Top 4 What Is A Linear Bearing Suppliers (And How to Choose)

Introduction: Navigating the Global Market for what is a linear bearing

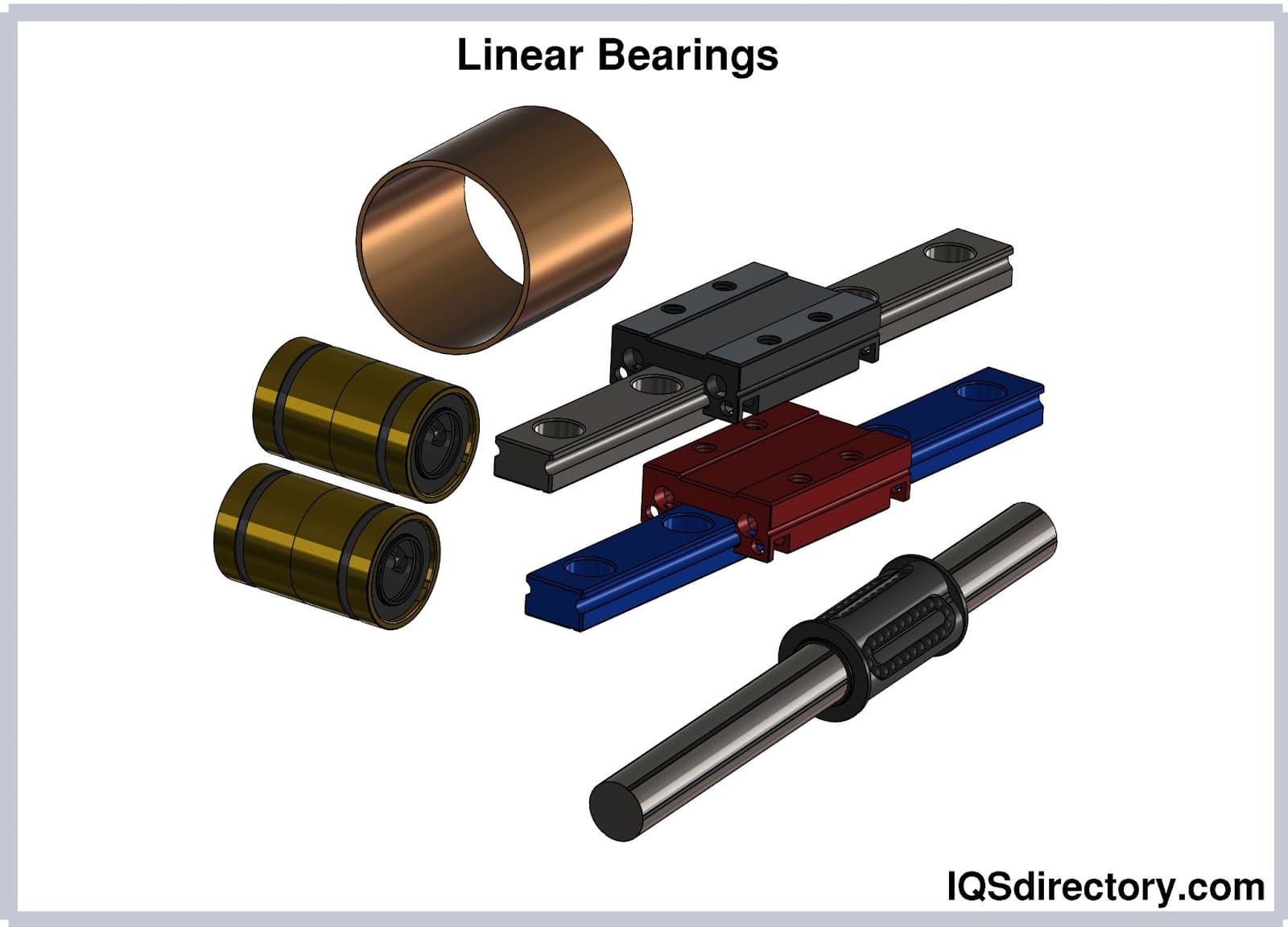

In today’s competitive manufacturing landscape, understanding what a linear bearing is and how to effectively source them is crucial for B2B buyers navigating the global market. These essential components facilitate smooth and precise linear motion in machinery, making them indispensable across various industries, from automotive to aerospace. However, the challenge lies in identifying the right type of linear bearing for specific applications while ensuring reliability, cost-effectiveness, and supplier integrity.

This comprehensive guide delves into the diverse types of linear bearings, such as closed, open, and super linear bearings, each tailored for different operational needs. We will explore their wide-ranging applications, shedding light on how they enhance efficiency in processes like CNC machining, 3D printing, and robotics. Additionally, the guide provides insights into the critical aspects of vetting suppliers, understanding cost structures, and recognizing industry standards, ensuring that international buyers from regions like Africa, South America, the Middle East, and Europe (including countries like Nigeria and Vietnam) can make informed purchasing decisions.

By equipping you with the necessary knowledge and actionable insights, this guide empowers B2B buyers to navigate the complexities of sourcing linear bearings, ultimately driving operational excellence and fostering sustainable growth in your business endeavors.

Understanding what is a linear bearing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed Type | Operates on unsupported shafts; offers high precision and stability | Robotics, CNC machines, conveyor systems | Pros: High precision, versatility. Cons: May require more maintenance. |

| Super Linear Bearings | Enhanced self-alignment and load capacity; adaptable design | Semiconductor manufacturing, automotive assembly | Pros: Excellent performance under misalignment. Cons: Higher cost. |

| Open Type | Designed for supported shafts; simpler construction | Light-duty applications, packaging machinery | Pros: Cost-effective, easy to install. Cons: Lower load capacity. |

| Linear Rails | Provide a track for linear motion; often used with linear bearings | Manufacturing, assembly lines, robotics | Pros: Smooth motion, high load capacity. Cons: Requires precise installation. |

| Ball Screws | Converts rotational to linear motion; uses ball bearings | CNC machinery, automation equipment | Pros: High efficiency, precise control. Cons: More complex installation. |

