Top 5 Coiled Spring Suppliers (And How to Choose)

Introduction: Navigating the Global Market for coiled spring

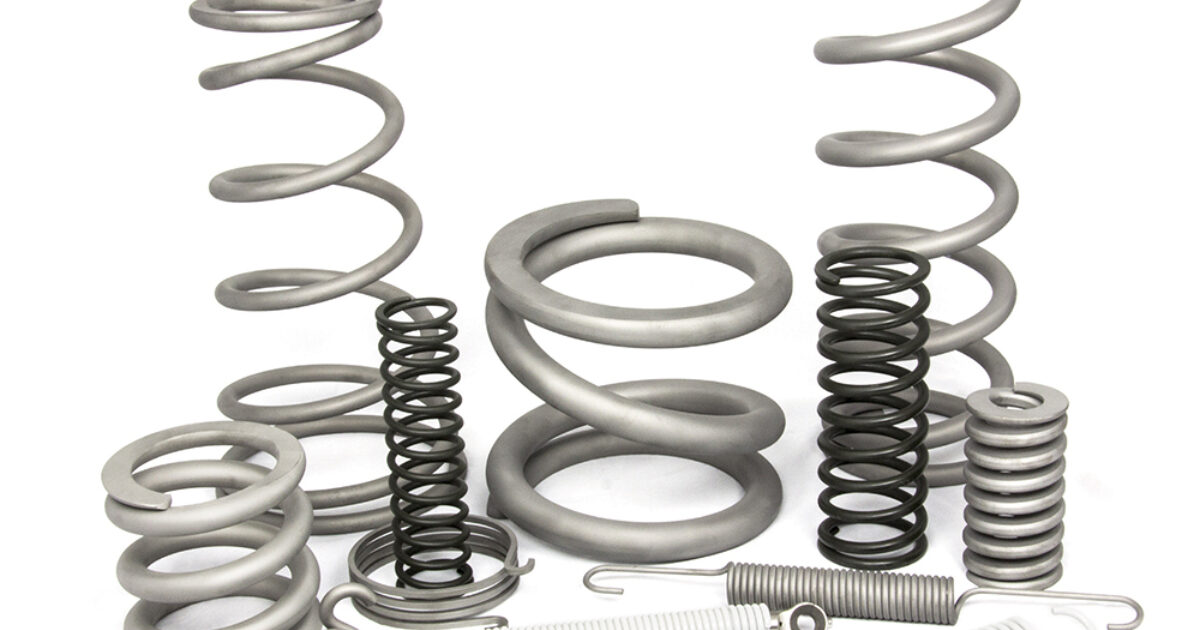

Navigating the intricacies of sourcing coiled springs can be a daunting challenge for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. With various types of coiled springs—including compression, extension, and torsion—each tailored for specific applications, understanding the unique requirements of your project is crucial. Buyers must also contend with factors such as supplier vetting, cost considerations, and compliance with regional standards, all of which can significantly impact procurement strategies.

This comprehensive guide serves as an essential resource for B2B buyers, offering in-depth insights into the types of coiled springs available, their applications across different industries, and practical advice on selecting reliable suppliers. By demystifying the complexities of coiled spring procurement, this guide empowers businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are sourcing coiled springs for manufacturing machinery in Nigeria, automotive applications in Saudi Arabia, or precision tools in Europe, understanding the nuances of each spring type and their respective market dynamics is vital. Equip yourself with the knowledge to navigate the global market confidently, ensuring that your supply chain remains efficient and competitive.

Understanding coiled spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Spring | Coils are spaced apart, designed to compress under load. | Automotive parts, medical devices, toys | Pros: Versatile, widely used. Cons: Requires precise calculations for load capacity. |

| Extension Spring | Coils are tightly wound, designed to extend when pulled. | Industrial machinery, electronics, tools | Pros: High energy storage, reliable. Cons: Limited to tensile forces only. |

