Top 5 Cortadora De Madera Suppliers (And How to Choose)

Introduction: Navigating the Global Market for cortadora de madera

In the fast-evolving landscape of global woodworking tools, sourcing the right cortadora de madera can present significant challenges for B2B buyers. As businesses expand their operations across diverse markets—from bustling urban centers in Europe to emerging industries in Africa and South America—understanding the nuances of different woodcutting machines becomes crucial. This guide offers a comprehensive exploration of cortadoras de madera, including various types, their applications, and essential considerations for selecting the right equipment for your needs.

Navigating through the complexities of supplier vetting, pricing structures, and after-sales support can be daunting. However, this resource aims to empower international buyers by providing actionable insights into the procurement process. It covers not only the technical specifications and functionalities of different models but also highlights key factors such as durability, efficiency, and safety standards that are vital in different regional contexts, including those in Vietnam and Nigeria.

By equipping businesses with the knowledge to make informed purchasing decisions, this guide ensures that you can confidently select the best cortadora de madera that aligns with your operational goals and budget constraints. Ultimately, it serves as a vital tool for enhancing productivity and ensuring quality in woodworking projects, enabling buyers to thrive in a competitive global market.

Understanding cortadora de madera Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Circular Saw | Rotating blade, portable, adjustable cutting depth and angle | Carpentry, furniture manufacturing | Pros: Versatile for various cuts; Cons: Requires careful handling due to potential kickback. |

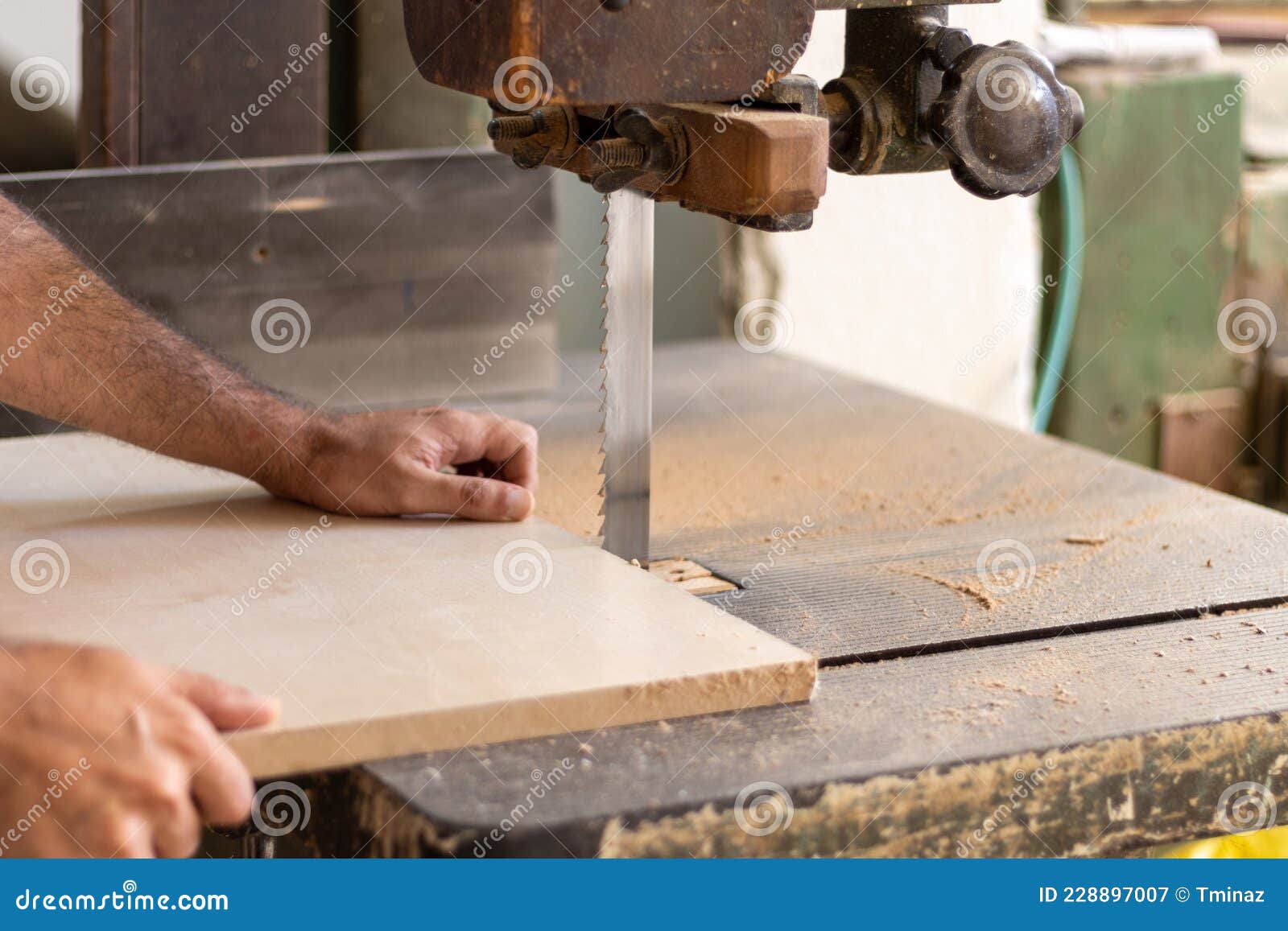

| Band Saw | Continuous blade loop, ideal for intricate curves and shapes | Woodworking, cabinetry, custom furniture | Pros: Excellent for detailed cuts; Cons: Limited to specific cutting tasks, not ideal for thick materials. |

| Table Saw | Stationary, large cutting surface, precise for long boards | Mass production, woodworking shops | Pros: High accuracy and repeatability; Cons: Less portable, requires significant workspace. |

| Jigsaw | Uses a reciprocating blade for intricate cuts | Crafting, detailed woodworking projects | Pros: Great for curves and detailed work; Cons: Slower than other saws, may struggle with thicker materials. |

| Miter Saw | Specialized for angled cuts, often used for trim and molding | Construction, furniture assembly | Pros: Quick and easy angle cuts; Cons: Limited to crosscuts, may require additional tools for complex angles. |

What are the Key Features and Applications of Different Types of Cortadora de Madera?

