Top 4 What Is A Mattress Bag Suppliers (And How to Choose)

Introduction: Navigating the Global Market for what is a mattress bag

Navigating the complexities of sourcing high-quality mattress bags can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding what a mattress bag is and its various applications is essential for safeguarding valuable assets during transit or storage. Mattress bags serve as protective coverings, designed to shield mattresses from dirt, moisture, pests, and other environmental factors that can compromise their integrity.

This comprehensive guide explores the myriad types of mattress bags available, including heavy-duty options and those designed for specific mattress sizes, along with their unique features and benefits. Buyers will learn about the applications of mattress bags, from moving and storage to seasonal protection, ensuring they make informed decisions that align with their operational needs. Additionally, the guide addresses critical aspects of supplier vetting, helping businesses identify reliable manufacturers and distributors that can meet their quality standards and logistical requirements.

By providing insights into pricing structures and cost-effective purchasing strategies, this guide empowers B2B buyers to navigate the global market with confidence. Whether you are sourcing for a logistics company in Vietnam or a furniture retailer in Germany, understanding the nuances of mattress bags will enhance your procurement process and ultimately protect your investments.

Understanding what is a mattress bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Mattress Bags | Made from heavy-grade polyethylene, basic protection | Moving companies, storage facilities | Pros: Cost-effective, widely available. Cons: Limited features, less durable than heavy-duty options. |

| Heavy-Duty Mattress Bags | Thicker material (up to 4-mil), enhanced moisture and pest protection | Furniture retailers, logistics companies | Pros: Superior durability, better protection. Cons: Higher cost, may be bulkier. |

| Sealable Mattress Bags | Double adhesive seal, designed to keep out dirt and pests | E-commerce businesses, long-term storage firms | Pros: Excellent sealing, ideal for extended storage. Cons: More expensive than standard bags. |

| Mattress Bags with Handles | Equipped with handles for easier lifting and transportation | Movers, event organizers | Pros: Easy to handle, convenient for large items. Cons: Limited availability in some regions. |

| Custom-Sized Mattress Bags | Tailored to specific mattress dimensions for optimal fit | Specialty mattress manufacturers, custom furniture stores | Pros: Perfect fit, reduces movement during transport. Cons: Longer lead times, potentially higher costs. |

What Are Standard Mattress Bags and Their Applications?

Standard mattress bags are typically constructed from heavy-grade polyethylene, providing basic protection against dust, dirt, and minor moisture. These bags are essential for moving companies and storage facilities that require an economical solution for mattress protection during transportation. While they are cost-effective and widely available, buyers should consider their limited features and potential durability issues compared to more robust options.

How Do Heavy-Duty Mattress Bags Stand Out?

Heavy-duty mattress bags utilize thicker materials, often up to 4-mil, offering enhanced protection against moisture, pests, and physical damage. They are ideal for furniture retailers and logistics companies that need reliable solutions for transporting high-value mattresses. Although they come at a higher price point, their durability and superior protective capabilities make them a worthy investment for businesses dealing with frequent moves or long-term storage.

Why Choose Sealable Mattress Bags for Long-Term Storage?

Sealable mattress bags feature a double adhesive seal designed to keep out dirt, moisture, and pests, making them particularly suitable for e-commerce businesses and long-term storage facilities. Their excellent sealing capabilities ensure that mattresses remain pristine during extended periods of storage. However, these bags tend to be more expensive than standard options, so businesses must weigh the benefits of enhanced protection against their budget constraints.

What Advantages Do Mattress Bags with Handles Offer?

Mattress bags with handles are designed for easier lifting and transportation, making them valuable for movers and event organizers. The added convenience of handles simplifies the handling of large items, especially in tight spaces. However, their availability may be limited in certain regions, and buyers should consider whether the added functionality justifies any potential premium pricing.

How Do Custom-Sized Mattress Bags Benefit Specialty Businesses?

Custom-sized mattress bags are tailored to specific mattress dimensions, ensuring an optimal fit that reduces movement during transport. They are particularly useful for specialty mattress manufacturers and custom furniture stores that require precise solutions for their products. While these bags provide the advantage of a perfect fit, businesses should anticipate longer lead times and potentially higher costs associated with custom orders.

Key Industrial Applications of what is a mattress bag

| Industry/Sector | Specific Application of what is a mattress bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Protecting mattresses during production and transport | Ensures quality control by preventing damage from dust, moisture, and pests | Need for durable materials and sizes that fit various mattress types |

| Moving and Storage | Safeguarding mattresses during relocation | Reduces risk of damage, ensuring customer satisfaction and minimizing returns | Requirement for waterproof, tear-resistant bags with easy sealing options |

| Hospitality | Storing mattresses in hotels and resorts | Maintains hygiene and extends the lifespan of bedding products | Focus on bulk purchasing and compliance with health regulations |

| E-commerce | Shipping mattresses directly to consumers | Enhances product presentation and protects against shipping damage | Consideration for lightweight, cost-effective packaging solutions |

| Retail | Display and storage of mattresses in showrooms | Keeps products clean and appealing to customers | Importance of clear labeling and easy handling features |

How Do Furniture Manufacturers Utilize Mattress Bags for Quality Control?

