Top 5 Decorative Metal Trim Molding Suppliers (And How to Choose)

Introduction: Navigating the Global Market for decorative metal trim molding

In the competitive landscape of construction and design, sourcing high-quality decorative metal trim molding presents a unique challenge for B2B buyers. As businesses increasingly seek to elevate their projects with durable and aesthetically pleasing materials, understanding the nuances of the global market for decorative metal trim molding becomes essential. This guide delves into the diverse types of metal trim, their applications across various sectors, and critical factors to consider when vetting suppliers.

By examining cost structures, material durability, and design options, this comprehensive resource equips international buyers—particularly those from Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Germany—with the knowledge to make informed purchasing decisions. Our insights will help you navigate the complexities of sourcing metal trim that not only meets functional requirements but also enhances the visual appeal of your projects.

Whether you are looking to incorporate decorative elements into commercial spaces or seeking reliable suppliers for large-scale projects, this guide serves as your roadmap to successfully integrating decorative metal trim molding into your business offerings. With a focus on quality, sustainability, and market trends, you’ll be well-prepared to elevate your design initiatives and achieve lasting results.

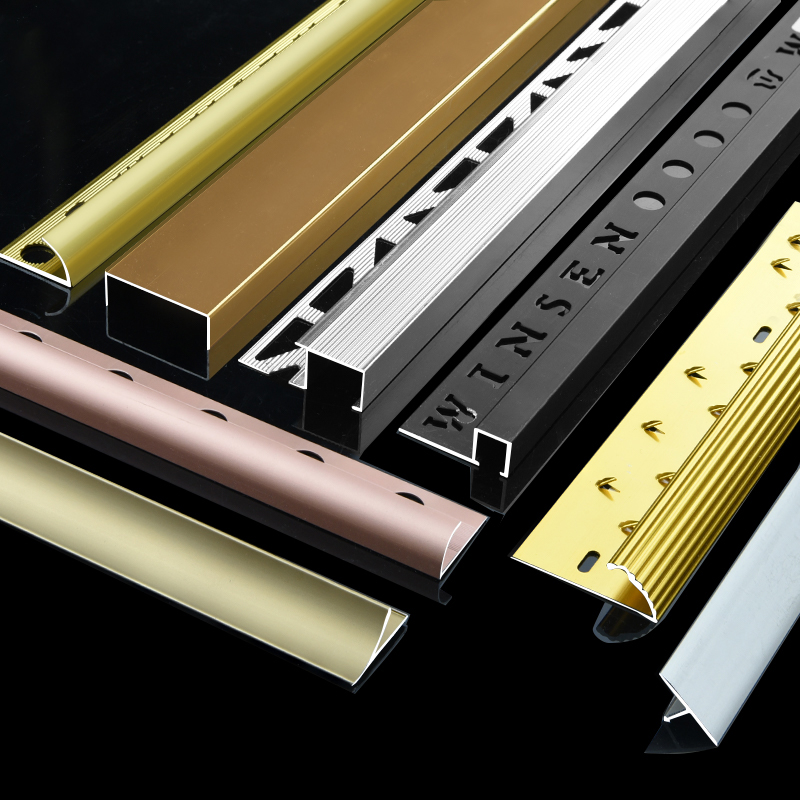

Understanding decorative metal trim molding Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crown Molding | Decorative profile at the junction of wall and ceiling | Residential and commercial interiors | Pros: Enhances aesthetics, adds value. Cons: Installation may require skilled labor. |

| Base Cap Molding | Sits at the base of walls, often with a rounded edge | Flooring transitions, wall protection | Pros: Protects walls from damage, easy to install. Cons: Limited decorative impact compared to other types. |

| Corner Molding | Designed for exterior or interior corners, often L-shaped | Building corners, door frames | Pros: Provides a finished look, reinforces corners. Cons: May not suit all design styles. |

| Drip Cap Molding | Installed above doors or windows to direct water away | Exterior applications, weatherproofing | Pros: Prevents water damage, enhances durability. Cons: Limited color options. |

| Chair Rail Molding | Positioned horizontally on walls, typically at chair height | Dining rooms, hallways, and formal spaces | Pros: Protects walls from furniture damage, adds visual interest. Cons: May not fit modern minimalist designs. |

What Are the Characteristics and Suitability of Crown Molding for B2B Buyers?

Crown molding is a classic decorative trim that enhances the transition between walls and ceilings, making it a popular choice in both residential and commercial spaces. Its intricate designs can elevate the aesthetic appeal of a room, thereby adding value to properties. B2B buyers should consider the installation complexity, as skilled labor may be required for perfect alignment and fitting. Additionally, the material choice—whether wood, metal, or synthetic—can impact both the durability and cost, making it essential to align with the intended design vision and budget.

How Does Base Cap Molding Serve B2B Applications?

Base cap molding is primarily used at the base of walls to provide a clean transition between flooring and wall surfaces. Its rounded edge offers a finished look while protecting walls from scuffs and damage caused by furniture. This type of molding is particularly favored in commercial environments where durability is paramount. B2B buyers should assess the ease of installation and the material’s resistance to wear and tear, especially in high-traffic areas. While it may not be as decorative as other trim types, its functional benefits make it a practical choice.

Why Choose Corner Molding for Your Projects?

Corner molding is specifically designed for both interior and exterior corners, often taking an L-shape to create a seamless finish. This type of molding is essential for reinforcing corners in buildings and can be used around door frames and window casings. Its practical application in construction makes it a staple for contractors and builders. Buyers should consider the material’s compatibility with their design requirements and the overall architectural style of the project. While corner molding adds a finished look, it may not suit more modern or minimalist aesthetics.

What Are the Advantages of Drip Cap Molding in Construction?

Drip cap molding is strategically installed above doors and windows to direct rainwater away from the building structure, preventing water damage. This type of molding is crucial in regions prone to heavy rainfall, making it a vital component for exterior applications. B2B buyers should evaluate the material’s corrosion resistance and overall durability, especially in harsh weather conditions. While it effectively enhances the longevity of buildings, its limited color options may restrict design flexibility.

How Does Chair Rail Molding Enhance Interior Spaces?

Chair rail molding is installed horizontally around a room at chair height, serving both decorative and protective functions. It prevents wall damage from furniture while adding an element of visual interest to dining rooms, hallways, and formal spaces. B2B buyers should consider the design compatibility with existing decor and the ease of installation. While chair rail molding offers aesthetic benefits, it may not align with modern minimalist designs, necessitating careful consideration of the target market’s preferences.

