Top 5 Industrial Sewing Companies Near Me Suppliers (And How to Choose)

Introduction: Navigating the Global Market for industrial sewing companies near me

In today’s global marketplace, sourcing reliable industrial sewing companies can pose significant challenges for B2B buyers, particularly those seeking tailored solutions for diverse applications. Whether you’re looking for manufacturers of custom bags, protective covers, or specialized garments, identifying the right partner can be daunting. This guide on “industrial sewing companies near me” aims to simplify your sourcing process by providing a comprehensive overview of the various types of industrial sewing services available, their applications across different industries, and strategies for effective supplier vetting.

The guide will delve into essential considerations such as cost structures, quality standards, and turnaround times, empowering international buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—to make informed purchasing decisions. By understanding the nuances of the industrial sewing landscape, you will be better equipped to select suppliers that align with your specific needs, ensuring that your projects are executed efficiently and to the highest quality standards.

Navigating the complexities of global sourcing can be overwhelming, but with this guide, you will gain the insights needed to confidently engage with industrial sewing companies, ensuring that your business remains competitive and responsive to market demands.

Understanding industrial sewing companies near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Contract Sewing | Custom production with skilled labor, often for specific designs. | Apparel, bags, covers, and protective gear. | Pros: Tailored solutions; Cons: Higher costs for small runs. |

| Cut and Sew | Utilizes printed designs on fabric, allowing for vibrant patterns. | Fashion, home textiles, promotional products. | Pros: High-quality prints; Cons: Longer lead times. |

| Industrial Fabrication | Focuses on heavy-duty materials and large-scale production. | Tarps, tents, and specialized industrial gear. | Pros: Durable products; Cons: Limited customization. |

| Medical Sewing | Specialized in sterile and non-sterile medical products. | Surgical drapes, gowns, and custom cases. | Pros: Compliance with regulations; Cons: Niche market. |

| Custom Bag Manufacturing | Produces various types of bags tailored to specific needs. | Transport, storage, and promotional bags. | Pros: Versatile designs; Cons: May require minimum order quantities. |

What Are the Characteristics of Contract Sewing Services?

Contract sewing companies are characterized by their ability to deliver customized production services across various sectors. They typically employ highly skilled workers and utilize advanced sewing technology to create tailored products such as bags, uniforms, and protective gear. For B2B buyers, the key consideration is the ability to meet specific design requirements and production timelines, which can vary based on order size and complexity. While these services offer bespoke solutions, buyers should be prepared for potentially higher costs, especially for smaller runs.

How Does Cut and Sew Differ from Other Sewing Methods?

Cut and sew services stand out due to their focus on printed designs applied to fabric before cutting. This technique allows for vibrant, edge-to-edge patterns that are particularly appealing in the fashion and promotional product industries. B2B buyers should evaluate their design requirements and consider the lead times associated with this method, as they may be longer than traditional sewing. While cut and sew offers high-quality output, the need for precise design specifications can make it less flexible for last-minute changes.

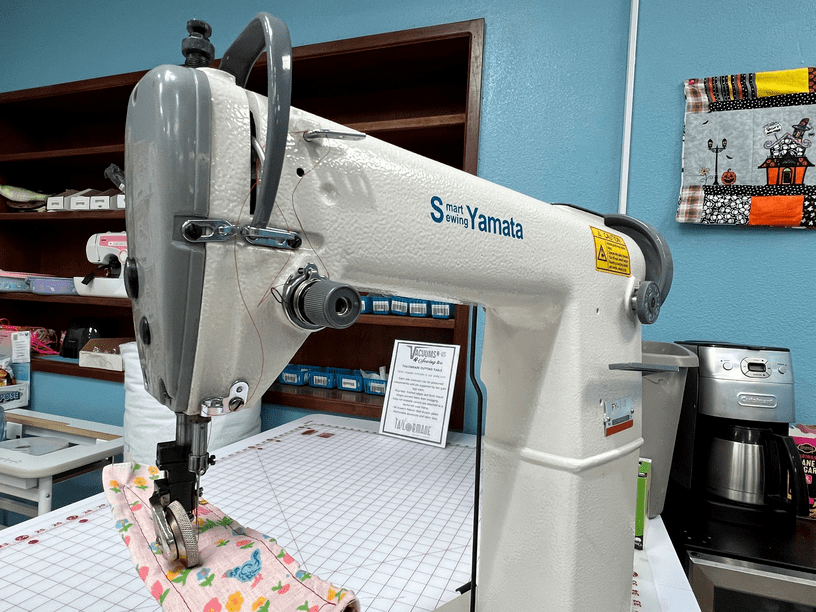

Illustrative image related to industrial sewing companies near me

What Should Buyers Know About Industrial Fabrication?

Industrial fabrication companies specialize in heavy-duty sewing applications, often using robust materials like canvas and vinyl. These firms cater to industries requiring large-scale production of items like tarps and tents. For B2B buyers, durability and functionality are paramount, especially in demanding environments. However, customization options may be limited, and the focus on large production runs can lead to less flexibility in terms of order quantities. Understanding the specific needs of your industry is crucial when considering these services.

Why Are Medical Sewing Services Unique?

Medical sewing companies are dedicated to producing sterile and non-sterile medical textiles, such as surgical gowns and drapes. These companies must adhere to strict regulatory standards, making them highly specialized. B2B buyers in the healthcare sector should prioritize compliance and quality assurance when selecting a provider. While the niche market can lead to higher prices, the assurance of meeting safety standards is invaluable. It’s essential for buyers to assess the supplier’s certifications and experience in the medical field.