Circular Saw

The circular saw is a highly versatile tool characterized by its rotating blade, which allows for adjustable cutting depths and angles. This saw is commonly used in carpentry and furniture manufacturing, making it a staple for B2B buyers in these sectors. When considering a circular saw, buyers should evaluate the power of the motor and the blade size, as these factors influence cutting efficiency and material compatibility. While circular saws offer great versatility, they require careful handling to mitigate risks associated with kickback.

Band Saw

The band saw features a continuous loop of blade, making it ideal for intricate curves and shapes. It is predominantly used in woodworking, cabinetry, and custom furniture production. B2B buyers should focus on the blade width and the saw’s throat capacity when selecting a band saw, as these specifications determine its cutting capabilities. Although band saws excel in detailed cuts, they may not be suitable for thicker materials, which can limit their application in certain projects.

Table Saw

Table saws are stationary tools with a large cutting surface, designed for precise cuts on long boards. They are widely utilized in mass production and woodworking shops, where accuracy and repeatability are crucial. B2B buyers should consider the table size, motor power, and safety features when purchasing a table saw. While they provide high accuracy, table saws require a significant amount of workspace and are less portable, which can be a drawback for businesses with limited facilities.

Jigsaw

A jigsaw operates with a reciprocating blade, making it particularly effective for intricate cuts and curves. It is often employed in crafting and detailed woodworking projects, appealing to B2B buyers in creative industries. When selecting a jigsaw, buyers should assess the stroke length and speed settings, which influence cutting performance. Although jigsaws are excellent for detailed work, they may be slower than other types of saws and can struggle with thicker materials.

Miter Saw

Miter saws are specialized tools designed for making angled cuts, commonly used in construction and furniture assembly for trim and molding. B2B buyers should focus on the saw’s bevel capacity and cutting diameter, as these factors determine its versatility for different projects. Miter saws are quick and efficient for angle cuts, but they are limited to crosscuts and may require additional tools for complex angles, which can affect workflow efficiency in larger projects.

Key Industrial Applications of cortadora de madera

| Industry/Sector | Specific Application of cortadora de madera | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Precision cutting for furniture components | Enhances product quality and reduces material waste | Look for precision, durability, and service support |

| Construction | Framing and structural wood cutting | Increases efficiency and reduces labor costs | Assess power, cutting capacity, and safety features |

| Woodworking & Carpentry | Custom cabinetry and decorative woodwork | Facilitates creativity and customization for clients | Ensure versatility in cuts and ease of use |

| Packaging Industry | Creating wooden pallets and crates | Streamlines logistics and reduces shipping costs | Focus on cutting speed and compatibility with wood types |

| Musical Instrument Manufacturing | Shaping and crafting wooden instrument parts | Ensures high-quality sound and craftsmanship | Prioritize precision and the ability to handle various wood types |

How is ‘cortadora de madera’ utilized in Furniture Manufacturing?

In the furniture manufacturing industry, cortadora de madera is essential for precision cutting of various wood components, such as tabletops, legs, and frames. This tool allows manufacturers to achieve accurate dimensions, which is crucial for assembling high-quality furniture. By minimizing material waste through precise cuts, businesses can significantly enhance their profitability. Buyers in this sector should seek machines that offer high durability, consistent performance, and reliable after-sales support to ensure long-term productivity.

Illustrative image related to cortadora de madera

What role does cortadora de madera play in Construction?

In construction, cortadora de madera is used for framing and cutting structural wood, which is vital for building integrity and safety. The ability to quickly and accurately cut materials helps reduce labor costs and time on-site. This tool is particularly beneficial in regions with high construction demand, where efficiency is paramount. Buyers should consider the machine’s power, cutting capacity, and safety features to meet the rigorous demands of the construction environment.

How is cortadora de madera applied in Woodworking & Carpentry?

Woodworkers and carpenters utilize cortadora de madera for creating custom cabinetry, furniture, and decorative woodwork. This tool enables artisans to execute intricate designs and precise cuts, allowing for greater creativity and customization in their projects. For international buyers, especially in regions with diverse woodworking traditions, it is essential to choose a machine that offers versatility in cutting options and ease of handling to cater to various designs and wood types.

Why is cortadora de madera important in the Packaging Industry?

In the packaging industry, cortadora de madera is utilized for crafting wooden pallets and crates that are essential for transporting goods. The efficiency of this tool streamlines the production process, helping businesses reduce shipping costs and improve logistics. When sourcing machines for this application, buyers should focus on cutting speed and compatibility with different types of wood to optimize their production line.

How does cortadora de madera enhance Musical Instrument Manufacturing?

For musical instrument manufacturers, cortadora de madera is critical in shaping and crafting wooden parts that contribute to the instrument’s sound quality and aesthetics. Precision in cutting is essential to ensure that each piece fits perfectly, enhancing the overall craftsmanship. Buyers in this niche market should prioritize machines that deliver high precision and can accommodate various wood types, as the quality of the wood directly affects the instrument’s sound.

