Top 5 Sock Job Suppliers (And How to Choose)

Introduction: Navigating the Global Market for sock job

Navigating the global market for sock jobs presents a unique challenge for international B2B buyers seeking to enhance their product offerings. Understanding the nuances of sourcing high-quality sock job materials, which cater to diverse consumer preferences, is crucial for businesses aiming to stay competitive. This comprehensive guide delves into various aspects of the sock job market, including types, applications, supplier vetting processes, and cost considerations.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—with actionable insights, this resource empowers informed purchasing decisions. Buyers will discover how to identify reliable suppliers, evaluate product quality, and navigate pricing structures effectively.

Additionally, the guide highlights market trends and consumer behavior, enabling businesses to align their strategies with evolving demands. With a focus on practical solutions and strategic sourcing, this guide aims to simplify the complexities of the sock job market, ensuring that buyers can confidently make choices that enhance their product lines and meet customer expectations.

Understanding sock job Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Sockjob | Basic footjob using socks; minimal props. | Casual entertainment; amateur content creators. | Pros: Easy to produce; low-cost. Cons: May lack uniqueness. |

| Themed Sockjob | Incorporates specific themes or costumes. | Niche markets; themed events and promotions. | Pros: Engaging for targeted audiences. Cons: Higher production costs. |

| Interactive Sockjob | Involves audience participation or live streaming. | Event marketing; brand engagement. | Pros: High viewer engagement; potential for viral content. Cons: Requires skilled performers. |

| Fetish Sockjob | Focuses on specific sock fetishes (e.g., colors, materials). | Specialized adult markets; fetish communities. | Pros: Strong niche appeal; loyal customer base. Cons: Limited mainstream reach. |

| Compilation Sockjob | A collection of various sockjob clips. | Content aggregation; subscription services. | Pros: Broad appeal; diverse content. Cons: May dilute brand identity. |

What Are the Characteristics of Classic Sockjob Variations?

The Classic Sockjob is characterized by its straightforward approach, typically featuring minimal props and a focus on the interaction between the performer and the audience. This type is ideal for casual entertainment and is often favored by amateur content creators looking to enter the market with low production costs. Buyers considering this type should be aware of the potential for high volume but may find that it lacks the uniqueness that can attract dedicated viewers.

How Does Themed Sockjob Cater to Niche Markets?

Themed Sockjobs incorporate specific themes or costumes to create a more immersive experience for viewers. This variation is particularly effective for targeting niche markets, such as those interested in cosplay or seasonal events. Buyers should consider the potential for higher production costs but will benefit from engaging a targeted audience that is more likely to convert into loyal customers.

What Makes Interactive Sockjob a Powerful Marketing Tool?

Interactive Sockjobs involve audience participation or live streaming elements, making them a powerful tool for event marketing and brand engagement. This type encourages viewer interaction, which can lead to a more engaged and loyal audience. For B2B buyers, this presents an opportunity to leverage real-time feedback and create viral content. However, it requires skilled performers and a solid understanding of audience dynamics.

Why Are Fetish Sockjobs Important for Specialized Adult Markets?

Fetish Sockjobs focus on specific sock fetishes, such as particular colors or materials, appealing to specialized adult markets. These variations often attract a dedicated customer base that is willing to pay a premium for tailored content. Buyers should weigh the strong niche appeal against the limited mainstream reach, as this type may not attract a broader audience but can yield high returns within its target demographic.

How Do Compilation Sockjobs Offer Diverse Content?

Compilation Sockjobs consist of a collection of various sockjob clips, providing a broad appeal to viewers. This format is particularly suitable for content aggregation and subscription services, allowing buyers to present diverse content that can keep audiences engaged over time. While this type can attract a wide range of viewers, buyers should be cautious of diluting their brand identity by relying too heavily on compilations rather than unique, standalone content.

Key Industrial Applications of sock job

| Industry/Sector | Specific Application of sock job | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Media | Adult Film Production | Enhances viewer engagement and marketability | Quality of content, compliance with regulations, talent availability |

| Fashion & Apparel | Sock Design and Manufacturing | Unique product offerings increase sales potential | Material sourcing, design innovation, production capacity |

| Marketing & Advertising | Promotional Campaigns | Innovative marketing strategies boost brand visibility | Target audience analysis, creative content development, ROI measurement |

| E-commerce & Retail | Online Sock Sales | Expands product range and attracts niche markets | Supply chain logistics, payment processing, customer service |

| Event Planning & Services | Thematic Events & Parties | Enhances guest experience and brand loyalty | Event customization, supplier reliability, cost management |

How is ‘sock job’ Utilized in Entertainment & Media?

In the adult film production industry, the concept of ‘sock job’ plays a pivotal role in enhancing viewer engagement through specialized content. This niche market demands high-quality and creative performances that resonate with diverse audiences. For international buyers, especially in regions like Africa and Europe, understanding local preferences and cultural sensitivities is crucial. Compliance with local regulations and ethical standards is also essential to ensure a sustainable business model.

