Top 5 Dc Dc Power Supply Module Suppliers (And How to Choose)

Introduction: Navigating the Global Market for dc dc power supply module

In today’s rapidly evolving technological landscape, sourcing reliable DC/DC power supply modules presents a significant challenge for B2B buyers, particularly those in emerging markets such as Nigeria and Brazil. As the demand for efficient and compact power solutions rises, understanding the intricacies of DC/DC modules becomes crucial. This guide serves as a comprehensive resource, exploring various types of DC/DC power supply modules, their diverse applications, and essential criteria for supplier vetting.

International buyers will find valuable insights into the latest innovations in power management, enabling them to make informed decisions that align with their operational needs. From evaluating product specifications to understanding cost implications and regulatory compliance, the guide covers every facet of the procurement process.

By equipping buyers with the knowledge to assess efficiency, performance, and integration capabilities, this guide empowers businesses across Africa, South America, the Middle East, and Europe to optimize their power supply solutions. With a focus on actionable insights and best practices, you can navigate the global market confidently, ensuring that your investments yield the highest returns while supporting your organization’s technological advancements.

Understanding dc dc power supply module Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Buck Converter | Steps down voltage with high efficiency; compact design | Consumer electronics, automotive, industrial | Pros: High efficiency, compact size. Cons: Limited to step-down applications. |

| Boost Converter | Steps up voltage; ideal for low-voltage applications | Renewable energy systems, battery-powered devices | Pros: Increases voltage; versatile. Cons: Lower efficiency compared to buck converters. |

| Buck-Boost Converter | Can step up or step down voltage; flexible output | Power management in various electronic devices | Pros: Versatile voltage adjustment. Cons: More complex design may increase costs. |

| Isolated DC/DC Modules | Provides electrical isolation; integrated transformer | Medical devices, telecommunications | Pros: Safety and noise reduction. Cons: Larger footprint; potentially higher cost. |

| Digital Power Modules | Incorporates digital control for improved performance | Data centers, high-performance computing | Pros: Enhanced efficiency and flexibility. Cons: Requires understanding of digital systems. |

What Are Buck Converters and Their B2B Relevance?

Buck converters are designed to efficiently step down voltage levels while maintaining high efficiency and a compact form factor. They are widely used in consumer electronics and automotive applications where space is limited, and efficiency is paramount. Buyers should consider the specific voltage requirements and load conditions when selecting a buck converter, as these factors will directly influence performance and cost.

How Do Boost Converters Function in Practical Applications?

Boost converters increase voltage from a lower input level to a higher output, making them essential for applications where battery-powered devices require higher operational voltages. They are commonly found in renewable energy systems and portable electronics. When purchasing, businesses should assess the load capacity and efficiency ratings, as these will impact overall system performance.

Why Choose Buck-Boost Converters for Versatile Applications?

Buck-boost converters offer the unique ability to step up or step down voltage, making them suitable for a variety of electronic devices that require flexible power management. They are particularly valuable in scenarios where input voltage can fluctuate above or below the desired output. Buyers must evaluate the complexity and potential cost implications of integrating a buck-boost solution into their designs.

What Are the Advantages of Isolated DC/DC Modules?

Isolated DC/DC modules are designed to provide electrical isolation between input and output, often incorporating an integrated transformer. This feature is crucial in applications such as medical devices and telecommunications, where safety and noise reduction are critical. Buyers should weigh the benefits of safety and performance against the typically larger footprint and higher costs associated with these modules.

How Do Digital Power Modules Enhance Performance?

Digital power modules utilize advanced digital control techniques to optimize efficiency and performance in power management applications. They are increasingly used in data centers and high-performance computing environments. When considering digital modules, businesses should assess their familiarity with digital systems, as well as the potential for improved performance and flexibility against the learning curve and integration complexity.

Key Industrial Applications of dc dc power supply module

| Industry/Sector | Specific Application of dc dc power supply module | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power supply for electric vehicle (EV) battery management systems | Enhances efficiency and reliability of battery performance | Ensure compatibility with high-voltage systems and compact size |

| Telecommunications | Powering network equipment and base stations | Supports uninterrupted service and reduces downtime | Focus on high efficiency and thermal management capabilities |

| Industrial Automation | Control systems for robotics and automation equipment | Increases operational efficiency and reduces downtime | Look for modules with robust protection features and scalability |

| Medical Devices | Power supplies for portable medical equipment | Ensures reliable operation and patient safety | Compliance with medical standards and low electromagnetic interference |

| Renewable Energy | DC/DC converters in solar inverters | Maximizes energy conversion and system performance | Evaluate environmental durability and efficiency ratings |

How Is the dc dc Power Supply Module Used in the Automotive Sector?

In the automotive industry, dc dc power supply modules are critical for electric vehicle (EV) battery management systems. They convert high voltage from batteries to lower voltages required for various vehicle electronics, enhancing efficiency and reliability. For international buyers, particularly in regions like Africa and South America, sourcing modules that can withstand extreme temperatures and ensure safety compliance is crucial, as these factors significantly influence performance and longevity in diverse climates.

What Role Do dc dc Power Supply Modules Play in Telecommunications?

In telecommunications, dc dc power supply modules are essential for powering network equipment and base stations. These modules ensure uninterrupted service by providing stable voltage regulation and minimizing downtime. B2B buyers in the Middle East and Europe should prioritize modules that offer high efficiency and thermal management capabilities to cope with the demands of dense network infrastructures and the heat generated in urban environments.

How Are dc dc Power Supply Modules Applied in Industrial Automation?

For industrial automation, dc dc power supply modules are utilized in control systems for robotics and automated machinery. They enhance operational efficiency by ensuring that devices receive the correct voltage and current levels, thereby reducing downtime. Buyers from regions with growing manufacturing sectors, like Nigeria and Brazil, should seek modules with robust protection features to safeguard against industrial noise and fluctuations in supply voltage.

Why Are dc dc Power Supply Modules Important for Medical Devices?

In the medical devices sector, dc dc power supply modules are used to power portable medical equipment, ensuring reliable operation and patient safety. These modules must comply with stringent medical standards and minimize electromagnetic interference to protect sensitive medical data. B2B buyers need to consider sourcing modules that demonstrate both high reliability and compact form factors, as space is often at a premium in medical settings.

How Do dc dc Power Supply Modules Support Renewable Energy Solutions?

In the renewable energy sector, particularly in solar energy systems, dc dc power supply modules function as converters in solar inverters. They maximize energy conversion from solar panels to usable electricity, significantly impacting system performance. Buyers in regions focusing on renewable energy development should evaluate the environmental durability of these modules, along with their efficiency ratings, to ensure they meet the rigorous demands of renewable installations in diverse climates.

