Top 5 1/2 Inch Hardware Cloth For Chicken Coop Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 1/2 inch hardware cloth for chicken coop

In the competitive landscape of poultry farming, sourcing high-quality 1/2 inch hardware cloth for chicken coops is essential for protecting livestock and ensuring operational success. As international B2B buyers face the challenge of selecting the right materials that offer both durability and security, understanding the nuances of hardware cloth becomes paramount. This comprehensive guide delves into the various types of hardware cloth, their applications in chicken coops, and critical considerations for supplier vetting.

From evaluating the gauge and material specifications to assessing installation ease and long-term performance, this resource equips buyers with the insights needed to make informed purchasing decisions. Special attention is given to the unique market dynamics in regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam. These insights are designed to help buyers navigate regional supplier landscapes and understand pricing trends, ensuring they secure the best value for their investments.

Ultimately, this guide serves as a valuable tool for B2B buyers seeking to enhance their poultry operations while mitigating risks associated with substandard materials. By emphasizing quality and reliability, it empowers businesses to make strategic choices that will lead to improved animal welfare and operational efficiency in the global market.

Understanding 1/2 inch hardware cloth for chicken coop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 1/2 inch Mesh | Galvanized steel, 19 gauge, 48″ x 100 ft rolls | Chicken coops, rabbit enclosures, garden fencing | Pros: Durable, rust-resistant; Cons: Heavier, may require additional support. |

| Heavy-Duty 1/2 inch Mesh | Thicker gauge (16 or 19), reinforced edges | High-security animal enclosures, commercial farms | Pros: Increased strength against predators; Cons: Higher cost, may be over-engineered for small operations. |

| Flexible 1/2 inch Mesh | Lightweight, easy to cut and shape | DIY projects, temporary fencing setups | Pros: Versatile, easy installation; Cons: Less robust than heavier options, may require frequent replacement. |

| PVC-Coated 1/2 inch Mesh | Coated for added weather resistance | Outdoor applications, humid environments | Pros: Enhanced durability, less rust; Cons: Higher initial investment, coating can wear over time. |

| Welded Wire 1/2 inch Mesh | Welded joints for added integrity | Permanent structures, high-density livestock housing | Pros: Long-lasting, robust structure; Cons: More complex installation process, heavier material. |

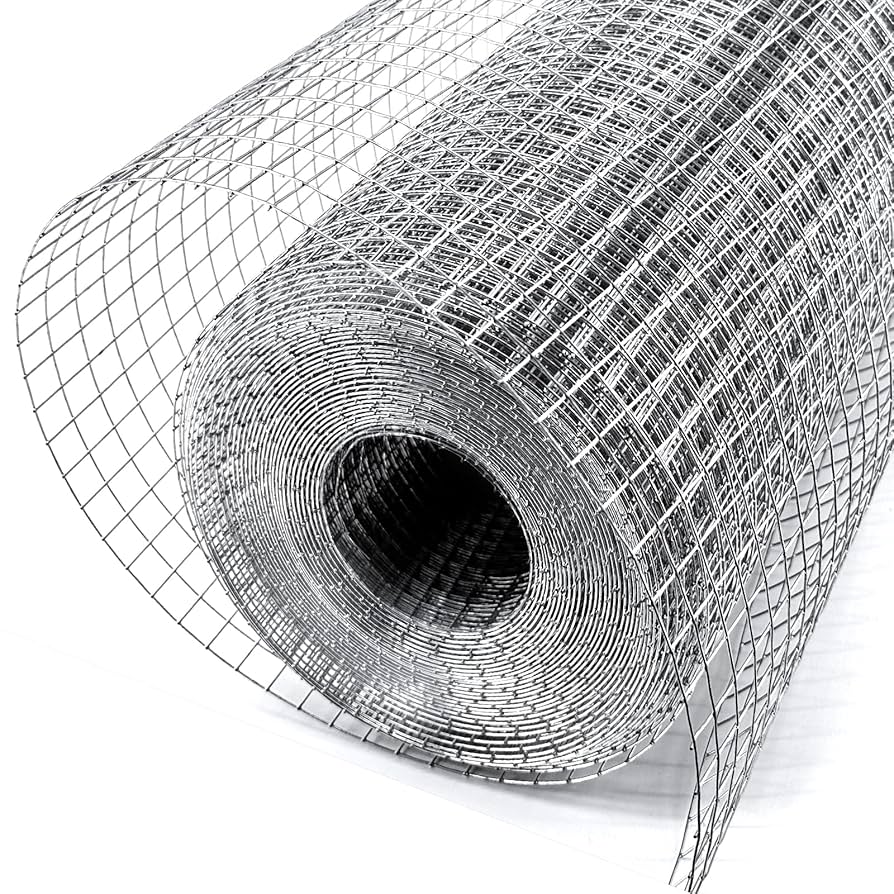

What Are the Characteristics of Standard 1/2 Inch Mesh Hardware Cloth?

The standard 1/2 inch mesh hardware cloth is typically made from galvanized steel and is available in 19-gauge thickness. It is often sold in 48-inch by 100-foot rolls, making it suitable for various applications such as chicken coops and garden fencing. B2B buyers should consider its durability and rust resistance, which ensure a long lifespan. However, its weight may necessitate additional support during installation, especially in larger projects.

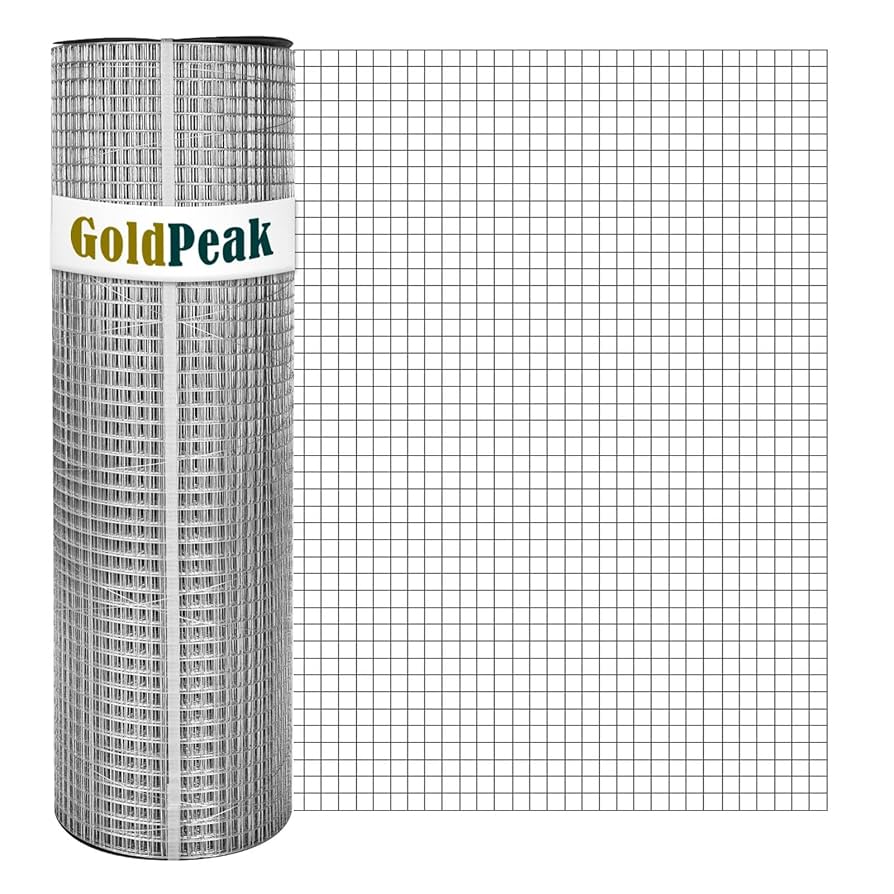

Illustrative image related to 1/2 inch hardware cloth for chicken coop

How Does Heavy-Duty 1/2 Inch Mesh Compare?

