Top 5 Diagram For Electric Motor Suppliers (And How to Choose)

Introduction: Navigating the Global Market for diagram for electric motor

In the competitive landscape of global trade, sourcing the right diagram for electric motor components can pose significant challenges for B2B buyers. With the increasing demand for efficient and reliable electric motors across industries, understanding the intricacies of their design and functionality is crucial. This comprehensive guide aims to demystify the various types of electric motors, their applications, and the essential components illustrated through detailed diagrams.

By exploring the differences between direct current (DC) and alternating current (AC) motors, alongside their respective operational principles, this resource provides valuable insights for informed purchasing decisions. Additionally, buyers will find guidance on vetting suppliers, assessing costs, and navigating regulatory considerations specific to their regions, including Africa, South America, the Middle East, and Europe, with a focus on key markets such as Brazil and Germany.

Empowered by this guide, international B2B buyers can confidently identify the right electric motor solutions tailored to their operational needs, ensuring enhanced performance and competitive advantage in their sectors. With a thorough understanding of the technical aspects and market dynamics, businesses can mitigate risks and capitalize on opportunities in the ever-evolving electric motor marketplace.

Understanding diagram for electric motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DC Motor | Utilizes direct current; features a commutator and brushes. | Robotics, automotive applications | Pros: High torque at low speeds. Cons: Requires maintenance due to brushes. |

| AC Motor | Operates on alternating current; commonly uses a squirrel cage. | HVAC systems, industrial machinery | Pros: Low maintenance, efficient. Cons: Less torque at startup compared to DC motors. |

| Brushless DC Motor | No brushes; uses electronic controllers for efficiency. | Electric vehicles, drones | Pros: Longer lifespan, reduced noise. Cons: Higher initial cost. |

| Stepper Motor | Moves in discrete steps; precise control over positioning. | 3D printers, CNC machines | Pros: Accurate positioning, easy to control. Cons: Limited speed range. |

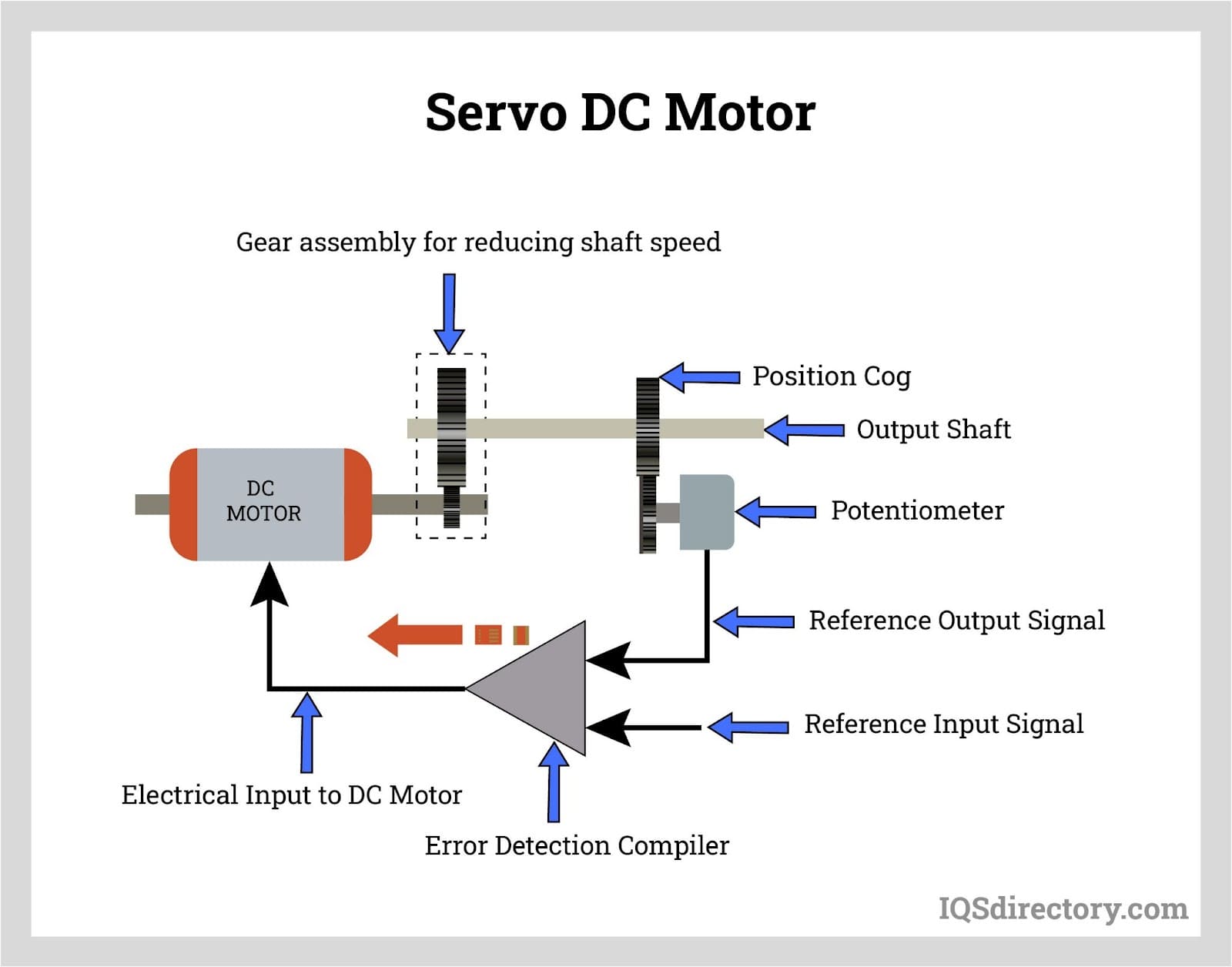

| Servo Motor | Provides precise control of angular position; feedback system. | Robotics, automated systems | Pros: High precision, fast response. Cons: More complex and expensive. |