In the furniture manufacturing industry, mattress bags are essential for protecting products during production and transport. These bags safeguard against dust, moisture, and pests, ensuring that mattresses arrive at retailers or customers in pristine condition. For B2B buyers, it is crucial to source durable materials that can accommodate various mattress sizes and types, ensuring a perfect fit and maximum protection throughout the supply chain.

What Role Do Mattress Bags Play in Moving and Storage Services?

For moving and storage companies, mattress bags are invaluable for safeguarding mattresses during relocation. These bags help reduce the risk of damage from dirt, moisture, and pests, which can lead to customer dissatisfaction and costly returns. B2B buyers in this sector should prioritize sourcing waterproof and tear-resistant options, along with easy sealing features to streamline the packing process and enhance customer service.

Why Are Mattress Bags Important for the Hospitality Sector?

In the hospitality industry, mattress bags are vital for storing mattresses in hotels and resorts. They maintain hygiene standards and protect bedding from potential contaminants, extending the lifespan of these investments. Buyers in this sector should consider bulk purchasing options, ensuring compliance with health regulations while maintaining a consistent supply of quality protective packaging.

How Do E-commerce Businesses Benefit from Using Mattress Bags?

E-commerce companies that sell mattresses directly to consumers find mattress bags beneficial for shipping. These bags enhance product presentation while protecting against damage during transit, which is critical for customer satisfaction. When sourcing, businesses should focus on lightweight and cost-effective solutions that do not compromise on protection, ensuring that products arrive at their destination in excellent condition.

What Advantages Do Retailers Gain from Mattress Bags in Showrooms?

Retailers use mattress bags to keep mattresses clean and presentable in showrooms. This not only protects the products from dust and wear but also enhances their appeal to potential buyers. Key considerations for B2B buyers in this sector include clear labeling for easy identification and handling features that facilitate movement within the showroom, thereby improving the overall shopping experience for customers.

3 Common User Pain Points for ‘what is a mattress bag’ & Their Solutions

Scenario 1: Protecting Mattresses During Transportation

The Problem: B2B buyers in the moving and logistics industry often face the challenge of ensuring that mattresses arrive at their destination in pristine condition. During transportation, mattresses are vulnerable to dirt, moisture, and pests, which can lead to significant damage. This is particularly concerning for businesses that rely on the quality of their products, such as hotels or furniture retailers. If a mattress is damaged, it not only affects customer satisfaction but can also lead to costly returns and replacements.