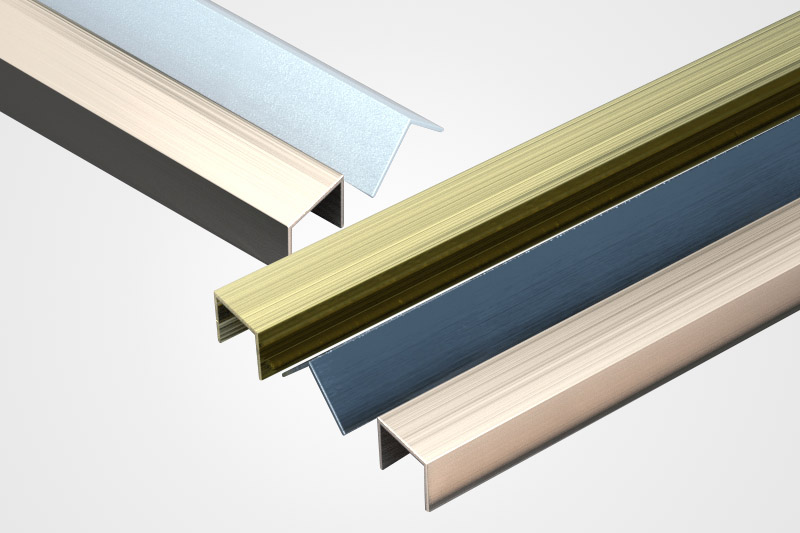

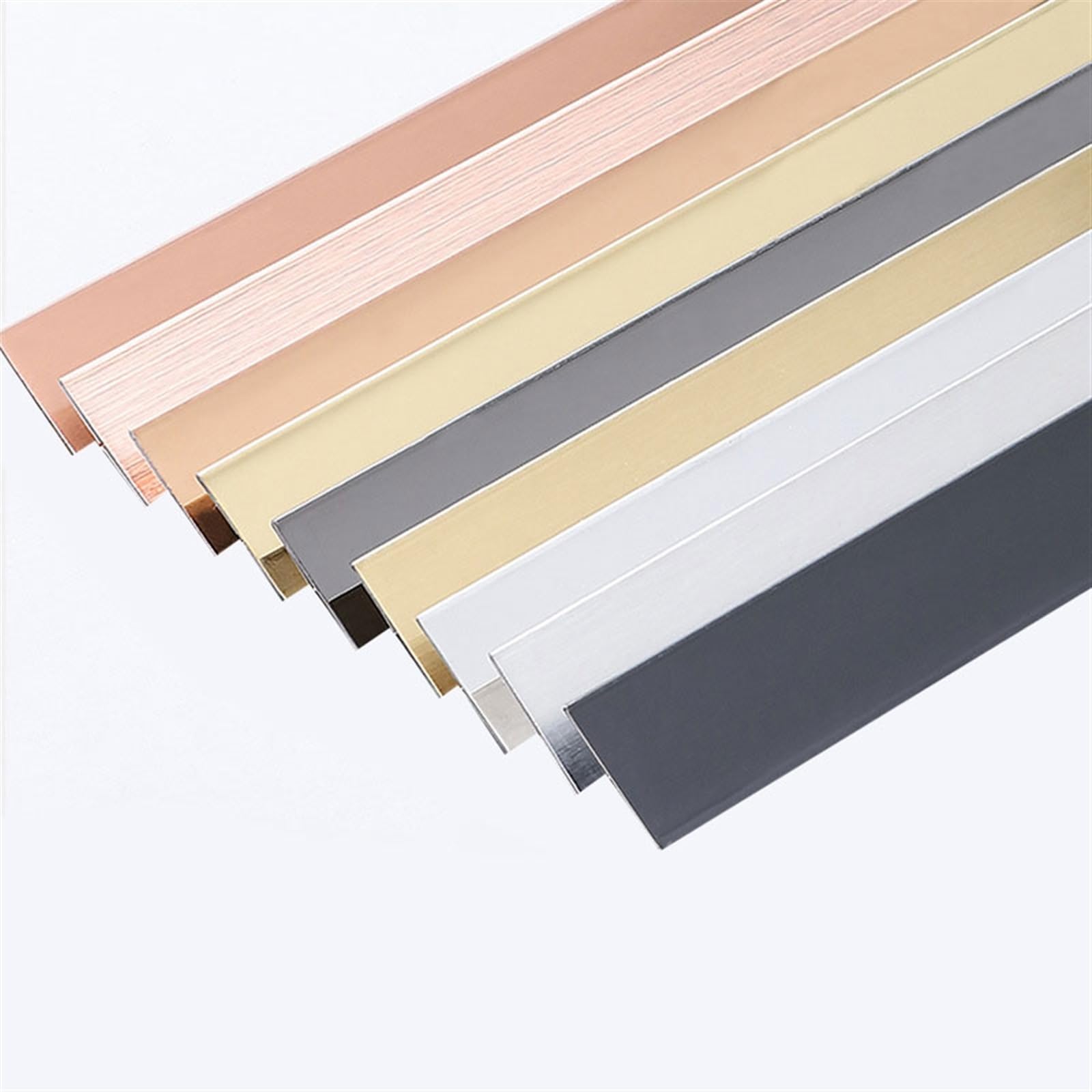

Illustrative image related to decorative metal trim molding

Key Industrial Applications of decorative metal trim molding

| Industry/Sector | Specific Application of Decorative Metal Trim Molding | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Decorative trim for hotel interiors and exteriors | Enhances aesthetic appeal, creating a luxurious atmosphere for guests | Look for corrosion-resistant materials suitable for high-traffic areas. |

| Retail | Store displays and fixtures | Improves product visibility and brand image through elegant design | Consider custom designs that align with branding and durability for frequent use. |

| Architectural Design | Historical restorations and new constructions | Maintains authenticity while meeting modern safety standards | Ensure compliance with local building codes and historical preservation guidelines. |

| Residential Construction | Interior design elements in homes | Adds value to properties and personalizes living spaces | Source sustainable materials that appeal to environmentally conscious consumers. |

| Transportation | Trim for commercial vehicles and public transport | Enhances durability and aesthetic appeal while ensuring safety | Prioritize lightweight materials that can withstand harsh environments. |

How is Decorative Metal Trim Molding Used in Hospitality?

In the hospitality industry, decorative metal trim molding is often utilized in both interior and exterior designs of hotels. It enhances the aesthetic appeal, providing a luxurious and inviting atmosphere that can significantly influence guest satisfaction. Buyers in this sector should prioritize corrosion-resistant materials, especially in humid climates, to ensure longevity and maintain the visual integrity of the property. Additionally, customization options can help align the trim with the hotel’s branding, making it a vital consideration for international buyers looking to elevate their properties.

What Role Does Decorative Metal Trim Molding Play in Retail?

In retail settings, decorative metal trim molding is crucial for store displays and fixtures. It not only improves product visibility but also contributes to a cohesive brand image, which can drive sales. B2B buyers in this sector should consider sourcing custom designs that reflect their brand identity while ensuring durability for high-traffic areas. Furthermore, the ability to integrate lighting and technology into these trims can enhance the shopping experience, making it an important factor for retailers looking to stand out in competitive markets.

How is Decorative Metal Trim Molding Used in Architectural Design?

Architectural design frequently employs decorative metal trim molding for both historical restorations and modern constructions. It plays a key role in maintaining the authenticity of historical buildings while incorporating modern safety standards. Buyers should ensure that the selected materials comply with local building codes and any historical preservation guidelines, especially in regions with rich architectural heritage. This attention to detail not only preserves cultural significance but also adds value to the property, making it an essential consideration for architects and developers.

What Benefits Does Decorative Metal Trim Molding Provide in Residential Construction?

In residential construction, decorative metal trim molding is used to add character and sophistication to homes. This not only enhances the property’s aesthetic appeal but also increases its market value. B2B buyers should focus on sourcing sustainable materials, as there is a growing trend toward environmentally friendly building practices. Additionally, the versatility of metal trims allows for personalization, catering to homeowners’ unique tastes and preferences, which can be a significant selling point in various international markets.

How Does Decorative Metal Trim Molding Enhance Transportation Design?

In the transportation sector, decorative metal trim molding is applied in commercial vehicles and public transport systems. It enhances both durability and aesthetic appeal, ensuring that vehicles not only look good but also meet safety standards. Buyers should prioritize lightweight materials that can withstand harsh environments while ensuring ease of maintenance. This consideration is particularly important for international buyers in regions with diverse climate conditions, as it can significantly impact the longevity and performance of the vehicles.

3 Common User Pain Points for ‘decorative metal trim molding’ & Their Solutions

Scenario 1: Difficulties in Sourcing the Right Type of Decorative Metal Trim Molding

The Problem: B2B buyers often struggle to identify and source the right decorative metal trim molding that meets their project specifications. With numerous materials available—such as aluminum, brass, and stainless steel—along with varying finishes and designs, the decision-making process can be overwhelming. Buyers may find themselves unsure of which material offers the best durability, aesthetic appeal, or compliance with local building codes. Additionally, shipping constraints and supplier reliability can complicate the sourcing process, leading to delays and increased costs.

The Solution: To overcome these sourcing challenges, B2B buyers should engage in thorough market research to identify reputable suppliers specializing in decorative metal trim molding. Utilizing online platforms, industry trade shows, and networking with industry professionals can provide insights into the latest trends and material innovations. Once potential suppliers are identified, buyers should request samples and detailed specifications for different materials to assess quality and suitability.

It is also essential to establish clear communication with suppliers regarding project requirements, timelines, and local compliance issues. Creating a checklist of must-have features—such as corrosion resistance, finish type, and installation compatibility—will help streamline the selection process. Additionally, leveraging technology for project management can aid in tracking orders and ensuring timely delivery, thus minimizing potential project delays.