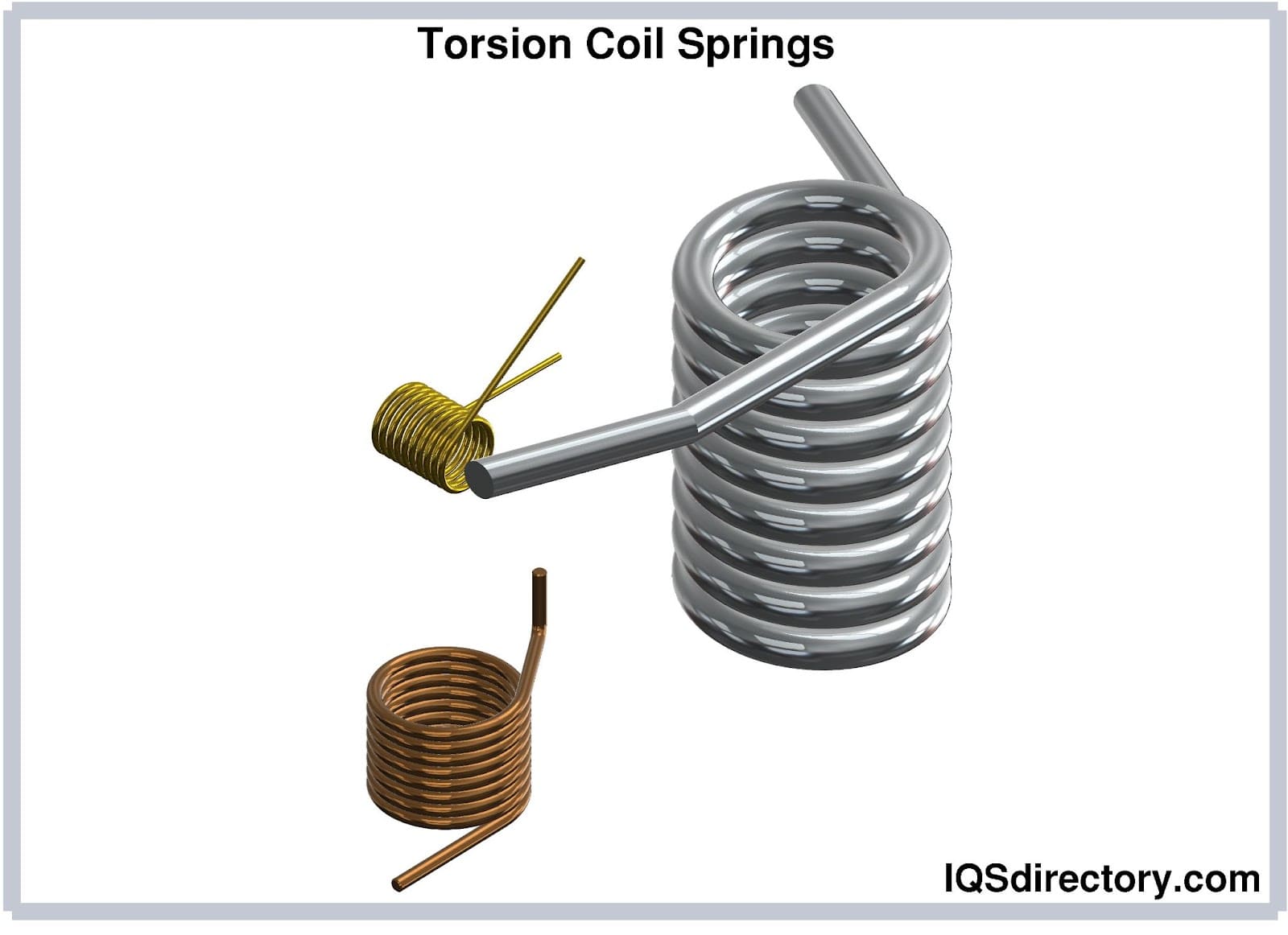

| Torsion Spring | Coils are twisted to store rotational energy. | Hinges, automotive applications, toys | Pros: Effective for torque applications. Cons: Complex design may increase costs. |

| Conical/Tapered Spring | A variation of compression springs, tapering in diameter. | Specialized machinery, automotive sectors | Pros: Space-efficient, tailored force characteristics. Cons: More challenging to manufacture. |

| Coiled Spring Pins | Pins made from coiled wire, offering flexibility and strength. | Assembly applications, machinery components | Pros: Easy to install, cost-effective. Cons: Limited load capacity compared to other spring types. |

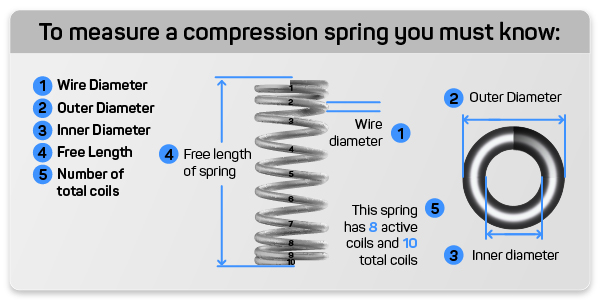

What are the Characteristics and Suitability of Compression Springs?

Compression springs are characterized by their open coils that allow them to compress when a load is applied. They are widely used across various industries, including automotive, medical, and consumer products. When purchasing compression springs, buyers should consider the spring rate, the number of active coils, and the material used, as these factors directly influence the spring’s performance and longevity. Precision in design is crucial to ensure that the spring meets the specific load requirements of the application.

How Do Extension Springs Function and Where are They Used?

Extension springs are designed to extend and store energy when pulled. Their tightly wound coils enable them to handle significant tensile forces, making them ideal for applications in industrial machinery, electronics, and tools. Buyers should focus on the spring’s load capacity, length, and wire diameter when sourcing extension springs to ensure they meet the operational demands of their projects. Proper installation and clearance are also critical to prevent friction and ensure optimal performance.

What Makes Torsion Springs Unique for B2B Applications?

Torsion springs are unique in their ability to store energy through rotational movement. Their design involves coils twisted around an axis, allowing them to exert a torque when twisted. They are commonly found in hinges, automotive applications, and various toys. For B2B buyers, understanding the specific torque requirements and installation space is vital when selecting torsion springs. The complexity of their design may lead to higher costs, but their effectiveness in torque applications often justifies the investment.

Why Consider Conical or Tapered Springs for Specialized Needs?

Conical or tapered springs are a specialized type of compression spring that decreases in diameter towards one end. This design allows for a more compact spring that can exert varying forces based on its position. They are particularly suitable for applications in specialized machinery and the automotive sector, where space and force characteristics are critical. Buyers should consider the specific application requirements and the complexity of manufacturing when opting for tapered springs, as they may involve higher production costs.

What are the Benefits and Limitations of Coiled Spring Pins?

Coiled spring pins are made from coiled wire and are designed for easy installation in assembly applications. They provide flexibility and strength, making them suitable for various machinery components. While they are cost-effective and straightforward to use, buyers should be aware of their limited load capacity compared to other spring types. It’s essential to evaluate the specific application requirements to ensure that coiled spring pins are the right choice for the intended use.

