Top 5 Automotive Bolt Suppliers (And How to Choose)

Introduction: Navigating the Global Market for automotive bolt

Navigating the global market for automotive bolts presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Sourcing reliable automotive bolts that meet specific application requirements can be daunting, given the vast array of products available and the varying standards across regions. This comprehensive guide aims to demystify the complexities of automotive bolt procurement by providing insights into different types, applications, and industry standards.

Buyers will discover crucial information on how to vet suppliers effectively, ensuring that quality and compliance standards are met. The guide also covers pricing dynamics and factors influencing costs, enabling businesses to make informed budgetary decisions. Additionally, it highlights the importance of understanding material specifications and grades, which are essential for ensuring safety and durability in automotive applications.

By equipping B2B buyers with actionable insights and best practices, this guide empowers them to navigate the intricacies of the automotive bolt market confidently. Whether you are looking to source bolts for production lines, aftermarket repairs, or specialized applications, the knowledge shared herein will facilitate smarter purchasing decisions that align with your business goals.

Understanding automotive bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Bolt | Hexagonal head, often used with a wrench | Engine assembly, chassis mounting | Pros: High strength; easy to install. Cons: Can seize if not properly lubricated. |

| Flange Bolt | Integrated washer, provides load distribution | Body panels, wheel attachments | Pros: Reduces risk of loosening; simplifies installation. Cons: Limited adjustment once installed. |

| Carriage Bolt | Round head, square neck prevents spinning | Wood applications, frame repairs | Pros: Secure fastening; prevents loosening. Cons: Requires pre-drilled holes. |

| Specialty Bolt | Custom designs for specific applications | Unique automotive components | Pros: Tailored solutions; enhances performance. Cons: Higher cost and longer lead times. |

| Machine Screw | Threaded along the entire length, flat or round head | Electrical components, interior fixtures | Pros: Versatile; available in various sizes. Cons: May not provide as strong a hold as bolts. |

What Are the Characteristics of Hex Head Bolts in Automotive Applications?

Hex head bolts are among the most commonly used fasteners in automotive applications. Their hexagonal shape allows for easy installation and removal using standard wrenches. Typically made from high-strength materials, these bolts are used in critical areas such as engine assembly and chassis mounting. When purchasing hex head bolts, consider the grade and coating, as these factors influence strength and corrosion resistance. Proper lubrication is crucial to prevent seizing, especially in high-stress environments.

How Do Flange Bolts Enhance Automotive Assembly?

Flange bolts are characterized by their built-in washer, which distributes load evenly across the surface. This feature reduces the chances of loosening due to vibration, making them ideal for applications like body panels and wheel attachments. For B2B buyers, flange bolts offer ease of installation and reliability. However, once installed, they provide limited adjustment options, so precise alignment during installation is essential. Sourcing high-quality flange bolts can enhance the durability of automotive assemblies.

What Makes Carriage Bolts Suitable for Frame Repairs?

Carriage bolts have a unique design featuring a round head and a square neck that prevents spinning when tightened. This design makes them particularly useful in applications where a secure fastening is required, such as in wood applications and frame repairs. B2B buyers should note that carriage bolts require pre-drilled holes, which can add to installation time. However, their ability to maintain a tight grip makes them a preferred choice for many automotive repair tasks.

Why Choose Specialty Bolts for Unique Automotive Components?

Specialty bolts are designed for specific applications and often feature custom designs to meet unique requirements. These bolts are essential for specialized automotive components that demand high performance. While they provide tailored solutions that can enhance overall vehicle performance, the cost is typically higher, and lead times may be longer compared to standard bolts. B2B buyers should evaluate the performance benefits against the cost implications when considering specialty bolts for their projects.

How Do Machine Screws Differ from Traditional Bolts?

Machine screws are fully threaded fasteners that can be used in a variety of applications, including securing electrical components and interior fixtures. Their versatility and availability in multiple sizes make them a go-to option for many automotive applications. However, machine screws may not provide the same strength as traditional bolts, especially in high-stress situations. B2B buyers should assess the specific requirements of their applications to determine if machine screws are a suitable choice.

Key Industrial Applications of automotive bolt

| Industry/Sector | Specific Application of automotive bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine assembly and mounting | Ensures structural integrity and performance of vehicles | Material specifications, corrosion resistance, and grade |

| Heavy Machinery | Frame and chassis assembly | Provides durability and safety in heavy-duty applications | Load capacity, compliance with international standards |

| Transportation and Logistics | Trailer coupling and hitch systems | Enhances safety and reliability in transportation | Compatibility with existing systems and material strength |

| Automotive Repair and Maintenance | Replacement of worn-out fasteners | Reduces downtime and enhances vehicle performance | Availability of OEM specifications and quick delivery |

| Aerospace and Defense | Specialized fastening in aircraft components | Ensures safety and performance in critical applications | Compliance with military and aviation standards |

How Are Automotive Bolts Used in Automotive Manufacturing?