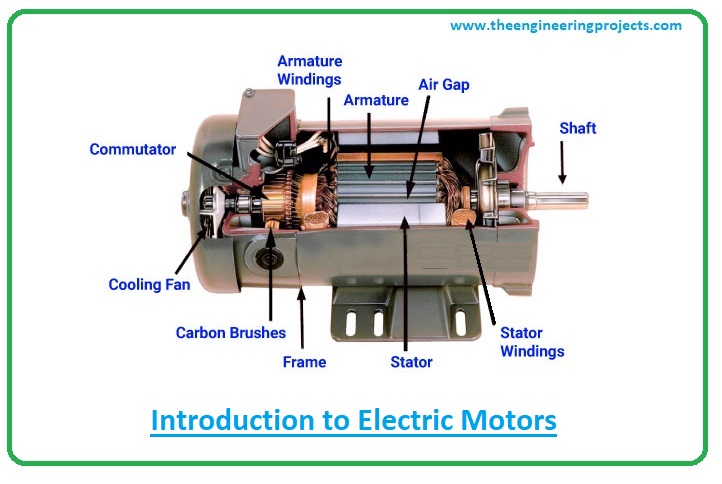

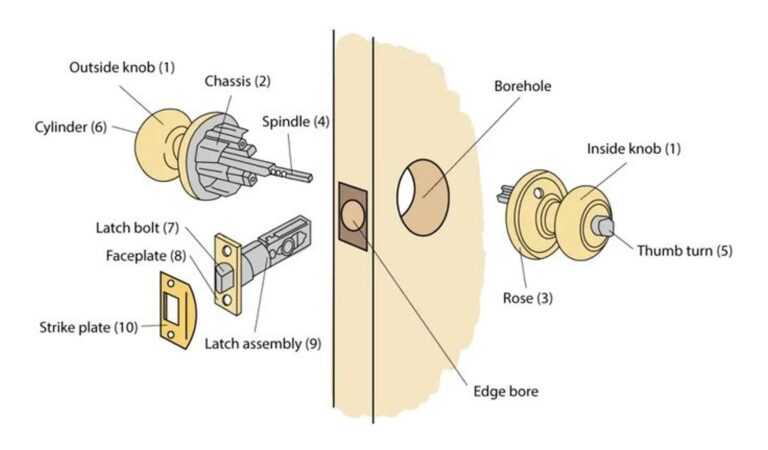

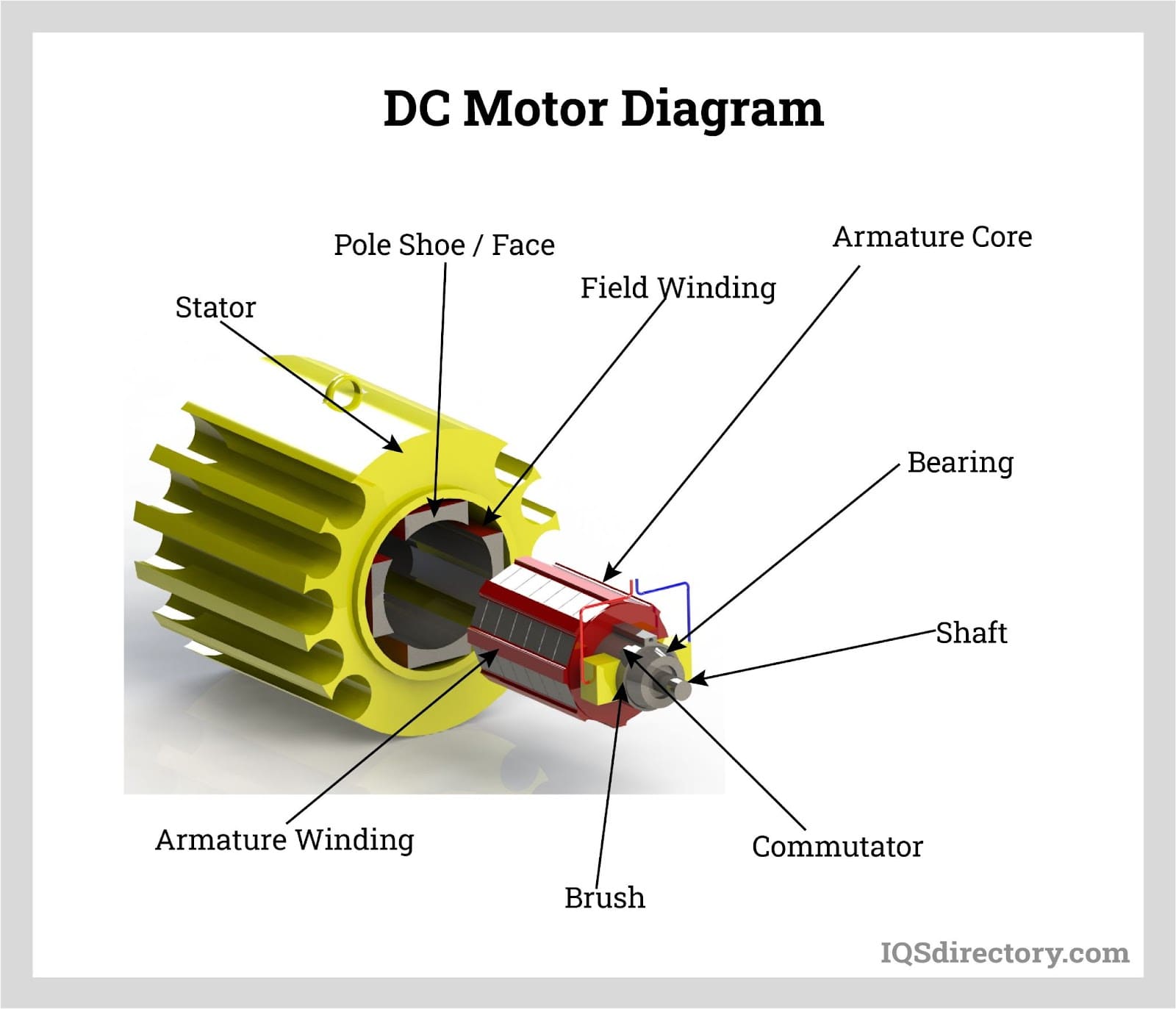

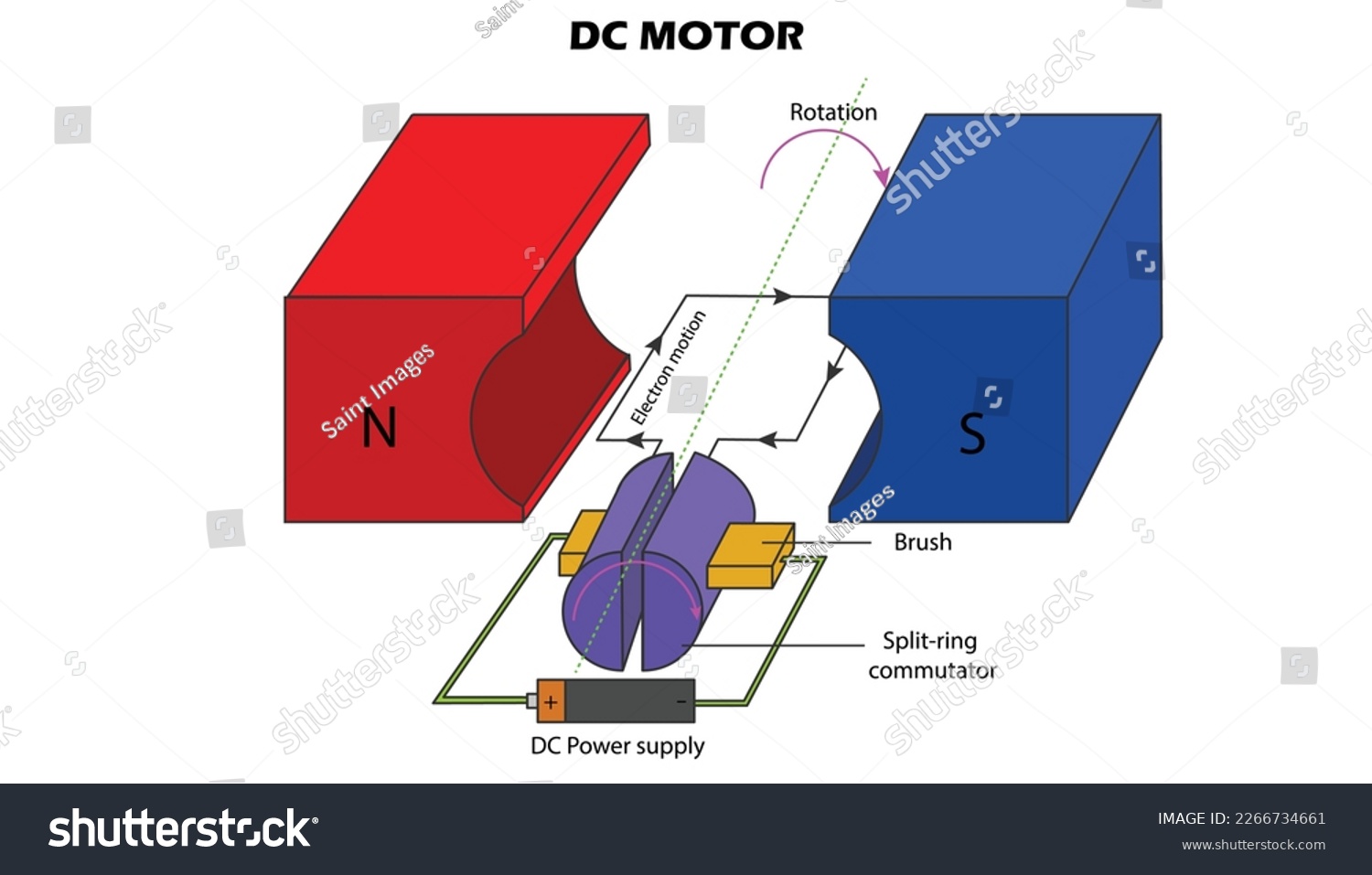

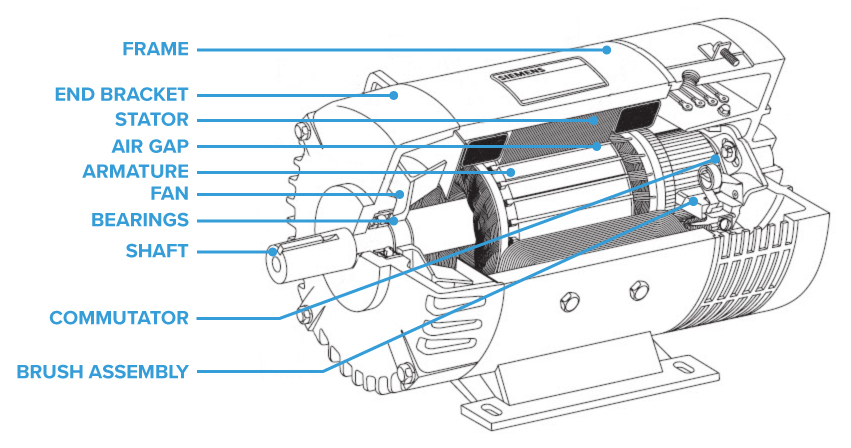

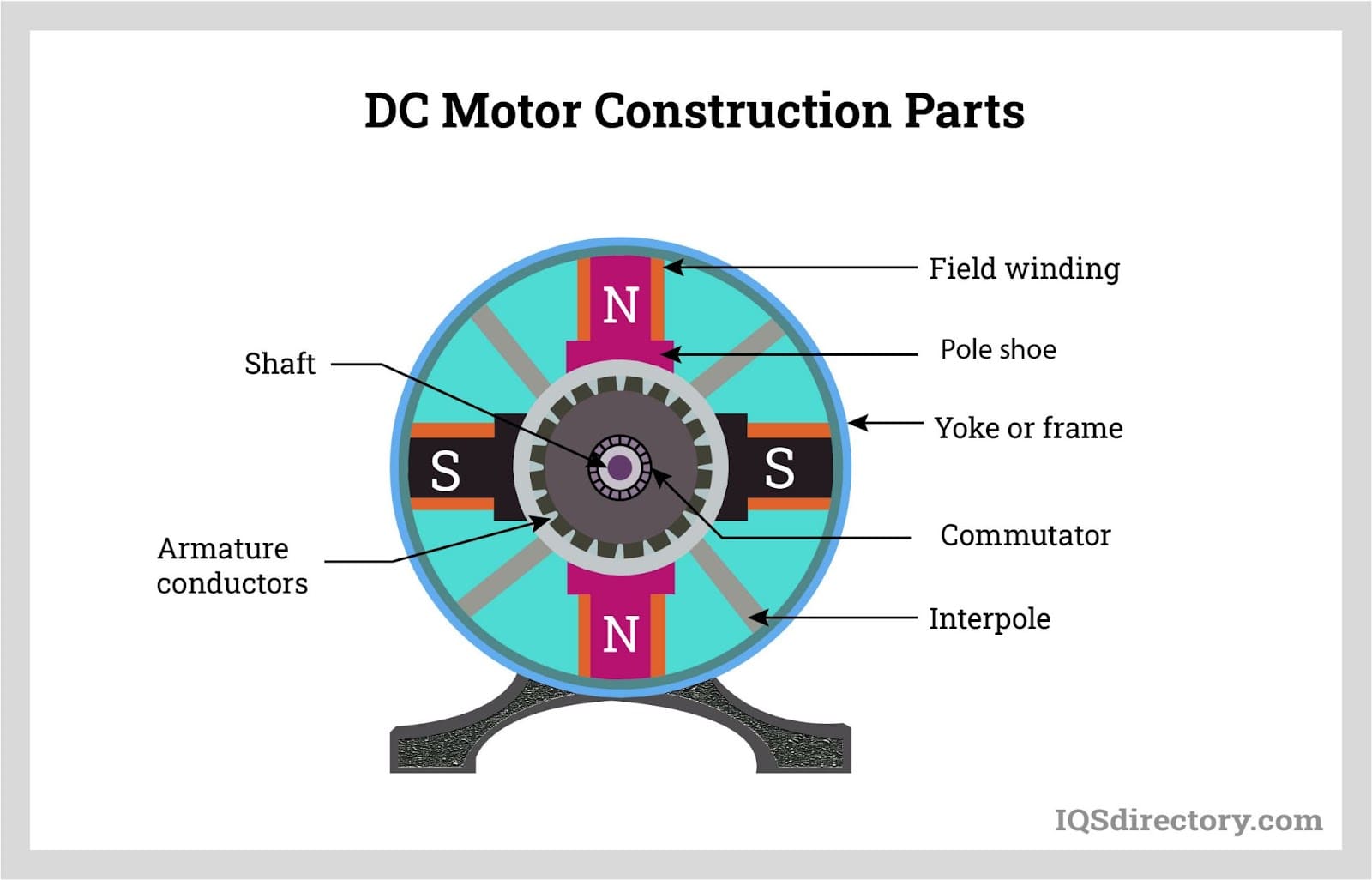

What are the characteristics of a DC Motor and its B2B purchasing considerations?

DC motors are characterized by their use of direct current and the inclusion of a commutator and brushes, which facilitate the rotation of the rotor. They are well-suited for applications requiring high torque at low speeds, such as robotics and automotive systems. When considering a purchase, B2B buyers should evaluate the motor’s maintenance needs, as the brushes can wear out and require replacement. Additionally, the efficiency and power output specifications should align with the operational requirements of the intended application.

How does an AC Motor differ from other electric motors in B2B applications?

AC motors operate on alternating current and typically employ a squirrel cage rotor, which allows for simple and efficient operation. They are widely used in HVAC systems and various industrial machinery due to their low maintenance requirements and durability. B2B buyers should consider the efficiency ratings and torque characteristics, especially in applications where startup torque is critical. The choice of an AC motor may also depend on the existing electrical infrastructure and power availability in the region.

What advantages do Brushless DC Motors offer to B2B buyers?