Heavy-duty 1/2 inch mesh features a thicker gauge, often 16 or 19, providing enhanced strength against potential predators. This variant is ideal for high-security environments such as commercial farms or facilities housing valuable livestock. While it offers superior protection, buyers should weigh the increased cost against their specific needs, as this option may be more than what smaller operations require.

What Are the Benefits of Flexible 1/2 Inch Mesh?

Flexible 1/2 inch mesh is designed for ease of use, allowing for quick cuts and shaping to fit various DIY projects or temporary fencing setups. This type is lightweight, making it easier to handle during installation. B2B buyers looking for a versatile solution will appreciate its adaptability. However, its lighter construction may lead to a shorter lifespan compared to heavier-duty options, particularly in high-stress environments.

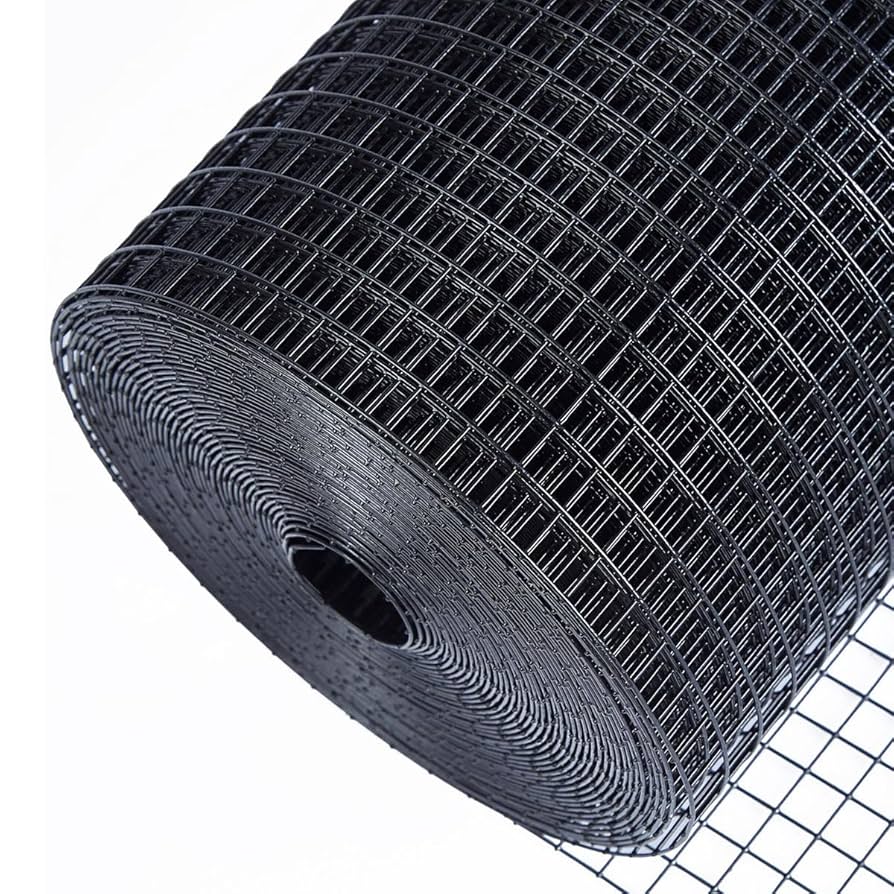

Why Choose PVC-Coated 1/2 Inch Mesh?

PVC-coated 1/2 inch mesh is an excellent choice for outdoor applications, particularly in humid or wet environments. The coating provides additional weather resistance, enhancing the longevity of the product. While the initial investment is higher, the reduced risk of rust can lead to lower maintenance costs over time. Buyers should consider the trade-off between upfront costs and long-term durability when selecting this option.

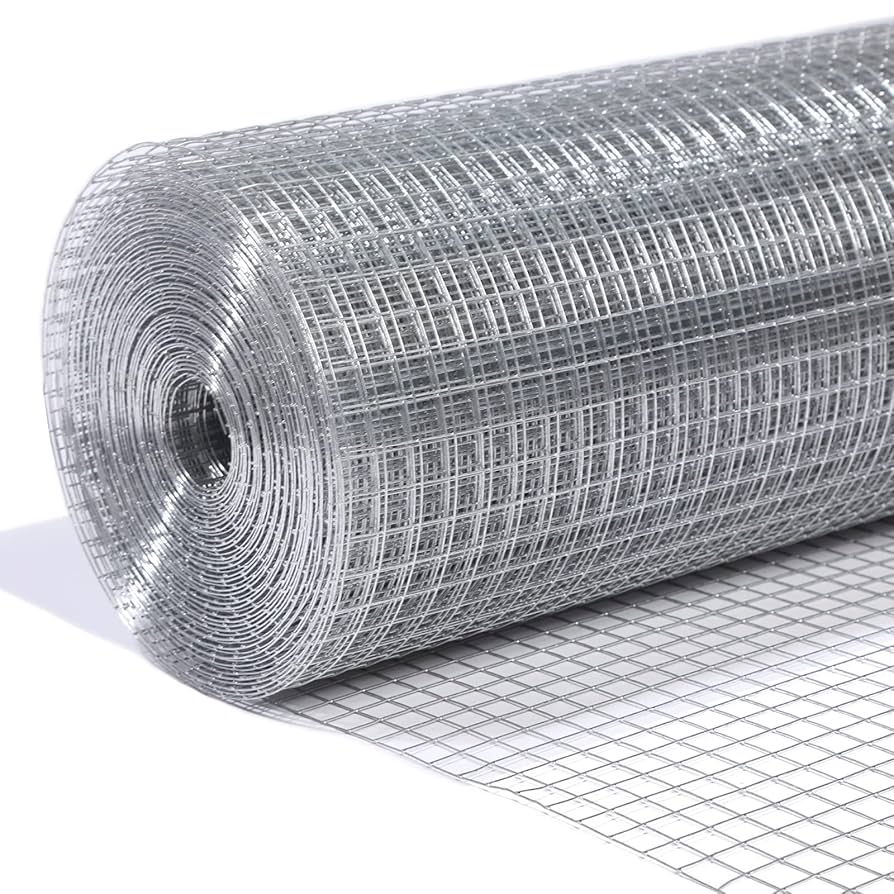

Illustrative image related to 1/2 inch hardware cloth for chicken coop

How Does Welded Wire 1/2 Inch Mesh Enhance Security?

Welded wire 1/2 inch mesh features welded joints that enhance structural integrity, making it suitable for permanent installations and high-density livestock housing. This type is particularly effective in environments where security is paramount. While its robustness offers peace of mind, the installation process can be more complex, and the heavier material may require additional labor and resources. B2B buyers should assess their specific security needs when considering this option.

Key Industrial Applications of 1/2 inch hardware cloth for chicken coop

| Industry/Sector | Specific Application of 1/2 inch hardware cloth for chicken coop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Poultry Farming | Enclosure and protection for chicken coops and runs | Provides robust protection against predators, ensuring flock safety and reducing losses. | Sourcing from reputable manufacturers that offer galvanized options for durability and rust resistance. |

| Agricultural Equipment | Support structures for mobile chicken coops | Enhances mobility while maintaining security, leading to healthier and more productive flocks. | Consider local suppliers to reduce shipping costs and ensure timely delivery. |

| Landscaping and Gardening | Use as protective barriers for gardens and crops | Prevents animal intrusion, safeguarding crops and maximizing yield. | Look for bulk purchasing options for cost-effectiveness and ensure compatibility with local climate conditions. |

| Construction and Renovation | Reinforcement for building projects involving animal enclosures | Adds structural integrity to enclosures, meeting safety standards and enhancing longevity. | Evaluate gauge strength and corrosion resistance, especially in humid or coastal regions. |

| Eco-Tourism and Agritourism | Creating secure habitats for free-range chickens in resorts | Attracts customers interested in sustainable practices and animal welfare, enhancing brand image. | Assess local regulations regarding animal enclosures to ensure compliance. |