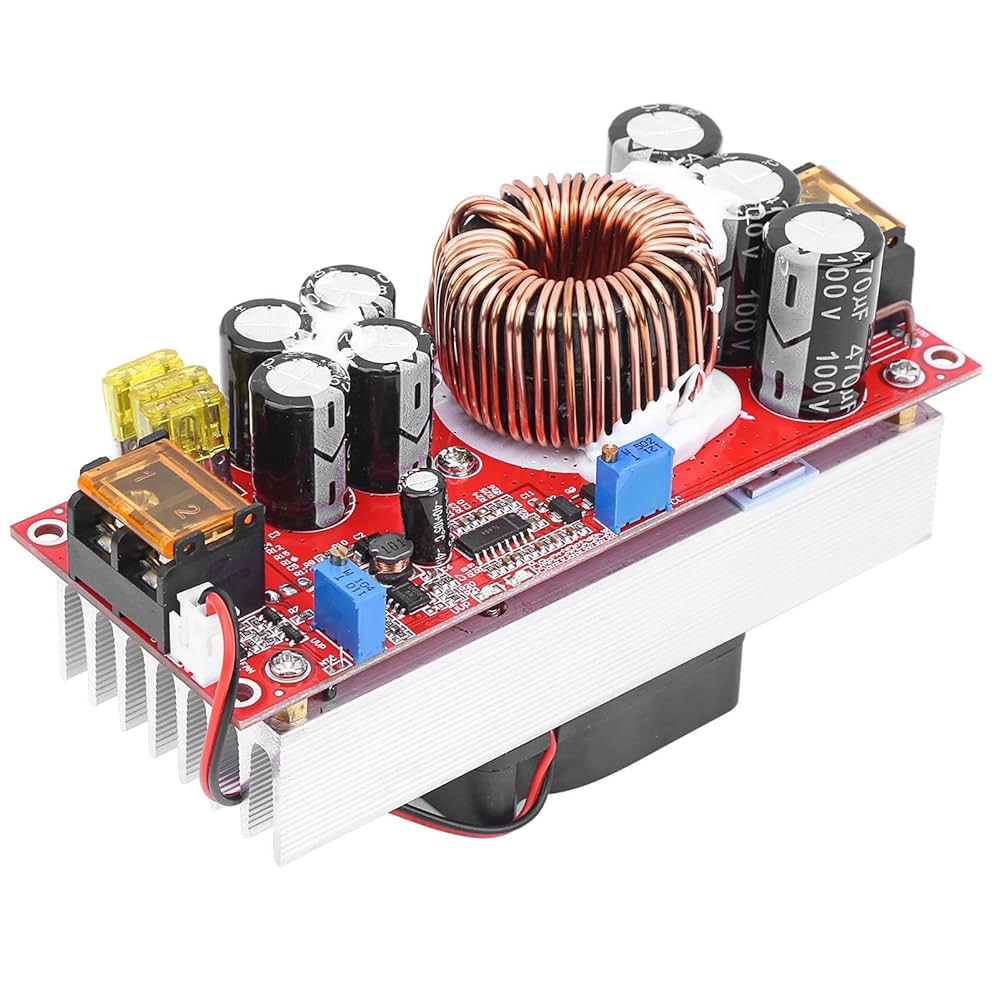

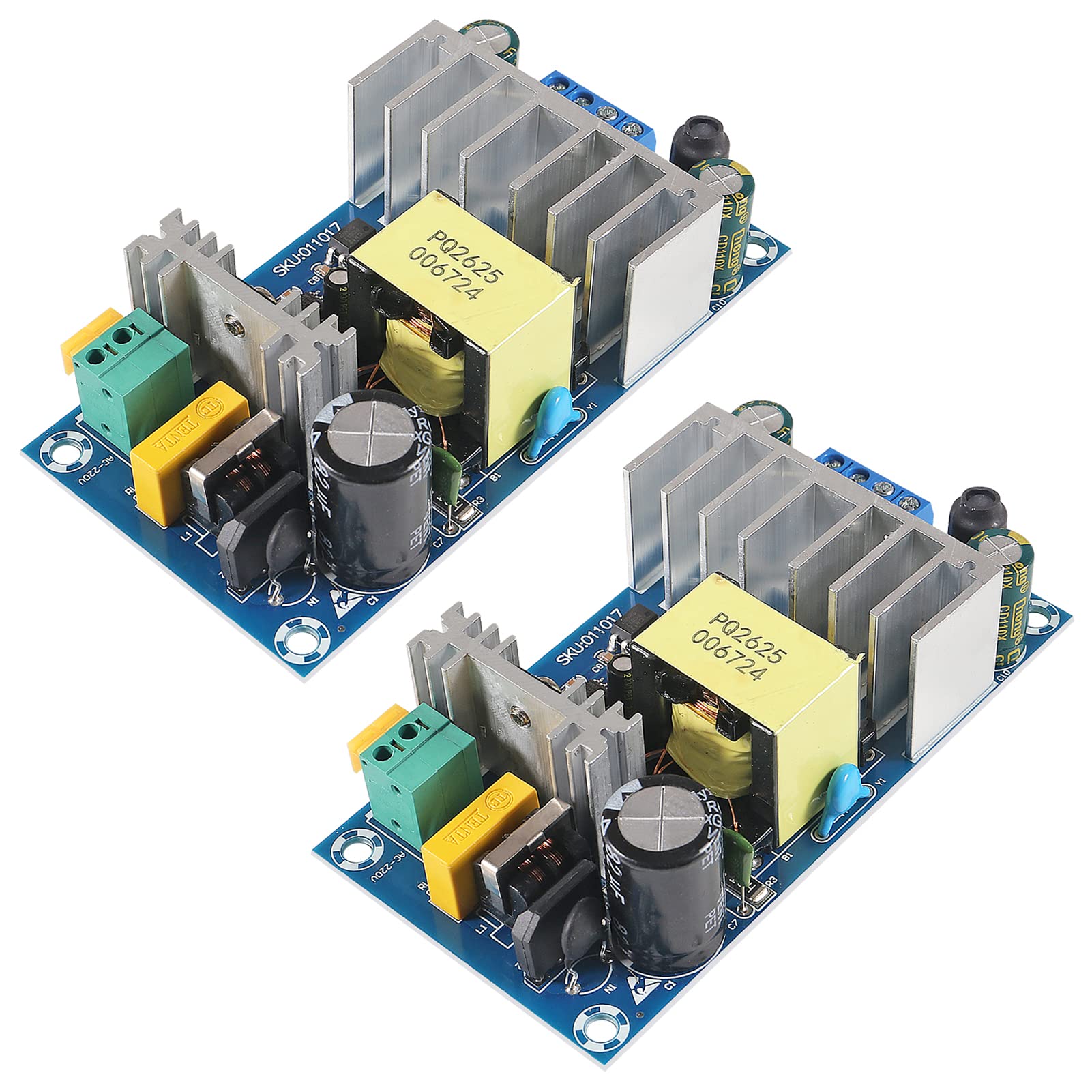

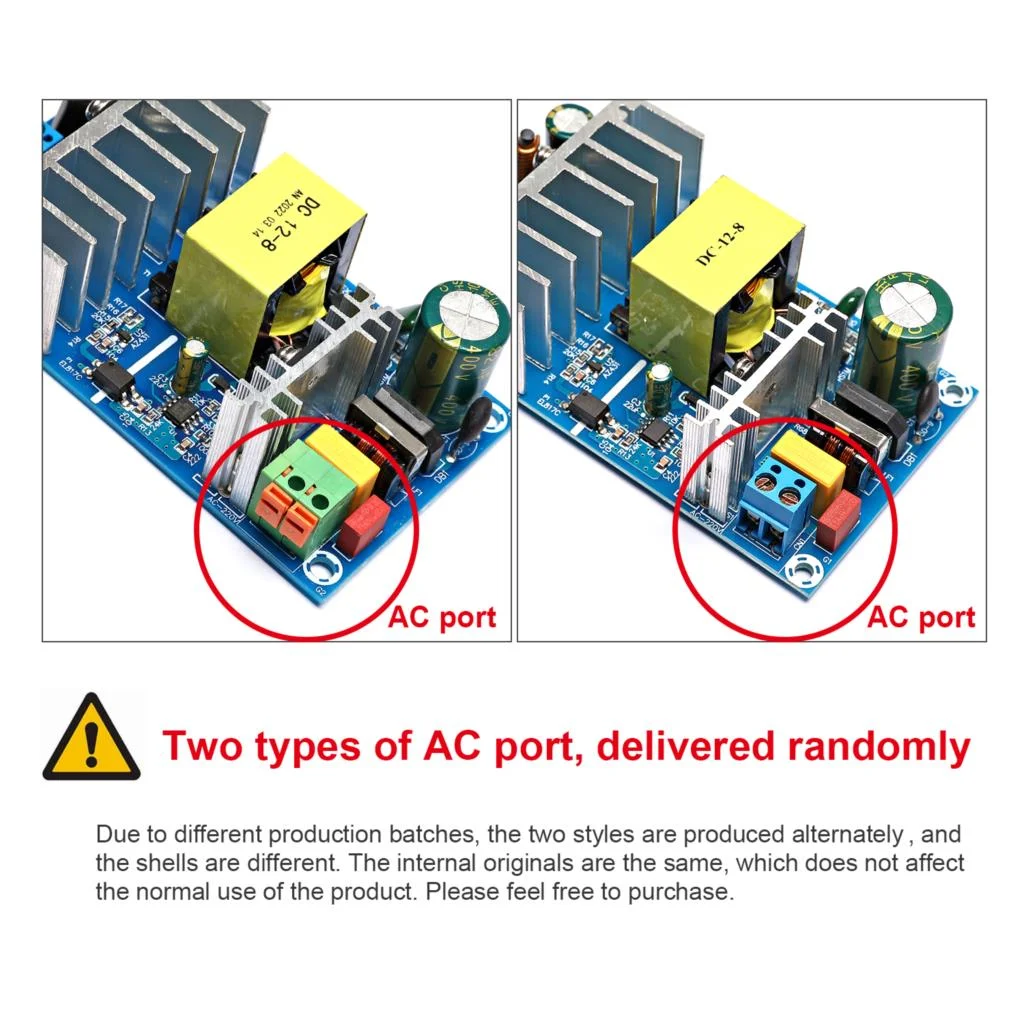

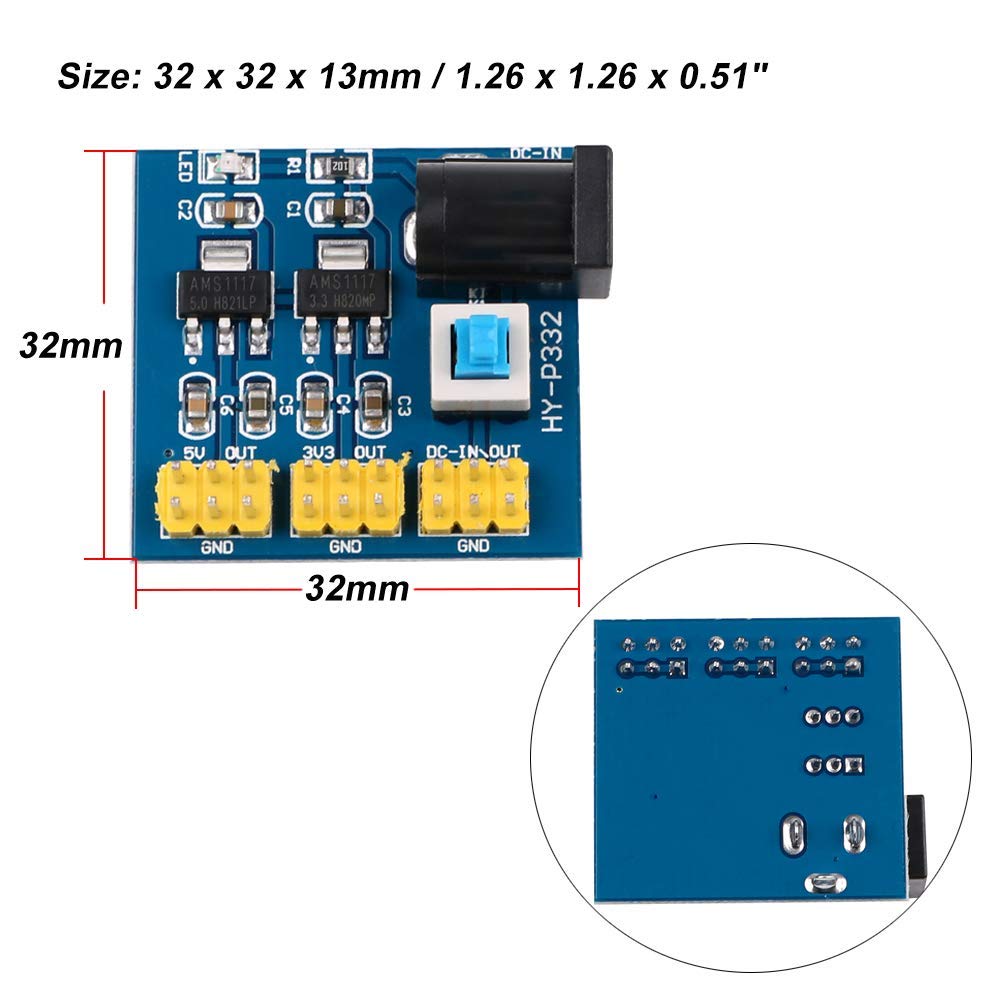

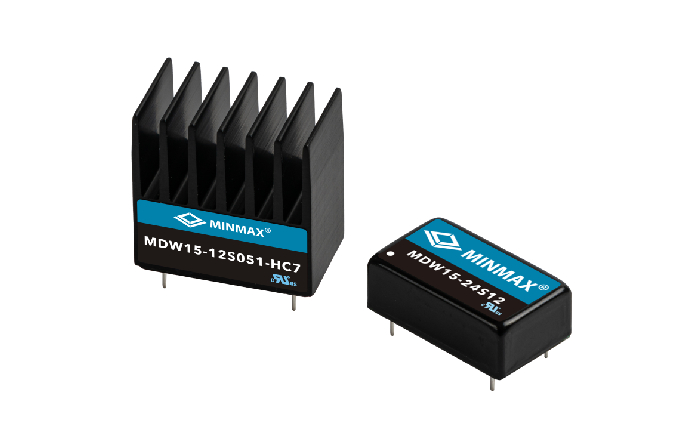

Illustrative image related to dc dc power supply module

3 Common User Pain Points for ‘dc dc power supply module’ & Their Solutions

Scenario 1: Difficulty in Achieving Compact Design in Power Solutions

The Problem: In the competitive landscape of electronics manufacturing, many B2B buyers struggle with the challenge of creating compact designs without sacrificing performance. As projects become more complex, the need for high-density components increases. Buyers often find themselves constrained by the physical size of traditional power supplies, which can lead to increased costs and delays in product development. This issue is particularly prevalent in sectors like telecommunications and automotive, where space is at a premium.

The Solution: To effectively tackle this problem, buyers should consider sourcing integrated DC/DC power supply modules that combine multiple components into a single package. For instance, modules that integrate inductors, controllers, and passive components can significantly reduce the overall footprint on the PCB. Buyers should prioritize products that leverage 3D integration technology, as these designs can offer higher power density while minimizing electromagnetic interference (EMI). Furthermore, using simulation tools like WEBENCH® Power Designer can help optimize the design before physical prototyping, ensuring that the chosen module meets both size and performance criteria.

Scenario 2: Challenges with EMI Compliance in High-Performance Applications

The Problem: Many B2B buyers in industries such as aerospace and medical devices face stringent EMI regulations that complicate the design and implementation of DC/DC power supply modules. Non-compliance can lead to costly delays, redesigns, and even product recalls, which can severely impact a company’s reputation and bottom line. Buyers are often unsure of how to select modules that can operate efficiently while meeting these compliance standards.

The Solution: To navigate this challenge, buyers should focus on sourcing DC/DC power modules specifically designed with low EMI characteristics. It is essential to evaluate products that include built-in filtering and shielding features, which can greatly minimize interference. Additionally, engaging with suppliers who offer extensive technical resources and application notes can provide insights into best practices for EMI management during the design phase. Buyers should also consider conducting thorough EMI testing during the prototype stage to identify potential issues early in the development process, allowing for timely adjustments before mass production.