Scenario 2: Installation Complications with Decorative Metal Trim Molding

The Problem: Installation of decorative metal trim molding can pose significant challenges for B2B buyers, especially when dealing with complex architectural designs or uneven surfaces. Improper installation can lead to aesthetic inconsistencies, increased material waste, and additional labor costs. Buyers may also encounter issues with the compatibility of metal trim with other materials, resulting in difficulties during the fitting process.

The Solution: To mitigate installation complications, B2B buyers should prioritize training for installation teams. Providing comprehensive training sessions on the specific handling and installation techniques for various types of metal trim is crucial. This includes understanding the tools required, such as specialized cutting tools for metal, and the best practices for securing the trim without compromising its integrity.

Furthermore, buyers should consider pre-fabricated or custom-fit solutions that can simplify the installation process. Collaborating with suppliers that offer design assistance can help ensure that the selected trim is tailored to the unique specifications of the project. Utilizing software that simulates the installation process can also help identify potential issues before actual installation begins, allowing for adjustments in design or material choice as needed.

Scenario 3: Cost Management and Budget Constraints

The Problem: Many B2B buyers face budget constraints when sourcing decorative metal trim molding. The initial costs of high-quality metal trims can be significant, and unexpected expenses due to installation challenges or sourcing delays can strain project budgets. Buyers may find it difficult to balance quality and cost, leading to compromises that can affect the overall project outcome.

The Solution: To effectively manage costs while maintaining quality, buyers should adopt a strategic sourcing approach. This includes conducting a cost-benefit analysis to compare the long-term value of investing in durable, high-quality materials against the initial expenditure. Engaging in bulk purchasing or long-term contracts with suppliers can also lead to cost savings.

Moreover, buyers should explore alternative materials that offer similar aesthetic benefits at a lower price point, such as metal-like finishes or hybrid materials that combine metal with other composites. Conducting a thorough market analysis to identify various suppliers and pricing options can further enhance budget management. Finally, creating a contingency budget to cover unexpected costs will help maintain financial stability throughout the project lifecycle, ensuring that quality is not compromised due to budget constraints.

Strategic Material Selection Guide for decorative metal trim molding

What Are the Key Properties of Common Materials for Decorative Metal Trim Molding?

When selecting materials for decorative metal trim molding, it’s essential to evaluate their properties, advantages, and limitations. The most common materials used in this sector include aluminum, stainless steel, brass, and copper. Each material offers unique characteristics that can significantly influence the final product’s performance and suitability for various applications.

Aluminum: Lightweight and Versatile

Aluminum is a popular choice for decorative metal trim molding due to its lightweight nature and excellent corrosion resistance. It has a good temperature rating, making it suitable for various environments, including humid conditions. Aluminum can be easily extruded and formed into intricate designs, which is advantageous for aesthetic applications.

Pros:

– Lightweight and easy to handle.

– Corrosion-resistant, ideal for outdoor applications.

– Cost-effective for large-scale production.

Illustrative image related to decorative metal trim molding

Cons:

– Less durable than heavier metals like stainless steel.

– Can be prone to denting and scratching.

Impact on Application: Aluminum’s lightweight nature makes it suitable for applications where weight is a concern, such as in transportation or temporary installations.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is crucial. Buyers in regions like Europe may prefer aluminum with specific anodized finishes for enhanced durability.

Stainless Steel: Strength and Aesthetic Appeal

Stainless steel is renowned for its strength, durability, and aesthetic appeal. It offers excellent corrosion resistance and can withstand high temperatures, making it suitable for various applications, including kitchens and bathrooms. The material’s sleek finish adds a modern touch to decorative trim.

Pros:

– Highly durable and resistant to corrosion.

– Aesthetic appeal with a modern finish.

– Suitable for high-temperature environments.

Illustrative image related to decorative metal trim molding

Cons:

– Higher cost compared to aluminum and other materials.

– Can be challenging to work with due to its toughness.

Impact on Application: Stainless steel is ideal for high-end applications where durability and aesthetics are paramount, such as in luxury hotels or commercial buildings.

Considerations for International Buyers: Buyers should ensure compliance with standards such as DIN and JIS, particularly in European and Asian markets, to meet local regulations.

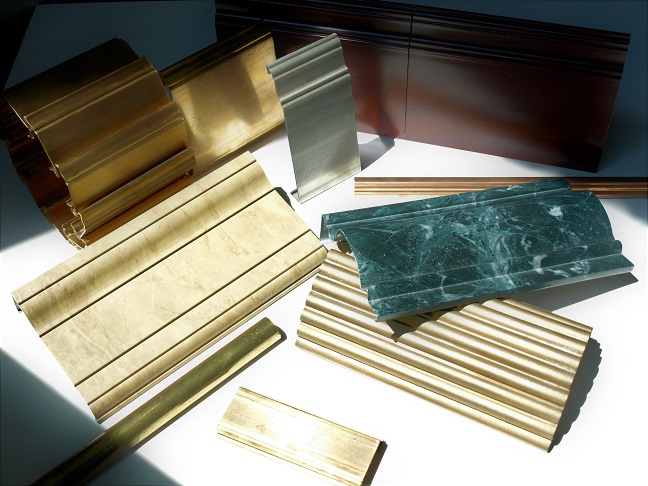

Brass: Timeless Elegance

Brass is often used for decorative trim molding due to its classic appearance and intrinsic resistance to corrosion. It is particularly valued in high-end applications where aesthetics play a crucial role. Brass can be polished to a high shine or left to develop a patina over time.

Pros:

– Offers a classic, timeless aesthetic.

– Naturally resistant to corrosion and tarnishing.

– Easy to machine and fabricate.

Cons:

– More expensive than aluminum and some stainless steel options.

– Can tarnish over time if not properly maintained.

Impact on Application: Brass is often used in luxury interiors and historical restorations, where maintaining an authentic look is essential.

Considerations for International Buyers: Understanding local preferences for finishes and compliance with environmental regulations is vital, especially in markets like Germany, where sustainability is a significant concern.

Copper: Unique Character and Antimicrobial Properties

Copper is known for its distinctive color and patina that develops over time, adding character to decorative trim. It also possesses natural antimicrobial properties, making it suitable for applications in healthcare and food service environments.

Pros:

– Unique aesthetic that improves with age.

– Antimicrobial properties beneficial for hygiene-sensitive areas.

– Excellent thermal and electrical conductivity.

Cons:

– Higher cost and weight compared to aluminum.

– Requires maintenance to preserve its appearance.

Impact on Application: Copper is ideal for applications where both aesthetics and hygiene are critical, such as in hospitals or restaurants.

Considerations for International Buyers: Compliance with health and safety standards is crucial, particularly in regions where copper’s antimicrobial properties can be leveraged.

Summary Table of Material Options

| Material | Typical Use Case for Decorative Metal Trim Molding | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications, outdoor environments | Corrosion-resistant and cost-effective | Less durable than heavier metals | Low |

| Stainless Steel | High-end interiors, kitchens, and bathrooms | Highly durable and modern aesthetic | Higher cost and difficult to fabricate | High |

| Brass | Luxury interiors, historical restorations | Timeless aesthetic and corrosion resistance | More expensive and requires maintenance | Med |

| Copper | Healthcare and food service environments | Unique character and antimicrobial properties | Higher cost and requires upkeep | High |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions regarding decorative metal trim molding, considering both performance and regional compliance factors.