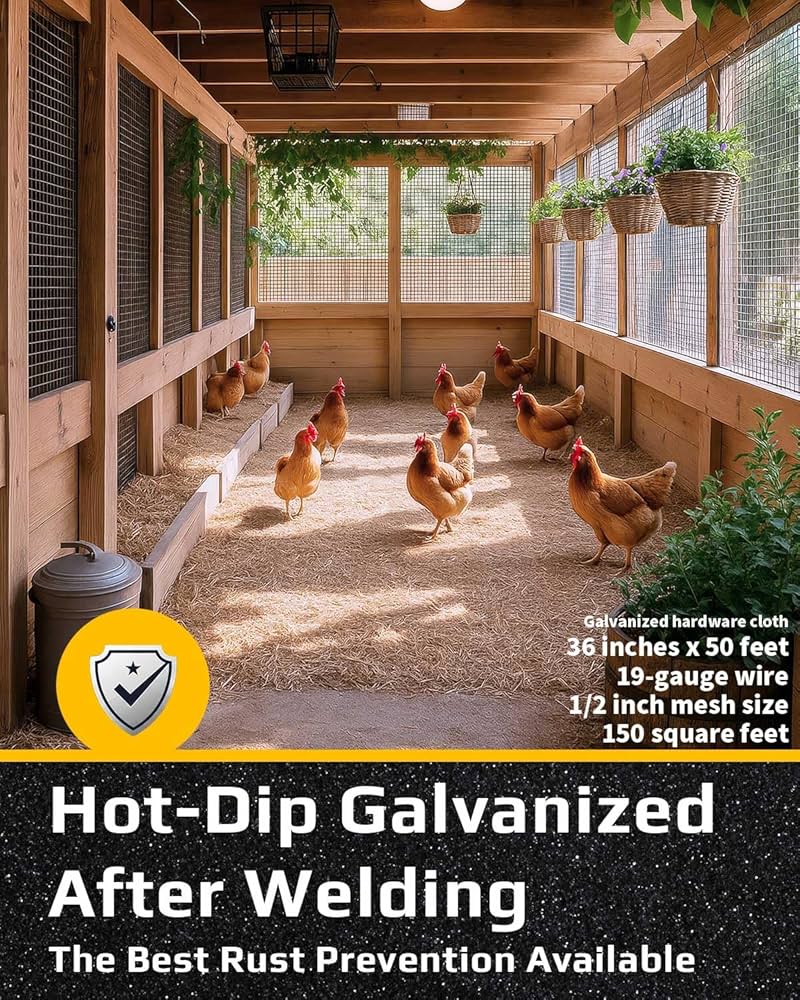

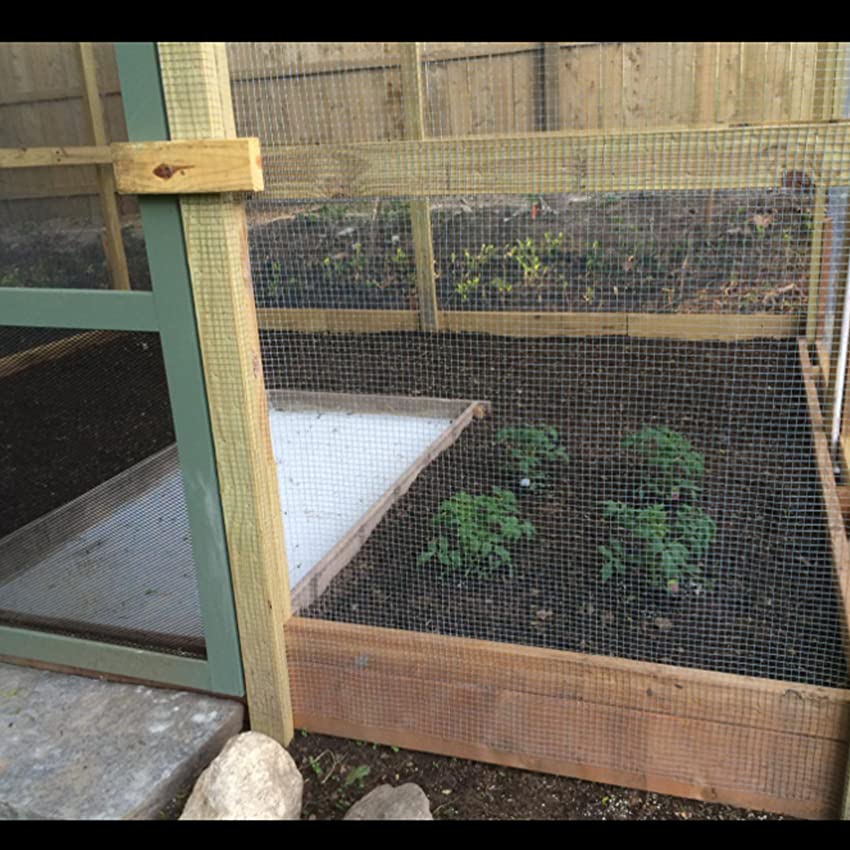

How is 1/2 Inch Hardware Cloth Used in Poultry Farming?

In poultry farming, 1/2 inch hardware cloth is primarily utilized for building secure chicken coops and runs. Its robust construction effectively keeps out predators such as raccoons, foxes, and hawks, safeguarding the flock from potential threats. By minimizing losses due to predation, farmers can ensure higher productivity and profitability. For international buyers, particularly in regions with diverse wildlife, sourcing high-quality, galvanized hardware cloth is essential to withstand local environmental conditions.

What Role Does 1/2 Inch Hardware Cloth Play in Agricultural Equipment?

Mobile chicken coops, often used in rotational grazing systems, benefit greatly from 1/2 inch hardware cloth. This material not only provides security but also allows for easy mobility across different terrains. By ensuring that the chickens are safely contained while being moved to new grazing areas, farmers can promote healthier flocks and improve soil quality through natural fertilization. Buyers should consider local suppliers who can deliver products quickly to avoid delays in agricultural operations.

How is 1/2 Inch Hardware Cloth Applied in Landscaping and Gardening?

In landscaping and gardening, 1/2 inch hardware cloth serves as a protective barrier against small animals that may damage crops. It effectively prevents intrusion from rabbits, gophers, and other pests while allowing for proper air and water flow. This application is particularly valuable in regions where crop damage can severely impact yield. Buyers should look for bulk purchasing options to maximize cost-effectiveness, especially in agricultural regions where large quantities may be needed.

Why is 1/2 Inch Hardware Cloth Important in Construction and Renovation?

During construction or renovation projects involving animal enclosures, 1/2 inch hardware cloth is crucial for reinforcing structures. It provides additional strength and durability, ensuring that enclosures meet safety standards. This is particularly important in regions prone to extreme weather or wildlife challenges. Buyers should assess the gauge strength and corrosion resistance of the material to ensure it is suitable for their specific environmental conditions.

