Top 5 Plastic Crate Vs Wire Crate Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plastic crate vs wire crate

In today’s competitive landscape, sourcing the right storage solutions, such as plastic crates versus wire crates, can significantly impact operational efficiency and cost management for businesses. With diverse applications across various industries—ranging from agriculture and logistics to retail and manufacturing—understanding the nuances between these two crate types is essential. This guide delves into the key differences between plastic and wire crates, exploring their structural integrity, durability, and suitability for specific uses.

International B2B buyers, particularly those in Africa, South America, the Middle East, and Europe (including Germany and Vietnam), face unique challenges in selecting the most appropriate storage solutions. Factors such as local market conditions, supply chain dynamics, and cost implications can complicate the decision-making process. This comprehensive guide empowers buyers by providing actionable insights on types, applications, supplier vetting, and pricing strategies, enabling informed purchasing decisions that align with their specific operational needs.

By equipping businesses with the knowledge to evaluate the benefits and limitations of plastic and wire crates, this resource serves as a crucial tool for enhancing logistical efficiency and optimizing storage practices. Whether you’re looking to invest in long-lasting solutions or seeking cost-effective options, understanding the right crate for your operations is key to driving success in the global market.

Understanding plastic crate vs wire crate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Crates | Durable, non-toxic materials, often stackable | Food storage, pharmaceuticals, logistics | Pros: Long-lasting, easy to clean. Cons: Prone to chewing by aggressive animals. |

| Wire Crates | Lightweight, collapsible, often with a removable tray | Pet care, transport, temporary storage | Pros: Easy to transport and store. Cons: Less durable, can injure pets. |

| Heavy-Duty Plastic Crates | Reinforced construction, often escape-proof | Industrial shipping, heavy-duty storage | Pros: High durability, secure. Cons: Bulkier, may require more space. |

| Collapsible Wire Crates | Folds flat for storage, often adjustable | Temporary housing, travel, exhibitions | Pros: Space-saving, versatile. Cons: Less secure, can be flimsy. |

| Insulated Plastic Crates | Temperature control, insulated walls | Food transportation, sensitive materials | Pros: Maintains temperature, durable. Cons: Heavier, can be more expensive. |

What Are the Key Characteristics of Plastic Crates in B2B Settings?

Plastic crates are widely recognized for their durability and resistance to moisture, making them ideal for various applications, including food storage and pharmaceuticals. They are often stackable, which optimizes storage space and facilitates easy transport. When considering plastic crates, B2B buyers should evaluate the material quality, ensuring it meets industry standards for safety and hygiene. Additionally, while they are generally robust, buyers should be aware of potential chewing damage from animals, which could necessitate choosing heavier-duty options for certain applications.

How Do Wire Crates Compare for B2B Use?

Wire crates are lightweight and designed for convenience, making them suitable for temporary storage and transport, especially in the pet care industry. Their collapsible nature allows for easy storage when not in use, which can be advantageous for businesses with limited space. However, buyers should consider the structural integrity of wire crates, as they may not withstand aggressive use or escape attempts by pets. This could lead to safety concerns and additional costs for replacements, making it essential to assess the intended use before purchasing.

What Are the Benefits of Heavy-Duty Plastic Crates?

Heavy-duty plastic crates are engineered for high-stress environments, making them suitable for industrial shipping and heavy-duty storage. Their reinforced construction provides enhanced security, ensuring that contents remain protected during transport. B2B buyers should prioritize these crates for applications that demand durability and reliability. While they may require more space due to their bulkier design, the long-term investment in quality often outweighs the initial costs, especially when considering the potential for reduced damage and loss.

Illustrative image related to plastic crate vs wire crate

Why Choose Collapsible Wire Crates for Flexibility?

Collapsible wire crates are an excellent choice for businesses needing versatile storage solutions. Their ability to fold flat allows for efficient space management, making them ideal for temporary housing, travel, or exhibitions. However, buyers should be cautious about their durability; while convenient, these crates may lack the security needed for more permanent applications. Evaluating the specific needs of the business will help determine if the flexibility of collapsible wire crates is worth the trade-off in robustness.

What Makes Insulated Plastic Crates a Smart Choice?

Insulated plastic crates are essential for businesses that require temperature control during transportation, particularly in the food and pharmaceutical sectors. Their insulated walls help maintain the integrity of sensitive materials, making them a reliable option for perishable goods. While they tend to be heavier and more expensive than standard crates, the investment is justified for businesses prioritizing quality and safety in their logistics. B2B buyers should consider their specific temperature requirements and the potential return on investment when selecting insulated crates.

Key Industrial Applications of plastic crate vs wire crate

| Industry/Sector | Specific Application of Plastic Crate vs Wire Crate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting fruits and vegetables | Plastic crates provide better hygiene and durability. | Ensure crates comply with food safety regulations; consider UV resistance for outdoor storage. |

| Agriculture | Harvesting and storing crops | Plastic crates reduce spoilage and are easier to clean. | Look for stackability and durability under various weather conditions. |

| Retail and E-commerce | In-store display and storage | Wire crates offer visibility for products; plastic crates are more robust. | Consider the aesthetic appeal and weight capacity for ease of transport. |

| Pharmaceuticals | Storing and transporting medical supplies | Plastic crates prevent contamination; wire crates allow ventilation. | Ensure compliance with health regulations; consider anti-static options for sensitive items. |

| Logistics and Warehousing | General storage and transportation | Plastic crates are lightweight and stackable; wire crates are collapsible for efficient storage. | Evaluate the crate dimensions for compatibility with existing storage systems. |

How are Plastic Crates Used in the Food and Beverage Industry?