Key Industrial Applications of coiled spring

| Industry/Sector | Specific Application of coiled spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension Systems | Enhances vehicle stability and comfort for passengers | Material quality, load capacity, and corrosion resistance |

| Aerospace | Landing Gear Mechanisms | Ensures reliability and safety during takeoff and landing | Compliance with industry standards and weight considerations |

| Medical Devices | Surgical Instruments | Provides precise control and reliability in critical tasks | Biocompatibility, sterilization, and durability requirements |

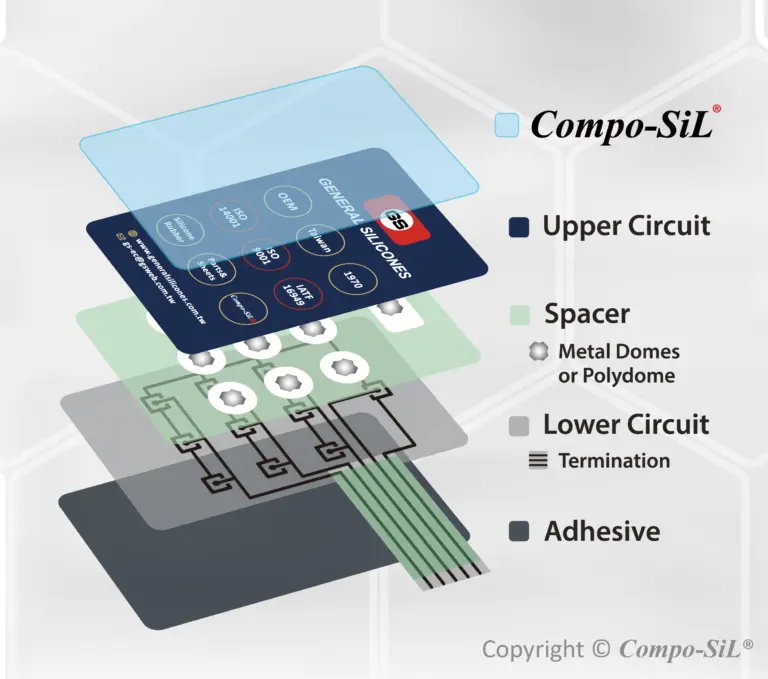

| Consumer Electronics | Keyboards and Remote Controls | Improves user experience through tactile feedback | Size, force exertion, and lifespan of the spring |

| Industrial Machinery | Machinery Controls | Facilitates smooth operation and reduces wear and tear | Customization options, load requirements, and environmental factors |

How Are Coiled Springs Used in the Automotive Sector?

In the automotive industry, coiled springs are integral to suspension systems, providing essential support and stability. They absorb shocks from the road, enhancing passenger comfort and vehicle handling. Buyers in this sector must consider factors such as material quality, load capacity, and corrosion resistance, especially in regions with extreme weather conditions, like those found in the Middle East and Africa. Ensuring compliance with safety regulations is also critical for international buyers.

What Role Do Coiled Springs Play in Aerospace Applications?

Coiled springs are vital in aerospace, particularly in landing gear mechanisms, where they absorb and dissipate energy during landing. Their reliability is paramount for the safety of passengers and cargo. International buyers must focus on sourcing springs that meet stringent industry standards, including weight considerations and material strength, to ensure performance under varying atmospheric conditions. Compliance with aviation regulations is essential for suppliers aiming to penetrate this market.

Illustrative image related to coiled spring

How Are Coiled Springs Utilized in Medical Devices?

In the medical field, coiled springs are used in surgical instruments to provide precise control and reliability. They are crucial in devices where accurate motion is necessary, such as in surgical clamps and retractors. Buyers need to ensure that the springs are biocompatible and can withstand sterilization processes, which is vital for patient safety. Additionally, durability is a key consideration, as medical devices must operate effectively over extended periods, particularly in regions with limited access to replacement parts.

What Are the Benefits of Coiled Springs in Consumer Electronics?

In consumer electronics, coiled springs are commonly found in keyboards and remote controls, where they enhance user experience by providing tactile feedback. The design and specifications of these springs must align with the product’s ergonomics, ensuring comfort during use. Buyers should pay attention to the size, force exertion, and lifespan of the springs, as these factors directly impact product performance and user satisfaction. Sourcing from reliable manufacturers is crucial to maintain quality standards.

How Are Coiled Springs Applied in Industrial Machinery?

Coiled springs serve critical functions in industrial machinery, particularly in control mechanisms that require smooth operation. They help to reduce wear and tear on components, prolonging the life of machinery. When sourcing coiled springs for this application, businesses should consider customization options to meet specific load requirements and environmental factors, such as exposure to dust or moisture. Ensuring that the springs can withstand the operational stresses typical in industrial settings is vital for maintaining efficiency and reducing downtime.

3 Common User Pain Points for ‘coiled spring’ & Their Solutions

Scenario 1: Navigating the Complexity of Spring Specifications

The Problem: Many B2B buyers struggle with the intricacies of specifying coiled springs for their applications. The challenge often arises from the need to accurately determine the required dimensions, spring rate, and load capacity. This complexity can lead to costly mistakes, such as ordering springs that are either too weak to withstand operational demands or too strong, resulting in unnecessary expenses. Additionally, different types of coiled springs—compression, extension, and torsion—each have unique specifications that can confuse decision-makers.

The Solution: To avoid specification errors, buyers should engage in a thorough needs assessment before sourcing coiled springs. This involves clearly defining the application requirements, including load conditions, space constraints, and desired spring performance characteristics. Utilizing tools like spring calculators can greatly simplify this process. These calculators allow users to input parameters such as free length, deflected length, and load requirements to derive the necessary spring specifications. Furthermore, consulting with manufacturers or suppliers can provide valuable insights into material selection and design considerations, ensuring that the springs meet the exact needs of the application.

Illustrative image related to coiled spring

Scenario 2: Managing Quality Control and Consistency

The Problem: Ensuring the quality and consistency of coiled springs can be a major pain point for B2B buyers, especially when sourcing from multiple suppliers or overseas. Variations in manufacturing processes can lead to discrepancies in spring performance, affecting the reliability of the final product. This inconsistency can result in product failures, increased warranty claims, and damage to the buyer’s reputation in the market.

