Top 4 Why Is Heat Treatment Important Suppliers (And How to Choose)

Introduction: Navigating the Global Market for why is heat treatment important

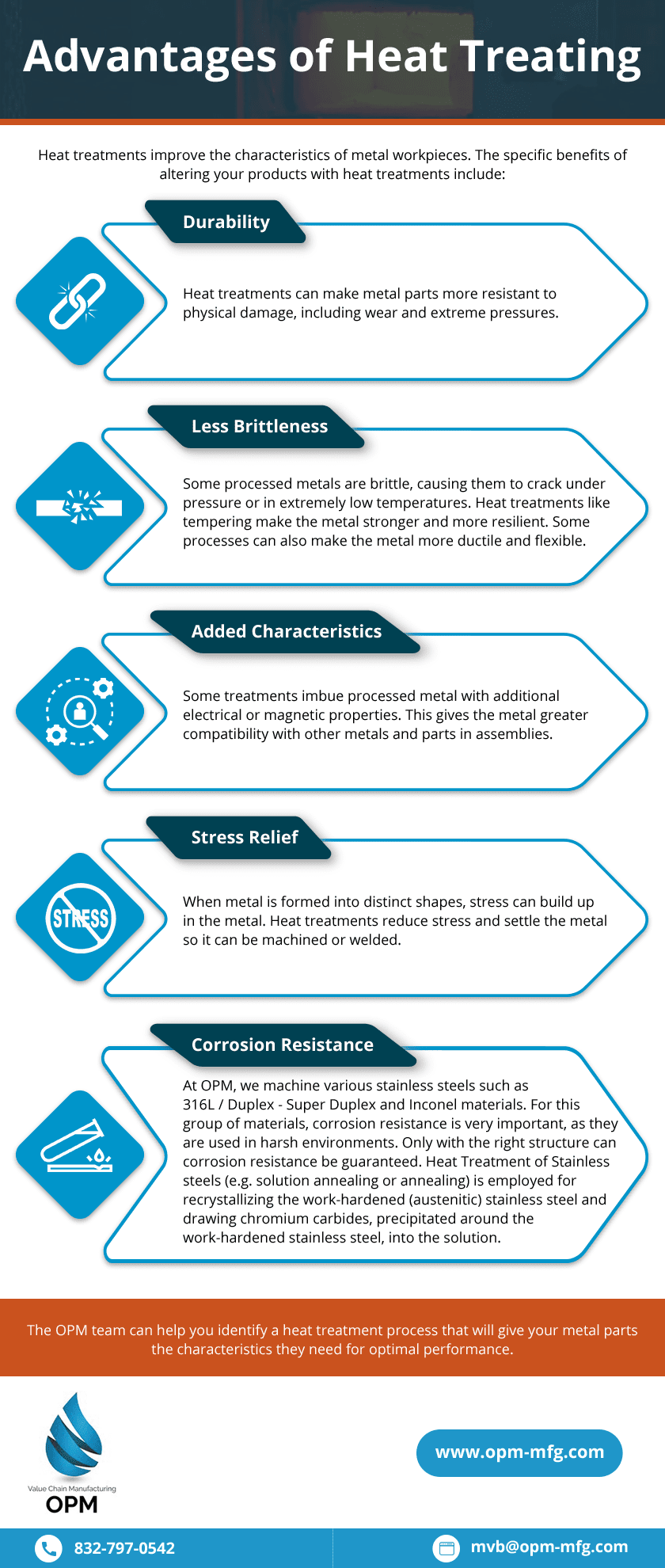

In the fast-paced world of manufacturing, understanding why heat treatment is important can significantly influence the performance and longevity of metal components. For international B2B buyers, especially those sourcing for industries in Africa, South America, the Middle East, and Europe, the challenge lies in identifying reliable suppliers who can deliver quality heat-treated metals that meet stringent application requirements. This guide offers a comprehensive exploration of heat treatment processes, including types such as hardening, annealing, and tempering, along with their specific applications across various industries like aerospace, automotive, and construction.

By delving into the nuances of heat treatment, this guide empowers buyers to make informed purchasing decisions. It addresses critical considerations such as supplier vetting, cost implications, and the performance benefits of heat-treated materials. With insights into optimizing material properties—like strength, ductility, and wear resistance—B2B buyers will be equipped to enhance product reliability and efficiency in their operations.

Furthermore, by understanding the global landscape of heat treatment services, buyers can better navigate potential partnerships, ensuring that their sourcing aligns with both quality standards and cost-effectiveness. This resource is designed to help you not only find the right suppliers but also leverage heat treatment as a strategic advantage in your manufacturing processes.

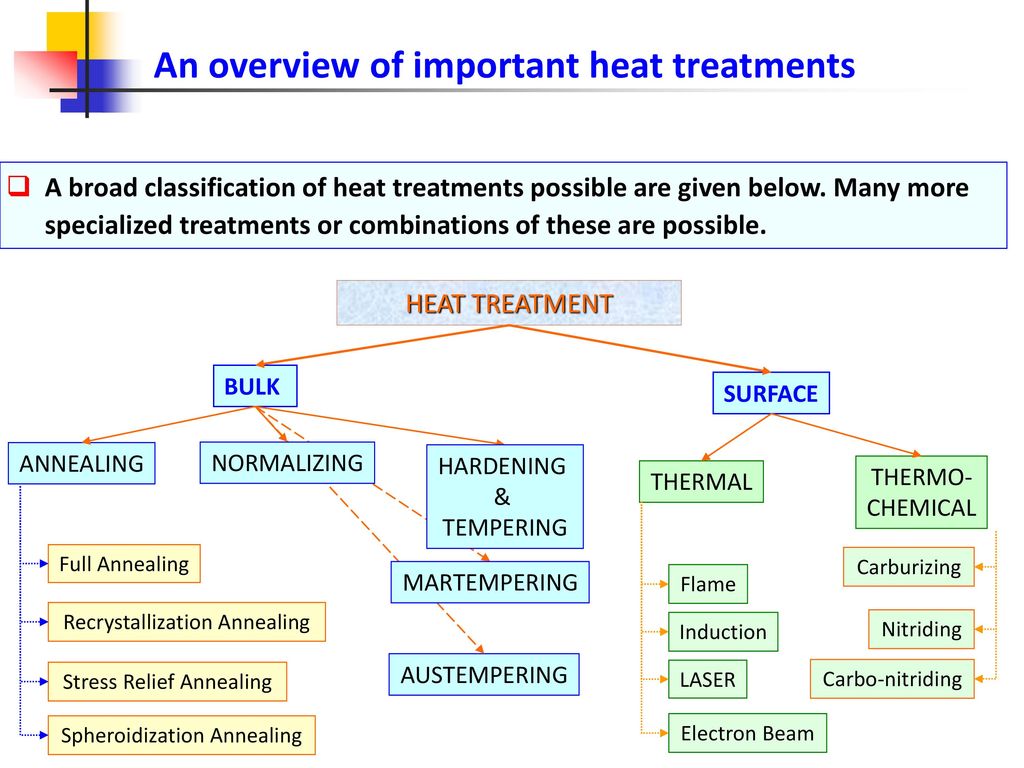

Understanding why is heat treatment important Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hardening | Increases hardness and strength; involves rapid cooling. | Aerospace, automotive, machinery | Pros: Enhanced strength; better wear resistance. Cons: May lead to brittleness if not tempered. |