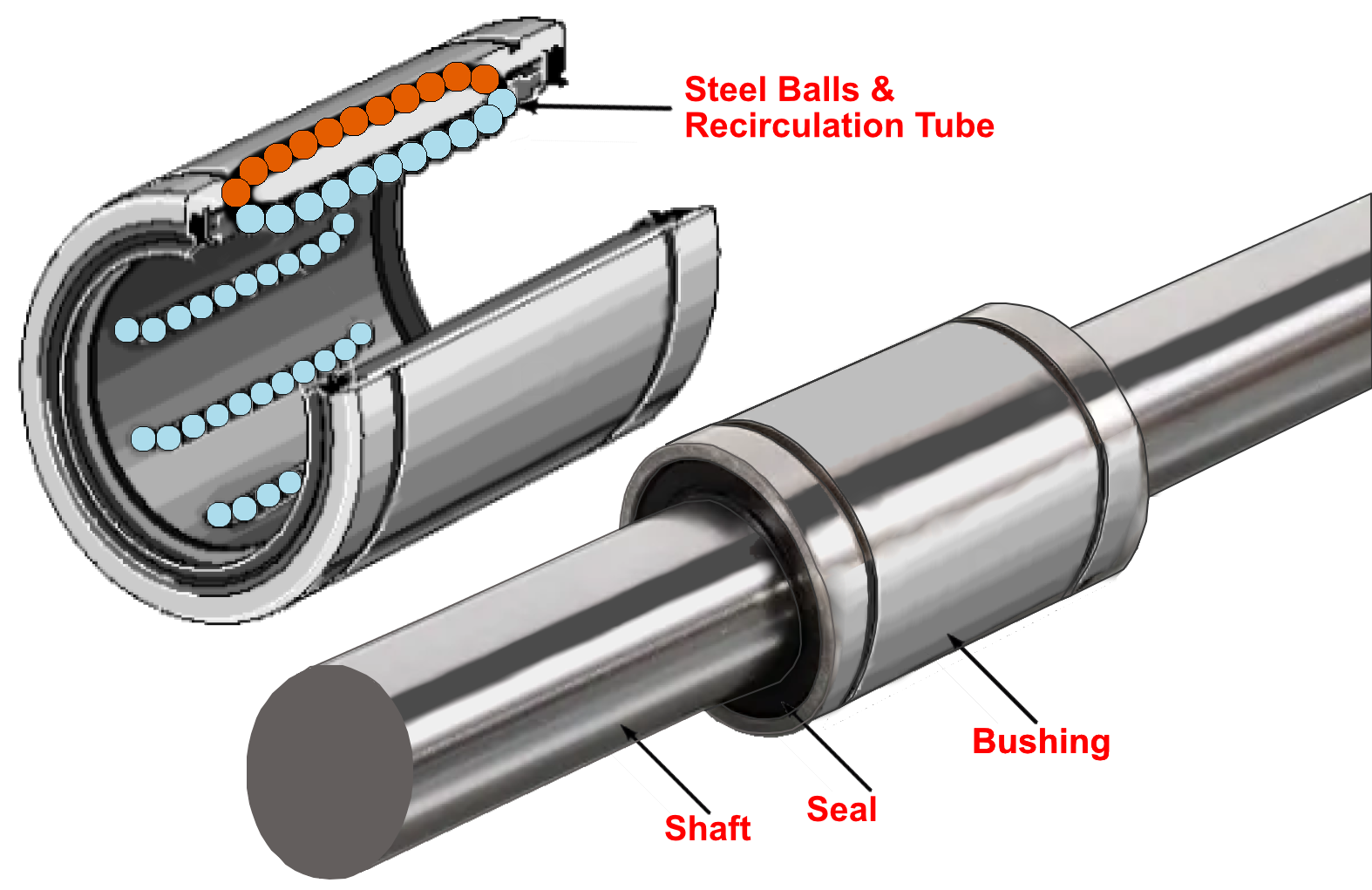

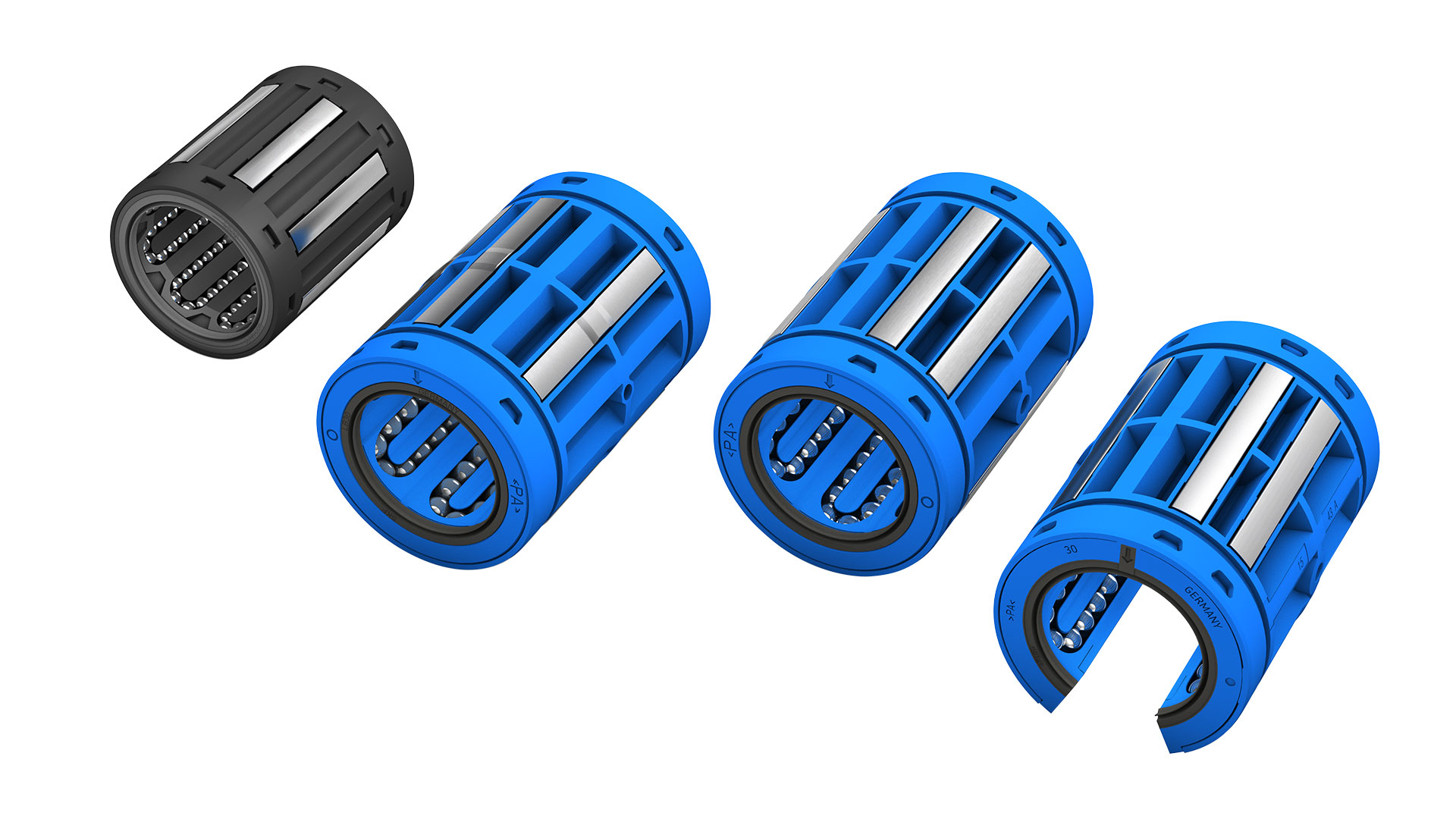

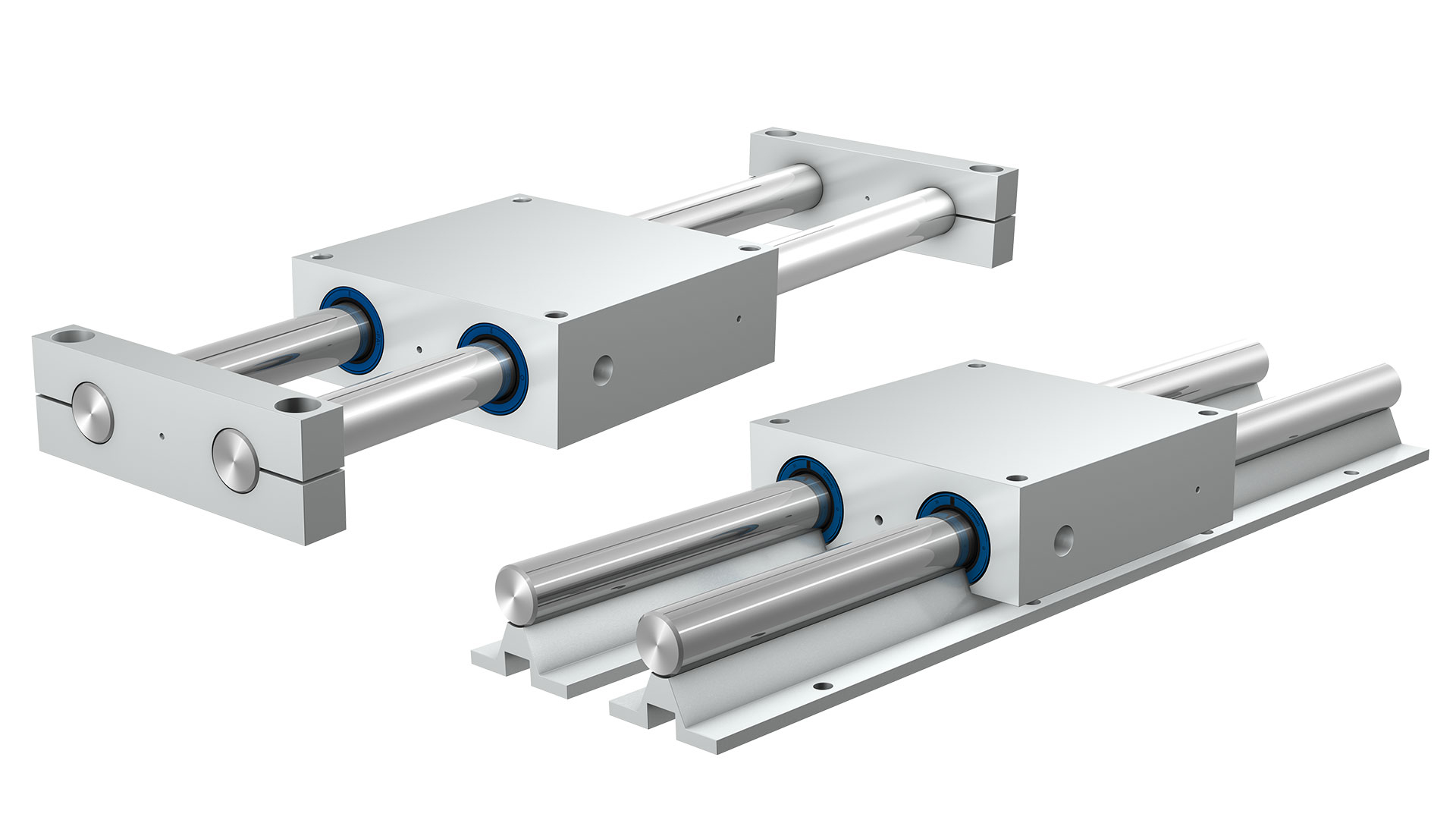

What Are the Characteristics of Closed Type Linear Bearings?

Closed type linear bearings are engineered to operate on unsupported linear shafts, delivering exceptional precision and stability. These bearings are available in various configurations, including flanged and housed variants, which cater to diverse industrial requirements. Their robust design makes them suitable for demanding applications such as robotics, CNC machines, and conveyor systems. When purchasing closed type bearings, buyers should consider factors like load capacity, environmental conditions, and maintenance needs to ensure optimal performance in their specific applications.

Illustrative image related to what is a linear bearing

How Do Super Linear Bearings Stand Out?

Super linear bearings are a specialized variant of closed type bearings, known for their enhanced self-alignment and greater load capacity. Their innovative design allows them to maintain functionality even in situations with misalignment or uneven loading. This feature makes them particularly valuable in high-precision environments such as semiconductor manufacturing and automotive assembly lines. Buyers should weigh the benefits of their advanced capabilities against the higher cost, ensuring that the investment aligns with their operational demands.

What Are the Benefits of Open Type Linear Bearings?

Open type linear bearings are characterized by their ability to operate on supported linear shafts, making them a simpler and often more cost-effective solution for various applications. These bearings are commonly utilized in light-duty tasks such as packaging machinery and smaller automation systems. While they are easier to install and generally more affordable, buyers should be mindful of their lower load capacity compared to closed type bearings. Evaluating the specific load requirements and operational conditions is essential when considering open type bearings.