The Solution: Implementing a robust quality assurance process is critical for managing these challenges. Buyers should establish clear quality standards and communicate these requirements to suppliers upfront. Conducting regular audits of manufacturing facilities and requiring certificates of compliance can help ensure that the springs produced meet the specified standards. Additionally, investing in advanced testing methods, such as fatigue testing and dimensional inspections, can further validate spring performance. By fostering strong relationships with trusted suppliers and maintaining open lines of communication, buyers can enhance quality control and achieve greater consistency in their spring supply.

Scenario 3: Addressing Lead Times and Supply Chain Disruptions

The Problem: Lead times for coiled springs can often be unpredictable, particularly in today’s global supply chain landscape. This unpredictability can lead to production delays and missed deadlines, significantly impacting project timelines and costs. Buyers may find themselves in a bind, especially if they rely on just-in-time manufacturing practices or have tight schedules for product launches.

Illustrative image related to coiled spring

The Solution: To mitigate risks associated with lead times, buyers should adopt a proactive supply chain strategy. This includes diversifying their supplier base to avoid over-reliance on a single source, thereby reducing the impact of potential disruptions. Establishing long-term contracts with key suppliers can also provide more predictable lead times and priority service during peak demand periods. Additionally, buyers should maintain a safety stock of critical components, including coiled springs, to buffer against unexpected delays. Engaging in regular communication with suppliers about inventory levels and upcoming demands can help facilitate better planning and responsiveness. By taking these steps, buyers can enhance their operational resilience and maintain smoother production flows.

Strategic Material Selection Guide for coiled spring

What Are the Key Materials for Coiled Springs in B2B Applications?

When selecting materials for coiled springs, it’s essential to consider the specific performance requirements and environmental conditions they will face. Below is an analysis of four common materials used for coiled springs, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Music Wire

Key Properties: Music wire is a high-carbon steel known for its excellent tensile strength and fatigue resistance. It typically has a temperature rating up to 300°F (150°C) and can withstand moderate pressure.

Pros & Cons: The primary advantage of music wire is its high strength-to-weight ratio, making it suitable for applications requiring high load capacities. However, it is susceptible to corrosion if not properly treated, which may limit its use in humid or corrosive environments. Manufacturing music wire springs can be complex, requiring precision in winding and heat treatment.

Impact on Application: Music wire is commonly used in automotive and aerospace applications due to its strength and resilience. However, it may not be suitable for environments exposed to moisture without protective coatings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, as music wire may need to meet ASTM A228 specifications. In areas with high humidity, additional corrosion protection measures should be considered.

2. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and can handle temperatures up to 800°F (427°C). Its mechanical properties vary depending on the alloy, with common grades including 302 and 316.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for applications in harsh environments. However, it is generally more expensive than carbon steel and can be more challenging to manufacture due to its toughness.

Impact on Application: Stainless steel springs are often used in medical devices, food processing, and marine applications where corrosion resistance is critical. The choice of alloy can significantly affect the spring’s performance in specific media.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that meet their industry standards, such as DIN or JIS. Compliance with international standards for food safety or medical applications is crucial.

3. Oil-Tempered Steel

Key Properties: Oil-tempered steel is treated to enhance its strength and fatigue resistance, with a temperature rating similar to that of music wire. It exhibits good wear resistance and is less prone to deformation under load.

Pros & Cons: The advantage of oil-tempered steel is its balance of strength and ductility, making it suitable for high-stress applications. However, it may not offer the same level of corrosion resistance as stainless steel, which could limit its use in specific environments.

Impact on Application: This material is often used in automotive and industrial machinery springs, where high performance under load is essential. Its properties make it suitable for dynamic applications where springs experience repeated stress.

Considerations for International Buyers: Buyers should consider the local availability of oil-tempered steel and its compliance with ASTM A313 standards. Understanding the specific environmental conditions where the springs will be used is crucial for ensuring longevity.

4. Phosphor Bronze

Key Properties: Phosphor bronze is known for its excellent corrosion resistance and good electrical conductivity. It has a lower tensile strength compared to steel but offers superior fatigue resistance and thermal stability.

Pros & Cons: The main advantage of phosphor bronze is its resistance to corrosion and wear, making it suitable for applications in marine and electrical environments. However, its cost is generally higher than that of steel, and it may not be suitable for high-load applications.

Impact on Application: Phosphor bronze springs are commonly used in electrical connectors and marine applications, where corrosion resistance is paramount. Its properties make it ideal for applications requiring both mechanical and electrical performance.

Considerations for International Buyers: Buyers should ensure that phosphor bronze meets local standards for electrical applications. Awareness of the material’s properties in different climates, especially in humid regions, is essential for ensuring optimal performance.

Summary Table of Material Selection for Coiled Springs

| Material | Typical Use Case for Coiled Spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Music Wire | Automotive, aerospace | High strength-to-weight ratio | Susceptible to corrosion | Medium |

| Stainless Steel | Medical devices, food processing | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Oil-Tempered Steel | Industrial machinery | Good balance of strength and ductility | Limited corrosion resistance | Medium |

| Phosphor Bronze | Electrical connectors, marine | Superior corrosion resistance | Lower tensile strength | High |

This guide provides a comprehensive overview of material options for coiled springs, emphasizing the importance of selecting the right material based on application requirements and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for coiled spring

What Are the Main Stages in the Manufacturing Process of Coiled Springs?

The manufacturing of coiled springs involves several critical stages that ensure the final product meets the required specifications and performance standards. Understanding these stages helps B2B buyers assess potential suppliers more effectively.

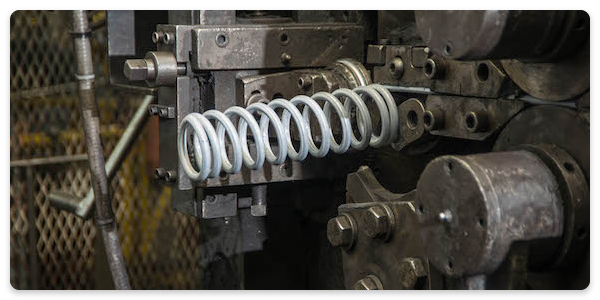

Illustrative image related to coiled spring

Material Preparation: What Materials Are Typically Used?