| Annealing | Softens metal, improves ductility; slow cooling process. | Electronics, metal fabrication | Pros: Improved workability; reduced internal stresses. Cons: May not enhance hardness. |

| Tempering | Reduces brittleness while maintaining strength; reheating process. | Tool manufacturing, construction | Pros: Balances hardness and toughness. Cons: Requires precise temperature control. |

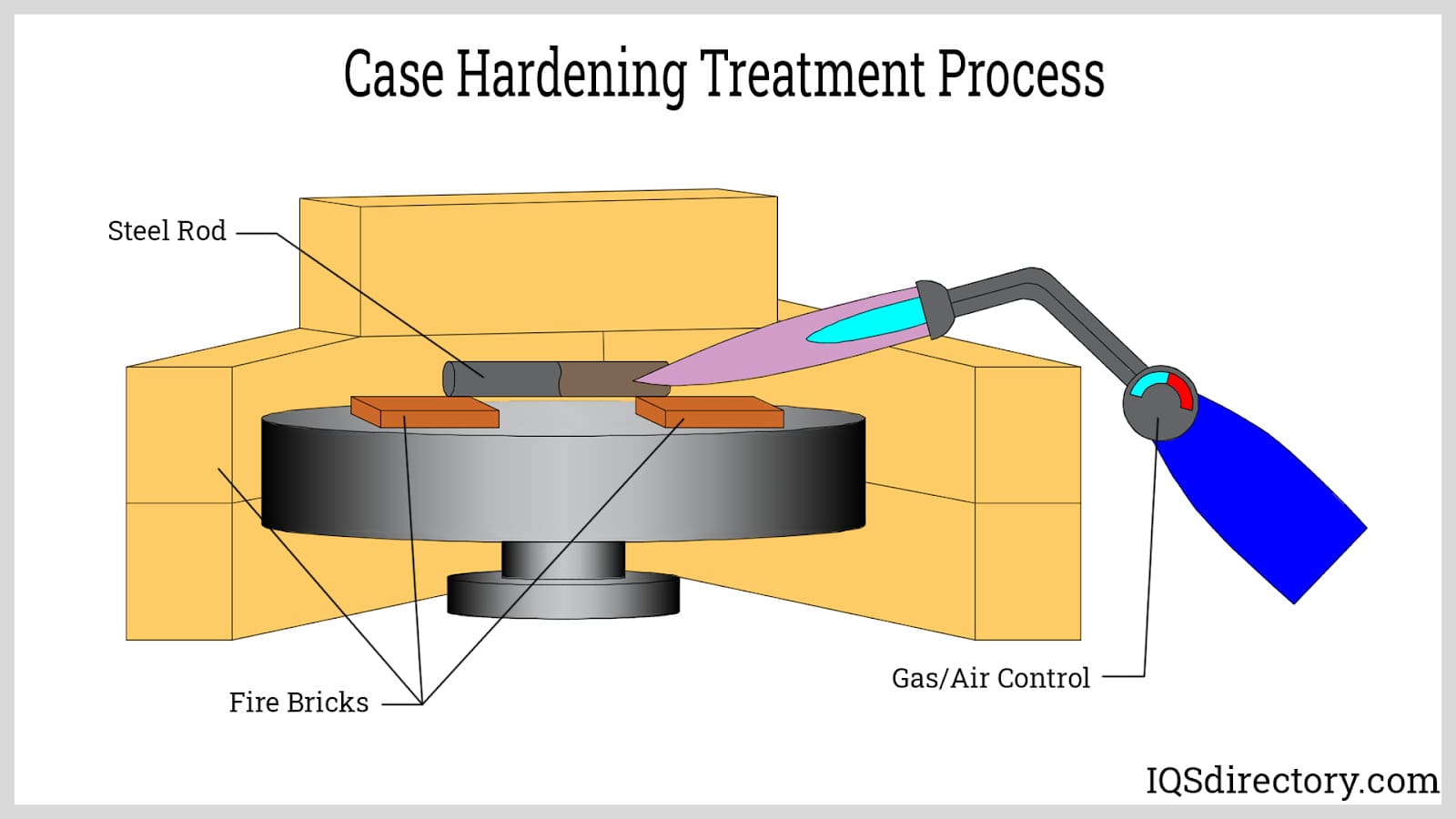

| Case Hardening | Hardens surface while keeping the core softer; prevents brittleness. | Gear manufacturing, automotive parts | Pros: Durable surface with flexible core. Cons: Surface hardening may not be uniform. |

| Normalizing | Produces uniform microstructure; involves heating and air cooling. | Steel production, structural applications | Pros: Enhances toughness and ductility. Cons: Less effective for non-ferrous metals. |

