Top 5 Types Of Spring Hinges Suppliers (And How to Choose)

Introduction: Navigating the Global Market for types of spring hinges

In today’s competitive global market, sourcing the right types of spring hinges can be a significant challenge for B2B buyers, especially when considering factors like quality, cost, and application suitability. Spring hinges, known for their ability to automatically close doors and secure access points, are essential components in various industries, from construction to manufacturing and even furniture design. This comprehensive guide will navigate you through the diverse types of spring hinges available, their specific applications, and the nuances of supplier vetting.

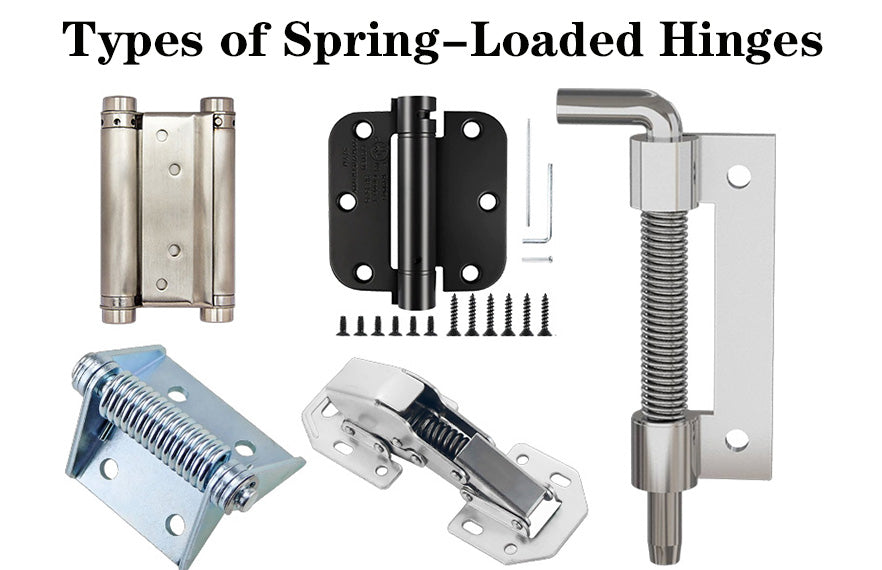

Understanding the different varieties—such as single-acting, double-acting, barrel, butt, and surface-mounted hinges—will empower you to make informed decisions that meet your operational needs. Additionally, we will delve into critical aspects such as cost considerations, international shipping logistics, and compliance with regional standards, particularly for buyers in Africa, South America, the Middle East, and Europe, including markets like Vietnam and Saudi Arabia.

By providing detailed insights and actionable advice, this guide aims to equip international B2B buyers with the knowledge necessary to streamline their sourcing process, ensuring that they select the most appropriate spring hinges for their projects while maximizing value and efficiency.

Understanding types of spring hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Barrel Spring Hinge | Light-duty design with two barrel pins for pivoting motion | Cabinets, chests, light doors | Pros: Compact, easy to install; Cons: Limited load capacity. |

| Butt Spring Hinge | Two leaf plates mounted on the edge of the door | Entry doors, passage doors, cabinets | Pros: Strong, versatile; Cons: Requires precise installation. |

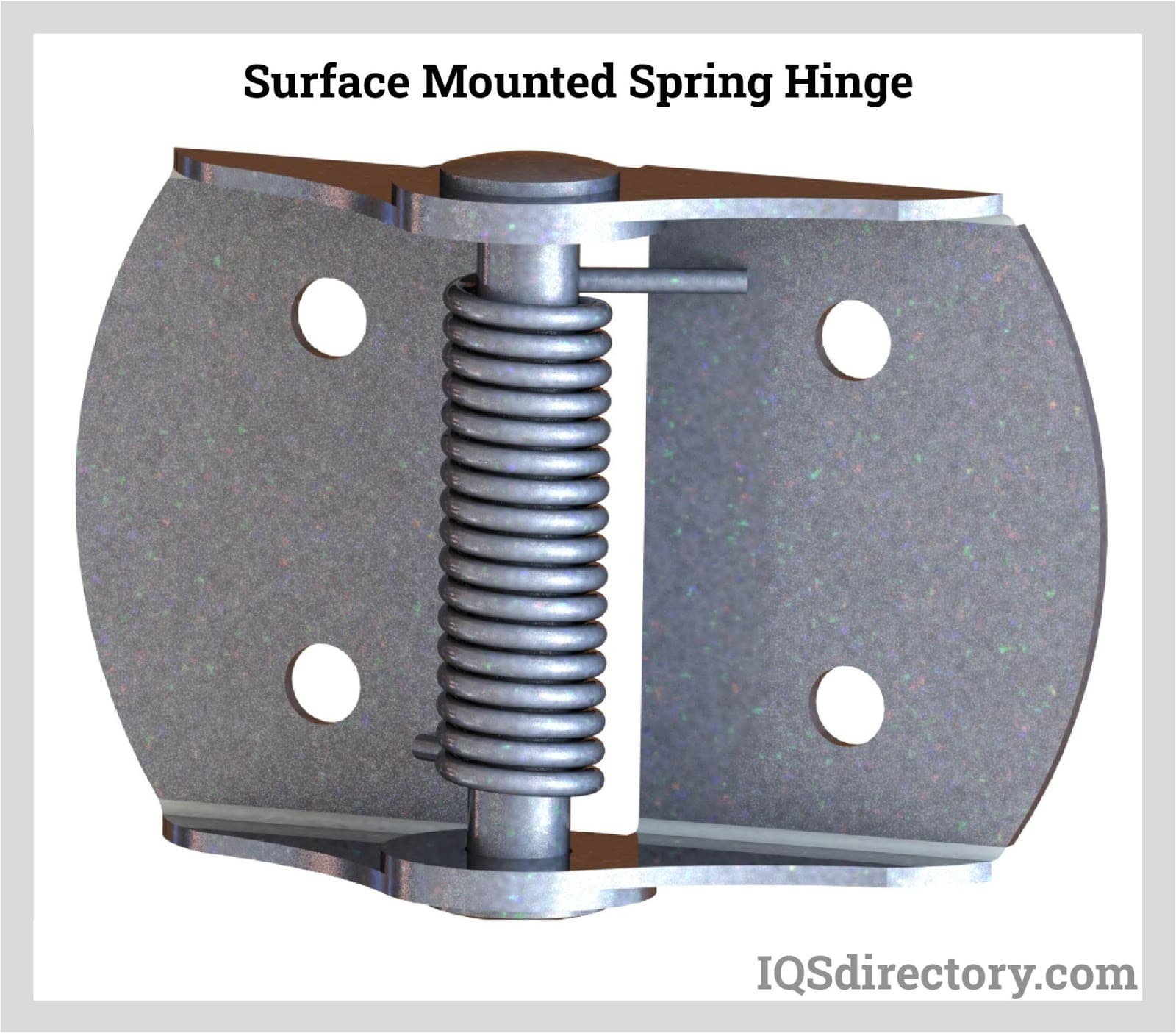

| Surface-Mount Spring Hinge | Mounted externally without mortising | Industrial applications, access panels | Pros: Easy installation; Cons: Less aesthetic appeal. |

| Double-Action Spring Hinge | Allows doors to swing both ways | Cafés, restaurants, high-traffic areas | Pros: Efficient for high-traffic; Cons: More complex mechanism. |

| Custom Spring Hinge | Tailored specifications for specific needs | Specialized industrial applications | Pros: Perfect fit for unique applications; Cons: Higher cost and lead time. |

