Top 5 Seat Check Valve Suppliers (And How to Choose)

Introduction: Navigating the Global Market for seat check valve

In the ever-evolving landscape of industrial applications, sourcing the right seat check valve can be a pivotal challenge for B2B buyers across diverse markets. With a myriad of options available—from soft-seated to metal-seated variants—understanding the nuances of each type is crucial for optimizing system performance and ensuring reliability. This guide serves as a comprehensive resource, delving into various types of seat check valves, their applications across sectors such as water management, oil and gas, and manufacturing, as well as critical considerations for supplier vetting and cost management.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—will find actionable insights tailored to their unique needs. The guide not only highlights the technical specifications and operational benefits of different valve types but also emphasizes the importance of compliance with regional standards and certifications. By equipping buyers with the knowledge to make informed purchasing decisions, this resource aims to streamline the procurement process, reduce downtime, and enhance overall operational efficiency. With the right information at their fingertips, B2B buyers can confidently navigate the complexities of the global market for seat check valves, ensuring they select products that align with their strategic objectives and operational requirements.

Understanding seat check valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soft Seated Check Valve | Utilizes elastomer O-ring for sealing; quieter operation. | Water treatment, hydraulic systems. | Pros: Tight seal, minimal leakage. Cons: Limited temperature and chemical compatibility. |

| Hard Seated Check Valve | Metal-on-metal sealing; more durable against wear. | Oil & gas, industrial applications. | Pros: Longer service life, versatile. Cons: May allow slight leakage; not suitable for all media. |

| Resilient Seated Check Valve | Ductile iron construction, fusion-bonded epoxy coating. | Municipal water systems, fire protection. | Pros: Zero leakage, minimal maintenance. Cons: Potentially higher initial cost. |

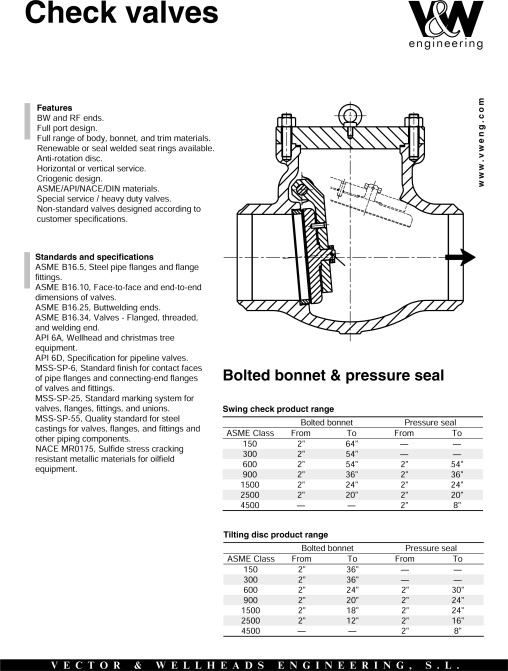

| Swing Check Valve | Disc swings on a hinge; suitable for large flow rates. | HVAC systems, drainage. | Pros: High flow capacity, simple design. Cons: Requires more space; can be affected by backflow. |

| Vertical Check Valve | Installed in a vertical position; compact design. | Pump systems, water supply. | Pros: Space-saving, efficient in tight areas. Cons: May require specific installation conditions. |

What are the Characteristics of Soft Seated Check Valves?

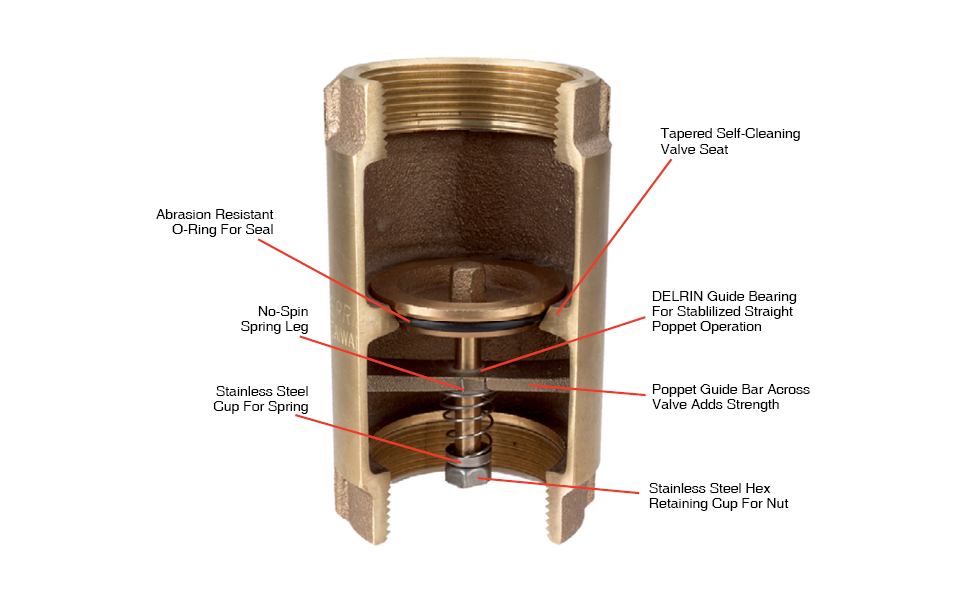

Soft seated check valves feature an elastomer O-ring that provides a reliable seal, making them ideal for applications requiring minimal leakage. These valves are particularly suitable for water treatment and hydraulic systems, where a tight seal is paramount. When purchasing, buyers should consider the compatibility of the elastomer with the medium being handled, as well as the operating temperature range. Although they offer quieter operation and reduced wear, their sensitivity to extreme conditions may limit their application in some industrial environments.

Why Choose Hard Seated Check Valves for Your Applications?

Hard seated check valves employ metal-on-metal contact to create a seal, which significantly enhances their durability against wear and tear. They are frequently used in oil and gas industries and other demanding environments due to their longer service life. When selecting these valves, buyers should assess the compatibility of the materials with the fluid medium and the acceptable leakage specifications, especially in critical applications where even minor leaks can have severe consequences. While they are versatile, their sealing may not be as tight as soft seated options.

