Top 5 Panel Latch Hardware Suppliers (And How to Choose)

Introduction: Navigating the Global Market for panel latch hardware

In today’s global marketplace, sourcing reliable panel latch hardware can be a daunting task for B2B buyers, particularly those in dynamic regions such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality products but also in navigating an increasingly complex supply chain that varies by geography and application. This guide aims to demystify the intricacies of panel latch hardware, providing buyers with essential insights into various types, their specific applications, and the critical aspects of supplier vetting.

Throughout this comprehensive resource, you will discover a wide array of panel latch options, including key locks, compression latches, and slide mechanisms, tailored to different industrial needs—from automotive to electronics. We will also explore factors influencing pricing, such as material choices and manufacturing processes, empowering you to make cost-effective decisions. Moreover, the guide emphasizes the importance of thorough supplier evaluation, ensuring that you partner with manufacturers who meet international standards for quality and reliability.

By leveraging the information presented here, international B2B buyers will be better equipped to navigate the complexities of sourcing panel latch hardware. This guide not only serves as a reference point but also as a strategic tool, enabling you to enhance your procurement processes and foster successful partnerships in the global market.

Understanding panel latch hardware Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Latches | Provides a tight seal when closed, often adjustable | Enclosures, automotive, and industrial cases | Pros: Enhanced security and weather resistance. Cons: May require precise alignment for effective sealing. |

| Slam Latches | Automatically locks when the door is closed | Shipping containers, toolboxes, and cabinets | Pros: Quick and easy operation; no need for a key. Cons: Potential for accidental locking if not monitored. |

| Keyed Locks | Offers controlled access, typically with a key mechanism | Secure storage, electronic enclosures | Pros: High security; restricts unauthorized access. Cons: Risk of losing keys; may require rekeying or replacement. |

| Slide Latches | Simple mechanism; slides to open and close | Light-duty applications like cabinet doors | Pros: Cost-effective and easy to install. Cons: Limited security features; not suitable for high-security needs. |

| Lift & Turn Latches | Requires lifting and turning to engage or disengage | Access panels and doors in various sectors | Pros: Provides secure closure; versatile design. Cons: May require additional space for operation. |

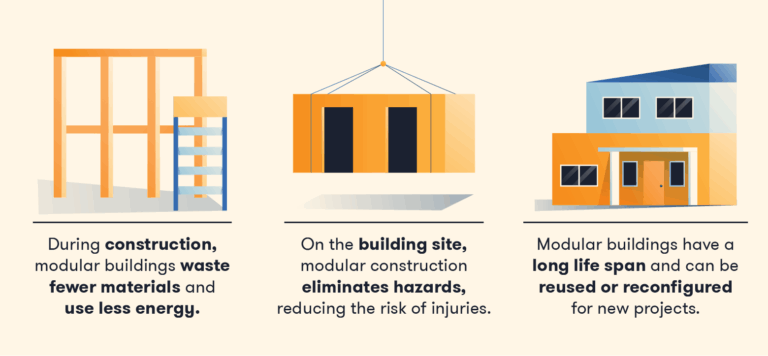

What Are Compression Latches and Their Applications?

Compression latches are designed to ensure a tight seal upon closure, making them ideal for applications that require protection against dust and moisture. These latches are commonly found in enclosures for electronics, automotive components, and industrial cases. When considering compression latches, B2B buyers should evaluate the material durability, adjustability for various panel thicknesses, and ease of installation. The enhanced security and sealing capabilities make them a worthwhile investment for applications where environmental factors are a concern.