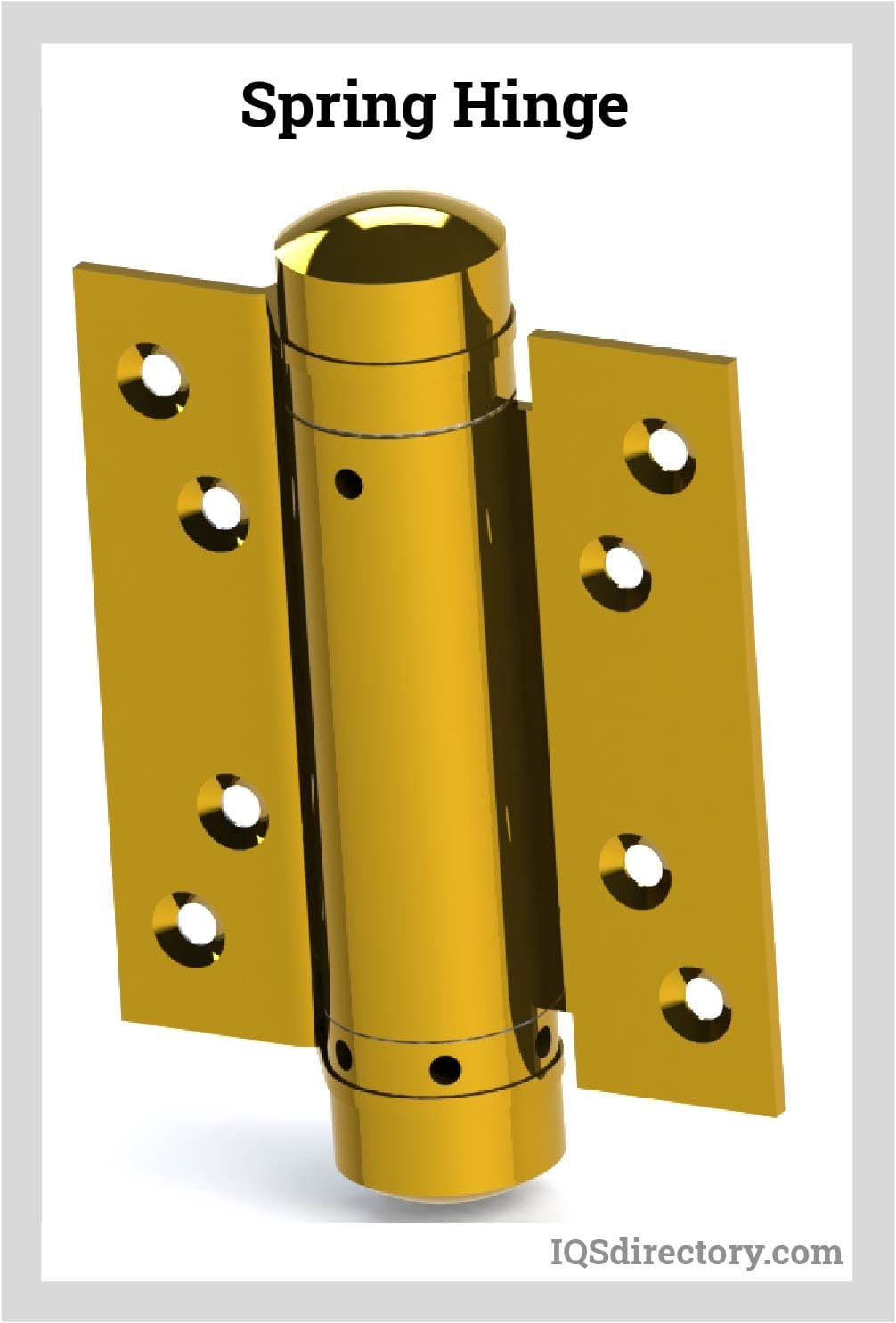

What Are the Characteristics of Barrel Spring Hinges?

Barrel spring hinges are designed primarily for light-duty applications, making them ideal for cabinets and chests. They feature a simple pivoting mechanism with two barrel pins that recess into the door and frame. This type of hinge is easy to install and adjust, providing a reliable solution for lightweight doors. B2B buyers should consider the weight limits and the intended use of the hinge to ensure optimal performance.

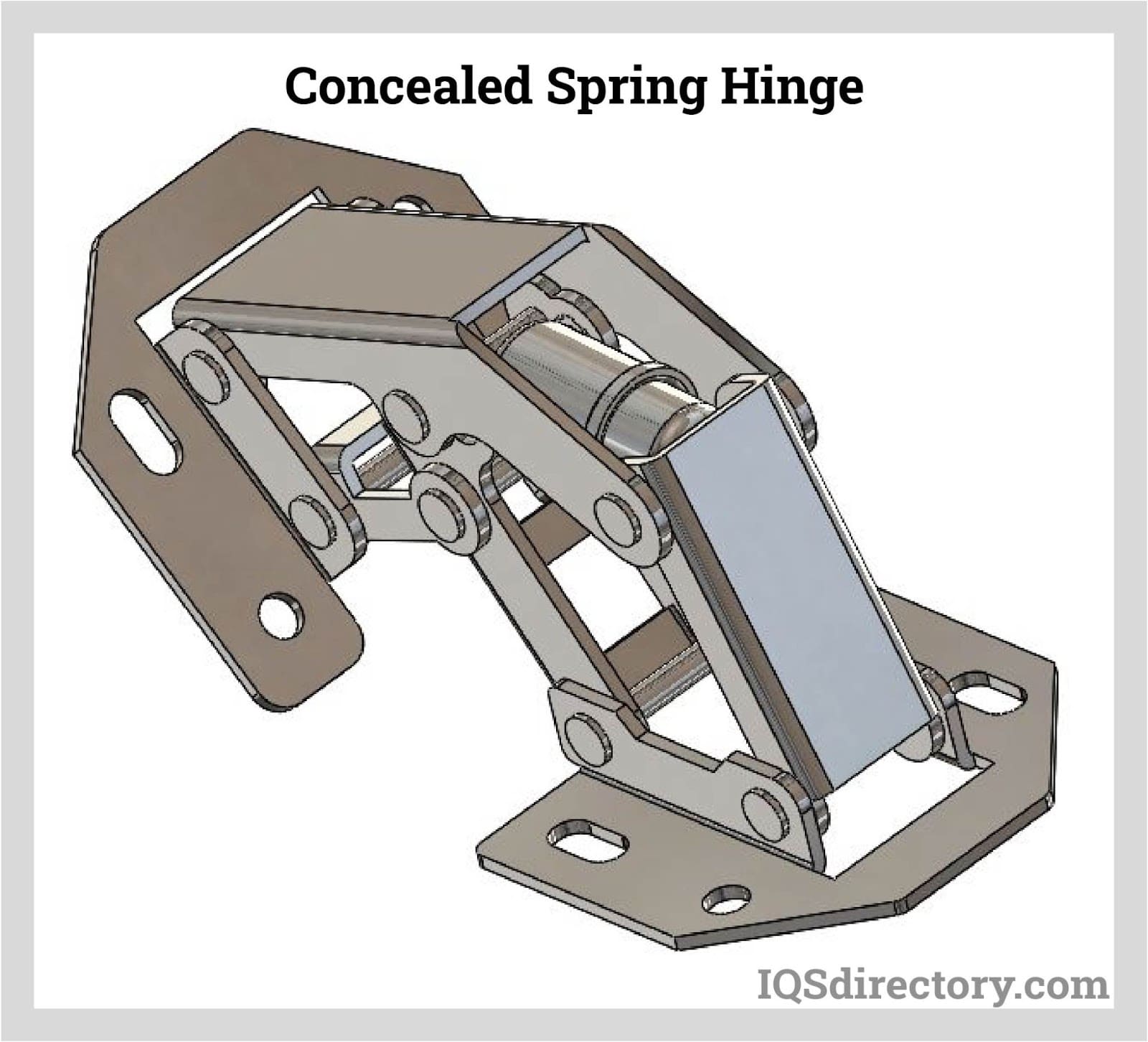

Illustrative image related to types of spring hinges

Why Choose Butt Spring Hinges for Your Business?

