Top 5 Ominix Belt Suppliers (And How to Choose)

Introduction: Navigating the Global Market for ominix belt

In the rapidly evolving global marketplace, sourcing the right Omix belt can be a daunting task for B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality products but also in ensuring compatibility with various vehicle models and applications. This comprehensive guide aims to demystify the complexities surrounding Omix belts, offering insights into different types, their applications, and how to effectively vet suppliers.

Navigating the intricate landscape of suppliers and pricing can be overwhelming, especially for international buyers. By providing an in-depth analysis of available Omix belt options—including V-belts and serpentine belts—this guide empowers businesses to make informed purchasing decisions. It covers crucial aspects such as cost considerations, warranty offerings, and essential specifications that align with regional requirements.

Whether you are a fleet manager in Brazil looking to enhance vehicle performance or a procurement officer in Saudi Arabia tasked with sourcing durable automotive components, this guide serves as a valuable resource. It not only highlights the key factors influencing your purchasing strategy but also ensures you have the tools to negotiate effectively and establish robust supplier relationships. By leveraging this knowledge, international B2B buyers can confidently navigate the global market for Omix belts, ultimately driving operational efficiency and cost-effectiveness.

Understanding ominix belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| V-Belts | Triangle-shaped cross-section, tension required | Agricultural machinery, HVAC systems | Pros: Cost-effective, easy to replace. Cons: Limited power transmission, shorter lifespan. |

| Serpentine Belts | Flat, multi-groove design, runs multiple accessories | Automotive engines, industrial equipment | Pros: Efficient power transfer, compact. Cons: More complex installation, potential for slipping. |

| Gilmer Belts | Tooth-like design for positive engagement | High-performance vehicles, racing | Pros: High torque capability, precise operation. Cons: Higher cost, requires precise alignment. |

| Timing Belts | Reinforced rubber with teeth for synchronization | Engine timing systems, machinery | Pros: Accurate timing, quiet operation. Cons: Requires regular replacement, sensitive to oil exposure. |

| Flat Belts | Smooth surface, typically used in conveyor systems | Manufacturing, packaging industries | Pros: Versatile, low maintenance. Cons: Limited grip, may slip under heavy load. |

What Are the Characteristics of V-Belts and Their B2B Suitability?

V-belts feature a triangular cross-section that allows them to fit into pulley grooves, providing a reliable grip under tension. These belts are widely used in agricultural machinery and HVAC systems, where they efficiently transmit power between components. For B2B buyers, V-belts are appealing due to their cost-effectiveness and ease of replacement. However, their limited power transmission capacity and shorter lifespan compared to other belt types may necessitate more frequent replacements, impacting long-term costs.

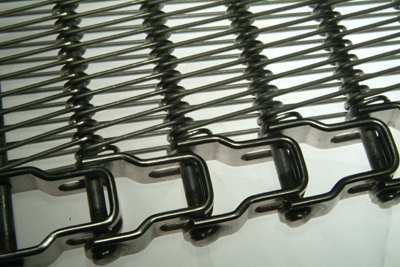

How Do Serpentine Belts Differ and Where Are They Commonly Used?

Serpentine belts are characterized by their flat design with multiple grooves that allow them to drive several accessories simultaneously, such as alternators and air conditioning compressors. Commonly found in automotive engines and industrial equipment, serpentine belts are known for their efficient power transfer and compact design. B2B buyers benefit from their versatility and space-saving features, but they can be more complex to install and may slip if not properly tensioned, which could lead to operational issues.

What Advantages Do Gilmer Belts Offer for High-Performance Applications?

Gilmer belts are distinguished by their toothed design, which ensures positive engagement with pulleys, making them ideal for high-performance applications such as racing vehicles. These belts excel in transmitting high torque and maintaining precise operation, which is crucial in performance-driven environments. While they provide significant advantages in terms of performance, B2B buyers should consider their higher cost and the need for precise alignment during installation, which may require specialized knowledge.

Why Are Timing Belts Important and What Are Their Key Features?

Timing belts are made from reinforced rubber and feature teeth that allow them to synchronize the operation of engine components. Their primary applications include engine timing systems and various machinery that require precise timing. For B2B buyers, timing belts are essential for ensuring accurate operation and quiet functioning. However, they require regular replacement and are sensitive to oil exposure, which can lead to premature failure if not monitored closely.

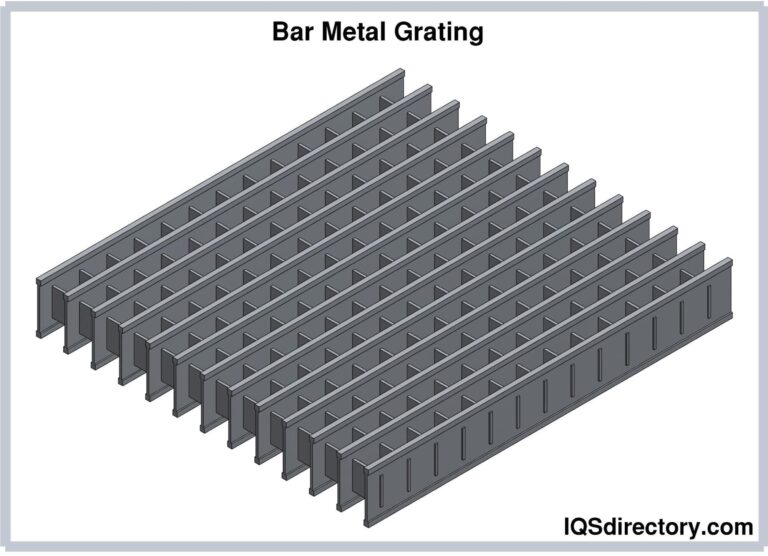

What Role Do Flat Belts Play in Manufacturing and Packaging Industries?

Flat belts have a smooth surface and are commonly used in conveyor systems across manufacturing and packaging industries. Their versatility makes them suitable for various applications, allowing for efficient movement of materials. Flat belts are low maintenance and can be easily replaced, appealing to B2B buyers looking for operational simplicity. However, they may have limited grip and can slip under heavy loads, which is a consideration for industries handling substantial weights.