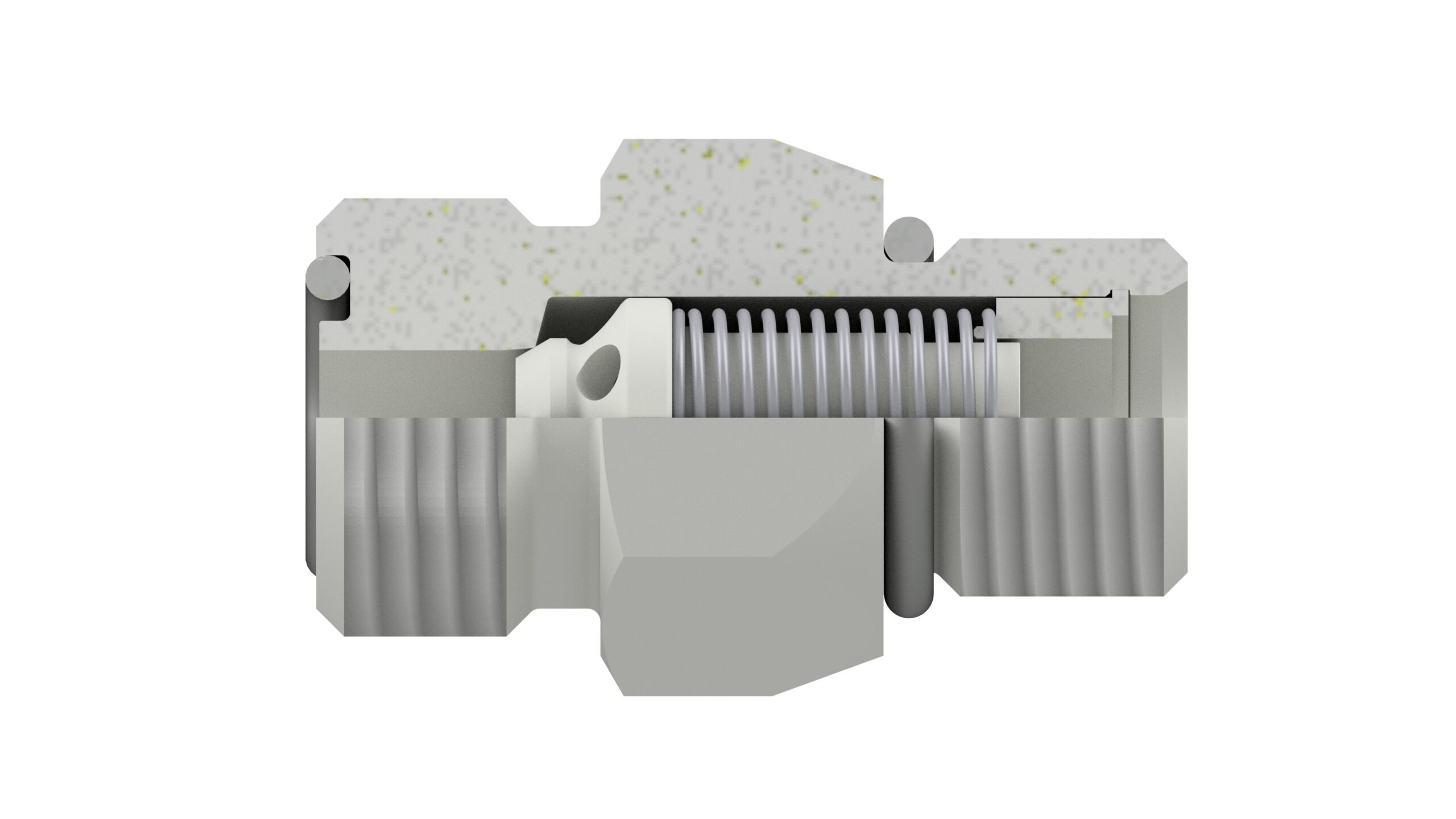

Illustrative image related to seat check valve

What Makes Resilient Seated Check Valves Stand Out?

Resilient seated check valves are constructed from ductile iron and coated with fusion-bonded epoxy, ensuring high performance in municipal water systems and fire protection applications. Their design allows for zero leakage and minimal maintenance, making them a cost-effective choice over time. Buyers should evaluate the initial investment against long-term savings from reduced maintenance and operational reliability. Additionally, the absence of traditional wear components reduces the risk of failure, making these valves a smart choice for critical installations.

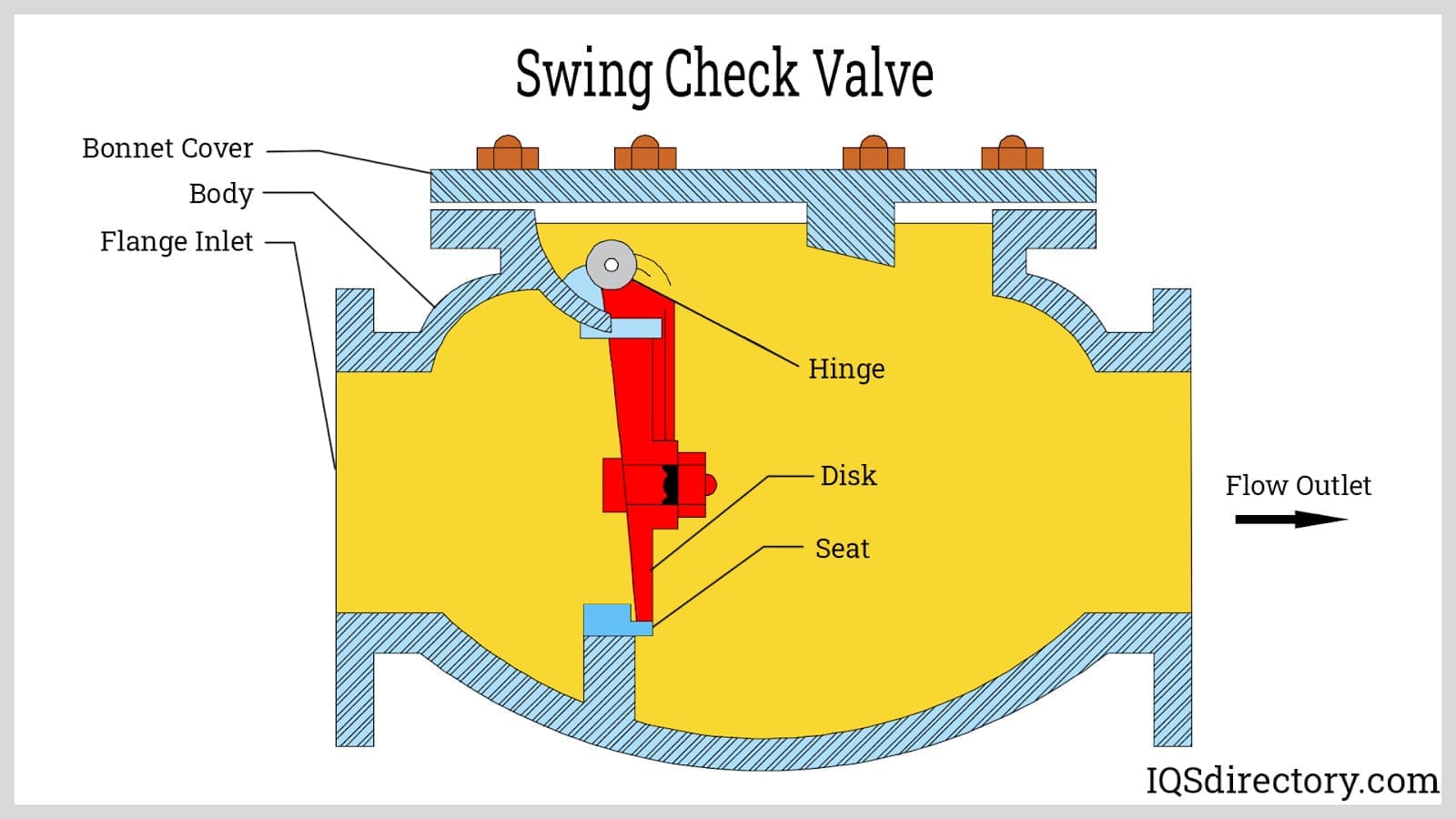

When Should You Use Swing Check Valves?