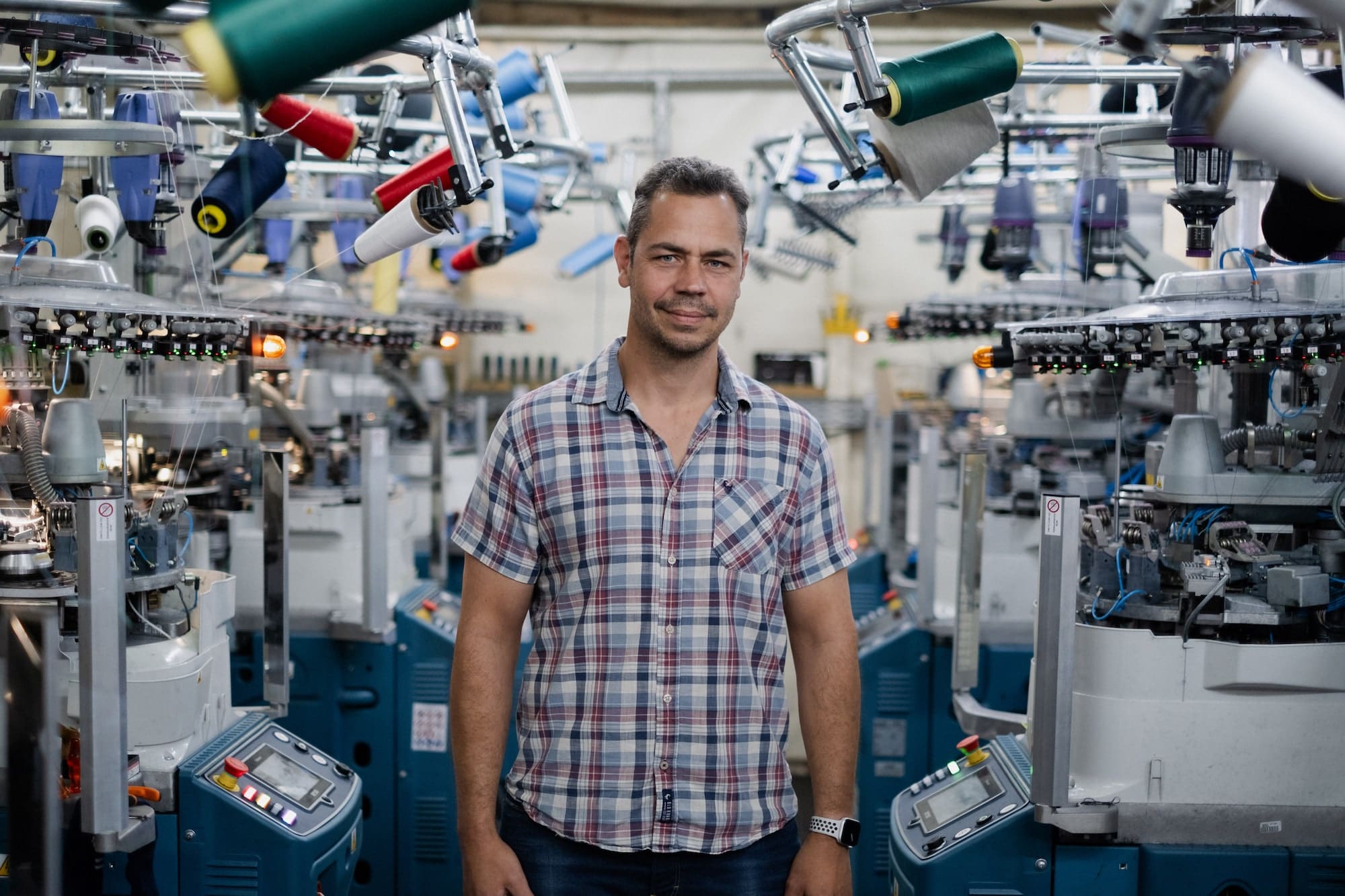

Illustrative image related to sock job

What Role Does ‘sock job’ Play in Fashion & Apparel?

The fashion industry leverages ‘sock job’ by incorporating unique sock designs into their product lines. This approach not only differentiates brands in a saturated market but also caters to specific consumer segments looking for novelty and style. Buyers must focus on sourcing high-quality materials and innovative designs to remain competitive. Additionally, understanding market trends and consumer preferences in regions like South America and the Middle East can significantly enhance sales potential.

How Can ‘sock job’ Enhance Marketing & Advertising Strategies?

In marketing, ‘sock job’ can be utilized as a creative element in promotional campaigns, particularly for brands targeting niche audiences. This innovative approach can boost brand visibility and create memorable experiences for consumers. When sourcing for this application, businesses should conduct thorough audience analysis and develop compelling content that aligns with their brand message. Measuring ROI and effectiveness of campaigns is vital for ongoing success.

Why is ‘sock job’ Important for E-commerce & Retail?

E-commerce platforms can benefit from the ‘sock job’ concept by expanding their product offerings to include unique and themed socks. This not only attracts niche markets but also enhances customer loyalty through diverse product ranges. Buyers in this sector need to consider efficient supply chain logistics, secure payment processing, and exceptional customer service to ensure a seamless shopping experience, particularly in emerging markets across Africa and South America.

Illustrative image related to sock job

How Does ‘sock job’ Impact Event Planning & Services?

In event planning, incorporating ‘sock job’ themes can enhance guest experiences, making events more memorable and engaging. This application is particularly effective for themed parties or corporate events looking to create a unique atmosphere. Event planners must focus on customization options and reliable supplier partnerships to deliver high-quality experiences. Cost management and alignment with client expectations are also critical for ensuring successful outcomes in various regions, including the Middle East and Europe.

3 Common User Pain Points for ‘sock job’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Sock Jobs

The Problem: A common challenge B2B buyers face when sourcing sock jobs is ensuring the quality of the materials used. Many suppliers may offer low-cost options that compromise on comfort, durability, and hygiene, which can lead to customer dissatisfaction. Buyers in regions like Africa and South America, where the market is burgeoning, often struggle to find reliable suppliers who provide high-quality socks that meet the specific preferences of their target demographic.

The Solution: To address this issue, buyers should prioritize working with reputable manufacturers that specialize in sock production. Conducting thorough market research and leveraging online platforms can help identify suppliers with positive reviews and certifications. Requesting samples before placing bulk orders is crucial; this allows buyers to assess the quality firsthand. Additionally, establishing direct communication with manufacturers can provide insights into their production processes and material sourcing, ensuring the socks meet industry standards and customer expectations. Engaging in local trade shows can also facilitate connections with trusted suppliers, fostering long-term partnerships.

Scenario 2: Navigating Cultural Preferences in Sock Job Designs

The Problem: In the diverse international markets of Europe, the Middle East, and Africa, cultural preferences significantly influence the design and acceptance of sock jobs. Buyers may find it challenging to create products that resonate with local tastes and customs. For instance, certain colors or patterns may be favored in one region but considered inappropriate in another, leading to potential market misalignment and wasted inventory.

Illustrative image related to sock job

The Solution: To successfully navigate these cultural nuances, buyers should invest in understanding regional preferences through market analysis and customer feedback. Engaging local design experts or consultants can provide valuable insights into popular styles and acceptable designs. Additionally, conducting focus groups or surveys with target customers can guide product development, ensuring the designs are culturally appropriate and appealing. Offering customization options allows buyers to cater to local tastes while also providing a unique selling proposition that distinguishes their products in a competitive market.