Illustrative image related to cortadora de madera

3 Common User Pain Points for ‘cortadora de madera’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Wood Cutter for Specific Applications

The Problem:

B2B buyers often face challenges in selecting the appropriate wood cutter for their specific operational needs. Different projects may require varying cutting capabilities, such as depth, angle, and type of wood. For instance, a company focused on high-precision cabinetry may struggle with a standard circular saw that is not designed for intricate cuts or harder woods. This can lead to inefficiencies, increased costs, and even project delays, as the wrong tool may not perform adequately, resulting in compromised quality and wasted materials.

The Solution:

To overcome this challenge, buyers should conduct a thorough assessment of their specific needs prior to purchasing a wood cutter. Consider factors such as the types of wood most commonly used, the required depth of cuts, and the precision needed for different angles. For projects requiring intricate cuts, investing in specialized tools like a miter saw or a jigsaw may be beneficial. Additionally, suppliers often provide detailed specifications and use cases for each model, so buyers should consult with sales representatives or technical experts to clarify which machine suits their applications best. Making informed decisions based on a clear understanding of project requirements will streamline operations and enhance overall productivity.

Scenario 2: Managing Maintenance and Downtime Issues with Wood Cutting Equipment

The Problem:

Regular maintenance of wood cutting equipment is a common pain point for B2B buyers, particularly in regions where access to skilled technicians is limited. Equipment failure or suboptimal performance due to poor maintenance can lead to significant downtime, disrupting workflow and causing financial losses. For instance, if a wood cutter’s blades are not regularly sharpened or replaced, the machine may perform poorly, increasing the risk of injury and leading to additional repair costs.

The Solution:

To mitigate maintenance issues, companies should establish a proactive maintenance schedule that includes regular inspections and servicing of all wood cutting equipment. This can be achieved by training in-house personnel on basic maintenance tasks, such as blade replacement and machine calibration. Additionally, consider sourcing equipment from suppliers that offer comprehensive warranties and support services, which can provide peace of mind regarding maintenance needs. Implementing a maintenance tracking system can also help ensure that machines are serviced timely, thus minimizing the risk of unexpected downtime and extending the lifespan of the equipment.

Scenario 3: Ensuring Safety and Compliance in Wood Cutting Operations

The Problem:

Safety is a paramount concern in any woodworking operation, especially in B2B environments where multiple employees handle heavy machinery. Buyers often grapple with ensuring that their wood cutting equipment meets local safety standards and regulations. The risk of accidents, such as cuts or equipment-related injuries, not only endangers employees but can also lead to costly legal liabilities and damage to a company’s reputation.

The Solution:

To enhance safety and compliance, buyers should prioritize purchasing wood cutters that adhere to international safety standards and come equipped with essential safety features, such as blade guards, emergency stops, and ergonomic designs. It is also crucial to provide comprehensive training for all employees on the safe operation of wood cutting equipment. Regular safety audits and the establishment of clear operational protocols can further enhance workplace safety. Collaborating with suppliers who offer safety equipment and training resources can also significantly contribute to fostering a culture of safety within the organization, ultimately protecting both employees and the business itself.

Strategic Material Selection Guide for cortadora de madera

What are the Key Materials Used in Cortadora de Madera Manufacturing?

When selecting materials for cortadora de madera (wood cutting machines), it’s essential to consider various factors that affect performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of these machines, focusing on their properties, pros and cons, and implications for international B2B buyers.

1. High-Carbon Steel

Key Properties: High-carbon steel is known for its hardness and wear resistance. It typically has a carbon content of 0.6% to 1.4%, which contributes to its strength. This material can withstand high temperatures and pressures, making it suitable for cutting applications.

Pros & Cons: The durability of high-carbon steel makes it an excellent choice for blades and cutting tools. However, it is prone to corrosion if not properly treated, which can affect longevity. Additionally, while high-carbon steel is relatively affordable, the manufacturing process can be complex due to the need for heat treatment.

Impact on Application: High-carbon steel blades are ideal for cutting various types of wood, including hardwoods. However, their susceptibility to rust necessitates careful handling and maintenance.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM A681 for tool steels. In regions with high humidity, additional corrosion-resistant coatings may be necessary.

Illustrative image related to cortadora de madera

2. Carbide-Tipped Materials

Key Properties: Carbide-tipped tools feature a hard carbide material bonded to a steel base. This combination allows for exceptional hardness and wear resistance, making them ideal for heavy-duty applications.

Pros & Cons: The primary advantage of carbide-tipped tools is their longevity and ability to maintain sharpness over extended use. However, they are more expensive than high-carbon steel options and can be more challenging to manufacture due to the bonding process.

Impact on Application: Carbide-tipped blades are suitable for cutting dense hardwoods and engineered wood products. Their performance can significantly enhance productivity in commercial settings.

Considerations for International Buyers: Buyers should verify that carbide-tipped products meet international standards such as ISO 9001 for quality management systems. Additionally, understanding local market preferences for blade types can influence purchasing decisions.

3. Stainless Steel

Key Properties: Stainless steel is known for its corrosion resistance and aesthetic appeal. It typically contains chromium, which forms a protective layer against rust and corrosion.

Pros & Cons: The main advantage of stainless steel is its resistance to rust, making it suitable for environments with high moisture levels. However, it is generally less durable than high-carbon steel and carbide materials in terms of hardness, which may limit its effectiveness in heavy-duty applications.

Illustrative image related to cortadora de madera

Impact on Application: Stainless steel is often used in components that require frequent cleaning, such as in woodworking shops. Its corrosion resistance makes it ideal for humid environments.