Butt spring hinges are among the most commonly used hinges, consisting of two leaf plates that are affixed to the edge of the door and the door frame. This design offers a robust solution suitable for entry and passage doors, as well as cabinets. Their versatility allows them to be used in various settings, from residential to commercial. Buyers should pay attention to the installation requirements and ensure compatibility with the door thickness for effective use.

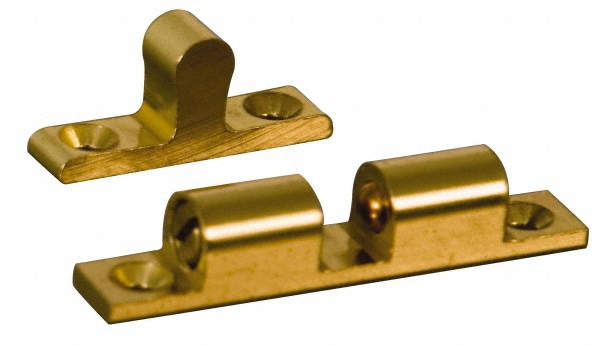

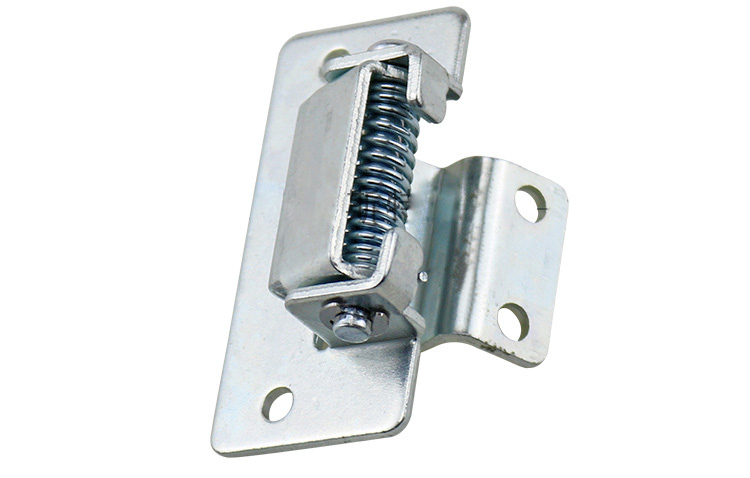

How Do Surface-Mount Spring Hinges Benefit Industrial Applications?

Surface-mount spring hinges are advantageous for applications where mortising is impractical. They are attached directly to the surface of the door and frame, making installation straightforward. This type of hinge is frequently used in industrial settings and access panels, where ease of access is crucial. B2B buyers should consider the aesthetic implications and the hinge’s visibility, as it may not blend seamlessly with all design styles.

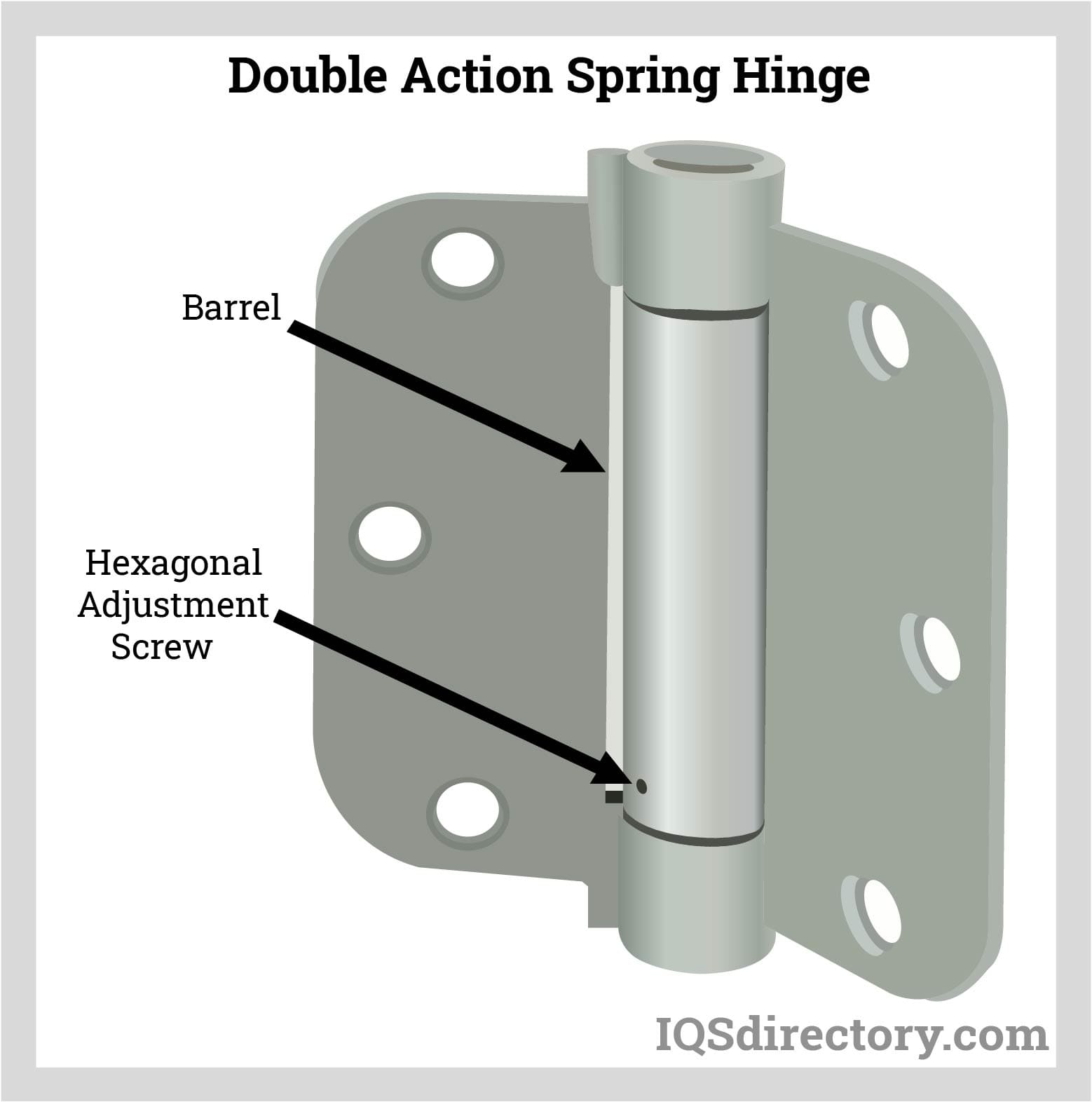

What Makes Double-Action Spring Hinges Ideal for High-Traffic Areas?

Double-action spring hinges allow doors to swing open in both directions, automatically returning to the closed position. This feature is particularly beneficial in high-traffic environments such as cafés and restaurants, where quick access is essential. While they enhance efficiency, the complexity of their mechanism may require more careful installation and maintenance. Buyers should weigh the benefits of convenience against potential installation challenges.