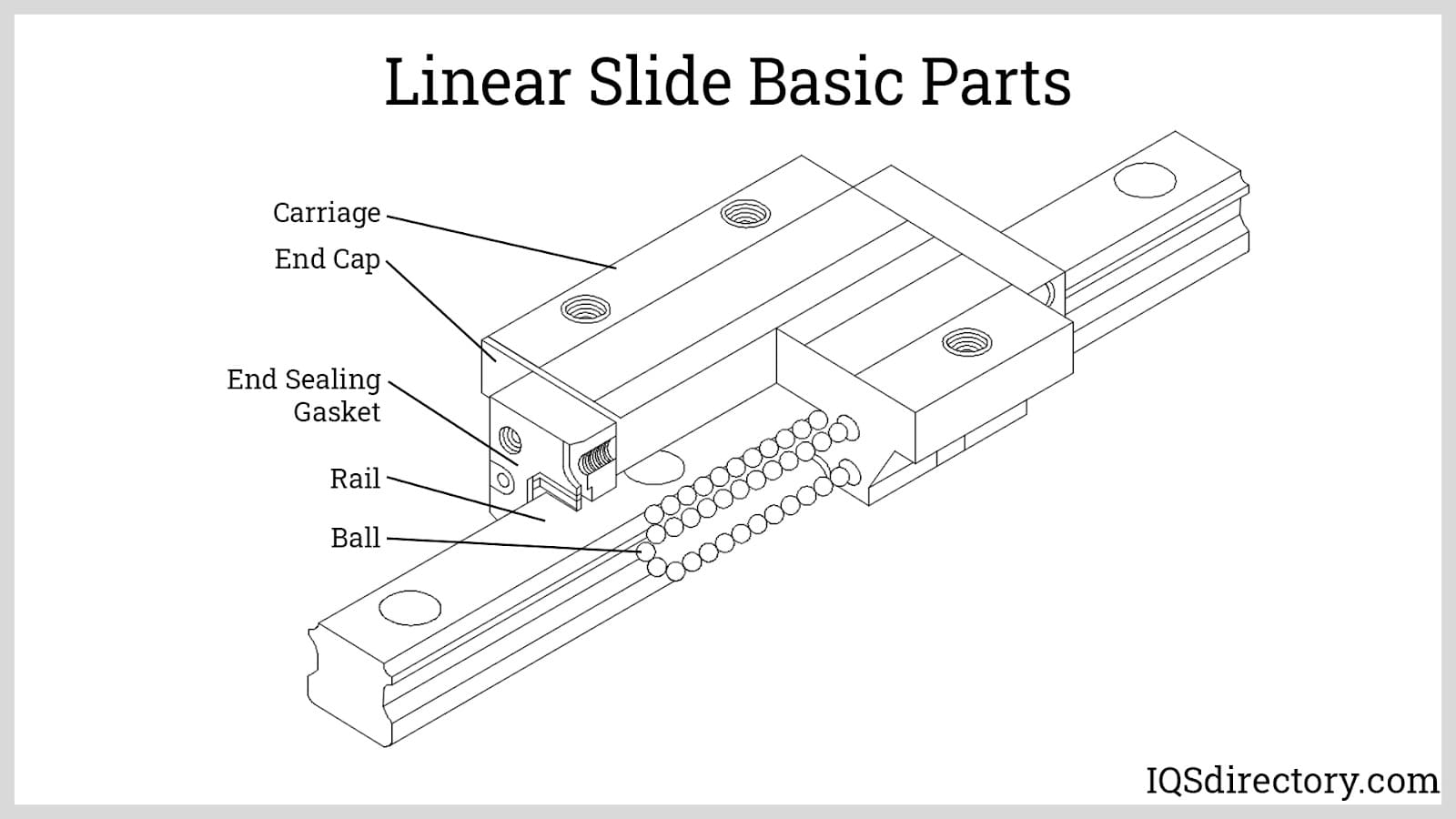

Why Are Linear Rails Important for Industrial Applications?

Linear rails provide a structured path for linear motion, commonly used in conjunction with linear bearings to enhance motion efficiency. Their design allows for smooth and precise movement, making them indispensable in manufacturing, assembly lines, and robotic systems. When selecting linear rails, buyers must consider factors such as the load capacity, installation precision, and compatibility with existing machinery. The right choice can significantly improve operational efficiency and reduce maintenance costs.

How Do Ball Screws Enhance Linear Motion Control?

Ball screws are mechanical devices that convert rotational motion into linear displacement, utilizing ball bearings to minimize friction. This technology is particularly beneficial in CNC machinery and automation equipment, where precise control of movement is critical. When considering ball screws, buyers should assess their efficiency, load capacity, and installation complexity. Understanding these factors can help ensure that the selected ball screw meets the specific needs of their applications, ultimately enhancing productivity and performance.

Key Industrial Applications of what is a linear bearing

| Industry/Sector | Specific Application of what is a linear bearing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision positioning in assembly lines | Enhances efficiency and accuracy, reducing operational costs | Look for high load capacity and durability under dynamic conditions. |

| Aerospace | Landing gear systems and satellite deployment | Ensures reliability and safety in critical applications | Consider weight, corrosion resistance, and compliance with industry standards. |

| Medical Devices | Imaging equipment and surgical robots | Provides smooth movement, essential for precision in procedures | Focus on biocompatibility and ease of sterilization. |

| 3D Printing | Guiding print heads along multiple axes | Improves print accuracy and quality, reducing material waste | Assess compatibility with various materials and ease of integration. |

| CNC Machining | Movement of cutting tools and workpieces | Increases machining precision, enhancing product quality | Prioritize high precision and low friction characteristics. |

How are Linear Bearings Used in the Automotive Industry?

In the automotive sector, linear bearings are critical for the precise positioning of components on assembly lines. They facilitate smooth and accurate movement, which is vital for tasks such as welding, painting, and component placement. The ability to handle heavy loads while maintaining precision reduces downtime and enhances productivity. For international buyers, sourcing bearings that can withstand varying environmental conditions and provide long-term reliability is essential to ensure consistent production quality.

What Role Do Linear Bearings Play in Aerospace Applications?

Linear bearings are integral to aerospace applications, particularly in landing gear systems and satellite deployment mechanisms. These components must operate with exceptional reliability and precision due to the high stakes involved in aviation and space exploration. Buyers in this sector should prioritize bearings that offer lightweight designs and high corrosion resistance, as well as compliance with stringent safety standards. Ensuring the bearings can withstand extreme conditions is crucial for operational success.

How are Linear Bearings Essential in Medical Devices?

In the medical field, linear bearings are used in imaging equipment and robotic surgical systems to ensure smooth and precise movement. Their role is critical in maintaining the accuracy of diagnostics and procedures, where any deviation can have serious implications. Buyers should focus on sourcing bearings that are biocompatible and easy to sterilize, as these features directly impact the safety and effectiveness of medical devices. Additionally, the ability to maintain performance in cleanroom environments is a key consideration.

What is the Importance of Linear Bearings in 3D Printing?

In 3D printing, linear bearings guide the print head along the X, Y, and Z axes, enabling accurate positioning and layer deposition. This precision is crucial for producing high-quality prints while minimizing material waste. For businesses in this sector, sourcing linear bearings that are compatible with various printing materials and offer low friction is essential. Buyers should also consider the ease of integration into existing systems to optimize production efficiency.

How Do Linear Bearings Enhance CNC Machining Operations?

Linear bearings are vital in CNC machining for the movement of cutting tools and workpieces along multiple axes. They enhance machining precision, which is essential for creating high-quality parts in various manufacturing processes. Buyers should prioritize bearings that offer high load capacity, low friction, and durability to ensure optimal performance over time. Additionally, understanding the specific machining conditions and material requirements is crucial for making informed sourcing decisions.

3 Common User Pain Points for ‘what is a linear bearing’ & Their Solutions

Scenario 1: Misalignment Issues in Linear Motion Systems

The Problem: B2B buyers often encounter challenges with misalignment in linear motion systems, which can lead to excessive wear on linear bearings and reduced operational efficiency. For instance, in an assembly line setting, if a linear bearing is not properly aligned with the linear rail, it can cause uneven load distribution, resulting in premature failure of both the bearing and the machinery. This not only leads to costly downtimes but also negatively impacts the quality of the products being manufactured.