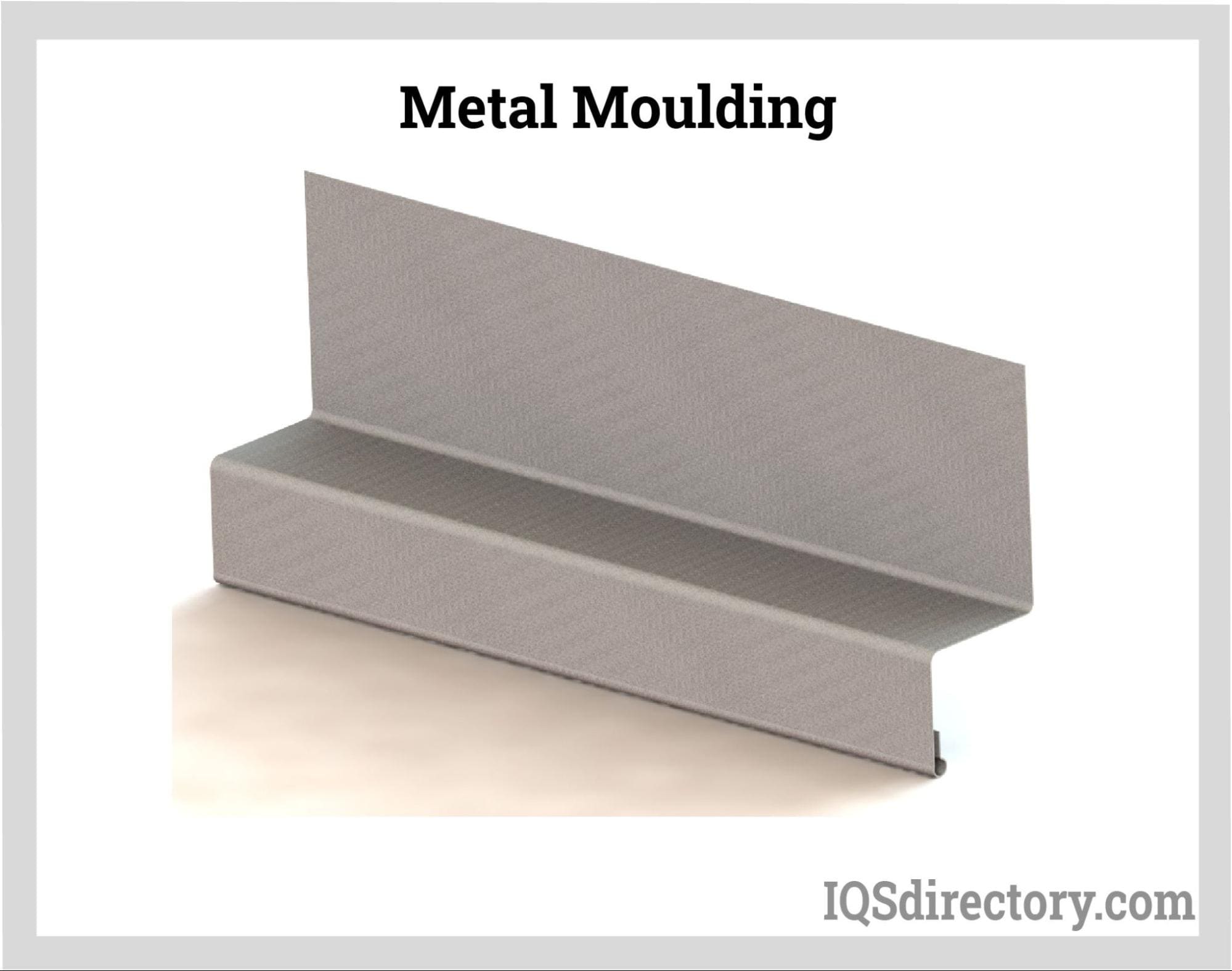

In-depth Look: Manufacturing Processes and Quality Assurance for decorative metal trim molding

The manufacturing of decorative metal trim molding is a complex process that combines advanced technology with traditional craftsmanship. Understanding the stages involved in production and the quality assurance measures in place is essential for B2B buyers, especially those operating in international markets like Africa, South America, the Middle East, and Europe.

Illustrative image related to decorative metal trim molding

What Are the Main Stages in the Manufacturing Process of Decorative Metal Trim Molding?

Material Preparation: What Types of Metals Are Typically Used?

The journey of decorative metal trim molding begins with the selection of high-quality raw materials. Common metals used in production include aluminum, stainless steel, brass, copper, and bronze. Each metal type offers unique properties; for instance, aluminum is lightweight and corrosion-resistant, while brass provides a classic aesthetic and durability. The materials are sourced based on the specific requirements of the molding design, such as strength, finish, and application environment.

Once the materials are selected, they undergo thorough inspection to ensure they meet required specifications. This step is critical in avoiding defects that could compromise the final product’s integrity.