Scenario 3: Difficulty in Balancing Cost and Performance in High-Current Applications

The Problem: In sectors such as renewable energy and industrial automation, buyers often need high-current DC/DC power supplies that deliver exceptional performance without inflating costs. The trade-off between achieving the required power levels and maintaining budget constraints can be particularly challenging. Buyers frequently encounter the dilemma of opting for cheaper solutions that may not meet performance expectations or investing in high-quality modules that exceed their budget.

The Solution: To strike the right balance between cost and performance, buyers should adopt a strategic approach to sourcing DC/DC power modules. Investigating manufacturers that provide a range of products, from high-current solutions to more budget-friendly options, can offer flexibility. Utilizing digital power modules with programmable features allows for tailored performance that meets specific application needs while optimizing energy efficiency. Additionally, buyers should leverage volume purchasing agreements and negotiate pricing based on long-term commitments to achieve more favorable terms. Regularly reviewing and updating supplier relationships can also lead to discovering new, cost-effective technologies that can enhance overall project viability.

Strategic Material Selection Guide for dc dc power supply module

What Are the Key Materials Used in DC-DC Power Supply Modules?

When selecting materials for DC-DC power supply modules, several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials utilized in these modules: aluminum, copper, thermoplastics, and ferrite. Each material has unique properties and implications for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Aluminum Perform in DC-DC Power Supply Modules?

Aluminum is widely used in the construction of DC-DC power supply modules due to its excellent thermal conductivity and lightweight nature. Key properties include a high strength-to-weight ratio and resistance to corrosion, making it suitable for various environmental conditions.

Pros: Aluminum is relatively inexpensive and easy to manufacture, allowing for cost-effective production. Its lightweight nature helps reduce overall module weight, which is crucial for applications in mobile or portable devices.

Illustrative image related to dc dc power supply module

