustainability goals.

Furthermore, buyers are encouraged to prioritize suppliers who demonstrate a commitment to ethical practices throughout their supply chains. This includes transparency in sourcing raw materials and adherence to labor standards, which is essential for maintaining a responsible brand image. In regions such as Africa and South America, where regulatory environments may vary, ethical sourcing can also serve as a competitive advantage, appealing to customers who value corporate social responsibility.

As sustainability becomes a non-negotiable aspect of procurement, weld wire suppliers who can offer eco-friendly products and demonstrate sustainable practices are likely to gain a competitive edge. This trend not only supports environmental initiatives but can also lead to long-term cost savings through improved efficiency and waste reduction.

What Is the Historical Context of the Weld Wire Sector That Buyers Should Know?

The evolution of the weld wire sector dates back to the early 20th century when the first electric arc welding techniques were developed. This innovation laid the groundwork for the production of specialized welding wires, which have since evolved to meet the demands of various industrial applications. Over the decades, advancements in metallurgy and welding technology have led to the development of diverse weld wire types, including stainless steel, aluminum, and nickel alloys, each catering to specific needs within industries like construction, automotive, and aerospace.

The modern weld wire market has transformed significantly with the globalization of supply chains, allowing for broader access to high-quality products from various regions. As buyers today navigate an increasingly complex landscape, understanding the historical context and technological advancements that have shaped the industry can provide valuable insights into current sourcing trends and future opportunities. By recognizing the foundational changes in the market, buyers can make more informed decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of weld wire

-

How do I solve issues with weld wire quality?

To address quality issues with weld wire, first, ensure you are sourcing from ISO-certified suppliers, as this indicates adherence to international quality standards. Request Material Safety Data Sheets (MSDS) and Technical Data Sheets (TDS) for the specific wire types you are purchasing. Conduct periodic quality inspections during production and upon receipt to verify compliance with your specifications. Engaging in regular communication with your supplier about quality expectations and feedback can also help to address any concerns proactively. -

What is the best type of weld wire for stainless steel applications?

For stainless steel applications, the best choice is typically ER308L MIG wire or E308L TIG rods, as they provide excellent corrosion resistance and strength. For specific projects, consider the grade of stainless steel you are working with, as different grades may require tailored wire compositions. It’s essential to consult with your supplier about the appropriate wire for your specific application, taking into account factors such as the environment and intended use of the welded product. -

How can I vet a supplier for weld wire effectively?

When vetting a supplier for weld wire, consider their industry certifications, such as ISO 9001:2015, which indicates a commitment to quality management. Review their product range to ensure they can meet your specific needs and check their references and customer reviews for credibility. Request samples of their weld wire to evaluate quality firsthand. Additionally, inquire about their logistics capabilities, lead times, and customer service support to ensure they align with your operational needs. -

What are the common minimum order quantities (MOQs) for weld wire?

Minimum order quantities for weld wire can vary significantly depending on the supplier and the type of wire. Generally, MOQs can range from as low as 100 kg to several tons for bulk orders. It is advisable to discuss your specific needs with potential suppliers, as some may offer flexibility on MOQs for first-time orders or ongoing partnerships. Understanding your consumption rate can also help in negotiating favorable terms. -

What payment terms should I expect when sourcing weld wire internationally?

Payment terms for international weld wire purchases can vary widely. Common options include full payment upfront, partial payments with a deposit, or net 30/60/90 days after delivery. It’s crucial to establish clear payment terms before finalizing any contracts. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always ensure that payment terms are documented in the purchase agreement to avoid misunderstandings. -

How can I customize weld wire for specific applications?

Customization of weld wire is possible and typically involves adjusting the chemical composition, diameter, or spool size to meet specific application requirements. To initiate customization, discuss your needs with the supplier’s technical team, providing detailed specifications and intended applications. Suppliers may also offer formulation adjustments for specific alloys or coatings. Be prepared to provide feedback on samples and conduct trials to ensure the customized wire meets your expectations. -

What logistics considerations should I keep in mind when importing weld wire?

When importing weld wire, consider the logistics of shipping, including freight costs, customs duties, and transit times. Ensure your supplier provides clear information on shipping methods and expected delivery timelines. Familiarize yourself with the import regulations in your country, including any certifications or documentation required. Establishing a reliable logistics partner can also help streamline the process and ensure timely delivery, minimizing disruptions to your operations. -

How do I ensure compliance with international trade regulations when sourcing weld wire?

To ensure compliance with international trade regulations, first, familiarize yourself with the import/export laws in your region and the supplier’s country. This includes understanding tariffs, quotas, and any relevant trade agreements. Request necessary documentation from your supplier, such as certificates of origin and compliance with safety standards. Regularly consult with a customs broker or legal expert to navigate complex regulations and avoid costly delays or penalties.

Top 5 Weld Wire Manufacturers & Suppliers List

1. Washington Alloy & Forney – Welding Wire

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: Welding Wire | Flux Core & Mig Wire

– Mig Wire diameters: .023, .030 & .035

– Available spool sizes: 2#, 11#, and 33#

– Brands: Washington Alloy and Forney

– Flux Core wire diameters: .023, .030 & .035

– Available spool sizes: 2# & 11#

2. Welding Mart – Flux Core & MIG Wire Solutions

Domain: weldingmart.com

Registered: 1999 (26 years)

Introduction: Flux Core Welding Wire, MIG Wire, and Aluminum Options available for strong, reliable welds. Suitable for steel, stainless, and aluminum projects in fabrication, repair, and construction. Various options categorized by diameter, package size, and AWS classification.

3. Cyberweld – Welding Alloys

Domain: store.cyberweld.com

Registered: 1999 (26 years)

Introduction: This company, Cyberweld – Welding Alloys, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Airgas – Welding MIG Wire

Domain: airgas.com

Registered: 1995 (30 years)

Introduction: This company, Airgas – Welding MIG Wire, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Forney – MIG Welding Wire

Domain: forneyind.com

Registered: 1997 (28 years)

Introduction: This company, Forney – MIG Welding Wire, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for weld wire

How Can Strategic Sourcing Enhance Your Weld Wire Procurement?

In today’s competitive market, strategic sourcing is essential for B2B buyers seeking high-quality weld wire. By understanding the diverse offerings—from stainless steel to aluminum and nickel alloys—buyers can align their procurement strategies with industry demands and specific project requirements. This approach not only ensures access to superior products but also optimizes cost efficiency, reducing overall expenditure.

The value of strategic sourcing extends beyond immediate savings; it fosters long-term partnerships with suppliers who can provide technical support and adaptability to changing market conditions. For buyers in Africa, South America, the Middle East, and Europe, leveraging local and international suppliers can enhance supply chain resilience, particularly in the face of global disruptions.

Looking ahead, the welding industry is poised for growth, driven by advancements in technology and increasing infrastructure projects worldwide. B2B buyers are encouraged to actively engage with suppliers, explore innovative materials, and stay informed about market trends. By prioritizing strategic sourcing, you position your business for success and ensure that your projects are supported by the best welding solutions available. Take the next step—connect with suppliers today to secure your welding needs for tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.