Swing check valves are designed with a disc that pivots on a hinge, allowing for high flow rates and simple operation. They are commonly used in HVAC systems and drainage applications. While they offer a straightforward design, buyers must consider the spatial requirements for installation and the potential for backflow issues. Their ability to handle large volumes of fluid makes them advantageous in various industrial contexts, but understanding the specific flow characteristics of the application is crucial for optimal performance.

How Do Vertical Check Valves Benefit Space-Constrained Installations?

Vertical check valves are specifically designed for installation in tight spaces, making them ideal for pump systems and water supply applications where horizontal space is limited. Their compact design allows for efficient operation in vertical orientations. Buyers should ensure that installation conditions are suitable for vertical valves, as improper placement can lead to performance issues. While they offer space-saving advantages, considerations regarding flow direction and mounting stability are essential for effective operation.

Key Industrial Applications of seat check valve

| Industry/Sector | Specific Application of seat check valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater Management | Backflow prevention in municipal water systems | Ensures safe drinking water by preventing contamination | Compliance with local regulations and certifications (e.g., NSF) |

| Oil and Gas | Flow control in pipeline systems | Protects equipment from reverse flow and pressure surges | Material compatibility with hydrocarbons and high-pressure ratings |

| Agriculture | Irrigation systems for crop management | Maintains consistent water supply, enhancing crop yield | Durability against sediment and corrosion in varying climates |

| HVAC Systems | Preventing backflow in heating and cooling units | Increases system efficiency and lifespan | Temperature and pressure ratings suitable for specific HVAC needs |

| Chemical Processing | Control of corrosive substances in pipelines | Minimizes leaks and ensures safety in handling chemicals | Material selection based on chemical compatibility and temperature limits |

How is a seat check valve used in water and wastewater management?

In water and wastewater management, seat check valves are crucial for backflow prevention in municipal systems. They ensure that contaminated water does not flow back into the clean water supply, safeguarding public health. Buyers in this sector must prioritize valves that comply with local regulations and certifications such as NSF/ANSI 61, which ensures the materials used are safe for drinking water. Additionally, the valve’s design should facilitate easy installation and maintenance, reducing downtime and operational costs.

What role do seat check valves play in the oil and gas industry?

In the oil and gas sector, seat check valves are integral to flow control in pipeline systems. They prevent reverse flow and pressure surges, which can lead to equipment damage and hazardous leaks. For buyers, it is essential to source valves made from materials that are compatible with hydrocarbons and can withstand high-pressure conditions. Additionally, valves should be designed for easy maintenance to minimize disruptions in operations, especially in remote locations where access to parts may be limited.

How do seat check valves benefit agricultural irrigation systems?

Seat check valves are employed in irrigation systems to maintain a consistent water supply for crop management. By preventing backflow, they help ensure that water flows in the desired direction, which is crucial for effective irrigation. This leads to improved crop yields and resource efficiency. Buyers in agriculture should consider the valve’s durability against sediment and corrosion, especially in regions with varying climate conditions. Additionally, sourcing valves that can handle fluctuations in pressure and flow rates is vital for optimal performance.

Why are seat check valves important in HVAC systems?

In HVAC systems, seat check valves prevent backflow, ensuring that heated or cooled air circulates efficiently without contamination from return lines. This functionality enhances system efficiency and prolongs the lifespan of HVAC equipment. Buyers should focus on valves that meet specific temperature and pressure ratings suited to their HVAC applications. Moreover, selecting valves that are easy to install and maintain can significantly reduce operational downtime and costs, making them a smart investment for facility managers.

How are seat check valves utilized in chemical processing?

In chemical processing, seat check valves are essential for controlling the flow of corrosive substances within pipelines. They minimize the risk of leaks and ensure safety during the handling of hazardous materials. Buyers must pay close attention to material selection, ensuring compatibility with the specific chemicals being processed and adherence to temperature limits. Additionally, sourcing valves that offer reliable sealing and are designed for easy maintenance can enhance operational safety and efficiency, making them critical components in chemical facilities.

Illustrative image related to seat check valve

3 Common User Pain Points for ‘seat check valve’ & Their Solutions

Scenario 1: Frequent Valve Failures Leading to System Downtime

The Problem: A manufacturing plant in Nigeria is facing frequent failures of their check valves, leading to unexpected downtime and costly repairs. The current metal-seated check valves are suffering from wear and tear due to abrasive materials in the fluid they handle. This not only disrupts operations but also affects production schedules and increases maintenance costs, frustrating the management team.

The Solution: To address this issue, the plant should consider switching to soft-seated check valves made from materials that offer better resistance to abrasion and chemical compatibility. When sourcing these valves, it’s essential to evaluate the specific application requirements, including the type of fluid, temperature, and pressure conditions. Opting for valves with a fusion-bonded epoxy coating can also enhance durability and prevent corrosion. Additionally, implementing a regular maintenance schedule that includes inspections can help identify wear before it leads to failure, allowing for proactive replacements rather than reactive repairs.

Scenario 2: Incompatibility Issues Causing Leaks

The Problem: A water treatment facility in Germany is experiencing leaks from their check valves, which compromises the integrity of the system and poses regulatory compliance issues. The existing valves are made of materials that are not compatible with the chemicals used in the treatment process, leading to seal degradation and leaks that result in costly fines and environmental concerns.

The Solution: The facility should conduct a thorough assessment of the materials used in their check valves, focusing on chemical compatibility with the fluids they handle. Transitioning to resilient seated check valves, which utilize elastomeric seals designed for chemical resistance, can mitigate this issue. When specifying these valves, ensure they meet relevant industry standards, such as NSF/ANSI certifications for potable water applications. Additionally, consider investing in training for maintenance personnel to recognize signs of seal wear early, allowing for timely replacements and preventing leaks before they become a significant problem.