Key Industrial Applications of ominix belt

| Industry/Sector | Specific Application of ominix belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Drive Systems | Enhances vehicle performance and reliability | Compatibility with specific vehicle models and OEM standards |

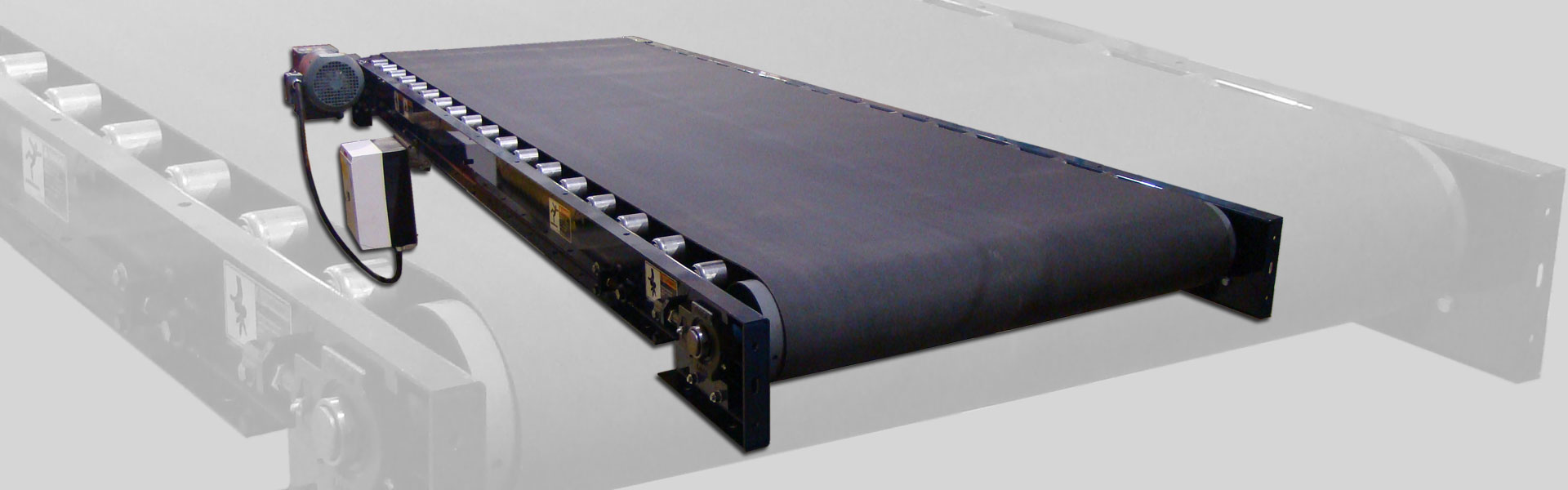

| Manufacturing | Conveyor Systems | Increases operational efficiency and reduces downtime | Durability and resistance to wear, tailored to specific loads |

| Agriculture | Agricultural Equipment | Improves machinery efficiency and reduces maintenance costs | Ability to withstand harsh environmental conditions and heavy loads |

| Construction | Heavy Machinery | Ensures consistent power transfer and reliability | Compliance with safety standards and material durability |

| Mining | Conveying and Processing Equipment | Enhances material handling efficiency and reduces breakdowns | Customization for specific mining applications and resistance to abrasion |

How is the ominix belt utilized in the automotive sector?

In the automotive industry, the ominix belt is primarily used in engine drive systems, connecting various components such as the alternator, water pump, and power steering pump. This belt is crucial for ensuring optimal performance and reliability in vehicles. For international buyers, particularly in regions like Africa and South America, understanding the compatibility of the ominix belt with specific vehicle models is essential. The belts must meet OEM standards to avoid performance issues and ensure longevity, which is vital in markets where vehicle maintenance resources may be limited.

What role does the ominix belt play in manufacturing operations?

In manufacturing, ominix belts are integral to conveyor systems, facilitating the movement of materials and products throughout production lines. By utilizing these belts, businesses can significantly increase operational efficiency and minimize downtime caused by equipment failures. For B2B buyers in Europe and the Middle East, sourcing belts that are durable and resistant to wear is critical, especially in high-load environments. Additionally, manufacturers should consider the specific load requirements and the belt’s adaptability to different machinery to optimize performance.

How does the ominix belt enhance agricultural machinery performance?

Agricultural equipment relies heavily on the ominix belt to improve efficiency and reduce maintenance costs. These belts are used in tractors and harvesters, ensuring that power is effectively transmitted to various machine components. For buyers in regions like Brazil, where agricultural machinery is frequently subjected to tough working conditions, sourcing belts that can withstand high levels of stress and environmental factors is vital. The ability of ominix belts to reduce wear and enhance machinery performance can lead to significant cost savings over time.