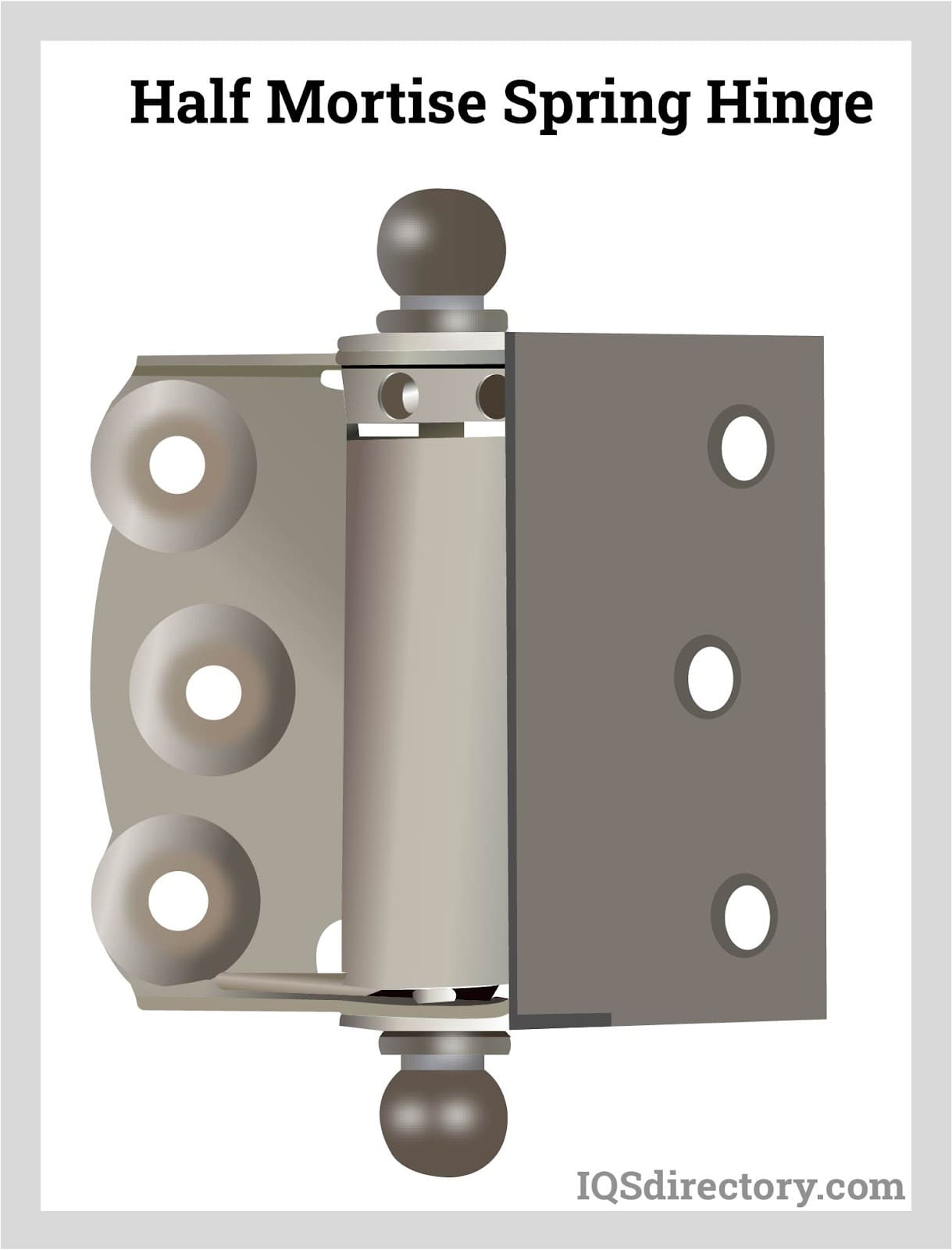

Illustrative image related to types of spring hinges

When Should You Consider Custom Spring Hinges?

Custom spring hinges are tailored to meet specific requirements, making them suitable for unique industrial applications. They can be designed in various sizes and spring tensions, accommodating specialized needs. While these hinges offer a perfect fit for unique applications, they often come with a higher cost and longer lead times. B2B buyers should assess the necessity of customization against their project timelines and budget constraints.

Key Industrial Applications of types of spring hinges

| Industry/Sector | Specific Application of types of spring hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Heavy-duty doors in factories | Enhanced safety and durability, reducing maintenance costs | Material quality, load capacity, and compliance with safety standards |

| Construction | Automatic closing doors in commercial buildings | Improved energy efficiency and security | Customization options, weather resistance, and aesthetic finishes |

| Automotive | Access panels in vehicles | Streamlined assembly and maintenance processes | Compatibility with vehicle specifications and weight considerations |

| Furniture | Self-closing cabinet doors | Increased user convenience and improved aesthetics | Design flexibility, finish options, and size compatibility |

| Food Service | Doors for walk-in refrigerators | Ensured temperature control and food safety | Hygiene compliance, corrosion resistance, and ease of installation |

How Are Spring Hinges Used in Manufacturing and What Problems Do They Solve?

In the manufacturing sector, heavy-duty spring hinges are commonly employed on factory doors to facilitate safe and efficient operations. These hinges automatically return doors to a closed position, enhancing workplace safety by preventing accidental injuries. For international buyers, sourcing hinges that meet specific load capacities and safety standards is crucial. Additionally, the choice of materials, such as stainless steel for durability, can significantly reduce maintenance costs and extend the product’s lifespan.

What Are the Benefits of Spring Hinges in Construction Applications?

In construction, spring hinges are often used in automatic closing doors within commercial buildings. This application promotes energy efficiency by ensuring doors close promptly, maintaining climate control and security. Buyers should consider customization options to meet architectural requirements and ensure that the selected hinges can withstand varying weather conditions. Aesthetic finishes also play a role in enhancing the overall design of the building, making sourcing a key factor for contractors.

How Do Spring Hinges Enhance Automotive Applications?

The automotive industry utilizes spring hinges for access panels in vehicles, allowing for streamlined assembly and easier maintenance access. These hinges contribute to the overall efficiency of vehicle production by simplifying the installation process. Buyers in this sector must focus on compatibility with vehicle specifications and consider weight limitations to ensure optimal performance. Sourcing hinges that are lightweight yet robust is essential for maintaining vehicle integrity and safety.

Why Are Spring Hinges Valuable in Furniture Design?

In the furniture industry, spring hinges are utilized for self-closing cabinet doors, enhancing user convenience and improving the aesthetic appeal of furniture pieces. These hinges help maintain a tidy appearance while preventing slamming, which can damage both the furniture and its contents. Buyers should look for design flexibility, as various styles and finishes can be tailored to specific furniture designs. Size compatibility is also a vital consideration, ensuring that the hinges fit seamlessly into the intended applications.

How Do Spring Hinges Contribute to Food Service Operations?

In the food service industry, spring hinges are essential for doors on walk-in refrigerators, ensuring they close automatically to maintain temperature control and food safety. This application helps prevent energy loss and protects food products from spoilage. When sourcing hinges for this sector, buyers must prioritize hygiene compliance and corrosion resistance to withstand the demanding environment of food service. Additionally, ease of installation can facilitate quicker setups in commercial kitchens, making sourcing efficiency a priority.

Illustrative image related to types of spring hinges

3 Common User Pain Points for ‘types of spring hinges’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Spring Hinge for Specific Applications

The Problem: B2B buyers often struggle with choosing the appropriate type of spring hinge for their specific applications, whether for industrial doors, cabinets, or furniture. The vast variety of spring hinges—such as barrel, butt, and surface-mounted—can lead to confusion. Additionally, buyers may not fully understand the implications of hinge size, material, and action type (single-acting vs. double-acting) on performance. This lack of clarity can result in costly mistakes, such as purchasing hinges that don’t meet operational requirements or that are incompatible with existing hardware.

The Solution: To effectively select the right spring hinge, buyers should conduct a thorough assessment of their application needs. Start by evaluating the door or cabinet’s weight, frequency of use, and environment (e.g., humidity levels, exposure to chemicals). Once these factors are established, consult with suppliers who can provide expert guidance on hinge specifications. A hands-on approach is also beneficial; ordering samples for testing can help ensure that the chosen hinge meets performance expectations. Additionally, consider hinges with adjustable tension features, allowing for customization based on door weight and closing speed, which adds versatility to your hardware options.

Scenario 2: Issues with Installation and Adjustment of Spring Hinges

The Problem: Many B2B buyers encounter difficulties during the installation and adjustment of spring hinges. Improper installation can lead to malfunctioning doors that don’t close properly or that require excessive force to operate. This not only affects user experience but can also lead to increased wear and tear on the hinges and doors. Additionally, adjusting the tension of spring hinges can be a complex process, especially for those who lack technical expertise.