Scenario 3: Difficulty in Sourcing the Right Size and Type

The Problem: A construction company in South America is struggling to find the correct size and type of check valves for a large irrigation project. The specifications are unique due to the varying pressure requirements and flow rates across different sections of the system. This has led to project delays, increased costs, and frustration among project managers.

The Solution: To overcome sourcing difficulties, the company should engage with suppliers who offer a diverse range of check valve sizes and types. Utilizing a vendor who can provide customized solutions may also be beneficial. It’s crucial to communicate specific project needs, including pressure ratings, flow characteristics, and material preferences, to ensure the right product is sourced. Additionally, collaborating with an engineering consultant during the design phase can help in accurately determining the specifications needed, preventing delays and ensuring that the right check valves are procured from the outset. This proactive approach will streamline the procurement process and contribute to the project’s overall success.

By understanding these common pain points and implementing the suggested solutions, B2B buyers can enhance their operations, reduce costs, and maintain compliance in their respective industries.

Strategic Material Selection Guide for seat check valve

What Are the Key Properties of Common Materials Used in Seat Check Valves?

When selecting materials for seat check valves, it is essential to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials: brass, cast iron, stainless steel, and ductile iron.

Illustrative image related to seat check valve

How Does Brass Perform as a Material for Seat Check Valves?

Brass is a popular choice for smaller check valves, particularly in applications involving water and low-pressure systems. Key properties include good corrosion resistance, moderate temperature tolerance (up to 200°F), and a pressure rating typically around 150 PSI.

Pros: Brass is lightweight, easy to machine, and cost-effective for small-scale applications. Its corrosion resistance makes it suitable for potable water systems.

Cons: However, brass can be susceptible to dezincification in aggressive environments, which may lead to premature failure. Additionally, its pressure rating limits its use in high-pressure applications.

Impact on Application: Brass seat check valves are ideal for low to moderate pressure applications, especially in residential plumbing and irrigation systems.

What Advantages Does Cast Iron Offer for Check Valves?

Cast iron is favored for larger check valves, especially in industrial and municipal applications. It boasts high tensile strength, excellent durability, and can handle higher temperatures (up to 450°F) and pressures (up to 200 PSI).

Pros: The material’s robustness makes it suitable for heavy-duty applications, and its ability to withstand high pressures and temperatures adds to its versatility.

Cons: Cast iron is heavier and more expensive to manufacture, which can increase shipping costs. Additionally, it is prone to corrosion if not properly coated or maintained.

Illustrative image related to seat check valve

Impact on Application: Cast iron check valves are often used in water treatment plants, oil and gas industries, and other applications where durability is critical.

Why Choose Stainless Steel for Seat Check Valves?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it suitable for a wide range of applications, including those involving harsh chemicals. It can withstand temperatures up to 800°F and pressures exceeding 300 PSI, depending on the grade.

Pros: The material’s durability and resistance to corrosion make it ideal for harsh environments. Stainless steel also has a long service life, reducing the need for frequent replacements.

Cons: The primary drawback is its higher cost compared to brass and cast iron, which may deter budget-sensitive projects. Additionally, manufacturing stainless steel components can be more complex.

Impact on Application: Stainless steel seat check valves are commonly used in chemical processing, food and beverage industries, and marine applications where corrosion resistance is paramount.

What Makes Ductile Iron a Preferred Material for Check Valves?

Ductile iron combines the strength of cast iron with enhanced ductility, making it an excellent choice for check valves. It typically has a pressure rating of up to 250 PSI and can handle temperatures up to 250°F.

Pros: Ductile iron is lighter than traditional cast iron, easier to handle, and offers superior tensile strength. Its resistance to corrosion can be enhanced with protective coatings.

Cons: While ductile iron is more cost-effective than stainless steel, it may still be more expensive than brass. Moreover, it requires proper maintenance to prevent corrosion.

Impact on Application: Ductile iron check valves are widely used in municipal water systems, wastewater treatment, and fire protection systems due to their balance of strength and weight.

Summary Table of Material Selection for Seat Check Valves

| Material | Typical Use Case for seat check valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Residential plumbing, irrigation | Good corrosion resistance | Susceptible to dezincification | Low |

| Cast Iron | Industrial, municipal applications | High strength and durability | Heavy, prone to corrosion | Med |

| Stainless Steel | Chemical processing, food industry | Exceptional corrosion resistance | Higher cost, complex manufacturing | High |

| Ductile Iron | Municipal water, wastewater treatment | Superior strength and ductility | Requires maintenance to prevent corrosion | Med |

This guide provides a comprehensive overview of the materials used in seat check valves, allowing B2B buyers to make informed decisions based on their specific application needs and regional standards.

Illustrative image related to seat check valve

In-depth Look: Manufacturing Processes and Quality Assurance for seat check valve

What Are the Main Stages in the Manufacturing Process of Seat Check Valves?

The manufacturing process of seat check valves involves several critical stages that ensure the final product meets industry standards and customer specifications. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials used for seat check valves include brass, stainless steel, and ductile iron. The choice of material is crucial, as it directly affects the valve’s durability, resistance to corrosion, and suitability for various applications.

Once the materials are selected, they undergo several processes such as cutting, machining, and heat treatment. For instance, ductile iron components may be subjected to a heat treatment process to enhance their tensile strength and durability. Quality assurance begins at this stage, with incoming quality control (IQC) checks ensuring that the materials meet specified standards.

How Are Seat Check Valves Formed?

After material preparation, the next step is forming the components. This typically involves machining processes such as turning, milling, and drilling to create the valve body, disc, and seat. Advanced techniques like CNC (Computer Numerical Control) machining are often employed for precision and repeatability.

For soft-seated check valves, elastomeric materials are molded or extruded to form seals that provide a tight closure. In contrast, hard-seated valves require careful machining to ensure a perfect metal-to-metal seal. Throughout this stage, in-process quality control (IPQC) measures are implemented to monitor dimensions and tolerances, ensuring that components are within specifications.

What Does the Assembly Process Involve for Seat Check Valves?

The assembly of seat check valves involves bringing together all the machined components. This stage typically includes fitting the disc into the valve body and securing it with fasteners, often made of stainless steel for corrosion resistance. The assembly process must be conducted in a clean environment to prevent contamination and ensure the integrity of the seals.

Once assembled, the valves undergo a series of tests to check for leaks and ensure proper functionality. These tests are critical, as they directly impact the performance of the valve in real-world applications. Final quality checks (FQC) are performed at this stage to ensure the assembled product meets all specified criteria.

What Finishing Techniques Are Commonly Used for Seat Check Valves?

Finishing processes enhance both the aesthetic and functional characteristics of seat check valves. Common techniques include surface treatment, painting, and coating. For instance, fusion-bonded epoxy coatings are often applied to prevent corrosion, especially in valves intended for use in harsh environments.