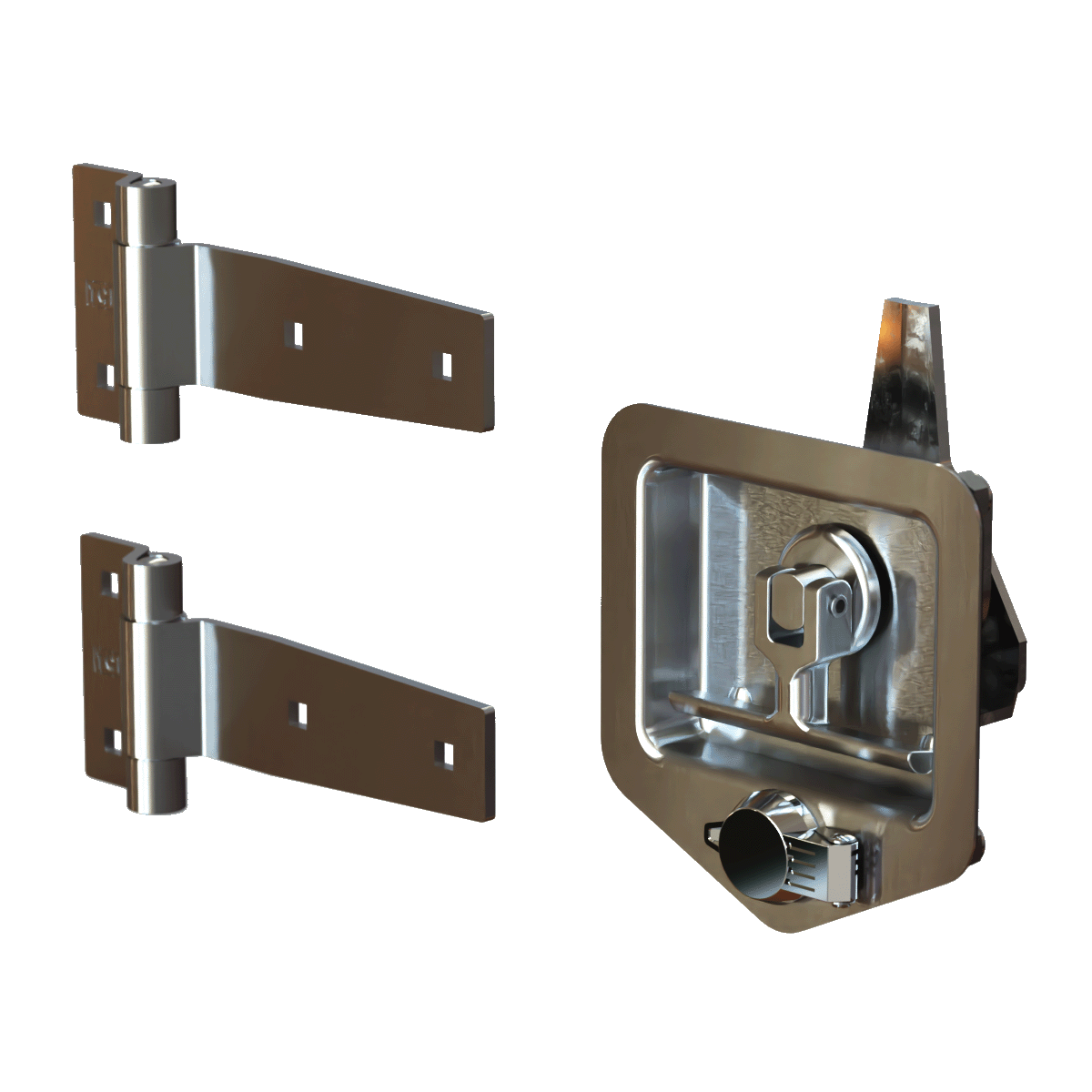

How Do Slam Latches Function and Where Are They Used?

Slam latches operate automatically by locking when a door or panel is closed, providing convenience in high-traffic environments. They are particularly useful in shipping containers, toolboxes, and cabinets where quick access is essential. Buyers should consider the latch’s material for durability and resistance to environmental wear. While slam latches offer rapid operation without the need for keys, there is a risk of accidental locking, which could lead to operational delays.

Why Choose Keyed Locks for Security?

Keyed locks are favored for their ability to restrict access, making them suitable for secure storage and electronic enclosures. These locks provide a higher level of security compared to other latch types, ensuring that only authorized personnel can access sensitive areas. B2B buyers should assess the quality of the locking mechanism, key duplication policies, and the potential need for rekeying services. Although keyed locks enhance security, they come with the downside of key loss, which can lead to additional costs and operational interruptions.