In the automotive manufacturing sector, bolts are crucial for engine assembly and mounting. They secure engine components, ensuring structural integrity and optimal performance of vehicles. Buyers in this sector must prioritize material specifications, corrosion resistance, and the appropriate grade of bolts to meet the demands of high-performance engines. With a focus on quality, manufacturers can enhance vehicle longevity and reduce warranty claims.

What Role Do Automotive Bolts Play in Heavy Machinery?

Heavy machinery relies on automotive bolts for frame and chassis assembly. These bolts must withstand significant loads and vibrations, providing durability and safety in demanding environments. For international buyers, especially in regions like Africa and South America where infrastructure projects are ramping up, sourcing bolts that comply with international standards is essential. Load capacity and material quality are critical factors that can influence project outcomes.

How Are Automotive Bolts Essential in Transportation and Logistics?

In the transportation and logistics industry, automotive bolts are vital for trailer coupling and hitch systems. They enhance safety and reliability, ensuring that cargo is securely transported. Buyers should consider compatibility with existing systems and the strength of materials used in these bolts to prevent failures during transit. This is particularly important for international buyers who may face varying regulations and standards across different regions.

Why Are Automotive Bolts Important for Automotive Repair and Maintenance?

Automotive bolts are frequently used in repair and maintenance scenarios, especially for replacing worn-out fasteners. Using high-quality bolts reduces downtime and enhances vehicle performance, making them a critical component for automotive service providers. Buyers must ensure that they have access to OEM specifications and quick delivery options, particularly in regions where vehicle repair services are in high demand.

What Are the Applications of Automotive Bolts in Aerospace and Defense?

In the aerospace and defense sectors, automotive bolts are used for specialized fastening in aircraft components. These bolts must meet rigorous safety and performance standards due to the critical nature of their applications. Buyers in this industry need to ensure compliance with military and aviation standards, focusing on the reliability and strength of the fasteners. This attention to detail is essential to maintain the safety and integrity of aerospace operations.

3 Common User Pain Points for ‘automotive bolt’ & Their Solutions

Scenario 1: Sourcing the Right Automotive Bolt for Specific Applications

The Problem: B2B buyers often struggle with identifying the correct type and grade of automotive bolts needed for various applications. This challenge is exacerbated by the wide variety of bolts available, each designed for specific functions such as holding body panels, securing engines, or fastening wheels. Misidentifying the right bolt not only leads to delays in production but can also compromise the safety and performance of vehicles. This issue is particularly pressing for buyers in regions with diverse automotive needs, such as Africa and South America, where local supply may vary significantly.

Illustrative image related to automotive bolt

The Solution: To effectively source the right automotive bolt, buyers should begin by thoroughly understanding the specifications required for their applications. This includes knowing the required bolt grade, thread type, and material. Collaborating with manufacturers or suppliers that offer customized solutions can also be beneficial. For instance, consider suppliers that provide detailed catalogs with specifications for each bolt type, including dimensions, materials, and suitable applications. Additionally, utilizing digital tools and platforms that allow for easy comparison of products can streamline the selection process. Implementing a thorough inventory management system to track the types and quantities of bolts used can prevent sourcing mistakes and ensure that the correct fasteners are always on hand.

Scenario 2: Managing Inventory for Automotive Fasteners

The Problem: Managing inventory for automotive bolts can be a daunting task, especially for businesses that handle a wide range of vehicle types and applications. Frequent stockouts can lead to project delays, while overstocking can tie up capital in unused inventory. This balancing act is complicated by fluctuating demand and the need for specific fastener types that may not be readily available in the local market, particularly in regions like the Middle East and parts of Europe.

The Solution: Implementing an efficient inventory management system is crucial for addressing this pain point. Buyers should consider using inventory management software that tracks usage patterns and forecasts future needs based on historical data. Additionally, establishing relationships with multiple suppliers can ensure a steady flow of necessary fasteners and allow for quicker replenishment. Regularly reviewing inventory levels and adjusting orders based on seasonal trends or project demands can help maintain the right balance. For businesses operating in multiple regions, creating a centralized database of fastener specifications can aid in quicker decision-making when sourcing bolts.

Scenario 3: Ensuring Compliance with Automotive Standards

The Problem: B2B buyers in the automotive sector often face challenges in ensuring that the bolts they procure meet regional and international standards for safety and performance. Non-compliance can lead to legal repercussions and damage to reputation, especially in stringent markets like Germany or when exporting to other regions. Furthermore, with varying standards across countries, keeping up with compliance requirements can be overwhelming.

The Solution: To navigate compliance challenges, buyers should invest time in understanding the relevant automotive standards and regulations applicable in their target markets. This includes familiarizing themselves with the SAE (Society of Automotive Engineers) standards and ISO (International Organization for Standardization) specifications for fasteners. Working closely with suppliers that have a robust quality assurance process and certification can significantly mitigate risks. It’s also advisable to request documentation and certifications for all bolts purchased, ensuring they meet the required specifications. Regular training sessions for procurement teams on compliance and quality assurance can further enhance a company’s ability to maintain high standards in their sourcing practices. By prioritizing compliance, buyers not only safeguard their operations but also enhance trust with customers and partners.