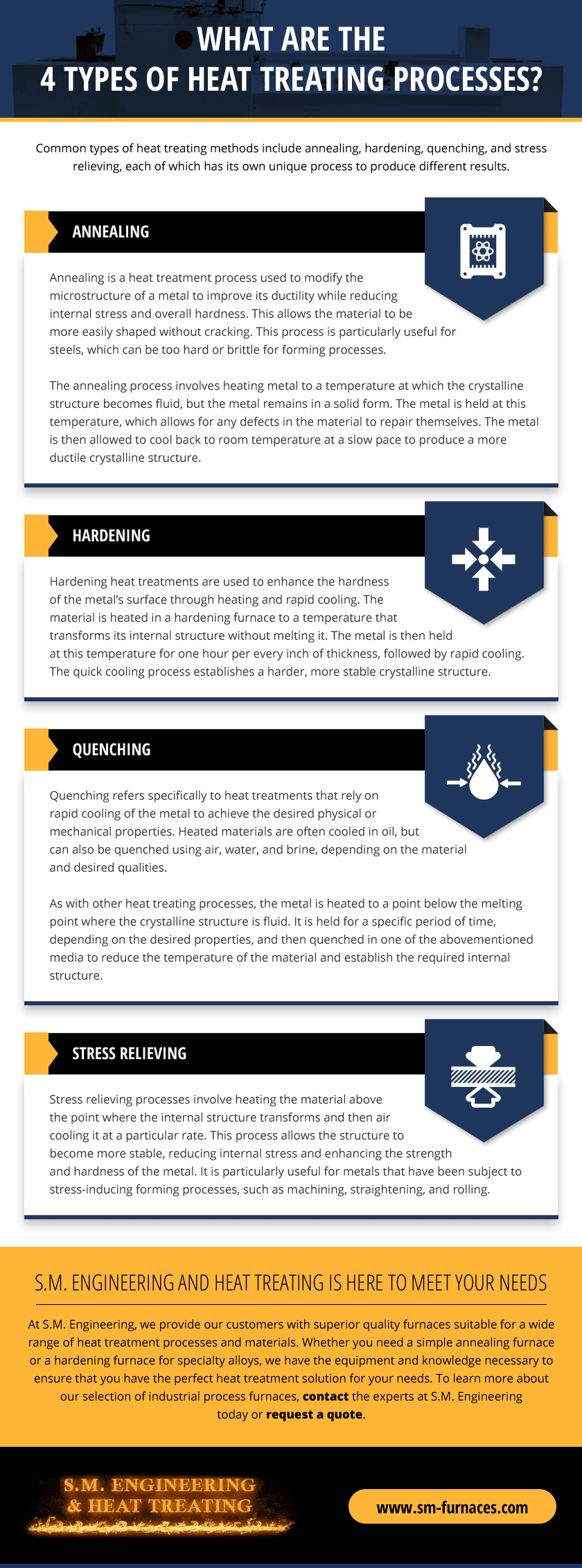

What is Hardening and Its B2B Relevance?

Hardening is a critical heat treatment process that significantly enhances the hardness and strength of metals through rapid cooling after heating. This process is essential in industries like aerospace and automotive, where components must withstand high stress and wear. Buyers should consider the trade-off between increased hardness and potential brittleness, necessitating additional processes like tempering to achieve desired performance characteristics. Understanding the specific requirements of their applications is vital for selecting the right hardening process.

How Does Annealing Benefit B2B Operations?

Annealing is characterized by its ability to soften metals, making them more ductile and workable. This is particularly beneficial in electronics and metal fabrication, where ease of machining is crucial. The slow cooling process involved reduces internal stresses, which can lead to failures during subsequent operations. Buyers should evaluate the suitability of annealing for their materials, as it may not enhance hardness but is invaluable for improving the overall manufacturability of components.

What Are the Advantages of Tempering?

Tempering is an essential process for balancing the hardness and brittleness of metals, particularly iron-based alloys. By reheating hardened materials to a lower temperature, tempering enhances toughness, making it a preferred choice in tool manufacturing and construction. Buyers must understand the importance of precise temperature control during tempering to achieve optimal results, as inadequate tempering can result in material failure under stress.

Why Choose Case Hardening for Your Products?

Case hardening focuses on hardening the surface of a metal while keeping the core soft, which is particularly useful in applications like gear manufacturing and automotive parts. This process allows for a durable surface that can withstand wear while maintaining flexibility in the core. Buyers should consider the potential for uneven surface hardening and ensure that the specific needs of their products align with the capabilities of case hardening processes.

What is Normalizing and Its Limitations?

Normalization is a heat treatment process that aims to produce a uniform microstructure in metals, enhancing their toughness and ductility. It is particularly effective for steel production and structural applications. However, this process is less effective for non-ferrous metals, making it essential for buyers to assess the material types and intended applications before opting for normalizing as a treatment method. Understanding the limitations will help in selecting the most suitable heat treatment processes for their specific needs.

Key Industrial Applications of why is heat treatment important

| Industry/Sector | Specific Application of why is heat treatment important | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Strengthening aircraft components through heat treatment | Enhanced safety and performance of aircraft, reducing failure rates | Compliance with stringent aerospace standards and certifications |

| Automotive | Hardening engine parts and transmission components | Improved durability and efficiency, leading to lower maintenance costs | Quality assurance and traceability of heat-treated components |

| Oil & Gas | Stress relieving and hardening drilling tools | Increased tool life and reliability, reducing downtime and costs | Material compatibility and adherence to industry-specific regulations |

| Manufacturing | Improving machinability of metal parts via annealing | Enhanced production efficiency and reduced scrap rates | Expertise in specific heat treatment processes for various alloys |

| Electronics | Magnetic annealing for components in electronic devices | Improved performance and reliability of electronic products | Precision in heat treatment processes to meet electronic specifications |

How is Heat Treatment Important in Aerospace Manufacturing?

In the aerospace industry, heat treatment is crucial for enhancing the strength and durability of aircraft components. By applying processes like hardening and tempering, manufacturers can ensure that parts withstand extreme conditions and stresses during flight. This not only improves safety but also reduces the risk of component failure, which can have catastrophic consequences. International B2B buyers in this sector must consider compliance with rigorous aerospace standards and certifications, as well as the ability to deliver high-quality, heat-treated components consistently.

What Role Does Heat Treatment Play in Automotive Applications?

Heat treatment is vital in the automotive sector, particularly for engine parts and transmission components, where enhanced durability is essential. Processes such as case hardening and quenching increase the wear resistance of these components, leading to improved vehicle performance and reduced maintenance costs. B2B buyers from regions like South America and Africa should prioritize suppliers who can guarantee quality assurance and traceability of heat-treated parts, as these factors are critical for meeting industry standards and ensuring vehicle safety.

How Does Heat Treatment Enhance Oil & Gas Operations?

In the oil and gas industry, heat treatment is used to improve the performance of drilling tools through stress relieving and hardening processes. These treatments increase the lifespan and reliability of tools, thereby minimizing downtime and operational costs. Buyers in this sector must ensure that their suppliers adhere to industry-specific regulations and provide materials that are compatible with the harsh conditions often encountered in oil extraction.

Why is Heat Treatment Essential for Manufacturing Efficiency?

Manufacturers frequently employ heat treatment to improve the machinability of metal parts, particularly through processes like annealing. This treatment reduces internal stresses and enhances the workability of materials, leading to increased production efficiency and lower scrap rates. International buyers should look for suppliers with expertise in various heat treatment processes tailored to different alloys, as this knowledge is crucial for optimizing manufacturing operations.

How Does Heat Treatment Affect Electronic Component Performance?

In the electronics industry, heat treatment processes such as magnetic annealing play a significant role in enhancing the performance of electronic components. By precisely controlling the heat treatment parameters, manufacturers can achieve the desired magnetic properties, which is essential for the reliability of electronic devices. B2B buyers in this field need to ensure that their suppliers can deliver precision heat treatment processes that meet strict electronic specifications, as even minor deviations can lead to performance issues.