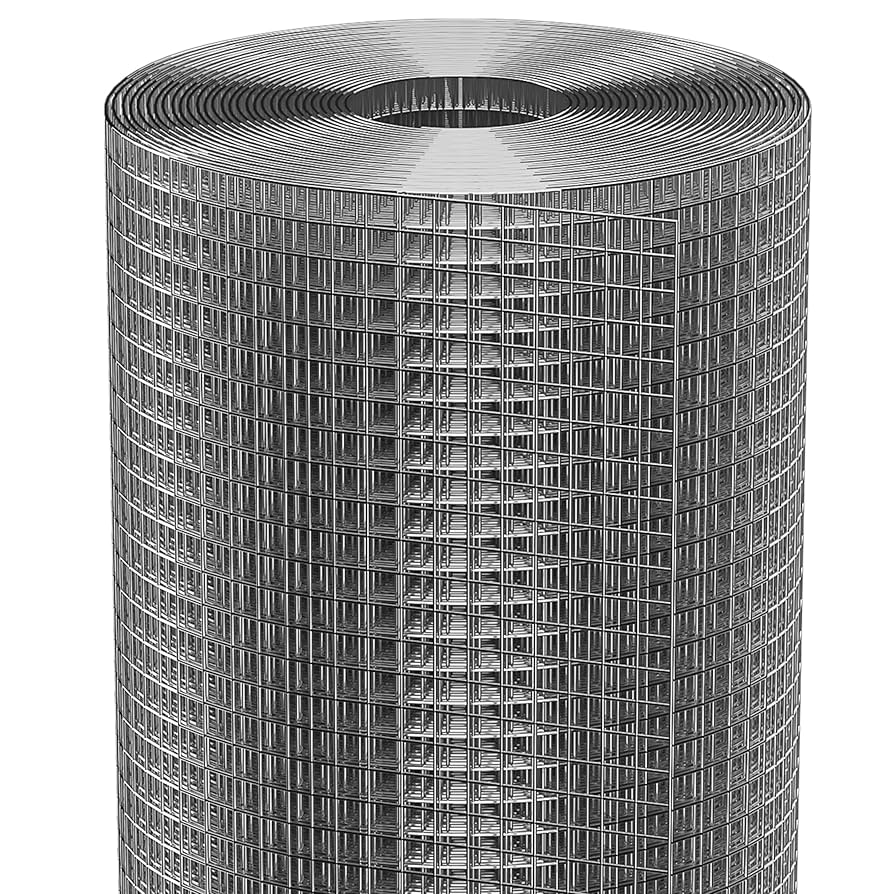

Illustrative image related to 1/2 inch hardware cloth for chicken coop

How Can 1/2 Inch Hardware Cloth Enhance Eco-Tourism and Agritourism?

In eco-tourism and agritourism, 1/2 inch hardware cloth is used to create secure habitats for free-range chickens, contributing to sustainable farming practices. This not only enhances animal welfare but also appeals to environmentally conscious customers seeking authentic experiences. For buyers in this sector, understanding local regulations regarding animal enclosures is essential to ensure compliance and promote responsible tourism practices.

3 Common User Pain Points for ‘1/2 inch hardware cloth for chicken coop’ & Their Solutions

Scenario 1: Inadequate Protection Against Predators

The Problem:

For many B2B buyers in regions like Africa and South America, ensuring the safety of poultry from local predators is a significant concern. In particular, the 1/2 inch hardware cloth is often considered, yet the fear of it being insufficient to deter larger predators, such as foxes or raccoons, looms large. Buyers may worry that their investment won’t provide the necessary security for their chicken coops, leading to potential losses that can devastate their operations.

The Solution:

To address these concerns, it’s essential to choose a higher gauge of 1/2 inch hardware cloth, ideally at least 19 gauge, which provides superior strength compared to thinner options. When installing, ensure that the cloth is securely fastened to the coop structure using strong metal ties or staples. Additionally, consider overlapping multiple layers of hardware cloth at critical points of entry to create an extra barrier against determined intruders. For enhanced security, bury the cloth at least 12 inches deep along the perimeter to prevent digging predators. This layered approach not only fortifies the coop but also reassures buyers that their investment in poultry protection is sound.

Scenario 2: Difficulty in Installation and Handling

The Problem:

Many B2B buyers report challenges when it comes to the installation of 1/2 inch hardware cloth, particularly due to its weight and rigidity. This can be especially problematic for small-scale operators or those without specialized tools, leading to frustration and potential delays in securing their chicken coops. The fear of improper installation may also deter buyers from making a commitment to purchase.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

The Solution:

To streamline the installation process, buyers should consider utilizing a pre-cut hardware cloth option, which can significantly reduce the complexity of the task. If custom sizes are needed, using heavy-duty wire cutters and a pair of gloves can help manage the cloth more effectively. For easier handling, consider laying the cloth flat in the sun for a short period to increase its flexibility. Moreover, employing a team approach during installation can make the process smoother. Clear guidance or video tutorials from suppliers on proper installation techniques can also empower buyers, ensuring that they feel confident in their capabilities and the longevity of their investment.

Scenario 3: Misunderstanding Product Specifications

The Problem:

International buyers often face confusion regarding product specifications, especially when it comes to the differences between wire gauge and mesh size. This lack of clarity can lead to purchasing decisions based on incorrect assumptions, resulting in a product that does not meet their specific needs. For example, some buyers may mistakenly believe that a lower gauge number automatically means better durability without considering the mesh size and its implications for predator protection.

The Solution:

To combat this misunderstanding, suppliers should provide comprehensive product guides that clearly explain the relationship between wire gauge and mesh size. It’s crucial for buyers to understand that while a 19 gauge is thicker and stronger than a 23 gauge, the mesh size of 1/2 inch can still offer adequate protection against common threats. Educating buyers on how to evaluate their specific needs based on local predator threats will help them make informed decisions. Furthermore, offering consultation services or customer support can assist buyers in selecting the most appropriate hardware cloth for their specific chicken coop requirements, ensuring that they achieve optimal protection without overspending on unnecessary features.

Strategic Material Selection Guide for 1/2 inch hardware cloth for chicken coop

What Are the Key Properties of Different Materials Used in 1/2 Inch Hardware Cloth for Chicken Coops?

When selecting 1/2 inch hardware cloth for chicken coops, understanding the properties of various materials is crucial for ensuring durability, effectiveness, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of hardware cloth: galvanized steel, stainless steel, vinyl-coated wire, and aluminum.

How Does Galvanized Steel Perform in Chicken Coop Applications?

Key Properties: Galvanized steel is coated with zinc to enhance corrosion resistance, making it suitable for outdoor applications. It typically withstands temperatures ranging from -40°F to 200°F without losing structural integrity.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Pros & Cons: The primary advantage of galvanized steel is its strength and durability, ensuring long-lasting protection against predators. However, it can be susceptible to rust if the coating is damaged, and its weight may complicate installation.

Impact on Application: Galvanized steel is effective in protecting against a variety of predators, including raccoons and foxes. Its robust nature makes it suitable for high-stress environments, but it may not be the best choice in extremely humid or coastal areas due to potential rusting.

Considerations for International Buyers: Compliance with ASTM standards for galvanized products is essential. In regions like Africa and the Middle East, buyers should ensure that the material meets local corrosion resistance requirements.

What Advantages Does Stainless Steel Offer for Hardware Cloth?

Key Properties: Stainless steel is known for its exceptional corrosion resistance and can withstand extreme temperatures. It is often rated for high-pressure applications, making it highly durable.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Pros & Cons: The key advantage of stainless steel is its longevity and resistance to rust, even in harsh environments. However, it is significantly more expensive than galvanized options, which may deter budget-conscious buyers.

Impact on Application: Stainless steel hardware cloth is ideal for areas prone to high moisture or salt exposure, such as coastal regions. Its durability ensures that it can withstand the rigors of outdoor use without degrading over time.

Considerations for International Buyers: Buyers in Europe and South America should check for compliance with DIN and JIS standards for stainless steel products, ensuring they meet local regulations.