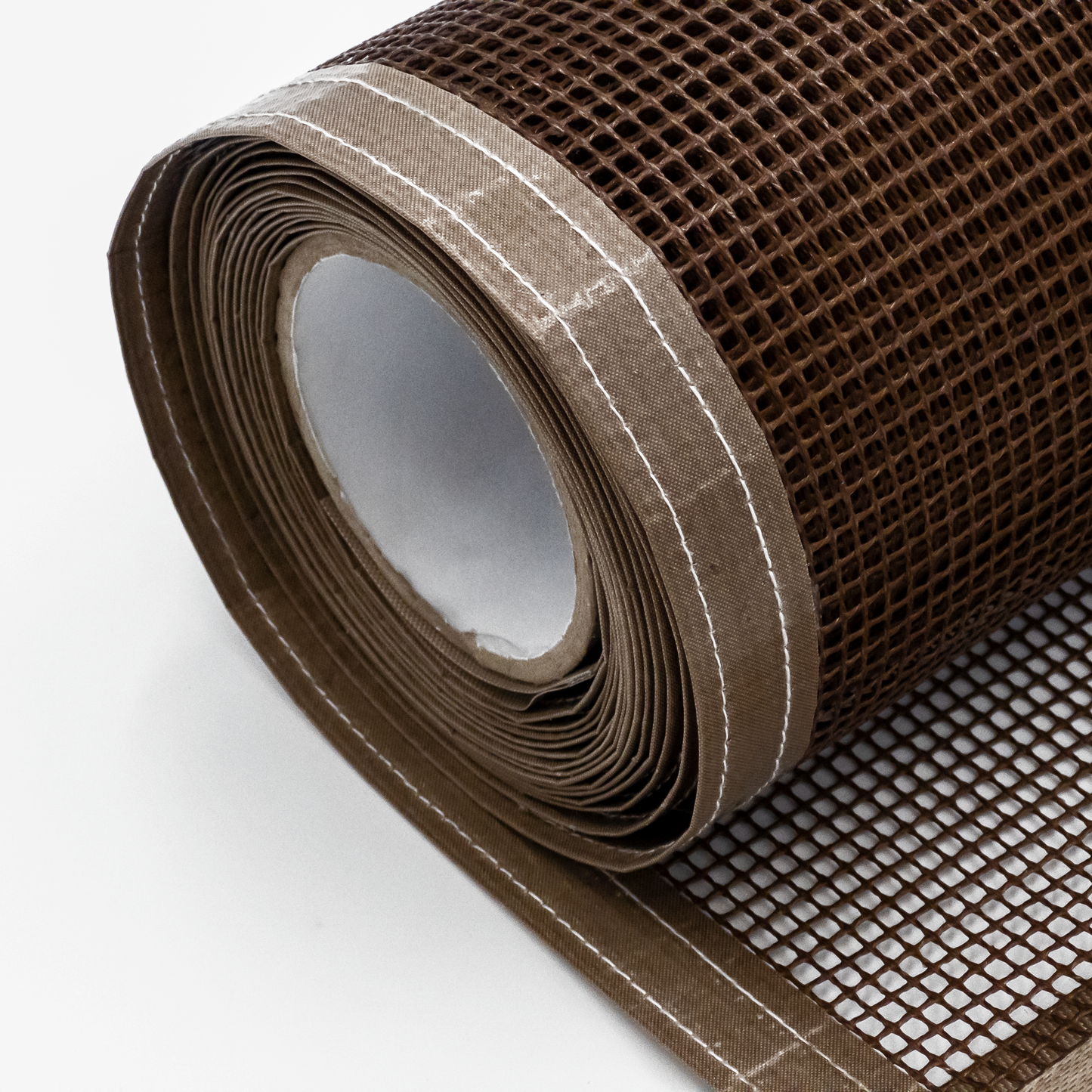

Illustrative image related to ominix belt

Why is the ominix belt essential for construction machinery?

In the construction sector, ominix belts are critical for heavy machinery, ensuring reliable power transfer for operations such as digging and lifting. The durability of these belts helps prevent breakdowns, which can lead to costly project delays. For buyers in the Middle East and Europe, it is essential to ensure that the belts comply with safety standards and are made from materials that can withstand the rigors of construction work. Proper sourcing can lead to improved safety and efficiency on construction sites.

How does the ominix belt improve efficiency in mining operations?

In mining, the ominix belt is utilized in various conveying and processing equipment, where its role is to enhance material handling efficiency. The belts are designed to reduce the frequency of breakdowns, which is crucial in maintaining operational continuity in challenging environments. International buyers, especially from regions with significant mining activities, should focus on sourcing belts that are customizable to specific applications and resistant to abrasion. This ensures that the belts can handle the demands of heavy-duty mining operations while maintaining performance over time.

3 Common User Pain Points for ‘ominix belt’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Ominix Belt for Specific Applications

The Problem: B2B buyers often encounter challenges when trying to source the correct Ominix belt for specific machinery or vehicle models. With a diverse range of belts available, each designed for various applications, the risk of ordering an incompatible product is high. This not only leads to delays in operations but can also result in increased costs due to returns and restocking fees. Buyers may struggle with identifying the exact specifications needed, such as length, width, and groove count, particularly if they lack detailed product knowledge.

The Solution: To mitigate sourcing issues, B2B buyers should establish a systematic approach to identifying the correct Ominix belt. Start by consulting the equipment’s service manual or manufacturer’s specifications, which typically outline the exact belt requirements. If the documentation is unavailable, utilizing online resources and databases that provide detailed specifications for various Ominix belts can be invaluable. Engaging with suppliers who offer belt identification services can also streamline the process. Additionally, building a relationship with a reliable distributor can facilitate quicker access to the right products and reduce lead times, ensuring that you have the necessary belts on hand for operational continuity.

Scenario 2: Challenges with Belt Durability and Performance

The Problem: Another common pain point for B2B buyers is the premature wear and tear of Ominix belts, which can lead to unexpected breakdowns and costly repairs. Factors such as extreme operating conditions, improper installation, or subpar maintenance practices often contribute to this issue. Buyers may find themselves frequently replacing belts, which not only disrupts workflow but also strains budgets.

The Solution: To enhance the durability and performance of Ominix belts, it is crucial to implement a comprehensive maintenance strategy. Start by ensuring that all belts are installed according to the manufacturer’s guidelines, paying special attention to tension and alignment. Regularly scheduled inspections can help identify signs of wear before they lead to failure. Additionally, consider utilizing belts specifically designed for high-stress environments, as they often feature advanced materials that resist heat, abrasion, and oil exposure. Training maintenance personnel on best practices for belt care and monitoring operational conditions can also significantly extend the life of Ominix belts.

Illustrative image related to ominix belt

Scenario 3: Inadequate Support and Technical Guidance

The Problem: Many B2B buyers experience frustration when they lack access to adequate support and technical guidance regarding the installation and maintenance of Ominix belts. This can result in improper installation, leading to performance issues and increased downtime. Buyers may feel overwhelmed by the technical specifications and installation processes, especially in industries that require a high level of precision.

The Solution: To overcome this obstacle, buyers should actively seek out suppliers that provide comprehensive support services. Look for distributors that offer technical resources, including installation guides, video tutorials, and dedicated customer service representatives. Participating in training workshops or webinars hosted by the supplier can also empower teams with the necessary knowledge and skills to handle Ominix belt installations and maintenance effectively. Furthermore, creating a feedback loop where maintenance teams can share experiences and challenges can foster continuous improvement and support the development of best practices within the organization. By prioritizing education and support, buyers can ensure the optimal performance of Ominix belts and reduce the likelihood of operational disruptions.