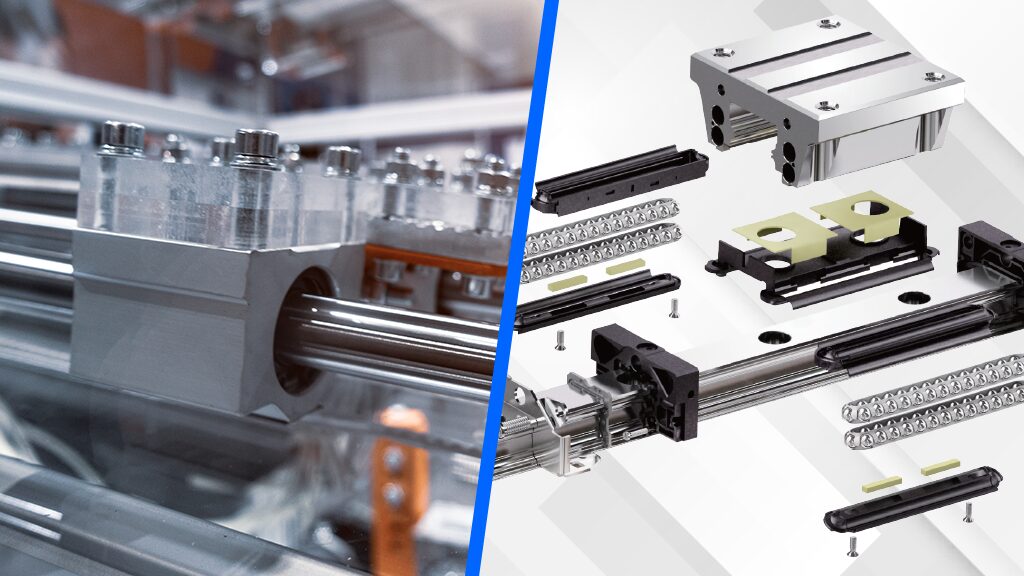

Illustrative image related to what is a linear bearing

The Solution: To mitigate misalignment issues, it’s crucial to conduct a thorough assessment of the installation process. Buyers should ensure that the mounting surfaces for the linear bearings and rails are level and properly aligned before installation. Using adjustable linear rails can also provide flexibility to correct minor misalignments during setup. Additionally, implementing a regular maintenance schedule that includes checks for alignment and wear can help identify potential issues early. Leveraging advanced technologies like laser alignment tools can further enhance precision in alignment, ensuring that the bearings operate smoothly and efficiently.

Scenario 2: Contamination Leading to Bearing Failure

The Problem: Contamination from dust, dirt, and moisture is a common concern for B2B buyers, particularly in industries like manufacturing and logistics. Linear bearings exposed to harsh environments can suffer from decreased performance due to debris entering the bearing housing, leading to increased friction and eventual failure. This scenario often results in unexpected maintenance costs and extended downtimes, which can be detrimental to productivity.

The Solution: To combat contamination, buyers should prioritize selecting linear bearings with effective sealing mechanisms designed to keep out contaminants. Closed-type linear bearings often come with integrated seals that provide an additional layer of protection. Implementing a proactive maintenance strategy that includes routine cleaning and lubrication can also prolong the lifespan of the bearings. For environments with high levels of contamination, consider investing in protective covers or using linear bearings specifically designed for harsh conditions. Establishing a clean workspace and training staff on best practices for maintenance will further minimize the risk of contamination.

Scenario 3: Incompatibility with Existing Systems

The Problem: Buyers may face compatibility challenges when integrating new linear bearings into existing machinery or systems. This is particularly true for industries where legacy equipment is prevalent. For example, a company may invest in high-quality linear bearings, only to find that their dimensions or load ratings do not match the specifications of their current machinery, leading to wasted resources and potential operational delays.

The Solution: To avoid compatibility issues, thorough research and planning are essential before making a purchase. Buyers should closely examine the specifications of their existing systems, including shaft sizes, load capacities, and any specific design requirements. Engaging with suppliers who offer customizable linear bearings can provide tailored solutions that fit existing systems. Additionally, creating a detailed compatibility checklist that includes dimensions, load ratings, and environmental considerations can streamline the selection process. Finally, consider consulting with engineering teams or bearing specialists to ensure that the chosen linear bearings will meet both current and future operational needs, ensuring a seamless integration into existing workflows.

Strategic Material Selection Guide for what is a linear bearing

What Materials Are Commonly Used in Linear Bearings?

When selecting materials for linear bearings, it’s essential to consider their physical properties, performance characteristics, and suitability for specific applications. The following analysis covers four common materials used in linear bearings: steel, aluminum, plastic, and stainless steel. Each material presents unique advantages and disadvantages, impacting their performance in various industrial environments.

What Are the Key Properties of Steel in Linear Bearings?

Steel is a widely used material in the manufacturing of linear bearings due to its high strength and durability. It typically exhibits excellent load-bearing capacity and can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Steel bearings often have a temperature rating of up to 120°C (248°F) and are resistant to deformation under heavy loads.

Pros & Cons: The primary advantage of steel is its robustness, which translates to a long service life in demanding environments. However, steel is prone to corrosion, which can limit its use in humid or chemically aggressive environments unless treated or coated. Additionally, steel bearings can be heavier and more expensive than alternatives like plastic.

Impact on Application: Steel bearings are ideal for applications requiring high precision and load capacity, such as CNC machines and automotive assembly lines. However, their susceptibility to corrosion necessitates careful consideration in environments with moisture or corrosive substances.

How Does Aluminum Perform as a Material for Linear Bearings?

Aluminum is another popular choice for linear bearings, particularly in applications where weight reduction is crucial. It is lightweight, has good corrosion resistance, and can be anodized for enhanced durability. Aluminum bearings typically perform well at temperatures up to 80°C (176°F) and are suitable for moderate load applications.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can lead to energy savings in applications requiring movement. However, aluminum is less durable than steel and may not withstand high loads as effectively. Additionally, it can be more expensive than plastic options.

Impact on Application: Aluminum linear bearings are commonly used in aerospace and automotive applications where weight is a critical factor. They are also suitable for environments where corrosion resistance is essential, such as in marine applications.

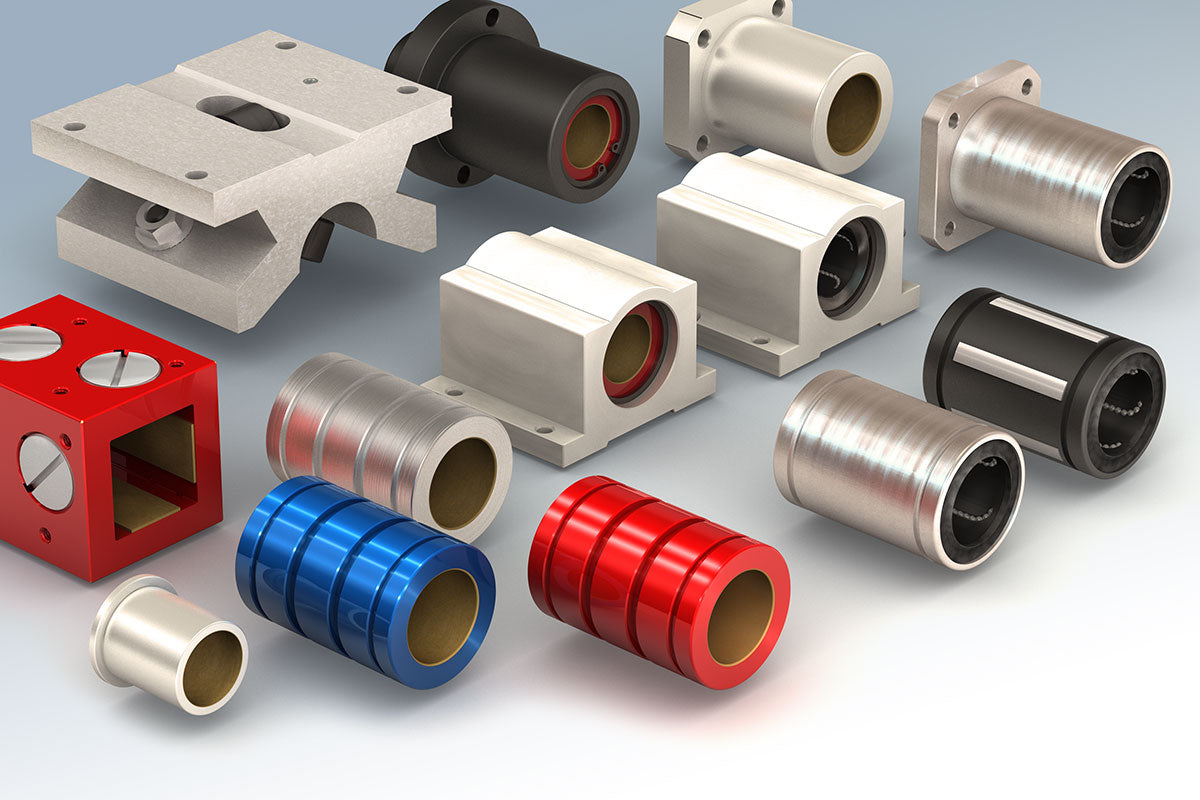

Illustrative image related to what is a linear bearing

What Are the Benefits of Using Plastic in Linear Bearings?