What Advantages Do Custom Bag Manufacturers Offer?

Custom bag manufacturers focus on producing a wide variety of bags tailored to specific client needs, from promotional items to specialized transport solutions. Their versatility allows for unique designs that can enhance branding efforts for businesses. B2B buyers should consider the minimum order quantities and potential lead times, as these can impact project timelines. While custom bags offer significant branding opportunities, the initial investment may be higher compared to off-the-shelf options.

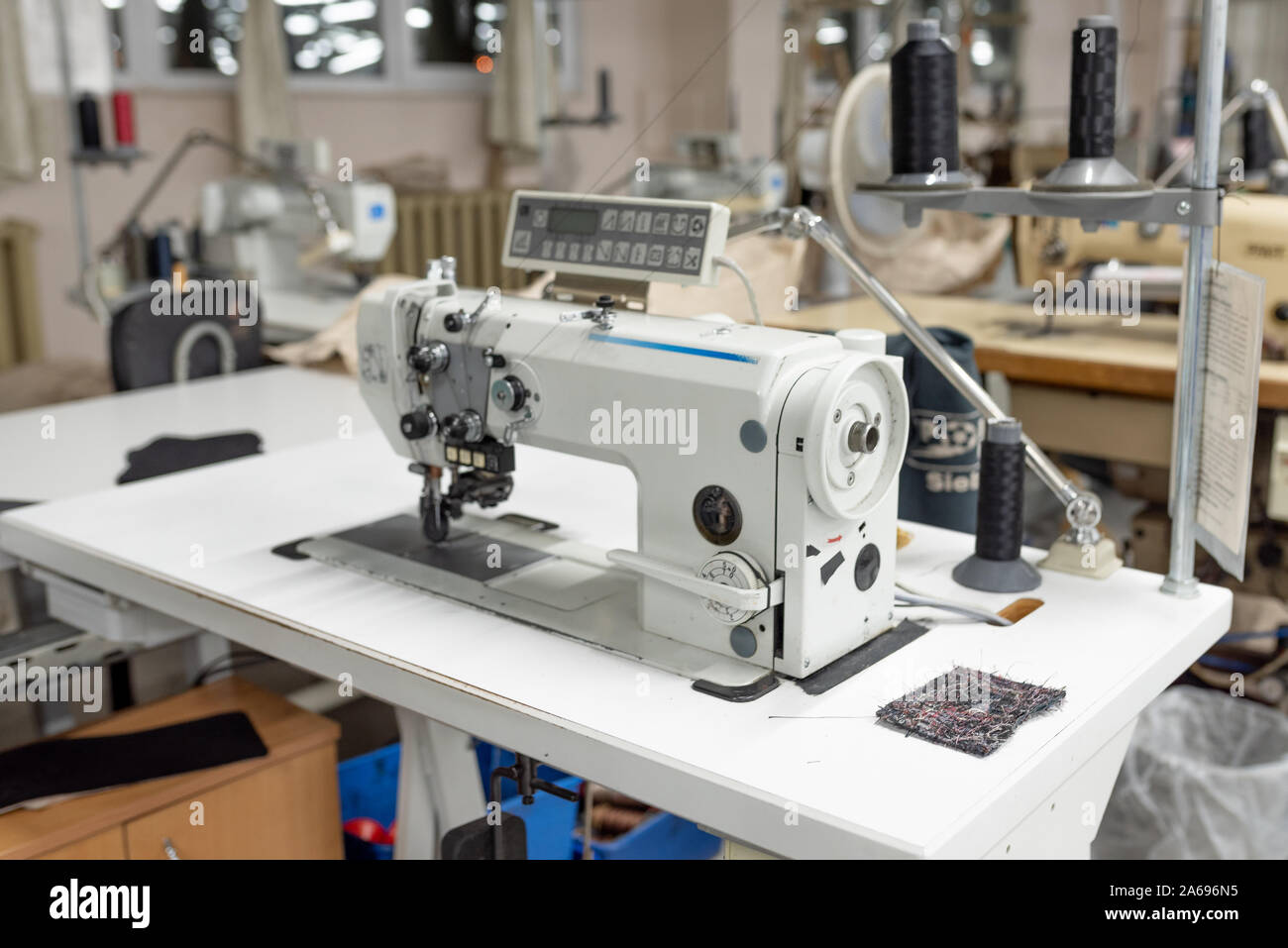

Illustrative image related to industrial sewing companies near me

Key Industrial Applications of industrial sewing companies near me

| Industry/Sector | Specific Application of industrial sewing companies near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Custom sewn cases and covers for medical instruments | Enhanced protection and organization of equipment | Compliance with medical standards, durability, and custom designs |

| Automotive | Upholstery and interior components for vehicles | Improved aesthetics and comfort for end-users | Material quality, design specifications, and lead times |

| Oil and Gas | Custom tarps and protective covers for equipment | Weather protection and increased equipment longevity | Resistance to harsh conditions and custom sizing |

| Military | Tactical gear and uniforms | Reliability and functionality in critical situations | Compliance with military specifications and durability |

| Agriculture | Custom bags and covers for equipment | Protection from environmental elements | Material strength, custom sizes, and quick turnaround times |

How Are Industrial Sewing Companies Near Me Used in the Medical Sector?