In the food and beverage sector, plastic crates are widely utilized for transporting fruits, vegetables, and other perishable goods. Their smooth surfaces and durability ensure that they meet hygiene standards, reducing the risk of contamination. Unlike wire crates, which can harbor bacteria in crevices, plastic options are easier to clean and maintain. B2B buyers should focus on sourcing crates that comply with food safety regulations and offer UV resistance for outdoor storage, particularly in regions with intense sun exposure.

What Role Do Plastic and Wire Crates Play in Agriculture?

In agriculture, both plastic and wire crates serve vital roles in harvesting and storing crops. Plastic crates are preferred for their durability and ease of cleaning, which significantly reduce spoilage during transport. They can be stacked to optimize space, an essential factor for farmers looking to maximize storage efficiency. Buyers should prioritize crates that can withstand various weather conditions, ensuring longevity and reliability throughout the harvesting season.

Illustrative image related to plastic crate vs wire crate

How Do Retailers Benefit from Using Plastic vs Wire Crates?

In retail and e-commerce, plastic and wire crates are used for in-store displays and storage. Wire crates provide visibility for products, enhancing customer engagement, while plastic crates are sturdier and better suited for heavy items. Retailers must consider the aesthetic appeal of the crates, as well as their weight capacity, to ensure that they can handle the demands of a busy retail environment. Sourcing crates that blend functionality with visual appeal can drive sales and improve customer experience.

Why Are Plastic Crates Preferred in the Pharmaceutical Sector?

In the pharmaceutical industry, the choice between plastic and wire crates can significantly impact the safety and integrity of medical supplies. Plastic crates are favored for their ability to prevent contamination, while wire crates allow for ventilation, which can be crucial for certain products. B2B buyers need to ensure that the crates comply with health regulations and consider anti-static options for sensitive items, particularly when transporting pharmaceuticals that require strict temperature control.

What Advantages Do Plastic and Wire Crates Offer in Logistics and Warehousing?

In logistics and warehousing, both plastic and wire crates play essential roles in storage and transportation. Plastic crates are lightweight and stackable, making them ideal for maximizing space and reducing shipping costs. Conversely, wire crates can be collapsed when not in use, providing flexibility for storage. Buyers should evaluate the dimensions of the crates to ensure compatibility with their existing storage systems, considering how efficiently they can be integrated into their operations.

3 Common User Pain Points for ‘plastic crate vs wire crate’ & Their Solutions

Scenario 1: The Dilemma of Durability in Storage Solutions

The Problem: B2B buyers often face the challenge of choosing between plastic and wire crates based on durability. For instance, a logistics company in South America may require crates to withstand heavy loads during transport. Wire crates might initially seem appealing due to their lower cost; however, they frequently bend or break under pressure, leading to costly disruptions and replacements. This scenario is particularly concerning for businesses that prioritize long-term investment and reliability in their supply chain operations.

The Solution: To address durability concerns, buyers should prioritize sourcing high-quality plastic crates that are designed for heavy-duty use. When evaluating suppliers, look for crates made from high-density polyethylene (HDPE) or other robust materials that can withstand the rigors of transportation and storage. Additionally, consider crates with reinforced corners and stacking capabilities to maximize space and minimize damage during transit. Establishing relationships with reputable manufacturers who provide detailed specifications can ensure that the chosen crate meets the required durability standards for your operations.

Illustrative image related to plastic crate vs wire crate

Scenario 2: Safety Risks of Wire Crates in the Workplace

The Problem: Safety is a paramount concern for businesses, especially those in the food service or manufacturing sectors. Wire crates, while economical, pose significant risks due to their sharp edges and potential for structural failure. A B2B buyer in the Middle East may encounter issues where employees or products are injured or damaged due to the unsafe design of wire crates. This not only jeopardizes the well-being of staff but can also lead to costly liability claims and damage to products.

The Solution: To mitigate safety risks, businesses should transition to plastic crates that eliminate sharp edges and offer a sturdier structure. When selecting plastic crates, ensure they are certified for safety standards relevant to your industry, such as FDA approval for food handling. Furthermore, consider implementing a training program for staff on the proper handling and stacking of crates to further reduce the likelihood of accidents. Investing in crates that are ergonomically designed can also enhance employee safety and efficiency.

Scenario 3: Storage and Space Efficiency Challenges

The Problem: Many companies, particularly those in urban areas of Europe, struggle with limited storage space. Wire crates can be folded for storage, but their lightweight construction makes them less suitable for frequent use. As a result, a logistics manager may find that the time spent setting up and collapsing wire crates ultimately outweighs the benefits of their compact design. This inefficiency can lead to operational delays and increased labor costs.