Cons: While it is resistant to corrosion, aluminum can be prone to oxidation if not properly treated. Additionally, its thermal conductivity can be a double-edged sword; while it dissipates heat well, it may require careful thermal management in high-power applications.

Impact on Application: Aluminum is compatible with various media, making it suitable for both consumer electronics and industrial applications. However, buyers should consider the specific operating environment when selecting aluminum components.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, especially in regions like Europe. Buyers should ensure that aluminum components meet local regulations regarding material safety and environmental impact.

What Role Does Copper Play in DC-DC Power Supply Modules?

Copper is another critical material in DC-DC power supply modules, primarily used for its excellent electrical conductivity. It is often employed in wiring and PCB traces within the modules.

Pros: Copper’s high conductivity ensures efficient power transmission, minimizing energy loss. It also has good thermal properties, which help in heat dissipation.

Illustrative image related to dc dc power supply module

Cons: The primary drawback of copper is its cost, which can be significantly higher than aluminum. Additionally, copper is susceptible to corrosion, particularly in humid environments, unless it is properly coated or treated.

Impact on Application: Copper is ideal for applications requiring high efficiency and low resistance, such as in automotive or aerospace sectors. However, its weight and cost may be limiting factors for some applications.

Considerations for International Buyers: Buyers should verify that copper components comply with international standards, particularly in regions with stringent electrical safety regulations.

How Are Thermoplastics Used in DC-DC Power Supply Modules?

Thermoplastics are increasingly being utilized in DC-DC power supply modules for insulation and structural components. Their properties include high dielectric strength and resistance to chemicals.

Pros: Thermoplastics are lightweight and can be molded into complex shapes, providing design flexibility. They also offer good electrical insulation, which is vital for safety in power supply applications.

Cons: While thermoplastics are generally durable, they may not withstand high temperatures as well as metals. Their mechanical strength can be lower than that of metals, which may limit their use in high-stress applications.

Impact on Application: Thermoplastics are suitable for low- to medium-power applications where weight savings and insulation are critical. However, they may not be suitable for high-temperature environments.