Strategic Material Selection Guide for ominix belt

When selecting materials for the Omix belt, it’s essential to consider the performance characteristics, cost implications, and suitability for specific applications. Below is an analysis of four common materials used in the manufacturing of Omix belts, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Rubber in Omix Belts?

Rubber is the most widely used material for Omix belts due to its excellent elasticity and durability. It can withstand a wide range of temperatures, typically from -30°C to 100°C, making it suitable for various environments. Additionally, rubber exhibits good resistance to abrasion and wear, which is critical for belts that undergo constant friction and tension.

Pros: Rubber is relatively low-cost, easy to manufacture, and provides excellent grip and flexibility. It is also compatible with a variety of media, including oils and fuels.

Cons: Rubber can degrade over time when exposed to UV light and extreme temperatures, which may limit its lifespan. It also has a lower resistance to certain chemicals compared to synthetic alternatives.

Impact on Application: Rubber belts are ideal for automotive applications, especially in environments with fluctuating temperatures and exposure to oils.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM D2000 for rubber materials, especially when sourcing from different regions.

How Does Polyurethane Compare as a Material for Omix Belts?

Polyurethane is another material option that offers superior abrasion resistance and flexibility. It typically operates effectively within a temperature range of -30°C to 80°C, making it suitable for moderate environments.

Pros: Polyurethane belts are highly durable and resistant to cuts and tears, which enhances their longevity. They also maintain their flexibility over a wide temperature range.

Cons: The manufacturing complexity of polyurethane can lead to higher costs compared to rubber. Additionally, it may not perform well in high-temperature applications beyond its rated limits.

Impact on Application: These belts are often used in applications requiring high wear resistance, such as in industrial machinery.

Considerations for International Buyers: Buyers should be aware of the specific grades of polyurethane that meet regional standards, such as DIN 7720, for material specifications.

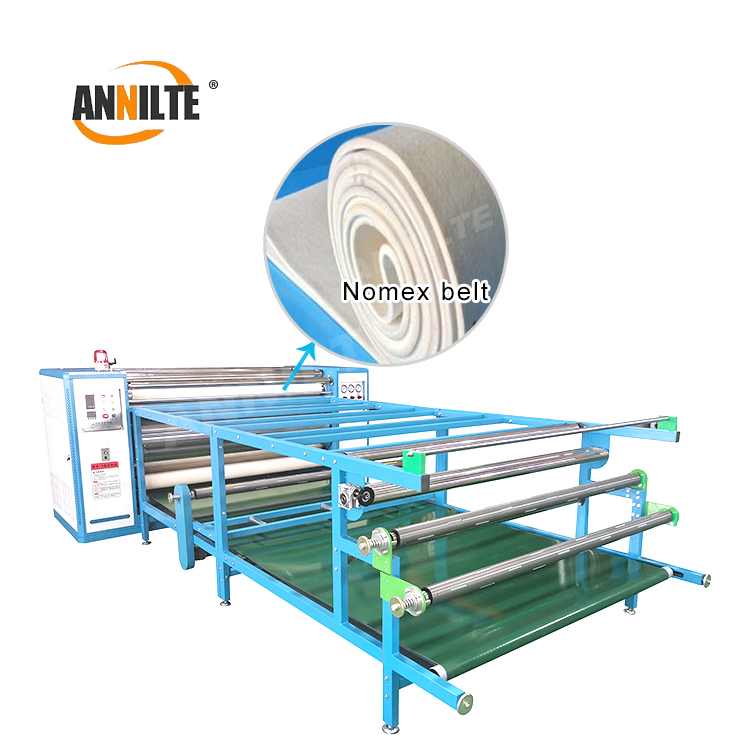

What Are the Advantages of Nylon in Omix Belts?

Nylon is known for its strength and resistance to wear and tear, making it a viable option for specific Omix belt applications. It can withstand temperatures up to 120°C and has excellent tensile strength.

Illustrative image related to ominix belt

Pros: Nylon belts are lightweight and have high resistance to impact and fatigue, making them suitable for high-performance applications.

Cons: Nylon can absorb moisture, which may lead to dimensional changes and affect performance. It also tends to be more expensive than rubber and polyurethane.

Impact on Application: Nylon belts are well-suited for applications in high-stress environments, such as automotive and aerospace industries.

Illustrative image related to ominix belt

Considerations for International Buyers: Compliance with international standards like ISO 180 for impact resistance is crucial when sourcing nylon belts.

How Does Polyester Perform in Omix Belt Applications?

Polyester is often used for its high strength-to-weight ratio and excellent resistance to stretching and shrinking. It operates efficiently in temperatures up to 100°C.

Pros: Polyester belts are resistant to abrasion and have good dimensional stability, making them ideal for precision applications.

Illustrative image related to ominix belt

Cons: While polyester is durable, it is less flexible than rubber, which may limit its application in certain environments. Additionally, it can be more expensive than traditional rubber belts.

Impact on Application: Polyester is commonly used in applications where precision and stability are critical, such as in conveyor systems.

Considerations for International Buyers: Buyers should ensure that the polyester belts meet standards like ASTM D5034 for breaking strength.

Summary Table of Material Selection for Omix Belts

| Material | Typical Use Case for Omix Belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Automotive applications | Excellent elasticity and durability | Degrades under UV and extreme temps | Low |

| Polyurethane | Industrial machinery | High abrasion resistance | Higher manufacturing complexity | Med |

| Nylon | High-stress environments | Lightweight and high tensile strength | Absorbs moisture and dimensionally unstable | High |

| Polyester | Precision applications | Good dimensional stability | Less flexible than rubber | Med |

This material selection guide provides B2B buyers with essential insights into the various materials available for Omix belts, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for ominix belt

What Are the Key Stages in the Manufacturing Process of Ominix Belts?

The manufacturing process of Ominix belts involves several critical stages that ensure the final product meets stringent quality and performance standards. Understanding these stages is essential for B2B buyers, as it provides insights into the reliability and efficiency of the belts they intend to purchase.