The Solution: To mitigate installation challenges, buyers should invest in comprehensive installation guides or seek professional installation services when necessary. Many manufacturers offer detailed instructions, including diagrams and recommended tools, which should be closely followed. For tension adjustments, look for hinges that come with easy-to-use tensioning mechanisms. Some hinges feature visual indicators for correct tension settings. Buyers should also consider training sessions for their maintenance staff, ensuring they are equipped with the skills needed to perform adjustments and maintenance effectively.

Illustrative image related to types of spring hinges

Scenario 3: Poor Performance and Longevity of Spring Hinges

The Problem: A common concern among B2B buyers is the premature failure of spring hinges, which can lead to frequent replacements and maintenance downtime. Factors such as poor material quality, inadequate lubrication, and exposure to harsh environmental conditions contribute to this issue. Buyers may find themselves repeatedly sourcing replacements, which not only increases operational costs but also disrupts workflow.

The Solution: To enhance the longevity and performance of spring hinges, prioritize sourcing high-quality products from reputable manufacturers. Look for hinges made from durable materials such as stainless steel or brass, which offer better resistance to corrosion and wear. Additionally, implementing a regular maintenance schedule that includes cleaning and lubricating the hinges can significantly extend their lifespan. Consider using hinges with built-in self-lubricating features to minimize maintenance requirements. Finally, educate your purchasing team on the importance of quality over cost—investing in reliable hinges upfront can save money and prevent disruptions in the long run.

Strategic Material Selection Guide for types of spring hinges

What Are the Key Properties of Common Materials Used in Spring Hinges?

When selecting spring hinges for various applications, the choice of material is paramount. Different materials offer distinct properties that can significantly influence performance, durability, and suitability for specific environments. Below, we analyze four common materials used in spring hinges: stainless steel, brass, zinc-plated steel, and aluminum.

How Does Stainless Steel Perform in Spring Hinge Applications?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it ideal for high-demand environments. Key properties include a high tensile strength and the ability to withstand extreme temperatures, which is essential for applications in both hot and cold climates.

Pros: Stainless steel offers durability and longevity, making it suitable for heavy-duty applications such as industrial doors and outdoor settings. Its resistance to rust and corrosion ensures a longer lifespan, reducing maintenance costs over time.

Illustrative image related to types of spring hinges

Cons: The primary drawback is its cost, which tends to be higher than other materials. Additionally, manufacturing stainless steel components can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including moisture-laden environments, making it a preferred choice for applications in humid regions like parts of Africa and coastal areas in Europe.

What Advantages Does Brass Offer for Spring Hinges?

Brass is another popular material for spring hinges, known for its aesthetic appeal and moderate corrosion resistance. It is often used in applications where appearance is a priority, such as residential doors and cabinetry.

Pros: Brass hinges are relatively easy to manufacture and can be finished in various ways, enhancing their visual appeal. They also provide good wear resistance and are less prone to galling compared to other metals.

Cons: However, brass is not as strong as stainless steel and may not perform well in high-stress environments. Its corrosion resistance is also limited compared to stainless steel, making it less suitable for outdoor applications.

Impact on Application: Brass is often favored in regions with moderate climates, where aesthetic considerations are essential. Compliance with local standards is generally straightforward, but buyers should ensure that the finish is appropriate for their specific environmental conditions.

Why Choose Zinc-Plated Steel for Cost-Effective Spring Hinges?

Zinc-plated steel is a cost-effective option that provides a decent level of corrosion resistance due to the zinc coating. It is often used in applications where budget constraints are significant.

Pros: The primary advantage of zinc-plated steel is its affordability and availability. It is suitable for light to moderate-duty applications, making it a popular choice for commercial settings.

Cons: The main limitation is its susceptibility to corrosion if the zinc layer is compromised. Additionally, it may not perform well in extreme temperature variations.

Impact on Application: Zinc-plated steel is commonly used in regions with dry climates, where corrosion is less of a concern. Buyers should ensure that the coating meets local compliance standards, such as ASTM or DIN.

What Are the Benefits of Using Aluminum in Spring Hinges?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for applications requiring reduced weight and enhanced mobility.

Pros: The lightweight nature of aluminum allows for easy installation and operation. It also provides good corrosion resistance, especially in non-saltwater environments.

Cons: However, aluminum is generally less strong than steel, which may limit its use in heavy-duty applications. Its cost is typically moderate, but it can vary based on alloy compositions.

Impact on Application: Aluminum hinges are particularly suitable for applications in regions with high humidity or coastal areas, where corrosion can be a significant issue. International buyers should verify that the aluminum meets relevant standards for strength and durability.

Summary Table of Material Selection for Spring Hinges

| Material | Typical Use Case for types of spring hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial doors, outdoor applications | Exceptional corrosion resistance and strength | Higher cost and complex manufacturing | High |

| Brass | Residential doors, cabinetry | Aesthetic appeal and moderate corrosion resistance | Limited strength and lower corrosion resistance | Medium |

| Zinc-Plated Steel | Commercial settings, light-duty applications | Cost-effective and widely available | Susceptible to corrosion if coating is damaged | Low |

| Aluminum | Lightweight applications, high humidity areas | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

This guide provides a comprehensive overview of materials used in spring hinges, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for types of spring hinges

What Are the Key Stages in the Manufacturing Process of Spring Hinges?

The manufacturing process of spring hinges involves several critical stages that ensure the final product meets the quality standards expected by B2B buyers. Understanding these stages can help buyers evaluate potential suppliers and their capabilities.

Material Preparation: What Materials Are Commonly Used in Spring Hinges?

The first step in manufacturing spring hinges is selecting the right materials. Common materials include stainless steel, brass, and zinc-plated steel, each chosen for their durability and resistance to corrosion. For instance, stainless steel is often favored for its strength and aesthetic appeal, making it suitable for high-end applications.

Once the materials are selected, they undergo preparation processes such as cutting, shearing, or punching to create the basic shapes needed for the hinges. This step ensures that the raw materials are ready for the forming process, which is crucial for maintaining the integrity of the hinge.

How Are Spring Hinges Formed?

The forming stage is where the actual shape of the spring hinge is crafted. This can involve several techniques, including stamping, bending, and machining.

-

Stamping: This technique uses a die to cut and shape the metal sheets into precise parts. It is efficient for mass production and allows for intricate designs.

-

Bending: In this process, the metal is bent into the desired angles to create the hinge components. This is typically done using hydraulic presses or mechanical benders.

-

Machining: For high-precision parts, machining may be employed to achieve exact dimensions and finishes. CNC (Computer Numerical Control) machines are commonly used in this stage to ensure accuracy.

Each of these techniques contributes to the strength and functionality of the final product, making it essential for manufacturers to choose the appropriate method based on the hinge design and application.

What Does the Assembly Process Involve for Spring Hinges?

After the components are formed, the next step is assembly. This process can vary significantly depending on the type of spring hinge being produced.

-

Single and Double-Action Hinges: For single-action hinges, the assembly involves attaching the spring mechanism to the hinge plates. In contrast, double-action hinges require a more complex assembly, where the springs are installed in a way that allows the hinge to function in both directions.

-

Surface-Mounted vs. Mortise Hinges: Surface-mounted hinges typically require less intricate assembly since they do not need mortising into the door or frame. However, mortise hinges involve precise fitting and alignment, which can be more labor-intensive.

Quality during assembly is crucial, as misalignment or improper fitting can lead to functional issues in the final product.

How Are Finishing Processes Applied to Spring Hinges?

The finishing stage is vital for enhancing the durability and appearance of spring hinges. Common finishing processes include:

-

Plating: Many hinges undergo plating processes, such as zinc plating or nickel plating, to improve corrosion resistance and aesthetic appeal. This is particularly important for hinges used in outdoor or high-moisture environments.