Scenario 3: Ensuring Compliance with International Standards

The Problem: Compliance with international quality and safety standards is a major concern for B2B buyers involved in the sock job industry. Buyers must ensure that their products meet regulations set forth by different countries, which can be especially complex when dealing with multiple markets across continents. Failure to comply can result in costly recalls, legal repercussions, and damage to brand reputation.

The Solution: To mitigate compliance risks, buyers should familiarize themselves with the specific regulations for each target market. This includes understanding materials safety, labeling requirements, and environmental standards. Collaborating with legal experts or consultants who specialize in international trade can provide clarity on necessary certifications. Establishing a quality assurance process that includes regular audits and inspections of the manufacturing process can help ensure compliance from the outset. Furthermore, maintaining open lines of communication with suppliers about compliance expectations can facilitate a smoother production process and minimize the risk of non-compliance.

Strategic Material Selection Guide for sock job

What Are the Key Materials for Sock Job Applications?

When selecting materials for sock jobs, it is crucial to consider their specific properties, advantages, and disadvantages. This section explores four common materials used in sock job applications, providing insights for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties: Nylon is known for its high tensile strength and excellent abrasion resistance. It can withstand a wide temperature range, making it suitable for various environments.

Illustrative image related to sock job

Pros & Cons: Nylon is durable and lightweight, which enhances the performance of sock jobs. However, it can be susceptible to UV degradation and may not be the most cost-effective option for bulk applications.

Impact on Application: Nylon’s compatibility with various media makes it versatile, but it may not perform well in extreme chemical environments.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential. Buyers in regions with high UV exposure may need to consider additional protective measures.

2. Polyester

Key Properties: Polyester offers excellent resistance to moisture and chemicals, making it suitable for sock jobs in diverse applications. It also maintains its shape well under stress.

Pros & Cons: The material is relatively low-cost and highly durable, but it can be less flexible than other options, which may limit its application in certain environments.

Impact on Application: Polyester is particularly effective in applications where moisture resistance is critical, such as in humid climates.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding chemical resistance and environmental impact, especially in regions with stringent safety standards.

3. Rubber

Key Properties: Rubber is known for its excellent elasticity and resistance to various chemicals, making it ideal for applications requiring flexibility and durability.

Pros & Cons: While rubber provides superior grip and shock absorption, it can be more expensive and may require complex manufacturing processes.

Impact on Application: Rubber is particularly effective in applications that involve high friction or require a non-slip surface.

Considerations for International Buyers: Buyers should be aware of the varying quality standards across regions. For instance, compliance with JIS standards may be crucial for buyers in Japan or other Asian markets.

4. Vinyl

Key Properties: Vinyl is a synthetic material that offers good resistance to chemicals and moisture. It is also relatively lightweight and cost-effective.

Illustrative image related to sock job

Pros & Cons: Vinyl is easy to manufacture and can be produced in various colors and textures. However, it may not be as durable as other materials and can degrade under UV exposure.

Impact on Application: Vinyl is suitable for applications that require a cost-effective solution but may not be ideal for high-stress environments.

Considerations for International Buyers: Buyers should ensure that vinyl products comply with local safety regulations, especially in regions with strict environmental laws.

Illustrative image related to sock job

Summary Table of Material Selection for Sock Job

| Material | Typical Use Case for sock job | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General-purpose applications | High tensile strength | UV degradation susceptibility | Medium |

| Polyester | Moisture-resistant applications | Low cost and high durability | Less flexibility | Low |

| Rubber | High-friction applications | Excellent elasticity | Higher cost and manufacturing complexity | High |

| Vinyl | Cost-sensitive applications | Easy to manufacture | Lower durability | Low |

This analysis provides a comprehensive overview of the materials commonly used in sock job applications, enabling B2B buyers to make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sock job

What Are the Key Manufacturing Processes for Sock Job Production?

The manufacturing of sock jobs, often characterized by their unique design and functionality, involves several critical stages that ensure product quality and consistency. Understanding these stages is essential for B2B buyers looking to source reliable sock job products.