Considerations for International Buyers: Compliance with standards like ASTM A240 for stainless steel is crucial. Buyers in regions with stringent environmental regulations may prefer stainless steel for its recyclability and lower environmental impact.

4. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight and resistant to corrosion. They are often used in the frames and housings of cutting machines due to their strength-to-weight ratio.

Pros & Cons: The lightweight nature of aluminum alloys makes them easy to handle and transport. However, they are not as strong as steel options and may not withstand high-stress cutting applications.

Impact on Application: Aluminum is suitable for portable cutting machines and applications where weight is a critical factor. However, its lower strength limits its use in heavy-duty industrial settings.

Illustrative image related to cortadora de madera

Considerations for International Buyers: Buyers should ensure that aluminum products comply with standards such as ASTM B221 for aluminum alloys. Understanding local preferences for machine weight and portability can influence purchasing decisions.

Summary Table of Material Selection for Cortadora de Madera

| Material | Typical Use Case for cortadora de madera | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Carbon Steel | Blades for general wood cutting | Excellent durability | Prone to corrosion | Medium |

| Carbide-Tipped | Heavy-duty cutting applications | Maintains sharpness, long-lasting | Higher cost, complex manufacturing | High |

| Stainless Steel | Components in humid environments | Corrosion-resistant | Less durable than steel options | Medium |

| Aluminum Alloys | Portable cutting machines | Lightweight, easy to handle | Lower strength for heavy-duty use | Low |

This material selection guide provides critical insights for B2B buyers in the wood cutting industry, enabling informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cortadora de madera

What Are the Key Stages in the Manufacturing Process of Cortadora de Madera?

The manufacturing process of a cortadora de madera (wood cutter) involves several critical stages, each designed to ensure high-quality output and reliability. Understanding these stages is essential for B2B buyers seeking to assess suppliers effectively.

Material Preparation: What Materials Are Used and How Are They Prepared?

The manufacturing of cortadoras de madera typically begins with the selection of high-grade raw materials, such as carbon steel for blades, durable plastics for housing, and aluminum or steel for frames. The quality of these materials directly influences the performance and longevity of the machine.

Once selected, materials undergo various processes including cutting, shaping, and surface treatment. For instance, steel sheets may be cut into specific dimensions, and aluminum components may be extruded to achieve desired shapes. This step is critical as it lays the foundation for the machine’s strength and durability.

Forming: How Are Wood Cutters Shaped and Assembled?

The forming stage involves shaping the prepared materials into functional components. Techniques such as stamping, forging, and CNC machining are commonly used to create precision parts. The use of CNC (Computer Numerical Control) technology allows manufacturers to achieve high levels of accuracy, which is crucial for ensuring that components fit together seamlessly.

After forming, components are often subjected to heat treatment processes, which enhance their hardness and resistance to wear. This stage is vital for ensuring that the cortadora de madera can withstand rigorous use in various environments, particularly in regions with demanding woodworking applications.

Illustrative image related to cortadora de madera

Assembly: What Does the Assembly Process Entail?

Once all components are shaped, the assembly process begins. This stage typically involves fitting together the motor, blade, and housing. Skilled technicians carefully assemble each machine, ensuring that all parts are aligned correctly and function as intended.

Quality control checkpoints are integrated throughout the assembly process. For example, assembly quality may be verified through visual inspections and operational tests to confirm that the machine operates smoothly and meets specified performance standards.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage involves the application of protective coatings and the installation of safety features. Coatings such as powder coating or painting not only enhance the aesthetic appeal of the cortadora de madera but also provide protection against corrosion and wear.

Safety features, such as emergency stop buttons and blade guards, are also installed during this phase. Given the importance of safety in industrial equipment, this step is crucial for ensuring compliance with international safety standards.

Illustrative image related to cortadora de madera

What Quality Assurance Measures Are Essential for Cortadora de Madera?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that each cortadora de madera meets international standards and buyer expectations.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 play a significant role in quality management systems for manufacturers. ISO 9001 certification indicates that a supplier adheres to established quality management practices, which can significantly reduce risk for buyers.

Additionally, industry-specific certifications, such as CE marking in Europe and API standards in the oil and gas sector, may apply depending on the machine’s intended use. Buyers should verify that suppliers hold relevant certifications to ensure compliance with regional regulations.

Illustrative image related to cortadora de madera

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure product integrity. The main checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): This stage entails monitoring the manufacturing processes to detect any deviations from quality standards during production.

- Final Quality Control (FQC): Before shipment, the finished product undergoes comprehensive testing and inspection to ensure it meets all quality and safety standards.

Common testing methods include performance testing, where machines are operated under various conditions to assess functionality, and durability testing, which evaluates the machine’s resilience over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure that they receive a reliable product. Here are several strategies to assess quality assurance:

What Types of Audits Should Buyers Conduct?

Conducting audits of potential suppliers can provide valuable insights into their quality control processes. Buyers may consider both announced and unannounced audits to gauge the consistency of manufacturing practices. Audits should focus on compliance with international standards, adherence to quality protocols, and the presence of necessary certifications.

How Important Are Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide transparency regarding their production processes and testing outcomes. These reports should detail testing methods, results, and any corrective actions taken for non-conformities.

Illustrative image related to cortadora de madera

Additionally, third-party inspections can serve as an impartial assessment of a supplier’s quality control measures. Engaging third-party inspectors can help validate that the cortadoras de madera meet all specified standards before shipment.

What Nuances Should International B2B Buyers Be Aware Of?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality certification and compliance is crucial. Buyers should be aware that different regions may have varying regulatory requirements and quality standards.