The process begins with the selection of appropriate materials, which often include high-carbon steel, stainless steel, or alloy steel, depending on the application requirements. The wire is sourced in various diameters, and the choice of material influences the spring’s strength, elasticity, and corrosion resistance. The wire is then subjected to processes like annealing, which improves its ductility and reduces brittleness, making it easier to work with in subsequent stages.

How Are Coiled Springs Formed?

Once the wire is prepared, the next stage is forming. This typically involves winding the wire around a mandrel to create the desired coil shape. The specific type of spring—compression, extension, or torsion—will determine the winding technique. For example, compression springs are created by winding the wire in a helical shape with specific pitch, while extension springs are wound tightly without any space between the coils. Advanced CNC machines often automate this process, ensuring precision and consistency in coil dimensions.

What Happens During Assembly and Finishing?

After forming, the springs may undergo assembly if they are part of a larger system or product. This stage may involve the addition of components like end fittings or attachments. Following assembly, springs are subjected to finishing processes such as shot peening, surface hardening, or coating to enhance their durability and performance. These treatments can help in mitigating issues like fatigue and corrosion, which are common in spring applications.

What Quality Control Measures Are Typically Implemented?

Quality assurance is paramount in the manufacturing of coiled springs, as they are often used in critical applications where failure can have serious consequences. B2B buyers must be aware of the quality control (QC) measures that suppliers employ to ensure product reliability.

Illustrative image related to coiled spring

Which International Standards Should B2B Buyers Consider?

Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on maintaining a quality management system. Additionally, industry-specific certifications like CE for European markets or API for oil and gas applications may also be relevant. These certifications provide assurance that the manufacturer meets certain quality and safety benchmarks.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are crucial throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections ensure that the production process remains within specified tolerances.

- Final Quality Control (FQC): Once the springs are completed, they undergo final inspection and testing to confirm that they meet the required specifications and performance standards.

How Are Coiled Springs Tested for Quality Assurance?

Testing methods vary based on the intended application of the coiled springs. Common testing methods include:

- Tensile Testing: Measures the spring’s strength and elasticity.

- Fatigue Testing: Assesses how the spring performs under repeated stress.

- Dimensional Inspection: Ensures that the spring meets the specified dimensions and tolerances.

- Surface Finish Inspection: Evaluates the quality of surface treatments applied to the springs.

What Should B2B Buyers Know About Verifying Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some strategies to consider:

How Can Buyers Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess the quality management systems in place. Buyers should look for evidence of compliance with international standards and industry-specific certifications. Audits can be scheduled regularly or on an as-needed basis, particularly before placing significant orders.

What Reports and Documentation Should Buyers Request?

Buyers should request quality reports, including IQC, IPQC, and FQC documentation. This information can provide insights into the supplier’s manufacturing processes, testing results, and compliance with quality standards.

Are Third-Party Inspections a Viable Option for Quality Assurance?

Third-party inspections can further assure buyers of the quality of coiled springs. Engaging an independent organization to conduct inspections can provide an unbiased evaluation of the supplier’s quality control practices and product performance.

What Are the Specific QC Considerations for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be mindful of specific quality control nuances. These include:

- Cultural and Regulatory Differences: Understanding the local regulations and cultural practices regarding quality standards is essential. Different regions may have varying expectations for quality assurance.

- Logistical Challenges: International shipping can pose risks to product integrity. Buyers should ensure that suppliers have robust packaging and handling procedures to protect springs during transport.

- Language Barriers: Clear communication is vital. Buyers should work with suppliers who can provide documentation and support in a language they understand to avoid misinterpretations.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for coiled springs is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing rigorous quality control measures, suppliers can deliver reliable and high-performance products that meet the diverse needs of international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coiled spring’

To assist B2B buyers in sourcing coiled springs effectively, this practical guide provides a structured checklist. Each step is designed to ensure a comprehensive understanding of your needs, supplier evaluation, and quality assurance.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of your coiled springs is crucial. Identify the type of spring needed (compression, extension, or torsion) based on your application. Consider dimensions, load capacity, material, and environmental conditions.

- Key Considerations:

- Determine the number of active coils and the spring’s end type, as these factors influence performance.

- Specify tolerances and any industry standards that must be met.

Step 2: Conduct Market Research

Before engaging with suppliers, perform thorough market research to understand industry trends and pricing. This step will help you identify potential suppliers and benchmark their offerings against your requirements.

- Action Points:

- Research various suppliers from different regions, particularly focusing on those with a strong presence in Africa, South America, the Middle East, and Europe.

- Gather insights on the typical lead times, pricing structures, and available customization options.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for suppliers with a proven track record in your industry and request company profiles, case studies, and references from buyers in a similar sector.

Illustrative image related to coiled spring

- What to Look For:

- Assess their production capabilities and whether they can meet your specific requirements.

- Verify their certifications and compliance with international quality standards, such as ISO 9001.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples to evaluate their products. This step is essential for assessing quality, performance, and suitability for your specific application.

- Testing Criteria:

- Check for consistent manufacturing quality and adherence to the specifications you provided.

- Perform load testing to ensure the springs meet your operational demands.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier holds relevant certifications that demonstrate their commitment to quality and safety standards. This verification is critical for minimizing risks associated with sourcing.

- Certifications to Consider:

- Look for ISO certifications, material certifications, and compliance with specific industry regulations that apply to your application.

- Confirm their quality assurance processes and whether they conduct regular audits.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that protect your interests. Discuss pricing, payment terms, delivery schedules, and warranty conditions.

- Negotiation Tips:

- Be clear about your expectations regarding quality and delivery timelines.