3 Common User Pain Points for ‘why is heat treatment important’ & Their Solutions

Scenario 1: Struggling with Material Performance in Harsh Environments

The Problem: B2B buyers in industries such as aerospace, automotive, and oil and gas often face challenges with material performance under extreme conditions. Metals and alloys that are not heat-treated may fail to withstand high stress, wear, or corrosion. This can lead to equipment malfunctions, increased downtime, and costly replacements. For instance, a manufacturer of aircraft components may discover that untreated aluminum parts are deforming or cracking during use, compromising safety and reliability.

The Solution: To overcome these issues, buyers should prioritize heat treatment processes such as hardening and case hardening for critical components. By working closely with metallurgists and heat treatment specialists, buyers can specify the correct treatment processes tailored to their specific materials and applications. For example, implementing a hardening process to improve the strength and wear resistance of aluminum alloys can significantly enhance performance in demanding environments. Additionally, establishing long-term partnerships with reputable heat treatment service providers ensures consistent quality and expertise in meeting industry standards.

Illustrative image related to why is heat treatment important

Scenario 2: High Manufacturing Costs Due to Frequent Failures

The Problem: Many manufacturers experience high operational costs stemming from frequent failures of untreated metal parts. In sectors like construction or machinery, the continuous need to replace parts not only strains budgets but also disrupts production schedules. For instance, a construction equipment manufacturer might find that untreated steel components wear down quickly, leading to unexpected downtime and repair costs.

The Solution: Implementing heat treatment as a standard procedure can dramatically reduce the frequency of part failures. Buyers should invest in understanding the specific heat treatment processes that enhance durability, such as tempering and annealing. By integrating these processes into the manufacturing workflow, companies can produce parts with improved toughness and wear resistance. Furthermore, conducting a cost-benefit analysis can illustrate the long-term savings achieved through reduced replacement rates and maintenance costs, making a compelling case for the adoption of heat treatment.

Scenario 3: Navigating Complex Industry Standards and Specifications

The Problem: B2B buyers often grapple with the complexities of meeting industry standards and specifications that dictate the properties of materials used in their products. In highly regulated industries like defense and aerospace, the ramifications of using improperly treated materials can be severe, including regulatory fines and safety risks. A manufacturer in Europe might face challenges in sourcing heat-treated components that comply with stringent standards such as MIL-SPEC or ISO certifications.

The Solution: To effectively navigate these complexities, buyers should establish a robust sourcing strategy that includes collaborating with certified heat treatment facilities experienced in compliance with relevant industry standards. It’s vital to request detailed documentation of the heat treatment processes used, including adherence to specified temperatures, soak times, and cooling methods. Additionally, buyers should engage in regular communication with suppliers to ensure that any changes in standards or specifications are promptly addressed. By prioritizing partnerships with reputable suppliers who can provide compliant heat-treated materials, companies can enhance product safety and reliability while minimizing regulatory risks.

Strategic Material Selection Guide for why is heat treatment important

What are the Key Properties of Steel in Heat Treatment?

Steel is one of the most commonly heat-treated materials due to its versatility and strength. Key properties of heat-treated steel include enhanced hardness, improved tensile strength, and increased wear resistance. These properties are critical for applications in automotive, aerospace, and construction industries, where components must withstand high stress and abrasive conditions.

Pros and Cons of Steel Heat Treatment: The primary advantage of heat-treated steel is its durability, which can significantly extend the lifespan of components. However, the heat treatment process can increase manufacturing complexity and costs, particularly for high-performance grades. Additionally, while heat-treated steel can resist corrosion better than untreated steel, it may still require protective coatings in harsh environments.

Impact on Application: Heat-treated steel is suitable for high-pressure applications, such as hydraulic systems, where failure can lead to catastrophic results. Its ability to maintain integrity under extreme conditions makes it a preferred choice for critical components.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should be aware of compliance with standards such as ASTM and DIN, which dictate the quality and performance of heat-treated steel. Understanding local regulations and quality certifications is crucial for ensuring product reliability.

How Does Aluminum Benefit from Heat Treatment?

Aluminum alloys are often heat-treated to enhance their mechanical properties, including strength and ductility. Key properties include lightweight characteristics and excellent corrosion resistance, making aluminum ideal for applications in the aerospace and automotive industries.

Pros and Cons of Aluminum Heat Treatment: The main advantage of heat-treated aluminum is its high strength-to-weight ratio, which is essential for reducing overall vehicle weight and improving fuel efficiency. However, heat-treated aluminum can be more expensive than other materials and may require specialized handling during manufacturing to avoid deformation.

Illustrative image related to why is heat treatment important

Impact on Application: In aerospace applications, heat-treated aluminum is crucial for components that must endure high temperatures and pressures. Its corrosion resistance also makes it suitable for marine applications, where exposure to saltwater is a concern.

Considerations for International Buyers: Buyers from South America and Africa should consider local availability and cost of heat-treated aluminum. Compliance with international standards such as JIS can also affect sourcing decisions, as different regions may have varying specifications for aluminum alloys.

What Role Does Titanium Play in Heat Treatment?

Titanium is known for its exceptional strength and corrosion resistance, making it a prime candidate for heat treatment. Key properties include high strength-to-weight ratio and biocompatibility, which are particularly valuable in medical and aerospace applications.

Pros and Cons of Titanium Heat Treatment: The advantage of heat-treated titanium lies in its ability to maintain strength at elevated temperatures, which is crucial for aerospace components. However, titanium is generally more expensive than steel and aluminum, and its machining can be complex, leading to higher production costs.

Impact on Application: In the medical field, heat-treated titanium is often used for implants and surgical instruments due to its biocompatibility. In aerospace, it is employed in components that must endure extreme conditions without compromising structural integrity.

Illustrative image related to why is heat treatment important

Considerations for International Buyers: Buyers from Europe and the Middle East should be aware of the stringent regulations surrounding titanium products, particularly in medical applications. Compliance with ISO standards is essential for ensuring product safety and efficacy.

How Does Copper Alloy Heat Treatment Affect Performance?

Copper alloys, such as brass and bronze, are frequently heat-treated to enhance their mechanical properties, including strength and ductility. Key properties include excellent electrical and thermal conductivity, making them ideal for electrical and plumbing applications.

Pros and Cons of Copper Alloy Heat Treatment: The primary advantage of heat-treated copper alloys is their improved strength while maintaining good workability. However, the heat treatment process can be less effective in improving corrosion resistance compared to other materials, necessitating additional protective measures.

Impact on Application: Heat-treated copper alloys are widely used in electrical connectors and plumbing fixtures, where conductivity and corrosion resistance are vital. Their ability to withstand high temperatures makes them suitable for various industrial applications.