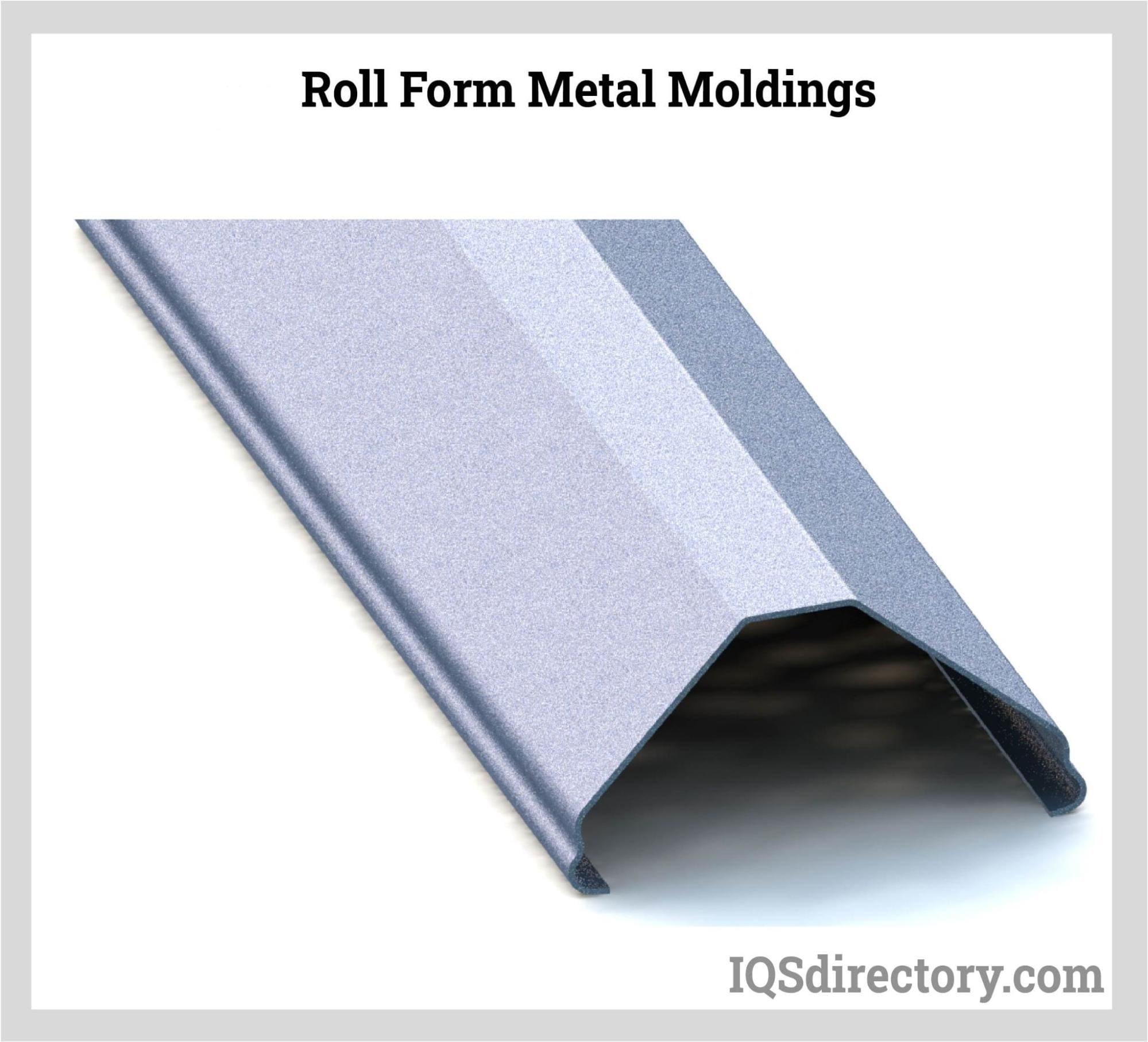

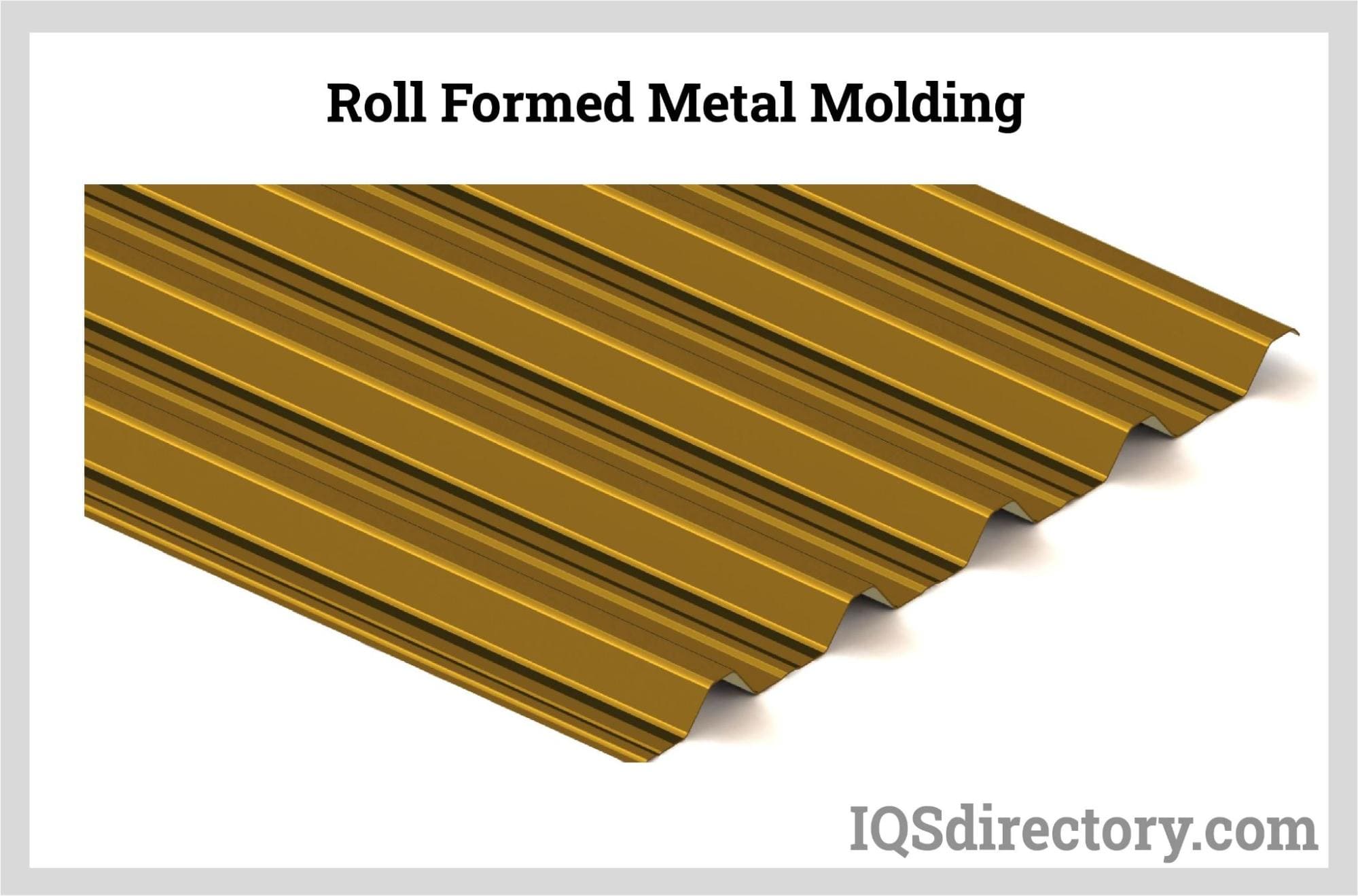

Forming: How Is the Metal Shaped Into Molding?

The forming stage involves various techniques to shape the metal into the desired trim profiles. Common methods include:

-

Roll Forming: This continuous process involves feeding metal sheets through a series of rollers to achieve the desired shape. It is efficient for producing long lengths of consistent profiles.

-

Extrusion: In this process, heated metal is forced through a die to create specific cross-sectional shapes. This method is particularly useful for complex profiles that require precision.

-

Stamping: This technique uses a die to cut and shape the metal into specific designs. Stamping is ideal for creating intricate patterns and can be used for both small and large production runs.

-

Laser Cutting: For more intricate designs, laser cutting provides precision and the ability to create complex patterns without compromising the material’s integrity.

Assembly: How Are the Different Components Joined?

In many cases, decorative metal trim molding consists of multiple components that need to be assembled. This can involve welding, riveting, or using adhesives, depending on the design and intended use. Each joining method has its advantages; for instance, welding provides a strong, permanent bond, while adhesives can offer flexibility in design.

The assembly process requires skilled labor to ensure that each component is accurately aligned and securely fastened. Quality checks during assembly help identify any misalignments or defects early in the process.

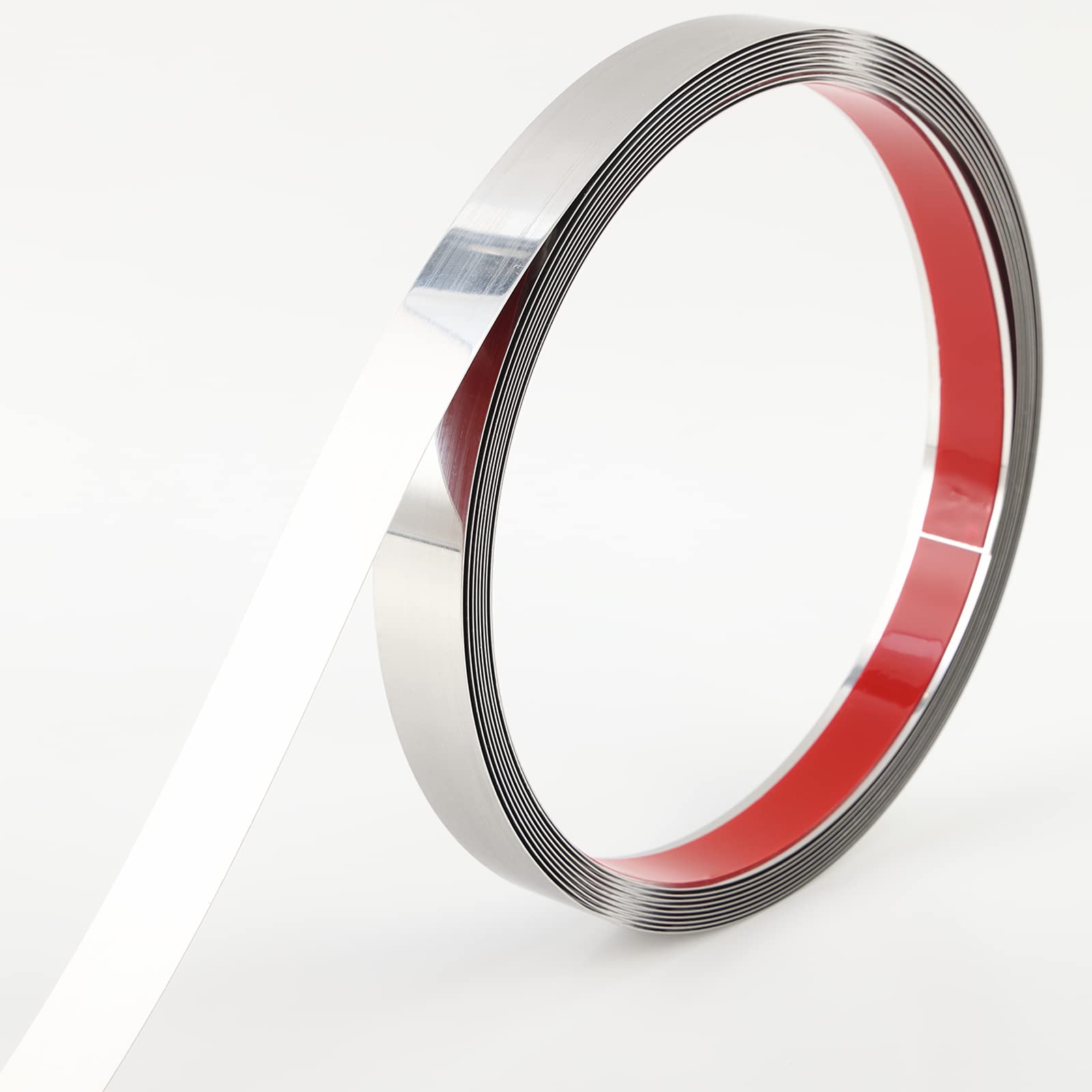

Finishing: What Are the Common Techniques for Surface Treatment?