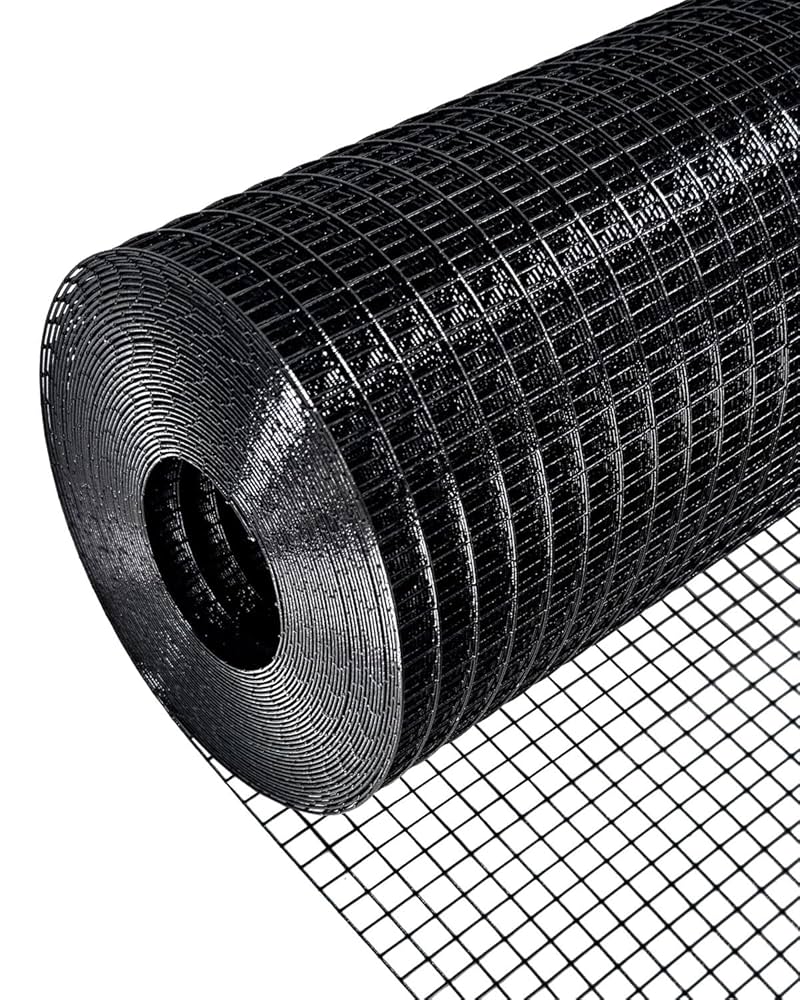

How Does Vinyl-Coated Wire Compare for Chicken Coops?

Key Properties: Vinyl-coated wire is typically made from galvanized steel coated with a layer of vinyl, providing additional protection against corrosion. It can handle moderate temperatures and is flexible, making it easy to work with.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Pros & Cons: The vinyl coating offers enhanced aesthetics and additional rust protection, making it suitable for decorative applications. However, it may not be as robust as bare galvanized or stainless steel, leading to potential wear over time.

Impact on Application: Vinyl-coated wire is effective in protecting against smaller predators but may not withstand larger animals. It is often used in residential settings where appearance matters.

Considerations for International Buyers: Compliance with local safety and environmental standards is essential, particularly in regions like Africa where regulations may vary. Buyers should ensure that the vinyl used is free from harmful chemicals.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

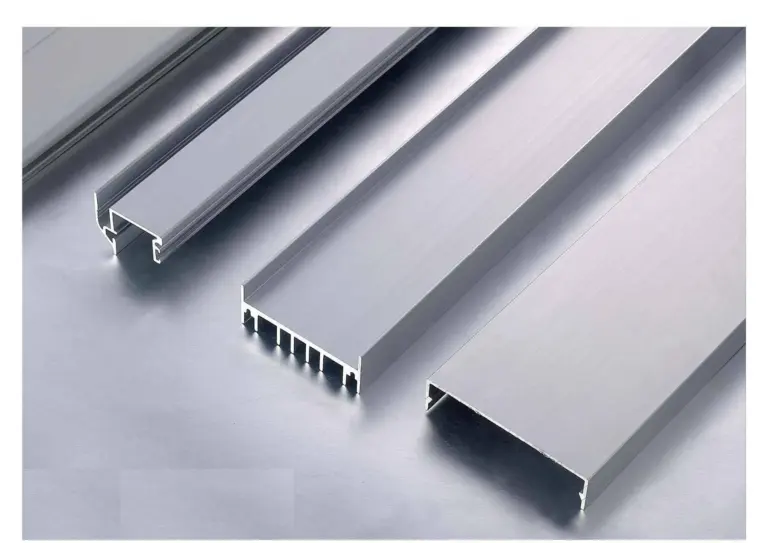

What Role Does Aluminum Play in Hardware Cloth Applications?

Key Properties: Aluminum is lightweight and resistant to corrosion, making it suitable for various outdoor applications. It can handle a range of temperatures but is less robust than steel options.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which simplifies installation. However, its lower strength makes it less suitable for high-predator areas, as larger animals can breach it more easily.

Impact on Application: Aluminum hardware cloth can be effective for smaller animals and in environments where weight is a concern. However, its limited strength may necessitate additional reinforcement in predator-heavy areas.

Considerations for International Buyers: Buyers in regions like the Middle East should be aware of local standards regarding aluminum use in construction and agricultural applications, ensuring compliance with any relevant regulations.

Summary of Material Selection for 1/2 Inch Hardware Cloth

| Material | Typical Use Case for 1/2 inch hardware cloth for chicken coop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | General predator protection in various climates | Strong and durable | Susceptible to rust if damaged | Medium |

| Stainless Steel | Coastal or high-moisture environments | Exceptional corrosion resistance | Higher cost | High |

| Vinyl-Coated Wire | Residential and decorative applications | Aesthetic appeal and rust protection | Less robust than steel options | Medium |

| Aluminum | Lightweight applications and small animal protection | Lightweight and easy to install | Lower strength against predators | Low |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions when selecting the appropriate material for 1/2 inch hardware cloth in chicken coop applications.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

In-depth Look: Manufacturing Processes and Quality Assurance for 1/2 inch hardware cloth for chicken coop

What Are the Main Stages in the Manufacturing Process of 1/2 Inch Hardware Cloth for Chicken Coops?

The manufacturing process for 1/2 inch hardware cloth involves several critical stages that ensure the final product meets the necessary durability and safety standards required for chicken coops.

-

Material Preparation: The process begins with the selection of high-quality raw materials. Typically, this includes hot-dipped galvanized steel wire, known for its resistance to rust and corrosion. The wire is sourced from reputable suppliers to ensure consistency in quality. Before production, the wire is cut to specific lengths, which will be used for weaving.

-

Forming: In this stage, the cut wires are fed into a weaving machine that interlaces them into a mesh pattern. The spacing is precisely controlled to create the 1/2 inch openings that are optimal for preventing predators while allowing for ventilation. Advanced machinery ensures uniformity in the mesh size and tension, which is crucial for maintaining structural integrity.

-

Assembly: Once the mesh is formed, it is rolled into large sheets or rolls, typically measuring 48 inches by 100 feet. During this phase, additional processes such as cutting and shaping may occur, depending on the specific requirements of the buyer. The rolls are then packaged for shipment, ensuring they are protected from damage during transit.

-

Finishing: The final stage involves applying protective coatings to enhance the product’s durability. In most cases, the hardware cloth undergoes a hot-dip galvanization process, which provides a thick layer of zinc coating. This not only prevents rust but also extends the lifespan of the product, making it suitable for outdoor use in varying climates.

How Is Quality Assurance Ensured in the Production of 1/2 Inch Hardware Cloth?

Quality assurance (QA) is an essential aspect of the manufacturing process, particularly for products intended for agricultural use. For international B2B buyers, understanding the QA measures in place can significantly influence purchasing decisions.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which specifies requirements for a quality management system (QMS). Compliance with these standards ensures that the manufacturing processes are efficient and that the final products consistently meet customer expectations.

-

Industry-Specific Certifications: Depending on the region, specific certifications may be required. For example, the CE marking in Europe indicates compliance with health, safety, and environmental protection standards. In the Middle East, products may need to meet specific Gulf Standards (GSO). B2B buyers should inquire about these certifications when evaluating suppliers.

-

Quality Control Checkpoints: Quality control is typically divided into three main checkpoints:

– Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the manufacturing facility. The materials are tested for specifications such as tensile strength, diameter, and coating thickness.

– In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to ensure that the mesh is being produced according to the specified dimensions and quality standards. This includes assessing the weaving tension and monitoring for any defects in the mesh.