Considerations for International Buyers: Buyers from Africa and South America should consider the availability of heat-treated copper alloys and their compliance with local standards. Understanding the specific requirements for electrical and plumbing applications can help in making informed sourcing decisions.

| Material | Typical Use Case for why is heat treatment important | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive components, construction materials | High durability and strength | Increased manufacturing complexity | Medium |

| Aluminum | Aerospace structures, automotive parts | Lightweight and corrosion-resistant | Higher cost and specialized handling | High |

| Titanium | Medical implants, aerospace components | Exceptional strength at high temps | High cost and machining complexity | High |

| Copper Alloy | Electrical connectors, plumbing fixtures | Excellent conductivity | Limited corrosion resistance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for why is heat treatment important

What Are the Key Stages in the Manufacturing Process of Heat Treatment?

Heat treatment is a critical process in the manufacturing of metal components, influencing their mechanical properties and overall performance. Understanding the main stages of manufacturing and the associated techniques can help B2B buyers select the right suppliers and ensure they receive high-quality products.

What Is the Role of Material Preparation in Heat Treatment?

The first stage in the heat treatment process is material preparation. This involves selecting the appropriate metal or alloy based on the desired properties and application. Common materials include various grades of steel, aluminum, titanium, and non-ferrous metals.

Before heat treatment, materials often undergo surface cleaning to remove any contaminants that might affect the process. This can include physical cleaning (like sandblasting) or chemical cleaning (using solvents). Proper preparation ensures uniform heating and optimal results in subsequent heat treatment stages.

Illustrative image related to why is heat treatment important

How Do Forming Techniques Impact Heat Treatment Outcomes?

After material preparation, the next stage is forming, where the metal is shaped into its intended configuration. Techniques such as forging, casting, or machining can be employed. The choice of forming technique can significantly affect the material’s microstructure and, subsequently, its response to heat treatment.

For instance, forged components typically exhibit better mechanical properties than cast ones due to their refined grain structure. Understanding these nuances allows buyers to choose materials that will perform well in heat treatment, enhancing the overall durability and reliability of the final product.

What Is the Importance of Assembly in Heat Treatment?

In some cases, heat treatment is performed on assembled components rather than individual parts. This is particularly true for complex machinery where assembly tolerances and interactions between parts are crucial.

Illustrative image related to why is heat treatment important

Heat treatment can help relieve internal stresses introduced during the assembly process, ensuring that parts fit together seamlessly and function as intended. B2B buyers should discuss assembly requirements with suppliers to ensure that heat treatment processes are tailored to the specific needs of their applications.

Why Is Finishing Critical After Heat Treatment?

Finishing processes, such as machining, grinding, or polishing, are often applied after heat treatment to achieve the final dimensions and surface quality of components. These processes may also involve additional heat treatments to fine-tune mechanical properties, such as tempering or stress relieving.

Selecting a supplier that understands the importance of finishing in conjunction with heat treatment is essential for achieving the desired product specifications. Buyers should inquire about the finishing techniques used by their suppliers and how these integrate with the heat treatment processes.

How Is Quality Assurance Implemented in Heat Treatment Processes?

Quality assurance (QA) is vital in ensuring that heat-treated components meet the required specifications and standards. Various international and industry-specific standards guide the QA processes in manufacturing, particularly in heat treatment.

What Are the Relevant International Standards for Heat Treatment?

ISO 9001 is one of the most recognized quality management standards applicable to heat treatment and other manufacturing processes. It establishes a framework for consistent quality control and improvement, ensuring that manufacturers meet customer and regulatory requirements.

In addition to ISO standards, other industry-specific certifications may apply, such as CE marking for products sold in Europe or API standards for oil and gas applications. B2B buyers should verify that suppliers hold relevant certifications, as this can indicate adherence to quality and safety practices.

What Are the Key QC Checkpoints in Heat Treatment?

Quality control in heat treatment typically involves several checkpoints, including:

- Incoming Quality Control (IQC): This step checks raw materials for compliance with specifications before they enter the production process.

- In-Process Quality Control (IPQC): Continuous monitoring during heat treatment ensures that parameters such as temperature and soak time remain within specified limits.

- Final Quality Control (FQC): After heat treatment, finished products undergo testing to confirm that they meet the desired mechanical properties and dimensions.

Implementing these checkpoints helps to catch potential issues early, ensuring that the final products meet quality standards.

Illustrative image related to why is heat treatment important

What Common Testing Methods Are Used in Quality Assurance?

Testing methods for heat-treated components vary based on the intended application but commonly include:

- Hardness Testing: Measures the hardness of materials using techniques such as Rockwell or Brinell tests.

- Tensile Testing: Evaluates the material’s strength and ductility.

- Impact Testing: Assesses the toughness of the material, especially important for components used in high-stress applications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing can reveal internal defects without damaging the component.

B2B buyers should ask suppliers about the specific testing methods employed and the results from these tests to ensure compliance with quality expectations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards in heat treatment, B2B buyers should consider conducting thorough audits and assessments. This can include:

Illustrative image related to why is heat treatment important

- Supplier Audits: Regular audits of suppliers’ facilities can provide insights into their quality management practices and compliance with international standards.

- Review of Quality Reports: Requesting detailed quality reports, including test results and compliance documentation, can help buyers verify the quality of heat-treated products.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of various nuances in quality control. Differences in regulatory requirements, quality standards, and cultural approaches to manufacturing can affect supplier relationships.

Understanding local standards and practices, as well as conducting thorough due diligence, can help mitigate risks associated with international procurement. Establishing clear communication with suppliers regarding quality expectations and compliance can further enhance the partnership.

In conclusion, heat treatment is a multifaceted process that significantly impacts the performance of metal components. By understanding the manufacturing processes and quality assurance measures involved, B2B buyers can make informed decisions that ensure they receive high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘why is heat treatment important’

This guide provides an actionable checklist for B2B buyers seeking to understand the significance of heat treatment in their manufacturing processes. Heat treatment is a critical factor in enhancing the properties of metals, impacting durability, strength, and performance. By following this checklist, buyers can ensure they make informed decisions when sourcing heat treatment services or materials.

Illustrative image related to why is heat treatment important

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the materials you need heat-treated. This includes understanding the desired properties such as hardness, ductility, or wear resistance, based on the application of the final product.

– Key Considerations: Identify whether you need processes like hardening, annealing, or tempering, and the material types you are working with, such as steel or aluminum.

Step 2: Research and Identify Potential Suppliers

Start by compiling a list of potential suppliers that specialize in heat treatment services relevant to your industry. Look for companies with a proven track record and expertise in the specific types of heat treatment you require.