Considerations for International Buyers: Buyers should ensure that thermoplastic materials meet relevant safety and performance standards, especially in regions with high regulatory scrutiny.

What Advantages Do Ferrites Offer in DC-DC Power Supply Modules?

Ferrite materials are primarily used in the magnetic components of DC-DC power supply modules, such as inductors and transformers. They have high magnetic permeability and low electrical conductivity.

Pros: Ferrites are excellent for reducing electromagnetic interference (EMI), which is crucial for maintaining performance in sensitive electronic applications. They are also lightweight and can be manufactured in various shapes.

Cons: Ferrites can be brittle and may require careful handling during manufacturing and assembly. Additionally, their performance can degrade at high temperatures.

Impact on Application: Ferrites are ideal for applications requiring high-frequency operation and low EMI, such as in telecommunications and consumer electronics. However, they may not be suitable for high-power applications due to thermal limitations.

Considerations for International Buyers: Buyers should consider the specific ferrite material grades and their compliance with international standards, particularly in regions where EMI regulations are strict.

Summary Table of Material Selection for DC-DC Power Supply Modules

| Material | Typical Use Case for dc dc power supply module | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components, heat sinks | Lightweight and cost-effective | Prone to oxidation | Low |

| Copper | Wiring and PCB traces | Excellent electrical conductivity | Higher cost and corrosion risk | High |

| Thermoplastics | Insulation and structural components | Design flexibility and good insulation | Lower mechanical strength | Medium |

| Ferrites | Magnetic components (inductors, transformers) | Reduces EMI, lightweight | Brittle and thermal limitations | Medium |

This guide provides a strategic overview of material selection for DC-DC power supply modules, emphasizing the importance of understanding the unique properties and implications of each material for B2B buyers across different global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for dc dc power supply module

What Are the Main Stages of Manufacturing DC/DC Power Supply Modules?

The manufacturing process of DC/DC power supply modules involves several critical stages that ensure the final product meets both performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, such as semiconductors, inductors, and capacitors. Suppliers are carefully vetted to ensure compliance with international standards. Materials are then inspected for quality and specifications before moving on to the next stage.

-

Forming: In this phase, the raw materials undergo physical shaping. Techniques like die-cutting and PCB etching are employed to create circuit boards and other components. This step is crucial, as precision in forming directly impacts the efficiency and reliability of the power module.

-

Assembly: Assembly is where the individual components come together. Automated pick-and-place machines are often used for high-volume production, ensuring accuracy and speed. Manual assembly may also be employed for more complex modules, especially those requiring specialized expertise. During this stage, critical components like controllers, MOSFETs, and inductors are integrated into the assembly.

-

Finishing: The final stage involves encapsulation and testing. Encapsulation protects the module from environmental factors and mechanical stress. This is followed by functional testing to ensure that the module operates within specified parameters. Any defective units are identified and corrected before the products are packaged for distribution.

How Is Quality Control Implemented in DC/DC Power Supply Manufacturing?

Quality control (QC) is integral to the manufacturing of DC/DC power supply modules, ensuring that products meet both industry standards and customer expectations. Various international and industry-specific standards guide these QC processes.

Illustrative image related to dc dc power supply module

-

Adherence to International Standards: Compliance with ISO 9001 is essential for manufacturers, as it outlines a quality management system aimed at enhancing customer satisfaction through effective processes. Additionally, certifications like CE and API may be relevant, depending on the application of the power supply modules.

-

Quality Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint inspects raw materials upon arrival, verifying that they meet the required specifications before they enter the production line.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC monitors operations to detect any anomalies early. This includes regular inspections during forming and assembly stages to ensure that assembly techniques and processes are being followed correctly.

– Final Quality Control (FQC): Once the modules are assembled, FQC involves rigorous testing, including thermal cycling, load testing, and electrical safety checks to confirm that the modules operate as intended. -

Common Testing Methods: Manufacturers often employ a range of testing techniques, such as:

– Electrical Testing: To verify performance metrics like efficiency, output voltage accuracy, and transient response.

– Environmental Testing: Assessing the module’s performance under various temperature and humidity conditions.

– EMI/EMC Testing: Ensuring that the modules comply with electromagnetic interference and compatibility standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance with local regulations.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should assess the supplier’s adherence to international standards and their internal quality management systems.

-

Quality Reports: Requesting detailed quality reports, including data on past performance, defect rates, and compliance with relevant standards, can help buyers gauge a supplier’s reliability. This information can often be found in supplier documentation or through direct communication with the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can verify compliance with specified standards and ensure that the products meet the buyer’s requirements before shipment.

-

Certification Verification: Buyers should confirm that suppliers possess the necessary certifications, such as ISO 9001 or CE marking. This can often be done through the certifying body’s database, ensuring that the certifications are valid and up-to-date.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control in the manufacturing of DC/DC power supply modules is essential for navigating the complexities of global supply chains.

-

Cultural Differences: Buyers should be aware that quality expectations and manufacturing practices can vary significantly across regions. Establishing clear communication and understanding cultural norms can enhance the relationship between buyers and suppliers.

-

Regulatory Compliance: Different regions may have varying regulations regarding electrical components. Buyers must ensure that the products they source comply with local laws and standards, especially when operating in markets with strict safety and environmental regulations.

-

Logistical Considerations: Quality control does not end at the factory. Buyers should consider how transportation and storage conditions may affect product quality. Engaging suppliers that understand and implement best practices in logistics can mitigate risks associated with damage or degradation during shipping.

-

Long-Term Partnerships: Establishing long-term relationships with reliable suppliers can lead to improved quality and consistency over time. Regularly reviewing and updating quality agreements can help maintain high standards and adapt to any changes in the market or technology.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they source high-quality DC/DC power supply modules that meet their specific needs.

Illustrative image related to dc dc power supply module

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc dc power supply module’

Introduction

Sourcing a DC/DC power supply module requires careful consideration of various technical and supplier-related factors. This guide provides a structured checklist to help international B2B buyers streamline their procurement process, ensuring they select the right module to meet their specific needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in the sourcing process. Specify the input voltage range, output voltage, current capacity, and any particular features such as isolation or efficiency ratings. This clarity will help narrow down your options and ensure compatibility with your existing systems.

- Input/Output Requirements: Identify the voltage levels and current ratings your application needs.

- Efficiency Standards: Look for modules with high efficiency to minimize energy losses and thermal management issues.

Step 2: Research Market Trends and Innovations

Stay updated on the latest trends in DC/DC power supply technologies. Innovations such as integrated inductors or digital control systems can significantly enhance performance and reduce design complexity. Understanding these advancements will equip you to make informed decisions.

- Emerging Technologies: Investigate the latest advancements that can offer better performance or reduced costs.

- Industry Standards: Familiarize yourself with relevant industry standards that may influence your choice.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product catalogs, and references from similar industries. A reliable supplier should have a proven track record of quality and customer satisfaction.