– Final Quality Control (FQC): Before shipment, the finished rolls of hardware cloth undergo a final inspection. This includes checking for overall quality, packaging integrity, and ensuring that the product meets the agreed-upon specifications. -

Testing Methods: Common testing methods include tensile strength tests, corrosion resistance tests, and visual inspections. These tests help ensure that the hardware cloth can withstand the environmental conditions it will face in use, such as exposure to moisture and varying temperatures.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

Illustrative image related to 1/2 inch hardware cloth for chicken coop

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing practices and quality assurance protocols. Buyers should request access to their facilities to observe production processes and quality control measures firsthand.

-

Quality Assurance Reports: Requesting documented quality assurance reports can give buyers an overview of the supplier’s performance over time. These reports should detail any issues encountered during production and how they were resolved.

-

Third-Party Inspections: Engaging third-party inspection services can serve as an impartial method of verifying product quality. These organizations can conduct tests and inspections to ensure that products meet specified standards before shipment.

-

Certifications and Compliance Documentation: Buyers should ask for copies of relevant certifications and compliance documentation. This includes ISO certificates, CE markings, and any other certifications that validate the quality of the manufacturing processes.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must navigate unique challenges when it comes to quality assurance for hardware cloth. Here are some critical considerations:

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding product quality and safety standards. Understanding these differences can help buyers set realistic expectations and ensure compliance with local regulations.

-

Communication Barriers: Language differences can complicate the verification process. Establishing clear communication channels and employing bilingual representatives can facilitate smoother interactions between buyers and suppliers.

-

Shipping and Handling: Quality assurance doesn’t stop at production. Buyers should consider how products are handled during shipping and storage. Proper packaging and handling procedures are essential to prevent damage and ensure that the hardware cloth arrives in optimal condition.

-

Market-Specific Needs: Different markets may have specific requirements based on local wildlife, climate, and agricultural practices. Buyers should communicate these needs to suppliers to ensure that the hardware cloth meets the intended use in the target market.

By understanding the manufacturing processes and quality assurance measures for 1/2 inch hardware cloth, B2B buyers can make informed decisions that not only meet their operational needs but also ensure the safety and security of their poultry operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1/2 inch hardware cloth for chicken coop’

To effectively procure 1/2 inch hardware cloth for chicken coops, a systematic approach is essential. This guide outlines the necessary steps to ensure that B2B buyers make informed decisions when sourcing this critical material for poultry protection.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the hardware cloth is vital. Consider the mesh size, gauge, and material type. For chicken coops, a 1/2 inch mesh with a 19-gauge galvanized steel is commonly recommended for its durability and predator resistance.

- Mesh Size: Ensure it is 1/2 inch to prevent small predators from accessing the coop.

- Gauge: A thicker gauge (like 19) offers greater strength against larger animals.

Step 2: Research Suppliers and Manufacturers

Begin your sourcing process by identifying reputable suppliers who specialize in hardware cloth. Look for manufacturers with a proven track record in providing high-quality products.

- Check Reviews: Look for feedback from other B2B customers in your industry to gauge reliability.

- Assess Experience: Prefer suppliers with a history of working with agricultural or poultry industries.

Step 3: Evaluate Product Quality and Certifications

Before purchasing, it’s crucial to evaluate the quality of the hardware cloth being offered. Request samples if possible to inspect the material firsthand.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

- Certifications: Ensure the product is certified for safety and compliance with local regulations.

- Material Properties: Look for galvanized steel for rust resistance, especially in humid environments.

Step 4: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing and payment options. Cost-effectiveness is key, but it shouldn’t compromise quality.

- Bulk Discounts: Inquire about pricing for bulk orders, as many suppliers offer discounts for larger quantities.

- Payment Flexibility: Ensure the supplier offers reasonable payment terms that align with your cash flow requirements.

Step 5: Review Shipping and Delivery Options

Understand the logistics involved in getting the hardware cloth to your location. Efficient shipping can save time and reduce costs.

- Lead Times: Confirm how quickly the supplier can fulfill your order and ship it to your destination.

- Shipping Costs: Factor in shipping fees when comparing overall costs between suppliers.

Step 6: Verify After-Sales Support and Warranty

After securing your supplier, evaluate their after-sales support and warranty policies. This is crucial for addressing any potential issues post-purchase.

- Customer Support: Ensure the supplier provides accessible customer service for inquiries and support.

- Warranty Terms: Check if there are warranties or guarantees on the product to safeguard your investment.

Step 7: Finalize the Order and Document Everything

Once you’ve made your decision, finalize the order with clear documentation. This includes contracts, invoices, and delivery timelines.

- Written Agreements: Ensure all terms discussed are documented to avoid misunderstandings.

- Track Orders: Maintain a record of your order and correspondence for future reference.

By following this step-by-step checklist, B2B buyers can confidently source high-quality 1/2 inch hardware cloth for chicken coops, ensuring the protection of their poultry investments against various predators.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Comprehensive Cost and Pricing Analysis for 1/2 inch hardware cloth for chicken coop Sourcing

What Are the Key Cost Components for Sourcing 1/2 Inch Hardware Cloth?

When considering the procurement of 1/2 inch hardware cloth for chicken coops, understanding the cost structure is essential. The primary cost components include:

-

Materials: The raw material cost is significantly influenced by the type of steel used, typically galvanized to enhance durability against rust and corrosion. High-quality 19-gauge hot-dipped galvanized steel is common, and its price can fluctuate based on market conditions.

-

Labor: Labor costs encompass the workforce involved in manufacturing and quality assurance. This includes wages for employees in production facilities, which can vary by region and labor laws.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility operations. Efficient manufacturing processes can help reduce these costs, impacting overall pricing.

-

Tooling: Investment in specialized machinery for cutting and shaping the hardware cloth can add to the cost. Suppliers may pass these costs on to buyers, especially if they lack automation.

-

Quality Control (QC): Ensuring that the hardware cloth meets specified standards involves costs for inspection and testing. Quality certifications can also affect the price, as suppliers may charge a premium for certified products.

-

Logistics: Transportation costs are critical, particularly for international shipping. Factors such as shipping distance, mode of transport, and freight charges can significantly impact the final cost.

-

Margin: Suppliers will add a markup to cover their operational costs and profit margin, which can vary widely based on market competition and supplier reputation.

How Do Price Influencers Affect Hardware Cloth Pricing?

Several factors can influence the pricing of 1/2 inch hardware cloth, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract lower per-unit prices due to economies of scale. Buyers should inquire about bulk discounts, which can significantly reduce costs.

-

Specifications and Customization: Custom specifications, such as dimensions or coatings, can increase costs. Standard sizes and specifications often have more competitive pricing due to higher production volumes.

-

Material Quality and Certifications: Hardware cloth made from higher-grade materials or with specific certifications (e.g., ISO) may command a premium. Buyers must weigh the long-term benefits of investing in higher-quality products against initial costs.

-

Supplier Factors: The supplier’s location, reliability, and manufacturing capabilities can affect pricing. Suppliers with a strong reputation for quality and service may charge more but offer better value in the long run.

-

Incoterms: Understanding shipping terms (such as FOB, CIF) is crucial for budgeting. These terms dictate who is responsible for shipping costs and insurance, which can affect the total landed cost.

What Tips Can Help Buyers Optimize Costs for International Sourcing?

International buyers should consider several strategies to optimize costs when sourcing hardware cloth:

-

Negotiation: Engaging in negotiations can yield better pricing, especially for larger orders. Establishing a good rapport with suppliers may also lead to favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, shipping, handling, and potential maintenance costs. This approach helps in making informed decisions that go beyond initial pricing.

-

Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variations due to currency fluctuations, tariffs, and local market conditions. Understanding these nuances can help in budgeting effectively.

-

Supplier Diversity: Sourcing from multiple suppliers can create competition and lead to better pricing. It also mitigates risks associated with relying on a single source.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to more favorable pricing and terms as trust and reliability develop over time.