– Resources to Use: Utilize industry directories, trade associations, and online marketplaces to find qualified suppliers.

Step 3: Evaluate Supplier Certifications and Standards

It’s essential to verify that potential suppliers adhere to recognized industry standards and certifications. This ensures they maintain quality control and comply with safety regulations.

– What to Look For: Certifications such as ISO 9001 or specific metallurgical certifications can indicate a supplier’s commitment to quality.

Step 4: Request Detailed Service Information

Inquire about the specific heat treatment processes offered by each supplier. Understanding their capabilities will help you assess whether they can meet your technical specifications.

– Questions to Ask: What types of heat treatment do they specialize in? Can they accommodate your required batch sizes and material types?

Step 5: Assess Equipment and Technology Used

Investigate the technology and equipment utilized by suppliers in their heat treatment processes. Advanced technology can lead to more precise treatments and better end-product quality.

– Important Factors: Check for modern furnaces, temperature control systems, and monitoring capabilities that ensure consistent results.

Illustrative image related to why is heat treatment important

Step 6: Review Case Studies and References

Request case studies or references from previous clients to gauge the supplier’s experience and reliability. This can provide insight into their ability to handle projects similar to yours.

– What to Consider: Look for examples where the supplier successfully met specific technical challenges or enhanced the performance of treated materials.

Step 7: Evaluate Cost and Turnaround Time

Finally, assess the pricing structure and expected turnaround times from potential suppliers. While cost is a significant factor, it should be weighed against quality and service capabilities.

– Considerations: Ensure that the pricing aligns with your budget while also considering the urgency of your project deadlines.

By following these steps, B2B buyers can navigate the complexities of sourcing heat treatment services effectively, ensuring they select the right partners to enhance their manufacturing processes.

Comprehensive Cost and Pricing Analysis for why is heat treatment important Sourcing

What Are the Key Cost Components in Heat Treatment Sourcing?

Understanding the cost structure of heat treatment is crucial for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. The primary cost components involved in heat treatment include:

-

Materials: The choice of metals and alloys directly impacts the cost. High-performance materials like titanium or high-carbon steels may command higher prices due to their enhanced properties and processing requirements.

-

Labor: Skilled labor is essential for executing heat treatment processes effectively. Technicians and metallurgists are required to ensure that the procedures meet the specified standards and achieve the desired outcomes.

-

Manufacturing Overhead: This encompasses facility costs, utilities, equipment maintenance, and other indirect expenses related to the production environment. It can vary significantly based on the location and scale of operations.

-

Tooling: Investment in specialized tools and equipment for heat treatment processes adds to the cost. Advanced technologies, such as induction heating systems, can enhance efficiency but also require higher initial capital.

-

Quality Control (QC): Rigorous QC processes ensure that the heat-treated materials meet industry standards and specifications. This adds an additional layer of cost but is essential for reliability and performance.

-

Logistics: Transportation and warehousing costs can fluctuate based on geographic location and the mode of transport. International buyers must factor in potential tariffs and customs duties as well.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition, demand, and the uniqueness of the service provided.

How Do Price Influencers Affect Heat Treatment Costs?

Several factors influence pricing in the heat treatment market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom heat treatment processes tailored to specific applications can increase costs. However, investing in customized solutions can lead to better performance and longevity of the materials.

-

Materials: The choice of materials not only affects the initial cost but also the long-term value. Heat-treated metals are often more durable, potentially reducing total lifetime costs.

-

Quality and Certifications: Higher quality materials and certified processes (e.g., ISO standards) generally come at a premium. Buyers should assess the value of these certifications against their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher prices due to their experience and quality assurance, while newer suppliers may provide competitive rates to gain market share.

-

Incoterms: The agreed terms of shipment can significantly influence costs. Buyers should understand the implications of different Incoterms, as they dictate who bears the costs and risks during transportation.

What Buyer Tips Can Enhance Cost Efficiency in Heat Treatment Sourcing?

B2B buyers can adopt several strategies to optimize their sourcing of heat treatment services:

-

Negotiation: Leverage relationships with suppliers to negotiate better terms. Establishing long-term partnerships can often lead to discounts and more favorable pricing structures.

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. Consider factors such as durability, maintenance, and potential downtime when evaluating heat-treated components.

-

Pricing Nuances for International Sourcing: Understand regional pricing variations and currency fluctuations that can affect costs. For buyers in Africa, South America, and the Middle East, being aware of local market conditions can provide an edge in negotiations.

-

Market Research: Conduct thorough research on different suppliers and their offerings. Comparing quotes and services can help identify the best value for specific heat treatment needs.

-

Utilizing Technology: Embrace digital tools for sourcing, such as online platforms that connect buyers with suppliers. These tools can streamline the procurement process and facilitate better decision-making.

Disclaimer

The prices mentioned in this analysis are indicative and can vary widely based on specific requirements, market conditions, and negotiation outcomes. Always consult with multiple suppliers to obtain accurate quotes tailored to your needs.

Alternatives Analysis: Comparing why is heat treatment important With Other Solutions

Exploring Alternatives to Heat Treatment in Material Strengthening

In the quest for enhancing material properties, particularly in metals and alloys, heat treatment stands out as a traditional and effective method. However, various alternatives can achieve similar objectives, each with its own set of advantages and drawbacks. This analysis will compare heat treatment with two prominent alternatives: surface hardening and polymer coating.

Comparison Table

| Comparison Aspect | Why Is Heat Treatment Important | Surface Hardening | Polymer Coating |

|---|---|---|---|

| Performance | Enhances strength, durability, and ductility. | Increases surface hardness and wear resistance. | Provides corrosion resistance and some abrasion protection. |

| Cost | Moderate initial investment; reduces long-term costs due to durability. | Typically lower cost than heat treatment. | Low to moderate cost, depending on the polymer used. |

| Ease of Implementation | Requires specialized equipment and skilled operators. | Easier to implement with less specialized equipment. | Simple application process; often requires minimal training. |

| Maintenance | Low maintenance; components tend to last longer. | Moderate maintenance; surface may wear over time. | Regular inspections needed; may require reapplication. |

| Best Use Case | Ideal for high-stress applications like aerospace and automotive. | Suitable for tools and components exposed to wear. | Best for components needing corrosion resistance without heavy wear. |

What Are the Pros and Cons of Surface Hardening?

Surface hardening techniques, such as carburizing and nitriding, focus on altering the surface properties of a material without affecting its core characteristics. The primary advantage of surface hardening is its ability to enhance wear resistance while maintaining the toughness of the underlying material. This makes it particularly effective for tools and machine components that experience high friction. However, one drawback is that surface hardening may not provide the same overall strength enhancement as heat treatment, which modifies the entire material structure. Additionally, the process may require specific conditions and monitoring, which can complicate implementation in some manufacturing environments.