The Solution: For businesses facing space constraints, plastic crates offer a solution that balances storage efficiency and usability. Choose plastic crates that are designed for stackability, allowing for maximum space utilization while maintaining stability. Additionally, consider crates with modular designs that can be customized based on the specific needs of your operations. Implementing a systematic approach to crate organization can streamline operations and reduce the time spent managing storage solutions. Engaging with suppliers who provide versatile and space-efficient options can lead to a more effective inventory management strategy.

Strategic Material Selection Guide for plastic crate vs wire crate

What Are the Key Properties of Common Materials Used in Plastic and Wire Crates?

When evaluating plastic and wire crates for B2B applications, understanding the materials used in their construction is crucial. Each material offers unique properties that affect performance, durability, and suitability for various applications.

How Do Plastic Crates Perform in Various Conditions?

Plastic crates are typically made from high-density polyethylene (HDPE) or polypropylene (PP). These materials provide excellent resistance to moisture, chemicals, and UV radiation, making them suitable for both indoor and outdoor use. They can withstand a temperature range of -40°C to 60°C, which is beneficial for various storage and transport conditions.

Pros: Plastic crates are lightweight, stackable, and resistant to corrosion. They are also easy to clean and maintain, which is essential for industries like food and pharmaceuticals. The manufacturing process is relatively straightforward, allowing for customization in size and shape.

Cons: However, plastic crates can be susceptible to impact damage and may not hold up well under extreme pressure or heavy loads. They can also be more expensive than wire crates, which may deter budget-conscious buyers.

Impact on Application: Plastic crates are ideal for transporting perishable goods, pharmaceuticals, and other sensitive materials that require a controlled environment. Their chemical resistance makes them suitable for industries dealing with corrosive substances.

What Are the Advantages and Disadvantages of Wire Crates?

Wire crates are typically constructed from steel or aluminum, providing a sturdy framework. They are often coated with a protective finish to prevent rust and corrosion, although this can vary based on the manufacturer.

Pros: Wire crates are generally more durable than plastic crates and can support heavier loads. They are also collapsible, which makes them easy to store when not in use. Their open design allows for ventilation, making them suitable for transporting items that require airflow.

Cons: The main drawback of wire crates is their susceptibility to rust and corrosion, especially in humid or wet environments. Additionally, the sharp edges of wire can pose safety risks, and they may not provide adequate protection for fragile items.

Impact on Application: Wire crates are often used in industrial settings for transporting tools, equipment, and non-perishable goods. Their durability makes them suitable for heavy-duty applications, but their limitations in terms of moisture resistance can restrict their use in certain environments.

What Should International B2B Buyers Consider When Choosing Between Plastic and Wire Crates?

For international buyers, compliance with regional standards is critical. In Europe, for instance, crates must meet DIN standards, while in the U.S., ASTM standards apply. Buyers from Africa and South America should also consider local regulations regarding materials and safety.

Illustrative image related to plastic crate vs wire crate

Specific Considerations: Buyers must assess the climate and storage conditions in their regions. For instance, humid environments may favor plastic crates due to their corrosion resistance, while dry conditions may allow for the use of wire crates. Additionally, the cost of shipping and potential import tariffs can impact the overall cost-effectiveness of each option.

Summary Table of Material Properties

| Material | Typical Use Case for plastic crate vs wire crate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Transporting perishable goods, pharmaceuticals | Excellent moisture and chemical resistance | Susceptible to impact damage | Medium |

| Polypropylene (PP) | Storage and transport of sensitive items | Lightweight and easy to clean | May not withstand heavy loads | Medium |

| Steel | Industrial applications for tools and equipment | Highly durable and supports heavy loads | Prone to rust and corrosion | High |

| Aluminum | Lightweight transport solutions | Corrosion-resistant and lightweight | Less durable than steel under heavy loads | High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for plastic and wire crates, facilitating informed decision-making based on specific industry needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic crate vs wire crate

What Are the Typical Manufacturing Processes for Plastic Crates?

Manufacturing plastic crates typically involves several key stages, each crucial for ensuring the durability and functionality of the final product.

1. Material Preparation: What Materials Are Used in Plastic Crate Production?

The primary material used for plastic crates is high-density polyethylene (HDPE) or polypropylene (PP), known for their strength and resistance to environmental factors. Before production, these plastics undergo a granulation process where they are cut into small pellets. This preparation phase is essential as the quality of raw materials directly affects the final product’s strength and longevity.

2. Forming: How Are Plastic Crates Shaped and Molded?

The forming stage primarily uses injection molding or blow molding techniques. In injection molding, plastic pellets are melted and injected into molds that shape the crate. This method allows for intricate designs and uniformity. Blow molding, on the other hand, is often used for hollow crates and involves inflating a heated plastic tube within a mold to form the desired shape.

Both techniques require precise temperature control and timing to ensure that the crates are formed correctly without defects.

3. Assembly: How Are Plastic Crates Assembled?

Most plastic crates are designed to be one-piece products, minimizing the need for assembly. However, if a crate includes additional features like handles or ventilation holes, these components are added during this phase. Automated assembly lines are often employed to enhance efficiency and maintain consistent quality.

4. Finishing: What Surface Treatments Are Applied to Plastic Crates?

In the finishing stage, crates may undergo several processes such as trimming, surface smoothing, and application of UV-resistant coatings. These treatments enhance the crate’s aesthetic appeal and durability, ensuring they can withstand exposure to sunlight and various weather conditions.