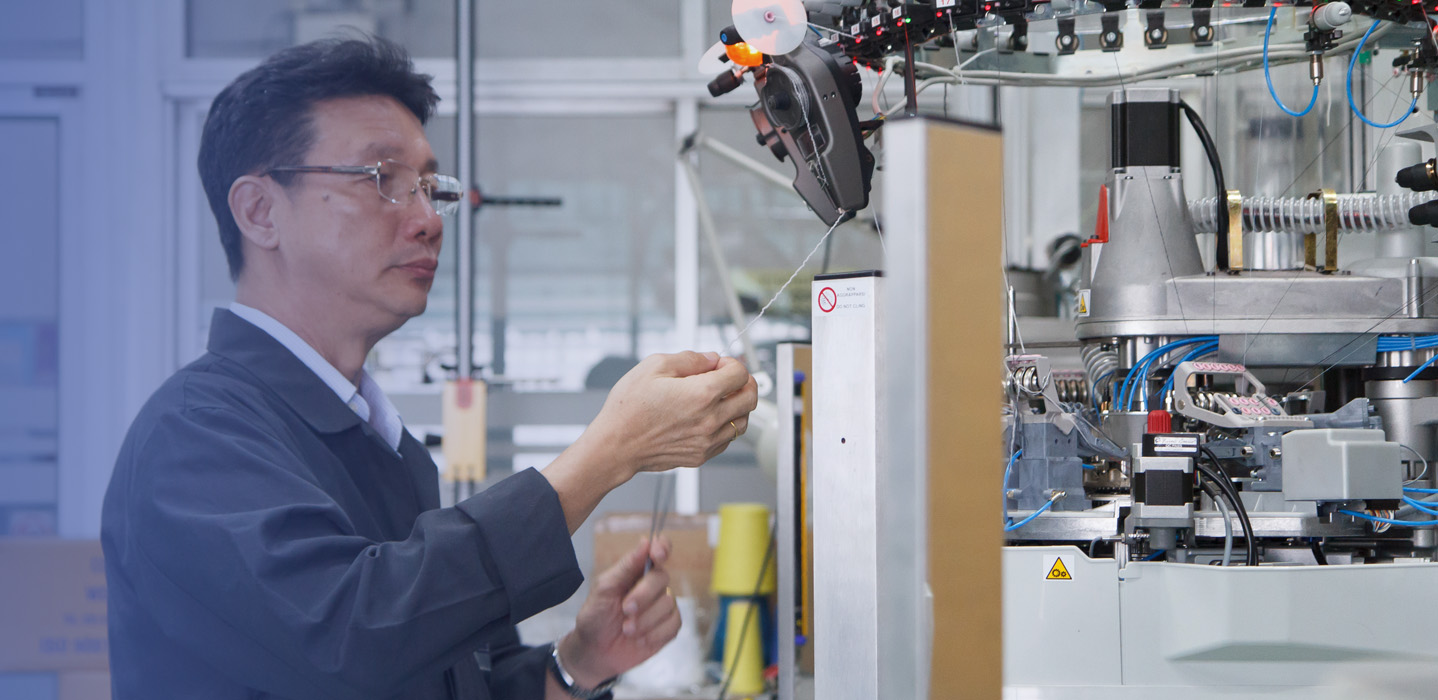

1. Material Preparation: What Materials Are Used in Sock Job Production?

The first step in the sock job manufacturing process is material preparation. High-quality materials such as cotton, polyester, and spandex are commonly used due to their durability and comfort. The selection of raw materials significantly affects the final product’s performance, including breathability and stretchability.

Manufacturers often source materials from certified suppliers to guarantee compliance with international standards. Buyers should inquire about the origin and certification of the materials used, as this can impact the overall quality of the sock jobs.

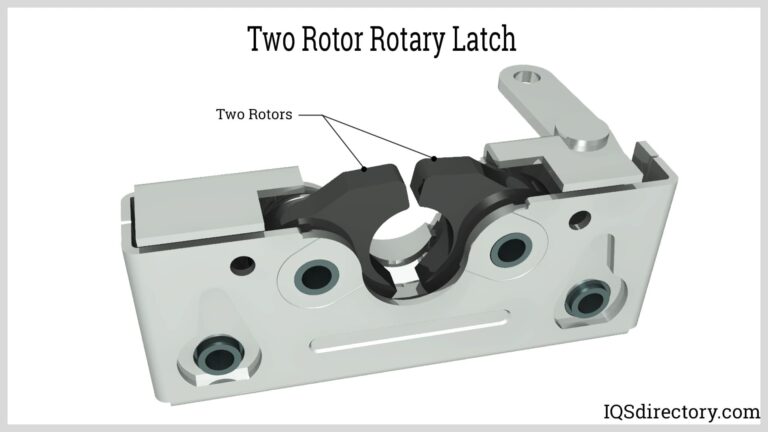

2. Forming: How Are Sock Jobs Shaped and Designed?

Once materials are prepared, the next stage is forming. This process typically involves knitting or weaving techniques to create the sock structure. Advanced machinery, such as computerized knitting machines, allows for precise control over design patterns and dimensions.

For sock jobs, specific techniques like seamless knitting may be employed to enhance comfort and fit. B2B buyers should consider suppliers who utilize modern technology in their manufacturing processes, as this can result in superior product quality.

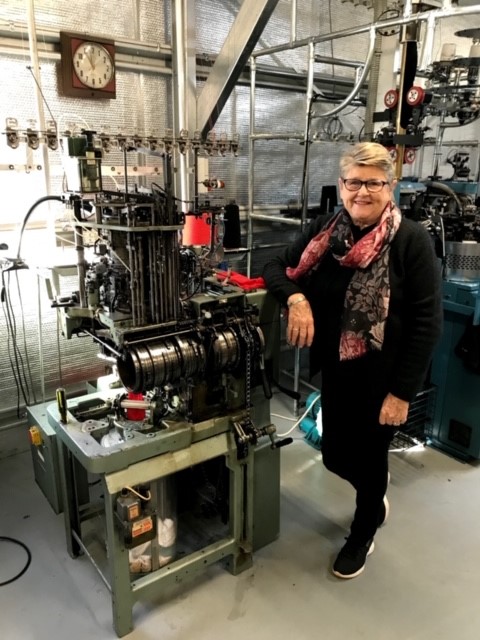

3. Assembly: What Steps Are Involved in Assembling Sock Jobs?

After forming, the sock jobs undergo assembly. This stage includes sewing, linking, and finishing processes that integrate various components, such as elastic bands and decorative elements. Quality control checkpoints are essential during assembly to ensure that each sock job meets the required specifications.

Buyers should look for manufacturers who implement thorough assembly protocols, as this can prevent defects and ensure product reliability. Regular monitoring and process adjustments can enhance the efficiency and quality of the assembly process.

4. Finishing: How Is the Final Product Prepared for Distribution?

The finishing stage encompasses all final touches applied to the sock jobs before packaging. This may include dyeing, printing logos, or adding special treatments for moisture-wicking or odor resistance. Proper finishing is crucial as it directly affects the product’s appeal and functionality.

B2B buyers should verify that suppliers have robust finishing processes in place, including adherence to environmental standards, particularly for dyeing and chemical treatments.

What Quality Assurance Measures Are Essential for Sock Job Manufacturers?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the sock jobs produced meet both international and industry-specific standards. Understanding these measures is vital for B2B buyers in assessing potential suppliers.

1. Which International Standards Should Sock Job Manufacturers Comply With?

Manufacturers should adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO standards indicates that a manufacturer has established processes to ensure product quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking (for products sold in Europe) or API standards (for petroleum-related products) may also be relevant. B2B buyers should request documentation proving compliance with these standards to validate the manufacturer’s commitment to quality.

2. What Are the Key Quality Control Checkpoints in Sock Job Production?

Quality control checkpoints are essential throughout the manufacturing process to detect defects early and maintain product quality. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Quality checks during the manufacturing process help identify and rectify issues as they arise.

- Final Quality Control (FQC): This step entails a comprehensive inspection of the finished sock jobs to ensure they meet all quality standards before packaging and shipment.

B2B buyers should inquire about the frequency and methods of these quality checks to ensure comprehensive quality management.

Illustrative image related to sock job

3. What Common Testing Methods Are Used for Sock Jobs?

Various testing methods are employed to assess the quality of sock jobs, including:

- Physical Testing: Evaluates attributes such as stretchability, durability, and comfort.

- Chemical Testing: Ensures that materials are free from harmful substances and comply with safety regulations.

- Performance Testing: Assesses the sock job’s functionality, including moisture-wicking ability and odor resistance.