Polishing may also be employed to create a smooth finish, reducing the potential for debris accumulation in the valve body. Each finishing technique is selected based on the intended application of the valve and the specific requirements outlined by the customer.

Which International Standards Govern the Quality Assurance of Seat Check Valves?

Quality assurance for seat check valves is governed by several international standards, ensuring that products meet safety and performance criteria. One of the most widely recognized standards is ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has implemented effective processes for quality control throughout the production cycle.

In addition to ISO standards, industry-specific certifications such as CE marking for the European market and API standards for the oil and gas industry may apply. These certifications require adherence to stringent testing and quality assurance processes, providing further assurance to B2B buyers regarding product reliability and safety.

What Are Common Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are critical at various stages of the manufacturing process to ensure that each valve meets the required specifications. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During production, regular inspections and tests are conducted to monitor dimensions and functionality.

-

Final Quality Control (FQC): Once the valves are assembled, they undergo rigorous testing for leaks, pressure ratings, and operational performance.

Testing methods may include hydrostatic testing, where the valve is subjected to water pressure to check for leaks, and functional testing to ensure proper operation.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial. Here are several ways to ensure that suppliers maintain high-quality standards:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This provides insights into the supplier’s adherence to international standards.

-

Documentation and Reports: Requesting documentation related to quality control processes, including inspection reports and certifications, can help buyers evaluate the supplier’s compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality assurance practices. This is especially important for buyers looking to establish long-term partnerships with reliable suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing seat check valves. Different regions may have specific regulations and standards that must be adhered to. For example, European buyers may require CE certification, while buyers in the Middle East may look for compliance with local regulations.

Understanding these nuances is vital for ensuring that products meet both local and international quality standards. Buyers should also consider the logistics of shipping and delivery, as these factors can impact the product’s quality upon arrival. Establishing clear communication with suppliers regarding quality expectations can mitigate risks and ensure a smooth procurement process.

By understanding the manufacturing processes and quality assurance practices associated with seat check valves, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘seat check valve’

When sourcing seat check valves, it’s essential to follow a structured approach to ensure you choose the right product for your specific needs. This guide outlines critical steps to help you navigate the procurement process effectively, ensuring you consider all relevant factors for your application.

Step 1: Define Your Technical Specifications

Start by determining the specific technical requirements for the seat check valve you need. Consider the valve size, pressure rating, and material compatibility with the fluids it will handle. This step is crucial because mismatched specifications can lead to operational failures and increased costs.

- Flow Characteristics: Understand the flow direction and pressure conditions in your system.

- Material Selection: Choose between metal-seated or soft-seated options based on your application’s requirements.

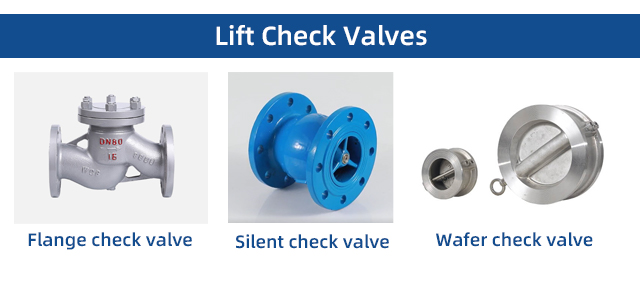

Step 2: Research Different Valve Types

There are various types of check valves, such as swing, lift, and ball check valves, each suited for different applications. Researching these types will help you identify which design is most effective for your system.

- Swing Check Valves: Often used in larger pipelines and can handle higher flow rates.

- Lift Check Valves: Suitable for applications with fluctuating pressures.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with international standards, such as ANSI, ISO, and NSF. This step ensures that the valves meet quality and safety requirements, which is particularly important when dealing with critical applications.

Illustrative image related to seat check valve

- Quality Assurance: Look for suppliers with a track record of quality manufacturing and testing.

- Regulatory Compliance: Ensure that the products are certified for the specific industry standards relevant to your region.

Step 4: Request Product Samples or Specifications

To assess the quality and suitability of the valves, request product samples or detailed specifications from potential suppliers. This allows you to evaluate the materials, design, and performance characteristics firsthand.

- Physical Inspection: Check for build quality, material integrity, and any signs of wear or defects.

- Performance Data: Review test results and specifications to ensure they align with your operational needs.

Step 5: Assess Lead Times and Availability

Understanding the lead times for delivery is vital for project planning. Inquire about the availability of the valves and the supplier’s capacity to fulfill orders on time.

- Production Capacity: Ensure the supplier can meet your demand, especially for large-scale projects.

- Shipping Options: Explore shipping methods and timeframes to minimize downtime.

Step 6: Compare Pricing and Terms

Once you have a shortlist of potential suppliers, compare their pricing structures and payment terms. Ensure that you understand what is included in the price, such as warranties, technical support, and after-sales service.

- Total Cost of Ownership: Consider long-term costs, including maintenance and potential replacements.

- Negotiation: Don’t hesitate to negotiate terms that work best for your budget and project timelines.

Step 7: Finalize Your Purchase Agreement

After selecting the supplier, finalize the purchase agreement. Ensure that all terms, including delivery schedules, payment conditions, and warranty details, are clearly outlined to avoid any misunderstandings.

- Legal Review: It may be beneficial to have a legal team review the contract to ensure compliance and protection of your interests.

- Post-Purchase Support: Confirm the availability of customer service for any future inquiries or issues.

By following this checklist, you can streamline your procurement process for seat check valves, ensuring that you make informed decisions that meet your operational needs.

Comprehensive Cost and Pricing Analysis for seat check valve Sourcing

What Are the Key Cost Components for Sourcing Seat Check Valves?

Understanding the cost structure of seat check valves is essential for international B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The type of materials used significantly impacts the cost. Common materials include brass, stainless steel, and cast iron, with variations such as soft-seated and hard-seated designs. Soft-seated valves typically cost more due to the inclusion of elastomer seals, which provide a tighter seal but can be more sensitive to temperature and chemical exposure.

-

Labor and Manufacturing Overhead: Labor costs vary by region and complexity of the valve design. Manufacturing overhead encompasses expenses related to the production process, including machinery, utilities, and indirect labor. These costs can fluctuate based on the supplier’s location and operational efficiencies.

-

Tooling: Tooling costs are influenced by the required molds and dies for production. Customization often necessitates higher tooling costs, which can be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Investing in quality control processes is crucial, especially for valves used in critical applications. Suppliers with certifications (e.g., ANSI, NSF) may charge a premium for ensuring compliance with international standards, but this can reduce the risk of failures and associated costs in the long run.

-

Logistics: Shipping costs can vary widely based on the supplier’s location, order size, and chosen Incoterms. Buyers should consider both freight charges and potential tariffs when sourcing internationally, as these can significantly influence overall costs.