Strategic Material Selection Guide for automotive bolt

When selecting materials for automotive bolts, it is essential to consider various factors that can impact performance, durability, and cost. Below, we analyze four common materials used in automotive bolts, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Steel for Automotive Bolts?

Steel is the most widely used material for automotive bolts due to its excellent mechanical properties. Key properties include high tensile strength, good ductility, and the ability to withstand high temperatures and pressures. Steel bolts can also be treated with various coatings to enhance corrosion resistance, making them suitable for diverse environments.

Pros & Cons: Steel bolts offer high durability and strength, making them ideal for critical applications like engine components and chassis. However, they can be prone to rust if not properly coated, and their manufacturing process can be complex, impacting costs.

Impact on Application: Steel bolts are compatible with a wide range of automotive applications, including those exposed to high stress and temperature. However, their susceptibility to corrosion may limit their use in coastal areas or environments with high humidity.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A307 or DIN 931. In regions like Europe and the Middle East, buyers often prefer bolts with specific corrosion-resistant coatings to meet environmental regulations.

How Does Stainless Steel Compare for Automotive Bolts?

Stainless steel is known for its superior corrosion resistance, making it an excellent choice for automotive applications exposed to moisture and chemicals. Its key properties include high strength, durability, and the ability to withstand extreme temperatures.

Pros & Cons: The primary advantage of stainless steel bolts is their resistance to rust and corrosion, which extends their lifespan. However, they are generally more expensive than standard steel bolts and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel bolts are particularly suitable for automotive applications in humid or corrosive environments, such as marine vehicles or regions with heavy rainfall.

Considerations for International Buyers: Compliance with standards such as ASTM A193 or JIS G4305 is crucial. Buyers in Africa and South America may need to consider local availability and pricing, as stainless steel can be significantly more costly.

What Are the Benefits of Using Aluminum for Automotive Bolts?

Aluminum bolts are lightweight and offer good corrosion resistance, making them an attractive option for applications where weight savings are critical, such as in performance vehicles.

Pros & Cons: The main advantage of aluminum bolts is their lightweight nature, which can improve fuel efficiency and performance. However, they have lower tensile strength compared to steel, making them less suitable for high-stress applications.

Impact on Application: Aluminum bolts work well in non-structural applications or where weight reduction is a priority. They are often used in trim pieces, body panels, and other components where strength is not the primary concern.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades and their properties, such as 6061 or 7075, which may be subject to different standards in various regions. Additionally, the cost of aluminum can fluctuate, impacting budget considerations.

How Do Composite Materials Perform in Automotive Bolt Applications?

Composite materials, such as reinforced plastics or carbon fiber composites, are increasingly being used for automotive bolts, especially in lightweight and high-performance vehicles. They offer unique properties, including low weight and resistance to corrosion.

Pros & Cons: The primary advantage of composite bolts is their lightweight nature, which can significantly reduce overall vehicle weight. However, they may not provide the same level of strength as metal bolts and can be more expensive to produce.

Illustrative image related to automotive bolt

Impact on Application: Composite bolts are ideal for applications where weight reduction is critical, such as in electric vehicles or racing cars. However, they may not be suitable for high-load applications due to their lower tensile strength.

Considerations for International Buyers: Buyers should consider the specific applications and standards applicable to composite materials. Compliance with industry standards and certifications is essential, particularly in Europe, where regulations around lightweight materials are evolving.

Summary Table of Material Selection for Automotive Bolts

| Material | Typical Use Case for automotive bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Engine components, chassis, high-stress applications | High strength and durability | Prone to corrosion without coating | Medium |

| Stainless Steel | Humid or corrosive environments, marine vehicles | Superior corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Non-structural applications, trim pieces | Lightweight, improves efficiency | Lower tensile strength | Medium |

| Composite | Lightweight vehicles, performance applications | Significant weight reduction | Lower strength, higher production cost | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties and applications of various materials used in automotive bolts. Understanding these factors will help in making informed purchasing decisions tailored to specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive bolt

When considering the manufacturing processes and quality assurance protocols for automotive bolts, it is crucial for B2B buyers to understand the stages involved and the standards that govern the quality of these components. This knowledge not only ensures the reliability and safety of the products but also facilitates smoother transactions and partnerships across international markets.

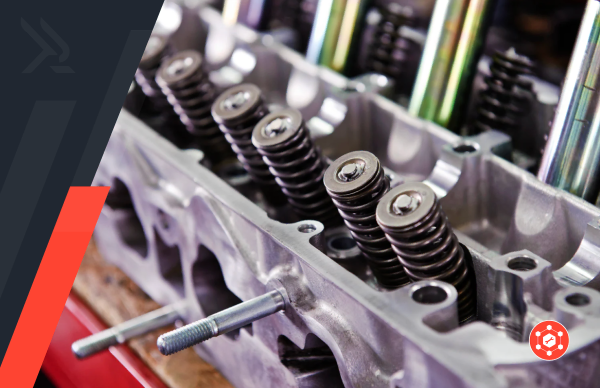

What Are the Main Stages in the Manufacturing Process of Automotive Bolts?