Plastic linear bearings, often made from materials like acetal or nylon, offer excellent corrosion resistance and are lightweight. They can operate effectively in temperatures ranging from -40°C to 80°C (-40°F to 176°F) and are suitable for applications involving moisture or chemicals.

Pros & Cons: The primary advantage of plastic bearings is their resistance to corrosion and low friction properties, which can lead to reduced wear and maintenance. However, they generally have lower load capacities compared to metal bearings and may not perform well under high temperatures or heavy loads.

Impact on Application: Plastic linear bearings are ideal for applications in the food processing and pharmaceutical industries, where cleanliness and resistance to chemicals are paramount. They are also suitable for lighter-duty applications in automation and robotics.

Why Choose Stainless Steel for Linear Bearings?

Stainless steel is an excellent choice for linear bearings that require both strength and corrosion resistance. It typically has a temperature rating similar to that of carbon steel but offers enhanced resistance to rust and corrosion, making it suitable for harsh environments.

Pros & Cons: The key advantage of stainless steel is its durability and ability to withstand corrosive environments, which extends the service life of the bearing. However, it is generally more expensive than carbon steel and can be heavier, which may not be suitable for all applications.

Illustrative image related to what is a linear bearing

Impact on Application: Stainless steel bearings are commonly used in food processing, medical equipment, and marine applications where hygiene and corrosion resistance are critical. They are ideal for environments with high humidity or exposure to chemicals.

Summary Table of Material Selection for Linear Bearings

| Material | Typical Use Case for what is a linear bearing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | CNC machines, automotive assembly lines | High strength and load capacity | Prone to corrosion, heavier | High |

| Aluminum | Aerospace, automotive applications | Lightweight and good corrosion resistance | Less durable under heavy loads | Medium |

| Plastic | Food processing, pharmaceutical industries | Excellent corrosion resistance, low friction | Lower load capacity, less heat resistance | Low |

| Stainless Steel | Food processing, medical equipment | Durability and corrosion resistance | Higher cost, heavier than alternatives | High |

This material selection guide provides valuable insights for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, where compliance with local standards and environmental conditions must be considered. Understanding the properties and applications of these materials can help in making informed decisions for linear bearing procurement.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a linear bearing

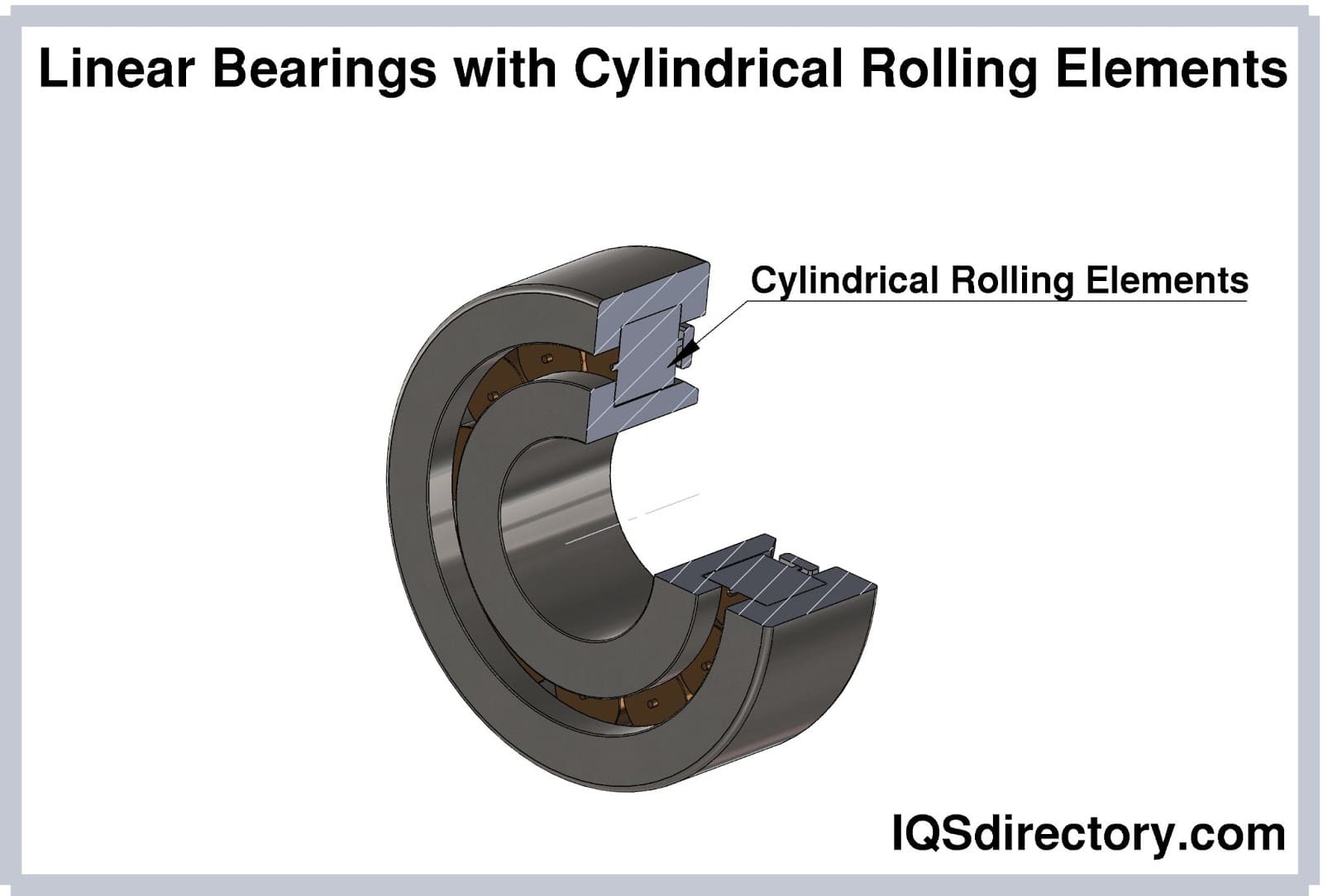

What Are the Main Stages in the Manufacturing Process of Linear Bearings?

The manufacturing process of linear bearings is a complex series of stages that ensure precision, reliability, and durability in their performance. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

How is Material Prepared for Linear Bearings?