-

Margin: Suppliers typically apply a margin that accounts for their operational costs and profit goals. Understanding the market dynamics and competitor pricing can help buyers negotiate better margins.

What Factors Influence Pricing for Seat Check Valves?

Several factors influence the pricing of seat check valves, which buyers should be aware of to make informed purchasing decisions.

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger volumes. Suppliers typically offer tiered pricing structures, so understanding the MOQ can help buyers optimize their orders for cost savings.

-

Specifications and Customization: Custom specifications, such as unique sizes or materials, can lead to higher costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Quality and Certifications: Valves that comply with specific industry standards or have additional certifications will generally be more expensive. However, investing in higher-quality products can reduce maintenance and replacement costs, contributing to a lower total cost of ownership.

-

Supplier Factors: The supplier’s reputation, reliability, and historical performance can also impact pricing. Established suppliers may charge a premium, but their track record can justify the cost through better service and quality assurance.

-

Incoterms: The terms of shipping and delivery can affect the overall cost. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers gauge their total landed costs.

How Can Buyers Negotiate Better Prices for Seat Check Valves?

International buyers should employ strategic negotiation tactics to optimize costs while ensuring quality.

-

Leverage Volume Discounts: Communicate expected order volumes to suppliers to negotiate better pricing. Bulk purchases can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also long-term costs associated with maintenance, reliability, and downtime. This holistic view can justify higher upfront costs for superior products.

-

Understand Regional Pricing Nuances: Familiarize yourself with market conditions in different regions. For instance, prices may vary significantly between Europe and Africa due to local manufacturing capabilities and supply chain dynamics.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers who demonstrate loyalty and reliability.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide a benchmark for pricing and create competition, leading to better deals.

In conclusion, understanding the cost components, pricing influences, and negotiation strategies can empower B2B buyers to make informed decisions when sourcing seat check valves. A thorough analysis will not only ensure competitive pricing but also enhance the overall purchasing strategy.

Alternatives Analysis: Comparing seat check valve With Other Solutions

When evaluating fluid control solutions, it’s essential to consider the various alternatives to the seat check valve. This analysis will explore two viable alternatives: the swing check valve and the resilient seated check valve. Each option has distinct advantages and limitations, making them suitable for different applications.

| Comparison Aspect | Seat Check Valve | Swing Check Valve | Resilient Seated Check Valve |

|---|---|---|---|

| Performance | Excellent for high back pressure; prevents backflow effectively. | Good for low to moderate pressure; may slam closed, causing water hammer. | Offers zero leakage at low pressures; less prone to slam due to unique geometry. |

| Cost | Generally moderate; varies by material and size. | Often lower initial cost; however, may incur higher maintenance costs over time. | Typically higher due to advanced materials and design features. |

| Ease of Implementation | Simple installation; compatible with many systems. | Straightforward installation; requires adequate space for operation. | Slightly more complex due to additional features, but still manageable. |

| Maintenance | Low maintenance; fewer moving parts. | Moderate; may require regular inspection for wear and tear. | Minimal; only one moving part, reducing failure points. |

| Best Use Case | Ideal for high-pressure applications in critical systems. | Suitable for gravity-fed systems or low-pressure applications. | Best for municipal water systems and applications requiring minimal leakage. |

What are the Advantages and Disadvantages of Swing Check Valves?

Swing check valves are widely used due to their cost-effectiveness and straightforward design. They operate by using a disc that swings open and closed based on flow direction. The primary advantage is their lower initial cost, making them attractive for budget-conscious projects. However, they can pose challenges in high-pressure applications due to the potential for water hammer, which can lead to system damage over time. Regular maintenance is necessary to inspect the disc for wear, which can increase long-term costs.

How Do Resilient Seated Check Valves Compare?

Resilient seated check valves provide a modern solution with a focus on reliability and efficiency. They feature a ductile iron body with a rubber-encapsulated disc, ensuring a tight seal that minimizes leakage. This design is particularly beneficial for municipal water systems where maintaining water quality is paramount. Although they may come with a higher upfront cost, their long-term reliability and low maintenance needs can justify the investment. Their unique design also reduces the risk of water hammer, enhancing system longevity.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers, selecting the appropriate valve solution hinges on specific application needs, budget constraints, and long-term maintenance considerations. If high pressure and minimal leakage are critical, the seat check valve may be the best choice. In contrast, for projects with lower budgets and pressure requirements, swing check valves could suffice. Resilient seated check valves represent a robust option for applications demanding high reliability and minimal maintenance. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for seat check valve

What are the Key Technical Properties of Seat Check Valves?

Understanding the technical specifications of seat check valves is crucial for B2B buyers, as these properties directly impact performance, reliability, and suitability for specific applications. Below are several critical specifications to consider:

Illustrative image related to seat check valve

-

Material Grade

– Definition: The grade of material used in the valve, such as ductile iron, brass, or stainless steel.

– Importance: Material selection affects corrosion resistance, durability, and pressure ratings. For instance, stainless steel is ideal for high-pressure applications, while ductile iron offers superior strength and resistance to wear. -

Pressure Rating

– Definition: The maximum pressure that a valve can withstand without failure, typically measured in PSI (pounds per square inch).

– Importance: Knowing the pressure rating is vital to ensure the valve can handle the specific demands of your system. Using a valve with an inadequate pressure rating can lead to leaks or failures, impacting operational efficiency. -

Temperature Tolerance

– Definition: The range of temperatures within which the valve can operate effectively, often specified in degrees Fahrenheit or Celsius.

– Importance: Different applications may expose valves to extreme temperatures. Selecting a valve with the right temperature tolerance ensures reliable performance in varying conditions, such as steam or hot water applications. -

Flow Coefficient (Cv)

– Definition: A measure of the valve’s capacity to allow fluid flow; higher Cv values indicate greater flow capacity.

– Importance: This specification helps buyers assess the efficiency of the valve in their specific systems. A valve with an appropriate Cv can optimize flow rates and reduce energy costs. -

Seal Type

– Definition: The mechanism used to prevent backflow, which can be either hard-seated (metal-to-metal) or soft-seated (using elastomeric materials).

– Importance: Soft-seated valves typically provide a tighter seal, reducing leakage. However, hard-seated valves may have a longer service life in abrasive environments. Understanding the seal type helps buyers choose the right valve for their application needs. -

End Connections

– Definition: The type of fittings used to connect the valve to piping systems, such as flanged, threaded, or welded connections.

– Importance: Proper end connections ensure compatibility with existing systems and facilitate easier installation. This consideration can save time and resources during the procurement process.

What are the Common Trade Terms Related to Seat Check Valves?