Brushless DC motors eliminate the need for brushes by using electronic controllers to manage the motor’s operation. This design results in reduced wear and tear, leading to a longer lifespan and quieter operation. They are particularly advantageous in high-performance applications such as electric vehicles and drones. Buyers should weigh the higher initial costs against the long-term savings in maintenance and operational efficiency. Additionally, compatibility with existing systems and the availability of controllers should be considered.

Why are Stepper Motors ideal for precision applications in B2B sectors?

Stepper motors are distinguished by their ability to move in precise steps, offering excellent control over positioning and speed. They are commonly used in 3D printers and CNC machines, where accuracy is paramount. B2B buyers should assess the motor’s step angle and holding torque to ensure it meets the specific requirements of their applications. While stepper motors provide great control, buyers must also consider their limited speed range and potential overheating issues during prolonged use.

What makes Servo Motors a preferred choice in automated systems?

Servo motors are designed for precise control of angular position and speed, utilizing feedback systems to enhance accuracy. They are extensively used in robotics and automated systems where quick response times and high precision are essential. B2B buyers should evaluate the motor’s torque ratings and feedback mechanisms to ensure they align with their automation goals. Although servo motors tend to be more complex and costly, their performance benefits often justify the investment, particularly in high-stakes applications.

Key Industrial Applications of diagram for electric motor

| Industry/Sector | Specific Application of diagram for electric motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increases production efficiency and reduces labor costs | Reliability of motor diagrams for maintenance and upgrades |

| Agriculture | Irrigation systems | Enhances crop yield through efficient water management | Compatibility with local power systems and environmental conditions |

| Transportation | Electric vehicles | Reduces carbon footprint and operational costs | Compliance with regional safety and environmental regulations |

| HVAC Systems | Air conditioning units | Improves energy efficiency and comfort for users | Energy ratings and serviceability of electric motors |

| Mining | Conveyor belt systems | Maximizes material handling efficiency and safety | Durability under harsh conditions and ease of sourcing parts |

How Is the Diagram for Electric Motors Used in Manufacturing Automation?

In the manufacturing sector, electric motors are integral to automated assembly lines. The diagram for electric motors provides critical insights into motor design and operational mechanics, allowing companies to optimize performance and troubleshoot issues effectively. By implementing well-designed electric motor systems, businesses can achieve higher production rates while minimizing labor costs, thus enhancing profitability. Buyers should prioritize sourcing reliable diagrams that facilitate easy maintenance and upgrades, ensuring long-term operational efficiency.

Illustrative image related to diagram for electric motor

What Role Does the Diagram for Electric Motors Play in Agriculture?

In agriculture, electric motors power irrigation systems that are essential for maximizing crop yields. The diagram for electric motors helps farmers understand the mechanics behind these systems, enabling them to select the right motor for their specific irrigation needs. Efficient water management through electric motors can lead to significant resource savings and improved crop health. Buyers in this sector must consider compatibility with local power systems and environmental conditions to ensure optimal performance.

How Do Electric Motors Impact the Transportation Sector?

The transportation industry increasingly relies on electric motors for electric vehicles (EVs), which are pivotal in reducing greenhouse gas emissions. The diagram for electric motors aids manufacturers in designing efficient propulsion systems that enhance vehicle performance. By adopting electric motors, companies can lower operational costs and contribute to a more sustainable future. International buyers should focus on compliance with regional safety and environmental standards to ensure their products meet market demands.

What Benefits Do Electric Motors Bring to HVAC Systems?

In HVAC (Heating, Ventilation, and Air Conditioning) systems, electric motors are crucial for air conditioning units. The diagram for electric motors provides insights into energy-efficient designs that improve overall system performance. By leveraging electric motors, businesses can enhance user comfort while reducing energy consumption, leading to cost savings. When sourcing motors for HVAC applications, buyers should prioritize energy ratings and serviceability to ensure long-term reliability and efficiency.

How Are Electric Motors Utilized in Mining Operations?

In the mining industry, electric motors drive conveyor belt systems that facilitate material handling. The diagram for electric motors is essential for understanding the layout and mechanics of these systems, enabling operators to maximize efficiency and ensure safety. By using robust electric motors, mining companies can enhance productivity and minimize downtime. Buyers must focus on the durability of motors under harsh conditions and the ease of sourcing replacement parts to maintain continuous operations.

3 Common User Pain Points for ‘diagram for electric motor’ & Their Solutions

Scenario 1: Inaccurate Diagrams Leading to Installation Errors

The Problem: B2B buyers often face challenges when the diagrams for electric motors they receive are inaccurate or poorly annotated. This can lead to installation errors that may cause significant downtime and increased costs. For instance, a manufacturing plant may find that the motor they have sourced does not align with the schematic provided, resulting in improper connections and functionality. This not only hampers production but can also lead to costly repairs or replacements.

The Solution: To mitigate this issue, buyers should insist on obtaining comprehensive and verified diagrams from suppliers before making a purchase. Requesting detailed technical specifications, including dimensional drawings and connection layouts, can help ensure compatibility. Furthermore, buyers can utilize digital tools that allow for 3D visualizations of electric motor installations. Engaging with suppliers that offer clear, standardized diagrams and technical support can reduce the risk of installation errors significantly. Conducting a pre-installation review meeting with the supplier’s technical team can also provide a platform for addressing any uncertainties before the actual installation.

Scenario 2: Difficulty in Understanding Motor Functionality

The Problem: Many B2B buyers may struggle to understand how different electric motor types function based on their diagrams, especially if they lack technical expertise. For example, a purchasing manager at an automotive parts manufacturer might be overwhelmed by the complexities of AC versus DC motor diagrams, leading to confusion about which motor type best suits their application. This lack of understanding can hinder informed decision-making and impact overall operational efficiency.

The Solution: To address this knowledge gap, companies should invest in training sessions for their procurement and engineering teams. Partnering with suppliers who offer educational resources, such as webinars or detailed guidebooks on electric motor functionality, can empower teams to make better decisions. Additionally, creating a standardized evaluation checklist for different motor types based on their diagrams can help streamline the selection process. This checklist should include key factors such as torque requirements, energy efficiency ratings, and maintenance needs, allowing teams to confidently compare options and select the most suitable motor for their specific applications.

Scenario 3: Inconsistent Diagrams Across Suppliers

The Problem: When sourcing electric motors from various suppliers, buyers often encounter inconsistencies in the diagrams provided. This can lead to confusion and miscommunication among teams, especially when different suppliers use different terminologies or symbols in their schematics. For instance, a buyer in South America may find that a diagram from a European supplier does not align with their existing systems, complicating integration efforts. Such discrepancies can lead to project delays and increased costs, ultimately affecting the company’s bottom line.

The Solution: To combat this challenge, it is essential for buyers to establish clear communication and standardization across their supplier base. Implementing a standardized diagram format or requesting suppliers to adhere to specific industry standards (like IEC or NEMA) can help create uniformity. Buyers should also consider creating a centralized database where all motor diagrams can be stored and accessed by relevant teams. This repository should include notes on variations and clarifications for each diagram, making it easier for teams to reference and align on specifications. Regular meetings with suppliers to review and discuss any discrepancies can further ensure that all parties are on the same page, minimizing confusion and enhancing collaboration.

Illustrative image related to diagram for electric motor

Strategic Material Selection Guide for diagram for electric motor

What Are the Key Materials Used in Electric Motor Diagrams?

When selecting materials for electric motor diagrams, it is crucial to understand the properties, advantages, disadvantages, and specific considerations that affect performance and compliance in various international markets. Below are analyses of four common materials used in electric motor components.