How Does Polymer Coating Compare to Heat Treatment?

Polymer coatings offer a different approach to enhancing material properties, focusing primarily on corrosion resistance. These coatings can be applied to a wide range of substrates and provide a barrier against environmental factors. The application process is generally straightforward and can be performed with minimal training, making it accessible for many manufacturers. However, polymer coatings may not significantly improve mechanical properties such as strength or hardness, which can limit their effectiveness in high-stress applications. Furthermore, while they are cost-effective, coatings may need to be reapplied over time, leading to increased maintenance and operational costs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate method for enhancing material properties hinges on specific application requirements. Buyers should consider the performance needs of their products, the cost implications over the product lifecycle, and the ease of implementation within their existing operations. For high-stress environments demanding maximum durability, heat treatment remains the gold standard. Conversely, for applications focused on wear resistance with less emphasis on core strength, surface hardening may suffice. Lastly, for components primarily exposed to corrosive environments, polymer coatings present a viable option that balances cost and ease of application. Understanding these factors will enable B2B buyers to make informed decisions tailored to their operational needs and long-term goals.

Essential Technical Properties and Trade Terminology for why is heat treatment important

What Are the Key Technical Properties Impacted by Heat Treatment?

Understanding the technical properties enhanced through heat treatment is crucial for B2B buyers looking to optimize their manufacturing processes. Here are some critical specifications:

-

Material Grade

Material grade refers to the classification of metals based on their chemical composition and mechanical properties. Different grades respond uniquely to heat treatment processes, affecting their strength, ductility, and wear resistance. For example, steel grades like AISI 4140 are commonly heat-treated to enhance their toughness and fatigue resistance, making them suitable for applications in automotive and aerospace sectors. -

Hardness

Hardness measures a material’s resistance to deformation, typically evaluated using scales like Rockwell or Brinell. Heat treatment processes such as quenching increase hardness, which is essential for components exposed to wear and tear. In sectors such as manufacturing and construction, harder materials lead to longer-lasting products, reducing replacement costs and downtime. -

Ductility

Ductility is the ability of a material to deform under tensile stress. Heat treatment processes like annealing improve ductility, making metals more workable during machining and forming. For industries that rely on intricate shapes and designs, such as electronics and automotive, enhanced ductility allows for better fabrication and reduces the risk of material failure. -

Tensile Strength

This property measures the maximum stress a material can withstand while being stretched before breaking. Heat treatment methods like tempering increase tensile strength, which is vital for structural components in heavy machinery and construction. Higher tensile strength translates to improved safety and reliability in critical applications. -

Wear Resistance

Wear resistance is crucial in applications where materials are subject to friction and abrasion. Heat treatment techniques such as case hardening enhance surface hardness while maintaining a tougher core. This property is essential for parts like gears and bearings in machinery, as it significantly extends their service life.

What Are Common Trade Terms in the Heat Treatment Industry?

Familiarity with industry jargon can facilitate smoother communication and negotiation between B2B buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In heat treatment, understanding OEM specifications ensures that treated components meet the quality and performance standards required for specific applications. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. For heat-treated components, knowing the MOQ can help buyers plan their inventory and production schedules, ensuring they meet demand without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the context of heat treatment, a well-prepared RFQ can expedite the procurement process and ensure that potential suppliers understand the buyer’s requirements clearly. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing logistics and ensuring that heat-treated products are delivered according to agreed-upon conditions, thus minimizing risk and potential disputes. -

Soak Time

Soak time refers to the duration a material is held at a specific temperature during heat treatment. This term is important as it directly affects the material’s microstructure and properties. Buyers should consult with metallurgists to determine optimal soak times for their specific applications. -

Quenching

Quenching is the rapid cooling of a metal after it has been heated, often using water or oil. This process is essential for achieving desired hardness and strength. Knowing about quenching can help buyers specify the appropriate treatment for their materials, ensuring they meet performance standards.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding heat treatment, ultimately enhancing their product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the why is heat treatment important Sector

What Are the Global Drivers Influencing the Heat Treatment Market?

The heat treatment sector is currently experiencing significant growth driven by the increasing demand for high-performance materials across diverse industries. Key sectors such as automotive, aerospace, and energy are pushing for advanced materials that can withstand extreme conditions, enhancing the importance of heat treatment processes. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek reliable suppliers, understanding these dynamics is crucial.

Emerging technologies are reshaping the heat treatment landscape. Innovations in automation and Industry 4.0 technologies are streamlining processes, reducing lead times, and improving quality control. Additionally, the integration of data analytics into heat treatment operations allows for real-time monitoring and optimization, resulting in increased efficiency and lower operational costs. B2B buyers should consider suppliers that leverage such technologies to ensure they receive the best quality products while maximizing their return on investment.

Moreover, the shift towards lightweight materials, particularly in the automotive and aerospace sectors, is driving the demand for heat-treated components. As countries focus on reducing carbon emissions, the need for materials that enhance fuel efficiency becomes paramount. This trend presents an opportunity for B2B buyers to explore partnerships with heat treatment service providers who specialize in advanced materials like titanium and aluminum alloys.

How Are Sustainability and Ethical Sourcing Impacting the Heat Treatment Sector?

Sustainability is becoming a critical consideration for B2B buyers in the heat treatment sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, necessitates a shift towards more sustainable practices. Heat treatment processes can be energy-intensive, making it essential for companies to adopt energy-efficient technologies and practices. Buyers should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable energy sources or innovative heat treatment methods that minimize energy use.

Ethical sourcing is also gaining traction as businesses recognize the importance of responsible supply chains. This includes ensuring that the materials used in heat treatment processes are sourced from suppliers who adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainable practices. By choosing suppliers with these certifications, B2B buyers can not only meet regulatory requirements but also enhance their brand reputation in a market that increasingly values corporate responsibility.

Furthermore, the use of ‘green’ materials in heat treatment processes is emerging as a trend. For instance, the adoption of bio-based lubricants and non-toxic quenching oils can significantly reduce the environmental impact of heat treatment. Buyers should engage with suppliers who are innovating in this space, ensuring that their sourcing practices align with broader sustainability goals.

What Is the Historical Context of Heat Treatment in B2B?

The practice of heat treatment dates back centuries, with early applications seen in blacksmithing and metalworking. Historically, artisans would heat metals to improve their strength and durability, laying the groundwork for modern metallurgical practices. The industrial revolution marked a significant evolution in heat treatment techniques, as the demand for stronger and more reliable materials surged.