Navigating the B2B landscape requires familiarity with specific terminology that streamlines communication and transaction processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. It can affect procurement strategies, especially for smaller businesses or projects. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price proposals from suppliers for specific goods or services.

– Importance: An RFQ allows buyers to compare pricing and terms from multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC).

– Importance: Incoterms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, reducing the risk of misunderstandings in cross-border transactions. -

Lead Time

– Definition: The time it takes from placing an order to delivery.

– Importance: Understanding lead times is critical for project planning and inventory management. Delays can impact operational timelines, so it’s essential to factor this into procurement decisions. -

Certification Compliance

– Definition: The process of ensuring that products meet industry standards and regulations.

– Importance: Certifications, such as NSF/ANSI for drinking water applications, assure buyers of product safety and reliability, making them vital for regulatory compliance in various markets.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding seat check valves, ensuring they select the right products for their operational needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the seat check valve Sector

What Are the Current Market Dynamics and Key Trends in the Seat Check Valve Sector?

The global seat check valve market is witnessing significant growth driven by increasing industrialization and infrastructure development across various regions, especially in Africa, South America, the Middle East, and Europe. The demand for reliable and efficient fluid control systems in sectors such as oil and gas, water treatment, and manufacturing is propelling the market forward. With the ongoing push for automation and smart manufacturing, B2B buyers are increasingly seeking check valves integrated with advanced technologies like IoT for real-time monitoring and predictive maintenance.

Emerging trends include a shift towards soft-seated check valves, which offer superior sealing capabilities and reduced leakage, making them preferable in critical applications where fluid integrity is paramount. The rise of sustainability initiatives is also reshaping sourcing practices, with buyers prioritizing suppliers that adhere to environmentally friendly manufacturing processes. Additionally, as regulatory frameworks tighten globally, compliance with standards such as NSF/ANSI and AWWA is becoming essential for suppliers to gain market access.

International buyers must navigate a complex landscape of local regulations and standards, particularly in diverse markets like Nigeria and Germany. Understanding regional supply chain dynamics, including logistics and tariffs, is crucial for optimizing procurement strategies. Moreover, the increasing availability of online platforms for sourcing valves offers buyers greater flexibility and access to competitive pricing, enhancing their ability to make informed purchasing decisions.

How Are Sustainability and Ethical Sourcing Impacting the Seat Check Valve Market?

Sustainability is a critical consideration in the seat check valve sector, as environmental concerns influence procurement decisions. The production of check valves often involves materials and processes that can have significant ecological footprints. Therefore, B2B buyers are increasingly drawn to manufacturers that utilize sustainable practices, such as reducing waste, conserving energy, and minimizing emissions during production.

Illustrative image related to seat check valve

Ethical sourcing is equally important, as companies seek to ensure that their supply chains are free from exploitation and contribute positively to local communities. Buyers are advised to look for suppliers that have transparent supply chains and are certified by recognized environmental and social governance standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) provide assurance of a company’s commitment to sustainable practices.

Furthermore, the use of ‘green’ materials, such as recycled metals and eco-friendly coatings, is gaining traction. These materials not only reduce the environmental impact but also appeal to a growing segment of customers who prioritize sustainability. By selecting suppliers that align with these values, B2B buyers can enhance their brand reputation and meet the increasing demand for environmentally responsible products.

How Has the Seat Check Valve Sector Evolved Over Time?

The evolution of seat check valves dates back to the early days of industrialization when the need for reliable fluid control mechanisms became apparent. Initially, check valves were predominantly metal-seated, providing durability but often suffering from issues related to leakage. As technology advanced, manufacturers began to innovate, leading to the introduction of soft-seated check valves that significantly improved sealing performance and reduced maintenance needs.

The development of new materials, such as ductile iron and advanced elastomers, has further enhanced the performance and longevity of check valves. Today, the focus is not only on functionality but also on integrating smart technologies that allow for better monitoring and control of fluid systems. This evolution reflects the industry’s response to the growing demands for efficiency, reliability, and sustainability, positioning the seat check valve sector as a vital component in modern industrial applications.

By understanding these dynamics, B2B buyers can make more informed decisions, ensuring they select the right products that meet their operational needs while aligning with broader sustainability goals.

Illustrative image related to seat check valve

Frequently Asked Questions (FAQs) for B2B Buyers of seat check valve

-

How do I determine the right size of a seat check valve for my application?

To select the appropriate size of a seat check valve, consider the pipe diameter and the flow rate of the medium being transported. The valve size should match the pipe size to ensure minimal pressure drop and optimal flow efficiency. Additionally, evaluate the application’s pressure and temperature conditions to ensure compatibility. Consulting with manufacturers or suppliers can provide insights into sizing charts and help confirm the best valve type for your specific needs. -

What materials are commonly used in seat check valves, and which is best for my application?

Seat check valves are typically made from materials such as brass, stainless steel, ductile iron, and PVC. Brass and stainless steel are preferred for their corrosion resistance and durability, making them suitable for water and oil applications. Ductile iron is often used in larger valves due to its strength. The choice of material should align with the medium’s chemical compatibility, temperature, and pressure requirements to ensure long-term performance. -

What are the key features to look for in a reliable seat check valve?

When sourcing a seat check valve, prioritize features such as a robust sealing mechanism, material durability, and pressure ratings. Look for valves with a minimal number of moving parts for easier maintenance and reduced risk of failure. Additional features like backflushing capabilities and zero-leakage ratings are also important, particularly for critical applications. Certifications such as NSF/ANSI compliance can further indicate the valve’s reliability and safety. -

What are the typical lead times for seat check valve orders?

Lead times for seat check valves can vary based on the supplier, order quantity, and customization requirements. Generally, standard valves may have a lead time of 2-4 weeks, while custom specifications could extend this to 6-8 weeks or more. It’s advisable to confirm production and shipping timelines with the supplier during the ordering process to align with your project schedules. -

What are the minimum order quantities (MOQs) for seat check valves?

Minimum order quantities for seat check valves vary by manufacturer and supplier. Some may offer flexible MOQs for standard products, while custom valves often require higher MOQs due to the complexity of production. As a buyer, clarify MOQs before placing an order, especially when sourcing from international suppliers, to ensure that the quantities meet your operational needs without incurring unnecessary costs. -

How can I ensure quality assurance (QA) for the seat check valves I purchase?

To ensure quality assurance when sourcing seat check valves, request certifications and compliance documentation from suppliers. Look for manufacturers that adhere to international standards such as ISO 9001, which indicates a commitment to quality management systems. Additionally, consider conducting third-party inspections or audits, especially for larger orders or critical applications, to verify product quality before shipment. -

What payment terms should I negotiate when purchasing seat check valves internationally?