-

Painting: For hinges that require specific colors or finishes, powder coating or spray painting is applied. This not only enhances appearance but also provides an additional layer of protection against wear and tear.

-

Quality Check: After finishing, hinges should undergo a visual inspection to ensure that the finish is consistent and free from defects.

By investing in high-quality finishes, manufacturers can significantly enhance the lifespan and performance of their products.

What Quality Assurance Standards Should Buyers Look for in Spring Hinges?

Quality assurance is crucial in the hinge manufacturing process, especially for international B2B buyers. To ensure that suppliers meet the required standards, buyers should be familiar with both international and industry-specific quality standards.

Which International Standards Are Relevant for Spring Hinges?

ISO 9001 is one of the most recognized quality management standards globally. It ensures that organizations consistently provide products that meet customer and regulatory requirements. B2B buyers should look for suppliers that have ISO 9001 certification as it reflects a commitment to quality management and continuous improvement.

Additionally, other relevant certifications may include CE marking for products sold in Europe, which indicates compliance with EU safety and environmental requirements. For specific industries, certifications like API (American Petroleum Institute) may also be necessary, particularly for hinges used in oil and gas applications.

What Quality Control Checkpoints Should Be Implemented?

Quality control (QC) checkpoints are critical throughout the manufacturing process to ensure that products meet specifications. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that materials meet specified standards helps prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring processes to identify any deviations from standards. This can include checking the dimensions and mechanical properties of the components at various stages.

-

Final Quality Control (FQC): Once the assembly and finishing are complete, a final inspection is conducted to ensure that the finished product meets all specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

To verify the quality control processes of potential suppliers, B2B buyers should consider the following methods:

-

Supplier Audits: Conducting audits allows buyers to assess the supplier’s manufacturing processes, quality control systems, and compliance with relevant standards firsthand.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certifications.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. This is particularly important for international transactions where buyers may not be able to visit the manufacturing facility.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control.

-

Cultural Differences: Different countries may have varying approaches to quality assurance. Understanding these cultural differences can help buyers communicate more effectively with suppliers.

-

Regulatory Compliance: Each region may have specific regulations governing product safety and quality. It is essential for buyers to ensure that their suppliers are compliant with local regulations to avoid potential legal issues.

-

Logistics and Supply Chain: International shipping can introduce additional risks to product quality. Buyers should consider how their suppliers manage logistics to ensure that products are not damaged during transport.

By being informed about the manufacturing processes and quality assurance measures in spring hinge production, B2B buyers can make more educated decisions, ensuring they partner with suppliers who meet their quality standards and operational needs.

Illustrative image related to types of spring hinges

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of spring hinges’

Introduction

When sourcing spring hinges for industrial or commercial applications, buyers must navigate a range of options to find the right fit for their needs. This guide provides a systematic checklist to ensure that you make informed decisions while procuring spring hinges, helping you to meet both operational requirements and budget constraints.

Step 1: Define Your Technical Specifications

Before beginning your search, clarify the specific requirements for your spring hinges. Consider factors such as size, weight capacity, and the intended application—whether for doors, cabinets, or specialized equipment.

– Size and Dimensions: Determine the necessary length and thickness to ensure a proper fit.

– Load Requirements: Assess the weight of the doors or items the hinges will support to avoid premature wear or failure.

Step 2: Understand the Different Types of Spring Hinges

Familiarize yourself with the various types of spring hinges available on the market. Each type serves different functions and applications, influencing your choice significantly.

– Single-Acting vs. Double-Acting: Single-acting hinges allow movement in one direction, while double-acting hinges can swing both ways, ideal for high-traffic areas.

– Material Considerations: Choose between materials such as stainless steel for durability or lighter options like zinc-plated steel for cost-effectiveness.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. A trustworthy supplier can be pivotal in maintaining your supply chain efficiency.

– Company Background: Review company profiles, focusing on experience in the industry and reputation.

– References and Reviews: Seek testimonials from previous clients, especially those in similar markets or regions, to gauge satisfaction levels.

Step 4: Verify Product Standards and Certifications

Ensure that the spring hinges meet relevant industry standards and certifications, which can impact performance and safety.

– Quality Certifications: Look for ISO certifications or compliance with local regulations, which indicate a commitment to quality.

– Testing Procedures: Inquire about their testing methods to ensure the hinges can withstand specified loads and conditions.

Step 5: Request Samples for Evaluation

Before finalizing your order, request samples of the hinges to assess their quality and functionality firsthand. This step is essential to confirm that the products meet your specifications and expectations.

– Testing in Real Conditions: Conduct tests under actual operating conditions to evaluate durability and performance.

– Compatibility Checks: Ensure that the samples fit seamlessly with your existing systems or installations.

Illustrative image related to types of spring hinges

Step 6: Review Pricing and Payment Terms

Analyze the pricing structures offered by various suppliers and ensure they align with your budgetary constraints.

– Bulk Order Discounts: Inquire about price breaks for larger orders, which can significantly impact overall costs.

– Payment Flexibility: Assess payment terms and conditions to facilitate smoother transactions, especially for international purchases.

Step 7: Establish a Clear Communication Channel

Maintain open lines of communication with your supplier throughout the sourcing process. This can prevent misunderstandings and delays.

– Regular Updates: Set expectations for updates on order status, shipping, and any potential issues.

– Point of Contact: Identify a reliable contact person within the supplier’s organization for efficient resolution of queries or concerns.

By following this checklist, B2B buyers can streamline the sourcing process for spring hinges, ensuring they select the best products for their specific applications while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for types of spring hinges Sourcing

When sourcing spring hinges, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components associated with spring hinges, the factors influencing their prices, and provide actionable tips for buyers to ensure optimal procurement.

What Are the Key Cost Components for Spring Hinges?

-

Materials: The choice of materials significantly impacts the cost of spring hinges. Common materials include stainless steel, brass, and zinc-coated steel. Stainless steel, while more expensive, offers superior corrosion resistance, making it ideal for outdoor or humid environments. Brass hinges are often favored for aesthetic applications but may have higher material costs.

-

Labor: Labor costs encompass the expenses related to the workforce involved in manufacturing spring hinges. This includes wages, benefits, and potential overtime for skilled workers, especially in regions with higher labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, factory rent, and maintenance of machinery. Overhead can vary significantly based on the location of the manufacturing plant and its operational efficiency.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs or specialized specifications. These costs are typically amortized over the production run, influencing the price per unit.

-

Quality Control (QC): Ensuring that each batch of spring hinges meets quality standards incurs costs associated with testing and inspection. High-quality certifications may increase costs but can be essential for markets demanding stringent compliance.

-

Logistics: Shipping and handling fees are critical components, especially for international buyers. Costs will vary based on the distance, shipping method, and any tariffs or customs duties applicable in the buyer’s country.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and investment risks. Margins can fluctuate based on market competition and demand.

Which Factors Influence Spring Hinge Pricing?

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower unit prices. Negotiating for a higher MOQ can yield significant savings, but it requires careful assessment of demand to avoid overstock.

-

Specifications and Customization: Customized hinges tailored to specific applications may incur higher prices due to the additional labor and material costs. Standard sizes and types generally offer more competitive pricing.

-

Quality and Certifications: Higher quality hinges with certifications (e.g., ISO, ASTM) typically command higher prices. Buyers should weigh the importance of certifications against their specific application needs.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium for their products, but they often provide better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Are the Best Negotiation Tips for International B2B Buyers?

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher volume thresholds, which can lead to lower per-unit costs.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like durability, maintenance, and potential replacement costs when evaluating hinge options.

-

Seek Multiple Quotes: Comparing prices from various suppliers can provide leverage during negotiations. Be transparent about competing offers to encourage better pricing.

-

Understand Local Market Dynamics: Familiarize yourself with local suppliers and market conditions in your region. This knowledge can aid in negotiating better terms and prices.

-

Be Mindful of Currency Fluctuations: For international transactions, currency exchange rates can impact pricing. Locking in prices or negotiating in a stable currency can mitigate this risk.