In the medical industry, industrial sewing companies provide tailored solutions such as custom cases and covers for medical instruments. These products ensure that delicate equipment is protected during transportation and storage, thereby reducing the risk of damage and enhancing organization. For international buyers, particularly from regions like Africa and the Middle East, understanding compliance with medical standards and the importance of durable materials is crucial when sourcing these items.

What Role Does Industrial Sewing Play in the Automotive Industry?

In the automotive sector, industrial sewing is vital for producing high-quality upholstery and interior components. These sewn products not only enhance the aesthetic appeal of vehicles but also contribute to passenger comfort. B2B buyers from South America and Europe should prioritize sourcing companies that can provide materials meeting specific design specifications and ensure timely delivery to align with production schedules.

How Are Industrial Sewing Companies Beneficial to the Oil and Gas Industry?

The oil and gas industry relies heavily on custom tarps and protective covers to shield expensive equipment from harsh weather conditions. Industrial sewing companies near you can create tailored solutions that increase the longevity of these assets, ultimately saving costs in replacements. For international buyers, it’s essential to consider the resistance of materials to extreme conditions and the ability to customize sizes based on specific equipment dimensions.

Why Is Industrial Sewing Critical for Military Applications?

In military applications, industrial sewing companies produce tactical gear and uniforms designed for reliability and functionality in demanding environments. These products must adhere to strict military specifications, ensuring they can withstand various operational challenges. B2B buyers, particularly from regions with active military operations, should focus on sourcing partners who understand these specifications and can deliver durable, high-performance products.

How Do Agricultural Businesses Benefit from Industrial Sewing Solutions?

Agricultural businesses utilize industrial sewing companies for custom bags and covers designed to protect equipment from environmental elements. These sewn solutions are crucial for maintaining the integrity of agricultural machinery and supplies. International buyers should look for manufacturers that offer strong materials, custom sizing, and quick turnaround times to meet the dynamic needs of the agricultural sector.

Illustrative image related to industrial sewing companies near me

3 Common User Pain Points for ‘industrial sewing companies near me’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Projects

The Problem: B2B buyers often face challenges when seeking industrial sewing companies that can provide highly customized solutions. Many suppliers offer limited options, which can be frustrating for businesses that require specific designs or materials to meet their unique operational needs. This is particularly crucial for sectors like medical, automotive, or military, where specifications can be strict and varied. If a buyer approaches a company that lacks the capability for customization, it can lead to project delays, increased costs, and compromised product quality.

The Solution: To overcome this challenge, B2B buyers should conduct thorough research to identify industrial sewing companies that specialize in custom manufacturing. Look for suppliers with a diverse portfolio and a proven track record in handling tailored projects. During initial discussions, provide detailed specifications, including material types, design requirements, and any industry standards that must be met. Request samples or prototypes to evaluate the quality of work before committing to larger orders. Utilizing platforms that list sewing contractors can also streamline the process, allowing buyers to filter options based on their specific needs and capabilities.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Many B2B buyers experience frustration with long lead times when sourcing products from industrial sewing companies. Delays can occur due to various factors, such as high demand, limited production capacity, or inefficient supply chain management. For companies in fast-paced industries, these delays can disrupt production schedules, lead to missed deadlines, and ultimately affect customer satisfaction and revenue.

Illustrative image related to industrial sewing companies near me

The Solution: To mitigate lead time issues, B2B buyers should prioritize finding industrial sewing companies that offer clear timelines and reliable communication. When initiating contact, inquire about their production capabilities, average turnaround times, and any potential bottlenecks in their operations. Establishing a strong relationship with suppliers can facilitate smoother communication and allow for priority handling of urgent orders. Additionally, consider negotiating contracts that include penalties for delays or incentives for meeting deadlines. This approach can help create accountability and encourage suppliers to adhere to agreed timelines.

Scenario 3: Quality Control and Compliance Challenges

The Problem: Quality control is paramount in industrial sewing, especially for businesses in regulated industries such as medical or aerospace. B2B buyers may find that some suppliers do not meet the necessary compliance standards or quality benchmarks, which can lead to costly recalls, legal implications, and damage to brand reputation. It can be challenging to ascertain the quality of a supplier’s work without a thorough vetting process.

The Solution: To address quality control concerns, buyers should implement a rigorous supplier evaluation process. Start by requesting certifications and documentation that demonstrate compliance with industry standards (e.g., ISO certifications, safety standards). Conduct site visits or audits to assess production facilities and quality assurance processes. Additionally, ask for references from other clients in similar industries to gauge reliability and quality. Establishing clear quality expectations upfront, including detailed specifications and inspection processes, can help ensure that products meet required standards before delivery. This proactive approach reduces the risk of quality issues and fosters a more trustworthy supplier relationship.

Strategic Material Selection Guide for industrial sewing companies near me

What Are the Key Materials Used by Industrial Sewing Companies?

When selecting materials for industrial sewing applications, understanding the properties, advantages, and limitations of various fabrics is essential for international B2B buyers. Here, we analyze four common materials used in industrial sewing, focusing on their suitability for diverse applications and the specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Which Synthetic Fabrics are Commonly Used in Industrial Sewing?

Polyester is a widely used synthetic fabric in industrial sewing due to its excellent durability and resistance to shrinking and stretching. It has a high tensile strength, making it suitable for products that undergo significant wear and tear, such as bags and outdoor gear. However, polyester can be less breathable than natural fibers, which may impact comfort in applications like uniforms.

Illustrative image related to industrial sewing companies near me

Pros: High durability, moisture-wicking properties, and resistance to UV light.