Material Preparation

The manufacturing of automotive bolts begins with the selection and preparation of raw materials, typically high-strength steel or alloy steel. The material is often sourced based on specific strength requirements and should comply with international standards. The preparation phase involves cutting the material into specified lengths, followed by processes like heat treatment to enhance the mechanical properties of the steel, ensuring that it meets the necessary strength and durability criteria for automotive applications.

Forming Techniques

Forming is the next critical stage where various techniques such as cold forging, hot forging, or machining are employed to shape the bolts. Cold forging is particularly popular due to its cost-effectiveness and ability to produce high-strength parts with a fine surface finish. During this stage, the raw material is shaped under high pressure without exceeding its recrystallization temperature, allowing for improved material properties. Other techniques may include thread rolling, which creates the bolt threads through deformation, enhancing the bolt’s tensile strength and fatigue resistance.

Assembly and Finishing Processes

Once formed, the bolts undergo assembly, which may involve adding specific features like washers or nuts depending on the design requirements. The finishing process is vital as it ensures corrosion resistance and enhances the aesthetic appeal of the bolts. Common finishing techniques include galvanization, zinc plating, and black oxide coating. Each of these methods not only improves the appearance but also protects the bolts from environmental factors that could lead to rust or degradation over time.

Illustrative image related to automotive bolt

How Is Quality Assurance Implemented in Automotive Bolt Manufacturing?

What International Standards Are Relevant for Automotive Bolt Quality?

Quality assurance in the automotive industry is governed by a range of international standards, with ISO 9001 being the most widely recognized. This standard focuses on ensuring a systematic approach to quality management and continuous improvement in manufacturing processes. Other industry-specific standards include CE marking, which is essential for products marketed within the European Union, and API specifications for bolts used in oil and gas applications. Understanding these standards is crucial for B2B buyers to ensure that the products they source are compliant with regulatory requirements.

What Are the Key Quality Control Checkpoints?

The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter the production process.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, random sampling and testing are performed to detect any deviations from quality standards early. This may include dimensional checks and mechanical property tests.

– Final Quality Control (FQC): At the end of the manufacturing process, finished bolts undergo rigorous testing, including tensile strength tests, surface finish checks, and dimensional inspections to ensure they meet all specifications.

What Testing Methods Are Commonly Used for Automotive Bolts?

Common testing methods for automotive bolts include:

– Tensile Testing: Measures the force required to pull the bolt to its breaking point, providing insights into its strength.

– Hardness Testing: Determines the material’s resistance to deformation and wear, which is critical for performance in automotive applications.

– Salt Spray Testing: Assesses the corrosion resistance of the finishing treatments applied to the bolts, simulating long-term exposure to harsh environments.

How Can B2B Buyers Verify Supplier Quality Control?

What Are the Best Practices for Supplier Audits?

B2B buyers can implement several best practices to verify a supplier’s quality control measures:

– Conducting Supplier Audits: Regular audits of manufacturing facilities can help assess compliance with quality standards and uncover any potential issues in the production process.

– Requesting Quality Assurance Documentation: Buyers should ask for documentation such as quality control reports, inspection records, and certificates of compliance to verify the supplier’s adherence to international standards.

– Third-Party Inspections: Engaging independent third-party inspection services can provide unbiased evaluations of product quality and manufacturing practices.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is essential. Different countries may have specific certifications that are required for automotive components, such as the ECE Regulation in Europe or local safety standards in the Middle East. Buyers should also be aware of the logistical aspects of quality control, including the potential for delays in shipping and the impact of tariffs on the cost of compliance.

Additionally, cultural differences in business practices can affect how quality assurance is perceived and implemented. Establishing clear communication channels and expectations with suppliers can help mitigate these challenges and foster stronger partnerships.

Conclusion

In summary, the manufacturing processes and quality assurance protocols for automotive bolts are intricate and governed by stringent standards. B2B buyers must be proactive in understanding these processes, implementing rigorous supplier verification practices, and ensuring compliance with international regulations. By doing so, they can secure high-quality components that meet the demanding needs of the automotive industry, ultimately leading to safer and more reliable vehicles.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive bolt’

In the competitive landscape of automotive parts procurement, sourcing automotive bolts requires a systematic approach. This guide provides a step-by-step checklist tailored for B2B buyers aiming to secure high-quality bolts for their projects, ensuring that all critical aspects are covered to facilitate informed decision-making.

Illustrative image related to automotive bolt

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the automotive bolts you need. Consider factors such as size, material, grade, and thread type. This clarity will help narrow down your options and ensure compatibility with your vehicle or project specifications.

- Materials: Determine whether you require stainless steel, carbon steel, or alloy options based on environmental conditions and load requirements.

- Grades: Familiarize yourself with the necessary strength grades (e.g., SAE or metric) to ensure that the bolts can withstand operational stresses.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in automotive bolts. Utilize industry-specific directories, trade shows, and online marketplaces to compile a list of potential vendors.