Buyers should ask potential suppliers about their testing protocols and the certifications associated with these tests to ensure compliance with safety and quality standards.

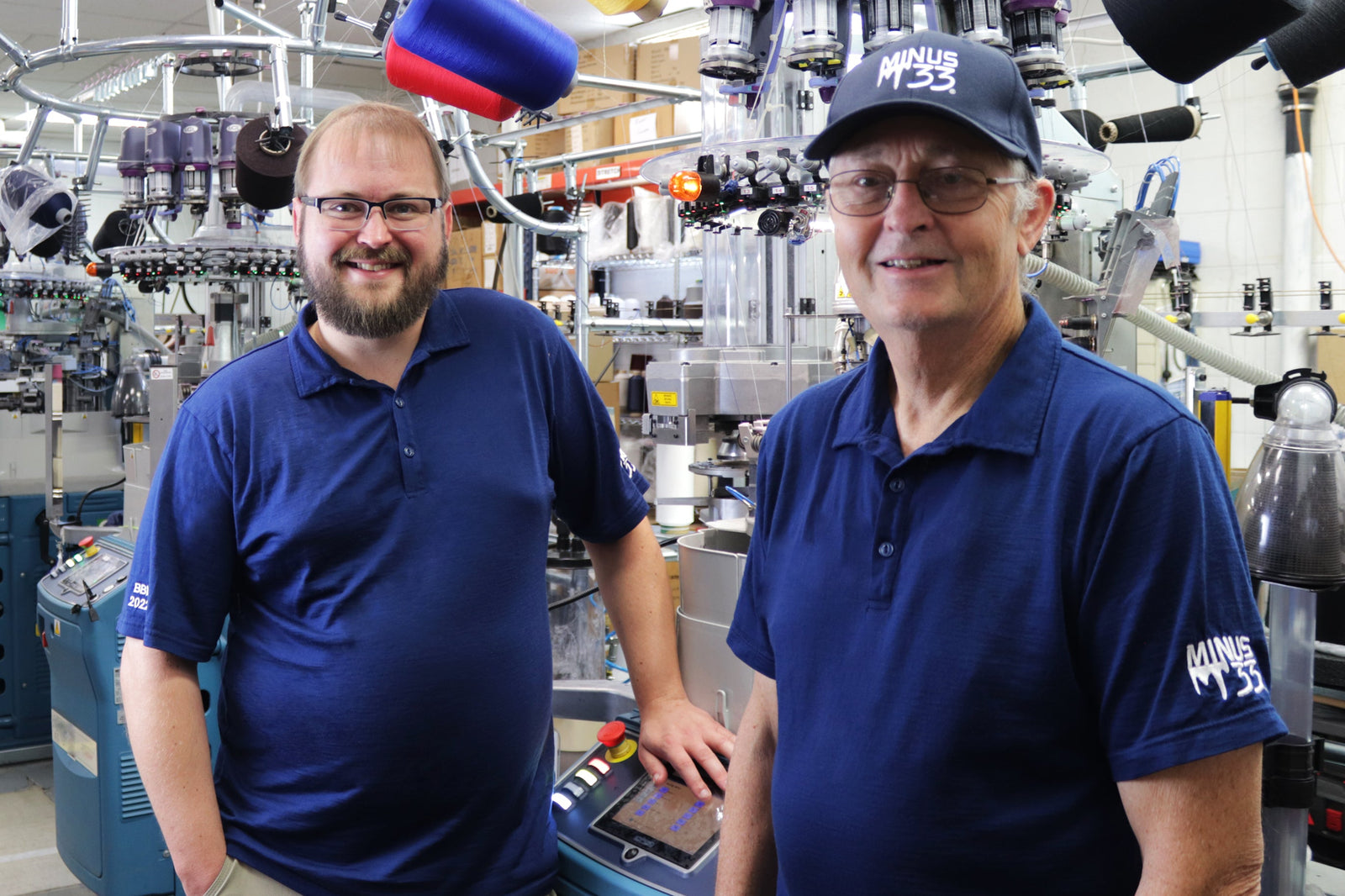

How Can B2B Buyers Verify Supplier Quality Control Practices?

Due diligence is critical when selecting suppliers for sock jobs. B2B buyers can take several steps to verify quality control practices:

1. What Audit Processes Should Buyers Implement?

Conducting audits is an effective way to assess a supplier’s quality management system. Buyers can perform on-site audits or request third-party audit reports to evaluate compliance with international standards. These audits can reveal insights into the supplier’s manufacturing processes and quality assurance measures.

Illustrative image related to sock job

2. How Can Buyers Request Quality Reports and Certifications?

Buyers should proactively request quality assurance reports and certifications from potential suppliers. These documents provide transparency regarding the manufacturer’s commitment to quality and compliance with industry standards. Regular updates on quality metrics can also be beneficial in maintaining a productive supplier relationship.

3. What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can add an additional layer of assurance. These inspections can be conducted at various stages of production to verify that quality standards are met. B2B buyers should consider incorporating third-party inspections into their sourcing strategy, particularly when dealing with international suppliers.

Conclusion: Ensuring Quality in Sock Job Sourcing

In conclusion, understanding the manufacturing processes and quality assurance measures for sock jobs is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing processes, as well as verifying compliance with international standards and implementing thorough quality control practices, buyers can ensure they are sourcing high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sock job’

To aid international B2B buyers in sourcing ‘sock job’ products effectively, this guide presents a structured checklist designed to streamline the procurement process. Understanding the nuances of sourcing in this niche market is crucial for ensuring quality, compliance, and supplier reliability.

Step 1: Define Your Requirements

Before initiating the sourcing process, clearly outline your specifications. Determine the types of sock job products you need, including materials, sizes, and any specific features relevant to your market.

– Consider regional preferences: Different markets may have unique requirements based on cultural or climatic conditions.

– Establish quantity needs: Knowing your volume can help in negotiations and pricing discussions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Utilize online platforms, industry directories, and trade shows to compile a list of potential partners.

– Check for industry experience: Suppliers with a proven track record in the sock job niche will likely offer higher quality and reliability.

– Evaluate their market presence: A supplier with a strong foothold in your target market may better understand local demand and compliance issues.

Illustrative image related to sock job

Step 3: Evaluate Supplier Credentials

Before moving forward, vet potential suppliers by reviewing their credentials. Look for certifications that demonstrate compliance with industry standards.