Cons: Can be more expensive than natural fibers and may not be as environmentally friendly.

Impact on Application: Ideal for outdoor products and items exposed to harsh conditions.

Considerations for Buyers: Compliance with environmental standards (e.g., REACH in Europe) is essential, as is familiarity with ASTM standards for textile performance.

How Does Nylon Compare in Industrial Sewing Applications?

Nylon is another synthetic option known for its exceptional strength and elasticity. It is often used in manufacturing items like tarps, tents, and protective covers due to its resistance to abrasion and chemicals. While nylon is lightweight and easy to sew, it can be susceptible to UV degradation over time.

Pros: Lightweight, strong, and versatile for various applications.

Cons: Can be prone to UV degradation and may require coatings for enhanced durability.

Impact on Application: Suitable for outdoor and industrial applications where strength is critical.

Considerations for Buyers: Buyers should ensure that the nylon meets local standards for fire resistance and environmental impact, particularly in regions with stringent regulations.

What Role Does Cotton Play in Industrial Sewing?

Cotton is a natural fiber that offers excellent breathability and comfort, making it a popular choice for uniforms and workwear. It is biodegradable and generally more environmentally friendly than synthetic options. However, cotton is less durable than polyester or nylon and may not withstand harsh conditions as effectively.

Pros: Comfortable, breathable, and biodegradable.

Cons: Lower durability and can shrink or fade over time.

Impact on Application: Ideal for indoor applications and products requiring comfort.

Considerations for Buyers: Buyers should be aware of sourcing organic cotton options to meet sustainability goals and comply with certifications like GOTS.

How Are Specialty Fabrics Used in Industrial Sewing?

Vinyl is frequently used for protective covers and tarps due to its waterproof properties and resistance to chemicals. It is easy to clean and maintain, making it suitable for various industrial applications. However, vinyl can be heavy and may not be as flexible as other materials.

Pros: Waterproof, easy to clean, and highly durable.

Cons: Heavier and less flexible, which may complicate sewing processes.

Impact on Application: Excellent for outdoor and industrial uses requiring moisture protection.

Considerations for Buyers: Ensure compliance with local regulations regarding chemical usage and disposal, particularly in regions with strict environmental laws.

Summary of Material Properties for Industrial Sewing

| Material | Typical Use Case for industrial sewing companies near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Outdoor gear, bags, uniforms | High durability and UV resistance | Less breathable than natural fibers | Medium |

| Nylon | Tarps, tents, protective covers | Lightweight and strong | Prone to UV degradation | Medium |

| Cotton | Workwear, uniforms | Comfortable and breathable | Lower durability, can shrink | Low |

| Vinyl | Protective covers, tarps | Waterproof and easy to clean | Heavy and less flexible | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing materials for industrial sewing projects. Understanding the properties and implications of each material will help ensure the selection of the most suitable options for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for industrial sewing companies near me

What Are the Main Stages of Manufacturing Processes in Industrial Sewing?

Industrial sewing companies typically engage in a systematic manufacturing process that consists of several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to industrial sewing companies near me

-

Material Preparation: This initial stage involves sourcing and preparing the materials required for production. Common materials include various fabrics, threads, and specialized components such as zippers and buttons. B2B buyers should ensure that suppliers use high-quality, durable materials that meet their specific needs. For instance, if a company requires products for outdoor applications, fabrics should be water-resistant and UV-protective.

-

Forming: During this stage, patterns are cut from the prepared materials. Advanced techniques such as automated cutting machines or laser cutting may be employed to ensure precision and efficiency. The use of technology in forming can significantly reduce waste and improve production speed, which is crucial for meeting tight deadlines.

-

Assembly: This phase involves stitching the cut pieces together using industrial sewing machines. Companies often utilize specialized machines depending on the complexity of the product. For example, heavy-duty sewing machines may be required for items like tarps or industrial bags, while lighter machines are suitable for clothing. The assembly stage is critical for ensuring product durability and functionality.

-

Finishing: The final stage includes quality checks, trimming excess threads, adding labels, and packaging the finished products. It’s essential that all products undergo a thorough inspection to ensure they meet the required specifications before they are shipped out.

How Do Industrial Sewing Companies Ensure Quality Assurance?

Quality assurance (QA) is paramount in the industrial sewing sector, particularly for B2B buyers who are reliant on product consistency and reliability. Most companies adhere to international standards such as ISO 9001, which sets the criteria for a quality management system. Here’s how quality assurance is typically implemented:

-

Relevant International Standards: Besides ISO 9001, companies might also comply with industry-specific standards such as CE marking for products sold in Europe or API standards for oil and gas-related products. Understanding these standards can help buyers assess the credibility of potential suppliers.

-

Quality Control Checkpoints: Quality control is often integrated throughout the manufacturing process. Common checkpoints include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Quality checks during production help catch defects early, reducing waste and rework.

– Final Quality Control (FQC): The final inspection ensures that the products meet all quality and safety standards before shipment. -

Common Testing Methods: Products may undergo various tests depending on their intended use. These can include tensile strength tests, colorfastness tests, and dimensional stability tests. B2B buyers should inquire about the testing methods employed by their suppliers to ensure that the products will perform as expected in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of industrial sewing companies:

-

Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and industry best practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their QC processes. These reports should outline the results of inspections and tests, highlighting any non-conformities and how they were addressed.