The finishing stage enhances both the appearance and performance of the metal trim. Common finishing techniques include:

Illustrative image related to decorative metal trim molding

-

Anodizing: Often applied to aluminum, this electrochemical process increases corrosion resistance and can provide a variety of colors.

-

Powder Coating: This method involves applying a dry powder that is then cured under heat to form a tough, protective coating. It is available in numerous colors and finishes.

-

Plating: Involves coating the metal with a thin layer of another metal (e.g., chrome or nickel) to enhance appearance and corrosion resistance.

-

Polishing and Buffing: These techniques are used to achieve a high-gloss finish, particularly important for decorative applications.

What Quality Assurance Measures Are Implemented During Manufacturing?

Which International Standards Are Relevant for Decorative Metal Trim Molding?

Quality assurance is crucial in maintaining the integrity and performance of decorative metal trim molding. International standards like ISO 9001 provide a framework for quality management systems, ensuring consistent quality and customer satisfaction. For markets in Europe, compliance with CE marking is often required, indicating that products meet EU safety, health, and environmental protection standards.

Industry-specific standards such as those from the American Petroleum Institute (API) may also apply, especially when the trim is used in specialized applications like oil and gas facilities.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This step is critical to prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor the forming, assembly, and finishing processes. This allows for immediate corrections if deviations from standards occur.

-

Final Quality Control (FQC): After production, each batch of molding undergoes comprehensive testing to verify that it meets design specifications and quality standards. This includes visual inspections, dimensional checks, and performance tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should perform due diligence when selecting suppliers for decorative metal trim molding. This can include:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s processes, equipment, and adherence to quality standards.

-

Reviewing Quality Reports: Requesting access to quality control documentation, including inspection reports and compliance certifications, can help verify the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an independent assessment of the supplier’s quality control processes and product quality.

What Are the QC Considerations for International Buyers?

For international buyers, understanding the nuances of quality control is essential. Different countries may have varying standards and regulations. For example, buyers in Europe must ensure that their suppliers comply with CE marking, while those in the Middle East may require adherence to specific local standards.

Illustrative image related to decorative metal trim molding

Additionally, cultural differences in business practices can affect communication regarding quality expectations. Establishing clear specifications and quality requirements from the outset can help mitigate misunderstandings.

In summary, the manufacturing processes and quality assurance measures for decorative metal trim molding are critical components that B2B buyers must consider. By understanding these processes and implementing robust verification methods, buyers can ensure they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘decorative metal trim molding’

In the competitive landscape of decorative metal trim molding, sourcing the right products requires careful consideration and strategic planning. This guide offers a step-by-step checklist tailored for B2B buyers seeking to procure decorative metal trim molding effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the decorative metal trim molding meets your project’s requirements. Consider factors such as material type (aluminum, brass, stainless steel), dimensions, and finishes. Defining these specifications helps prevent miscommunication with suppliers and ensures that the products you receive align with your design vision.

Step 2: Research Market Trends

Stay informed about current trends in decorative metal trim molding, particularly in your target regions. Understanding the latest styles, colors, and applications can provide insight into what is popular among your clientele. This research can also influence your sourcing decisions, enabling you to offer products that meet market demands.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers specializing in decorative metal trim molding. Look for manufacturers with a solid reputation and experience in your industry. Resources such as trade shows, industry directories, and online platforms can help you identify reputable suppliers.

Step 4: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers possess relevant certifications and quality standards. Certifications such as ISO 9001 can indicate a supplier’s commitment to quality management. Additionally, check for compliance with local regulations and standards specific to your region, as this can impact product usability and acceptance.

Step 5: Request Samples and Catalogs

Always request product samples and catalogs from shortlisted suppliers. Samples allow you to assess the quality, finish, and suitability of the metal trim molding for your specific needs. Catalogs can provide a broader view of the supplier’s offerings, helping you gauge their capability to fulfill larger orders or custom requests.

Step 6: Negotiate Terms and Pricing

Engage in discussions about pricing, payment terms, and delivery schedules with your chosen suppliers. Clear negotiation can help ensure you receive competitive pricing while maintaining product quality. Consider factors such as bulk order discounts, lead times, and shipping costs as part of the negotiation process.

Step 7: Establish Quality Control Measures

Once you finalize your supplier, establish quality control measures to ensure that the products delivered meet your specifications. This can include setting criteria for inspections upon delivery, ensuring that products are free from defects, and aligning with your quality standards. Regular communication with your supplier can facilitate ongoing quality assurance.

By following these steps, B2B buyers can streamline the sourcing process for decorative metal trim molding, ensuring they find the right products to meet their needs while building strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for decorative metal trim molding Sourcing

What Are the Key Cost Components for Decorative Metal Trim Molding?

Understanding the cost structure of decorative metal trim molding is essential for B2B buyers aiming to source effectively. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of metal—such as aluminum, stainless steel, or brass—significantly influences material costs. Higher-grade metals typically command higher prices, but they also offer superior durability and aesthetic appeal, which can justify the investment.

-

Labor: Labor costs can vary by region and depend on the complexity of the molding design. Regions with lower labor costs may offer competitive pricing, but it’s crucial to assess the skill level of the workforce to ensure quality production.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should consider whether the investment in custom molds will yield significant long-term savings or if standard profiles can meet their needs.

-

Quality Control: Rigorous QC processes can add to costs but are essential for maintaining product integrity, especially for decorative applications where aesthetics are critical.

-

Logistics: Shipping costs are influenced by distance, shipping method, and volume. Buyers should factor in these costs, particularly when sourcing internationally, as they can significantly impact total expenses.

-

Margin: Supplier margins vary widely based on market conditions and the supplier’s business model. Understanding the markup can help buyers negotiate better deals.

What Influences Pricing in Decorative Metal Trim Molding Sourcing?

Several factors can influence the pricing of decorative metal trim molding.

-

Volume/MOQ: Larger orders often lead to volume discounts. Establishing a minimum order quantity (MOQ) can help leverage better pricing.

-

Specifications and Customization: Customized designs or specific material requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Products with certifications for sustainability or quality (e.g., ISO standards) may come at a premium, but they can enhance brand reputation and customer trust.

-

Supplier Factors: The supplier’s reputation, production capacity, and geographic location can affect pricing. Engaging with established suppliers can mitigate risks related to quality and delivery.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical. Incoterms dictate who bears shipping costs and risks, influencing the final price.

How Can Buyers Negotiate for Better Prices on Decorative Metal Trim Molding?

Effective negotiation strategies can lead to substantial cost savings in decorative metal trim molding sourcing.

-

Research and Benchmarking: Conduct market research to understand standard pricing and identify competitive suppliers. Use this information as leverage during negotiations.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Regular communication fosters trust, which can be beneficial during negotiations.

-

Focus on Total Cost of Ownership (TCO): Rather than solely comparing initial prices, consider the TCO, which includes installation, maintenance, and potential replacement costs. This broader view can justify a higher upfront investment if it leads to lower long-term costs.

-

Be Transparent About Your Needs: Clearly communicate your specifications, budget constraints, and delivery timelines. This can help suppliers tailor their offers more effectively.

-

Explore Multiple Suppliers: Obtaining quotes from multiple suppliers allows for comparison and can create competition, potentially leading to better pricing.

What Pricing Nuances Should International B2B Buyers Consider?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of several pricing nuances when sourcing decorative metal trim molding.