– Request documentation: Ask for ISO certifications or other relevant quality assurance certifications to ensure they meet international standards.

– Investigate customer feedback: Reading reviews and testimonials can provide insights into the supplier’s reliability and product quality.

Step 4: Request Samples

Once you’ve narrowed down your list, request samples of the products. This step is critical to assess quality firsthand and ensure that the products meet your specifications.

– Test for durability and comfort: Check how the materials hold up under various conditions to ensure they align with your expectations.

– Assess customization options: If your project requires branding or specific designs, ensure the supplier can accommodate your requests.

Step 5: Negotiate Terms and Pricing

After assessing samples and verifying supplier credentials, enter into negotiations. Discuss pricing, payment terms, and delivery schedules to find a mutually beneficial agreement.

– Be transparent about your budget: This can foster goodwill and lead to better pricing options.

– Consider long-term partnerships: Establishing a long-term relationship can lead to more favorable terms in future orders.

Step 6: Finalize Contracts

Once negotiations are complete, finalize contracts with clear terms and conditions. Ensure that all aspects, including delivery timelines, payment schedules, and quality guarantees, are documented.

– Include clauses for quality assurance: Protect your interests by specifying penalties or remedies in case of non-compliance with quality standards.

– Review legal considerations: Ensure that the contract adheres to local laws and regulations to avoid future disputes.

Step 7: Monitor Supplier Performance

After the initial order, continuously monitor the supplier’s performance. Regular feedback sessions can help in maintaining quality and addressing any issues promptly.

– Track delivery times and product quality: Consistent evaluations will help in making informed decisions about future orders.

– Build a feedback loop: Encourage open communication to foster a strong supplier relationship that benefits both parties.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing sock job products efficiently, ensuring they meet their business needs while fostering reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for sock job Sourcing

What Are the Key Cost Components in Sock Job Sourcing?

When sourcing sock jobs, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Illustrative image related to sock job

-

Materials: The type of materials used significantly influences cost. For sock jobs, options range from basic cotton to specialized synthetic fibers. Buyers should assess the quality and durability of materials to align with their product positioning.

-

Labor: Labor costs vary by region and complexity of the sock job. In regions with lower labor costs, like parts of Africa and South America, buyers may find more competitive pricing. However, skilled labor may command higher rates, especially for intricate designs.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses associated with production. Efficient factories with established processes can offer lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment. Buyers should consider whether the tooling costs will be amortized over large production runs to reduce per-unit costs.

-

Quality Control (QC): Implementing stringent quality control processes ensures product consistency and meets international standards. The costs associated with QC should be factored into the overall pricing strategy.

-

Logistics: Shipping and handling costs can vary greatly depending on the supplier’s location and chosen Incoterms. Buyers need to account for these costs to avoid surprises in their total expenditure.

-

Margin: Suppliers typically apply a markup on their costs to ensure profitability. Understanding the margin expectations within different markets can provide insight into pricing negotiations.

How Do Price Influencers Affect Sock Job Sourcing?

Several factors can influence pricing in the sock job market:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to volume discounts, making it crucial for buyers to evaluate their needs carefully.

-

Specifications/Customization: Customized sock jobs, whether in design, size, or branding, can incur additional costs. Buyers should weigh the benefits of customization against the potential for increased pricing.

-

Materials and Quality Certifications: Higher quality materials or those with certifications (e.g., organic, eco-friendly) typically command higher prices. Buyers focused on sustainability may need to balance costs with their environmental goals.

-

Supplier Factors: Supplier reputation, reliability, and location can all influence pricing. Established suppliers may charge a premium for their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and duties. Understanding these terms can help buyers better estimate total costs and mitigate risks.

What Are Effective Buyer Tips for Cost-Efficiency in Sock Job Sourcing?

To achieve cost-efficiency in sock job sourcing, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Building long-term relationships can lead to better deals and more favorable terms over time.

-

Total Cost of Ownership: Assess not just the purchase price but also the total cost of ownership, which includes logistics, storage, and potential returns. This holistic view helps in making more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from different regions may face unique challenges, such as tariffs, currency fluctuations, and import duties. Understanding these factors is critical for accurate budgeting.

-

Market Research: Conduct thorough market research to understand regional pricing trends and supplier capabilities. This knowledge can empower buyers during negotiations and decision-making.

-

Flexible Sourcing Strategies: Consider diversifying suppliers across different regions to take advantage of competitive pricing and reduce dependency on a single source.

Disclaimer on Indicative Prices

Prices for sock job sourcing can vary significantly based on the factors outlined above. Buyers are encouraged to conduct their due diligence and obtain multiple quotes to ensure they are making informed purchasing decisions. Always consider local market conditions and fluctuations in material costs when evaluating pricing.

Alternatives Analysis: Comparing sock job With Other Solutions

Understanding Alternatives in the Context of Sock Job

When considering the implementation of a “sock job,” it is essential for B2B buyers to explore various alternatives that may offer similar benefits. Each solution comes with distinct features, costs, and implementation challenges. This comparison aims to provide valuable insights for decision-makers seeking the most effective method for their specific needs.

Comparison Table

| Comparison Aspect | Sock Job | Alternative 1: Manual Job | Alternative 2: Automated Job |

|---|---|---|---|

| Performance | High engagement; niche appeal | Moderate, dependent on skill level | High consistency and speed |

| Cost | Relatively low; primarily labor | Moderate; labor-intensive | Higher initial investment, but lower long-term costs |

| Ease of Implementation | Simple, quick setup | Requires training for skill development | Complex; needs technical setup |

| Maintenance | Minimal; low upkeep | Moderate; depends on workforce turnover | High; needs regular updates and technical support |

| Best Use Case | Niche markets with specific preferences | General use in various environments | High-volume operations needing efficiency |

Detailed Breakdown of Alternatives

Alternative 1: Manual Job

The manual job approach relies on skilled labor to perform tasks that a sock job would typically handle. One of the key advantages of this method is its flexibility; workers can adapt to various scenarios and provide personalized service. However, the effectiveness largely depends on the skill level of the labor force, which can vary significantly. Additionally, training costs can add to the overall expenditure, making it a less viable option for companies looking to scale quickly.