-

Third-Party Inspections: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. This is particularly beneficial for international buyers who may not be able to conduct on-site audits.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is crucial for establishing reliable supplier relationships:

-

Cultural and Regulatory Differences: Different regions may have varying quality standards and regulations. For instance, European standards may differ from those in Africa or South America. Buyers should familiarize themselves with the local regulations that may affect product quality and safety.

-

Language Barriers: Communication can pose challenges, especially when dealing with suppliers in different countries. It is advisable to establish clear channels of communication and possibly engage a translator to ensure that specifications and quality requirements are understood.

-

Documentation and Certification: Requesting documentation such as ISO certification, product test results, and compliance certificates is essential. This documentation serves as proof that suppliers adhere to quality standards. Buyers should verify the authenticity of these documents, as counterfeit certifications can lead to significant risks.

-

Building Relationships: Establishing long-term relationships with suppliers can enhance trust and facilitate better communication regarding quality issues. Regular visits and ongoing discussions about quality improvements can foster a collaborative environment that benefits both parties.

Conclusion

For B2B buyers looking to engage with industrial sewing companies, understanding the manufacturing processes and quality assurance practices is essential. By focusing on the main stages of production, relevant quality standards, and verification methods, buyers can make informed decisions that align with their quality expectations and operational needs. With a thorough assessment of potential suppliers, businesses can secure reliable partners that contribute to their success in a competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘industrial sewing companies near me’

Introduction

When sourcing industrial sewing companies, particularly for B2B operations across diverse regions such as Africa, South America, the Middle East, and Europe, having a structured approach is vital. This guide provides a step-by-step checklist to ensure you choose a reliable and capable supplier that meets your specific needs.

-

Define Your Technical Specifications

Clearly outline your project requirements before engaging potential suppliers. Consider the types of materials, dimensions, and production volumes needed. Detailed specifications help you communicate effectively with suppliers and ensure they can meet your quality and design expectations. -

Conduct Market Research

Investigate the landscape of industrial sewing companies in your area. Utilize online directories and industry-specific platforms to identify potential suppliers. Pay attention to their specializations, such as custom sewing, contract manufacturing, or specific industry experience, to find the best fit for your needs. -

Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they align with your business goals. Request company profiles, case studies, and references from previous clients, especially those in your industry. This step is crucial in assessing their reliability, quality of work, and ability to meet deadlines. -

Verify Supplier Certifications

Check for relevant certifications and compliance with industry standards. Certifications such as ISO or industry-specific qualifications ensure that suppliers adhere to quality and safety standards. This verification minimizes risks and enhances your confidence in their capabilities. -

Request Samples and Prototypes

Before making a large commitment, ask for samples or prototypes of their work. This allows you to evaluate the quality of materials and craftsmanship firsthand. Look for attention to detail, durability, and alignment with your design specifications. -

Discuss Production Capabilities

Inquire about the supplier’s production capabilities, including their equipment, workforce, and technology. Understanding their capacity to handle your order size and complexity is essential for timely delivery and scalability. Ensure they can accommodate any potential increases in demand. -

Establish Communication Protocols

Set clear communication channels and protocols with your chosen supplier. Regular updates and open lines of communication can help manage expectations and address issues promptly. Establishing a point of contact ensures that both parties are aligned throughout the production process.

By following these steps, B2B buyers can effectively navigate the sourcing process for industrial sewing companies, leading to successful partnerships and high-quality outcomes.

Comprehensive Cost and Pricing Analysis for industrial sewing companies near me Sourcing

What Are the Key Cost Components in Industrial Sewing Services?

Understanding the cost structure of industrial sewing services is crucial for B2B buyers seeking to optimize their sourcing strategies. The primary cost components include:

Illustrative image related to industrial sewing companies near me

-

Materials: The choice of materials significantly affects pricing. For example, high-quality fabrics such as Cordura nylon or leatherette trims will increase the overall material costs. Buyers should specify materials early in negotiations to receive accurate quotes.

-

Labor: Labor costs can vary based on the complexity of the sewing required and the skill level of the workforce. Custom and intricate designs often necessitate more skilled labor, which can elevate costs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. A well-equipped facility may have higher overhead, which can influence the price.

-

Tooling: Initial tooling costs, such as patterns and specialized sewing machines, can be significant for custom orders. These costs are often amortized over larger production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to overall costs. Companies that emphasize quality certification may charge higher prices due to these added measures.

-

Logistics: Shipping and handling can become a substantial part of the total cost, especially for international shipments. Incoterms will play a pivotal role in determining who bears these costs.

-

Margin: Lastly, suppliers will include their profit margins, which can vary widely depending on market conditions and competition.

How Do Pricing Influencers Impact Industrial Sewing Costs?

Several factors influence the pricing of industrial sewing services, which are essential for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the unit cost due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Premium materials or those with certifications (like flame-retardant properties) will naturally increase costs. Buyers should weigh the necessity of these features against their budget.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers with a history of reliability may charge a premium for their services.

-

Incoterms: Understanding Incoterms is vital as they determine responsibilities for shipping costs and risks. Clarity in these terms can prevent misunderstandings that may lead to additional costs.

What Tips Can Help Buyers Negotiate Better Pricing?

When sourcing industrial sewing services, international B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiate Terms and Pricing: Always approach negotiations with flexibility. Consider proposing longer-term contracts in exchange for lower prices, which can benefit both parties.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial pricing. Assess the long-term costs associated with quality, durability, and logistics to determine the best value.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations can impact pricing. Buyers from regions like Africa, South America, the Middle East, and Europe should factor in these variables when budgeting.