- Supplier Reputation: Look for reviews, ratings, and testimonials from other B2B buyers to gauge reliability and product quality.

- Market Presence: Consider suppliers with a strong presence in regions relevant to your operations, such as Europe or the Middle East, to ensure logistical efficiency.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with industry standards. This is crucial for ensuring product quality and safety.

Illustrative image related to automotive bolt

- Quality Assurance: Check for ISO certifications or other relevant quality management systems that indicate adherence to high manufacturing standards.

- Material Compliance: Ensure that the bolts meet specific regulations applicable in your region, such as RoHS or REACH in Europe.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the bolts for testing. This step allows you to evaluate the product firsthand.

- Testing for Compatibility: Assess the samples for fitment and performance under simulated operational conditions.

- Quality Checks: Look for consistency in dimensions, finish, and tensile strength to ensure they meet your specified criteria.

Step 5: Compare Pricing and Terms

Obtain detailed quotes from multiple suppliers and compare pricing, payment terms, and delivery schedules. This will help you identify the best overall value.

- Total Cost of Ownership: Consider not just the upfront costs but also shipping, customs duties, and potential tariffs that could affect your budget.

- Negotiation: Use your findings to negotiate better terms or volume discounts, particularly if you’re planning to make larger purchases.

Step 6: Confirm Logistics and Delivery Options

Evaluate the logistics capabilities of your chosen supplier to ensure timely delivery. Understand their shipping methods, lead times, and return policies.

- Regional Considerations: For international buyers, check if the supplier can handle customs clearance and local delivery efficiently.

- Tracking and Communication: Ensure that the supplier provides tracking options and clear communication regarding shipment status.

Step 7: Establish Long-Term Relationships

Once you’ve successfully sourced your automotive bolts, consider establishing a long-term relationship with the supplier. This can lead to better pricing, priority service, and tailored solutions for future needs.

- Feedback Loop: Maintain open communication to provide feedback and discuss any issues that may arise with the products.

- Future Collaboration: Explore opportunities for collaborative projects or bulk purchasing agreements that can benefit both parties.

By following these steps, B2B buyers can confidently navigate the sourcing process for automotive bolts, ensuring they acquire the right products to meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for automotive bolt Sourcing

What Are the Key Cost Components in Automotive Bolt Sourcing?

When sourcing automotive bolts, understanding the cost structure is critical for B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for automotive bolts are alloy steel, stainless steel, and carbon steel, with prices varying based on availability and market demand. Specialized coatings for corrosion resistance can also add to material costs.

-

Labor: Labor costs encompass the expenses associated with manufacturing the bolts, including wages for workers, benefits, and training. Countries with higher labor costs, like Germany, may see increased pricing compared to regions with lower labor expenses, such as parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and other indirect expenses. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: The initial setup for manufacturing specialized bolts often requires significant investment in tooling. Custom designs or unique specifications may require bespoke tooling, increasing upfront costs.

-

Quality Control (QC): Ensuring that bolts meet safety and performance standards is crucial. Quality control processes, including testing and inspections, add to the overall cost but are essential for maintaining product integrity.

-

Logistics: Transporting bolts from manufacturers to buyers involves shipping, handling, and storage costs. Buyers should consider the distance from the supplier, as international shipping can add significant expenses, especially under certain Incoterms.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market competition, demand, and the supplier’s positioning within the market.

How Do Price Influencers Affect Automotive Bolt Costs?

Several factors can influence the pricing of automotive bolts:

-

Volume/MOQ: Bulk orders often result in lower per-unit costs due to economies of scale. Buyers should consider Minimum Order Quantities (MOQs) and negotiate for better pricing based on their purchasing power.

-

Specifications/Customization: Customized bolts tailored to specific applications can significantly increase costs. Standardized products are typically more economical.

-

Materials: The choice between standard and premium materials can lead to price variations. For instance, bolts made from high-grade stainless steel are generally more expensive than those made from carbon steel.

-

Quality/Certifications: Higher-quality bolts that meet stringent certifications (like ISO or ASTM standards) often command premium prices. Buyers should evaluate the importance of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more due to their quality assurance processes and customer service.

-

Incoterms: The terms of trade impact total costs. Buyers should understand who bears the cost of shipping, insurance, and tariffs to make informed purchasing decisions.

What Tips Can Help Buyers Negotiate Better Prices for Automotive Bolts?

-

Effective Negotiation: Engage in open discussions with suppliers about pricing, especially when placing large orders. Suppliers may be willing to offer discounts or flexible payment terms to secure your business.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes the initial purchase price, maintenance, and replacement costs over time. Sometimes, investing in higher-quality bolts can result in lower long-term expenses.

-

Understand Pricing Nuances: Buyers from regions like Africa or South America may encounter different pricing structures due to local market conditions and economic factors. Understanding these nuances can help in negotiating better terms.

-

Build Strong Supplier Relationships: Developing long-term partnerships with suppliers can lead to more favorable pricing and terms, as suppliers may prioritize loyal customers.