The first step in manufacturing linear bearings involves selecting high-quality materials, typically high-carbon steel or stainless steel, known for their durability and resistance to wear. The material is then subjected to heat treatment to enhance hardness and tensile strength, ensuring it can withstand the mechanical stresses it will encounter during operation. This stage is critical, as the choice of material directly influences the bearing’s performance and lifespan.

What Techniques are Used in the Forming Process?

Following material preparation, the forming process commences. This usually involves precision machining techniques such as turning, grinding, and milling to create the inner and outer races of the bearing.

- Turning: This technique shapes the material into cylindrical forms, essential for the bearing’s races.

- Grinding: After turning, grinding ensures a smooth surface finish and precise dimensional tolerances, which are crucial for reducing friction and wear.

- Milling: This is used for creating features like mounting flanges or grooves in the bearing components.

Advanced techniques such as CNC (Computer Numerical Control) machining can be employed for high precision and repeatability, which is particularly important in high-demand applications like aerospace and medical equipment.

What Steps Are Involved in the Assembly of Linear Bearings?

Once the components are formed, they move to the assembly stage. This process involves several key actions:

- Ball Insertion: Ball bearings, typically made from high-grade steel or ceramic, are inserted between the inner and outer races. The arrangement is designed to minimize friction and maximize load-bearing capacity.

- Caging: The balls are housed in a cage that keeps them evenly spaced and prevents them from colliding with each other during operation.

- Sealing: Seals are added to protect the internal components from contaminants such as dust and moisture, thus prolonging the bearing’s life.

Each of these assembly steps must be carried out with precision to ensure optimal performance.

How is the Finishing Process Conducted for Linear Bearings?

The finishing stage includes several processes designed to enhance the bearing’s performance and aesthetics. Common techniques include:

- Surface Treatment: Processes like hardening or coating (e.g., zinc plating or anodizing) are applied to increase corrosion resistance and reduce friction.

- Quality Inspection: Each bearing undergoes rigorous quality checks to ensure it meets the specified tolerances and performance criteria.

This final stage is critical as it not only ensures the functionality of the bearing but also its reliability in demanding applications.

What Quality Assurance Measures Are Applied in Linear Bearing Production?

Quality assurance is a vital aspect of the linear bearing manufacturing process. B2B buyers should be aware of the various international standards and quality control checkpoints that ensure product integrity.

Which International Standards Are Relevant to Linear Bearings?

International standards such as ISO 9001 are fundamental in ensuring a quality management system is in place. This standard requires manufacturers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

Illustrative image related to what is a linear bearing

In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API standards for the oil and gas industry are crucial. These certifications indicate that the products have undergone stringent testing and meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Linear Bearing Manufacturing?

Quality control in linear bearing manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial check verifies the quality of raw materials before they enter the production line. Suppliers must provide certificates of compliance and material test reports.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to ensure that processes remain within specified limits. This includes monitoring dimensions, surface finish, and assembly accuracy.

-

Final Quality Control (FQC): After assembly, the bearings undergo comprehensive testing, including load testing, friction testing, and noise level assessments. This ensures that they meet or exceed performance specifications.

What Common Testing Methods Are Used to Ensure Linear Bearing Quality?

Several testing methods are employed to assess the quality of linear bearings:

- Dimensional Inspection: This involves measuring critical dimensions using calipers and gauges to ensure they meet design specifications.

- Load Testing: Bearings are subjected to loads beyond their rated capacity to assess their performance and durability.

- Friction Testing: This measures the friction generated during operation, which is crucial for understanding the bearing’s efficiency.

- Environmental Testing: Bearings may be exposed to simulated operational environments to evaluate their performance under extreme conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are partnering with reliable suppliers, B2B buyers should take proactive steps to verify quality control measures.

What Audits and Reports Should Buyers Request from Suppliers?

Buyers should request documentation of quality management systems, including:

- ISO Certification: Proof that the supplier adheres to ISO 9001 or other relevant standards.

- Quality Control Reports: These should detail inspection results, testing outcomes, and any corrective actions taken during production.

How Can Third-Party Inspections Enhance Supplier Reliability?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be scheduled at various stages of production, ensuring compliance with agreed specifications before products are shipped.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of potential challenges in quality assurance. Language barriers, differing regulatory standards, and varying quality expectations can complicate supplier relationships. Establishing clear communication channels and conducting site visits or audits can help mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance measures for linear bearings is crucial for B2B buyers looking to procure reliable components. By focusing on supplier capabilities, adherence to international standards, and robust quality control practices, buyers can ensure they receive products that meet their specific needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a linear bearing’

To aid B2B buyers in sourcing linear bearings effectively, this guide provides a structured checklist designed to streamline the procurement process. Understanding linear bearings is crucial for applications in various sectors, including manufacturing, automation, and transportation. The following steps will help ensure you select the right product for your needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your linear bearing application. Consider factors such as load capacity, speed, and environmental conditions. Clear specifications help narrow down options and ensure compatibility with existing machinery.

- Load Capacity: Assess the maximum weight the bearing must support.

- Speed Requirements: Determine the operational speed to ensure the bearing can handle the intended motion efficiently.

Step 2: Research Different Types of Linear Bearings

Familiarize yourself with the various types of linear bearings available, such as closed-type, open-type, and super linear bearings. Each type has unique features suited for different applications.

- Closed-Type Bearings: Ideal for unsupported shafts and heavy loads.

- Open-Type Bearings: Suitable for supported shafts and cost-effective solutions.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure reliability and quality. Look for suppliers with a proven track record in the industry.

- Request Documentation: Ask for technical datasheets, certifications, and case studies.

- Check References: Contact previous clients to gather insights about their experiences with the supplier.

Step 4: Assess Quality Control Measures

Quality assurance is vital in ensuring the performance and longevity of linear bearings. Inquire about the quality control processes implemented by the supplier.

- Testing Procedures: Understand how bearings are tested for performance and durability.

- Certifications: Look for ISO certifications or other industry standards that indicate adherence to quality protocols.

Step 5: Understand Lead Times and Delivery Options

Discuss lead times and shipping logistics with suppliers to ensure timely delivery. Delays can affect production schedules, so it’s essential to align timelines with your project needs.

- Production Time: Confirm how long it takes to manufacture the bearings.

- Shipping Methods: Explore available shipping options, including express services for urgent needs.

Step 6: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, engage in negotiations regarding pricing, payment terms, and warranties. Competitive pricing can significantly impact overall project costs.

Illustrative image related to what is a linear bearing

- Volume Discounts: Inquire about discounts for bulk orders.

- Warranty Terms: Ensure you understand the warranty policy and what it covers.

Step 7: Finalize Purchase Agreement

After selecting a supplier and negotiating terms, finalize the purchase agreement. Ensure all specifications, pricing, and delivery terms are clearly outlined in the contract.

- Review Contract: Double-check for any discrepancies or missing details.

- Establish Communication: Set up a point of contact for any post-purchase inquiries or support.

By following these steps, B2B buyers can navigate the complexities of sourcing linear bearings effectively, ensuring that they select the right products for their operational needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for what is a linear bearing Sourcing

What Are the Key Cost Components in Linear Bearing Sourcing?