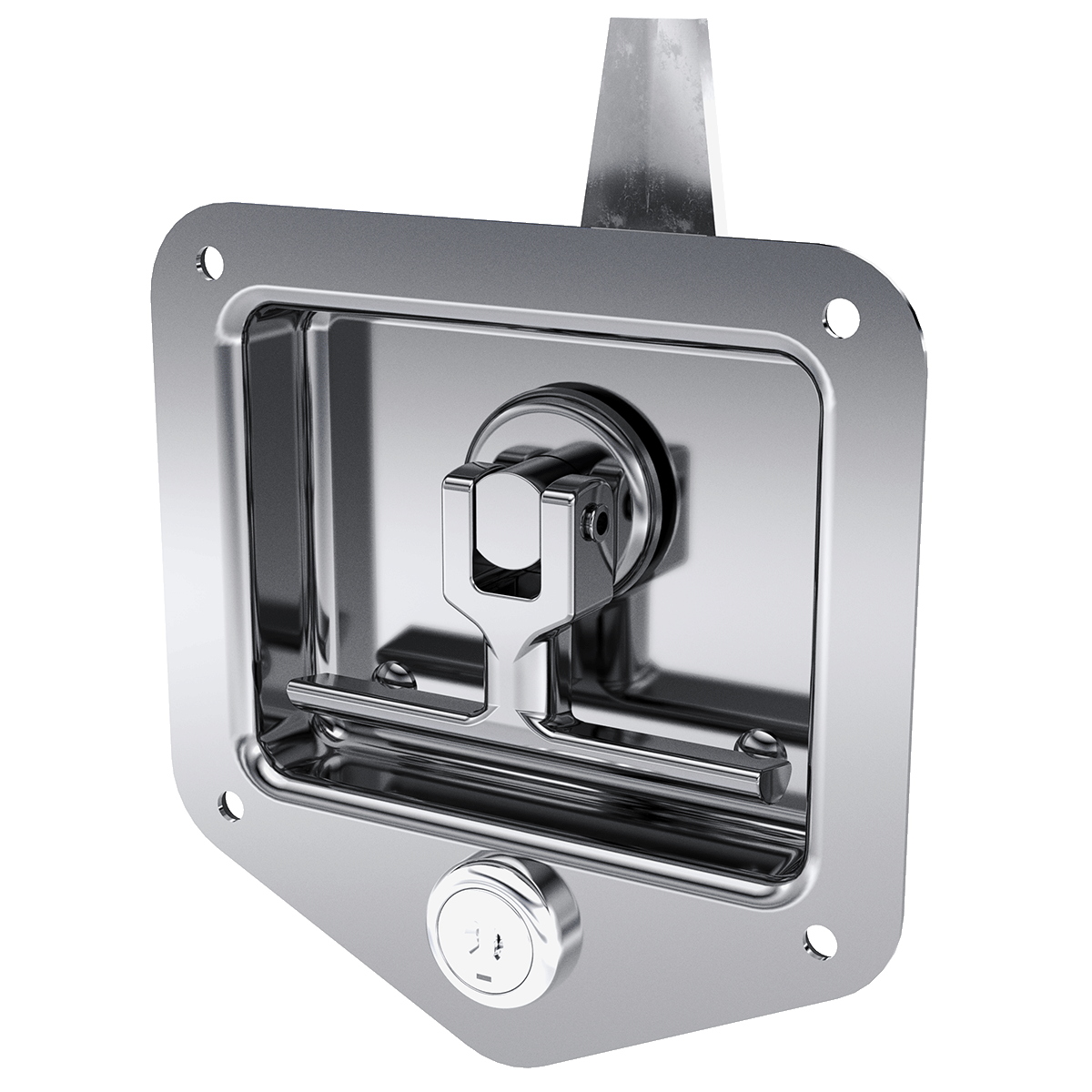

Illustrative image related to panel latch hardware

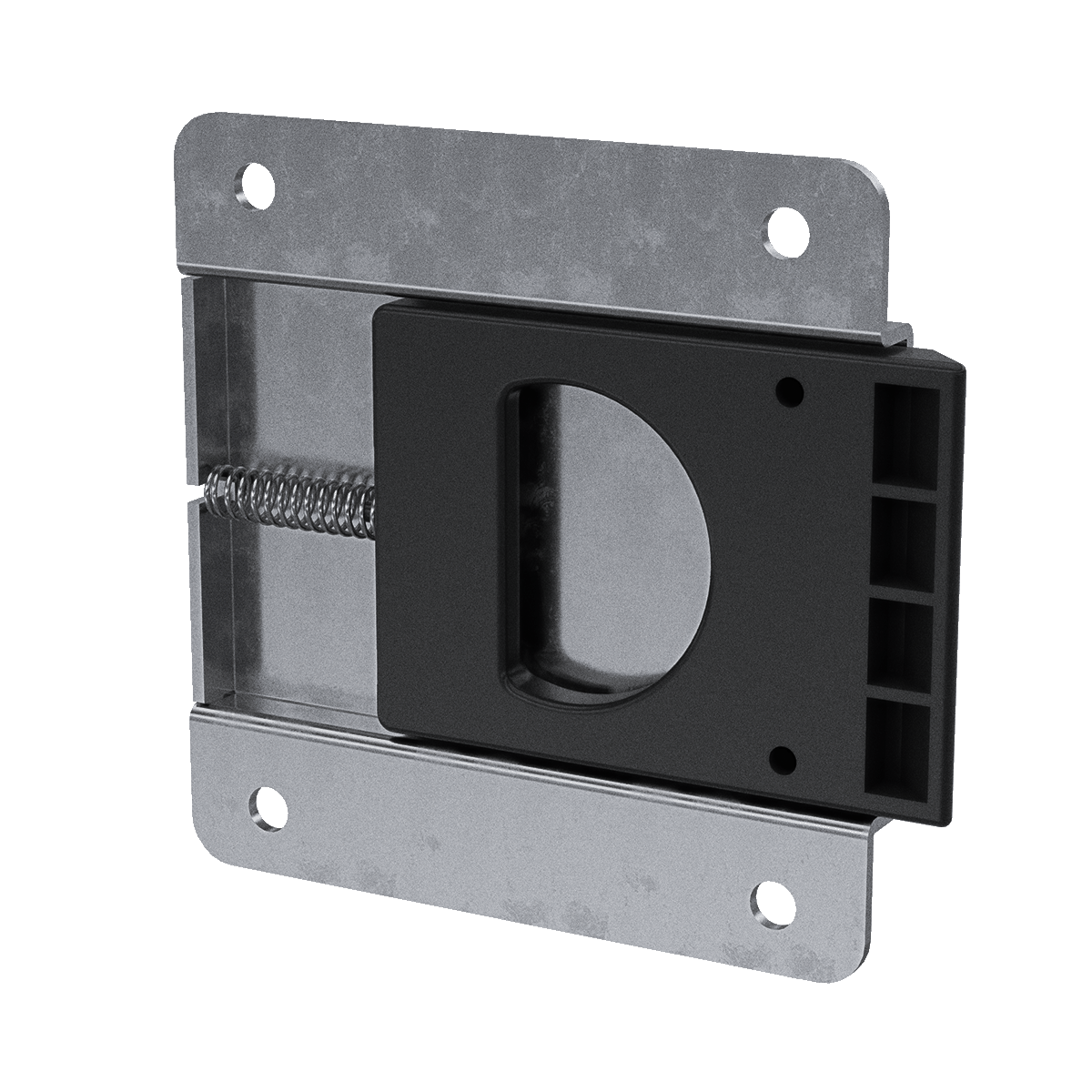

What Are the Benefits of Slide Latches?

Slide latches are characterized by their straightforward mechanism that allows users to slide the latch to open or close. These latches are primarily used in light-duty applications, such as cabinet doors. They are cost-effective and easy to install, making them a popular choice for budget-conscious projects. However, buyers should be aware that slide latches may not provide the security needed for high-risk applications, as they typically lack advanced locking features.

How Do Lift & Turn Latches Work?

Lift & turn latches require the user to lift a handle and turn it to engage or disengage the latch. This design is versatile and commonly used in access panels and doors across various sectors. When selecting lift & turn latches, B2B buyers should consider the space required for operation and the latch’s compatibility with their existing hardware. While these latches offer secure closure, they may require more space than simpler designs, which could be a limiting factor in tight installations.

Key Industrial Applications of panel latch hardware

| Industry/Sector | Specific Application of panel latch hardware | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Secure access panels in vehicle manufacturing | Enhances safety and security of vehicle components | Durability under extreme conditions; compliance with automotive standards |

| Electronics | Enclosures for electronic devices | Protects sensitive equipment from damage and tampering | Precision fit; compatibility with various enclosure designs |

| Construction | Access panels in building infrastructure | Facilitates easy maintenance and access to utilities | Corrosion resistance; ability to withstand environmental elements |

| Military & Defense | Secure storage for sensitive equipment | Ensures the safety of critical assets | High-security features; robust materials for harsh environments |

| Industrial Equipment | Access points for machinery and control panels | Improves operational efficiency and safety | Customization options; resistance to wear and tear |

How is Panel Latch Hardware Used in the Automotive Industry?

In the automotive sector, panel latch hardware is crucial for securing access panels in vehicle manufacturing. These latches ensure that components remain safe during transit and assembly, thereby enhancing the overall safety and security of the vehicle. Buyers in this industry should consider durability under extreme conditions, as well as compliance with strict automotive standards, ensuring that the latches can withstand both temperature fluctuations and physical stress.

What Role Does Panel Latch Hardware Play in Electronics?

Panel latch hardware is widely used in the electronics industry to secure enclosures for sensitive devices. This application prevents unauthorized access and protects equipment from damage, dust, and moisture. Buyers should prioritize precision fit and compatibility with various enclosure designs, as mismatched hardware can lead to operational failures and increased costs.

How Does Panel Latch Hardware Benefit Construction Projects?

In construction, panel latches are employed in access panels throughout building infrastructure, facilitating easy maintenance and access to essential utilities. This application is critical in ensuring that maintenance personnel can quickly access electrical and plumbing systems without causing significant disruption. Buyers should focus on corrosion-resistant materials and the ability of the latches to withstand environmental elements, especially in regions with extreme weather conditions.

Why is Panel Latch Hardware Essential for Military and Defense Applications?

For military and defense applications, panel latch hardware secures storage for sensitive equipment, ensuring the safety of critical assets. The latches must provide high-security features to prevent unauthorized access while maintaining ease of operation for authorized personnel. Buyers in this sector need to ensure that the hardware is made from robust materials capable of withstanding harsh environments, thus enhancing the longevity and reliability of the equipment.