- Ensure that all agreements are documented to avoid any misunderstandings later.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your supplier can lead to better pricing, improved service, and more favorable terms in the long run. Regular communication is key to maintaining this relationship.

- Strategies for Engagement:

- Schedule periodic reviews to discuss performance and any potential improvements.

- Keep an open line of communication to address any issues promptly and efficiently.

By following this checklist, B2B buyers can streamline their sourcing process for coiled springs, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for coiled spring Sourcing

What Are the Key Cost Components in Coiled Spring Manufacturing?

When sourcing coiled springs, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of material used significantly impacts the cost. Common materials include carbon steel, stainless steel, and specialty alloys. Prices fluctuate based on market conditions, availability, and specifications. For example, high-strength alloys may incur higher material costs but offer better performance.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the manufacturing process. The complexity of the spring design and the level of craftsmanship required can lead to varying labor costs. In regions with a higher labor cost, such as Europe, these expenses can be a substantial portion of the total cost.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Custom tooling for specific spring designs can be a significant upfront investment. The costs of dies, molds, and other equipment must be factored in, especially for custom orders. In many cases, suppliers may share tooling costs with buyers, depending on the volume of the order.

-

Quality Control (QC): Ensuring that coiled springs meet quality standards requires investment in QC processes. This may involve testing, certifications, and compliance with industry standards, which can add to the overall cost.

-

Logistics: Shipping and handling costs depend on the destination, weight, and dimensions of the springs. International buyers should be aware of potential tariffs and customs duties that can affect the final pricing.

-

Margin: Suppliers will typically apply a margin on top of their costs to ensure profitability. This margin can vary widely based on market competition, the supplier’s positioning, and perceived value.

What Influences the Pricing of Coiled Springs?

Several factors can influence the pricing of coiled springs:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to negotiate Minimum Order Quantities (MOQs).

-

Specifications and Customization: Custom designs or specific tolerances can increase costs. When requesting quotes, clearly define specifications to avoid unexpected price increases.

-

Materials and Quality Certifications: The choice of materials and the presence of certifications (like ISO or ASTM) can impact pricing. Higher quality materials and certifications often justify higher prices.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and geographical location can affect pricing. Established suppliers may charge a premium for their reliability and experience.

-

Incoterms: The terms of shipping and responsibility for logistics can influence overall costs. Understanding Incoterms (like FOB, CIF, etc.) is crucial for international transactions.

How Can Buyers Negotiate for Better Prices on Coiled Springs?

-

Leverage Volume Discounts: Buyers should assess their purchasing needs and consider consolidating orders to qualify for volume discounts.

-

Explore Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the purchase price but the total cost over the lifecycle of the spring, including maintenance, replacement, and operational costs.

-

Understand Pricing Nuances: International buyers should be aware of fluctuations in currency exchange rates and economic conditions in the supplier’s country, which can affect pricing.

-

Build Long-Term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing, improved service, and priority during high-demand periods.

-

Be Prepared to Walk Away: Buyers should have a clear understanding of their budget and be willing to seek alternative suppliers if negotiations do not meet their financial criteria.

Conclusion: What Should International Buyers Keep in Mind?

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should approach coiled spring sourcing with a comprehensive understanding of cost structures, pricing influences, and negotiation strategies. Awareness of local market conditions, supplier capabilities, and logistical challenges can significantly enhance the procurement process. Always seek transparency in pricing and be proactive in discussions to ensure a mutually beneficial arrangement.

Disclaimer: Prices and costs mentioned are indicative and can vary based on market conditions, specifications, and supplier negotiations. Always consult with multiple suppliers for accurate quotes.

Alternatives Analysis: Comparing coiled spring With Other Solutions

Exploring Alternative Solutions to Coiled Springs

When considering mechanical solutions for energy storage and force application, coiled springs are a popular choice due to their versatility and reliability. However, various alternatives may offer distinct advantages depending on the specific application and requirements. This analysis compares coiled springs against two viable alternatives: Gas Springs and Leaf Springs.

Comparison Table

| Comparison Aspect | Coiled Spring | Gas Spring | Leaf Spring |

|---|---|---|---|

| Performance | High load capacity, reliable energy storage | Adjustable force, consistent performance | Excellent for heavy loads, good shock absorption |

| Cost | Generally low-cost | Moderate cost | Variable cost, can be expensive for heavy-duty designs |

| Ease of Implementation | Simple installation | Requires specific mounting | More complex installation due to size |

| Maintenance | Low maintenance | Moderate maintenance due to seals | Low maintenance, but requires periodic checks |

| Best Use Case | General applications like automotive, medical devices | Applications needing adjustable force (e.g., hoods, seats) | Heavy-duty applications (e.g., trucks, trailers) |

Detailed Breakdown of Alternatives

Gas Springs

Gas springs utilize compressed gas to provide force and are often adjustable, allowing for variable levels of support. They excel in applications where a consistent force is required, such as in automotive hoods or office chairs. One significant advantage is their ability to provide a smooth and controlled motion, which can enhance user experience. However, gas springs can be more expensive than coiled springs and may require more maintenance due to the seals that prevent gas leakage.

Leaf Springs

Leaf springs consist of multiple layers of metal that are stacked to form a spring. They are particularly effective in heavy-duty applications, such as in trucks or trailers, where they can absorb shocks and support substantial loads. The primary benefit of leaf springs is their durability and ability to handle large weight distributions. However, they can be more complex to install compared to coiled springs and may not be as efficient in smaller applications. Additionally, their variable cost can make them less appealing for budget-conscious projects.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate spring solution ultimately depends on the specific requirements of your application. Coiled springs are an excellent choice for general applications due to their affordability and ease of installation. However, if you require adjustable force or are working with heavy loads, exploring gas or leaf springs may provide better performance and efficiency. It’s essential to assess factors such as load capacity, installation complexity, and maintenance needs to ensure you choose the best solution for your business needs. By carefully evaluating these alternatives, B2B buyers can make informed decisions that enhance their operational efficiency and product performance.