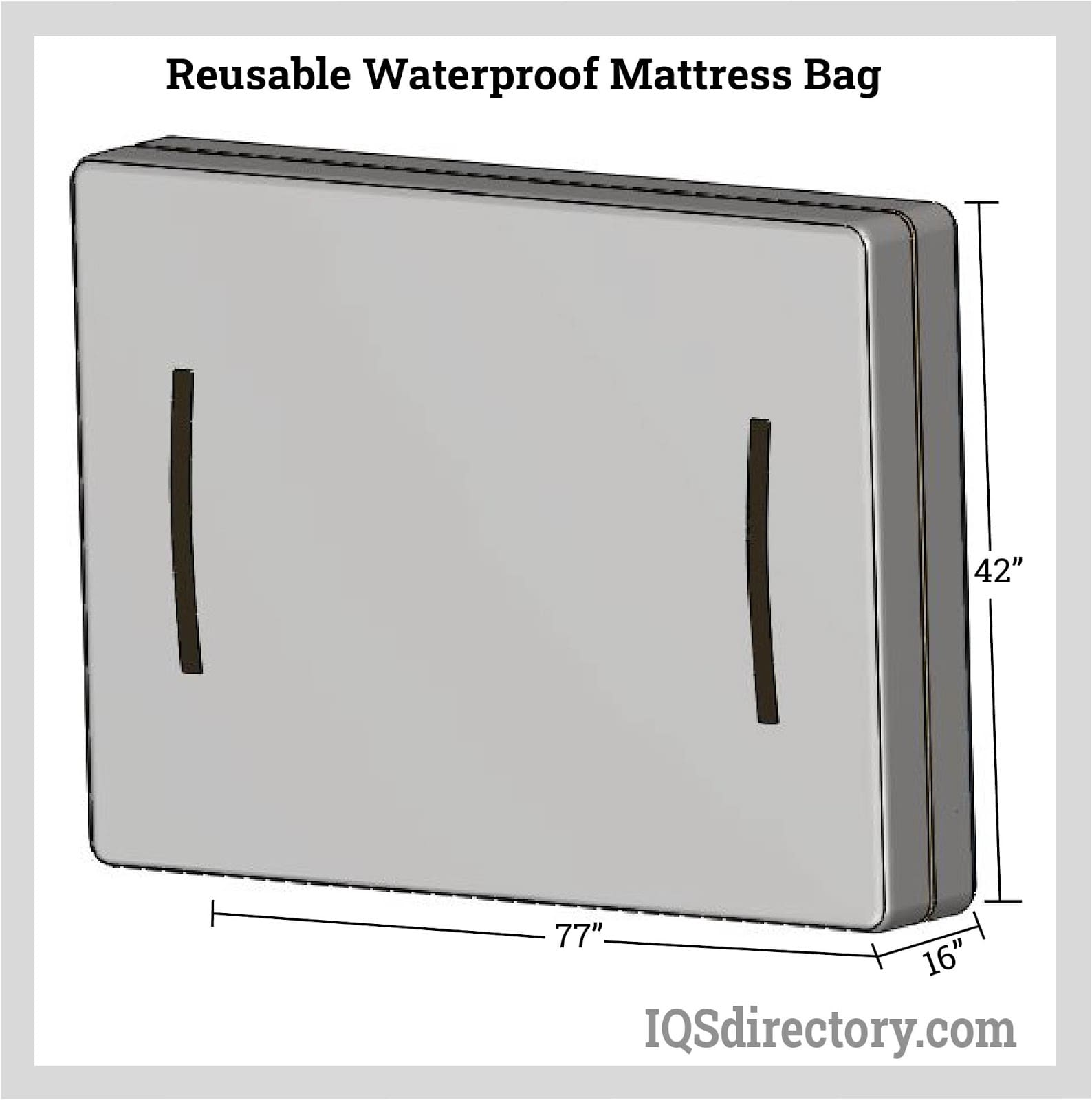

The Solution: To effectively protect mattresses during transport, sourcing high-quality mattress bags is essential. Buyers should look for heavy-duty options made from polyethylene plastic that are at least 3.0 mil thick. These bags should feature a double-adhesive seal to prevent moisture and pests from entering. Additionally, choosing bags with carrying handles can enhance ease of handling and reduce the risk of damage when loading and unloading. It’s crucial to ensure that the mattress bags are appropriately sized for the mattresses being transported, accommodating various thicknesses to provide full coverage. By implementing these protective measures, businesses can safeguard their investments and maintain their reputation for quality.

Illustrative image related to what is a mattress bag

Scenario 2: Storage Solutions for Seasonal Inventory

The Problem: Retailers and wholesalers often face the challenge of managing seasonal inventory, particularly mattresses that may not be sold immediately. Storing these items in a way that prevents damage from dust, moisture, and insects is critical. Without proper storage solutions, mattresses can degrade over time, leading to a loss in value and increased costs associated with replacements or disposal.

The Solution: Utilizing mattress bags specifically designed for long-term storage can solve this problem. Buyers should seek out bags that offer additional features such as UV protection and moisture-wicking properties to enhance preservation. For businesses that frequently rotate inventory, investing in transparent or semi-transparent bags can help with quick identification of mattress sizes and types without needing to open each bag. It’s also advisable to implement a systematic inventory management process, marking each bag with the date of storage and any relevant product information. This will not only protect the mattresses but also facilitate easier access and inventory tracking when needed.

Scenario 3: Ensuring Compliance with Health and Safety Regulations

The Problem: In regions with strict health and safety regulations, businesses in the hospitality and rental sectors must ensure that all mattresses are free from contaminants, including dust mites and bed bugs. Failing to comply with these regulations can lead to fines, legal issues, and reputational damage. This is particularly challenging for companies that operate in multiple countries with varying regulations concerning mattress storage and transportation.

Illustrative image related to what is a mattress bag

The Solution: To ensure compliance, B2B buyers should prioritize sourcing mattress bags that meet international safety standards. Look for bags that are explicitly labeled as pest-resistant and made from materials that prevent the infiltration of allergens. Furthermore, educating staff on proper usage and handling of these bags is crucial; training should cover how to seal bags effectively and store mattresses in a manner that minimizes exposure to potential contaminants. Implementing a regular inspection schedule for stored mattresses and using mattress bags during transportation will help maintain compliance with health regulations. By taking these steps, businesses can protect their assets and ensure they meet necessary legal standards.

Strategic Material Selection Guide for what is a mattress bag

What Materials Are Commonly Used for Mattress Bags?

When selecting materials for mattress bags, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in the production of mattress bags from a B2B perspective.

How Does Polyethylene Perform in Mattress Bag Applications?

Polyethylene (PE) is one of the most widely used materials for mattress bags due to its excellent moisture resistance and durability. Typically available in various thicknesses, PE can withstand temperature fluctuations and is resistant to corrosion from chemicals.

Pros: Polyethylene is lightweight, cost-effective, and offers good protection against dirt, dust, and moisture. Its manufacturing process is relatively straightforward, making it accessible for mass production.

Illustrative image related to what is a mattress bag

Cons: However, it may not provide the same level of puncture resistance as other materials, and its longevity can be affected by UV exposure if used outdoors.

Impact on Application: PE is suitable for short-term storage and moving applications, making it a common choice for residential and commercial use.

Considerations for International Buyers: Compliance with international standards such as ASTM for material safety is crucial. Buyers from regions like Europe may prefer PE that meets specific environmental regulations, while those in Africa and South America may focus on cost-effectiveness.

What Are the Benefits of Using Heavy-Duty Polyethylene?

Heavy-duty polyethylene (HDPE) offers enhanced durability compared to standard polyethylene. It is thicker and more robust, providing superior protection against tears, punctures, and moisture.

Pros: The key advantage of HDPE is its high strength-to-weight ratio, making it ideal for long-distance transportation and extended storage periods. It also offers excellent resistance to various chemicals.

Cons: The increased thickness can lead to higher production costs and manufacturing complexity.

Impact on Application: HDPE is particularly suitable for high-value mattresses that require extra protection during transit or long-term storage.

Considerations for International Buyers: Buyers should ensure that HDPE products comply with local regulations regarding material safety and environmental impact, especially in regions with stringent compliance requirements like Germany.