In the 20th century, advancements in technology led to the development of more sophisticated heat treatment methods, such as vacuum heat treatment and controlled atmosphere processes. These innovations enhanced the precision and effectiveness of heat treatment, allowing manufacturers to meet the stringent requirements of emerging industries like aerospace and automotive. Today, heat treatment continues to evolve, driven by technological advancements and the increasing need for sustainable practices, making it a vital area for B2B buyers to consider when sourcing materials.

Frequently Asked Questions (FAQs) for B2B Buyers of why is heat treatment important

-

How do I ensure the quality of heat-treated components for my projects?

To guarantee the quality of heat-treated components, start by vetting suppliers with a strong reputation in metallurgical processes. Request certifications and documentation that demonstrate adherence to international standards, such as ISO 9001 or ASTM. Additionally, consider suppliers who offer comprehensive quality assurance measures, including in-process inspections and final testing reports. Establishing a robust communication channel to clarify specifications and quality expectations can also mitigate risks associated with substandard materials. -

What are the advantages of heat treatment in manufacturing?

Heat treatment enhances the mechanical properties of metals, making them stronger, more durable, and resistant to wear and corrosion. This process can improve ductility, toughness, and hardness, which are crucial for the performance of components in demanding applications, such as aerospace or automotive industries. By investing in heat-treated materials, manufacturers can reduce maintenance costs and extend the lifespan of their products, leading to improved reliability and customer satisfaction. -

What types of heat treatment processes should I consider for my products?

The choice of heat treatment process depends on the specific material and desired properties. Common processes include annealing for improved ductility, hardening for increased strength, and tempering to reduce brittleness. For components requiring a tough core and hard surface, consider case hardening. Consulting with metallurgists or suppliers can help identify the best process tailored to your product’s needs, ensuring optimal performance in its intended application. -

How do I negotiate payment terms with heat treatment suppliers?

Negotiating favorable payment terms with suppliers is crucial for maintaining cash flow. Start by understanding industry standards and the supplier’s financial policies. Propose terms such as net 30 or net 60 days to give your business time to manage receivables. Additionally, consider offering upfront partial payments for larger orders, which can enhance trust and secure better pricing. Building a long-term relationship may also lead to more favorable terms over time. -

What is the minimum order quantity (MOQ) for heat-treated components?

Minimum order quantities can vary significantly between suppliers and are often influenced by production costs and lead times. When sourcing heat-treated components, discuss your specific needs with potential suppliers to find those willing to accommodate smaller orders. Some suppliers may offer flexibility, especially for new customers or prototypes, while others might have strict MOQs to ensure cost-effectiveness. Always clarify these terms early in the negotiation process. -

How does heat treatment impact the logistics of international trade?

Heat treatment can affect the logistics of international trade by influencing shipping methods, lead times, and costs. Heat-treated components may require special handling to prevent damage during transit, which can add to shipping expenses. Additionally, consider the regulatory requirements for importing treated metals in your target market, as some countries impose strict compliance standards. Engaging with logistics experts who understand these nuances can streamline the process and minimize potential delays. -

What customization options are available for heat-treated products?

Many suppliers offer customization options for heat-treated products, allowing you to specify dimensions, tolerances, and specific heat treatment processes tailored to your applications. Discuss your requirements in detail to ensure that the supplier can meet your specifications. Customization may include variations in hardness, surface finish, or even specialized treatments like nitriding for enhanced wear resistance. Collaborating closely with your supplier can yield solutions that best fit your operational needs. -

What role does heat treatment play in sustainability and cost-effectiveness?

Heat treatment contributes to sustainability by enhancing the lifespan of components, reducing the frequency of replacements, and minimizing waste. By investing in durable, heat-treated materials, businesses can lower their overall production costs and resource consumption. Furthermore, using heat treatment effectively can lead to improved energy efficiency in machinery and reduced operational downtime. This not only benefits the bottom line but also aligns with global sustainability goals, appealing to environmentally conscious consumers and partners.

Top 4 Why Is Heat Treatment Important Manufacturers & Suppliers List

1. Ast Forged Wheels – Heat Treating Solutions

Domain: astforgedwheels.com

Registered: 2022 (3 years)

Introduction: Heat treating is a crucial process in manufacturing metal and alloy parts, enhancing properties such as strength, ductility, and corrosion resistance. Key benefits include safety, durability, and cost efficiency for various industries including aerospace, alternative energy, and forged wheels. The heat treating process involves several stages: heating, soaking, cooling, and aging, and utilizes met…

2. IQS Directory – Heat Treating Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Heat Treating: Types, Functions and Applications

1. **Definition**: Heat treatment involves subjecting a material to cycles of heating and cooling to improve its traits, strength, and performance, particularly in metals.

2. **Processes**: The heat treatment process typically consists of three primary steps:

– Gradually heating the metal to maintain a consistent temperature.

– Soaking the m…

3. J.F. Heat Treating Inc – Metal Heat Treating Services

Domain: jfheattreatinginc.com

Registered: 2014 (11 years)

Introduction: J.F. Heat Treating Inc specializes in metal heat treating services with over 34 years of experience. They offer controlled heating and cooling of metals to alter physical and mechanical properties without changing product shape. Their services include annealing, aging, quenching, and tempering, aimed at softening, hardening, stress relieving, and providing other material characteristics to parts a…

4. Caddi – Heat Treatment Solutions

Domain: us.caddi.com

Registered: 2003 (22 years)

Introduction: Heat treatment is a controlled process used to alter the microstructure of metals and alloys to change their physical and mechanical properties. Key processes include: 1. Annealing: Reduces hardness and increases ductility; involves heating, holding, and slow cooling. 2. Normalizing: Improves ductility and refines grain structure; involves heating above critical temperature and air cooling. 3. Har…

Strategic Sourcing Conclusion and Outlook for why is heat treatment important

How Can Heat Treatment Enhance Your Manufacturing Processes?

In summary, heat treatment is a critical process that significantly enhances the properties of metals, making them stronger, more durable, and better suited for demanding applications across various industries. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the importance of heat treatment can lead to improved product performance and reduced long-term costs. By strategically sourcing heat-treated materials, businesses can ensure that they are utilizing components that meet high standards of quality and reliability.

The benefits of heat treatment extend beyond immediate performance; they contribute to the longevity of products and can prevent costly failures. As industries evolve and technological advancements continue, the demand for high-quality, heat-treated materials will only increase. Buyers should prioritize partnerships with suppliers that offer comprehensive heat treatment solutions tailored to their specific needs.

As you evaluate your sourcing strategies, consider the long-term advantages of incorporating heat-treated materials into your supply chain. Engage with trusted suppliers who can provide expertise and innovation in heat treatment processes. By doing so, you position your business for success in a competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to why is heat treatment important