Essential Technical Properties and Trade Terminology for coiled spring

What Are the Essential Technical Properties of Coiled Springs?

Understanding the technical properties of coiled springs is crucial for B2B buyers, particularly when selecting the right spring for specific applications. Here are some key specifications:

1. Material Grade

Coiled springs are typically made from various grades of steel, such as music wire, stainless steel, or high-carbon steel. The choice of material affects the spring’s strength, corrosion resistance, and fatigue life. For instance, stainless steel springs are ideal for applications in humid or corrosive environments, making them a preferred choice in sectors like automotive and medical devices.

2. Spring Rate

The spring rate, measured in pounds per inch (lb/in) or newtons per millimeter (N/mm), indicates how much force is needed to compress or extend the spring by a certain distance. A higher spring rate means a stiffer spring, which is essential for applications requiring greater load-bearing capabilities. Understanding this property helps buyers ensure that the spring will perform adequately under specified loads.

3. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. It is crucial for ensuring that the spring fits perfectly within its intended assembly. Tight tolerances are vital in precision applications, such as aerospace and medical devices, where even minor deviations can lead to malfunction or failure.

4. Free Length and Solid Height

Free length is the length of the spring when it is not under any load, while solid height refers to the length of the spring when fully compressed. These measurements are essential for fitting the spring into its designated space and ensuring it can operate effectively within its mechanical system.

5. Active and Inactive Coils

Active coils are those that contribute to the spring’s function, while inactive coils do not exert force. The configuration and number of active coils directly impact the spring’s strength and performance. Buyers should consider how different end types (open, closed, or ground) affect the number of active coils when specifying their requirements.

What Are Common Trade Terms Related to Coiled Springs?

Familiarity with trade terminology is equally important for effective communication and negotiation in the coiled spring industry. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for buyers looking to source springs that meet the exact requirements of their end products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand, especially when planning inventory and budgeting for purchases. Knowing the MOQ can help in negotiating bulk orders, which can lead to cost savings.

Illustrative image related to coiled spring

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. In the coiled spring industry, an RFQ typically includes detailed specifications, such as material, dimensions, and quantity. This process is vital for comparing prices and understanding the market landscape.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to manage shipping costs, risks, and delivery timelines effectively. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the coiled spring industry, lead times can vary based on production schedules and material availability. Buyers should consider lead times when planning their supply chain to avoid delays in their projects.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when procuring coiled springs, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the coiled spring Sector

What Are the Current Market Dynamics and Key Trends in the Coiled Spring Sector?

The coiled spring market is experiencing significant transformation driven by technological advancements and evolving industrial demands. Key global drivers include the increasing automation in manufacturing processes and the rise of smart technologies that require precise and durable components. In regions such as Africa, South America, the Middle East, and Europe, there is a growing emphasis on the customization of coiled springs to meet specific industry requirements, particularly in automotive, aerospace, and medical sectors. This trend is prompting suppliers to offer tailored solutions that cater to the unique specifications of local markets.

Emerging B2B technologies, such as advanced manufacturing techniques, 3D printing, and digital supply chain management, are reshaping how coiled springs are produced and sourced. These technologies not only enhance efficiency but also allow for rapid prototyping and shorter lead times, which are critical for businesses looking to remain competitive. Furthermore, international buyers are increasingly leveraging e-commerce platforms and digital marketplaces to streamline their sourcing processes, providing access to a broader range of suppliers and products.

Market dynamics are also influenced by fluctuating raw material prices, which can impact the cost of coiled springs. Buyers must remain vigilant in monitoring these fluctuations and consider establishing long-term contracts with suppliers to mitigate risks. Additionally, the focus on quality and performance is leading to a growing demand for high-performance materials, making it essential for buyers to partner with reputable manufacturers who prioritize quality assurance.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Coiled Spring Industry?

Sustainability has become a pivotal concern in the coiled spring sector, influencing purchasing decisions and supplier relationships. The environmental impact of manufacturing processes, particularly those involving non-renewable resources, is prompting buyers to seek suppliers that prioritize sustainable practices. This includes the use of recycled materials and energy-efficient production methods, which not only reduce the carbon footprint but also appeal to environmentally conscious consumers.

Ethical sourcing is gaining traction as businesses recognize the importance of maintaining transparent supply chains. Buyers are increasingly interested in suppliers that adhere to ethical labor practices and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for evaluating potential suppliers.

Incorporating ‘green’ certifications and materials into sourcing strategies not only enhances a company’s reputation but can also lead to cost savings in the long run. For example, utilizing materials that are both sustainable and high-performing can result in longer-lasting products, reducing the need for frequent replacements. As the demand for sustainable products continues to rise, B2B buyers in the coiled spring market must prioritize partnerships with suppliers that align with their sustainability goals and ethical standards.

Illustrative image related to coiled spring

What Is the Historical Context of Coiled Springs in B2B Applications?

The evolution of coiled springs dates back to the early industrial revolution, where they were primarily utilized in machinery and transportation. Initially crafted from wrought iron, advancements in material science led to the use of high-carbon steel and other alloys, enhancing the performance and durability of coiled springs. Over the decades, the introduction of mass production techniques further streamlined their manufacturing, making them more accessible to various industries.

As technology progressed, the applications for coiled springs expanded significantly. Today, they are critical components in a myriad of products ranging from consumer electronics to complex automotive systems. The historical context of coiled springs not only highlights their versatility but also underscores the importance of innovation in meeting the ever-changing demands of global markets. B2B buyers must appreciate this evolution to better understand the capabilities and future potential of coiled springs in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of coiled spring

-

How do I choose the right coiled spring for my application?