Why Choose Non-Woven Fabric for Mattress Bags?

Non-woven fabric is another viable option for mattress bags, particularly for applications requiring breathability. This material is made from synthetic fibers that are bonded together, providing a soft and flexible structure.

Pros: Non-woven fabric allows for air circulation, reducing moisture buildup and the risk of mold growth. It is also lightweight and can be produced in various colors and designs.

Cons: However, it may not be as durable as plastic options and can be more susceptible to tearing.

Impact on Application: This material is ideal for short-term storage or transport, especially in climates with high humidity.

Considerations for International Buyers: Buyers should consider the fabric’s compliance with international standards for textile safety and environmental impact, particularly in regions like the Middle East, where humidity can be a concern.

What Role Does PVC Play in Mattress Bag Manufacturing?

Polyvinyl Chloride (PVC) is a versatile plastic that is sometimes used in mattress bags, particularly for its flexibility and strength.

Pros: PVC offers excellent resistance to chemicals and is highly durable, making it suitable for various environmental conditions. It can also be manufactured in a range of thicknesses, providing options for different levels of protection.

Cons: On the downside, PVC can be more expensive than other materials and may have environmental concerns related to its production and disposal.

Impact on Application: PVC is often used for high-end mattress protection, especially in environments where chemical exposure is a concern.

Illustrative image related to what is a mattress bag

Considerations for International Buyers: Compliance with environmental regulations is critical, particularly in Europe, where PVC use is scrutinized. Buyers should also consider the cost implications of using PVC in their supply chain.

Summary Table of Mattress Bag Materials

| Material | Typical Use Case for what is a mattress bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Short-term storage and moving | Lightweight and cost-effective | Limited puncture resistance | Low |

| Heavy-Duty Polyethylene | Long-distance transport and extended storage | High strength-to-weight ratio | Higher production costs | Medium |

| Non-Woven Fabric | Short-term storage in humid climates | Breathable, reducing moisture buildup | Less durable than plastic options | Medium |

| Polyvinyl Chloride | High-end mattress protection | Excellent chemical resistance | Higher cost and environmental concerns | High |

This analysis provides B2B buyers with a clear understanding of the materials used in mattress bags, enabling informed decisions based on their specific needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a mattress bag

What Are the Key Manufacturing Processes for Mattress Bags?

The manufacturing of mattress bags involves several critical stages, ensuring the final product is durable, effective, and meets customer specifications. Understanding these processes is vital for B2B buyers looking to source high-quality mattress bags.

How Is Material Prepared for Mattress Bags?

The first stage in the manufacturing process is material preparation. Mattress bags are predominantly made from polyethylene, a versatile plastic known for its strength and moisture resistance. Manufacturers typically source high-density polyethylene (HDPE) or low-density polyethylene (LDPE) based on the desired thickness and durability.

The material is then subjected to quality checks to ensure it meets specific standards for thickness, tensile strength, and flexibility. This phase may involve testing samples for clarity and durability to guarantee that the final product will withstand the rigors of moving and storage.

What Techniques Are Used in Forming Mattress Bags?

Once the materials are prepared, the next step is forming the mattress bags. This stage typically employs techniques such as extrusion and blow molding.

- Extrusion: In this method, plastic pellets are melted and formed into a continuous sheet. This sheet is then cut to the desired size for various mattress dimensions.

- Blow Molding: This technique allows for the production of hollow forms. It can be used to create bags with handles or specific features that enhance usability.

The choice of technique can affect the bag’s weight capacity and barrier properties. Manufacturers often adjust the thickness of the material based on the intended use—whether for short-term moves or long-term storage.

How Is the Assembly of Mattress Bags Conducted?

After forming, the assembly phase involves sealing and finishing the bags. Various sealing methods, such as heat sealing or adhesive bonding, are utilized to ensure that the bags are airtight and waterproof.

Illustrative image related to what is a mattress bag

Features such as double-adhesive seals and carrying handles may be integrated at this stage, providing added functionality. Quality assurance measures, such as visual inspections, are essential to ensure that there are no defects in the seams or closures.

What Are the Finishing Processes for Mattress Bags?

The finishing stage includes additional treatments that enhance the product’s performance. This may involve applying anti-static treatments or coatings that improve resistance to moisture and pests. Labels and branding may also be added during this stage, ensuring that the bags meet specific market requirements.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is crucial in the manufacturing of mattress bags, as it guarantees the product’s reliability and safety. B2B buyers should be aware of various international and industry-specific standards that govern the quality of these products.

Which International Standards Are Relevant for Mattress Bags?

One of the primary international standards for quality management systems is ISO 9001. This standard ensures that manufacturers implement processes to consistently produce quality products. Compliance with ISO 9001 indicates that a manufacturer has a systematic approach to quality management and is committed to continuous improvement.

In addition to ISO standards, mattress bags may also need to comply with industry-specific certifications such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in Mattress Bag Production?

Quality control during mattress bag production typically includes several critical checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to identify any deviations from quality standards.

- Final Quality Control (FQC): After production, the finished products undergo rigorous testing to ensure they meet all specifications before packaging and shipping.

Common testing methods include tensile strength testing, puncture resistance testing, and moisture barrier testing, all of which are essential for ensuring that the mattress bags will perform as expected in real-world scenarios.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is paramount.