Illustrative image related to ominix belt

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing Ominix belts is the careful selection of raw materials. High-quality rubber compounds and textiles are typically used to ensure durability and performance under various operating conditions. The rubber is often treated to enhance its resistance to oil, heat, and abrasion, which is crucial for automotive applications.

Once selected, the materials undergo preparation, which includes mixing and compounding. This process involves blending rubber with additives such as carbon black, which improves strength and wear resistance. The resulting material is then tested for consistency and performance before moving on to forming.

Forming: What Techniques Are Used to Shape Ominix Belts?

The forming stage is where the rubber material is shaped into the desired belt form. This is typically achieved through processes such as extrusion and molding. In extrusion, the rubber is forced through a die to create a continuous length of belt, while molding involves placing the rubber into a pre-designed mold to achieve specific shapes and dimensions.

Advanced techniques like precision machining may also be employed to ensure that the belts meet exact specifications. This attention to detail is critical, especially for B2B buyers who require components that fit perfectly within their machinery or vehicles.

Illustrative image related to ominix belt

Assembly: How Are Ominix Belts Constructed for Optimal Performance?

After the belts are formed, they undergo an assembly process where additional components, such as tensioners or pulleys, may be integrated. This is particularly important for serpentine belts, which need to work seamlessly with various engine components.

The assembly process often utilizes automated systems to enhance efficiency and consistency, minimizing human error. For international buyers, understanding this aspect can provide assurance of the belt’s reliability, as automated systems typically yield higher precision.

Finishing: What Quality Measures Are Implemented in the Final Stages?

The finishing stage includes various processes aimed at enhancing the belt’s surface quality and performance characteristics. This may involve treatments to improve adhesion and reduce noise during operation. Additionally, belts are often subjected to rigorous cleaning processes to remove any contaminants that may affect performance.

Final inspections are conducted to ensure that the belts meet all specifications before packaging. This stage is crucial for maintaining the quality that B2B buyers expect from Ominix products.

What Quality Assurance Standards Are Essential for Ominix Belts?

Quality assurance is a fundamental aspect of the manufacturing process for Ominix belts. Adhering to international standards not only ensures product reliability but also builds trust with B2B buyers across various regions.

Which International Standards Apply to Ominix Belt Manufacturing?

Ominix belts are typically manufactured in accordance with ISO 9001 standards, which focus on quality management systems. This standard ensures that manufacturers maintain consistent quality in their processes, ultimately leading to reliable products.

In addition to ISO 9001, industry-specific certifications such as CE marking for safety and compliance in Europe, and API specifications for automotive components, may also be relevant. These certifications provide additional assurance to international buyers regarding the safety and performance of the belts.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process of Ominix belts, with several key checkpoints:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected for quality and compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to ensure that the production process adheres to established standards. This includes monitoring temperature, pressure, and material consistency.

-

Final Quality Control (FQC): After the belts are completed, a thorough inspection is performed to ensure that each belt meets the required specifications. This may include visual inspections, dimensional checks, and performance testing.

How Can B2B Buyers Verify the Quality Control of Ominix Belt Suppliers?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some actionable steps:

What Methods Can Buyers Use to Conduct Supplier Audits?

Buyers can conduct audits of potential suppliers to assess their quality control processes. This may involve visiting the manufacturing facility, reviewing quality assurance documentation, and examining their compliance with international standards.

Additionally, buyers can request audits from third-party organizations that specialize in quality assurance. These independent audits provide an unbiased assessment of the supplier’s practices and compliance.

How Can Buyers Access Quality Reports and Testing Results?

Requesting quality reports and testing results from suppliers is another effective way to verify their QC processes. Suppliers should provide documentation that details their quality control measures, including test results from both raw materials and finished products.

Illustrative image related to ominix belt

Buyers should also look for transparency regarding any certifications the supplier holds, as this can further validate their commitment to quality.

What Nuances Should International Buyers Consider Regarding QC?

International buyers should be aware of regional differences in quality standards and compliance requirements. For instance, certain countries may have specific regulations that differ from international standards. It is crucial for buyers to understand these nuances to ensure that the products they import comply with local regulations.

Additionally, language barriers can sometimes complicate communication about quality assurance practices. Establishing clear communication channels and expectations from the outset can help mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Ominix belts is essential for B2B buyers aiming to make informed purchasing decisions. By familiarizing themselves with the stages of production, relevant quality standards, and verification methods, buyers can ensure they source reliable and high-quality belts that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ominix belt’

This guide is designed to assist B2B buyers in effectively sourcing Omix belts, specifically focusing on V-belts and serpentine belts. It provides a practical checklist to ensure that procurement decisions are informed and strategic, ultimately contributing to operational efficiency and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for the Omix belts. This includes the belt type (V-belt or serpentine), dimensions, and compatibility with specific vehicle models or machinery. Understanding these specifications helps in narrowing down options and ensures that the belts will meet operational needs without compatibility issues.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers that specialize in Omix belts. Look for established companies with a solid reputation in the market. Utilize online platforms, industry directories, and trade shows to gather information about potential suppliers. Pay attention to their experience, product range, and customer reviews to assess their reliability.

Step 3: Evaluate Supplier Certifications

Verify the certifications of your shortlisted suppliers. Look for ISO certifications or other relevant industry standards that indicate quality assurance and compliance with safety regulations. Suppliers with recognized certifications are more likely to provide products that meet your quality expectations and minimize the risk of defects.

Step 4: Request Product Samples

Before finalizing a supplier, request samples of the Omix belts. This step allows you to evaluate the quality and suitability of the belts for your specific applications. Inspect the material, design, and durability of the samples to ensure they align with your requirements. This hands-on assessment is crucial for making an informed decision.

Illustrative image related to ominix belt

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, engage in negotiations regarding pricing and terms of sale. Consider factors such as bulk purchase discounts, payment terms, and delivery timelines. A clear understanding of these aspects can lead to cost savings and more favorable conditions for your procurement process.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by the supplier, including warranty terms and customer service availability. A reliable supplier should provide assistance in case of product failures or inquiries about installation and maintenance. A solid warranty can also protect your investment and ensure that you are covered for any manufacturing defects.