Alternative 2: Automated Job

The automated job method involves using technology to perform tasks traditionally done by manual labor or a sock job. This approach offers high consistency and speed, making it ideal for high-volume operations. However, the initial setup costs can be significant, and organizations may face ongoing maintenance and technical support challenges. Automation is best suited for businesses that prioritize efficiency and have the resources to invest in advanced technology, but it may not cater to niche markets as effectively as a sock job.

Conclusion: How to Choose the Right Solution for Your Needs

In selecting the most appropriate solution, B2B buyers should carefully evaluate their specific operational requirements, market dynamics, and budget constraints. The sock job offers a cost-effective and engaging method suitable for niche markets, while manual jobs provide flexibility but require skilled labor. On the other hand, automated jobs present a higher initial investment but can significantly enhance efficiency for high-volume operations. By weighing these factors, businesses can make informed decisions that align with their strategic goals and operational capabilities.

Essential Technical Properties and Trade Terminology for sock job

What Are the Key Technical Properties of a Sock Job?

When engaging in the procurement of sock jobs, understanding the critical technical properties is essential for ensuring quality and performance. Here are the main specifications to consider:

-

Material Grade

The type of material used in sock jobs significantly affects their durability and functionality. Common materials include cotton, polyester, and blends that enhance comfort and moisture-wicking properties. For B2B buyers, selecting the right material grade is vital for meeting end-user expectations and ensuring longevity in use. -

Size and Fit Tolerance

Accurate sizing and fit tolerance are crucial in sock jobs to ensure user comfort and satisfaction. Tolerance levels dictate how much variation is acceptable in dimensions, which can impact wearability. B2B buyers must prioritize manufacturers who can consistently meet these specifications to reduce returns and enhance customer satisfaction. -

Compression Levels

Many sock jobs are designed with varying levels of compression, which can aid in circulation and reduce fatigue. Understanding the compression properties can help buyers select products that align with specific health and performance needs, particularly in medical or athletic applications. -

Breathability Rating

The breathability of the sock material is essential for comfort, especially in warm climates or during physical activities. A higher breathability rating indicates better moisture management, which is crucial for preventing odor and maintaining comfort. B2B buyers should assess this property to ensure the socks meet the performance needs of their target markets. -

Color Fastness

Color fastness refers to how well the dye resists fading or running when exposed to washing or sunlight. This property is particularly important for branded products or those intended for fashion markets. Buyers should ensure that suppliers conduct rigorous testing to guarantee product longevity and brand integrity.

What Are Common Trade Terms Related to Sock Jobs?

Navigating the terminology associated with sock jobs can enhance communication and efficiency in procurement. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods that are sold under another company’s brand name. For buyers, partnering with OEMs can provide access to high-quality sock jobs tailored to specific requirements without the need for extensive in-house manufacturing capabilities. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can affect inventory management and cost efficiency. Negotiating favorable MOQs can lead to better pricing and reduced excess stock. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing information from suppliers. Issuing an RFQ allows buyers to compare prices and terms across multiple vendors, ensuring they make informed purchasing decisions based on competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, enabling more effective negotiations and smoother logistics. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. It is a critical factor in supply chain management. B2B buyers should assess lead times to ensure they can meet their own production schedules and customer demands without delays.

By understanding these essential properties and trade terms, international B2B buyers can make more informed decisions when sourcing sock jobs, ultimately leading to better product offerings and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the sock job Sector

What Are the Current Market Dynamics and Key Trends in the Sock Job Sector?

The sock job sector is experiencing significant growth, driven by a combination of changing consumer preferences and technological advancements. Globally, there is an increasing demand for adult content, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These regions are witnessing a surge in internet penetration and mobile device usage, facilitating easier access to adult content. B2B buyers in these markets should take note of the growing influence of local content creators and the increasing popularity of niche markets, including specialized genres like sock jobs.

Emerging technologies, such as virtual reality (VR) and augmented reality (AR), are also reshaping the landscape, offering immersive experiences that can enhance viewer engagement. Additionally, the rise of subscription-based models is changing the revenue dynamics, allowing creators to cultivate loyal audiences while ensuring a steady income stream. B2B buyers should focus on partnerships with platforms that prioritize user experience and offer innovative monetization strategies.

Illustrative image related to sock job

Another noteworthy trend is the shift towards personalized content, where algorithms tailor recommendations based on user preferences. This trend not only enhances user satisfaction but also provides valuable insights for B2B buyers looking to align their sourcing strategies with market demand. By investing in analytics tools, businesses can better understand consumer behavior and adjust their offerings accordingly.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in the Sock Job Sector?

As the sock job sector evolves, sustainability and ethical sourcing are becoming increasingly important for B2B buyers. The environmental impact of digital content creation, including energy consumption and electronic waste, cannot be overlooked. Companies are encouraged to adopt sustainable practices, such as utilizing renewable energy sources for data centers and minimizing their carbon footprints through efficient operational strategies.

Ethical supply chains are also a critical concern. B2B buyers should prioritize partnerships with content creators and platforms that adhere to ethical standards, ensuring fair compensation and working conditions for all involved. Certifications that demonstrate commitment to ethical practices, such as Fair Trade or Sustainable Business certifications, can provide assurance to buyers about the integrity of their supply chains.

Moreover, there is a growing demand for ‘green’ materials and practices within the adult entertainment industry. Buyers should explore options for sustainable packaging, energy-efficient production processes, and eco-friendly digital distribution methods. By embracing sustainability, B2B buyers not only contribute to environmental conservation but also align themselves with the values of increasingly conscious consumers.

Illustrative image related to sock job

What Is the Brief Evolution of the Sock Job Sector?

The sock job sector has evolved significantly over the past few decades, reflecting broader changes in the adult entertainment industry. Initially, adult content was largely distributed through physical media, but the advent of the internet revolutionized access and consumption patterns. The digital transformation allowed for greater diversity in content, enabling niche genres like sock jobs to gain visibility and popularity.

In recent years, the proliferation of social media and user-generated content platforms has further democratized the industry. This shift has empowered independent creators to reach global audiences without the need for traditional distribution channels. As a result, sock job content has become more mainstream, appealing to a wider demographic and facilitating cross-cultural exchanges in adult entertainment preferences.