How is Panel Latch Hardware Used in Industrial Equipment?

In industrial settings, panel latch hardware is vital for access points on machinery and control panels. It improves operational efficiency by allowing quick access to machinery for maintenance and troubleshooting. Buyers should consider customization options that fit specific machinery designs and resistance to wear and tear, ensuring that the latches will function effectively over time, even in demanding conditions.

3 Common User Pain Points for ‘panel latch hardware’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security for Sensitive Equipment

The Problem: For many businesses, ensuring the security of sensitive equipment or valuable assets housed in cabinets or enclosures is a paramount concern. B2B buyers often face challenges with traditional latching mechanisms that may not provide the level of security required. This can lead to theft, tampering, or unauthorized access, particularly in industries such as electronics, pharmaceuticals, or military applications. Buyers might feel overwhelmed by the variety of options available and uncertain about which panel latch will best meet their security needs.

The Solution: To address these security concerns, businesses should consider investing in high-security panel latch hardware that incorporates advanced locking mechanisms. Look for products that feature key locking systems, such as those offered by Southco or Penn Elcom, which provide robust protection against unauthorized access. It’s also wise to specify latches made from durable materials, such as stainless steel, which are resistant to tampering. Additionally, assess the specific application requirements, such as environmental factors (e.g., moisture, dust) and installation constraints, to ensure that the chosen latches not only secure the equipment but also fit seamlessly into the existing setup. Engage with suppliers who offer customization options to tailor solutions to your specific security needs, ensuring peace of mind.

Scenario 2: Challenges with Compatibility Across Different Applications

The Problem: B2B buyers often struggle with compatibility issues when sourcing panel latch hardware for various applications. For instance, a manufacturer may require different types of latches for various enclosures or equipment but find that some latches do not fit the existing mounting or operational requirements. This can lead to increased costs and project delays as companies scramble to find compatible products, causing frustration and wasted resources.

The Solution: To mitigate compatibility issues, buyers should take a comprehensive inventory of their equipment specifications before making a purchase. This includes understanding the dimensions, mounting styles, and operational requirements (like push-to-close or slam latches) for each application. It is beneficial to collaborate with suppliers who offer a wide range of latch types and configurations, such as TCH or Sugatsune, as they can provide guidance on the most suitable options for specific applications. Moreover, investing in modular latch systems can provide flexibility, allowing for easy swapping and upgrading as needs change. Implementing a thorough testing phase for any new latch hardware before full-scale deployment can help identify compatibility issues early, saving time and resources.

Scenario 3: Difficulties in Maintaining Latch Performance Over Time

The Problem: Many businesses experience performance degradation of panel latch hardware over time, particularly in environments subjected to high levels of stress, such as industrial settings. Frequent wear and tear can lead to latches becoming stuck, difficult to operate, or failing altogether, which can disrupt operations and increase maintenance costs. B2B buyers often find themselves caught in a cycle of replacing faulty latches, which can be both time-consuming and expensive.

The Solution: To enhance the longevity and performance of panel latch hardware, it is essential to select products designed for durability and ease of maintenance. Look for latches that feature corrosion-resistant finishes and robust materials, such as those rated for heavy-duty use. Regular maintenance, such as lubrication and inspection, is also critical; suppliers often provide guidelines on how to care for their products effectively. Additionally, consider sourcing latches with built-in features that mitigate wear, such as compression latches that maintain a tight seal without excessive force. Implementing a maintenance schedule can help ensure that latches remain functional and reliable over time, thereby reducing the need for frequent replacements and associated costs.

Illustrative image related to panel latch hardware

Strategic Material Selection Guide for panel latch hardware

What Are the Key Properties of Common Materials Used in Panel Latch Hardware?

When selecting materials for panel latch hardware, several options are commonly utilized, each with unique properties that can significantly impact performance and suitability for specific applications. Here, we analyze four prevalent materials: steel, aluminum, plastic, and stainless steel.

How Does Steel Perform as a Material for Panel Latch Hardware?

Steel is renowned for its strength and durability, making it a popular choice for panel latch hardware. It typically exhibits high tensile strength, excellent resistance to deformation under pressure, and can withstand significant wear and tear. However, steel is prone to corrosion if not properly treated, which can be a critical factor in humid or coastal environments.

Pros: Steel offers exceptional durability and is cost-effective for mass production. It is suitable for heavy-duty applications and can handle high-stress environments.

Cons: The main drawback is its susceptibility to rust and corrosion, which necessitates protective coatings or finishes. Additionally, the weight of steel can be a disadvantage in applications where weight savings are crucial.

What Advantages Does Aluminum Offer for Panel Latch Hardware?

Aluminum is another widely used material, particularly valued for its lightweight nature and resistance to corrosion. It is often used in applications where weight is a concern, such as in aerospace or portable equipment. Aluminum can be anodized for additional surface protection, enhancing its durability.

Pros: The lightweight characteristic of aluminum makes it ideal for portable applications. Its natural corrosion resistance reduces maintenance needs, and it can be easily machined.

Cons: Aluminum has lower tensile strength compared to steel, making it less suitable for heavy-duty applications. It can also be more expensive than steel, depending on the alloy and finish used.

Why Is Plastic Considered for Panel Latch Hardware?

Plastic materials, such as polycarbonate or nylon, are often used for panel latch hardware due to their lightweight and non-corrosive properties. They can be molded into complex shapes, allowing for innovative designs and functionalities.

Pros: Plastic is resistant to corrosion and can be produced at a lower cost compared to metals. It is also non-conductive, making it suitable for electrical applications.

Cons: The primary limitation of plastic is its lower strength and durability compared to metals, making it unsuitable for high-stress applications. Temperature resistance can also be a concern, as many plastics can deform under high heat.

What Role Does Stainless Steel Play in Panel Latch Hardware?

Stainless steel combines the strength of steel with enhanced corrosion resistance, making it an excellent choice for panel latch hardware exposed to harsh environments. It is available in various grades, allowing for selection based on specific application needs.

Pros: Stainless steel is highly durable and resistant to corrosion, which is crucial for outdoor or marine applications. Its aesthetic appeal also makes it suitable for visible hardware.