Choosing the right coiled spring involves considering the spring type (compression, extension, or torsion) based on the force requirements and movement direction. Evaluate the spring’s dimensions, including wire diameter, coil count, and overall length. Additionally, assess the specific load and deflection needs of your project, as well as environmental factors such as temperature and corrosion resistance. Utilizing a spring calculator can help ensure precise specifications are met, and consulting with suppliers can provide insights tailored to your application. -

What is the best material for coiled springs used in harsh environments?

For applications in harsh environments, stainless steel is often the best material for coiled springs due to its excellent corrosion resistance and durability. Other options include high-carbon steel for strength and fatigue resistance, or specialty alloys designed for specific applications, such as aerospace or automotive. It’s important to consider factors like temperature, moisture, and exposure to chemicals when selecting the material to ensure the longevity and performance of the spring. -

What customization options are available for coiled springs?

Most suppliers offer a range of customization options for coiled springs, including varying wire diameters, coil counts, end types, and heat treatments. Custom lengths and diameters can also be specified to meet unique application requirements. Some manufacturers provide prototyping services, allowing buyers to test springs before full production. Discussing specific needs with suppliers can lead to tailored solutions that optimize performance and efficiency for your projects. -

What are the typical minimum order quantities (MOQs) for coiled springs?

Minimum order quantities (MOQs) for coiled springs can vary widely among suppliers, typically ranging from a few dozen to several hundred pieces, depending on the complexity and customization of the springs. For standard springs, MOQs tend to be lower, while custom-designed springs may have higher MOQs due to production setup costs. It’s advisable to communicate your requirements upfront with potential suppliers to ensure they can accommodate your needs within acceptable MOQs. -

How can I ensure the quality of coiled springs from international suppliers?

To ensure quality when sourcing coiled springs internationally, verify the supplier’s certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples to assess material quality and performance under your application conditions. Additionally, consider conducting a factory audit or utilizing third-party inspection services to evaluate manufacturing processes. Clear communication about quality expectations and specifications is also critical to maintaining standards. -

What payment terms should I expect when sourcing coiled springs internationally?

Payment terms can vary significantly based on the supplier and the nature of the transaction. Common terms include advance payment, net 30, or net 60, where payment is due within 30 or 60 days after invoice receipt. Some suppliers may also offer payment through letters of credit, which provides security for both parties. It’s essential to discuss and negotiate payment terms upfront to ensure they align with your cash flow and budgeting needs. -

What logistics considerations should I keep in mind when importing coiled springs?

When importing coiled springs, consider shipping methods (air vs. sea), customs regulations, and potential tariffs or duties that may apply. Collaborating with a logistics provider experienced in international trade can help navigate these complexities. Ensure that the supplier provides accurate documentation, including certificates of origin and compliance, to facilitate a smooth customs clearance process. Lastly, factor in lead times for production and shipping to align with your project timelines. -

How do I handle potential issues or disputes with my coiled spring supplier?

To handle potential issues or disputes with your coiled spring supplier, establish clear communication channels and document all agreements in writing. If problems arise, address them promptly with the supplier, providing specific details and evidence of the issue. Many suppliers value long-term relationships and may be willing to negotiate solutions, such as refunds or replacements. If resolution cannot be reached, consider mediation or legal options, depending on the severity of the issue and the terms outlined in your contract.

Top 5 Coiled Spring Manufacturers & Suppliers List

1. MasterSpring – Coil Springs

Domain: masterspring.com

Registered: 1998 (27 years)

Introduction: Coil springs are helical-shaped mechanical devices that store mechanical potential energy. They can be made from elastic materials or metals like hardened steel. Common applications include clocks, automobiles, retractable pens, door handles, toasters, gates, toys (e.g., Slinky), and garage doors. Master Spring offers custom coil springs including compression springs (helical, conical, barrel, hou…

2. MW Components – Coil Springs & Custom Solutions

Domain: mwcomponents.com

Registered: 2017 (8 years)

Introduction: Coil Springs – Suspension Coil, Compression, Extension & More | MW Components. Product categories include Custom Springs, Hot Wound Springs, Coiled Springs, Compression Springs, Extension Springs, Torsion Springs, Automotive Springs, Drawbar Springs, Constant Force Springs, Belleville Washers / Disc Springs, Flat Springs, Machined Springs, POP Display Solutions, Spring Anchors, Urethane Springs, W…

3. Lesjofors – Coil Springs

Domain: lesjoforssprings.com

Registered: 2021 (4 years)

Introduction: Coil springs are mechanical devices made from elastic materials, coiled into a helical shape, used to absorb shock, maintain force, support structures, and facilitate controlled movement in various mechanical applications. There are three main types of coil springs: compression springs, tension springs (extension springs), and torsion springs. Compression springs store and release energy under com…

4. Forum – Coiled Spring

Domain: forum.wordreference.com

Registered: 1999 (26 years)

Introduction: This company, Forum – Coiled Spring, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. McMaster – Spring Pins Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Spring Pins Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for coiled spring

How Can Strategic Sourcing Enhance Your Coiled Spring Procurement?

In conclusion, strategic sourcing is essential for B2B buyers looking to optimize their procurement of coiled springs. By understanding the various types of coiled springs—compression, extension, and torsion—buyers can make informed decisions that align with their specific application needs. The nuances of spring design, including the impact of active and inactive coils, can significantly affect performance and longevity, making it crucial to collaborate with suppliers who offer customizable solutions.

International buyers from regions such as Africa, South America, the Middle East, and Europe should leverage strategic sourcing not only to reduce costs but also to ensure quality and reliability in their supply chains. Engaging with trusted manufacturers who understand local market dynamics can lead to better pricing strategies and improved service levels.

As you move forward, consider evaluating your current sourcing strategies and exploring new partnerships that can enhance your supply chain resilience. The future of coiled spring procurement is promising, and by taking proactive steps today, you position your business for success in an increasingly competitive landscape. Connect with suppliers who can provide innovative solutions tailored to your needs, and stay ahead of the curve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to coiled spring

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.