Conclusion

Navigating the complexities of spring hinge sourcing requires a thorough understanding of the cost components and pricing influencers. By leveraging strategic negotiation techniques and considering the total cost of ownership, B2B buyers can optimize their procurement strategies, ensuring they receive high-quality products at competitive prices. Always remember that while indicative prices may provide a baseline, actual costs can vary significantly based on the discussed factors.

Illustrative image related to types of spring hinges

Alternatives Analysis: Comparing types of spring hinges With Other Solutions

Exploring Alternatives to Spring Hinges in B2B Applications

In the realm of door and cabinet hardware, spring hinges are a popular choice due to their automatic closing feature and ease of use. However, there are alternative solutions that may better suit specific applications or preferences. This section provides a comparative analysis of spring hinges against two viable alternatives: Pneumatic Door Closers and Magnetic Door Holders. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions.

| Comparison Aspect | Types of Spring Hinges | Pneumatic Door Closers | Magnetic Door Holders |

|---|---|---|---|

| Performance | Reliable for light to heavy doors with adjustable tension | Smooth operation, ideal for high-traffic areas | Strong hold, but may not be suitable for heavy doors |

| Cost | Moderate ($15 – $150) | Higher ($50 – $300) | Low to moderate ($20 – $100) |

| Ease of Implementation | Simple installation; no special tools required | Requires more tools and alignment | Easy to install; minimal tools needed |

| Maintenance | Low maintenance; occasional lubrication needed | Moderate; may require periodic adjustments | Very low; requires minimal upkeep |

| Best Use Case | Cabinets, entry doors, and passage doors | High-traffic commercial spaces | Light doors in residential and some commercial settings |

What Are the Advantages and Disadvantages of Pneumatic Door Closers?

Pneumatic door closers utilize air pressure to ensure that doors close automatically after being opened. This solution excels in high-traffic areas, such as commercial buildings, where frequent access is necessary. They offer a smooth operation and can be adjusted for speed and force, making them versatile for various door sizes. However, the cost can be significantly higher than spring hinges, and installation may require more tools and expertise. Additionally, they may need periodic adjustments to maintain optimal performance, which can be a consideration for maintenance budgets.

How Do Magnetic Door Holders Compare to Spring Hinges?

Magnetic door holders provide a unique solution by using magnetic forces to keep doors open or closed. They are particularly effective for light doors, making them suitable for residential applications or less demanding commercial environments. Their ease of installation is a significant advantage, as they typically require minimal tools and can be mounted on various surfaces. However, they may not be strong enough for heavy doors, and their performance can be compromised by dirt or debris on the magnetic surfaces. Cost-wise, they are generally more affordable than pneumatic door closers but can vary based on the specific product features.

Making the Right Choice for Your Application

When selecting the appropriate solution for your door and cabinet hardware needs, consider the specific requirements of your application. Types of spring hinges offer a reliable, low-maintenance option suitable for a variety of doors, particularly in residential and light commercial settings. If you’re dealing with high traffic or need more control over door closing speed, pneumatic door closers may be the better choice despite their higher cost. Conversely, for lighter doors or less demanding applications, magnetic door holders provide an economical and easy-to-install solution. By thoroughly assessing performance, costs, and maintenance needs, B2B buyers can confidently choose the right hardware to optimize their operations.

Essential Technical Properties and Trade Terminology for types of spring hinges

What Are the Key Technical Properties of Spring Hinges?

When selecting spring hinges for various applications, understanding the technical properties is essential. Here are some critical specifications that B2B buyers should consider:

1. Material Grade

The material used for spring hinges affects durability, corrosion resistance, and overall performance. Common materials include stainless steel, brass, and zinc-plated steel. Stainless steel is particularly valued for its strength and resistance to rust, making it ideal for outdoor applications. Choosing the right material can significantly impact the longevity of the hinge, reducing maintenance costs and the need for replacements.

2. Spring Tension

Spring tension determines how forcefully the hinge closes a door. This property is crucial for applications requiring specific closing speeds or resistance. Adjustability in spring tension allows for customization based on the door’s weight and usage frequency. Understanding the necessary tension can help avoid issues like slamming or incomplete closure, which can lead to security concerns.

3. Size and Dimensions

The size of spring hinges, including length, thickness, and open width, must match the application requirements. Standard sizes vary, but custom options are often available. Incorrect sizing can lead to installation issues or inadequate performance, ultimately affecting the functionality of the door or cabinet. Buyers should ensure they have precise measurements before placing an order.

4. Torque Ratings

Torque ratings indicate the amount of rotational force needed to operate the hinge effectively. This is particularly relevant for heavy-duty applications where doors may be larger or heavier. Understanding torque requirements helps ensure that the hinge can handle the intended load without failure. Proper torque ratings also influence the ease of operation and the longevity of the hinge.

5. Finish and Coating

The finish on a spring hinge can affect both aesthetics and functionality. Options range from polished brass to powder-coated finishes. A good finish can enhance corrosion resistance and improve the hinge’s visual appeal, especially in exposed installations. Consideration of the environment where the hinge will be installed is vital for selecting the appropriate finish.

Illustrative image related to types of spring hinges

6. Load Capacity

Each spring hinge has a specific load capacity that indicates the maximum weight it can support. This is critical for ensuring that the hinge can adequately handle the weight of the door or application it is intended for. Exceeding the load capacity can lead to premature wear or failure, leading to costly repairs or replacements.

What Are Common Trade Terms Related to Spring Hinges?

Understanding industry jargon is essential for effective communication and negotiation. Here are some common terms used in the spring hinge market:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of spring hinges, OEMs often provide custom solutions tailored to specific requirements. Working with OEMs can ensure that products meet precise specifications, which is crucial for manufacturers and assembly operations.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget effectively. Suppliers often set MOQs to ensure profitability, so negotiating these terms can be beneficial, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Submitting an RFQ for spring hinges can help buyers compare options and negotiate better pricing. It is an essential step for bulk purchases or when seeking customized solutions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers, especially those involved in cross-border transactions, as they help clarify cost responsibilities and risk management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for planning and managing projects. Buyers should always inquire about lead times when placing orders for spring hinges to ensure timely delivery and avoid project delays.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring that the spring hinges they select meet their specific needs and applications.

Illustrative image related to types of spring hinges

Navigating Market Dynamics and Sourcing Trends in the types of spring hinges Sector

What Are the Key Market Dynamics and Trends Influencing the Types of Spring Hinges?

The global market for spring hinges is experiencing robust growth, driven by increasing demand across various sectors, including construction, automotive, and consumer goods. Key trends shaping this market include the rise of smart technologies and automation, leading to the development of more sophisticated hinge designs. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for hinges that offer enhanced functionality, such as self-closing mechanisms and adjustable tension features. Additionally, the shift towards online sourcing platforms has made it easier for international buyers to access a wider range of products, fostering competition among suppliers.

Another significant trend is the customization of spring hinges to meet specific industry requirements. Buyers are seeking suppliers who can provide tailored solutions, including various sizes, materials, and finishes. For instance, heavy-duty spring hinges made from stainless steel are in high demand for industrial applications, while lighter options are preferred for residential use. Furthermore, the increased focus on sustainability is influencing purchasing decisions, prompting manufacturers to develop eco-friendly products that align with buyers’ corporate social responsibility goals.

How Is Sustainability Shaping Sourcing Practices for Spring Hinges?

Sustainability is becoming a pivotal factor in the sourcing of spring hinges. As environmental concerns grow, B2B buyers are prioritizing suppliers who demonstrate a commitment to reducing their ecological footprint. This includes sourcing raw materials responsibly, minimizing waste during production, and ensuring that products are recyclable or biodegradable.