When negotiating payment terms for international purchases of seat check valves, consider options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60 days). Ensure that the terms align with your cash flow and risk management strategies. It’s also beneficial to discuss currency options and potential fluctuations that may affect the final price, particularly when dealing with suppliers from different countries. -

What logistics considerations should I keep in mind when importing seat check valves?

When importing seat check valves, consider shipping methods, customs clearance processes, and potential tariffs or duties that may apply. Choose a reliable logistics provider experienced in handling industrial products to ensure timely delivery. It’s crucial to verify that the valves meet local regulatory requirements to avoid delays at customs. Additionally, factor in lead times for both production and shipping to plan your inventory needs effectively.

Top 5 Seat Check Valve Manufacturers & Suppliers List

1. Irrigation King – 8 Cast Iron Swing Check Valve

Domain: irrigationking.com

Registered: 2016 (9 years)

Introduction: {“name”: “8” Cast Iron Swing Check Valve – Metal Seated”, “price”: {“original”: “$1,406.15”, “special”: “$1,301.27”}, “size”: “8””, “design_standard”: “MSS SP-71”, “connections”: “Flanged / ANSI 125”, “pressure_rating”: {“200_PSI”: “-20° to 150° F”, “125_PSI”: “450° F”}, “length”: “19.5””, “weight”: “247 lbs”, “availability”: “In stock, Only 6 left”, “sku”: “VK-SWC-308”, “features”: [“Suitable for…

2. AMERICAN – Series 2100 Resilient Seated Check Valves

Domain: american-usa.com

Registered: 2008 (17 years)

Introduction: Series 2100 Resilient Seated Check Valves by AMERICAN are designed for durability and improved performance over traditional metal-seated swing check valves. Key features include:

– Lightweight ductile iron body and bonnet, coated with fusion bonded epoxy.

– Type 304 stainless steel fasteners.

– Ductile iron has over twice the tensile strength of gray cast iron.

– Complies with ANSI/AWWA C508 a…

3. Electro Solenoid – Stainless Steel Swing Check Valve

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Stainless Steel Swing Check Valve”,”SKU”: “CV-S0-S”,”Availability”: “In Stock”,”Port Sizes”: [“1/2 inch”,”3/4 inch”,”1 inch”,”1-1/4 inch”,”1-1/2 inch”,”2 inch”],”Price”: “$19.58″,”Body Material”: “304 Stainless Steel”,”Disc Material”: “304 Stainless Steel”,”Hangar Pin”: “304 Stainless Steel”,”Plug Gasket”: “PTFE”,”Flow”: “Uni-Directional”,”Temperature Range”: “-4 to 356° F / -20 …

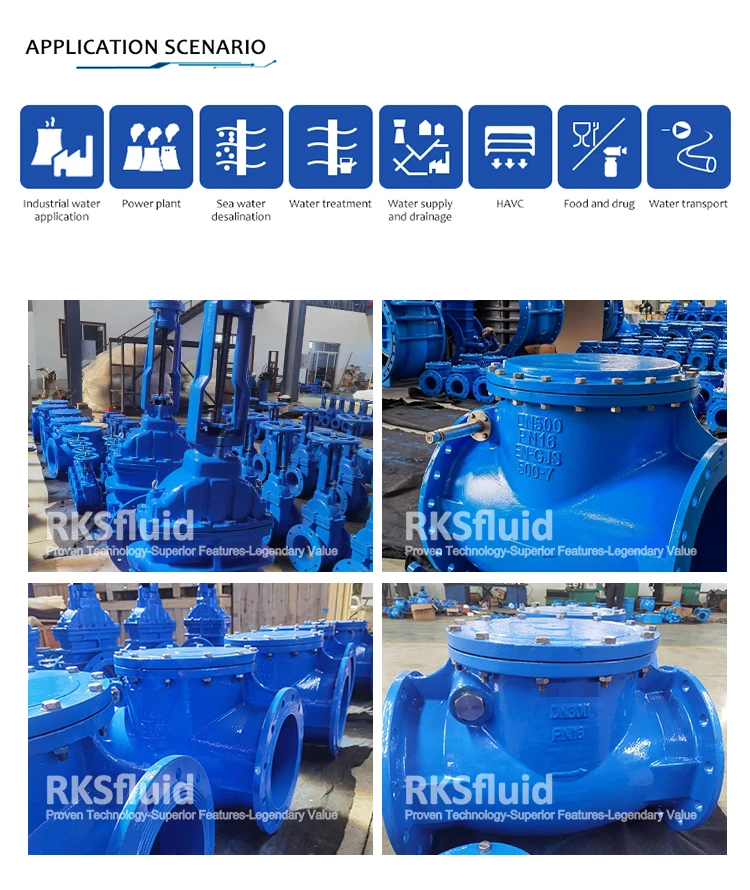

4. Flomatic – Swing Check Valves

Domain: flomatic.com

Registered: 1996 (29 years)

Introduction: Swing Check Valves are designed for water and wastewater applications, featuring a globe style valve body with a hinged valve disc to block reverse flow. They are available in metal-to-metal seat or resilient seating options, with resilient seated valves recommended for wastewater applications where dirt or particles may be present. The operation relies on gravity and reverse flow, with an externa…

5. Dynamic Fluid Components – VU Soft Seat Check Valve

Domain: dynamicfc.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “VU Soft Seat Check Valve”, “manufacturer”: “Dynamic Fluid Components, Inc.”, “address”: “2810 Blue Ridge Blvd West Union, SC 29696”, “phone”: “864-638-5544”, “construction_material”: “carbon steel”, “seal_material”: “Buna-N”, “cracking_pressure_options”: [“7 lb”, “70 lb”], “maximum_pressure”: “10,000 psi”, “thread_size_options”: [“1/4″ NPT”, “3/8″ NPT”, “1/2″ NPT”, “3/4″ NPT”, “1…

Strategic Sourcing Conclusion and Outlook for seat check valve

As the global demand for efficient fluid control solutions grows, the strategic sourcing of seat check valves becomes increasingly crucial for businesses across diverse industries. Understanding the differences between soft and hard seat options, as well as the specific applications of each type, allows buyers to make informed decisions that align with their operational needs. The benefits of resilient seated check valves, such as reduced maintenance and superior sealing performance, exemplify the importance of investing in high-quality products that enhance system reliability.

International buyers from regions like Africa, South America, the Middle East, and Europe must prioritize sourcing partners who not only offer competitive pricing but also ensure compliance with international quality standards. This commitment to quality will minimize downtime and operational disruptions, ultimately leading to cost savings and improved productivity.

Looking ahead, the evolving landscape of manufacturing and infrastructure development presents significant opportunities for businesses willing to invest in advanced valve technologies. By establishing strong supplier relationships and embracing innovative solutions, companies can position themselves for sustained growth in a competitive market. Now is the time to evaluate your sourcing strategy—partner with trusted suppliers and secure the best seat check valves to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.