-

Stay Informed on Market Trends: Keeping abreast of market trends, such as fluctuations in raw material prices or changes in manufacturing capabilities, can provide leverage during negotiations.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Buyers should conduct thorough research and request quotes from multiple suppliers to obtain the most accurate pricing.

Alternatives Analysis: Comparing automotive bolt With Other Solutions

When evaluating automotive fasteners, it’s essential to consider various alternatives to traditional automotive bolts. Each solution can offer distinct advantages and disadvantages based on specific applications, performance needs, and budget constraints. This analysis compares automotive bolts with two viable alternatives: Rivets and Adhesives.

Comparison Table

| Comparison Aspect | Automotive Bolt | Rivets | Adhesives |

|---|---|---|---|

| Performance | High tensile strength; reliable joint | Excellent shear strength; permanent | Varies; can be strong but depends on type |

| Cost | Generally low to moderate | Moderate; requires special tools | Low to moderate; depends on type |

| Ease of Implementation | Simple installation with tools | Requires special tools and training | Easy to apply but needs curing time |

| Maintenance | Requires inspection and potential replacement | Permanent; minimal maintenance | Can degrade over time; may need reapplication |

| Best Use Case | High-load applications; removable joints | Permanent joints in structural applications | Non-load bearing, lightweight assemblies |

Understanding Rivets as an Alternative

Rivets are a popular alternative to automotive bolts, particularly in applications where a permanent joint is necessary. They are installed by deforming the end of the rivet, creating a strong connection that can withstand significant shear forces. The primary advantage of rivets is their ability to join materials without needing threads, making them ideal for thin materials or where space is limited. However, the installation process can be more complex and requires specific tools, which may not be readily available to all users. Additionally, once installed, rivets cannot be easily removed, making them less flexible for repairs or modifications.

Illustrative image related to automotive bolt

Exploring Adhesives for Fastening Solutions

Adhesives present another alternative to automotive bolts, offering a unique solution for joining materials. They can bond a wide range of substrates, including metals, plastics, and composites. Adhesives are often easier to apply than mechanical fasteners, requiring no special tools beyond the adhesive itself. However, their performance can vary significantly based on the type of adhesive used and the environmental conditions to which the bond is exposed. While they can provide a strong bond in many applications, they may not be suitable for high-load situations or where disassembly is anticipated. Furthermore, the curing time can delay production processes.

Conclusion: Choosing the Right Fastening Solution

When selecting between automotive bolts, rivets, and adhesives, B2B buyers should consider several factors specific to their application. For projects requiring high-load-bearing capabilities and the option for future disassembly, automotive bolts are typically the best choice. Conversely, rivets are ideal for permanent joints in structural applications, while adhesives offer versatility for non-load-bearing connections. Buyers should assess their specific needs, including performance requirements, budget constraints, and installation capabilities, to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for automotive bolt

What Are the Key Technical Properties of Automotive Bolts That B2B Buyers Should Know?

Understanding the technical specifications of automotive bolts is essential for international B2B buyers to ensure that they procure the right components for their automotive applications. Here are some critical specifications:

1. Material Grade

Automotive bolts are typically made from various materials, including carbon steel, stainless steel, and alloy steel. The material grade indicates the strength and corrosion resistance of the bolt. For example, SAE grades 2, 5, and 8, or their metric equivalents, provide essential insights into the load-bearing capacity. Choosing the correct material grade is crucial for safety and performance, especially in high-stress automotive applications.

Illustrative image related to automotive bolt

2. Thread Pitch

Thread pitch refers to the distance between threads, measured in millimeters for metric bolts or threads per inch for SAE bolts. This specification is vital for ensuring proper fit and function with nuts and other components. Mismatched thread pitches can lead to assembly failures, increased wear, or safety hazards. Understanding thread pitch helps buyers select bolts that will reliably secure automotive parts.

3. Tolerance

Tolerance indicates the allowable variation in dimensions, which is critical for ensuring that the bolt fits snugly into its designated location without excessive play. Tight tolerances are often required in high-performance applications where precision is key. Buyers should pay close attention to tolerance specifications to avoid costly rework or failures in assembly lines.

4. Coating and Finish

The coating or finish applied to automotive bolts can significantly impact their durability and resistance to corrosion. Common finishes include zinc plating, black oxide, and phosphate coatings. The choice of finish affects the bolt’s lifespan and performance in different environments, particularly in regions with high humidity or exposure to chemicals. Selecting the appropriate finish can enhance the longevity of the fasteners in automotive applications.

5. Length and Diameter

The length and diameter of bolts are fundamental dimensions that determine their suitability for specific applications. Buyers need to ensure that the bolts they select can accommodate the thickness of the materials being fastened. Incorrect lengths or diameters can lead to inadequate fastening, which can compromise safety and performance.

What Are the Common Trade Terms Related to Automotive Bolts?