- Company Background: Look for suppliers with extensive experience and a solid reputation in power module manufacturing.

- Customer Reviews: Seek testimonials or case studies that demonstrate the supplier’s reliability and support capabilities.

Step 4: Verify Compliance and Certifications

Ensure that the products meet international safety and quality standards. Check for certifications such as ISO, RoHS, or CE, which indicate compliance with industry regulations. This step is critical to avoid future liabilities and ensure product reliability.

- Documentation: Request copies of relevant certifications and compliance documents.

- Quality Assurance: Inquire about the supplier’s quality assurance processes to ensure consistent product quality.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the DC/DC power supply modules you are considering. Testing samples in your application can help identify potential issues and confirm that the module meets your performance expectations.

- Performance Testing: Evaluate the samples under real-world conditions to assess efficiency, heat generation, and load handling.

- Integration Assessment: Ensure the module integrates seamlessly with your existing systems and meets your specifications.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier and product, negotiate the pricing, payment terms, and delivery schedules. Clear agreements on these aspects can prevent misunderstandings and ensure timely delivery.

Illustrative image related to dc dc power supply module

- Pricing Structure: Discuss bulk purchase discounts or payment terms that can improve cash flow.

- Delivery Timelines: Confirm lead times to align with your project schedules.

Step 7: Establish a Long-Term Partnership

Consider building a long-term relationship with your chosen supplier. A strong partnership can lead to better pricing, priority support, and early access to new products. Maintaining open communication will help both parties adapt to future needs.

- Ongoing Support: Discuss post-purchase support and service options.

- Future Collaboration: Explore possibilities for joint development projects or co-engineering efforts.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing DC/DC power supply modules, ensuring they make informed and strategic procurement decisions.

Comprehensive Cost and Pricing Analysis for dc dc power supply module Sourcing

What are the Key Cost Components in Sourcing DC/DC Power Supply Modules?

When sourcing DC/DC power supply modules, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The cost of raw materials such as semiconductors, capacitors, inductors, and other electronic components can vary significantly based on market demand and sourcing strategies. High-quality materials generally increase the price but can enhance performance and reliability.

-

Labor: Labor costs encompass the wages of skilled personnel involved in manufacturing, assembly, and testing. Regions with lower labor costs can provide a competitive edge, but quality assurance must be prioritized to prevent long-term issues.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient production processes can reduce overheads, allowing for more competitive pricing.

-

Tooling: Custom tooling for specialized designs can represent a significant upfront investment. However, the costs can be amortized over larger production runs, making it critical to evaluate volume commitments before proceeding.

-

Quality Control (QC): Implementing robust QC processes ensures that each module meets specified standards, which can add to costs but mitigates the risk of failures in the field. Certifications such as ISO or CE can further influence pricing.

-

Logistics: Shipping and handling costs can fluctuate based on the geographical location of suppliers, the chosen Incoterms, and the shipping method. Understanding these factors is crucial for accurate total cost calculations.

-

Margin: Supplier margins can vary widely based on brand reputation, product quality, and market positioning. Established suppliers may command higher prices but can offer reliability and support that justify the cost.

How Do Price Influencers Affect DC/DC Power Supply Module Costs?

Several factors influence the pricing of DC/DC power supply modules, particularly in international B2B transactions:

Illustrative image related to dc dc power supply module

-

Volume/MOQ: Bulk purchasing typically reduces the unit price. Suppliers may offer tiered pricing, where larger orders lead to more significant discounts. Understanding minimum order quantities (MOQs) is crucial for budgeting.

-

Specifications and Customization: Custom solutions tailored to specific applications can incur additional costs. Buyers should clearly define their specifications to avoid unexpected expenses during the design phase.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly affect pricing. Modules with higher efficiency ratings or those meeting stringent regulatory standards may command premium prices.

-

Supplier Factors: Supplier reliability, experience, and reputation can influence pricing. Established suppliers often provide warranties and support, which can justify higher costs.

-

Incoterms: Understanding the implications of Incoterms is vital for determining who bears the risk and cost of transportation. This can impact overall pricing and total cost calculations.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic negotiation can lead to cost savings:

-

Research and Compare: Gather quotes from multiple suppliers to establish a baseline for negotiation. This can help leverage competitive pricing.

-

Discuss Total Cost of Ownership (TCO): Emphasize the long-term value of quality and reliability over upfront costs. Suppliers may be more willing to offer discounts if they understand the potential for repeat business.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable negotiations.

-

Be Clear on Specifications: Clearly articulate your requirements to avoid costly revisions later. This clarity can also facilitate faster quotes and reduce negotiation time.

-

Consider Local Suppliers: Engaging with local suppliers can minimize logistics costs and lead times, providing a competitive advantage in pricing.

Disclaimer on Indicative Pricing

Prices for DC/DC power supply modules can fluctuate based on market conditions, supplier pricing strategies, and changes in material costs. The indicative prices mentioned in industry references should be viewed as a guideline, and buyers are encouraged to obtain specific quotes tailored to their needs.

Alternatives Analysis: Comparing dc dc power supply module With Other Solutions

When evaluating power solutions, it is essential to consider various alternatives to ensure the best fit for specific applications. The DC/DC power supply module is a widely adopted solution due to its compact design and high efficiency. However, there are other viable alternatives worth exploring. Below, we compare DC/DC power supply modules with linear voltage regulators and AC/DC power supplies.

| Comparison Aspect | Dc Dc Power Supply Module | Linear Voltage Regulator | AC/DC Power Supply |

|---|---|---|---|

| Performance | High efficiency, compact size | Moderate efficiency, larger footprint | High efficiency, larger size |

| Cost | Moderate, often higher due to integration | Generally low cost | Higher initial cost, but varies by capacity |

| Ease of Implementation | Easy to integrate, minimal external components | Simple, but requires heat sinking | Requires additional circuitry for voltage regulation |

| Maintenance | Low maintenance, robust design | Higher maintenance due to heat management | Low maintenance, but may require replacements over time |

| Best Use Case | Compact applications, high-density designs | Low-power applications, simple circuits | Industrial applications, where AC power is readily available |

What are the Pros and Cons of Using Linear Voltage Regulators as an Alternative?

Linear voltage regulators are often simpler and more cost-effective for low-power applications. They provide stable output voltage with minimal noise, making them ideal for sensitive electronics. However, their performance diminishes in high-current scenarios, where they can generate significant heat, requiring additional heat sinks and potentially complicating the design. This can limit their application in compact designs where space is a constraint.

How Do AC/DC Power Supplies Compare with DC/DC Power Modules?