Cons: The cost of stainless steel can be significantly higher than that of carbon steel or plastic, which may be a consideration for budget-sensitive projects. Additionally, it can be more challenging to machine compared to other materials.

Summary Table of Material Selection for Panel Latch Hardware

| Material | Typical Use Case for panel latch hardware | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | Exceptional durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight, portable equipment | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Plastic | Electrical enclosures, low-stress uses | Cost-effective and non-corrosive | Lower strength and temperature resistance | Low |

| Stainless Steel | Outdoor and marine applications | High durability and corrosion resistance | Higher cost and machining complexity | High |

This guide provides B2B buyers with essential insights into material selection for panel latch hardware, helping them make informed decisions that align with their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for panel latch hardware

What are the Main Stages in the Manufacturing Process of Panel Latch Hardware?

The manufacturing process for panel latch hardware involves several critical stages that ensure the final product meets the required specifications and quality standards. Each stage plays a vital role in achieving durability, functionality, and performance.

Material Preparation: Selecting the Right Raw Materials

The first step in manufacturing panel latches involves selecting the appropriate raw materials. Common materials include stainless steel, aluminum, and high-grade plastics, chosen for their strength, corrosion resistance, and durability. Material preparation includes cutting, machining, and treating the materials to meet the specifications for each latch type. Techniques such as laser cutting and CNC machining are often employed for precision and efficiency, ensuring that the dimensions are accurate and the surfaces are smooth.

Forming: Shaping the Components

Once the materials are prepared, the next stage is forming. This involves various processes such as stamping, bending, and molding, depending on the design and material used. For instance, metal components may be stamped into shape using hydraulic presses, while plastic components can be produced via injection molding. This stage is crucial as it defines the physical structure and functionality of the latch, ensuring that it will operate as intended when assembled.

Assembly: Bringing Components Together

Following the forming stage, the assembly of panel latch hardware takes place. This involves fitting together the various components, which may include latch bodies, locking mechanisms, and actuation handles. Manual or automated assembly techniques can be utilized, with a focus on precision to avoid misalignments that could affect performance. It is essential that each latch is tested for smooth operation during this stage to ensure that all moving parts function correctly.

Finishing: Ensuring Aesthetic and Functional Quality

The final manufacturing stage is finishing, which enhances both the aesthetic appeal and the durability of the panel latches. This can include processes such as surface treatment, coating, and painting. Common techniques include powder coating for a durable finish or anodizing for aluminum components to enhance corrosion resistance. Quality control during this stage ensures that the latches not only look good but also meet the functional requirements for various environments.

How is Quality Assurance Implemented in Panel Latch Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process for panel latches, ensuring that each product meets international and industry-specific standards. Implementing a robust QA system helps manufacturers maintain consistency and reliability in their products.

Illustrative image related to panel latch hardware

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are essential for manufacturers of panel latch hardware. ISO 9001 establishes criteria for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for European markets or API (American Petroleum Institute) standards for latches used in oil and gas applications are critical. These certifications signify that the products have undergone rigorous testing and meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process, typically categorized into three main areas:

-

Incoming Quality Control (IQC): This checkpoint occurs at the beginning of the manufacturing process, where raw materials are inspected for quality and compliance with specifications. Ensuring that only high-quality materials enter the production line is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): This stage involves monitoring the manufacturing process itself. Regular inspections during forming, assembly, and finishing ensure that any deviations from standards are identified and corrected promptly. Techniques such as statistical process control (SPC) can be employed to track performance metrics.

-

Final Quality Control (FQC): Before shipping, a thorough inspection of the finished products is conducted. This includes functional testing, dimensional checks, and surface quality assessments. Products that do not meet specifications are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability and performance. Here are several strategies to consider:

What Should Buyers Look for in Supplier Audits?

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance systems. Buyers should look for suppliers that have undergone third-party audits and hold relevant certifications. This transparency can help build trust and ensure that the supplier adheres to quality standards.

Illustrative image related to panel latch hardware

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers can provide valuable information regarding their QA processes and product performance. These reports should detail inspection results, testing methodologies, and any corrective actions taken for non-conforming products. Buyers should ensure that these reports are comprehensive and regularly updated.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further assure buyers of the quality of panel latch hardware. These independent entities can conduct pre-shipment inspections to verify that products meet specified standards and requirements. This additional layer of scrutiny can help mitigate risks associated with purchasing from international suppliers.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Illustrative image related to panel latch hardware

-

Cultural Differences: Understanding the local manufacturing culture can help buyers navigate communication and expectations. Some regions may have different approaches to quality management, which can affect the consistency of product quality.

-

Regulatory Compliance: Buyers should familiarize themselves with the regulatory standards applicable in their respective markets. This includes understanding how international standards are implemented locally and any additional certifications that may be required.

-

Logistics and Supply Chain Considerations: Quality assurance doesn’t end with manufacturing. Buyers must also consider logistics and how transportation conditions might impact the integrity of the products. Proper packaging and handling instructions should be provided by suppliers to mitigate risks during transit.

By understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing panel latch hardware. This knowledge not only helps in selecting reliable suppliers but also ensures that the products meet their operational requirements and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘panel latch hardware’

Introduction

Sourcing panel latch hardware effectively is vital for ensuring security, functionality, and durability in various applications. This checklist will guide international B2B buyers through the critical steps necessary to procure high-quality panel latch hardware, tailored to your specific needs. By following this structured approach, you can minimize risks and maximize value in your sourcing decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. Consider factors such as the latch type (e.g., compression, slam, or push-to-close), material (metal, plastic, etc.), size, and any specific industry standards. Defining these specifications upfront will help you communicate effectively with suppliers and ensure you receive products that meet your operational needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize online platforms, industry directories, and trade shows to find manufacturers and distributors known for quality panel latch hardware. Pay attention to their market presence, customer reviews, and reputation within your industry, which can provide insights into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier list, it is essential to verify their certifications. Check for ISO certifications or compliance with relevant safety and quality standards, which can indicate a commitment to quality and customer satisfaction. Suppliers with recognized certifications are generally more reliable and can offer better assurances regarding the performance of their products.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of their panel latch hardware. Testing samples allows you to assess the quality, functionality, and compatibility of the products with your applications. Evaluate aspects such as durability, ease of installation, and operational efficiency to ensure they meet your specifications.