What Are the Key Quality Assurance Procedures for Plastic Crates?

Quality assurance (QA) is vital in the manufacturing of plastic crates to ensure they meet international standards and customer expectations.

Relevant International Standards for Plastic Crates

Plastic crates must comply with various international standards, such as ISO 9001, which focuses on quality management systems. Compliance with standards like CE marking indicates that the products meet EU safety, health, and environmental protection requirements.

Key Quality Control Checkpoints for Plastic Crates

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet predefined specifications before production begins. Material samples are tested for mechanical properties, chemical composition, and physical characteristics.

-

In-Process Quality Control (IPQC): During manufacturing, real-time checks are performed to monitor processes. This includes checking for temperature consistency during molding and ensuring that production machinery is functioning correctly.

-

Final Quality Control (FQC): After production, finished crates undergo rigorous testing. This includes drop tests to assess impact resistance and load-bearing capacity tests to ensure they can withstand the intended weight.

Common Testing Methods for Plastic Crates

Testing methods for plastic crates include tensile strength tests, UV resistance tests, and chemical resistance tests. These assessments ensure that the crates can endure the rigors of transport and storage, particularly in diverse climates.

What Are the Manufacturing Processes for Wire Crates?

Wire crates, often preferred for their lightweight design and ventilation, follow a different manufacturing process compared to plastic crates.

1. Material Preparation: What Materials Are Used for Wire Crates?

Wire crates are typically made from steel or aluminum. The manufacturing process begins with sourcing high-quality metal wires, which are often galvanized to prevent rusting. The preparation phase includes cutting the wires to specific lengths and ensuring they meet industry specifications.

Illustrative image related to plastic crate vs wire crate

2. Forming: How Are Wire Crates Constructed?

The forming process for wire crates involves bending and welding. Automated machinery bends the wire into shape, and then the pieces are welded together at various joints to create the crate structure. This method allows for flexibility in design, but the quality of welding is critical to ensure structural integrity.

3. Assembly: How Are Wire Crates Assembled?

After forming, the assembly phase involves adding any additional components, such as dividers or doors. This can be done manually or through automated systems, depending on the production scale.

4. Finishing: What Surface Treatments Are Applied to Wire Crates?

Wire crates often undergo powder coating or galvanization as a finishing touch. Powder coating provides a protective layer that enhances durability and appearance, while galvanization protects against corrosion.

What Are the Key Quality Assurance Procedures for Wire Crates?

Just like plastic crates, wire crates also require stringent quality assurance measures.

Relevant International Standards for Wire Crates

Wire crates must adhere to standards such as ISO 9001 and may also require compliance with specific industry standards relevant to their application, such as API for crates used in oil and gas industries.

Key Quality Control Checkpoints for Wire Crates

-

Incoming Quality Control (IQC): Similar to plastic crates, wire materials undergo IQC to verify their quality before production.

-

In-Process Quality Control (IPQC): Throughout the welding and assembly process, checks are performed to ensure the welds are secure and the structure is sound.

-

Final Quality Control (FQC): Completed wire crates are subjected to tests such as load tests and stability tests to ensure they meet safety standards.

Common Testing Methods for Wire Crates

Testing methods include tensile strength tests and corrosion resistance tests, critical for assessing the durability and safety of wire crates in various environments.

Illustrative image related to plastic crate vs wire crate

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can implement several strategies to verify the quality control processes of suppliers, particularly when sourcing from international markets.

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the supplier’s manufacturing processes and quality control measures.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports that outline the testing methods used and the results obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and adherence to international standards.

-

Certifications: Verify that suppliers hold relevant certifications, such as ISO 9001 and CE marking, which indicate compliance with quality standards.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding regional standards and regulations is crucial. Different countries may have specific requirements regarding materials, testing, and certifications. Buyers should familiarize themselves with these nuances to ensure compliance and mitigate risks associated with quality discrepancies.

In summary, the manufacturing processes and quality assurance protocols for both plastic and wire crates are vital for delivering high-quality products to B2B buyers. By understanding these processes, buyers can make informed decisions and select suppliers that align with their quality expectations.

Illustrative image related to plastic crate vs wire crate

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic crate vs wire crate’

Introduction

When sourcing crates for your business, whether for storage, transportation, or logistical needs, understanding the differences between plastic and wire crates is essential. This guide provides a practical checklist to help B2B buyers make informed decisions based on their specific requirements, ensuring optimal investment in crate solutions.

Step 1: Assess Your Operational Needs

Before delving into supplier options, clarify your specific operational requirements. Consider factors such as the type of products being stored or transported, weight capacity, and environmental conditions (e.g., exposure to moisture or chemicals). This understanding will help you determine whether plastic or wire crates are more suitable for your use case.

Step 2: Define Your Budget Constraints

Establish a clear budget for your crate procurement. While plastic crates may have a higher upfront cost, their durability can lead to long-term savings by reducing replacement frequency. Conversely, wire crates might be cheaper initially but could incur higher costs due to damage or replacements over time. Ensure your budget reflects the total cost of ownership.