What Are Effective Strategies for Supplier Audits?

Conducting supplier audits can provide valuable insights into a manufacturer’s quality control processes. Buyers should consider the following approaches:

- On-Site Audits: Visiting the manufacturing facility allows buyers to assess the production processes, quality control measures, and overall operational efficiency.

- Requesting Quality Reports: Manufacturers should be willing to provide documentation detailing their quality control procedures and results from past tests.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International Buyers?

When sourcing mattress bags internationally, it’s important to consider regional differences in quality standards and regulations. For example, compliance with local environmental regulations and material safety standards may vary significantly from one country to another.

Illustrative image related to what is a mattress bag

B2B buyers should ensure that their suppliers are aware of and compliant with both international standards and local regulations to avoid potential issues related to product safety and market access.

Conclusion

Understanding the manufacturing processes and quality assurance practices for mattress bags is essential for B2B buyers looking to source high-quality products. By focusing on material preparation, forming techniques, assembly, and finishing processes, along with rigorous quality control measures, buyers can ensure they are partnering with reliable suppliers who meet their specific needs. Engaging in thorough supplier verification processes further enhances the likelihood of successful procurement, ultimately leading to satisfied customers and improved business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a mattress bag’

To assist B2B buyers in procuring mattress bags, this practical sourcing guide provides a step-by-step checklist to ensure you choose the right products for your needs. Mattress bags are essential for protecting mattresses during transport and storage, making it vital to understand the various options available.

Step 1: Identify Your Specific Needs

Understanding the requirements of your business is the first step in sourcing mattress bags. Consider factors such as the size of the mattresses you will be handling (twin, full, queen, king), the expected volume of procurement, and whether you need bags for short-term transport or long-term storage. Identifying these specifics will streamline your search for suitable products.

Illustrative image related to what is a mattress bag

Step 2: Research Material Types and Durability

Different mattress bags are made from various materials, each offering different levels of protection. Look for bags made from heavy-duty polyethylene, which can resist moisture, dust, and pests. Ensure that the thickness (measured in mils) is suitable for your use case; heavier bags (e.g., 3.0 mil and above) provide better protection.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, it is crucial to verify their certifications and compliance with industry standards. This ensures that the products meet safety and quality benchmarks. Look for certifications such as ISO, which indicates adherence to international quality standards, and inquire about their manufacturing processes.

Step 4: Check for Additional Features

Not all mattress bags are created equal; some come with added features that can enhance usability. Consider options with:

– Sealable closures: These prevent dirt and moisture from entering the bag.

– Handles: Facilitate easier lifting and transportation.

These features can significantly improve the efficiency of your operations.

Illustrative image related to what is a mattress bag

Step 5: Request Samples for Quality Assessment

Before finalizing your order, request samples from potential suppliers. This allows you to assess the quality of the material, the effectiveness of the sealing mechanisms, and the overall durability of the bags. Testing samples in real-world conditions can help prevent costly mistakes later on.

Step 6: Compare Pricing and Bulk Purchase Options

Once you have narrowed down your choices, compare the pricing structures of different suppliers. Many suppliers offer discounts for bulk purchases, which can be beneficial for businesses planning to buy in large quantities. Ensure that you consider the total cost, including shipping, handling, and any additional fees.

Step 7: Review Supplier Reputation and Customer Feedback

Finally, investigate the reputation of your shortlisted suppliers. Look for customer reviews and testimonials from businesses in similar sectors or regions. This feedback can provide insights into the reliability of the supplier, the quality of their products, and their customer service.

By following this checklist, B2B buyers can ensure they make informed decisions when sourcing mattress bags, ultimately enhancing their operational efficiency and product protection.

Comprehensive Cost and Pricing Analysis for what is a mattress bag Sourcing

When sourcing mattress bags for B2B purposes, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. This analysis outlines the key components that contribute to the overall cost and highlights factors that influence pricing, especially for international buyers.

What Are the Key Cost Components in Mattress Bag Manufacturing?

-

Materials: The primary cost component for mattress bags is the raw material, typically heavy-duty polyethylene or other durable plastics. The thickness of the material, usually measured in mils, affects both cost and protective capabilities. For example, a 4-mil heavy-duty bag generally costs more than a standard 2-mil option due to its enhanced durability and moisture resistance.

-

Labor: Labor costs are associated with the production process, which may vary significantly depending on the region of manufacturing. Countries with lower labor costs can offer more competitive pricing, but buyers should consider the trade-offs in quality and compliance with international standards.

-

Manufacturing Overhead: This includes costs related to factory operations, maintenance, and utilities. Efficient production processes can lower overhead costs, which can be reflected in the final price of the mattress bags.

-

Tooling and Setup: Initial setup costs for custom sizes or designs can be significant, especially for low-volume orders. Suppliers may charge a one-time tooling fee, which can influence the price per unit for initial orders.

-

Quality Control (QC): Implementing a robust QC process ensures that the mattress bags meet safety and performance standards. These costs are essential for maintaining quality but can add to the overall price, particularly for bags that require certifications or specific quality guarantees.

-

Logistics: Shipping and transportation costs play a crucial role in the final price, especially for international transactions. Factors such as distance, shipping method (air vs. sea), and customs duties can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the buyer’s negotiation power.

What Pricing Influencers Should B2B Buyers Consider?