AC/DC power supplies convert alternating current (AC) to direct current (DC) and are commonly used in industrial settings where AC is abundant. They are generally efficient for high-power applications and can handle larger loads. However, their bulkier size may not suit compact designs. Additionally, their higher initial cost and complexity may deter some buyers, especially in applications where space and budget are limited.

Conclusion: How Can B2B Buyers Choose the Right Power Solution?

When selecting a power solution, B2B buyers must consider factors such as application requirements, available space, budget constraints, and long-term operational costs. DC/DC power supply modules offer a high-efficiency, compact solution for modern electronic designs, while linear voltage regulators may suffice for simpler, low-power applications. AC/DC power supplies excel in industrial settings but may not fit every scenario. By assessing these aspects, buyers can make informed decisions that align with their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for dc dc power supply module

What Are the Key Technical Properties of DC/DC Power Supply Modules?

When evaluating DC/DC power supply modules, certain technical specifications are crucial for ensuring optimal performance and reliability. Here are some essential properties:

1. Input Voltage Range

The input voltage range specifies the minimum and maximum voltage that the module can accept. This property is critical as it determines compatibility with various power sources. Buyers must ensure that the selected module can handle the voltage levels present in their applications, especially in regions with fluctuating power supply conditions.

Illustrative image related to dc dc power supply module

2. Output Voltage and Current

Output voltage and current ratings indicate the module’s ability to deliver power to connected devices. Understanding these specifications is vital for selecting a module that meets the power requirements of the application, ensuring that it can operate efficiently without underpowering or overloading the system.

3. Efficiency Rating

Efficiency measures how effectively the module converts input power into output power, typically expressed as a percentage. Higher efficiency means less energy is wasted as heat, which is especially important in applications where thermal management is critical. For B2B buyers, selecting high-efficiency modules can lead to lower operational costs and improved reliability.

4. Form Factor

The form factor refers to the physical size and layout of the module. A compact form factor is advantageous for applications with space constraints, allowing for more efficient use of board space. Understanding the form factor is essential for OEMs looking to integrate these modules into existing designs without extensive modifications.

Illustrative image related to dc dc power supply module

5. Thermal Performance

Thermal performance indicates how well a module can manage heat dissipation during operation. This property is vital as excessive heat can lead to failures or reduced lifespan. Buyers should consider modules with robust thermal management features, especially in high-power applications or environments with limited cooling.

6. EMI/RFI Compliance

Electromagnetic interference (EMI) and radio-frequency interference (RFI) compliance are critical for ensuring that the module does not disrupt other electronic devices. Modules that meet these standards help maintain system integrity and reliability, making them essential for applications in sensitive environments.

What Are Common Trade Terminology and Acronyms in the DC/DC Power Supply Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of DC/DC power supplies, OEMs often integrate these modules into their products, making it essential for suppliers to understand OEM requirements and specifications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers as it impacts inventory costs and production planning. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ is a critical step in the procurement process, allowing them to compare offers and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of goods and logistics planning.

5. Lead Time

Lead time is the period between the initiation of an order and its fulfillment. Understanding lead times is crucial for buyers to plan their production schedules and inventory management effectively, ensuring that they have the necessary components when needed.

6. Certification Standards

Certification standards (like UL, CE, or RoHS) indicate that a product meets specific safety and regulatory requirements. For B2B buyers, ensuring that DC/DC power supply modules have the necessary certifications is essential for compliance and market acceptance.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their procurement strategies align with their operational goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the dc dc power supply module Sector

What are the Global Drivers and Key Trends in the DC-DC Power Supply Module Market?

The DC-DC power supply module market is witnessing significant growth driven by the increasing demand for efficient power management solutions across various sectors. Key global drivers include the rapid adoption of electric vehicles (EVs), renewable energy systems, and the proliferation of smart devices. As industries strive for higher energy efficiency and lower operational costs, the integration of advanced power modules that offer compact designs, high performance, and reduced electromagnetic interference (EMI) has become essential.

Emerging trends in the B2B tech landscape indicate a shift towards digital power management solutions, including modules with integrated control capabilities, which allow for real-time monitoring and adjustments. This trend is particularly relevant for international buyers from regions like Africa and South America, where industrial growth is accelerating, and the need for reliable power solutions is critical. Additionally, the demand for low-profile modules that conserve board space is on the rise, reflecting a broader industry move towards miniaturization.

International B2B buyers should also be aware of the increasing importance of local sourcing and partnerships to mitigate supply chain disruptions. Countries in the Middle East and Europe are focusing on establishing regional manufacturing capabilities to enhance reliability and responsiveness to market demands.

Illustrative image related to dc dc power supply module

How Can Sustainability and Ethical Sourcing Impact the DC-DC Power Supply Module Sector?

Sustainability and ethical sourcing are becoming integral considerations for B2B buyers in the DC-DC power supply module market. The environmental impact of manufacturing processes and the materials used in power modules cannot be overlooked. Buyers are increasingly seeking suppliers that prioritize sustainability, utilizing environmentally friendly materials and processes to reduce their carbon footprint.

Ethical supply chains are critical in ensuring that sourcing practices do not exploit labor or harm communities. Buyers should look for manufacturers that hold ‘green’ certifications, which validate their commitment to environmentally responsible practices. This includes the use of recyclable materials and adherence to strict environmental regulations.

Moreover, as global awareness of climate change grows, companies that demonstrate a commitment to sustainability may gain a competitive edge. Implementing green practices in sourcing not only aligns with corporate social responsibility (CSR) objectives but also appeals to end-users who are increasingly eco-conscious. Therefore, B2B buyers should prioritize partnerships with suppliers that share these values, ensuring that their procurement strategies contribute positively to the environment and society.

Illustrative image related to dc dc power supply module

What is the Brief Evolution of the DC-DC Power Supply Module Market?

The evolution of the DC-DC power supply module market has been marked by significant technological advancements. Initially, power supply solutions were bulky and less efficient, primarily serving basic voltage conversion needs. Over the years, as electronic devices became more sophisticated, the demand for compact, efficient, and high-performance power modules increased.

The introduction of integrated circuit technology allowed for the miniaturization of components, which drastically reduced the size of DC-DC modules while enhancing their efficiency. The development of digital control systems further revolutionized the market, enabling precise voltage regulation and monitoring capabilities.

Today, the market is characterized by a diverse range of products tailored to various applications, from automotive to telecommunications. This evolution reflects a broader trend towards energy efficiency and sustainability, as companies seek to optimize power management in response to both consumer demands and regulatory pressures. Understanding this historical context is crucial for B2B buyers aiming to make informed decisions in a rapidly changing market landscape.

Illustrative image related to dc dc power supply module

Frequently Asked Questions (FAQs) for B2B Buyers of dc dc power supply module

-

How do I solve issues with DC/DC power supply module compatibility in my application?