Step 3: Evaluate Material Specifications

Different materials offer various benefits and drawbacks. Plastic crates are typically more durable and resistant to moisture, making them ideal for humid environments. Wire crates, while lighter and foldable for easy storage, may pose safety risks if poorly constructed. Assess the material specifications to align with your operational demands.

Illustrative image related to plastic crate vs wire crate

Step 4: Verify Supplier Certifications

Ensure that potential suppliers adhere to industry standards and certifications relevant to your market. This verification process builds confidence in product quality and safety. Look for certifications such as ISO for quality management or specific safety standards for crates used in food storage or pharmaceuticals.

Step 5: Request Samples for Testing

Before finalizing any orders, request samples from shortlisted suppliers. Testing samples allows you to assess the quality, durability, and suitability of the crates in real-world scenarios. Pay attention to features such as stacking ability, weight tolerance, and ease of handling.

Step 6: Review Supplier Reputation and Experience

Investigate the reputation of potential suppliers within the industry. Look for reviews, case studies, and testimonials from other businesses that have used their products. A supplier with extensive experience in your specific sector can offer valuable insights and guidance, ensuring a better fit for your needs.

Step 7: Consider Logistics and Delivery Options

Finally, evaluate the logistics involved in sourcing your crates. Understand the lead times, shipping costs, and delivery methods offered by suppliers. Efficient logistics can significantly impact your operational timeline, especially if you require crates urgently for a new project or expansion.

Illustrative image related to plastic crate vs wire crate

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing the right crate solutions, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for plastic crate vs wire crate Sourcing

What Are the Key Cost Components for Sourcing Plastic and Wire Crates?

When evaluating the cost structure of plastic versus wire crates, several components must be considered.

-

Materials: Plastic crates typically utilize high-density polyethylene or polypropylene, which can be more expensive than the metal used in wire crates. This difference in material quality significantly affects the overall cost. Additionally, the durability of plastic often translates to a longer lifecycle, potentially reducing the total cost over time.

-

Labor: The labor costs associated with manufacturing plastic crates can be higher due to more complex molding processes compared to the simpler assembly of wire crates. This difference may impact pricing, especially in regions where labor costs are variable.

-

Manufacturing Overhead: Overhead costs can vary significantly based on the production methods. Plastic crates often require more sophisticated machinery and facilities, which can lead to higher overhead costs that are passed on to the buyer.

-

Tooling: Plastic crate production typically demands more significant upfront investment in tooling compared to wire crates. This includes the cost of molds that can be substantial but are amortized over a larger production run.

-

Quality Control (QC): Given the differences in materials and manufacturing processes, the QC processes may differ as well. Plastic crates may require more rigorous testing to ensure they meet safety and durability standards, impacting the overall cost.

-

Logistics: Both types of crates incur logistics costs, but plastic crates can often be lighter and more stackable, potentially reducing shipping costs. Conversely, wire crates may require more space and incur additional freight costs due to their design.

-

Margin: The profit margins can differ significantly. Manufacturers of plastic crates may operate on lower margins due to higher material costs, while wire crate producers might have higher margins due to lower production costs.

How Do Pricing Influencers Affect the Cost of Plastic and Wire Crates?

Several factors influence the pricing of both plastic and wire crates, particularly for international buyers.

Illustrative image related to plastic crate vs wire crate

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers negotiate better terms and reduce per-unit costs.

-

Specifications and Customization: Custom features, such as branding, size modifications, or specific design elements, can lead to increased costs. Buyers should assess whether such customizations are necessary for their operations.

-

Materials and Quality Certifications: The quality of materials and any certifications (such as ISO or ASTM standards) can significantly impact pricing. Buyers should consider the long-term benefits of investing in higher-quality products that comply with safety standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of delivering quality products may charge a premium but offer better customer service and reliability.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define who is responsible for shipping, insurance, and tariffs. This understanding can help buyers avoid unexpected costs.

What Buyer Tips Can Help Navigate the Cost and Pricing Landscape?

B2B buyers should consider several strategies to navigate the complex cost landscape effectively:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing or payment terms. Highlighting potential long-term partnerships can provide leverage.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors such as durability, replacement frequency, and potential damage costs associated with lower-quality crates.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and shipping costs that can affect the final price. Establishing relationships with local distributors may also lead to cost savings.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, material availability, and demand. Buyers should seek updated quotes and be prepared for variability in pricing.

By understanding these key components and strategies, international B2B buyers can make informed decisions when sourcing plastic or wire crates, ensuring they select the best option for their needs while optimizing costs.

Alternatives Analysis: Comparing plastic crate vs wire crate With Other Solutions

In the competitive landscape of logistics and storage solutions, selecting the right type of crate is crucial for businesses. While plastic and wire crates are popular choices, several alternative solutions are gaining traction. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs.

| Comparison Aspect | Plastic Crate Vs Wire Crate | Alternative 1: Stackable Metal Crates | Alternative 2: Collapsible Fabric Crates |

|---|---|---|---|

| Performance | Durable, better for heavy loads; wire crates can bend or break easily under stress. | High strength and durability; resistant to rust and corrosion. | Lightweight and portable, but may lack structural integrity for heavy items. |

| Cost | Moderate initial investment, but longer lifespan reduces long-term costs. | Higher upfront cost; however, they are a long-term investment. | Lower initial cost, but may require replacement more frequently. |

| Ease of Implementation | Easy to clean and maintain; can be stacked for efficient storage. | Requires more space due to fixed shapes; can be heavy to move. | Simple setup and teardown; easy to store when not in use. |

| Maintenance | Low maintenance; resistant to moisture and odors. | Minimal maintenance; can be cleaned easily. | Requires regular cleaning; can harbor odors if not maintained. |

| Best Use Case | Ideal for transporting liquids or fragile items due to sturdy design. | Best for heavy industrial applications where durability is paramount. | Suitable for light-duty tasks and temporary storage solutions. |

What Are the Advantages and Disadvantages of Stackable Metal Crates?