Step 5: Assess Pricing and Payment Terms

Pricing is a crucial factor in sourcing decisions. Compare quotes from different suppliers, but don’t focus solely on the lowest price; consider the overall value, including product quality and service. Additionally, clarify payment terms, including any available discounts for bulk orders, to ensure that the financial arrangements align with your budget and cash flow needs.

Step 6: Review Shipping and Delivery Options

Consider the logistics involved in procuring panel latch hardware. Review the supplier’s shipping options, lead times, and delivery reliability. It’s also important to understand any potential customs duties and regulations that may apply, especially for international shipments, to avoid unexpected costs and delays.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your chosen supplier can lead to better terms and improved service over time. Engage in regular communication, provide feedback on products and service, and explore opportunities for collaboration on future projects. A solid partnership can enhance your supply chain resilience and create more value in the long run.

Illustrative image related to panel latch hardware

By following this step-by-step checklist, you can streamline your sourcing process for panel latch hardware and make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for panel latch hardware Sourcing

Understanding the cost structure and pricing dynamics of panel latch hardware is crucial for B2B buyers looking to optimize their sourcing strategies. This analysis will delve into the various cost components, price influencers, and provide actionable tips for international buyers, particularly from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components of Panel Latch Hardware?

The cost structure of panel latch hardware comprises several components:

-

Materials: The choice of materials significantly impacts cost. Common options include steel, aluminum, and plastic, each offering different durability and price points. High-quality materials may increase upfront costs but can reduce long-term maintenance expenses.

-

Labor: Labor costs vary by region and manufacturing complexity. Automated processes may lower labor costs, while skilled craftsmanship may demand higher wages. Understanding local labor markets is essential for accurate cost projections.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. Efficient manufacturing practices can help reduce overhead, thereby lowering the final product price.

-

Tooling: Custom tooling for specific latch designs can incur significant one-time costs. Buyers should consider these expenses when evaluating total costs, especially for unique specifications.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability, but it also adds to costs. Buyers should weigh the benefits of enhanced quality against the associated expenses.

-

Logistics: Transportation and warehousing costs can vary widely based on the location of suppliers and buyers. International shipping may involve customs duties and tariffs, impacting overall expenses.

-

Margin: Suppliers typically include a margin in their pricing to cover risks and profit. This margin can fluctuate based on market competition and demand.

How Do Price Influencers Affect Panel Latch Hardware Costs?

Several factors influence the pricing of panel latch hardware:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders can lead to significant discounts. Suppliers often set MOQs, which can impact pricing structures. Buyers should assess their needs against these thresholds to optimize costs.

-

Specifications and Customization: Custom designs or features typically incur higher costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, UL) may increase costs but can provide assurance of product performance and safety, which is crucial for certain industries.

-

Supplier Factors: Supplier reputation, reliability, and location can influence prices. Established suppliers may charge a premium for their credibility and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital. These terms define responsibilities for shipping costs and risks, which can significantly impact total landed costs.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

To maximize value when sourcing panel latch hardware, consider these strategies:

-

Negotiate for Volume Discounts: Engage suppliers in discussions about pricing based on anticipated order volumes. Many suppliers are willing to offer better rates for larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, replacement, and operational costs associated with the hardware to assess the true value.

-

Understand Regional Pricing Nuances: Pricing can vary significantly by region due to differences in labor costs, material availability, and shipping logistics. Buyers should conduct thorough market research to identify competitive pricing in their target regions.

-

Utilize Local Suppliers When Possible: Sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various suppliers can provide leverage in negotiations and help identify the best pricing options.

Conclusion

Navigating the cost and pricing landscape of panel latch hardware requires a comprehensive understanding of the various components and influencing factors. By leveraging this knowledge, B2B buyers can make informed decisions that align with their operational needs and budget constraints. As always, it is advisable to approach negotiations with a clear strategy and awareness of the broader market dynamics.

Disclaimer: The prices referenced in this analysis are indicative and may vary based on specific supplier quotes and market conditions.

Illustrative image related to panel latch hardware

Alternatives Analysis: Comparing panel latch hardware With Other Solutions

Exploring Alternative Solutions to Panel Latch Hardware

In the realm of securing access panels, panel latch hardware is a popular choice, but it is not the only option available. Businesses often seek alternatives that might better suit their specific requirements in terms of performance, cost, and ease of implementation. This section presents a comparative analysis of panel latch hardware against two viable alternatives: sliding bolt locks and electronic access control systems.

Comparison Table

| Comparison Aspect | Panel Latch Hardware | Sliding Bolt Locks | Electronic Access Control Systems |

|---|---|---|---|

| Performance | Reliable, strong locking mechanism; suitable for various applications | Provides robust security; limited to manual operation | High security with programmable access; can monitor usage |

| Cost | Moderate initial investment; low long-term costs | Lower upfront cost; potential higher replacement costs | Higher initial investment; ongoing costs for maintenance and updates |

| Ease of Implementation | Straightforward installation; minimal tools required | Simple installation; requires some manual adjustments | Complex installation; may require professional services |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; may need regular adjustments | High maintenance; software and hardware updates needed |

| Best Use Case | Ideal for enclosures, cabinets, and cases requiring frequent access | Best for doors or gates needing manual secure closure | Suitable for high-security areas needing controlled access and tracking |

In-Depth Analysis of Alternatives

Sliding Bolt Locks

Sliding bolt locks are a straightforward alternative to panel latch hardware, offering a robust locking mechanism that is effective for securing doors and gates. Their primary advantage lies in their simplicity and low cost, making them an attractive option for budget-conscious projects. However, while sliding bolt locks provide a good level of security, they require manual operation and may not be as user-friendly in high-traffic scenarios. Additionally, they may demand more frequent adjustments and maintenance to ensure optimal performance.