To resolve compatibility issues with DC/DC power supply modules, first, ensure that the module’s voltage and current ratings align with your application’s requirements. Review the input and output specifications, including the voltage range, load current, and any isolation requirements. Additionally, check the footprint and connection type to ensure it fits your PCB design. If custom specifications are necessary, consider reaching out to suppliers who offer tailored solutions to meet your unique needs. -

What is the best DC/DC power supply module for automotive applications?

For automotive applications, look for DC/DC power supply modules that meet stringent automotive standards, such as AEC-Q100 certification. Modules like the TPSM33606-Q1 or UCC34141-Q1 are designed specifically for automotive use, offering high efficiency and a wide input voltage range. Ensure the module can handle the required output power and has features like thermal protection and EMI suppression, which are critical in automotive environments. -

What are the typical minimum order quantities (MOQs) for DC/DC power supply modules?

Minimum order quantities (MOQs) for DC/DC power supply modules vary by supplier and product type. Generally, MOQs can range from 100 to 1,000 units, depending on the manufacturer and the complexity of the module. It’s advisable to discuss your requirements with potential suppliers to negotiate MOQs, especially if you are testing a new application or require a smaller initial batch for prototyping. -

How can I ensure the quality of DC/DC power supply modules before purchasing?

To ensure quality, request samples from suppliers to test their performance in your application. Review certifications and compliance with international standards, such as ISO 9001 or specific industry standards relevant to your market. Additionally, ask for detailed datasheets and application notes, which provide insights into the module’s reliability and performance metrics. Engaging in a direct conversation with the supplier about their quality assurance processes can also provide reassurance. -

What payment terms should I expect when sourcing DC/DC power supply modules internationally?

Payment terms can vary significantly among suppliers. Common arrangements include upfront payment, 30% deposit with the balance upon shipment, or net 30/60 days for established accounts. It’s crucial to clarify these terms before placing an order and to consider using secure payment methods such as letters of credit for larger transactions. Additionally, inquire about any potential for discounts on early payments or bulk orders. -

What are the logistics considerations when importing DC/DC power supply modules?

When importing DC/DC power supply modules, consider shipping methods, customs duties, and import regulations specific to your country. Choose a reliable freight forwarder who understands the electronics industry to ensure timely and compliant delivery. Additionally, factor in lead times, as international shipping can introduce delays. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance. -

Can I customize DC/DC power supply modules for my specific application?

Many suppliers offer customization options for DC/DC power supply modules, allowing you to adjust parameters like input/output voltage, current ratings, and form factors. It’s best to communicate your specific requirements early in the sourcing process. Customization may involve longer lead times and higher costs, so be prepared for discussions around these factors with your supplier. -

What are the common applications for DC/DC power supply modules?

DC/DC power supply modules are widely used across various applications, including telecommunications, automotive, industrial automation, and consumer electronics. They are ideal for converting voltage levels to meet specific device requirements, enhancing efficiency, and saving space on PCBs. Understanding the intended application can help you select the right module with appropriate features like isolation, thermal management, and size constraints.

Top 5 Dc Dc Power Supply Module Manufacturers & Suppliers List

1. TI – TPSM81299

Domain: ti.com

Registered: 1986 (39 years)

Introduction: DC/DC power modules from TI offer integrated inductors or transformers for compact solutions, enhanced performance, low EMI, and ease of use. Key products include: TPSM81299 (95nA quiescent current, 5.5V boost module), UCC33020 (3V to 5.5V/5V, 1W isolated power module), TPSM33606-Q1 (Automotive, 3V to 36V input, 0.6A synchronous buck module), UCC34141-Q1 (Automotive, 5.5V-to-20V VIN, 1.5W isolated…

2. Acopian – Modular Regulated Power Supply

Domain: acopian.com

Registered: 1996 (29 years)

Introduction: Modular Regulated Power Supply: High Voltage DC to DC; Output ranges: 0-1,000 volts to 0-30,000 volts; DC inputs from 21.6 to 32.0 Vdc; Continuously adjustable outputs with 20-turn controls for precise setability; Designed to withstand severe arching and short circuits; Rugged construction with quality components for reliable service; Shipped within 6 days; Five Year Warranty (internal encapsulate…

3. Renesas – Key DC/DC Power Modules

Domain: renesas.com

Registered: 2002 (23 years)

Introduction: Renesas offers a range of DC/DC power modules with over ten years of experience in power module solutions. Key products include: RRM12120 Digital DC/DC PMBus 20A Module, RAA210130 Digital DC/DC PMBus 30A Module, RAA210040 5V, 4A Step-Down DC/DC Mini Module with Integrated Inductor, and RAA210030 5V, 3A Step-Down DC/DC Low Profile Mini Module with Integrated Inductor. These modules are complete sol…

4. Delta WW – Power Modules & Thermal Solutions

Domain: deltaww.com

Registered: 2001 (24 years)

Introduction: Standard Power Module (DC/DC Converter & AC/DC Module) includes various types of power adapters such as charging adapters, PoE injectors, and open frame modules. It also features EC centrifugal blowers, EC axial fans, and thermal solutions like heat sinks and heat exchangers. Additionally, it offers on-board charging modules, bi-directional on-board chargers, traction inverters, and integrated mot…

5. Arduino – DC-DC Power Module 25W

Domain: store-usa.arduino.cc

Registered: 2005 (20 years)

Introduction: {“name”: “DC-DC Power Module 25W”, “SKU”: “TPX00078”, “weight”: “0.03 kg”, “input_voltage_range”: “3.6V-25V”, “output_adjustable_range”: “3.3V-25V”, “constant_output_current”: “5A@5V”, “max_output_power”: “25W”, “switching_frequency”: “350KHz”, “output_interfaces”: “Three different output interfaces”, “original_voltage_output”: “One interface of original voltage output”, “price”: “$8.50”, “availab…

Strategic Sourcing Conclusion and Outlook for dc dc power supply module

In conclusion, the strategic sourcing of DC/DC power supply modules presents significant opportunities for B2B buyers across international markets, including Africa, South America, the Middle East, and Europe. Understanding the benefits of integrated solutions—such as reduced design time, lower costs, and enhanced efficiency—can empower businesses to streamline their supply chains and accelerate time-to-market. By leveraging advanced technologies and digital control features, companies can optimize their power management systems, ensuring they meet the growing demand for reliable and compact energy solutions.

As the market for DC/DC power modules continues to evolve, it is crucial for buyers to engage with reputable suppliers who offer comprehensive support, including design tools and technical resources. This collaboration can lead to innovative applications and improved performance in various sectors, from automotive to industrial electronics.

Looking ahead, B2B buyers should proactively explore partnerships with leading manufacturers to stay ahead of technological advancements and market trends. Embracing strategic sourcing not only enhances operational efficiency but also positions companies favorably in an increasingly competitive landscape. Take the next step in your sourcing strategy today and unlock the potential of DC/DC power supply modules for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.