Stackable metal crates offer exceptional durability and load-bearing capacity, making them suitable for heavy industrial applications. They are often made from high-quality steel or aluminum, which resists rust and corrosion, ensuring longevity in harsh environments. However, their higher upfront cost can be a deterrent for budget-conscious businesses. Additionally, their fixed shapes may require more space for storage and transport, which could be a limitation for companies with limited warehouse capacity.

How Do Collapsible Fabric Crates Compare?

Collapsible fabric crates are designed for portability and convenience. They are lightweight and easy to set up or take down, making them ideal for temporary storage or transport. Their lower initial cost is appealing, especially for businesses that require flexible solutions. However, they may not provide the structural integrity needed for heavier items and can be prone to wear and tear over time. Regular maintenance is essential to prevent odors and ensure cleanliness, which may add to the overall cost.

Conclusion: How Can B2B Buyers Choose the Right Crate Solution?

When selecting a crate solution, B2B buyers should consider their specific operational needs, including load requirements, storage space, and budget constraints. While plastic and wire crates are practical options, alternatives like stackable metal crates and collapsible fabric crates may offer better durability, portability, or cost-effectiveness depending on the application. A thorough assessment of these factors will empower buyers to choose a solution that enhances efficiency and aligns with their business goals.

Essential Technical Properties and Trade Terminology for plastic crate vs wire crate

What Are the Key Technical Properties of Plastic and Wire Crates?

Understanding the technical properties of plastic and wire crates is essential for B2B buyers to make informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

– Plastic Crates: Typically made from high-density polyethylene (HDPE) or polypropylene (PP), these materials provide durability and resistance to impact and chemicals.

– Wire Crates: Generally constructed from steel or other metals, often coated to prevent rust. The material grade can affect the weight capacity and longevity of the crate.

– B2B Importance: Selecting the right material can influence the crate’s lifespan, safety features, and the total cost of ownership. -

Weight Capacity

– This refers to the maximum weight the crate can safely hold. Plastic crates can often support significant weight while remaining lightweight, whereas wire crates may vary in strength based on their gauge.

– B2B Importance: Ensuring that crates meet specific weight requirements is crucial for logistics and storage efficiency, especially in sectors like agriculture or manufacturing. -

Tolerance

– This specification indicates the allowable deviation from standard measurements, which can affect how crates stack or fit in transport vehicles.

– B2B Importance: Proper tolerance ensures compatibility with existing systems, maximizing space utilization and reducing shipping costs. -

Dimensions

– Standard sizes may include length, width, height, and volume capacity. Plastic crates often come in specific dimensions tailored for particular applications (e.g., food storage), while wire crates may offer more variability in size.

– B2B Importance: Understanding dimensions is vital for inventory management and optimizing storage solutions. -

Stackability and Nestability

– Plastic crates are often designed to stack securely, whereas wire crates may be collapsible or foldable for easy storage.

– B2B Importance: Efficient stacking and nesting can significantly reduce storage space requirements and facilitate easier transport.

What Are Common Trade Terms in the Crate Industry?

Navigating the jargon of the crate industry can be daunting for non-technical decision-makers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the crate industry, an OEM might provide customized crates for specific client needs.

– Importance: Understanding OEM relationships can help buyers negotiate better terms and ensure product quality. -

MOQ (Minimum Order Quantity)

– This is the smallest number of units that a supplier is willing to sell in a single order. Manufacturers often set MOQs to cover production costs.

– Importance: Knowing the MOQ helps buyers plan their purchasing strategy and manage cash flow effectively. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers requesting a price quote for specified products or services. It often includes details on quantity, specifications, and delivery requirements.

– Importance: Using RFQs can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms is crucial for mitigating risks associated with international shipping and ensuring compliance with trade regulations. -

Lead Time

– This refers to the amount of time between placing an order and receiving it. Lead times can vary significantly based on the type of crate and the supplier’s production capacity.

– Importance: Understanding lead times is essential for inventory planning and meeting customer demand without delays. -

Customization

– This term indicates the ability to modify crates to meet specific business needs, such as branding, size adjustments, or enhanced features.

– Importance: Customization can differentiate products in the market and provide tailored solutions that enhance operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed choices when selecting between plastic and wire crates, ensuring that their investments align with their operational needs.

Illustrative image related to plastic crate vs wire crate

Navigating Market Dynamics and Sourcing Trends in the plastic crate vs wire crate Sector

What are the Current Market Dynamics Influencing Plastic and Wire Crate Sourcing?