Electronic Access Control Systems

For organizations prioritizing security and access management, electronic access control systems present a sophisticated alternative. These systems enable programmable access, allowing businesses to control who enters specific areas and to track usage. The primary benefits include enhanced security features and the ability to integrate with other security systems. However, the complexity of installation and the higher upfront costs can deter some buyers. Additionally, ongoing maintenance, including software updates and potential hardware replacements, can add to the overall cost of ownership.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating which access solution best meets your business requirements, consider your specific operational needs, budget constraints, and long-term maintenance capabilities. Panel latch hardware is an excellent choice for applications requiring reliable and frequent access with low maintenance. In contrast, if your focus is on high security and access management, investing in electronic access control systems may be warranted despite their complexity and cost. Sliding bolt locks can serve as a cost-effective solution for simpler applications. Ultimately, aligning the choice of hardware with your operational objectives will ensure optimal performance and security for your access panels.

Essential Technical Properties and Trade Terminology for panel latch hardware

What Are the Essential Technical Properties of Panel Latch Hardware?

Understanding the technical properties of panel latch hardware is crucial for B2B buyers, particularly when evaluating options for durability, security, and compatibility with specific applications. Here are key specifications to consider:

Illustrative image related to panel latch hardware

-

Material Grade

The material of panel latches—commonly stainless steel, zinc alloy, or plastic—affects durability and corrosion resistance. Stainless steel is ideal for outdoor applications due to its high resistance to rust and wear, while plastic latches may be suitable for lightweight or less demanding environments. Selecting the right material grade ensures longevity and reduces replacement costs, which is particularly important for buyers in harsh climates. -

Load Capacity

Load capacity refers to the maximum weight a latch can securely hold. This is critical for applications where the latch will bear significant weight or force, such as in heavy access panels or enclosures. Understanding load capacity helps buyers choose the appropriate latch for their specific needs, avoiding failures that can lead to safety hazards or product damage. -

Tolerance Levels

Tolerance indicates the allowable variation in dimensions during manufacturing. Tight tolerances ensure a snug fit, which is essential for maintaining security and functionality. For B2B buyers, especially in industries such as aerospace or automotive, high-tolerance components are vital for compliance with industry standards and preventing operational issues. -

Actuation Type

Panel latches can be actuated in various ways, including key, lever, or push-to-close mechanisms. The choice of actuation type impacts user convenience and security. For instance, key locks provide enhanced security, while push-to-close latches offer ease of use in high-traffic areas. Buyers should assess the operational context to determine the most suitable actuation method. -

Ingress Protection Rating (IP Rating)

The IP rating indicates the level of protection against dust and moisture. An IP rating of IP65, for example, signifies that the latch is dust-tight and protected against water jets. This is particularly relevant for outdoor applications or environments exposed to dust and moisture, making it a critical consideration for buyers focused on reliability and safety.

Which Common Trade Terms Are Used in the Panel Latch Hardware Industry?

Familiarity with industry terminology can greatly enhance communication and negotiation between B2B buyers and suppliers. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs can ensure high-quality components tailored to specific applications, leading to better integration with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs effectively. It helps in planning purchases to avoid excess stock or the need for frequent reorders. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers. It details the specifications and quantities of the desired products. For B2B buyers, issuing RFQs can streamline the procurement process and foster competitive pricing, ensuring better budget management. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowledge of these terms is crucial for international buyers to clarify costs and risks associated with transportation and delivery, thus preventing misunderstandings. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is vital for supply chain management, enabling buyers to plan projects and avoid delays in production or service delivery.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the most appropriate panel latch hardware for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the panel latch hardware Sector

What Are the Current Market Dynamics and Key Trends in the Panel Latch Hardware Sector?

The panel latch hardware market is experiencing robust growth, driven by several global factors. Firstly, the increasing demand for customized and secure solutions across various industries—such as automotive, aerospace, and electronics—is shaping the landscape. B2B buyers, particularly in emerging markets like Africa and South America, are seeking innovative hardware solutions that enhance security and functionality. The rise of e-commerce has also led to a surge in demand for efficient logistics and packaging solutions, where panel latch hardware plays a crucial role.

In terms of technology, manufacturers are increasingly integrating advanced materials and smart locking mechanisms into their products. Features such as electronic locking systems and remote access capabilities are becoming more common, catering to the needs of modern applications. Additionally, the trend towards modular designs allows for more flexible configurations, appealing to international buyers looking for versatile solutions.

Another noteworthy trend is the focus on supply chain optimization. B2B buyers are now prioritizing suppliers who can offer shorter lead times and reliable delivery. This has prompted manufacturers to adopt just-in-time production strategies and invest in local sourcing to meet the demands of their global clientele efficiently.

Illustrative image related to panel latch hardware

How Important Is Sustainability and Ethical Sourcing in the Panel Latch Hardware Market?

Sustainability has become a critical consideration for B2B buyers in the panel latch hardware sector. The environmental impact of manufacturing processes, particularly in metal and plastic production, has led to increased scrutiny from consumers and businesses alike. Buyers are now favoring suppliers that prioritize eco-friendly practices, such as using recycled materials and minimizing waste in production.

Ethical sourcing is equally important, with buyers increasingly demanding transparency in the supply chain. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming vital for companies looking to establish credibility and trust with their customers. Suppliers that can demonstrate compliance with these standards are likely to gain a competitive edge.

Incorporating ‘green’ materials into panel latch hardware—such as bio-based plastics or sustainably sourced metals—can also appeal to environmentally conscious consumers. This shift towards sustainability not only helps reduce environmental impact but can also lead to cost savings in the long run, making it a win-win for both suppliers and buyers.

Illustrative image related to panel latch hardware

How Has the Panel Latch Hardware Sector Evolved Over Time?

The evolution of panel latch hardware can be traced back to basic mechanical locking systems used in early industrial applications. Initially designed for functionality and security, these latches have transformed significantly with advancements in technology. The introduction of materials like stainless steel and high-grade plastics has improved durability and resistance to environmental factors.

Over the years, the sector has embraced innovation, moving towards more complex locking mechanisms and integrated smart technology. This evolution is a response to the growing needs for enhanced security and efficiency in various industries. As global supply chains continue to adapt and evolve, the panel latch hardware market is likely to see further advancements that cater to the increasingly diverse requirements of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of panel latch hardware

-

How do I choose the right panel latch hardware for my application?

Selecting the appropriate panel latch hardware depends on several factors, including the type of application, security requirements, and environmental conditions. Assess the materials needed—such as steel for durability or plastic for lightweight applications. Consider the latch style (e.g., compression, slam, or sliding) that best fits your design. Additionally, evaluate the latch’s locking mechanism, especially if security is a priority. Engaging with suppliers who offer customization can also help ensure that the hardware meets your specific requirements. -

What are the most common types of panel latches available?