It’s advisable for buyers to familiarize themselves with local regulations and standards that apply to woodworking machinery in their respective markets. This knowledge can aid in making informed decisions and selecting suppliers that align with their quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance practices for cortadoras de madera is vital for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can make informed choices that lead to successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cortadora de madera’

Introduction

Sourcing a cortadora de madera (wood cutter) can be a complex process, especially for B2B buyers across diverse international markets. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you select the right equipment for your business needs while minimizing risks.

Illustrative image related to cortadora de madera

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the specific technical requirements for your cortadora de madera. Consider factors such as cutting depth, power (measured in watts), and the types of wood the machine will handle. Clearly defined specifications will help you filter options effectively and ensure that the equipment meets your operational needs.

- Cutting Capacity: Determine the maximum thickness and types of wood (e.g., softwood vs. hardwood) you will be cutting.

- Power Requirements: Look for machines with sufficient wattage to handle your workload, typically between 1200W to 2000W for commercial applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in cortadoras de madera. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors. This step is crucial as the supplier’s reputation can significantly impact your purchasing decision.

- Supplier Reviews: Look for customer testimonials and reviews to gauge the reliability and quality of the supplier.

- Market Presence: Prioritize suppliers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Ensure that your shortlisted suppliers possess the necessary certifications and comply with international quality standards. Certifications such as ISO 9001 or CE marking are indicators of a supplier’s commitment to quality and safety.

- Quality Assurance: Inquire about their quality control processes to ensure consistent product performance.

- Safety Compliance: Verify that the equipment meets safety standards relevant to your region to minimize liability risks.

Step 4: Request Product Samples

Before finalizing your order, request samples or demonstrations of the cortadora de madera. This hands-on evaluation will allow you to assess the machine’s performance and suitability for your specific applications.

- Operational Testing: Test the equipment on various wood types to evaluate cutting efficiency and precision.

- User Experience: Assess ease of use, including ergonomics and safety features.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with your preferred suppliers regarding pricing, payment terms, and delivery schedules. Clear communication at this stage can help avoid misunderstandings later.

- Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce overall costs.

- Warranty and Support: Ensure that warranty terms are clearly defined, and inquire about post-purchase support and servicing options.

Step 6: Finalize Your Purchase Order

Once all terms are agreed upon, proceed to finalize your purchase order. Include all specifications, quantities, prices, and delivery timelines in the document to ensure clarity and accountability.

- Documentation: Keep copies of all correspondence and agreements for future reference.

- Payment Schedule: Establish a payment schedule that aligns with your cash flow and budgetary constraints.

Step 7: Plan for After-Sales Support

Consider the after-sales support offered by your supplier. Reliable customer service and access to spare parts are essential for maintaining your equipment’s performance over time.

- Technical Support: Ensure that the supplier offers technical assistance and training for your staff.

- Parts Availability: Confirm the availability of spare parts to minimize downtime in case of repairs.

By following this checklist, B2B buyers can navigate the sourcing process for cortadoras de madera more effectively, ensuring they make informed decisions that align with their operational requirements and business goals.

Comprehensive Cost and Pricing Analysis for cortadora de madera Sourcing

When sourcing a “cortadora de madera,” understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, especially in international markets like Africa, South America, the Middle East, and Europe. This analysis outlines the various cost components, price influencers, and provides actionable tips for effective negotiation and cost management.

What Are the Key Cost Components in Sourcing Cortadoras de Madera?

The cost structure of a cortadora de madera typically includes several key components:

-

Materials: The primary materials used in manufacturing wood cutters, such as high-grade steel for blades and durable plastic for housing, significantly influence the overall cost. High-quality materials not only increase the initial purchase price but also enhance durability and performance.

-

Labor: Labor costs can vary depending on the region of manufacture. Countries with lower labor costs can provide competitive pricing, but this may come at the expense of quality. It is crucial to evaluate the skill level of the workforce involved in production, as skilled labor can lead to better craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Overhead costs can differ greatly between manufacturers, affecting the final pricing of the cortadora.

-

Tooling: The initial investment in tooling for specific models can be substantial, especially for custom designs. This cost is often amortized over the production run, impacting the pricing for smaller orders.

-

Quality Control (QC): Strict QC measures are essential in manufacturing to ensure product reliability. Suppliers that implement comprehensive QC processes may charge a premium, but this investment often results in lower return rates and improved customer satisfaction.

-

Logistics: Shipping costs, tariffs, and insurance play a significant role in the total cost of ownership. International buyers should consider these factors when evaluating supplier quotes, as they can vary widely based on shipping methods and distances.

-

Margin: Suppliers will include their profit margins in the pricing, which can vary based on brand reputation, market demand, and competition.

What Factors Influence the Pricing of Cortadoras de Madera?

Several factors can influence the pricing of wood cutters, including:

-

Volume/MOQ: Purchasing in larger quantities often leads to bulk discounts. Minimum order quantities (MOQs) set by suppliers can impact pricing negotiations.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against the potential for higher prices.

-

Materials and Quality Certifications: Products made from superior materials or those that meet specific quality certifications (e.g., ISO, CE) may be priced higher but can offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence price. Established brands may command higher prices due to their perceived quality and after-sales support.

-

Incoterms: Understanding the Incoterms agreed upon can affect costs related to shipping responsibilities, insurance, and tariffs. Choosing the right terms can lead to significant savings.

How Can Buyers Negotiate for Better Pricing?

-

Research and Comparison: Conduct thorough market research to compare pricing from various suppliers. This knowledge empowers buyers during negotiations.

-

Leverage Volume: If possible, consolidate orders with other businesses to meet MOQs and achieve better pricing.