This evolution highlights the importance of adaptability for B2B buyers in the sock job sector, who must navigate an increasingly competitive landscape characterized by rapid technological advancements and shifting consumer attitudes. Embracing innovation and ethical practices will be crucial for success in this dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of sock job

-

How do I ensure the quality of sock job products from international suppliers?

To ensure quality, start by vetting potential suppliers through their certifications, customer reviews, and factory audits. Request samples to assess material quality and craftsmanship. Establish clear quality assurance protocols, including specific standards for materials, stitching, and finishing. Collaborating with third-party inspection agencies can provide additional assurance that products meet your specifications before shipping. -

What are the best practices for negotiating payment terms with sock job suppliers?

When negotiating payment terms, consider using secure methods such as letters of credit or escrow services to protect both parties. Typically, a 30% deposit upfront and 70% upon delivery is standard. However, be open to adjusting these terms based on the supplier’s reputation and your order size. Ensure that all terms are documented in the contract to avoid misunderstandings. -

What are the minimum order quantities (MOQ) for sock job products?

Minimum order quantities can vary significantly by supplier and product type. Many manufacturers have MOQs ranging from 500 to 5,000 units for custom designs. It’s advisable to inquire about MOQs during your initial discussions to assess feasibility. Some suppliers may be flexible with MOQs for repeat customers or larger orders, so it’s worth negotiating. -

How can I customize sock job products for my target market?

Customization options typically include materials, colors, sizes, and packaging. Discuss your specific requirements with the supplier, as many manufacturers are open to creating bespoke solutions. Providing detailed design specifications and samples can help ensure the final product aligns with your brand identity. Additionally, consider cultural preferences and trends in your target markets to enhance appeal. -

What logistics considerations should I keep in mind when sourcing sock jobs?

Logistics is crucial in ensuring timely delivery. Factor in shipping methods, lead times, and customs regulations in your target countries. Work with suppliers who have experience in international shipping and can provide reliable freight forwarding services. Establish a clear timeline for production and shipping to avoid delays and ensure that your inventory meets market demand. -

What are the common challenges faced when sourcing sock job products internationally?

Challenges may include language barriers, differing quality standards, and varying legal regulations. To mitigate these, establish clear communication with suppliers and consider hiring local agents or consultants who understand the market. Additionally, staying updated on international trade laws and tariffs can help avoid unexpected costs and ensure compliance with import/export regulations. -

How do I evaluate potential sock job suppliers effectively?

Begin by researching suppliers online and reading reviews from other buyers. Request references and case studies from previous clients to gauge their reliability. Conduct virtual or in-person visits to their facilities to assess production capabilities. Additionally, ensure they have a robust supply chain and can meet your demand consistently. -

What are the key factors to consider when choosing sock job suppliers?

When selecting suppliers, consider their production capacity, lead times, and flexibility to accommodate changes in orders. Evaluate their pricing structure and compare it with the quality of their products. It’s also crucial to assess their communication responsiveness and willingness to collaborate on design changes. Establishing a good rapport can lead to a more productive partnership over time.

Top 5 Sock Job Manufacturers & Suppliers List

1. XVideos – Sockjob Videos

Domain: xvideos.com

Registered: 1997 (28 years)

Introduction: sockjob videos, 96 results, categories include amateur, foot fetish, various sock styles (knee-high, ankle, mismatched), video lengths range from 4 seconds to 20 minutes, video quality available in 720p, 1080p, and 1440p, popular tags include footjob, cumshot, and sensual sockjob.

2. Sock Job – Comedy Film

Domain: imdb.com

Registered: 1996 (29 years)

Introduction: {“title”: “Sock Job”, “release_year”: 2016, “runtime”: “1h 10m”, “imdb_rating”: 6.6, “genre”: “Comedy”, “director”: “Mark Allen”, “writer”: “Mark Allen”, “star”: “Matthew Camp”, “release_date”: “December 31, 2016”, “country_of_origin”: “United States”, “language”: “English”, “filming_locations”: “Catskill, New York, USA”, “production_company”: “New York Foundation for the Arts”, “budget”: “$6,000 …

3. XNXX – Free Adult Videos

Domain: xnxx.com

Registered: 2002 (23 years)

Introduction: This company, XNXX – Free Adult Videos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Tubesafari – Free Sock Job Porn Videos

Domain: tubesafari.com

Registered: 2015 (10 years)

Introduction: Free Sock Job Porn Videos (4,480) – Tubesafari.com. Categories include Live Sex and Recommended Categories. Popular videos include: 6:24 She Controls His Cock and Moans – Rough Femdom Handjob with Tongue in His Ear, 31:53 Sockjob/Footjob & Handjob Cumshot Compilation, 6:48 Milked his cock in my SWEATY sock OUTSIDE on the balcony, 20:01 Sexy Sockjob, 7:13 Sasha Foxxx Sockjob, 13:19 Double sockjob f…

5. SpankBang – Free Sockjob Porn Videos

Domain: spankbang.com

Registered: 2011 (14 years)

Introduction: Sockjob Porn Videos: Free Sockjob Sex Videos – SpankBang. Categories include socks worship, shoejob, pantyhose footjob, nylon footjob, double footjob, and footjob cumshot. Video quality options: 720p, 1080p, 4k. Duration filters: 10+ minutes, 20+ minutes, 40+ minutes. Trending videos include various sockjob and footjob scenes featuring popular performers like Riley Reid, Smokie Flame, Kiara Cole, …

Strategic Sourcing Conclusion and Outlook for sock job

In conclusion, the strategic sourcing of sock job products presents a lucrative opportunity for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. Key takeaways from this guide emphasize the importance of understanding local market dynamics, including cultural preferences and purchasing behaviors. By leveraging strategic sourcing, businesses can enhance their competitive edge, improve supply chain efficiencies, and ultimately drive profitability.

Illustrative image related to sock job

Moreover, aligning sourcing strategies with regional demands can facilitate tailored marketing approaches that resonate with diverse consumer bases. As the market for sock job products continues to grow, staying ahead of trends and innovations will be crucial for success.

As you navigate your sourcing decisions, consider establishing partnerships with reliable suppliers who understand your unique needs and can deliver quality products. Embrace the potential of strategic sourcing to not only meet market demands but also to foster long-lasting relationships that can elevate your business in this dynamic landscape. Together, let’s shape the future of the sock job market and capitalize on the myriad opportunities it presents.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to sock job

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.