How Does Copper Contribute to Electric Motor Performance?

Copper is a widely used conductor in electric motors due to its excellent electrical conductivity and thermal properties. It typically has a temperature rating of up to 200°C and is resistant to corrosion, making it suitable for various environments.

Pros: Copper’s high conductivity ensures minimal energy loss, which enhances motor efficiency. It is also relatively easy to manufacture and can be formed into various shapes, such as wires and coils.

Cons: The primary disadvantage of copper is its cost, which is higher than alternatives like aluminum. Additionally, copper can be susceptible to oxidation if not properly insulated.

Illustrative image related to diagram for electric motor

Impact on Application: In electric motors, copper is essential for windings and connections, directly impacting the motor’s efficiency and performance.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Europe and Germany, adherence to RoHS directives regarding hazardous substances is also critical.

Why Is Aluminum a Popular Choice for Electric Motor Components?

Aluminum is often used in electric motors, particularly for the rotor and housing. It offers a good balance of strength, weight, and cost, with a temperature rating typically around 150°C.

Pros: Aluminum is lightweight, which reduces the overall weight of the motor, enhancing its efficiency. It is also less expensive than copper and has good corrosion resistance.

Cons: While aluminum has decent conductivity, it is not as efficient as copper. Additionally, its mechanical strength is lower, which may limit its use in high-stress applications.

Impact on Application: Aluminum is ideal for applications where weight savings are critical, such as in automotive or portable electric motors.

Considerations for International Buyers: Compliance with standards like DIN 1725 for aluminum alloys is necessary, especially in Europe. Buyers should also consider the local availability of aluminum and its recyclability, which is a growing concern in sustainability-focused markets.

Illustrative image related to diagram for electric motor

How Do Steel Alloys Enhance Electric Motor Durability?

Steel alloys, particularly those with high carbon content, are commonly used for the stator and rotor cores in electric motors. They provide excellent magnetic properties and mechanical strength, with temperature ratings typically reaching up to 300°C.

Pros: Steel’s durability and magnetic properties make it ideal for high-performance applications. It can withstand significant mechanical stress and is relatively cost-effective.

Cons: Steel is heavier than aluminum and copper, which can be a drawback in applications where weight is a concern. It is also prone to corrosion unless properly treated.

Impact on Application: The use of steel alloys enhances the motor’s overall efficiency and lifespan, particularly in heavy-duty applications such as industrial machinery.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 for structural steel. In regions with high humidity, additional corrosion resistance treatments may be necessary.

What Role Does Insulation Material Play in Electric Motor Functionality?

Insulation materials, such as polyimide and epoxy resins, are critical for electric motor performance. They typically have temperature ratings ranging from 180°C to 220°C and provide electrical insulation and mechanical support.

Pros: High-quality insulation materials enhance the motor’s safety and reliability by preventing short circuits and electrical failures. They also contribute to the motor’s thermal management.

Cons: The primary limitation is the cost of high-performance insulation materials, which can increase the overall manufacturing expenses.

Impact on Application: Insulation materials are vital for ensuring the longevity and safety of electric motors, especially in high-temperature environments.

Considerations for International Buyers: Compliance with international standards such as IEC 60085 for thermal insulation is crucial. Buyers should also consider the specific environmental regulations in their regions regarding hazardous substances in insulation materials.

Summary Table of Material Selection for Electric Motors

| Material | Typical Use Case for diagram for electric motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and connections | High electrical conductivity | Higher cost and oxidation risk | High |

| Aluminum | Rotor and housing | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Steel Alloys | Stator and rotor cores | Excellent durability and strength | Heavier and corrosion-prone | Medium |

| Insulation | Electrical insulation for windings | Enhances safety and reliability | Higher cost for high-performance | Medium to High |

This comprehensive overview of material selection for electric motors provides international B2B buyers with actionable insights to make informed decisions based on performance, cost, and compliance considerations.

Illustrative image related to diagram for electric motor

In-depth Look: Manufacturing Processes and Quality Assurance for diagram for electric motor

What Are the Main Stages of Manufacturing Electric Motors?

Manufacturing electric motors involves several critical stages that ensure the final product meets performance and durability standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Motor Production?

The manufacturing process begins with material preparation, where high-quality raw materials such as copper for windings, steel for laminations, and various polymers for insulation are sourced. Suppliers must provide materials that meet specific international standards, such as ASTM or ISO certifications, ensuring that they are suitable for electrical and mechanical applications.

During this phase, materials undergo rigorous inspections to verify their properties, including conductivity, tensile strength, and thermal resistance. This quality control step is essential as it lays the foundation for the motor’s overall performance.

What Techniques Are Used in the Forming Process of Electric Motors?

The forming stage involves shaping the raw materials into the necessary components of the motor. This includes stamping, machining, and winding processes.

-

Stamping: Steel sheets are stamped into precise shapes for the stator and rotor cores. This process often uses progressive dies to ensure accuracy and efficiency, which is critical for maintaining electromagnetic properties.

-

Machining: Components like shafts and housings are machined to exact specifications using CNC (Computer Numerical Control) technology. This ensures that each part fits together correctly, reducing friction and wear during operation.

-

Winding: Copper wire is wound around the stator and rotor to create electromagnetic fields. Automated winding machines are typically employed to increase efficiency and consistency, which is vital for large-scale production.

How Are Electric Motors Assembled?

The assembly phase is where all the components come together to create the finished motor. This typically involves:

-

Component Assembly: The rotor is inserted into the stator, and the commutator (for DC motors) or squirrel cage (for AC motors) is placed in position. Each component must be aligned accurately to ensure optimal performance.

-

Electrical Connections: Electrical connections are made, which may involve soldering or crimping wires to terminals. This stage requires precision to avoid potential short circuits or connection failures.

-

Final Assembly: The motor is then enclosed in its housing, and any additional components, such as fans or cooling systems, are integrated.

What Finishing Processes Are Important for Electric Motors?

Finishing processes enhance the durability and performance of electric motors. These can include:

-

Coating: Applying protective coatings to prevent corrosion and improve insulation. Epoxy coatings are commonly used to provide a robust barrier against environmental factors.

-

Balancing: The rotor is balanced to minimize vibrations during operation. Imbalances can lead to premature wear and operational inefficiencies.

-

Testing: Each motor undergoes a series of performance tests, including load testing and thermal imaging, to ensure it meets specifications.

How Is Quality Assurance Integrated into Electric Motor Manufacturing?

Quality assurance is a fundamental aspect of electric motor manufacturing, ensuring that each unit meets international standards and customer expectations.

What International Standards Are Relevant for Electric Motor Manufacturing?

Manufacturers typically adhere to several international quality standards, including:

-

ISO 9001: This standard focuses on quality management systems, ensuring that processes are efficient and consistent. Certification can enhance a manufacturer’s credibility in the international market.

-

CE Marking: For companies exporting to Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

-

API Standards: For motors used in specific industries, like oil and gas, adherence to API (American Petroleum Institute) standards is essential for ensuring reliability and safety.

What Are the Key Quality Control Checkpoints in Electric Motor Production?

Quality control (QC) checkpoints are integral to the manufacturing process, typically including:

-

Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early. This may include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Comprehensive testing of the finished product to verify that it operates within required parameters. This can include electrical testing, thermal testing, and noise level checks.

What Common Testing Methods Are Used for Electric Motors?