-

Discuss Payment Terms: Flexible payment terms can provide a means to negotiate better pricing or discounts.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial price but also maintenance, warranty, and replacement costs. A higher upfront cost may lead to lower TCO if the product is more durable.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better service, pricing, and terms in the long run.

What Should International Buyers Be Aware of?

International buyers must navigate various pricing nuances, including currency fluctuations, import duties, and compliance with local regulations. It is advisable to consult with local trade experts or legal advisors to avoid unexpected costs. Always request indicative prices and be mindful that final costs may vary based on the factors discussed.

By understanding these elements, B2B buyers can make informed decisions when sourcing cortadoras de madera, ensuring they achieve the best value for their investments.

Alternatives Analysis: Comparing cortadora de madera With Other Solutions

When considering the acquisition of a cortadora de madera (wood cutter), it is essential to evaluate various alternatives that can meet similar needs in woodworking and carpentry. This analysis aims to provide a comprehensive comparison of the cortadora de madera against two viable alternatives: the table saw and the band saw. Each of these solutions has unique characteristics that may better suit specific applications in different environments.

| Comparison Aspect | Cortadora De Madera | Table Saw | Band Saw |

|---|---|---|---|

| Performance | High precision for straight cuts; suitable for various wood types | Excellent for making long, straight cuts with versatility in thickness | Ideal for intricate cuts and curves in thicker materials |

| Cost | Moderate cost, varies by brand and features | Generally higher initial investment but offers long-term savings | Similar to table saws, can be expensive depending on size and brand |

| Ease of Implementation | User-friendly; requires minimal setup | Requires more setup and adjustment for accurate cuts | Can be complex to set up; requires skill for optimal use |

| Maintenance | Low maintenance; regular blade replacement needed | Moderate maintenance; adjustments and blade changes necessary | Higher maintenance due to blade tension and tracking adjustments |

| Best Use Case | General carpentry, furniture making, and cabinetry | Large-scale cuts, sheet goods, and precise woodworking | Curved cuts, resawing lumber, and intricate designs |

What Are the Advantages and Disadvantages of Using a Table Saw Compared to a Cortadora de Madera?

The table saw stands out for its ability to handle large sheets of plywood and perform precise cuts. It is particularly beneficial in high-volume environments, such as furniture manufacturing, where efficiency is critical. However, its larger footprint and more complex setup can be drawbacks for smaller workshops or DIY projects. Furthermore, table saws can pose safety risks if not used with proper precautions, making training essential for operators.

How Does a Band Saw Compare in Performance and Use Cases to a Cortadora de Madera?

The band saw excels in cutting curves and intricate designs, making it a preferred choice for detailed woodworking and resawing tasks. Its continuous blade allows for smoother cuts in thicker materials, which is advantageous for projects requiring custom shapes. However, the band saw generally requires more skill and experience to operate effectively, particularly in adjusting blade tension and alignment. Additionally, it may not be as efficient for straight cuts when compared to a cortadora de madera.

Conclusion: How Can B2B Buyers Choose the Right Wood Cutting Solution for Their Needs?

When selecting the right wood cutting solution, B2B buyers must consider their specific operational needs, budget constraints, and the type of projects they typically undertake. A cortadora de madera is ideal for straightforward carpentry tasks and furniture-making, while a table saw offers efficiency for larger cuts and sheet materials. Conversely, a band saw is best suited for detailed work and custom projects. By evaluating these alternatives against their unique requirements, buyers can make informed decisions that enhance productivity and quality in their woodworking operations.

Essential Technical Properties and Trade Terminology for cortadora de madera

What are the Key Technical Properties of a Cortadora de Madera?

When evaluating a cortadora de madera (wood cutter), several technical properties are critical for ensuring that the machine meets specific operational requirements and quality standards. Here are some essential specifications to consider:

-

Motor Power (Watts)

– The motor power, measured in watts, indicates the cutting capacity of the machine. A higher wattage generally means more robust performance, enabling the tool to cut through tougher woods like oak or mahogany. For instance, a cortadora with a 1200 W motor is ideal for professional carpentry, as it can handle various types of wood efficiently. -

Blade Diameter and Type

– The diameter of the cutting blade significantly affects the depth and type of cuts the machine can perform. Common sizes range from 7-1/4 inches to 10 inches. The blade type—such as carbide-tipped or high-speed steel—also influences durability and cutting precision. Selecting the right blade is crucial for achieving clean, accurate cuts, which is vital for high-quality woodwork. -

Cutting Depth and Angle Adjustability

– The maximum cutting depth at various angles (e.g., 90° and 45°) determines the versatility of the cutter. For example, a cutting depth of 7 cm at 90° allows for the creation of thick furniture pieces, while a 45° angle enables bevel cuts for joints and aesthetics. This adjustability is essential for various applications, from furniture making to intricate woodworking projects. -

Weight and Ergonomics

– The weight of the machine impacts portability and ease of use. A lightweight model can facilitate maneuverability, especially in job sites requiring frequent relocation. Additionally, ergonomic design elements, such as a comfortable grip and balanced weight distribution, enhance user experience and reduce fatigue during extended use. -

Safety Features

– Safety features, such as blade guards and electronic brakes, are crucial for minimizing risks during operation. A machine with a reliable safety mechanism ensures that operators can work efficiently without compromising safety. These features are often mandated by industry standards, making them essential for compliance and risk management.

What Trade Terms Should B2B Buyers Understand When Purchasing a Cortadora de Madera?