Disclaimer

Prices for 1/2 inch hardware cloth can vary significantly based on market conditions, supplier negotiations, and regional factors. It is advisable to request quotes from multiple suppliers and conduct thorough research to ensure competitive pricing.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Alternatives Analysis: Comparing 1/2 inch hardware cloth for chicken coop With Other Solutions

In the quest to secure chicken coops against predators, several solutions are available, each with its unique advantages and disadvantages. Evaluating these alternatives allows B2B buyers to make informed decisions based on specific needs and regional challenges. This analysis compares 1/2 inch hardware cloth with other viable fencing solutions, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | 1/2 Inch Hardware Cloth For Chicken Coop | Welded Wire Fencing | Electric Fencing |

|---|---|---|---|

| Performance | High resistance to predators; durable | Strong, but may be penetrable by determined animals | Effective deterrent; requires power source |

| Cost | Moderate ($137.08 for 48″x100′ roll) | Varies widely ($100-$300 depending on gauge and size) | Higher initial cost; ongoing electricity costs |

| Ease of Implementation | Relatively straightforward; requires tools for installation | Moderate; requires careful installation | Complex; needs setup of electrical system |

| Maintenance | Low; resistant to rust and corrosion | Moderate; may require periodic checks for damage | Moderate; needs monitoring of power supply |

| Best Use Case | Secure coops in areas with small to medium predators | Larger enclosures needing robust protection | Areas with high wildlife activity, where deterrence is key |

What Are the Benefits and Drawbacks of Welded Wire Fencing?

Welded wire fencing consists of rigid steel wires that are welded together, forming a strong barrier against various animals. Its primary advantage is its strength, which makes it a reliable option for larger enclosures. However, depending on the gauge, it may not be as predator-proof as 1/2 inch hardware cloth, especially against smaller animals like raccoons. Additionally, welded wire is typically more expensive and may require more complex installation techniques, which can deter some buyers.

How Does Electric Fencing Compare?

Electric fencing offers a unique approach to predator control by delivering a mild shock to deter animals from crossing the boundary. This method is particularly effective in areas with high wildlife activity. While it can be a strong deterrent, its effectiveness is contingent upon a continuous power supply and can incur ongoing costs. Moreover, installation can be more complex than other options, requiring knowledge of electrical systems. Maintenance also involves regular checks to ensure the system is functioning properly.

Conclusion: Which Fencing Solution is Right for Your Chicken Coop?

When deciding on the best fencing solution for a chicken coop, it is essential for B2B buyers to consider their specific circumstances, such as the types of predators in their region, budget constraints, and installation capabilities. While 1/2 inch hardware cloth provides a robust, cost-effective solution with low maintenance needs, alternatives like welded wire and electric fencing may offer better performance in specific scenarios. Ultimately, the choice should align with the operational goals and environmental factors unique to each buyer’s situation.

Essential Technical Properties and Trade Terminology for 1/2 inch hardware cloth for chicken coop

What Are the Key Technical Properties of 1/2 Inch Hardware Cloth for Chicken Coops?

When selecting 1/2 inch hardware cloth for chicken coops, several technical properties are critical for ensuring durability and effectiveness. Understanding these specifications helps B2B buyers make informed decisions that align with their operational needs.

-

Material Grade

The most common material for hardware cloth is galvanized steel, specifically hot-dipped galvanized, which provides excellent resistance to rust and corrosion. The material grade affects the longevity and strength of the product, making it suitable for outdoor applications. Buyers should seek out hardware cloth that adheres to industry standards for quality to ensure it withstands the elements and the wear from animals. -

Mesh Size

The mesh size, in this case, 1/2 inch, refers to the dimensions of each square in the wire grid. This size is crucial for keeping out various predators while still allowing for ventilation and visibility. A 1/2 inch mesh is typically effective against raccoons, snakes, and rodents, which are common threats to poultry. Buyers should consider local wildlife when selecting mesh sizes to ensure adequate protection. -

Gauge

Gauge refers to the thickness of the wire used in the hardware cloth. A 19-gauge wire is standard for 1/2 inch hardware cloth, providing a balance between strength and flexibility. The lower the gauge number, the thicker the wire. Thicker wires are typically more durable but can be heavier and harder to work with. B2B buyers must weigh the benefits of gauge against their specific installation needs and budget. -

Roll Dimensions

Hardware cloth is usually sold in rolls of varying lengths and widths. Common dimensions include 48 inches by 100 feet, which offers ample coverage for larger coops or runs. Understanding roll dimensions is essential for calculating material needs accurately, especially for larger projects where precise measurements are critical. -

Weight

The weight of the hardware cloth is an important consideration for installation. Heavier materials, while offering more strength, can be more challenging to handle and may require additional support structures. B2B buyers should evaluate their installation capabilities and ensure they have the necessary tools and workforce for heavier materials. -

Durability and Longevity

Durability relates to the expected lifespan of the hardware cloth in various environmental conditions. Factors like UV exposure, moisture, and physical wear from animals can affect durability. Buyers should look for warranties or guarantees from suppliers that indicate the expected longevity of their products.

What Are Common Trade Terms Relevant to 1/2 Inch Hardware Cloth?

Understanding trade terminology is essential for navigating B2B transactions effectively. Here are several key terms related to 1/2 inch hardware cloth:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hardware cloth, it could relate to companies that manufacture the raw materials or finished products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory costs and purchasing strategies. Buyers should negotiate MOQs to align with their operational needs while avoiding excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For hardware cloth, this allows buyers to compare prices and terms from different manufacturers, facilitating better purchasing decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. They clarify who is responsible for shipping costs, insurance, and liability during transit. Familiarity with Incoterms is vital for B2B transactions, especially in international trade, to avoid misunderstandings. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For hardware cloth, lead time can vary based on manufacturing processes and shipping logistics. Understanding lead time helps businesses plan their projects more effectively. -

Certification Standards

Certification standards refer to industry benchmarks that products must meet to be deemed safe and effective. For hardware cloth, certifications may include compliance with safety and quality assurance standards. Buyers should verify that their suppliers adhere to these standards to ensure product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategies and ensure the successful implementation of hardware cloth in chicken coops.

Navigating Market Dynamics and Sourcing Trends in the 1/2 inch hardware cloth for chicken coop Sector

What Are the Current Market Dynamics for 1/2 Inch Hardware Cloth for Chicken Coops?

The global market for 1/2 inch hardware cloth, particularly for chicken coops, is experiencing significant growth, driven by increasing poultry farming activities across various regions. The demand is particularly pronounced in Africa, South America, the Middle East, and Europe, where small-scale and commercial poultry farming is becoming more prevalent. Factors such as urbanization, a growing population, and rising consumer awareness of food security are propelling this trend. Additionally, the shift towards sustainable and self-sufficient food sources is making hardware cloth an essential component for secure and effective poultry management.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Emerging B2B tech trends include the rise of e-commerce platforms and online marketplaces that facilitate easier sourcing of hardware cloth. Buyers are increasingly seeking quality assurance through product reviews and certifications, which influence their purchasing decisions. Furthermore, advancements in manufacturing technologies are leading to higher quality materials with enhanced durability and resistance to environmental factors, thereby reducing long-term costs for buyers. As international trade regulations evolve, B2B buyers must stay informed about tariffs and import restrictions that may affect sourcing strategies.

How Important Is Sustainability and Ethical Sourcing for 1/2 Inch Hardware Cloth?

Sustainability and ethical sourcing have become paramount concerns in the B2B landscape, particularly for buyers of hardware cloth. The environmental impact of manufacturing processes, including the use of galvanized steel, has led to increased scrutiny from consumers and regulatory bodies alike. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

Ethical supply chains are crucial for ensuring that products are not only effective but also responsibly sourced. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability. B2B buyers should prioritize suppliers who adopt transparent sourcing practices and can provide documentation regarding their materials’ origins and environmental impact. By doing so, they not only enhance their brand reputation but also contribute positively to the global push for sustainability.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

How Has the 1/2 Inch Hardware Cloth Market Evolved Over Time?