Familiarity with industry jargon can streamline communication and improve procurement efficiency. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture parts used in a vehicle’s assembly. In the automotive industry, OEM bolts are designed to meet specific standards set by vehicle manufacturers. B2B buyers often prefer OEM parts for their reliability and compatibility with existing components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers looking to manage inventory costs effectively. It can also influence purchasing decisions, particularly for smaller businesses or startups that may not need large quantities of automotive bolts.

Illustrative image related to automotive bolt

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. This process helps buyers compare prices and terms from different vendors. Including detailed specifications in an RFQ can lead to more accurate quotes and better purchasing outcomes.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Knowledge of these terms is essential for B2B buyers engaged in cross-border purchases to ensure clarity in logistics and avoid unexpected costs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for effective inventory management and project planning. Buyers should consider lead times when placing orders, especially for components that are critical to production schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the reliability of their automotive applications.

Navigating Market Dynamics and Sourcing Trends in the automotive bolt Sector

What Are the Current Market Dynamics and Key Trends in the Automotive Bolt Sector?

The automotive bolt sector is experiencing significant transformation driven by globalization, technological advancements, and changing consumer preferences. International B2B buyers from Africa, South America, the Middle East, and Europe are increasingly influenced by the need for high-quality, reliable fasteners that meet stringent safety standards. Key trends include the rise of e-commerce platforms facilitating cross-border transactions, allowing buyers to access a wider range of suppliers and products. Additionally, the integration of advanced manufacturing technologies, such as automation and robotics, is enhancing production efficiency and reducing lead times.

Moreover, the shift towards electric and hybrid vehicles is creating a demand for specialized automotive bolts that can accommodate new materials and designs. As the automotive industry pivots to sustainability, the sourcing of eco-friendly materials is becoming a priority, prompting suppliers to innovate in bolt manufacturing processes. B2B buyers must stay attuned to these dynamics to capitalize on opportunities for cost savings and improved supply chain resilience.

How Does Sustainability and Ethical Sourcing Impact the Automotive Bolt Sector?

Sustainability has become a pivotal concern in the automotive bolt sector, driven by both regulatory pressures and consumer expectations. The environmental impact of bolt production, including resource extraction and waste generation, necessitates a focus on ethical sourcing practices. B2B buyers are increasingly prioritizing suppliers who can demonstrate sustainable practices and compliance with environmental regulations.

Certification programs such as ISO 14001 for environmental management systems and the use of recycled materials in manufacturing are becoming essential considerations for international buyers. The adoption of ‘green’ materials not only reduces the carbon footprint of automotive fasteners but also enhances brand reputation in markets that value sustainability. As buyers in Africa, South America, the Middle East, and Europe seek to align with global sustainability goals, they must evaluate their supply chains for ethical sourcing and environmental impact to ensure compliance and maintain competitiveness.

What Is the Brief Evolution and History of the Automotive Bolt Sector?

The automotive bolt sector has evolved significantly since the early days of the automotive industry in the late 19th century. Initially, bolts were made from wrought iron and later transitioned to steel, which offered greater strength and durability. The introduction of standardized fasteners in the early 20th century streamlined production processes and improved safety.

As automotive technology advanced, so did the specifications for bolts, with the introduction of various grades and materials tailored to specific applications. The late 20th century saw the rise of globalization, enabling manufacturers to source materials and components from a diverse range of suppliers worldwide. Today, the focus is shifting towards innovation, with the development of high-performance alloys and eco-friendly manufacturing processes that cater to the evolving needs of the automotive industry. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions in a competitive market.

Illustrative image related to automotive bolt

Frequently Asked Questions (FAQs) for B2B Buyers of automotive bolt

-

How do I choose the right automotive bolt for my project?

Choosing the right automotive bolt involves understanding the specific requirements of your application. Consider factors such as bolt grade, thread pitch, length, and material. For critical applications, refer to manufacturer specifications or consult an expert to ensure compatibility with your vehicle. Additionally, assess environmental conditions like exposure to moisture or chemicals, which may necessitate corrosion-resistant materials. Finally, ensure that the bolt’s head style is compatible with your tools for efficient installation. -

What is the best material for automotive bolts in high-stress applications?

For high-stress applications, Grade 8 bolts in SAE specifications or 10.9 to 12.9 in metric specifications are recommended due to their superior tensile strength. Materials like alloy steel or stainless steel with appropriate coatings (e.g., zinc plating) offer excellent durability and corrosion resistance. When sourcing bolts for critical components, always verify the manufacturer’s certifications and adhere to industry standards to guarantee performance and safety. -

What are the minimum order quantities (MOQs) for automotive bolts?

Minimum order quantities for automotive bolts can vary significantly depending on the supplier and the type of bolt required. Typically, MOQs range from 100 to 1,000 pieces for standard fasteners. For custom or specialty bolts, MOQs may be higher due to tooling and manufacturing costs. It’s essential to discuss your specific needs with suppliers to negotiate terms that suit your procurement strategy while ensuring you meet your project demands efficiently. -

How can I ensure the quality of automotive bolts sourced internationally?