Understanding trade terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms related to purchasing cortadoras de madera:

Illustrative image related to cortadora de madera

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of cortadoras de madera, knowing whether a supplier is an OEM can provide insights into the quality and reliability of the machines. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchasing strategy, especially when looking to negotiate bulk orders. It can also affect pricing, as larger orders may qualify for discounts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and other terms for specific products. This is a crucial step in the procurement process, allowing buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping costs and liability. -

Lead Time

– Lead time refers to the time it takes from placing an order until it is delivered. This is a critical factor for planning and inventory management, especially in industries where timely delivery can impact production schedules.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing cortadoras de madera, ensuring that they select the right equipment for their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the cortadora de madera Sector

What Are the Key Trends Shaping the Global Cortadora de Madera Market?

The cortadora de madera (wood cutter) market is experiencing transformative changes driven by technological advancements and evolving buyer expectations. A significant trend is the integration of smart technology into wood-cutting equipment, enhancing precision and operational efficiency. International buyers are increasingly looking for machines equipped with IoT capabilities that allow for remote monitoring and predictive maintenance. This shift not only reduces downtime but also optimizes production processes, making it essential for B2B buyers to consider tech-forward suppliers.

Moreover, the demand for high-performance, energy-efficient machines is on the rise. As businesses aim to reduce operational costs, tools that offer lower energy consumption without compromising performance are gaining traction. This trend is particularly relevant for buyers in Africa and South America, where energy costs can significantly impact overall profitability.

Illustrative image related to cortadora de madera

Additionally, the global push for sustainability is influencing sourcing decisions. B2B buyers are prioritizing suppliers who can demonstrate a commitment to sustainable manufacturing practices, including the use of recyclable materials and energy-efficient processes. This is especially pertinent in regions like Europe and the Middle East, where regulatory pressures for environmentally friendly practices are increasing.

How Important Is Sustainability and Ethical Sourcing in the Cortadora de Madera Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the cortadora de madera market. Environmental impacts associated with wood cutting and processing are under scrutiny, leading to a demand for equipment that minimizes waste and energy consumption. Suppliers are increasingly being evaluated on their ability to adhere to sustainable practices, such as responsible sourcing of raw materials and waste management.

Buyers should look for certifications that validate a supplier’s commitment to sustainability. Certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) indicate that the wood used in manufacturing is sourced from responsibly managed forests. Furthermore, the adoption of ‘green’ materials in the manufacturing of cortadoras de madera can enhance a buyer’s brand reputation and marketability, aligning with the growing consumer preference for environmentally friendly products.

In addition to compliance with environmental standards, ethical labor practices are paramount. Suppliers with transparent supply chains and fair labor practices not only contribute to a more sustainable industry but also mitigate risks associated with reputational damage and compliance violations.

How Has the Cortadora de Madera Market Evolved Over Time?

The evolution of the cortadora de madera sector has been marked by significant technological advancements and shifting market demands. Initially dominated by manual tools, the industry transitioned to electric and later to battery-operated machines, reflecting a broader trend towards automation and efficiency. The introduction of digital controls and automation in the late 20th century further revolutionized the market, enabling more precise and consistent cutting.

Illustrative image related to cortadora de madera

As global competition intensified, manufacturers began focusing on enhancing the durability and performance of their products to meet the diverse needs of international markets. This shift has paved the way for a more sophisticated product offering, with innovations such as laser-cutting technology and advanced safety features becoming standard.

Today, the market is characterized by a blend of traditional craftsmanship and modern technology, driven by the increasing demand for high-quality, efficient, and sustainable solutions. This evolution underscores the importance for B2B buyers to stay informed about technological advancements and market trends to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of cortadora de madera

-

How do I choose the right cortadora de madera for my business needs?

Choosing the right cortadora de madera involves evaluating the types of wood you will be cutting and the volume of work. Consider factors such as the power of the motor, cutting capacity (depth and angle), and the type of blade needed for different wood types. It’s also essential to assess the ergonomics and safety features of the tool, as they contribute to long-term usability and worker safety. Consulting with suppliers for specific recommendations based on your operational requirements can lead to more informed decisions. -

What are the key specifications to look for in a cortadora de madera?

When sourcing a cortadora de madera, focus on motor power (measured in watts), cutting depth at various angles, and blade size and type. Additionally, check for safety features like blade guards and emergency shut-off switches. Ergonomic design, which reduces user fatigue, is also crucial, especially for high-volume tasks. Furthermore, ensure the machine’s compatibility with the types of wood you work with, including softwoods and hardwoods. -

What is the minimum order quantity (MOQ) for cortadoras de madera?

MOQs can vary significantly based on the supplier and the specific model of cortadora de madera. Typically, manufacturers may set an MOQ to cover production costs, which can range from a few units to several dozen. It is advisable to communicate directly with suppliers to negotiate terms that align with your business needs. In many cases, suppliers may offer flexibility, especially for first-time orders or long-term partnerships. -

How do I ensure quality and reliability when purchasing cortadoras de madera?

To ensure quality, request product samples or detailed specifications from potential suppliers. Look for certifications that indicate adherence to international safety and quality standards. It’s beneficial to read reviews and seek testimonials from other businesses that have purchased similar equipment. Additionally, consider suppliers who provide warranties and after-sales support, as this can be a good indicator of product reliability and manufacturer confidence. -

What payment terms are commonly offered for international purchases of cortadoras de madera?

Payment terms can vary widely among suppliers. Common arrangements include upfront payment, partial payment upon order confirmation with the balance due before shipment, or payment upon delivery. For larger orders, consider negotiating terms such as letters of credit or escrow services to mitigate risks. Always clarify the payment methods accepted (e.g., bank transfers, credit cards) and any potential fees involved. -

What logistics considerations should I keep in mind when importing cortadoras de madera?