Testing methods for electric motors vary based on design and application but generally include:

-

Electrical Testing: Verifying insulation resistance, winding continuity, and operational voltage.

-

Mechanical Testing: Assessing vibration levels, torque output, and thermal performance under load conditions.

-

Environmental Testing: Subjecting motors to extreme temperatures and humidity levels to ensure reliability in diverse conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct thorough due diligence to ensure their suppliers maintain high-quality standards. Here are several strategies:

-

Supplier Audits: Conducting onsite audits can provide insights into a supplier’s manufacturing practices and quality control processes. This firsthand evaluation helps buyers assess compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC phases.

-

Third-Party Inspections: Engaging third-party inspection services can validate supplier claims regarding quality standards and product performance.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should be aware of several nuances in quality control:

-

Cultural Differences: Understanding the local business culture can impact communication and expectations regarding quality standards.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that affect product certification. Buyers should be well-informed about these to avoid compliance issues.

-

Logistics and Supply Chain: Quality can be affected by shipping conditions. Buyers should ensure that suppliers have robust logistics practices to maintain product integrity during transit.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting suppliers for electric motors, ensuring they receive high-quality, reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram for electric motor’

In the competitive landscape of electric motor procurement, having a clear and actionable sourcing checklist is essential for B2B buyers. This guide aims to equip you with practical steps to ensure that you make informed decisions when sourcing diagrams for electric motors, which are crucial for understanding motor designs and functionalities.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the electric motor diagrams you need. This includes details such as the type of motor (AC or DC), size, power rating, and operational environment. Understanding these specifications will help you effectively communicate your needs to potential suppliers and ensure that the diagrams you receive are relevant and useful.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in electric motor diagrams. Look for companies with a proven track record in providing high-quality technical drawings and documentation. Utilize online directories, industry forums, and trade shows to compile a list of potential vendors.

Step 3: Evaluate Supplier Credentials

Before committing to a supplier, it’s vital to verify their credentials. Check for relevant certifications, such as ISO standards, which demonstrate their commitment to quality and compliance. Additionally, assess their experience in your specific sector, as familiarity with industry standards can significantly impact the quality of the diagrams.

Step 4: Request Sample Diagrams

Ask potential suppliers for sample diagrams to evaluate the quality and clarity of their work. A well-structured diagram should clearly illustrate the components and workings of the motor, including labels and annotations. This step is crucial as it allows you to gauge whether the supplier’s style and detail level meets your expectations.

Step 5: Assess Customer Support and Communication

Strong customer support is essential when sourcing technical diagrams. Ensure that the supplier is responsive to inquiries and willing to provide clarification or additional information as needed. Effective communication can prevent misunderstandings and ensure that your project progresses smoothly.

Step 6: Review Pricing and Terms

Once you have shortlisted suppliers, review their pricing structures and terms of service. Look beyond just the cost; consider factors such as delivery timelines, revision policies, and payment terms. A supplier offering a slightly higher price may provide better value through superior service and faster turnaround times.

Step 7: Finalize the Agreement

Before finalizing your order, ensure that all terms are clearly outlined in a formal agreement. This should include details about the scope of work, timelines, and payment terms. Having a written contract helps protect both parties and provides a clear reference point for the project.

By following this checklist, you can streamline the procurement process for electric motor diagrams, ensuring that you select a supplier that meets your technical requirements and offers reliable support.

Comprehensive Cost and Pricing Analysis for diagram for electric motor Sourcing

What Are the Key Cost Components in Sourcing Diagrams for Electric Motors?

In the realm of electric motor sourcing, understanding the comprehensive cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The selection of materials is crucial, as high-quality magnets, copper wire, and steel can significantly impact the overall cost. Prices can vary based on market fluctuations and availability.

-

Labor: Labor costs depend on the region of production. For example, labor is often less expensive in developing countries, which may appeal to buyers from Africa or South America seeking cost-effective solutions.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and operational costs. Efficient production processes can help minimize overhead, impacting the final pricing.

-

Tooling: Custom tooling for specific motor designs can be a significant upfront investment. Buyers should consider whether standard tooling can be used to reduce costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. While this may increase costs, it can ultimately save buyers from future liabilities.

-

Logistics: Transportation and handling costs can vary widely based on the shipping method and destination. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding typical margins in your industry can help in negotiations.

How Do Price Influencers Impact the Sourcing of Electric Motor Diagrams?

Several factors can influence the pricing of electric motor diagrams, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should assess their needs to negotiate favorable terms.

-

Specifications and Customization: Custom designs or specifications can drive up costs. Buyers should determine if standard diagrams meet their requirements or if customization is necessary.

-

Material Choices: The quality and type of materials used in the motor will significantly affect pricing. Higher-quality materials typically yield better performance but come at a higher cost.

-

Quality and Certifications: Compliance with international standards (e.g., ISO, CE) can increase costs but provides assurance of quality, which is crucial for reliability in industrial applications.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence costs. Building long-term relationships with trusted suppliers can lead to better pricing.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) can affect logistics costs and responsibilities. Understanding these terms is vital for accurate cost estimation.

What Are Essential Buyer Tips for Cost-Efficiency in Electric Motor Sourcing?

To achieve cost-efficiency in sourcing diagrams for electric motors, buyers should consider the following strategies:

-

Negotiate Terms: Engaging in open negotiations with suppliers can lead to discounts or better payment terms. Don’t hesitate to discuss volume pricing or potential discounts for early payments.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial pricing, consider maintenance, energy consumption, and lifecycle costs. A higher upfront investment in quality can lead to lower TCO.

-

Understand Pricing Nuances for International Markets: Be aware of currency fluctuations, import tariffs, and local regulations that can affect final costs, especially for buyers in Africa, South America, the Middle East, and Europe.

-

Focus on Supplier Diversity: Engaging with multiple suppliers can provide insights into market pricing and help in finding the best deal.

-

Request Detailed Quotes: Ensure that quotes break down all cost components, allowing for a clearer comparison between suppliers.

Conclusion

In the competitive landscape of electric motor sourcing, understanding the intricacies of cost components and pricing influencers is vital for B2B buyers. By leveraging strategic negotiation and thorough market research, companies can make informed purchasing decisions that align with their operational needs and budget constraints. Always remember to seek clarity in pricing structures and maintain a proactive approach to managing costs throughout the sourcing process.

Disclaimer: Prices and costs mentioned are indicative and subject to change based on market conditions, supplier pricing strategies, and other economic factors.

Alternatives Analysis: Comparing diagram for electric motor With Other Solutions

Exploring Alternatives to ‘Diagram for Electric Motor’

In the realm of electric motors, understanding the operational diagrams is crucial for optimizing performance and efficiency. However, there are alternative solutions that can achieve similar objectives, each with its unique set of advantages and disadvantages. This analysis aims to provide a comparative overview of the ‘diagram for electric motor’ against alternative technologies, empowering B2B buyers to make informed decisions.