Buyers are also increasingly interested in “green” certifications that validate the sustainability of the manufacturing process. Certifications such as ISO 14001 for environmental management and the Forest Stewardship Council (FSC) for wood-based products are gaining traction. Manufacturers that utilize recycled materials, such as zinc-plated steel or sustainably sourced brass, are particularly appealing to buyers focused on ethical sourcing. By aligning their purchasing strategies with sustainability goals, companies not only enhance their brand reputation but also appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context of Spring Hinges in B2B Markets?

The evolution of spring hinges dates back to the early 20th century, when they were primarily used in residential applications. Initially, these hinges were simple mechanisms that required manual adjustments. Over time, advancements in materials science and manufacturing processes led to the development of more sophisticated designs. By the mid-20th century, spring hinges began to be utilized in commercial and industrial settings, where durability and reliability became paramount.

Today, the market has diversified significantly, with a range of options available to meet various functional requirements. Innovations such as double-acting and reverse-acting hinges have broadened their application scope, making them suitable for everything from kitchen cabinets to heavy industrial doors. This historical evolution reflects the ongoing demand for efficiency and functionality in B2B applications, setting the stage for future advancements in the spring hinge sector.

Frequently Asked Questions (FAQs) for B2B Buyers of types of spring hinges

-

1. How do I choose the right type of spring hinge for my application?

Choosing the right type of spring hinge depends on several factors, including the door’s weight, frequency of use, and required motion. For light-duty applications, barrel or light-duty butt hinges may suffice, while heavy-duty projects might require stainless steel or double-action spring hinges. Consider the environment as well; for outdoor use, corrosion-resistant materials like stainless steel are ideal. Additionally, assess if you need single-acting or double-acting hinges based on whether the door needs to swing in one direction or both. -

2. What is the best spring hinge for heavy-duty applications?

For heavy-duty applications, stainless steel spring hinges are often the best choice due to their strength and resistance to wear and corrosion. Look for hinges that are rated for high usage, such as those designed for commercial or industrial settings. Heavy-duty butt hinges or double-action spring hinges are commonly used in environments with frequent door traffic. Ensure the selected hinge can handle the specific weight and tension requirements of your door to maintain longevity and functionality. -

3. What are the customization options available for spring hinges?

Many suppliers offer customization options for spring hinges to meet specific application needs. Customizations can include size adjustments, material selection, spring tension variations, and finishes. You may also find suppliers willing to create unique designs based on your specifications. When requesting customization, provide detailed requirements to ensure the final product aligns with your expectations. This flexibility is particularly beneficial for specialized industries or unique architectural designs. -

4. What is the minimum order quantity (MOQ) for spring hinges?

Minimum order quantities for spring hinges can vary significantly between suppliers. Some may offer no minimum for standard items, while others might require a MOQ of 50 to 100 pieces for customized or specialty hinges. When sourcing, inquire about MOQs early in the negotiation process to avoid unexpected costs. Additionally, consider the potential for bulk purchasing to lower per-unit costs, especially if you anticipate a long-term need for hinges in your projects. -

5. How can I verify the reliability of a spring hinge supplier?

To verify the reliability of a spring hinge supplier, conduct thorough research including checking customer reviews, requesting references, and reviewing their certifications. Ensure they adhere to international quality standards, such as ISO certifications. Additionally, assess their manufacturing capabilities and lead times. Establishing a good relationship through direct communication can also provide insights into their reliability and customer service quality. Request samples to evaluate product quality before committing to larger orders. -

6. What payment terms should I expect when sourcing spring hinges internationally?

Payment terms when sourcing spring hinges internationally can vary widely depending on the supplier and the buyer’s location. Common terms include net 30 or net 60 days, but upfront payments or deposits are often required, especially for custom orders. International buyers should also consider factors such as currency fluctuations and transaction fees. It’s advisable to discuss payment options clearly with the supplier and consider using secure payment methods like letters of credit or escrow services to mitigate risk. -

7. What quality assurance measures should I look for in spring hinge suppliers?

Quality assurance measures are crucial when sourcing spring hinges to ensure product reliability. Look for suppliers that implement rigorous quality control processes, such as inspections at various production stages. Certifications like ISO 9001 indicate adherence to international quality management standards. Ask about their testing procedures for durability, corrosion resistance, and load capacity. Requesting samples for testing can also help ensure the hinges meet your quality expectations before placing a larger order. -

8. How do logistics and shipping impact the sourcing of spring hinges?

Logistics and shipping play a significant role in the sourcing of spring hinges, especially for international buyers. Consider factors such as shipping costs, delivery times, and customs regulations, which can vary by region. Work with suppliers that have experience in international shipping to avoid delays and complications. It’s also beneficial to understand the supplier’s shipping options and whether they can accommodate your timeline. Efficient logistics can significantly impact your project’s success, making timely delivery critical.

Top 5 Types Of Spring Hinges Manufacturers & Suppliers List

1. Hardwaresource – Spring Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Spring Hinges available in various types and finishes including: 4-1/2″ Heavy Duty Spring Hinge, Stainless Steel Spring Hinge, Double Action Spring Hinges, Light Duty Double Action Spring Hinge, Hold Open Light Duty Double Action Hinge, Ball Tip Spring Hinge, and more. Prices range from $13.85 to $399.97 depending on the type and specifications. Features include adjustable tension, compatibility w…

2. dormakaba – Spring Hinges

Domain: dhwsupport.dormakaba.com

Registered: 2015 (10 years)

Introduction: {“Product Type”:”Spring Hinges”,”Description”:”Self-closing hinges with a spring mechanism that allows automatic closing of doors, serving as an alternative to overhead mounted door closers.”,”Design”:”Full mortise design only”,”Sizes Available”:[“3.5×3.5″,”4×4″,”4.5×4″,”4.5×4.5″],”Common Applications”:”Standard commercial grade door hinges suitable for wood and metal doors, medium to heavy weight…

3. Guden – Spring Hinges

Domain: guden.com

Registered: 1995 (30 years)

Introduction: Guden offers a variety of Spring Hinges for industrial doors and cabinets, available in stock from 1.10 inches to 8.75 inches long. They are spring-loaded to open and close, with options for same-day shipment. The hinges can be customized to meet individual requirements. Available materials include steel, zinc plated steel, stainless steel, and aluminum. Stock items range from .75″ open by 1.25″ l…

4. Swinging Café Doors – Customizable Swinging Doors

Domain: swingingcafedoors.com

Registered: 2008 (17 years)

Introduction: Swinging Café Doors offers a wide range of customizable doors and hardware for both residential and commercial applications. Key products include: 1. Swinging Doors: Available in various sizes (24″-60″ door openings) and styles such as modern interior doors, barn style doors, French doors, and more. 2. Door Hardware: Includes double action hinges, single action door hinges, pivot hinges, hidden do…

5. Hinge Outlet – Spring Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Spring Hinges for doors; Spring loaded hinges; Solid Brass Hinges; Free Shipping on orders over $160; Available for both Commercial and Residential applications; Variety of finishes and sizes; Includes expert support at 888-250-8133.

Strategic Sourcing Conclusion and Outlook for types of spring hinges

In today’s competitive landscape, strategic sourcing of spring hinges is essential for ensuring product reliability and operational efficiency. By understanding the diverse types of spring hinges available—such as barrel, butt, and surface-mounted—international buyers can make informed decisions that align with their specific needs. Selecting the right spring hinge not only enhances functionality but also contributes to the longevity of doors and cabinets, reducing maintenance costs over time.

Moreover, sourcing from reputable manufacturers guarantees quality and compliance with international standards, fostering trust and reliability in supply chains. As markets across Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality, durable hardware solutions will only increase.

Looking forward, it is crucial for B2B buyers to stay proactive in their sourcing strategies. Engage with suppliers who offer customization options to meet unique project requirements and ensure your business remains at the forefront of innovation. Embrace the opportunity to optimize your sourcing process for spring hinges and elevate your operational capabilities. Let’s work together to build a more efficient, resilient future in hardware solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.