Common types of panel latches include compression latches, slam latches, sliding latches, and push-to-close latches. Compression latches are ideal for applications requiring a tight seal, while slam latches provide quick access without the need for keys. Sliding latches are often used in enclosures, and push-to-close latches offer convenience for frequent access. When selecting a latch type, consider the operational requirements, security level, and installation ease specific to your project. -

What factors should I consider when sourcing panel latch hardware internationally?

When sourcing panel latch hardware internationally, consider factors such as supplier reliability, compliance with international standards, and shipping logistics. Vet potential suppliers by reviewing their certifications, product quality, and customer feedback. Understand the import regulations and tariffs applicable in your country. Additionally, clear communication regarding product specifications, lead times, and payment terms is crucial to avoid misunderstandings and ensure a smooth transaction. -

What is the typical minimum order quantity (MOQ) for panel latch hardware?

Minimum order quantities (MOQ) for panel latch hardware can vary widely depending on the supplier and the specific type of latch. While some manufacturers may allow orders of as few as 100 units, others may require orders in the thousands for custom or specialized latches. It’s essential to discuss your needs with potential suppliers to understand their MOQs, as well as any flexibility they may offer for smaller orders. -

How can I ensure the quality of panel latch hardware before purchasing?

To ensure quality, request product samples and review technical data sheets from suppliers. Look for certifications indicating compliance with industry standards, such as ISO or RoHS, which can assure you of the product’s reliability and safety. Conduct a factory audit if possible, or consider third-party quality inspections before shipment. Establishing a good relationship with your supplier can also facilitate better quality control measures and communication. -

What payment terms are typically offered for international purchases of panel latch hardware?

Payment terms for international purchases can range from upfront payments to letters of credit or payment upon delivery. Many suppliers may require a deposit (often 30-50%) before manufacturing, with the remainder due upon shipment. Discussing terms in advance is crucial, as it helps align expectations and reduce financial risks. Additionally, consider using secure payment methods that provide buyer protection, especially for larger transactions. -

What are the logistics considerations when importing panel latch hardware?

Logistics considerations include shipping methods, transit times, and customs clearance processes. Choose a shipping method that balances cost and speed, such as sea freight for bulk orders or air freight for urgent needs. Ensure that all documentation is in order, including commercial invoices, packing lists, and certificates of origin to facilitate smooth customs clearance. Working with a freight forwarder can help navigate these complexities and ensure timely delivery. -

Can I customize panel latch hardware for my specific needs?

Yes, many manufacturers offer customization options for panel latch hardware. Customization can include variations in size, material, color, and locking mechanisms to better fit your application. When discussing customization, provide detailed specifications and requirements to your supplier. Be aware that custom orders may have longer lead times and higher MOQs, so plan accordingly to meet your project timelines.

Top 5 Panel Latch Hardware Manufacturers & Suppliers List

1. Reid Supply – Panel Latches

Domain: reidsupply.com

Registered: 2004 (21 years)

Introduction: Panel latches are essential components used to secure access points on enclosures, cabinets, and panels. They provide a reliable locking mechanism to ensure safety and security. Available in various styles and materials, panel latches can be used in a wide range of applications, including industrial, commercial, and residential settings. Key features may include ease of installation, durability, a…

2. Penn Elcom – Panel Locks

Domain: penn-elcom.com

Registered: 2003 (22 years)

Introduction: Panel Locks from Penn Elcom include various male and female panel locks designed for use with specific models. Key products include: 1. Male Panel Lock (9274M) – $13.94 (was $19.45, save 28%) 2. Female Panel Lock (9274F) – $6.49 3. Male Panel Lock (9284M) – $7.29 4. Female Panel Lock (9284F) – $4.11 5. Male Panel Lock (9280M) – $10.84 6. Female Panel Lock (9280F) – $4.32 7. Male Panel Lock (9290M)…

3. McMaster – Panel Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Panel Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. TCH – Southco Sliding Flush Latch

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: Access Panel Latches – TCH offers a variety of access panel latches including lockable, slide, flush, slam, push-to-close, lift & turn, and compression latches in various sizes. Materials include steel and plastic. Key products include: 1. Southco Sliding Flush Latch – B7-10-301-10, Price: $15.33 USD, SKU: 555-B71030110 2. Rear Mount Slam Latch with Spacer, Price: $22.54 USD, SKU: 501-8015800 3. F…

5. Sugatsune – LC-PK32 & LC-PL32 Panel Latch

Domain: global.sugatsune.com

Registered: 1996 (29 years)

Introduction: Product Name: LC-PK32, LC-PL32

Type: Panel Latch

Lock/Unlock Methods: Lever type and key type (compatible)

Unlock Mechanism: 90 degrees counterclockwise

Temporary Holding Function: Yes, allows multiple latches to be held in unlocked state

Key Type: Prevents unexpected door opening

Material: Flame retardant material rated UL94V-0

Spring Material: Stainless steel (SUS304)

Available Variants:

1. LC-P…

Strategic Sourcing Conclusion and Outlook for panel latch hardware

What Are the Key Takeaways for Sourcing Panel Latch Hardware?

In the evolving landscape of panel latch hardware, strategic sourcing emerges as a crucial factor for international buyers. Understanding diverse product offerings, from lockable slide latches to compression latches, allows businesses to tailor solutions that meet specific application needs. Buyers should prioritize suppliers that offer customization options and robust support services, ensuring that the products align with their operational requirements.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in strategic sourcing not only optimizes procurement costs but also enhances product quality and availability. As global supply chains become increasingly interconnected, leveraging relationships with manufacturers across regions—especially in Africa, South America, the Middle East, and Europe—can yield significant benefits. This proactive approach fosters innovation, reduces lead times, and improves responsiveness to market demands.

What Should International Buyers Do Next?

Looking ahead, international buyers are encouraged to explore new partnerships and expand their sourcing strategies. By engaging with suppliers who understand local market nuances and can offer tailored solutions, businesses can position themselves for success in a competitive environment. Embrace the opportunities within the panel latch hardware market to enhance your product offerings and drive business growth in the coming years.

Illustrative image related to panel latch hardware

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.