When importing cortadoras de madera, consider shipping methods, delivery times, and customs regulations in your country. Ensure that the supplier can provide necessary documentation, such as invoices and certificates of origin, to facilitate a smooth customs process. Additionally, factor in shipping costs and insurance to protect your investment during transit. Collaborating with a logistics partner experienced in international shipping can streamline this process. -

How can I customize cortadoras de madera to meet my specific needs?

Customization options for cortadoras de madera often include modifications to blade types, sizes, and additional features such as dust collection systems or ergonomic handles. Discuss your specific requirements with potential suppliers, as many manufacturers are willing to accommodate custom requests for bulk orders. Be prepared to provide detailed specifications and possibly pay additional costs for bespoke features. -

What are the common after-sales support services for cortadoras de madera?

After-sales support can include warranty services, maintenance, and repair options, as well as access to spare parts. Many suppliers offer training sessions for operating and maintaining the equipment, which is crucial for ensuring safety and efficiency. Before finalizing your purchase, inquire about the availability of customer support and the process for handling any issues that may arise post-purchase. A reliable after-sales service can greatly enhance your operational efficiency and equipment longevity.

Top 5 Cortadora De Madera Manufacturers & Suppliers List

1. Sierra – Circular Eléctrica De Mano 11A 6000 RPM

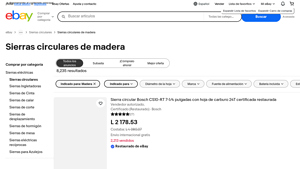

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1. Sierra Circular Eléctrica De Mano 11A 6000 RPM Cortadora de Madera Plástico 90° – Price: $69.99, Delivery: +$9.99, Location: Vietnam

2. Sierra Circular Eléctrica De Mano 12A 7-1/4″ Cortadora de Madera Plástico 0°/45° – Price: $113.09, Delivery: Free, Location: United States, Free returns

3. Cortadora De Papel Y Recortadora De Papel Con Guillotina De Madera Trimair De 12 – Price: $96.96, Deliver…

2. Milwaukee – 2522-20 Circular Saw

Domain: hn.ebay.com

Registered: 1995 (30 years)

Introduction: Las mejores ofertas en Sierras circulares de madera en eBay. Incluye marcas como DEWALT, Milwaukee, Makita, y más. Ejemplos de productos: Milwaukee 2522-20 3 in Circular Saw, DEWALT DCS438B 20V 4.5 inch Circular Saw, Milwaukee M18 FUEL 6-1/2″ Cordless Brushless Circular Saw, y Makita HS006GZ 125 mm Cordless Circular Saw. Precios desde L 496.70 hasta L 8,631.25. Productos nuevos y usados disponible…

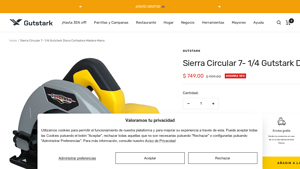

3. Gutstark – Sierra Circular 7-1/4 Disco Cortadora Madera

Domain: gutstark.com

Registered: 2019 (6 years)

Introduction: {“name”: “Sierra Circular 7-1/4 Gutstark Disco Cortadora Madera Mano”, “price”: “$749.00”, “original_price”: “$909.00”, “discount”: “18%”, “motor_power”: “1200 W”, “disc_diameter”: “18.5 cm”, “number_of_teeth”: “24”, “cutting_depth_90”: “7 cm”, “cutting_depth_45”: “5 cm”, “type”: “Cortadora para madera”, “power_type”: “AC corriente alterna”, “system_type”: “Eléctrico”, “frequency”: “50~60 Hz”, “co…

4. Home Center – Sierras Eléctricas y Accesorios

Domain: homecenter.com.co

Registered: 1998 (27 years)

Introduction: This company, Home Center – Sierras Eléctricas y Accesorios, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Promart – Sierras Circulares

Domain: promart.pe

Introduction: Sierras Circulares disponibles en Promart.pe. Marcas: AKSI, Black & Decker, Bosch, Dewalt, Dremel, Einhell, EMTOP, GENÉRICO, INGCO, JAPPRIME, Kaili, Kamasa, Makita, MAKUTE, Pretul, RONIX, Stanley, TOOLCRAFT, Truper, Werken. Colores: Amarillo, Azul, Blanco, Celeste, Gris, Multicolor, Naranja, Plata, Rojo, Verde. Tipos de entrega: Despacho express. Materiales: Acero, PVC/Metal, Metal/Plástico, ABS, …

Strategic Sourcing Conclusion and Outlook for cortadora de madera

In the ever-evolving landscape of the wood-cutting industry, strategic sourcing remains a pivotal component for international B2B buyers. The insights gathered indicate that selecting high-quality cortadora de madera not only enhances operational efficiency but also contributes significantly to cost management. Investing in reliable suppliers and understanding the nuances of different wood-cutting tools can lead to substantial long-term benefits, including improved productivity and reduced downtime.

As buyers from regions such as Africa, South America, the Middle East, and Europe explore their options, they should prioritize partnerships that emphasize quality, innovation, and sustainability. Engaging with trusted suppliers can provide access to advanced technologies, ensuring that businesses remain competitive in a global market.

Looking ahead, the demand for cortadora de madera is expected to grow, driven by increasing construction and woodworking activities worldwide. Now is the time for international buyers to position themselves strategically within this market. By aligning with reputable manufacturers and leveraging strategic sourcing practices, companies can secure their place in the future of the woodworking industry. Embrace these opportunities, and let quality sourcing be the cornerstone of your business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.