-

Volume and Minimum Order Quantity (MOQ): Pricing structures often favor bulk purchases. Suppliers typically offer discounts for larger orders, so understanding the MOQ can lead to significant cost savings.

-

Specifications and Customization: Custom sizes or features, such as built-in handles or adhesive seals, can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific industry standards can be more expensive. Certification can also enhance the product’s value, especially in markets with strict regulatory requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to perceived quality and reliability, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (Incoterms) is critical for international buyers. These terms define responsibilities for shipping costs, insurance, and tariffs, impacting the total cost of ownership.

What Are the Best Practices for Negotiating Mattress Bag Pricing?

-

Leverage Volume: When placing orders, negotiate based on potential future orders to secure better pricing. Suppliers are often willing to provide discounts for long-term contracts.

-

Assess Total Cost of Ownership (TCO): Consider not just the unit price but also logistics, potential damage during transport, and the lifespan of the product. A cheaper bag might lead to higher costs if it fails to protect the mattress effectively.

-

Explore Multiple Suppliers: Obtain quotes from various suppliers to understand the market rate. This competitive approach can strengthen your negotiating position.

-

Be Cautious of Hidden Costs: Ensure clarity on all costs, including shipping, customs duties, and any additional fees that may arise during the transaction.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and streamline communication, potentially leading to better pricing.

Conclusion

In summary, the cost structure and pricing of mattress bags are influenced by various factors, from material selection to logistics. By understanding these elements and employing strategic negotiation techniques, B2B buyers can optimize their sourcing decisions, ensuring both quality and cost-effectiveness in their purchases. Always remember that prices can vary widely based on market conditions and supplier practices, so thorough research and negotiation are essential.

Illustrative image related to what is a mattress bag

Alternatives Analysis: Comparing what is a mattress bag With Other Solutions

Exploring Alternatives to Mattress Bags for Moving and Storage

In the realm of transporting and storing mattresses, several solutions exist beyond the conventional mattress bag. Each option has distinct features, benefits, and drawbacks, making it essential for B2B buyers to evaluate them based on their specific needs. Below, we explore the performance, cost, ease of implementation, maintenance, and best use cases of mattress bags compared to alternative solutions.

| Comparison Aspect | What Is A Mattress Bag | Alternative 1 Name: Stretch Wrap | Alternative 2 Name: Mattress Cover |

|---|---|---|---|

| Performance | Protects against dirt, moisture, and pests during transport and storage. | Offers a tight seal that protects against dust and moisture but may not prevent pests. | Provides a protective layer but may not be as secure as a bag. |

| Cost | Typically ranges from $10 to $30 per bag, depending on size and quality. | Generally more economical, often priced around $5 to $15 for a roll. | Usually priced between $15 to $40, depending on material and thickness. |

| Ease of Implementation | Simple to use; just slide the mattress in and seal. | Requires wrapping technique; may need two people for larger mattresses. | Easy to fit over the mattress but may require additional securing methods. |

| Maintenance | Disposable or reusable; minimal maintenance required. | Reusable but may lose effectiveness after multiple uses. | Durable but can be damaged if not handled carefully. |

| Best Use Case | Ideal for moving and long-term storage. | Best for quick protection during short moves or temporary storage. | Suitable for protecting against dust and minor spills in a home environment. |

What Are the Pros and Cons of Stretch Wrap as an Alternative?

Stretch wrap is a versatile option that can be utilized for a variety of items, including mattresses. Its primary advantage lies in its cost-effectiveness and ability to create a tight seal that protects against dust and moisture. However, it does not offer complete protection against pests, and the wrapping process may require additional labor, especially with larger mattresses. This method is best suited for short-term moves where quick protection is needed.

What Are the Benefits and Drawbacks of Using Mattress Covers?

Mattress covers provide an alternative that focuses on safeguarding against allergens and minor spills. They are easy to fit over the mattress, offering a layer of protection without the need for wrapping. However, they may not be as secure as mattress bags, which can lead to exposure to dust and pests if not sealed properly. Mattress covers are ideal for long-term use in a home setting but may fall short during moving situations where complete protection is essential.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right solution for mattress protection, B2B buyers should consider the specific context of their needs. If the primary concern is transporting mattresses over long distances or storing them for extended periods, mattress bags are likely the best choice due to their comprehensive protective features. Conversely, for short-term needs or less critical environments, stretch wrap or mattress covers may suffice. Evaluating factors like cost, ease of use, and the level of protection required will guide businesses in making informed purchasing decisions tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for what is a mattress bag

What Are the Key Technical Properties of Mattress Bags?

Understanding the technical specifications of mattress bags is crucial for B2B buyers, especially when it comes to ensuring product quality and compliance with regional standards. Here are some critical specifications to consider:

Illustrative image related to what is a mattress bag

1. Material Grade

Mattress bags are typically made from polyethylene or polypropylene, with varying thickness levels measured in mils (thousandths of an inch). Higher-grade materials, such as heavy-duty 4-mil polyethylene, provide superior protection against moisture, dirt, and pests. For B2B buyers, selecting the right material grade is essential to ensure durability and reliability during transport and storage.