Comparison Table

| Comparison Aspect | Diagram For Electric Motor | Alternative 1: Pneumatic Systems | Alternative 2: Hydraulic Systems |

|---|---|---|---|

| Performance | High efficiency and torque | Moderate efficiency, high speed | High power density, precise control |

| Cost | Moderate initial investment | Lower initial cost, high operational costs | Higher initial cost, moderate operational costs |

| Ease of Implementation | Requires skilled labor for setup | Easier to implement, requires compressed air | Complex installation, requires hydraulic components |

| Maintenance | Moderate maintenance needs | Low maintenance, but air quality impacts performance | Higher maintenance due to fluid leaks |

| Best Use Case | Industrial applications with variable load demands | Quick-response applications like tools | Heavy-duty applications requiring consistent power |

Detailed Breakdown of Alternatives

Pneumatic Systems

Pneumatic systems utilize compressed air to power tools and machinery, making them a common alternative to electric motors. Their primary advantage lies in their simplicity and lower initial cost compared to electric motors. However, they generally offer moderate efficiency and can incur high operational costs due to the need for air compression and potential energy losses. Pneumatic systems are best suited for applications requiring rapid action and flexibility, such as assembly lines or handheld tools.

Hydraulic Systems

Hydraulic systems operate using pressurized fluid to transmit power, providing high power density and precise control. They excel in heavy-duty applications, such as construction machinery and material handling, where significant force is required. Despite their advantages, hydraulic systems come with a higher initial investment and ongoing maintenance challenges, such as fluid leaks and the need for regular checks on hydraulic components. They are ideal for tasks that require consistent and high levels of power, but may not be as cost-effective for smaller operations.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to the ‘diagram for electric motor,’ B2B buyers should consider factors such as performance requirements, cost implications, ease of implementation, and maintenance needs. Each solution has its strengths and weaknesses, making it essential to align the choice with specific operational demands. For instance, pneumatic systems may be preferable for applications requiring speed and flexibility, while hydraulic systems are better suited for heavy-duty tasks needing precision and power. By carefully assessing these aspects, buyers can select the most appropriate technology to meet their business objectives and enhance operational efficiency.

Essential Technical Properties and Trade Terminology for diagram for electric motor

What Are the Essential Technical Properties for Electric Motor Diagrams?

When evaluating electric motors, understanding their technical properties is crucial for making informed purchasing decisions. Here are several key specifications that B2B buyers should consider:

-

Material Grade

The materials used in electric motor construction, such as copper for windings and high-grade steel for the rotor and stator, significantly affect performance and durability. High-quality materials ensure better conductivity and resistance to wear, resulting in longer motor life and reduced maintenance costs. Buyers should prioritize sourcing motors made from recognized material grades to guarantee reliability. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension, which is critical in ensuring proper fitting and functionality. High tolerance levels lead to better alignment of motor components, which can enhance efficiency and reduce energy consumption. For industries where precision is paramount, such as automotive or aerospace, understanding tolerance specifications is essential for compatibility with existing systems. -

Power Rating

The power rating, usually expressed in watts (W) or horsepower (HP), indicates the motor’s output capacity. This property is vital for determining whether a motor can meet specific operational requirements. When selecting a motor, buyers must assess the power needs of their applications to avoid underperformance or energy waste. -

Efficiency Class

Electric motors are classified into efficiency classes (such as IE1, IE2, IE3, and IE4) based on their energy efficiency levels. Higher efficiency ratings mean lower operational costs and reduced environmental impact, making them a preferred choice in energy-conscious markets. Buyers should consider efficiency not only for cost savings but also for compliance with international energy regulations. -

Insulation Class

Insulation class indicates the maximum temperature that the motor can withstand without degrading. This specification is crucial in high-temperature environments, as inadequate insulation can lead to motor failure. Selecting motors with appropriate insulation ratings can prevent costly downtimes and extend equipment lifespan.

What Are Common Trade Terms Relevant to Electric Motor Purchases?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric motors, OEMs are critical as they ensure that the motors meet the specific requirements of the machinery they will be used in. Buyers should engage with reputable OEMs to guarantee quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for budget planning, especially for smaller businesses or those testing new products. Negotiating MOQs can lead to better pricing and inventory management. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Issuing an RFQ allows buyers to compare quotes and make informed decisions based on cost, delivery timelines, and terms of service. It is a crucial step in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and risks involved in the transport of electric motors. -

Lead Time

Lead time refers to the duration between the initiation of an order and its fulfillment. Knowing the lead time for electric motor delivery is vital for project planning and ensuring timely operations. Buyers should factor lead times into their procurement schedules to avoid disruptions.

By understanding these technical properties and trade terms, B2B buyers can make more strategic decisions when sourcing electric motors, ensuring they select products that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the diagram for electric motor Sector

What Are the Key Market Dynamics and Sourcing Trends in the Electric Motor Sector?

Market Overview & Key Trends

The electric motor sector is experiencing robust growth driven by increasing demand for energy-efficient solutions across various industries, including automotive, manufacturing, and renewable energy. Global initiatives aimed at reducing carbon emissions are propelling this trend, with electric motors playing a pivotal role in the transition to electric vehicles (EVs) and sustainable industrial practices. Key markets in Africa, South America, the Middle East, and Europe (notably Brazil and Germany) are witnessing heightened investments in electric motor technologies, spurred by government incentives and the need for modernization of infrastructure.

Illustrative image related to diagram for electric motor

Emerging B2B tech trends include the integration of IoT (Internet of Things) in electric motors, enabling predictive maintenance and real-time performance monitoring. This not only enhances operational efficiency but also reduces downtime, making electric motors more appealing to international buyers. Additionally, advancements in motor design, such as the development of brushless DC motors and high-efficiency AC motors, are reshaping sourcing strategies as businesses seek to leverage more reliable and energy-efficient products.

Furthermore, the market is witnessing a shift towards localized sourcing to mitigate risks associated with global supply chains, a trend intensified by recent geopolitical events and the COVID-19 pandemic. International buyers are increasingly looking for suppliers who can provide not only competitive pricing but also reliable delivery times and product quality assurance.

How Does Sustainability and Ethical Sourcing Impact the Electric Motor Sector?

Sustainability is becoming a critical focus in the electric motor sector, with buyers increasingly prioritizing environmentally friendly practices in their sourcing decisions. The production of electric motors often involves materials that can have significant environmental impacts, such as rare earth metals and various plastics. As a result, international buyers are encouraged to seek suppliers who adhere to sustainable sourcing practices, which include responsible mining and the use of recycled materials.

Ethical supply chains are also gaining importance, particularly in light of global awareness regarding labor practices and the environmental footprint of manufacturing processes. Certifications such as ISO 14001 for environmental management and the Responsible Business Alliance (RBA) code of conduct are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. Buyers are increasingly demanding transparency in the supply chain to ensure that the products they source are not only efficient but also ethically produced.

The adoption of ‘green’ materials, such as biodegradable composites and sustainable lubricants, is becoming more prevalent in electric motor manufacturing. This shift not only aligns with global sustainability goals but also appeals to environmentally conscious consumers and businesses, making ethical sourcing a competitive advantage in the market.

What Is the Brief Evolution and History of Electric Motors in the B2B Context?

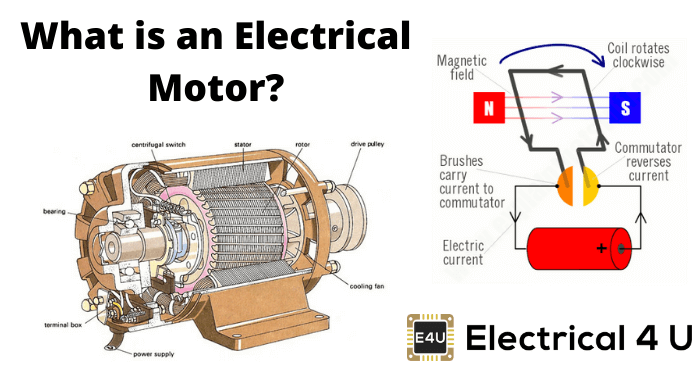

The evolution of electric motors dates back to the early 19th century, with significant advancements transforming them into crucial components of modern technology. Initially developed for basic applications, electric motors have evolved to become integral to industrial automation, transportation, and consumer electronics. The introduction of alternating current (AC) motors in the late 1800s revolutionized the industry, allowing for more efficient and versatile applications compared to direct current (DC) motors.