The evolution of the 1/2 inch hardware cloth market has been closely tied to advancements in agricultural practices and the growing recognition of the importance of animal welfare. Traditionally, poultry enclosures relied on lighter materials such as chicken wire, which were often inadequate for protecting livestock from predators. Over the years, as poultry farming has transitioned to more commercial operations, the demand for stronger, more reliable materials like hardware cloth has surged.

The introduction of galvanized steel and improvements in manufacturing processes have significantly enhanced the durability and effectiveness of hardware cloth. This evolution reflects a broader trend in agriculture where quality and security are prioritized to protect investments and ensure food safety. Today, 1/2 inch hardware cloth is recognized as a staple in poultry management, with ongoing innovations aimed at enhancing its performance and sustainability, making it an indispensable choice for B2B buyers in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 1/2 inch hardware cloth for chicken coop

-

How do I choose the right gauge of hardware cloth for my chicken coop?

Selecting the appropriate gauge for hardware cloth involves assessing the potential predators in your area and the specific needs of your chicken coop. A 19-gauge hardware cloth is commonly recommended due to its balance of strength and flexibility, providing adequate protection against larger predators like raccoons and foxes. For environments with smaller intruders, such as mice, a 1/4-inch gauge may be suitable. Evaluate the local wildlife threats and consider the longevity and durability of the material when making your choice. -

What is the best hardware cloth size for protecting chickens from predators?

For effective predator protection, 1/2-inch hardware cloth is widely regarded as the optimal choice. Its mesh size is large enough to prevent most small animals while still offering robust strength against larger threats. The 19-gauge version provides additional resistance to bending and tearing, making it ideal for securing chicken coops. Always ensure proper installation to maximize its protective capabilities and consider reinforcing vulnerable areas with additional layers if necessary. -

What are the key factors to consider when sourcing hardware cloth internationally?

When sourcing hardware cloth internationally, consider factors such as product specifications, shipping costs, customs regulations, and supplier reliability. Verify that the material meets your local standards for quality and safety. Additionally, assess the supplier’s reputation through reviews and references, and inquire about their manufacturing processes to ensure consistent quality. Understanding the total landed cost, including tariffs and taxes, is crucial for budgeting and pricing your products competitively. -

How can I vet suppliers for hardware cloth to ensure quality?

Vetting suppliers is essential for ensuring quality. Start by checking for certifications that align with international standards, such as ISO 9001 for quality management. Request samples to assess the material’s durability and compliance with your specifications. Conduct background checks, including reading reviews and testimonials from previous clients. Building a relationship with suppliers through direct communication can also provide insights into their manufacturing practices and reliability. -

What customization options are available for hardware cloth orders?

Customization options for hardware cloth can include variations in gauge, mesh size, and roll dimensions. Some suppliers may offer tailored solutions based on your project requirements, such as specific lengths or widths. It’s advisable to communicate your needs clearly to the supplier during the initial discussions. Additionally, inquire about the possibility of custom coatings or treatments for enhanced rust resistance, particularly if the cloth will be used in harsh environments. -

What is the minimum order quantity (MOQ) for hardware cloth purchases?

Minimum order quantities for hardware cloth can vary significantly between suppliers. Typically, MOQs range from a few rolls to several hundred, depending on the manufacturer’s production capabilities and your location. It’s essential to clarify these terms before placing an order, as some suppliers may be willing to accommodate smaller orders, particularly for new customers or bulk orders. Always discuss pricing implications related to different order sizes to optimize your procurement strategy. -

What payment terms should I expect when purchasing hardware cloth?

Payment terms can differ based on the supplier and the total order amount. Common arrangements include partial payments upfront with the balance due upon delivery or net 30/60 terms. It’s crucial to negotiate terms that work for both parties, ensuring a balance between supplier security and buyer flexibility. Consider using secure payment methods like letters of credit or escrow services for larger transactions to protect your investment. -

How do I ensure quality assurance during the logistics of hardware cloth shipments?

To ensure quality assurance during logistics, establish clear communication with your supplier regarding packaging and shipping standards. Request inspection reports before shipment and consider arranging third-party quality checks. Monitor shipping conditions closely, especially for long-distance shipments, to prevent damage. Upon arrival, conduct a thorough inspection to verify that the product meets your specifications and report any discrepancies immediately to the supplier for resolution.

Top 5 1/2 Inch Hardware Cloth For Chicken Coop Manufacturers & Suppliers List

1. National Supply – Hardware Cloth 1/2 inch 48in x 100 ft

Domain: nationalsupplys.com

Registered: 2016 (9 years)

Introduction: {‘name’: ‘Hardware Cloth 1/2 inch 48in x 100 ft’, ‘material’: ’19 gauge hot-dipped galvanized steel’, ‘mesh_opening’: ‘1/2 inch x 1/2 inch’, ‘dimensions’: ’48 inches x 100 feet’, ‘features’: [‘Robust Construction’, ‘Superior Durability’, ‘Versatile Use’, ‘Effective Protection’, ‘Easy to Install’, ‘Quality Assurance’], ‘applications’: [‘chicken coops’, ‘rabbit and snake enclosures’, ‘tree guards’, …

2. Backyard Chickens – Hardware Cloth Solutions

Domain: backyardchickens.com

Registered: 2000 (25 years)

Introduction: 1/4″ 23 gauge hardware cloth; 1/2″ 19 gauge hardware cloth; 1/2″ hardware cloth is easier to work with and heavier gauge; 1/4″ hardware cloth is preferred for preventing mice; both sizes are used to protect against predators like possums, raccoons, foxes, coyotes, and bobcats.

3. Reddit – Hardware Cloth

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hardware cloth is a type of wire mesh used for chicken coops and runs. It is considered stronger than chicken wire and is designed to deter predators. However, it is not completely predator proof, especially against larger animals like bears or mountain lions. The gauge and thickness of the hardware cloth can vary, affecting its strength and resistance to bending or breaking. A common size mention…

4. Imaginacres – Hardware Cloth

Domain: imaginacres.com

Registered: 2013 (12 years)

Introduction: Hardware cloth is made of heavier gauge, galvanized, stainless steel, or bare steel wires woven tightly together into smaller openings. It is more rigid and solid compared to chicken wire, which is made from lightweight galvanized wire twisted into a hexagon mesh pattern. Hardware cloth offers superior strength and durability, making it resistant to penetration and damage from predators. Recommend…

5. Villa Colibri – Hardware Cloth 1/2 Inch Wire Fence Mesh Rolls

Domain: villa-colibri-nosybe.com

Registered: 2022 (3 years)

Introduction: Hardware Cloth 1/2 Inch Wire Fence Mesh Rolls for Chicken Coop

Strategic Sourcing Conclusion and Outlook for 1/2 inch hardware cloth for chicken coop

In conclusion, the strategic sourcing of 1/2 inch hardware cloth is vital for ensuring the safety and longevity of chicken coops across diverse regions, from Africa to Europe. This versatile material, with its robust 19-gauge galvanized steel construction, provides superior protection against a variety of predators, including raccoons and coyotes. By selecting the right gauge and mesh size, B2B buyers can effectively mitigate risks associated with poultry farming, enhancing both productivity and animal welfare.

The importance of sourcing high-quality hardware cloth cannot be overstated. Not only does it serve as a physical barrier, but it also contributes to the overall sustainability of poultry operations by reducing losses due to predation. As demand for poultry products continues to rise globally, investing in durable and reliable fencing solutions like 1/2 inch hardware cloth will be a key differentiator in competitive markets.

Looking ahead, international buyers are encouraged to explore partnerships with reputable suppliers who can provide this essential material. By prioritizing quality and durability, businesses can ensure the success of their poultry farming ventures and contribute to food security in their respective regions. Engage with suppliers today to secure the best solutions for your needs and stay ahead in the ever-evolving agricultural landscape.

Illustrative image related to 1/2 inch hardware cloth for chicken coop

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.