2. Size Tolerance

Mattress bags come in various sizes to accommodate different mattress dimensions, including twin, full, queen, king, and California king. Accurate sizing is crucial as it ensures a proper fit, which minimizes the risk of damage. Businesses should consider tolerances for mattress thickness, typically ranging from 10 to 17 inches, to match diverse customer needs effectively.

3. Seal Mechanism

Many mattress bags feature advanced sealing mechanisms, such as double adhesive seals or flap closures. These designs help prevent moisture and pests from entering the bag. For B2B buyers, understanding the sealing technology is vital for assessing the level of protection offered, especially in regions prone to humidity or insect infestations.

4. Load Capacity

The load capacity indicates how much weight a mattress bag can handle without tearing. This specification is especially important for businesses involved in heavy-duty moving or storage solutions. A bag with a higher load capacity can accommodate bulkier mattresses and ensure they remain protected during transit.

Illustrative image related to what is a mattress bag

5. Reusability and Eco-Friendliness

Some mattress bags are designed for multiple uses, while others are disposable. Eco-friendly options made from recyclable materials are increasingly in demand due to growing sustainability concerns. B2B buyers should assess the lifecycle of the product, as reusable bags can lead to cost savings and a reduced environmental footprint.

What Are Common Trade Terms Related to Mattress Bags?

Familiarity with industry jargon is essential for effective communication in the B2B marketplace. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of mattress bags, an OEM may supply specialized bags tailored to the specifications of a mattress manufacturer or retailer. Understanding OEM relationships can help buyers identify reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers when negotiating contracts, as it can affect inventory levels and overall costs. Knowing the MOQ helps businesses plan purchases according to demand.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to solicit price quotes from suppliers. This process is critical for B2B transactions, as it allows companies to compare pricing and terms across multiple vendors. A well-prepared RFQ can streamline procurement processes and lead to better deals.

Illustrative image related to what is a mattress bag

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is essential to avoid misunderstandings and ensure smooth transactions, especially in global markets.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier assigned to each product variant for inventory management. In the context of mattress bags, SKUs help businesses track stock levels and manage orders efficiently. Using SKUs can enhance operational efficiency and minimize errors in order fulfillment.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing mattress bags, ensuring they meet the needs of their customers while optimizing operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the what is a mattress bag Sector

What Are the Key Market Trends Influencing the Mattress Bag Sector?

The mattress bag market is experiencing significant growth, driven by the increasing awareness of the importance of mattress protection during transportation and storage. As consumers recognize the need to safeguard their investments, especially in regions with high humidity or pest issues, demand for high-quality mattress bags is surging. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that offer a diverse range of products, including heavy-duty and sealable options.

Emerging trends include the rise of e-commerce platforms, which facilitate easier access to a variety of mattress bag suppliers. This shift is particularly relevant for buyers in developing markets, where traditional retail options may be limited. Additionally, advancements in materials technology are leading to the creation of more durable and eco-friendly products, which are appealing to a broader audience. As manufacturers innovate, the introduction of features like handles and double adhesive seals enhances usability and protection, aligning with the evolving preferences of consumers.

How is Sustainability and Ethical Sourcing Impacting the Mattress Bag Industry?

The mattress bag industry is increasingly focused on sustainability and ethical sourcing. The environmental impact of plastic waste is a significant concern, prompting buyers to look for products made from recycled or biodegradable materials. Suppliers who prioritize eco-friendly practices not only contribute to environmental preservation but also align with the growing consumer demand for sustainable products.

Ethical supply chains are becoming a critical factor for international B2B buyers. Transparency in sourcing and production processes is essential, as buyers are more inclined to partner with suppliers who demonstrate a commitment to responsible manufacturing practices. Certifications such as the Global Recycling Standard (GRS) and the Forest Stewardship Council (FSC) are gaining importance, as they provide assurance regarding the sustainability of materials used in mattress bags. For suppliers, adopting these certifications can enhance their marketability and appeal to a conscientious customer base.

Illustrative image related to what is a mattress bag

What is the Historical Context of Mattress Bags and Their Evolution in the B2B Market?

The concept of mattress bags has evolved significantly over the past few decades. Initially designed primarily for protecting mattresses during moves, these bags have transformed into essential products for both residential and commercial purposes. The early designs were basic, often made from thin plastic, providing minimal protection. However, with advancements in material science, modern mattress bags are now crafted from heavy-duty polyethylene and other durable materials, offering superior protection against moisture, pests, and dirt.

As the B2B market has expanded, so too has the variety of mattress bags available. Manufacturers now offer specialized options for different mattress sizes and types, including eco-friendly alternatives that meet the rising demand for sustainable products. This evolution reflects a broader trend in the packaging and moving supplies industry, where innovation and sustainability are increasingly prioritized to meet the needs of global buyers.

In summary, the mattress bag sector is poised for continued growth, driven by consumer awareness, technological advancements, and a shift toward sustainable practices. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a mattress bag

1. How do I choose the right mattress bag for my business needs?

Choosing the right mattress bag involves assessing the size of the mattresses you transport, the level of protection required, and your budget. Consider options like heavy-duty polyethylene for enhanced durability, especially if you need to prevent moisture and pests during storage or transit. Evaluate features such as sealable closures, handles for ease of movement, and thickness (measured in mils) to determine the best fit for your operations. It’s also beneficial to consult with suppliers about available sizes and custom options to meet specific requirements.