Illustrative image related to decorative metal trim molding

-

Currency Fluctuations: Exchange rates can impact costs. It’s prudent to negotiate prices in a stable currency to avoid unexpected expenses.

-

Import Duties and Taxes: Understanding local regulations regarding import duties and taxes is crucial. These additional costs can significantly impact the final price.

-

Cultural Considerations: Different regions may have varying expectations regarding negotiation styles and pricing transparency. Being culturally aware can facilitate smoother negotiations.

-

Logistical Challenges: Shipping times and customs clearance can affect project timelines. Plan accordingly to avoid delays that may incur additional costs.

Disclaimer

The prices and cost structures mentioned herein are indicative and may vary based on specific supplier quotes, regional market conditions, and individual buyer negotiations. Always conduct thorough due diligence before finalizing any agreements.

Alternatives Analysis: Comparing decorative metal trim molding With Other Solutions

In the realm of interior and exterior design, decorative metal trim molding serves as an elegant solution for enhancing aesthetics and functionality. However, various alternative solutions exist that can also fulfill similar roles. This analysis will compare decorative metal trim molding with two viable alternatives: wood trim molding and PVC trim molding. Understanding these options allows B2B buyers to make informed decisions based on performance, cost, and other critical factors.

| Comparison Aspect | Decorative Metal Trim Molding | Wood Trim Molding | PVC Trim Molding |

|---|---|---|---|

| Performance | High durability; fire and impact resistant; corrosion resistant | Moderately durable; can warp or split over time | Moisture resistant; less durable than metal |

| Cost | Higher initial investment; long-term savings due to durability | Moderate cost; can vary based on wood type | Generally lower cost; budget-friendly option |

| Ease of Implementation | Requires specialized installation techniques | Standard tools required; easier for DIY projects | Lightweight; easy to cut and install |

| Maintenance | Low maintenance; does not require painting; resistant to pests | Higher maintenance; prone to painting and refinishing | Low maintenance; can be cleaned easily |

| Best Use Case | High-traffic public spaces; luxury residential projects | Residential interiors; traditional designs | Budget-sensitive projects; moisture-prone areas |

What Are the Benefits and Drawbacks of Wood Trim Molding?

Wood trim molding offers a classic aesthetic that appeals to many designers and homeowners. Its natural beauty adds warmth and character to any space. However, wood is susceptible to warping, splitting, and pest infestations, which can increase maintenance costs over time. Additionally, wood requires regular painting or staining to maintain its appearance and integrity. This makes wood less suitable for high-traffic areas or environments where durability is critical.

Illustrative image related to decorative metal trim molding

How Does PVC Trim Molding Compare to Decorative Metal Trim?

PVC trim molding is an attractive alternative for those seeking a lightweight, budget-friendly solution. It is resistant to moisture, making it ideal for areas like bathrooms and kitchens. PVC is easy to install and can be cut with standard tools, allowing for quick project completion. However, it lacks the durability and aesthetic appeal of decorative metal trim molding, especially in high-end applications. Over time, PVC may not hold up as well against impact or extreme temperatures, leading to a less favorable long-term investment.

Conclusion: How Can B2B Buyers Select the Right Solution?

When selecting the right trim molding solution, B2B buyers must consider several factors, including the specific use case, budget, and desired aesthetic. Decorative metal trim molding excels in durability and is ideal for high-traffic areas or luxury projects. In contrast, wood trim may be more suitable for traditional designs but requires more maintenance. Meanwhile, PVC trim presents a cost-effective option for projects prioritizing moisture resistance. By evaluating these alternatives against their unique requirements, buyers can make informed decisions that align with their business goals and project specifications.

Essential Technical Properties and Trade Terminology for decorative metal trim molding

What Are the Key Technical Properties of Decorative Metal Trim Molding?

In the world of decorative metal trim molding, understanding key technical properties is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

1. Material Grade

The material grade of metal trim molding significantly influences its durability and performance. Common materials include stainless steel, aluminum, brass, and bronze. Each material has unique properties, such as corrosion resistance and strength. For example, stainless steel is ideal for environments prone to moisture, while aluminum is lightweight and cost-effective. Selecting the appropriate material grade ensures the trim molding can withstand environmental conditions, reducing the need for replacements.

Illustrative image related to decorative metal trim molding

2. Tolerance

Tolerance refers to the acceptable deviation from specified dimensions during manufacturing. It is crucial for ensuring that the molding fits perfectly in its intended application. A tighter tolerance often results in higher manufacturing costs but can be essential for projects requiring precision, such as architectural installations. Understanding tolerance levels helps buyers assess product quality and compatibility with their design specifications.

3. Finish Type

The finish type of metal trim molding affects its aesthetic appeal and functionality. Common finishes include polished, brushed, and powder-coated. A polished finish can enhance visual appeal, while powder coating provides additional protection against scratches and corrosion. Buyers should consider the finish type based on both aesthetic goals and functional requirements, such as maintenance and longevity.

4. Durability Ratings

Durability ratings indicate how well the trim molding can withstand wear and tear. Factors such as impact resistance, corrosion resistance, and scratch resistance are essential to consider, especially for high-traffic areas. Molding with high durability ratings minimizes maintenance costs and extends product lifespan, making it a smart investment for businesses.

5. Sustainability Certifications

With increasing emphasis on environmental responsibility, many buyers are now looking for sustainability certifications, such as LEED or ISO 14001. These certifications indicate that the materials used in the manufacturing process meet specific environmental standards. Opting for sustainably produced metal trim molding not only supports eco-friendly practices but can also enhance a company’s reputation in the market.

What Are Common Trade Terms Used in the Decorative Metal Trim Molding Industry?

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of decorative metal trim molding, buyers might engage with OEMs to source custom designs tailored to specific applications. Understanding OEM relationships can help buyers streamline procurement processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in the metal trim molding sector, where production costs can lead to higher MOQs. Knowing the MOQ helps buyers plan their purchases effectively and manage inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For decorative metal trim molding, submitting an RFQ allows buyers to compare costs and terms from multiple suppliers, leading to better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for buyers importing decorative metal trim molding, as they dictate who pays for shipping, insurance, and tariffs. Familiarity with these terms can help avoid misunderstandings and ensure smoother transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the decorative metal trim molding industry, lead times can vary significantly based on factors such as material availability and production schedules. Being aware of lead times allows buyers to plan projects effectively and avoid delays.

By understanding these technical properties and trade terms, B2B buyers can navigate the decorative metal trim molding market more effectively, ensuring they make informed purchasing decisions that align with their project goals.

Navigating Market Dynamics and Sourcing Trends in the decorative metal trim molding Sector

Global drivers in the decorative metal trim molding sector are shaped by a convergence of aesthetic demands, technological advancements, and sustainability trends. As urbanization accelerates in regions like Africa and South America, there is an increasing appetite for high-quality, durable decorative solutions in both residential and commercial spaces. Buyers are increasingly drawn to products that not only enhance visual appeal but also provide functional benefits, such as impact resistance and corrosion resistance—qualities inherent in metal trims compared to traditional materials.

The rise of e-commerce and digital platforms is transforming sourcing strategies. International B2B buyers can now access a broader range of suppliers, compare prices, and read reviews before making purchasing decisions. Technologies such as 3D printing and CAD (computer-aided design) are also emerging in product customization, allowing buyers to obtain tailor-made solutions that meet specific design requirements. Additionally, the trend towards prefabrication in construction is leading to increased demand for ready-to-install decorative metal trim products, streamlining the installation process and reducing labor costs.

In Europe, particularly in Germany, there is a pronounced emphasis on integrating decorative elements that reflect local culture and heritage, while in the Middle East, opulent designs are favored. This diversity in market preferences creates opportunities for suppliers to innovate and diversify their offerings to cater to varying tastes and requirements across different regions.

How Does Sustainability Influence Sourcing in the Decorative Metal Trim Molding Sector?

Sustainability has become a non-negotiable factor in B2B purchasing decisions. The decorative metal trim molding sector is no exception, with buyers increasingly prioritizing products made from recycled materials or those that adhere to strict environmental standards. Metal trims, particularly those made from stainless steel, aluminum, or other recyclable metals, offer a sustainable choice as they can be repurposed multiple times without losing integrity.