Step 7: Finalize the Order and Monitor Delivery

After completing all evaluations and negotiations, finalize your order with the chosen supplier. Monitor the delivery process closely to ensure that the belts arrive on time and meet the agreed specifications. Stay in communication with the supplier throughout this phase to address any potential issues that may arise during transit.

Illustrative image related to ominix belt

By following this checklist, B2B buyers can streamline their procurement of Omix belts, ensuring that they make informed decisions that align with their operational needs and business objectives.

Comprehensive Cost and Pricing Analysis for ominix belt Sourcing

What Are the Key Cost Components in Omix Belt Sourcing?

When evaluating the cost structure of Omix belts, several critical components come into play. The primary cost components include:

-

Materials: The type of rubber and other raw materials significantly influence the cost. Higher-quality materials that offer better heat and abrasion resistance may come at a premium but can enhance the product’s longevity and performance.

-

Labor: Labor costs vary significantly based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but quality assurance measures should not be compromised.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and maintenance. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The initial investment in molds and production tools can be substantial. However, when sourcing in bulk, these costs can be amortized over a larger production run, lowering the cost per unit.

-

Quality Control (QC): Stringent quality control processes ensure that the belts meet industry standards, which may add to the overall cost but can reduce returns and increase customer satisfaction.

-

Logistics: Transportation costs, including shipping and customs, are vital in determining the final price. The choice of shipping method can impact costs significantly, with air freight being faster but more expensive than sea freight.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Understanding typical margins in the industry can aid buyers in negotiating better prices.

How Do Price Influencers Affect Omix Belt Sourcing?

Several factors can influence the pricing of Omix belts, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing often leads to discounts. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing. Larger orders can also lead to improved shipping terms.

-

Specifications and Customization: Custom belts designed for specific applications may incur additional costs. Buyers should clarify requirements upfront to avoid unexpected charges.

-

Material Quality and Certifications: Products that adhere to international quality standards or certifications may command higher prices. Investing in certified products can mitigate risks associated with performance and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may offer better warranty terms and customer service, justifying a higher cost.

-

Incoterms: The terms of shipping and delivery, defined by Incoterms, can significantly impact total costs. Understanding whether costs cover shipping, insurance, and customs duties is crucial for accurate budgeting.

What Are Essential Buyer Tips for Cost-Efficiency in Omix Belt Sourcing?

Navigating the complexities of Omix belt sourcing requires strategic planning. Here are actionable tips for buyers:

-

Negotiation: Always be prepared to negotiate terms and prices. Establishing a good relationship with suppliers can lead to better deals and terms.

-

Focus on Total Cost of Ownership (TCO): While the initial purchase price is important, consider the long-term costs associated with maintenance, potential failures, and replacements. A slightly higher initial investment in quality belts may yield lower TCO.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should account for additional costs such as tariffs, taxes, and fluctuating exchange rates that can affect the final price.

-

Request Samples: Before committing to a large order, request samples to assess quality and ensure it meets specifications. This can prevent costly mistakes down the line.

-

Consider Local Regulations: Be aware of any local regulations that may impact costs, such as import duties or environmental standards that affect material usage.

Disclaimer for Indicative Prices

Prices for Omix belts can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions. Always consider the specific needs of your operation and the long-term implications of your sourcing choices.

Alternatives Analysis: Comparing ominix belt With Other Solutions

Understanding the Importance of Alternatives in Belt Solutions

In the highly competitive landscape of industrial and automotive applications, selecting the right belt solution can significantly impact operational efficiency and cost management. While the Ominix belt has gained recognition for its reliability and performance, it is essential for international B2B buyers to consider various alternatives that may better suit their specific needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to ominix belt

Comparison of Ominix Belt with Alternative Solutions

| Comparison Aspect | Ominix Belt | Gates Poly-V Belt | Continental Serpentine Belt |

|---|---|---|---|

| Performance | High durability, oil and heat resistant | Excellent flexibility and load capacity | Superior grip and reduced noise |

| Cost | Moderate pricing | Generally higher cost | Competitive pricing with premium features |

| Ease of Implementation | Simple installation, direct fit | Requires precise alignment | Straightforward installation |

| Maintenance | Low maintenance needs | Moderate maintenance required | Low maintenance, long service life |

| Best Use Case | Off-road and heavy-duty applications | High-performance engines | Standard automotive applications |

Pros and Cons of Alternative Solutions

Gates Poly-V Belt

The Gates Poly-V belt is renowned for its excellent flexibility and load-bearing capacity, making it an ideal choice for high-performance engines. Its design allows it to handle multiple accessory drives efficiently. However, the cost can be higher compared to the Ominix belt, which may be a consideration for budget-sensitive projects. Installation requires precise alignment, adding complexity to the implementation process.

Continental Serpentine Belt

The Continental serpentine belt is another viable alternative, celebrated for its superior grip and reduced noise levels during operation. This belt is particularly advantageous in standard automotive applications where noise reduction is a priority. While it offers competitive pricing and low maintenance requirements, it may not perform as well in extreme conditions as the Ominix belt, which is specifically designed for heavy-duty and off-road applications.

Making the Right Choice for Your Business Needs

When evaluating belt solutions, B2B buyers should consider factors such as the specific application, environmental conditions, and budget constraints. The Ominix belt excels in durability and performance under rugged conditions, making it suitable for off-road and heavy-duty use. In contrast, the Gates Poly-V belt is preferable for high-performance automotive applications where flexibility is crucial, while the Continental serpentine belt is ideal for standard vehicles prioritizing noise reduction.

Ultimately, the decision should align with the operational requirements and long-term goals of the business. By carefully analyzing the features and benefits of each option, buyers can make informed choices that enhance their operational efficiency and contribute to overall cost savings.

Essential Technical Properties and Trade Terminology for ominix belt

What Are the Key Technical Properties of Ominix Belts?