To ensure quality when sourcing automotive bolts internationally, conduct thorough supplier vetting. Request samples and certifications to assess compliance with industry standards, such as ISO 9001. Establish communication with the supplier to discuss quality control processes and inquire about their experience in your specific market. Additionally, consider third-party inspections before shipment to verify that the bolts meet your specifications and quality requirements. -

What payment terms are commonly accepted in international transactions for automotive bolts?

Payment terms in international transactions for automotive bolts typically include options like advance payment, letter of credit (LC), or payment upon delivery. Many suppliers prefer a partial upfront payment, followed by the balance upon delivery or after inspection. It’s essential to establish clear terms that protect both parties and consider using secure payment methods to mitigate risks associated with currency fluctuations and international trade. -

What logistics considerations should I keep in mind when importing automotive bolts?

When importing automotive bolts, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose between air and sea freight based on urgency and cost-efficiency. Ensure compliance with local import regulations, including tariffs and documentation requirements. Additionally, work with logistics partners who understand the automotive supply chain to streamline customs clearance and minimize delays. -

Can automotive bolts be customized for specific applications?

Yes, many suppliers offer customization options for automotive bolts to meet specific application requirements. Customizations can include variations in length, diameter, thread type, head style, and material specifications. When requesting custom bolts, provide detailed specifications and discuss your needs with the supplier to ensure they can accommodate your requirements while adhering to industry standards. -

What are the common certifications and standards for automotive bolts?

Common certifications for automotive bolts include ISO 9001 for quality management and ISO/TS 16949 for the automotive sector. Additionally, look for compliance with ASTM (American Society for Testing and Materials) standards or SAE (Society of Automotive Engineers) specifications. These certifications indicate that the bolts meet rigorous quality and safety requirements, ensuring reliability in automotive applications. Always request documentation from suppliers to verify compliance with these standards.

Top 5 Automotive Bolt Manufacturers & Suppliers List

1. Clips and Fasteners – M10 Hex Head Flange Bolt

Domain: clipsandfasteners.com

Registered: 2007 (18 years)

Introduction: Automotive Flange Bolts & Specialty Bolts; M10-1.50 x 75mm Hex Head Flange Bolt Non Serrated Class 10.9 Zinc DIN 6921; Diameter: 10mm; Thread Pitch: 1.50; Length: 75mm; Head Height: 9.2mm; Wrench Size: 15mm; Flange O.D.: 22.3mm; Thread Length: Partial Thread; Package Price: $2.64; M10 – 1.25 x 70mm JIS Hex Head Flange Bolt – Small Head, Class 10.9 Zinc; Diameter: 10mm; Thread Pitch: 1.25; Length: …

2. Auto Bolt – Fasteners and Bolts

Domain: autoboltusa.com

Registered: 2019 (6 years)

Introduction: Auto Bolt manufactures a variety of fasteners including threaded and unthreaded fasteners, square neck bolts, carriage bolts, plow bolts, bumper bolts, spring center suspension bolts, hex flange bolts, hex head cap screws, hex head bolts, pan head bolts, round head bolts, 12-point bolts, six lobe bolts, wheel bolts, wheel studs, rivets, pins, and military fasteners. They offer extensive fastener k…

3. The Industrial Depot – Automotive Fasteners

Domain: theindustrialdepot.com

Introduction: Automotive Fasteners from TheIndustrialDepot.com include a wide range of fasteners and hardware suitable for automotive applications. The assortment features various types of fasteners such as bolts, screws, nuts, washers, and specialty fasteners. Key categories include: 1. **Bolts**: Grade 2, Grade 5, Grade 8, and metric bolts in various finishes (zinc, galvanized, stainless steel). 2. **Screws**…

4. WURTH – Automotive Bolts & Fasteners

Domain: wurthusa.com

Registered: 1996 (29 years)

Introduction: WURTH offers a comprehensive range of high-quality automotive bolts, featuring popular sizes, threads, head styles, and materials. The product line includes specialty automotive bolts and fasteners suitable for imported cars and unique vehicles, ensuring that all automotive bolt needs are met.

5. Kent Automotive – Body Bolts & Nuts

Strategic Sourcing Conclusion and Outlook for automotive bolt

In the competitive landscape of automotive manufacturing and repair, strategic sourcing of automotive bolts is essential for maintaining quality and ensuring operational efficiency. By understanding the nuances of fasteners, such as material grades, thread types, and specific applications, international B2B buyers can make informed decisions that align with their operational needs. This knowledge not only mitigates risks associated with subpar components but also fosters long-term supplier relationships, leading to better pricing, reliability, and innovation.

As the automotive industry continues to evolve, with trends such as electric vehicles and advanced materials, the demand for specialized bolts and fasteners is expected to grow. Buyers from Africa, South America, the Middle East, and Europe should proactively engage with suppliers that offer a diverse range of products and customization options to stay ahead of industry changes.

Now is the time to refine your sourcing strategies and partner with suppliers who prioritize quality and service. By doing so, you will not only enhance your supply chain resilience but also position your business for future success in a dynamic market. Embrace the opportunity to innovate and elevate your automotive operations through strategic sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.