-

Research Local and Global Suppliers: Diversifying your supplier base can lead to better pricing options. Local suppliers may offer faster turnaround times, while international suppliers may provide cost benefits.

-

Request Samples: Before finalizing a large order, request samples to assess quality. This can prevent costly mistakes associated with poor-quality products.

Conclusion

Navigating the cost and pricing landscape of industrial sewing companies requires a thorough understanding of various cost components and pricing influencers. By applying strategic negotiation techniques and evaluating total costs, international B2B buyers can make informed decisions that align with their sourcing objectives. Always remember that indicative prices may vary based on market conditions and supplier capabilities, so thorough research and communication are essential.

Alternatives Analysis: Comparing industrial sewing companies near me With Other Solutions

Exploring Alternative Solutions to Industrial Sewing Companies

When considering industrial sewing options, it’s essential for B2B buyers to evaluate various solutions that could meet their production needs. While industrial sewing companies provide specialized services, alternative methods may offer unique benefits that align better with specific business objectives. This analysis compares industrial sewing companies with two viable alternatives: in-house sewing operations and automated sewing technology.

| Comparison Aspect | Industrial Sewing Companies Near Me | In-House Sewing Operations | Automated Sewing Technology |

|---|---|---|---|

| Performance | High-quality, specialized services; can handle complex designs. | Variable performance; dependent on staff skill and experience. | High-speed, consistent output; ideal for mass production. |

| Cost | Typically higher due to labor and expertise; pricing can vary significantly based on project scope. | Initial investment in equipment and materials; ongoing labor costs. | High initial investment; reduced long-term labor costs. |

| Ease of Implementation | Simple to engage with; requires minimal setup; quick turnaround for small to medium projects. | Time-consuming setup; requires hiring and training staff. | Requires significant setup; integration with existing systems can be complex. |

| Maintenance | Minimal maintenance; rely on contractor expertise for quality control. | Ongoing maintenance of equipment and training for staff. | Requires regular maintenance of machinery; potential downtime for repairs. |

| Best Use Case | Custom projects with unique specifications and small to medium volumes. | Projects that require frequent changes in design or production runs. | Large-scale production with high volume and uniformity in product design. |

In-House Sewing Operations: Pros and Cons

In-house sewing operations allow businesses to control the entire production process. The main advantage is flexibility; companies can quickly adapt to design changes and manage production schedules closely. However, this approach demands significant investment in equipment and skilled labor, which can be a barrier for small to medium-sized enterprises. Additionally, the quality of output is highly dependent on the capabilities of the workforce, potentially leading to inconsistent results.

Automated Sewing Technology: Advantages and Disadvantages

Automated sewing technology represents the cutting edge of textile manufacturing. These systems can produce items at an unprecedented speed and consistency, making them ideal for high-volume production needs. The significant downside, however, is the substantial upfront investment required to purchase and implement these systems. Furthermore, integrating automated solutions into existing workflows can be complex and may require specialized training. While they excel in mass production, they may not be suitable for custom or low-volume projects where flexibility is essential.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate sewing solution depends on a variety of factors, including production volume, budget, and specific project requirements. For businesses needing customized solutions or lower volumes, industrial sewing companies may provide the best balance of quality and service. However, companies with consistent production needs and the ability to invest in infrastructure might benefit from in-house operations or automated technologies. Ultimately, understanding your unique business needs will guide you to the most effective and efficient sewing solution.

Essential Technical Properties and Trade Terminology for industrial sewing companies near me

What Are the Key Technical Properties for Industrial Sewing Companies?

In the realm of industrial sewing, understanding technical properties is vital for ensuring product quality and suitability for specific applications. Below are several critical specifications that B2B buyers should be aware of:

-

Material Grade

– Material grade refers to the quality and specifications of the fabrics or materials used in sewing. Common grades include cotton, polyester, nylon, and specialized fabrics such as Cordura or rubber-coated nylon. The choice of material can affect durability, resistance to environmental factors, and overall functionality. Selecting the right material grade ensures that the final product meets the operational demands of its intended use, whether it’s for outdoor applications or medical equipment. -

Tolerance Levels

– Tolerance levels define the permissible limits of variation in dimensions and specifications of sewn products. For instance, a tolerance of ±1mm may be acceptable for some items, while more precision is required in medical applications. Understanding tolerance is crucial for B2B buyers, as it impacts product interoperability and the performance of components in larger systems. -

Stitch Density

– Stitch density refers to the number of stitches per inch (SPI) in a sewn product. Higher stitch densities can provide greater strength and durability, making them essential for heavy-duty applications like industrial tarps or military gear. Buyers should consider stitch density based on the intended use of the product to ensure optimal performance and lifespan. -

Seam Types

– Various seam types (e.g., flat-felled, bound, or double-stitched) offer different benefits depending on the application. For instance, flat-felled seams are known for their strength and durability, while bound seams provide a clean finish and protection against fraying. Understanding the appropriate seam type can significantly affect the quality and longevity of the product. -

Water Resistance Rating

– This rating indicates a material’s ability to repel water, which is crucial for products intended for outdoor use. The rating is typically expressed in millimeters of water pressure the fabric can withstand before leaking. For B2B buyers, knowing the water resistance rating is essential when sourcing products for environments exposed to moisture or rain.

Which Trade Terms Should B2B Buyers Understand in Industrial Sewing?