2. What is the best mattress bag for protecting against moisture and pests?

For optimal protection against moisture and pests, a heavy-duty mattress bag made from at least 3.0 mil polyethylene is recommended. These bags often feature a double-adhesive seal that creates a waterproof barrier, safeguarding against dirt, dust, and bed bugs. When sourcing, look for suppliers that offer specialized options like sealable bags with additional features, ensuring that your mattresses remain in pristine condition during storage or transport.

3. What customization options are available for mattress bags?

Customization options for mattress bags may include size variations, thickness specifications, and printing options for branding purposes. Many suppliers can accommodate custom sizes to fit unique mattress dimensions or specific packaging needs. Additionally, you can inquire about adding features like handles, different sealing mechanisms, or eco-friendly materials to align with your business values. Engaging with manufacturers early in the sourcing process can facilitate the development of a tailored solution.

4. What are the minimum order quantities (MOQ) for mattress bags?

Minimum order quantities (MOQ) for mattress bags can vary significantly based on the supplier and the specific product. Typically, MOQs may range from 100 to 1,000 units, depending on the size and customization of the bags. It’s essential to communicate your needs clearly with potential suppliers to understand their policies. Some manufacturers may offer flexibility in MOQs for bulk orders or long-term contracts, which can be advantageous for businesses looking to establish a consistent supply chain.

5. How do I vet potential suppliers for mattress bags?

Vetting suppliers for mattress bags involves assessing their industry reputation, product quality, and reliability. Start by checking reviews and testimonials from other B2B clients. Request samples to evaluate the material and durability of the bags firsthand. Additionally, verify certifications and compliance with international standards, particularly for businesses operating in multiple regions. Engaging in direct communication with suppliers and discussing their production processes can provide further assurance of their capabilities.

6. What payment terms should I expect when sourcing mattress bags internationally?

Payment terms for international sourcing of mattress bags can vary widely based on the supplier and the nature of the order. Common terms include a deposit upfront (usually 30% to 50%), with the balance due upon delivery or before shipping. Some suppliers may also offer net payment terms (e.g., net 30 or net 60 days) for established relationships. It’s crucial to negotiate clear payment terms upfront to avoid any misunderstandings and to consider using secure payment methods to mitigate risk.

7. How can I ensure quality assurance (QA) for mattress bags?

To ensure quality assurance for mattress bags, implement a multi-step approach that includes supplier audits, material inspections, and compliance testing. Establish clear quality standards and communicate them with your supplier at the outset. Consider incorporating third-party inspections during production and before shipment to verify adherence to agreed specifications. Maintaining open communication with your supplier throughout the production process can also help address any issues proactively.

8. What logistics considerations should I keep in mind when importing mattress bags?

When importing mattress bags, logistics considerations include shipping methods, customs clearance, and lead times. Evaluate whether air or sea freight is more cost-effective based on your urgency and budget. Ensure all necessary documentation is in order to facilitate smooth customs clearance, including invoices, packing lists, and certificates of origin. Additionally, factor in potential tariffs and local regulations that may apply to imported goods in your target markets. Collaborating with a reliable logistics partner can streamline the process and mitigate risks.

Top 4 What Is A Mattress Bag Manufacturers & Suppliers List

1. U-Haul – Mattress Bags

Domain: uhaul.com

Registered: 1995 (30 years)

Introduction: U-Haul offers a variety of mattress bags designed for moving and storage, made from heavy-grade polyethylene plastic to protect against dirt, dust, moisture, stains, and bed bugs. Key types include: 1. Mattress Bags with Handles: Designed for mattresses and box springs up to 14″ thick, made with 2.25 mil polyethylene. 2. Sealable Mattress Bags: Made with 3.0 mil polyethylene, featuring a double-ad…

2. Linenspa – Heavy Duty Mattress Storage Bag

3. Mattress Disposal – Affordable Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Mattress bag required for disposal by local trash company; costs approximately $7 on Amazon; alternative options mentioned include getting a bag from a furniture store or using the bag from a new mattress.

4. Puffy – Mattress Bag

Domain: puffy.com

Registered: 2003 (22 years)

Introduction: A mattress bag is a protective cover designed to fit over a mattress to safeguard it from dirt, dust, and damage during moving. Made from heavy-duty, durable plastic, these bags come in various sizes to match standard mattress dimensions (Twin to King) and accommodate different types like memory foam and pillow-top mattresses. Benefits include protection from dirt and dust, prevention of damage, s…

Strategic Sourcing Conclusion and Outlook for what is a mattress bag

In summary, the importance of mattress bags in the logistics and moving industries cannot be overstated. These protective covers serve a critical function by safeguarding mattresses from dirt, moisture, and pests during transport or storage. For international B2B buyers, understanding the specifications, materials, and features of various mattress bags is essential to making informed purchasing decisions. By strategically sourcing high-quality mattress bags, businesses can enhance their operational efficiency and customer satisfaction.

As global markets continue to expand, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable packing solutions will only grow. Buyers should prioritize suppliers that offer a range of products tailored to diverse needs—whether it’s heavy-duty options for long-term storage or affordable solutions for short-term moves.

Looking ahead, embracing innovation in product offerings and supplier partnerships will be key to staying competitive. We encourage businesses to explore new sourcing opportunities and invest in quality mattress protection solutions to safeguard their assets and ensure customer trust.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.