When considering Ominix belts, understanding their technical specifications is crucial for ensuring optimal performance and longevity in various applications. Here are some of the essential properties:

Illustrative image related to ominix belt

-

Material Composition

Ominix belts are typically made from high-quality rubber compounds that offer resistance to oil, heat, and abrasion. This durability is vital for industries such as automotive and manufacturing, where belts are subjected to extreme conditions. The choice of material directly influences the belt’s lifespan and efficiency. -

Effective Length and Width

The effective length of a belt (measured in inches or millimeters) is crucial for ensuring proper fit within a system. A mismatch can lead to slippage or premature wear. Additionally, the width of the belt determines its load-bearing capacity, making it a key factor in selecting the right belt for specific machinery or vehicles. -

Groove Configuration

Ominix belts often feature a specific groove design, such as the 6-groove serpentine style. This configuration affects how the belt interacts with pulleys and other components, impacting overall performance. Understanding groove specifications helps buyers select the right belt for their application, particularly in automotive settings where precise fitment is critical. -

Tensile Strength

The tensile strength of a belt is a measure of its ability to withstand pulling forces without breaking. This property is essential for maintaining performance under load, particularly in high-stress environments. Buyers should consider tensile strength to ensure that the belt can handle the demands of their specific applications. -

Temperature and Chemical Resistance

Ominix belts are designed to function effectively across a range of temperatures and in various chemical environments. This resistance is particularly important in industries like automotive, where exposure to heat and fluids is common. Selecting belts with appropriate resistance properties can prevent failures and reduce maintenance costs. -

Warranty and Quality Assurance

Many Ominix belts come with a limited warranty, which provides buyers with assurance regarding product quality and durability. Understanding warranty terms can influence purchasing decisions, as it reflects the manufacturer’s confidence in their product.

What Are Common Trade Terminologies Used in the Ominix Belt Industry?

Navigating the Ominix belt market requires familiarity with specific trade terms. Here are some essential terms and their meanings:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in the manufacturing of a final product. In the context of Ominix belts, OEM parts are designed to meet the exact specifications of the original parts, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and purchasing strategies. A high MOQ may lead to excess stock, while a low MOQ can limit purchasing flexibility. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. For Ominix belts, an RFQ can help buyers compare costs and terms from multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers involved in cross-border procurement of Ominix belts, as they dictate shipping costs, risks, and obligations. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. It is a critical factor in supply chain management, particularly for businesses that rely on timely delivery of Ominix belts to maintain operational efficiency. -

Fitment

Fitment describes how well a belt matches the specifications of the machinery or vehicle it is intended for. Proper fitment ensures optimal performance and reduces the risk of damage or failure, making it a vital consideration for B2B buyers.

Understanding these technical properties and trade terminologies can empower B2B buyers to make informed purchasing decisions, ensuring they select the right Ominix belts for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the ominix belt Sector

What Are the Key Market Dynamics and Trends in the Ominix Belt Sector?

The global market for the ominix belt sector is driven by several key factors, including increasing demand for durable and efficient automotive components, particularly in emerging markets like Africa, South America, and the Middle East. These regions are witnessing significant infrastructure development and vehicle sales growth, which in turn fuels the need for high-quality belts for various applications, including automotive, industrial, and agricultural machinery.

Emerging technologies such as IoT and advanced manufacturing processes are reshaping sourcing trends. B2B buyers are increasingly looking for suppliers that leverage smart technologies to enhance production efficiency and product quality. Additionally, the rise of e-commerce and digital platforms is facilitating easier access to suppliers and products, enabling buyers from diverse regions to compare options and make informed decisions quickly.

Furthermore, the trend towards modularity in design is influencing the development of belts, allowing for greater customization to meet specific client needs. Buyers are now seeking suppliers who can offer tailored solutions, including bespoke specifications for different vehicle models or machinery, reflecting a shift towards more collaborative relationships in the supply chain.

How Is Sustainability and Ethical Sourcing Impacting the Ominix Belt Market?

The environmental impact of production processes is becoming a paramount concern for B2B buyers in the ominix belt sector. As industries worldwide adopt more stringent sustainability goals, the demand for ethically sourced materials and environmentally friendly manufacturing practices is on the rise. Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainable practices, such as using recycled materials and reducing carbon footprints.

Ethical sourcing is not just a trend; it has become a critical factor in supplier selection. Buyers are now looking for certifications that validate a supplier’s commitment to sustainability, such as ISO 14001 for environmental management and other green certifications. These certifications not only enhance brand reputation but also align with the growing consumer demand for environmentally responsible products.

Illustrative image related to ominix belt

Moreover, the use of biodegradable or recyclable materials in the production of ominix belts can significantly reduce waste and environmental impact, making these products more appealing to buyers focused on sustainability. By incorporating these practices, suppliers can differentiate themselves in a competitive market, attracting buyers who are increasingly willing to pay a premium for sustainable options.

What Is the Historical Context of the Ominix Belt Sector?

The ominix belt sector has evolved significantly over the past few decades, reflecting changes in technology, consumer preferences, and market demands. Initially, the focus was primarily on basic rubber belts, but advancements in material science have led to the development of more durable and versatile options, such as serpentine and V-belts.

As the automotive industry grew, so did the complexity of the components required for vehicle performance. This evolution prompted manufacturers to innovate, leading to the incorporation of advanced materials that enhance performance and longevity. The sector has also seen a shift towards more standardized products that can be used across various vehicle models, catering to a global market.

In recent years, the integration of digital technologies in manufacturing has further transformed the sector, allowing for greater efficiency and customization. These historical shifts not only highlight the industry’s resilience but also its ability to adapt to changing market dynamics and buyer needs, positioning the ominix belt sector for continued growth in the international B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of ominix belt

-

How do I determine the right ominix belt for my machinery?

To select the correct ominix belt, first identify the specifications of the machinery it will be used with, including model, make, and year. Consult the equipment’s manual or manufacturer’s guidelines for compatibility. It’s also advisable to measure the existing belt for length and width, and note the number of grooves. If you’re still unsure, contact a supplier or manufacturer with your equipment details for personalized assistance. -

What is the best ominix belt for high-temperature applications?

For high-temperature applications, look for ominix belts specifically designed with heat-resistant materials. These belts are typically made from advanced rubber compounds that can withstand elevated temperatures without losing functionality. Ensure to check the temperature rating provided by the manufacturer and consult with your supplier to find the best match for your specific operational needs. -

What are the minimum order quantities (MOQ) for ominix belts?