The global market for plastic and wire crates has been influenced by several key drivers, particularly in regions such as Africa, South America, the Middle East, and Europe. The rising demand for efficient storage and transportation solutions across various industries, including agriculture, logistics, and retail, has propelled the crate market forward. Furthermore, the increasing adoption of e-commerce has heightened the need for durable packaging solutions, leading to a surge in demand for both plastic and wire crates.

Emerging B2B technology trends are also reshaping the sourcing landscape. Digital procurement platforms are becoming essential tools for buyers, facilitating easier comparisons of crate specifications, prices, and supplier ratings. Blockchain technology is gaining traction, offering enhanced transparency in supply chains, which is crucial for international buyers who need to ensure product authenticity and compliance with regulations. Additionally, the integration of IoT devices in supply chain management is optimizing inventory tracking and management, leading to more efficient operations.

International buyers must stay attuned to the fluctuating prices of raw materials, particularly in the plastic sector, as these can significantly affect sourcing costs. The ongoing shift towards lightweight and multi-functional crates is another critical trend, pushing manufacturers to innovate continually. As such, buyers should prioritize suppliers who demonstrate agility in adapting to these market dynamics while maintaining product quality.

How is Sustainability Shaping the Sourcing of Plastic vs. Wire Crates?

Sustainability is becoming a paramount concern in the sourcing of crates, impacting both plastic and wire crate markets. Environmental considerations are driving buyers to seek products that minimize ecological footprints. Plastic crates, often viewed as less sustainable due to their petroleum-based origins, are increasingly being produced from recycled materials or bioplastics, which offer a more environmentally friendly option. International buyers should look for suppliers who provide certified sustainable products, as this can enhance their brand image and appeal to eco-conscious consumers.

Illustrative image related to plastic crate vs wire crate

Ethical sourcing is also gaining traction, with buyers increasingly scrutinizing the supply chains of their suppliers. This includes ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. For wire crates, buyers should be aware of the sourcing of metals and consider the implications of mining practices on the environment.

Investing in sustainable crates not only meets regulatory demands but can also lead to cost savings over time. Durable, high-quality crates reduce the need for replacements and waste, ultimately benefiting both the bottom line and the planet.

What is the Historical Context of Plastic and Wire Crates in B2B Markets?

The evolution of plastic and wire crates dates back several decades, with wire crates being the traditional choice for storage and transport due to their low cost and lightweight nature. However, as industries evolved, the limitations of wire crates became apparent, particularly concerning durability and safety. The introduction of plastic crates in the late 20th century marked a significant shift, offering enhanced strength, versatility, and resistance to environmental factors.

Illustrative image related to plastic crate vs wire crate

Over time, technological advancements have further refined plastic crate designs, leading to innovations such as collapsible models that save space and improve transportation efficiency. Today, both plastic and wire crates serve distinct market needs, with plastic crates often favored for their durability and wire crates appealing to cost-sensitive buyers. Understanding this historical context allows B2B buyers to make informed decisions based on the evolving landscape of crate solutions tailored to their specific industry requirements.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic crate vs wire crate

-

How do I choose between plastic crates and wire crates for my business needs?

Choosing between plastic and wire crates depends on your specific requirements. Plastic crates are more durable and provide better protection against environmental factors, making them ideal for shipping and storage in various industries. On the other hand, wire crates are lighter and often foldable, which can save space during transport. Consider factors such as weight capacity, durability, safety, and the specific conditions of use when making your decision. -

What are the advantages of plastic crates over wire crates?

Plastic crates offer several advantages, including enhanced durability, resistance to moisture and chemicals, and safer handling due to the absence of sharp edges. They are also easier to clean and maintain, which is beneficial in industries like food and pharmaceuticals. Additionally, plastic crates can be designed for specific applications, offering customized solutions that wire crates may not provide. -

What is the typical minimum order quantity (MOQ) for plastic and wire crates?

MOQs can vary significantly between suppliers and regions. Generally, plastic crates may have a higher MOQ due to their manufacturing processes, while wire crates might be available in smaller quantities. It’s essential to discuss your needs with potential suppliers to negotiate MOQs that align with your operational requirements, especially if you are targeting international markets. -

How can I ensure the quality of the crates I purchase?

To ensure quality, vet suppliers thoroughly by checking their certifications and production standards. Request samples to assess the durability and functionality of the crates before placing large orders. Additionally, inquire about their quality assurance processes, warranty policies, and the materials used in production. Engaging with suppliers who have a proven track record in your industry can also provide added confidence in the quality of their products. -

What customization options are available for plastic and wire crates?

Many suppliers offer customization options, including size, color, branding, and additional features like ventilation or stacking capabilities. Discuss your specific requirements with suppliers to determine what modifications are possible. Custom crates can enhance your brand image and improve functionality, making it essential to find a manufacturer that can accommodate your needs. -

What are the payment terms commonly offered by suppliers for crate purchases?

Payment terms can vary widely among suppliers, often depending on your relationship with them and the size of your order. Common terms include advance payment, partial payment upon order confirmation, and the remainder upon delivery. Some suppliers may also offer credit terms for established customers. Always clarify payment terms upfront to avoid misunderstandings and ensure smooth transactions. -

How do I handle logistics when sourcing crates internationally?