Over the decades, innovations such as the development of variable frequency drives (VFDs) and the integration of digital technologies have enhanced the performance and efficiency of electric motors, making them essential for various B2B applications. As industries increasingly pivot towards automation and energy efficiency, the demand for advanced electric motors continues to rise, solidifying their place in the global marketplace.

This historical context is vital for B2B buyers, as it underscores the importance of understanding the evolution of electric motors to make informed sourcing decisions that align with future technological advancements and market demands.

Illustrative image related to diagram for electric motor

Frequently Asked Questions (FAQs) for B2B Buyers of diagram for electric motor

-

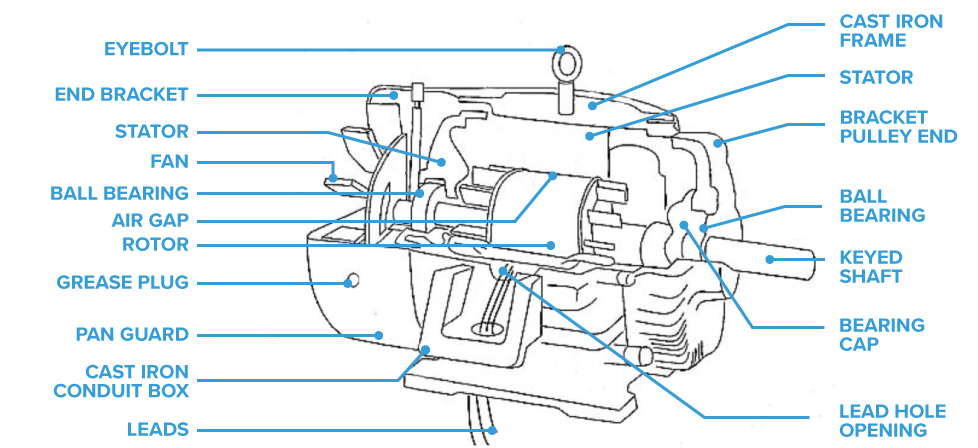

How do I solve issues with understanding electric motor diagrams?

Understanding electric motor diagrams can be challenging due to the complexity of components. Start by familiarizing yourself with the key parts such as the stator, rotor, commutator, and brushes. Look for resources that break down each component’s function, and consider reaching out to suppliers for technical support. Additionally, investing in training for your team on reading and interpreting these diagrams can significantly enhance your understanding and application in sourcing the right motors. -

What is the best type of electric motor for industrial applications?

The best type of electric motor for industrial applications often depends on the specific requirements of your operations. For continuous, high-torque applications, AC motors, particularly induction motors, are typically preferred due to their durability and efficiency. For applications requiring variable speed control, DC motors are advantageous. Assess your operational needs, including load requirements and energy efficiency, to determine the most suitable motor type. -

How can I vet potential suppliers for electric motor diagrams?

When vetting suppliers for electric motor diagrams, prioritize those with a solid reputation and extensive industry experience. Request references or case studies to assess their reliability and the quality of their products. Ensure they provide comprehensive technical support, including detailed diagrams and troubleshooting resources. Additionally, verify their compliance with international standards and certifications relevant to your market to ensure product safety and performance. -

What are the typical minimum order quantities (MOQs) for electric motors?

Minimum order quantities (MOQs) for electric motors can vary significantly based on the supplier and the type of motor. Generally, MOQs may range from 10 to several hundred units, especially for specialized or custom motors. Before placing an order, discuss your needs with the supplier to determine if they can accommodate smaller orders or offer flexible solutions, especially if you are entering a new market or testing a product line. -

What payment terms should I negotiate when sourcing electric motors internationally?

When sourcing electric motors internationally, it’s crucial to negotiate favorable payment terms to manage cash flow effectively. Common terms include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Consider using letters of credit for added security. Always clarify the currency for transactions and be aware of any additional fees related to international transactions, such as tariffs or shipping costs. -

How can I ensure quality assurance (QA) for electric motors?

To ensure quality assurance (QA) for electric motors, select suppliers who adhere to recognized international standards such as ISO 9001. Request detailed quality inspection reports and certifications for the motors you intend to purchase. Implement a robust QA process that includes pre-shipment inspections and testing of a sample batch before full delivery. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistics considerations should I keep in mind when importing electric motors?

When importing electric motors, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder who is experienced in handling industrial equipment. Ensure you understand the import duties and taxes applicable in your country, as these can impact total costs. Additionally, plan for potential delays in shipping and customs clearance by allowing extra time in your project timelines. -

How can I customize electric motor diagrams for specific applications?

Customizing electric motor diagrams for specific applications requires clear communication with your supplier regarding your needs. Provide them with detailed specifications about the operational environment, load requirements, and any unique features you require. Many manufacturers can design motors tailored to specific applications, but this may involve additional lead time and costs. Collaborate closely with their engineering team to ensure that the final product meets your expectations and operational requirements.

Top 5 Diagram For Electric Motor Manufacturers & Suppliers List

1. Pinterest – Electric Motor Diagram

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Diagram of Electric Motor Components

2. HowStuffWorks – Electric Motors

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Electric motors are devices that use magnets to create motion, functioning on the principle that opposites attract and likes repel. There are two main types of electric motors: AC (alternating current) and DC (direct current). A simple DC motor consists of six parts: stator (permanent magnet), rotor (moving part), commutator, brushes, axle, and a DC power supply. The rotor acts as an electromagnet…

3. Shutterstock – Electric Motor Diagram

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Electric Motor Diagram, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. AC Motor – Split Stator Coil

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: AC motor with split stator coil allowing for 120V or 240V connection. Wiring colors: Red and Black are line wires, Yellow, Blue, and White are field wires. Black wire has a thermal overload switch. Green is ground. The motor is a capacitor-run type that uses 120V for the phasing coil.

5. Electric Motor Warehouse – Wire Marking Solutions

Domain: electricmotorwarehouse.com

Registered: 1999 (26 years)

Introduction: This company, Electric Motor Warehouse – Wire Marking Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for diagram for electric motor

In conclusion, understanding the intricacies of electric motor diagrams is paramount for international B2B buyers looking to enhance their sourcing strategies. The two primary types—DC and AC motors—each present unique advantages that can cater to diverse applications across various industries. By leveraging detailed motor diagrams, buyers can make informed decisions that optimize performance, reduce costs, and enhance operational efficiency.

Strategic sourcing plays a critical role in ensuring that businesses not only acquire high-quality motors but also establish long-term partnerships with reliable suppliers. This approach allows for better negotiation leverage, improved supply chain management, and the potential for innovative solutions tailored to specific needs.

As we look ahead, the demand for electric motors is expected to grow, driven by advancements in automation and sustainability initiatives. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, now is the time to engage with suppliers who can provide comprehensive insights and robust product offerings. By prioritizing strategic sourcing, businesses can position themselves for success in an increasingly competitive marketplace. Embrace this opportunity to enhance your procurement processes and drive growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.