Ethical sourcing practices are also gaining traction. Buyers are seeking suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as LEED (Leadership in Energy and Environmental Design) and other ‘green’ labels are becoming critical in differentiating products in a competitive marketplace. By choosing products that meet these certifications, buyers not only align with environmental goals but also appeal to a growing demographic of eco-conscious consumers.

Moreover, the adoption of sustainable practices is often perceived as a value-added proposition that can enhance a company’s brand reputation. For B2B buyers, promoting the use of sustainable decorative metal trims can lead to stronger partnerships with environmentally aware clients and stakeholders.

What is the Historical Context of Decorative Metal Trim Molding in B2B Markets?

The decorative metal trim molding industry has a rich history that dates back over a century, with roots in early 20th-century architecture. Initially, metal trims were used in grand structures such as the Empire State Building and Rockefeller Center, where they contributed to the aesthetic and functional aspects of the design. As architectural styles evolved, so did the applications of decorative metal trims, transitioning from ornate designs to more streamlined, modern aesthetics.

Illustrative image related to decorative metal trim molding

Today, this historical legacy informs current trends, with many architects and designers seeking to incorporate traditional craftsmanship into contemporary projects. The enduring appeal of metal trim lies in its ability to blend historical authenticity with modern functionality, making it a sought-after choice for both new constructions and restorations. This evolution reflects the adaptability of the decorative metal trim molding sector, ensuring its relevance in an ever-changing marketplace.

By understanding these market dynamics, sustainability imperatives, and historical contexts, international B2B buyers can make informed decisions that enhance their product offerings and align with evolving consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of decorative metal trim molding

-

How do I choose the right decorative metal trim molding for my project?

Choosing the right decorative metal trim molding involves understanding the specific aesthetic and functional requirements of your project. Consider the material (e.g., aluminum, brass, or stainless steel) for its durability, resistance to corrosion, and maintenance needs. Additionally, evaluate the design profiles that complement your overall decor. Collaborate with architects or designers to align your selections with local architectural styles and standards, especially if your project spans multiple international markets. -

What are the key benefits of using decorative metal trim molding in construction?

Decorative metal trim molding offers numerous advantages, including enhanced durability, fire resistance, and aesthetic appeal. Unlike wood or MDF, metal does not chip or warp, making it ideal for high-traffic areas. Additionally, metal trim can be finished in various styles, from sleek modern to ornate vintage, allowing for versatile design applications. Its resistance to moisture and pests also makes it a sustainable choice for both interior and exterior projects. -

What customization options are available for decorative metal trim molding?

Many suppliers offer customization options for decorative metal trim molding, including bespoke dimensions, finishes, and profiles. Buyers can often request specific color treatments or textures to match their design themes. Some manufacturers allow for unique designs to be created based on client specifications. It’s essential to communicate your specific requirements clearly during the inquiry phase to ensure that the final product aligns with your vision. -

What are the minimum order quantities (MOQs) for decorative metal trim molding?

Minimum order quantities for decorative metal trim molding can vary significantly among suppliers. Typically, MOQs range from a few hundred to several thousand units, depending on the material and customization level. For international buyers, it’s advisable to discuss MOQs upfront to avoid unexpected costs. Some suppliers may offer lower MOQs for standard designs, while custom orders may require higher quantities to justify production costs. -

How can I vet suppliers of decorative metal trim molding?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching their reputation through reviews and testimonials from previous clients. Request samples of their products to assess quality firsthand. Inquire about their manufacturing processes, certifications, and compliance with international standards, especially if you are sourcing from different regions. Building relationships with suppliers who have a proven track record in your target market can also enhance trust and reliability. -

What payment terms should I expect when sourcing decorative metal trim molding?

Payment terms can vary widely based on supplier policies and the nature of the transaction. Common practices include partial upfront payments (often 30-50%) followed by the balance upon delivery or after inspection. For international transactions, consider discussing letter-of-credit options or other secure payment methods to mitigate risks. It’s essential to clarify payment terms in advance to ensure alignment and avoid misunderstandings during the procurement process. -

What quality assurance (QA) measures should I look for in suppliers?

When sourcing decorative metal trim molding, it’s important to assess the quality assurance measures employed by suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Suppliers should conduct regular inspections of materials and finished products, implementing rigorous testing protocols. Requesting documentation of QA processes and any relevant test results can provide further assurance of product quality and reliability. -

What logistics considerations should I keep in mind when importing decorative metal trim molding?

Logistics is a critical aspect of importing decorative metal trim molding. Consider shipping methods, lead times, and customs regulations specific to your destination country. Engage with logistics partners who specialize in international shipping to navigate potential challenges, including tariffs and duties. Additionally, ensure that your supplier provides necessary documentation for customs clearance to avoid delays in receiving your order. Planning for storage and handling upon arrival is also essential to maintain product integrity.

Top 5 Decorative Metal Trim Molding Manufacturers & Suppliers List

1. Dahlstrom – Decorative Metal Mouldings

Domain: dahlstromrollform.com

Registered: 1999 (26 years)

Introduction: Dahlstrom Metal Mouldings are decorative metal mouldings, casings, and trim used in interior and exterior design. They have been a premier supplier for over 120 years, with historical applications in notable buildings like the Empire State Building and Rockefeller Center. Key features include:

– Fire Resistance: Metal mouldings do not contribute fuel or smoke in fires, making them suitable for pub…

2. Outwater – Metal Like Decorative Trim

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater – Metal Like Decorative Trim, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Johnson Roll Forming – Key Products

Domain: johnsonrollforming.com

Registered: 2004 (21 years)

Introduction: Key Product Details: 1. Metal Mouldings (Moldings) 2. Aluminum Moulding (Molding) 3. Profiles, Special Shapes & Sections 4. Channels: U-Channels, J-Channels, C-Channels, Box Channels, Hat Channels, Strut Channels 5. Specialty Tubing: Shelf Support Tubing, Open Seam, Open Buttseam, Tubing with Gap Lock Seam, Flanged & Finned Seam Tubing, Hemmed Seam Tubing, Split Seam & Butt Seam Tubing, Telescopic…

4. Pinterest – Decorative Metal Trim

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Metal Ribbon, Metal Trim, Decorative Metal Strip, Filigree Decorative Strip, Rustic Cream Finish, for Furniture – Shelves – Crowns – Frames – Etsy UK

5. Brownwood Inc – Decorative Aluminum Bars

Domain: brownwoodinc.com

Registered: 2008 (17 years)

Introduction: Accent Trim – Aluminum components including decorative bars, L-channels, and strapping. Key products include:

– .25” Decorative Aluminum Bar (MSRP: $75.35)

– .25″ Decorative Aluminum Bar Sample Kit (MSRP: $66.60)

– .438″ Wide x .25″ Thick Angled Aluminum Bar (MSRP: $86.36)

– .5” Decorative Aluminum L-Channel (MSRP: $45.62)

– .5″ Aluminum L-Channel Sample Kit (MSRP: $37.74)

– .75” Decorative …

Strategic Sourcing Conclusion and Outlook for decorative metal trim molding

As the decorative metal trim molding market continues to evolve, international B2B buyers must prioritize strategic sourcing to enhance their product offerings and operational efficiencies. Sourcing quality metal moldings can significantly elevate design aesthetics while ensuring durability and resilience against environmental factors. Buyers should consider the unique attributes of metal trim, such as fire resistance, impact resistance, and sustainability, which not only meet modern architectural demands but also align with increasing consumer preferences for eco-friendly materials.

By fostering relationships with reputable suppliers and manufacturers, particularly those with a track record of delivering innovative solutions, businesses can secure a competitive advantage. Emphasizing customization options—ranging from material variety to finishes—will enable companies to cater to diverse market needs across regions such as Africa, South America, the Middle East, and Europe.

Looking ahead, the global demand for decorative metal trim is poised for growth, driven by trends in urbanization and sophisticated design aesthetics. Now is the time for B2B buyers to engage with industry leaders, explore new partnerships, and invest in premium products that promise to enhance both form and function in their projects. Embrace this opportunity to refine your sourcing strategy and position your business for success in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.