Handling logistics for international sourcing involves coordinating shipping methods, understanding customs regulations, and managing delivery timelines. Collaborate with freight forwarders experienced in your target regions to streamline the process. Ensure that your supplier is capable of providing the necessary shipping documents and that you are aware of any duties or tariffs applicable to your order to avoid unexpected costs. -

What are the best practices for maintaining and storing plastic and wire crates?

To maintain plastic crates, regularly clean them with mild detergents and store them in a dry area to prevent warping. Wire crates should be inspected for any bent or broken wires and cleaned to prevent rust. When storing crates, stack them properly to optimize space and prevent damage. Implementing these best practices will extend the life of your crates and ensure they remain functional for your business needs.

Top 5 Plastic Crate Vs Wire Crate Manufacturers & Suppliers List

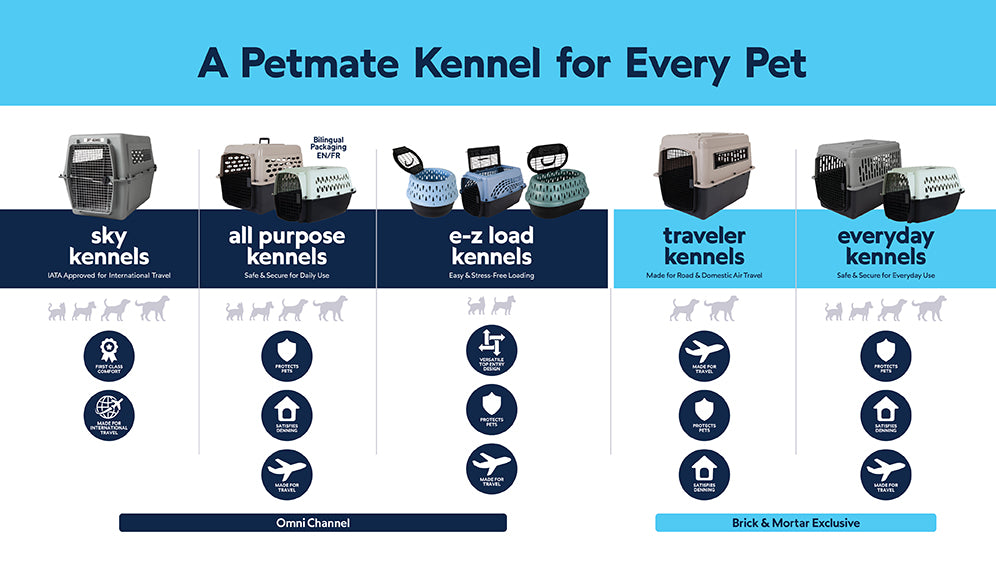

1. Reddit – Wire vs Plastic Crates

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Wire crates are easier to clean, provide better ventilation, and allow for attaching an x-pen. They can be covered for privacy and are useful for crate games. Plastic kennels are preferred for travel, easier to transport, and can be used for outdoor setups. Wire crates can be adjusted in size with a divider panel, while plastic kennels may require multiple sizes as puppies grow.

2. Impact Dog Crates – Heavy-Duty Aluminum Safety Crate

Domain: impactdogcrates.com

Registered: 2016 (9 years)

Introduction: Impact Dog Crates are built from heavy-duty aluminum, offering unparalleled safety and security for dogs. They feature a smooth aluminum material with no sharp wires or plastic corners, ensuring safety from injuries. The Impact Collapsible Dog Crate can fold down to just 8 inches tall for easy storage, while the High Anxiety Dog Crate is designed for anxious dogs with smaller ventilation holes to …

3. Germanshepherds – Wire vs. Plastic Crates for Beaucerons

Domain: germanshepherds.com

Registered: 1997 (28 years)

Introduction: The discussion revolves around the comparison between wire and plastic crates for dogs, specifically for a Beauceron. Key points include:

1. **Size Requirement**: The user needs a larger crate as their dog is outgrowing a 500 vari-kennel plastic crate.

2. **Cost**: Wire crates are noted to be cheaper than plastic crates.

3. **Concerns with Wire Crates**: Worries about the possibility of escape …

4. Facebook – Dog Comfort Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Dog Comfort Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Well Trained Mind – Wire Crate

Domain: forums.welltrainedmind.com

Registered: 1999 (26 years)

Introduction: This company, Well Trained Mind – Wire Crate, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for plastic crate vs wire crate

In navigating the choice between plastic and wire crates, international B2B buyers must consider several critical factors that influence both cost-efficiency and product longevity. Plastic crates typically offer superior durability and safety compared to their wire counterparts, which are prone to structural weaknesses and potential hazards. While wire crates may have a lower initial price point, the long-term costs associated with replacements and possible injury liabilities can significantly outweigh these savings.

Strategic sourcing becomes vital in this context, as it allows businesses to assess the total cost of ownership and align crate selection with their operational needs and safety standards. By prioritizing quality and longevity, companies can enhance their supply chain resilience and reduce the frequency of crate replacements.

Illustrative image related to plastic crate vs wire crate

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage this knowledge in their sourcing decisions. Investing in high-quality plastic crates not only safeguards your assets but also elevates your operational efficiency. Embrace the opportunity to optimize your supply chain with informed decisions that prioritize safety, durability, and long-term value.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.