Familiarity with industry jargon can help B2B buyers navigate the procurement process more effectively. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of industrial sewing, OEMs often provide specialized components that are critical for larger manufacturing processes. Understanding OEM relationships can help buyers identify reliable sources for high-quality parts. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory management and cost-efficiency. Knowing the MOQ can help businesses plan their purchases according to budget and demand forecasts. -

RFQ (Request for Quote)

– An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications and quantities. Submitting an RFQ is an essential step in the procurement process, as it helps ensure competitive pricing and clarity in requirements. -

Incoterms (International Commercial Terms)

– Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. They specify who pays for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B transactions, especially when sourcing from international suppliers, as they dictate the terms of delivery and risk management. -

Lead Time

– Lead time refers to the amount of time from placing an order to the delivery of the product. In industrial sewing, lead times can vary based on the complexity of the order and production capacity. Being aware of lead times helps buyers manage their supply chain and inventory effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when selecting industrial sewing companies to partner with, ensuring that they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the industrial sewing companies near me Sector

What Are the Current Market Dynamics and Key Trends in the Industrial Sewing Sector?

The industrial sewing sector is experiencing significant transformations influenced by global economic factors and evolving technological advancements. Key drivers include the growing demand for customized products across various industries, including medical, automotive, and fashion. Companies are increasingly adopting automation and advanced sewing technologies, such as computer-aided design (CAD) and robotic sewing systems, to enhance production efficiency and reduce lead times. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, there is a noticeable trend toward sourcing from manufacturers that offer flexibility and rapid prototyping services.

Furthermore, the rise of e-commerce is reshaping supply chains, enabling buyers to connect with suppliers more efficiently. This shift is particularly relevant for buyers in emerging markets, where access to diverse suppliers can facilitate competitiveness. Sustainability is also becoming a pivotal factor, with buyers increasingly prioritizing suppliers that demonstrate eco-friendly practices and materials. As businesses globally look to mitigate risks, there’s a growing emphasis on diversifying supply chains to avoid reliance on single-source suppliers, which can lead to vulnerabilities in times of disruption.

Illustrative image related to industrial sewing companies near me

How Are Sustainability and Ethical Sourcing Reshaping B2B Relationships in Industrial Sewing?

In the context of industrial sewing, sustainability and ethical sourcing have become critical considerations for B2B relationships. The environmental impact of textile production is substantial, contributing to pollution and resource depletion. As a result, there is a rising demand for suppliers that utilize sustainable practices, such as recycling materials and minimizing waste. Buyers are increasingly seeking partners who can provide transparency in their supply chains, ensuring that ethical labor practices are upheld throughout the production process.

Green certifications, such as Global Organic Textile Standard (GOTS) and OEKO-TEX, are gaining traction among buyers looking to verify the environmental credentials of their suppliers. These certifications not only demonstrate a commitment to sustainability but also enhance the marketability of products in a competitive landscape. For international buyers, particularly those in Europe, aligning with suppliers who uphold these standards is not just a matter of compliance; it has become a strategic advantage in attracting eco-conscious consumers.

How Has the Industrial Sewing Sector Evolved Over Time?

The industrial sewing sector has evolved dramatically over the decades, transitioning from manual processes to highly automated production environments. Initially dominated by small-scale artisans, the industry has shifted towards larger manufacturers capable of meeting the increasing demand for mass-produced items. The introduction of advanced machinery and technology has revolutionized operations, allowing for precision in design and efficiency in production.

Furthermore, globalization has expanded the reach of industrial sewing companies, enabling them to source materials and labor from diverse regions. This has created a more interconnected market where international buyers can access a broader range of products and services. As the sector continues to evolve, it remains essential for B2B buyers to stay informed about trends and innovations that can impact their sourcing strategies. By understanding the historical context and current dynamics, businesses can make informed decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of industrial sewing companies near me

-

How do I select the right industrial sewing company for my business needs?

To select the right industrial sewing company, start by assessing your specific requirements, such as the types of products you need manufactured, materials required, and production volume. Research potential suppliers by reviewing their portfolios, certifications, and client testimonials. It’s also beneficial to request samples to evaluate quality. Engage in direct communication to gauge responsiveness and willingness to customize solutions. Consider their experience in your industry, especially if you have specialized needs, such as medical or automotive applications. -

What are the key factors to consider when vetting industrial sewing suppliers?

Key factors to consider when vetting industrial sewing suppliers include their production capabilities, lead times, and quality assurance processes. Verify their experience in your specific industry, as familiarity with particular materials and standards can significantly impact production. Check for certifications (e.g., ISO) that indicate adherence to quality management systems. Additionally, assess their financial stability and track record for reliability, as these factors can influence their ability to meet your ongoing needs. -

What customization options are typically available with industrial sewing services?

Customization options in industrial sewing services can include a variety of factors such as design specifications, material choices, sizes, and features like pockets or closures. Many companies offer tailored solutions to meet unique project requirements, so it’s essential to communicate your needs clearly. Some suppliers may also provide design assistance, helping you refine your product concept. Additionally, inquire about minimum order quantities (MOQs) for customized products, as these can vary significantly among manufacturers. -

What is the typical minimum order quantity (MOQ) for industrial sewing products?

Minimum order quantities (MOQs) for industrial sewing products can vary widely based on the supplier and the complexity of the item being produced. Generally, MOQs can range from as low as 50 units for simpler items to several hundred or more for complex, customized products. When discussing MOQs with potential suppliers, consider your budget and inventory management needs. It’s also wise to negotiate terms, as some manufacturers may be flexible with lower MOQs for initial orders or ongoing partnerships. -

What payment terms should I expect when working with industrial sewing companies?