The minimum order quantity for ominix belts can vary by supplier and region. Typically, suppliers may set an MOQ ranging from 50 to 100 units to ensure cost-effectiveness in production and shipping. It’s best to discuss your specific requirements with the supplier to negotiate terms that suit your purchasing needs, especially if you are a new buyer or require a smaller trial order. -

What payment terms are commonly accepted for international orders of ominix belts?

International suppliers usually offer a variety of payment terms, including Letters of Credit (LC), advance payments, and wire transfers. Depending on your relationship with the supplier and order size, you may also be able to negotiate more favorable terms, such as partial payment upfront and the remainder upon delivery. Always clarify payment methods and terms before finalizing your order to avoid misunderstandings. -

How can I ensure the quality of the ominix belts I purchase?

To guarantee the quality of your ominix belts, select suppliers with a strong reputation and positive reviews in the industry. Request product certifications and quality assurance documentation to verify that the belts meet international standards. Additionally, consider asking for samples or conducting a quality inspection prior to placing large orders, especially for critical applications. -

What logistics options are available for shipping ominix belts internationally?

Logistics for shipping ominix belts internationally typically include air freight, sea freight, and courier services. The choice of shipping method often depends on the urgency of the delivery and the volume of the order. Discuss with your supplier about their preferred logistics partners and the possibility of tracking shipments to ensure timely delivery to your location. -

What are the common challenges faced when sourcing ominix belts internationally?

Common challenges include dealing with customs regulations, language barriers, and potential delays in shipping. It’s crucial to familiarize yourself with the import regulations of your country, as well as any tariffs that may apply. Building a relationship with reliable suppliers can help mitigate these challenges, as they can provide insights and support throughout the procurement process. -

Can I customize ominix belts for specific applications?

Yes, many suppliers offer customization options for ominix belts to meet specific application requirements. This may include adjustments in length, width, material composition, or groove design. When inquiring about customization, be prepared to provide detailed specifications and usage scenarios to help the manufacturer create a product tailored to your needs.

Top 5 Ominix Belt Manufacturers & Suppliers List

1. Omix-ADA – V Belts and Serpentine Belts

Domain: rv4x4.com

Registered: 1999 (26 years)

Introduction: V Belts and Serpentine Belts – OMIX ADA, Category: Belts, Brand: Omix-ADA, Series: Serpentine Belts, V-Belts, Contact: Call us Today at (717) 697-8418 for more Information!

2. OMIX – Seat Belts & Harnesses

Domain: quadratec.com

Registered: 1996 (29 years)

Introduction: OMIX Seat Belts & Harnesses include various options such as: 1. OMIX 60″ Lap Style Seat Belt – Price: $39.89 (In Stock) 2. OMIX 60″ Retractable Seat Belt for 87-95 Jeep Wrangler YJ – Price: $104.49 (In Stock) 3. OMIX Retractable Lap Style Seat Belt – Price: From $123.49 (In Stock) 4. OMIX 3-Point Retractable Seat Belt – Price: From $216.99 (In Stock) 5. OMIX Tri Lock Off Road Front Seat Belt for 8…

3. OMIX – Serpentine Belt 2.4L

Domain: caliraisedoffroad.com

Registered: 2016 (9 years)

Introduction: Omix Serpentine Belt 2.4L 02-06 Liberty and Wrangler; Brand: OMIX; SKU: OMI17111.31; MPN: 17111.31; Product type: Belts – Timing, Accessory; Price: $54.66; Fits: 2003-2006 Wrangler TJ and 2002-2005 Liberty KJ models with 2.4-liter engines and air conditioning; Belt type: 6-groove serpentine-style; Effective length: 85.04 inches; Replaces OE: 53013352AD; Warranty: Yes; Proposition 65 Warning: Cance…

4. Omix-Ada – Serpentine Belt for Jeep Wrangler YJ

Domain: rmsautomotiveinc.com

Registered: 2012 (13 years)

Introduction: {“Product Name”:”Omix-Ada 17111.06 Serpentine Belt”,”Vehicle Fitment”:”1991-1994 Jeep Wrangler YJ (4-cylinder and 6-cylinder engines with power steering and A/C)”,”Effective Length”:”96.85 inches”,”Grooves”:”6-groove serpentine-style”,”Material”:”Rubber”,”OE Replacement Part Number”:”53007539″,”Warranty”:”Limited 5 Year Warranty”,”Color”:”Black”,”Country of Origin”:”Italy”,”Install Time”:”Less tha…

5. Omix – Universal 3-Point Seat Belt

Domain: stage4motorsports.com

Registered: 2024 (1 years)

Introduction: {“product_name”:”Omix Universal 3-Point Seat Belt”,”brand”:”Omix”,”type”:”Seat Belt”,”features”:[“Universal fit”,”3-point design”,”Durable construction”,”Easy installation”],”color”:”Black”,”dimensions”:”Standard size”,”weight”:”Lightweight”,”material”:”High-quality fabric”,”safety_rating”:”Meets safety standards”}

Strategic Sourcing Conclusion and Outlook for ominix belt

In conclusion, strategic sourcing of Omix belts presents a myriad of opportunities for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The Omix brand is recognized for its high-quality serpentine and V-belts, ensuring reliability and performance in demanding applications. By prioritizing quality sourcing, businesses can reduce operational downtime, enhance equipment longevity, and ultimately drive profitability.

For buyers in regions such as Saudi Arabia and Brazil, forming partnerships with trusted suppliers of Omix belts can lead to significant cost savings and improved supply chain efficiency. The growing global demand for reliable automotive components underscores the importance of aligning with reputable manufacturers like Omix-ADA, known for their adherence to stringent quality standards.

Looking ahead, it is vital for B2B buyers to stay informed about the latest trends in belt technology and market dynamics. Engaging with suppliers who offer comprehensive support and warranty options can further enhance your procurement strategy. Take proactive steps today to secure a competitive edge in your market by investing in Omix belts—your business’s reliability and performance depend on it.

Illustrative image related to ominix belt

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to ominix belt