Payment terms for industrial sewing services can vary, but common practices include a deposit upfront (often 30-50% of the total cost) with the balance due upon delivery or completion of the order. Some suppliers may offer net terms (e.g., net 30 or net 60), allowing you to pay after receiving the goods. Always clarify payment terms in your contract, including any penalties for late payments. Additionally, consider the currency in which transactions will be conducted, as this can affect international trade. -

How do I ensure quality assurance in my industrial sewing orders?

To ensure quality assurance in your industrial sewing orders, request detailed quality control processes from your supplier. Many reputable manufacturers will perform inspections at various stages of production, from raw material sourcing to final product checks. Consider implementing a third-party inspection service if you’re ordering in large quantities or if the stakes are high. Clear communication of your quality expectations and specifications upfront will also help minimize discrepancies and ensure the final product meets your standards. -

What logistics considerations should I keep in mind when sourcing from international industrial sewing suppliers?

When sourcing from international industrial sewing suppliers, consider factors such as shipping costs, import duties, and delivery timelines. Research logistics partners that can efficiently handle customs clearance and transportation to your location. It’s also essential to discuss packaging requirements to ensure products arrive in good condition. Additionally, consider the supplier’s location and production capacity to avoid potential delays, especially during peak seasons or global disruptions. -

How can I navigate international trade regulations when sourcing industrial sewing products?

Navigating international trade regulations involves understanding the import/export laws of your country as well as those of the supplier’s country. Familiarize yourself with tariffs, quotas, and any necessary documentation required for customs clearance. Engaging a freight forwarder or customs broker can simplify this process, as they can provide expertise in navigating regulations. Additionally, ensure that your supplier complies with international standards and certifications relevant to your products, as this can facilitate smoother transactions and reduce potential legal issues.

Top 5 Industrial Sewing Companies Near Me Manufacturers & Suppliers List

1. Sewing Contractors – Custom Sewing Solutions

Domain: sewing-contractors.com

Registered: 2001 (24 years)

Introduction: Sewing contractor services including: Canopy, Canvas Bag, Clothing Label, Commercial Sewing, Contract Sewing, Custom Bag, Custom Embroidery, Custom Sewing, Cut and Sew, Industrial Sewing, Medical Sewing, Pouch, Protective Cover, Soft Luggage, Tarp. Companies serving North Carolina include Tytek Industries, Casco Manufacturing Solutions, Troy Sunshade, Inc., Versa-Flex, Inc., Integrated Textile Sol…

2. DSC Sewing – Heavy Duty Contract Sewing Services

Domain: dscsewing.com

Registered: 2016 (9 years)

Introduction: DSC’s Sewing offers heavy duty contract sewing manufacturing services, including prototyping, furniture upholstery, heavy duty sewing, and gear repair. They provide binding services for insulated foam panels and zippered cushion covers for Wayfarer Vans. They manufacture competition shooting bags for Traust using 500d cordura fabrics with double stitching for durability. The company emphasizes qua…

3. IQS Directory – Industrial Sewing Services and Custom Bags

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Industrial sewing services in Pennsylvania include custom manufacture of protective covers and tarpaulins, contract sewing for various industrial applications, custom sewing design, and a wide range of specialty bags such as cash bags, sports bags, travel sets, soft luggage, tote bags, and nylon bags. Companies also offer services in designing, cutting, and sewing for seat and cushion assembly, pr…

4. Carolina CoverTech – Industrial Sewing & Custom Solutions

Domain: carolinacovertech.com

Registered: 1999 (26 years)

Introduction: Industrial Contact Sewing Services, RF Welding and Heat Sealing, Industrial Sewing, Product Development, Rigid to Flexible Conversions, Rapid Prototyping Services, Custom Protective Covers, Custom Bladders, Environmental Spill Containment, Leak Diverter Manufacturers, Custom Bags, Industrial Products, Blackout Shades, Custom Non-Woven Geotextile Fabric, Custom Woven Geotextile Fabric, Custom Seat …

5. SunMaster Products – Contract and Production Sewing Services

Domain: sunmasterproducts.com

Registered: 1999 (26 years)

Introduction: SunMaster Products offers contract and production sewing services in San Diego County, CA, with over 50 years of experience. They provide low and high-volume contract sewing with no minimum requirements. Their facility in San Marcos, CA, is equipped with state-of-the-art machinery for various production applications, including bar-tack, single needle/double needle, and grommet/snap machines. They …

Strategic Sourcing Conclusion and Outlook for industrial sewing companies near me

In today’s global marketplace, the significance of strategic sourcing for industrial sewing companies cannot be overstated. By leveraging local expertise, businesses can ensure high-quality production tailored to specific needs, such as custom cases, protective covers, and specialized apparel. This not only enhances product quality but also contributes to reduced lead times and improved supply chain efficiency.

Illustrative image related to industrial sewing companies near me

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, establishing partnerships with reputable industrial sewing contractors can unlock new growth opportunities. Companies in these areas are increasingly recognizing the value of collaborating with skilled manufacturers that offer diverse capabilities, from medical sewing to contract manufacturing.

Looking ahead, the demand for innovative and sustainable sewing solutions will continue to rise. International buyers are encouraged to explore and engage with local industrial sewing companies to capitalize on their unique offerings. By doing so, they can position their businesses for success in an evolving market landscape. Don’t miss the opportunity to enhance your supply chain—connect with trusted sewing contractors today and take the first step towards elevating your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to industrial sewing companies near me

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.