When sourcing linear bearings, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality of materials used significantly impacts the cost. Linear bearings are often made from high-grade steel, aluminum, or plastic, with variations in material quality affecting durability and performance. For instance, bearings made with stainless steel will generally be more expensive due to their corrosion resistance and longevity.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with higher labor costs, such as Europe, might have different pricing compared to countries in Africa or South America, where labor may be less expensive. Skilled labor is essential for the precise assembly and quality assurance of linear bearings.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Manufacturers in regions with advanced technology may have lower overhead costs due to automation, affecting overall pricing.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or specialized linear bearings. This cost is often amortized over production runs, meaning larger orders can lead to reduced per-unit costs.

-

Quality Control (QC): Rigorous QC processes ensure the reliability of linear bearings. The costs associated with QC can vary based on the certifications required (e.g., ISO standards) and the complexity of the testing procedures.

-

Logistics: Shipping costs, including freight and insurance, can significantly influence the final price, especially for international buyers. Understanding the Incoterms (International Commercial Terms) can help buyers anticipate additional costs associated with transportation and customs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely depending on the supplier’s market positioning, brand reputation, and the degree of customization offered.

What Factors Influence Pricing for Linear Bearings?

Several factors can affect the pricing of linear bearings, including volume, specifications, materials, quality certifications, supplier reputation, and Incoterms.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to volume discounts. Suppliers are more likely to negotiate favorable terms for larger orders, which can significantly reduce the per-unit cost.

-

Specifications/Customization: Custom designs or specific performance requirements (e.g., load capacity, speed) can lead to increased costs due to the need for specialized materials or manufacturing processes. Standardized bearings tend to be less expensive than bespoke solutions.

-

Materials and Quality: Higher quality materials and certifications (like ISO or CE marks) typically command higher prices. Buyers should assess the trade-off between cost and quality based on their application needs.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers with a track record of reliability may charge a premium for their products.

-

Incoterms: Understanding the terms of delivery can help buyers manage costs effectively. For example, “CIF” (Cost, Insurance, and Freight) means the supplier covers shipping costs, while “FOB” (Free on Board) places the responsibility on the buyer once the goods are on the shipping vessel.

What Are the Best Practices for Negotiating Linear Bearing Prices?

International B2B buyers should consider several strategies to negotiate better pricing for linear bearings, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

-

Total Cost of Ownership (TCO): Assessing the TCO, which includes purchase price, maintenance, and replacement costs, can provide a clearer picture of the financial implications of sourcing decisions. This approach may justify higher upfront costs if they result in lower long-term expenses.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable negotiations.

-

Benchmarking: Researching market prices and comparing suppliers can empower buyers during negotiations. Understanding the competitive landscape helps in arguing for better rates.

-

Flexibility: Being open to adjusting order sizes or timelines can provide leverage in negotiations, allowing for more favorable terms.

In conclusion, a comprehensive understanding of the cost structure and pricing influences of linear bearings is essential for international B2B buyers. By considering these factors, businesses can make more informed sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing what is a linear bearing With Other Solutions

Exploring Alternatives to Linear Bearings

In the world of industrial motion control, linear bearings are often the go-to solution for facilitating smooth and precise linear motion. However, various alternatives offer unique benefits that may be better suited for specific applications. Understanding these options can help B2B buyers make informed decisions based on performance, cost, and operational requirements.

Illustrative image related to what is a linear bearing

| Comparison Aspect | What Is A Linear Bearing | Ball Bearings | Electric Actuators |

|---|---|---|---|

| Performance | High precision with minimal friction, ideal for heavy loads and high speeds. | Good load capacity but can generate more friction than linear bearings. | Excellent for applications requiring push/pull motion but may lack precision in linear guidance. |

| Cost | Moderate initial cost with low long-term maintenance. | Generally lower initial cost, but higher wear and replacement rates can increase lifetime costs. | Higher initial investment due to the electric motor and control systems. |

| Ease of Implementation | Relatively easy to install and integrate into existing systems. | Simple installation but may require additional components for optimal performance. | More complex setup due to electrical requirements and control systems. |

| Maintenance | Low maintenance; designed for longevity with seals to protect from contaminants. | Higher maintenance needs; lubrication and regular checks are necessary to prevent failure. | Low maintenance once installed, but motor and electrical components can require servicing. |

| Best Use Case | Ideal for CNC machines, robotics, and automated manufacturing processes requiring high precision. | Suitable for general-purpose applications where cost is a priority, such as consumer appliances. | Best for applications needing linear motion with controlled force, such as clamping and lifting tasks. |

Detailed Breakdown of Alternatives

1. Ball Bearings

Ball bearings serve as a popular alternative to linear bearings. They are effective for reducing friction and enabling rotational motion. However, while they are generally less expensive initially, their performance can degrade faster due to higher friction, leading to increased maintenance and replacement costs over time. They excel in applications where rotational movement is predominant but may not provide the same level of precision and smoothness in linear motion as linear bearings.

2. Electric Actuators

Electric actuators convert electrical energy into linear motion, making them an attractive option for applications that require controlled movement. They offer flexibility in motion control and can be programmed for various tasks. However, their complexity and higher initial costs can be a drawback. While electric actuators provide excellent force and motion control, they may lack the precision associated with linear bearings, especially in applications requiring high-speed linear movement.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a solution for linear motion control, B2B buyers must consider their specific operational needs, including performance requirements, budget constraints, and maintenance capabilities. Linear bearings offer high precision and low maintenance, making them ideal for demanding industrial applications. In contrast, ball bearings may suit cost-sensitive projects, and electric actuators can provide flexibility for controlled tasks. By evaluating these factors, buyers can make informed decisions that align with their operational goals and enhance overall productivity.

Essential Technical Properties and Trade Terminology for what is a linear bearing

What Are the Key Technical Properties of Linear Bearings?

When evaluating linear bearings for industrial applications, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some critical properties to consider:

-

Material Grade

Linear bearings are typically constructed from materials like stainless steel, aluminum, or polymer composites. The choice of material affects durability, corrosion resistance, and weight. For industries operating in harsh environments, selecting a bearing made from high-grade stainless steel can prevent rust and extend service life, ultimately reducing replacement costs. -

Load Capacity

This specification indicates the maximum load a linear bearing can support without failure. It is essential for ensuring that the bearing can handle the weight of the machinery or components it guides. In B2B transactions, understanding load capacity helps buyers select the right bearing for their specific applications, enhancing productivity and safety. -

Tolerance

Tolerance refers to the allowable deviation in dimensions of the bearing components. High tolerance levels ensure precise alignment and movement, which is critical in applications requiring exact positioning. For manufacturers and OEMs, tighter tolerances can lead to improved quality and efficiency, reducing the risk of operational errors. -

Speed Rating

This property defines the maximum speed at which a linear bearing can operate effectively. Knowing the speed rating helps in selecting bearings that can maintain performance without overheating or wearing out prematurely. This is particularly important in high-speed automation environments, where efficiency directly impacts output. -

Seal Type

Seals protect linear bearings from environmental contaminants like dust and moisture. Different types of seals, such as lip seals or labyrinth seals, offer varying levels of protection. Selecting the appropriate seal type is essential for maintaining the integrity and performance of bearings in demanding industrial applications, leading to reduced maintenance costs and downtime. -

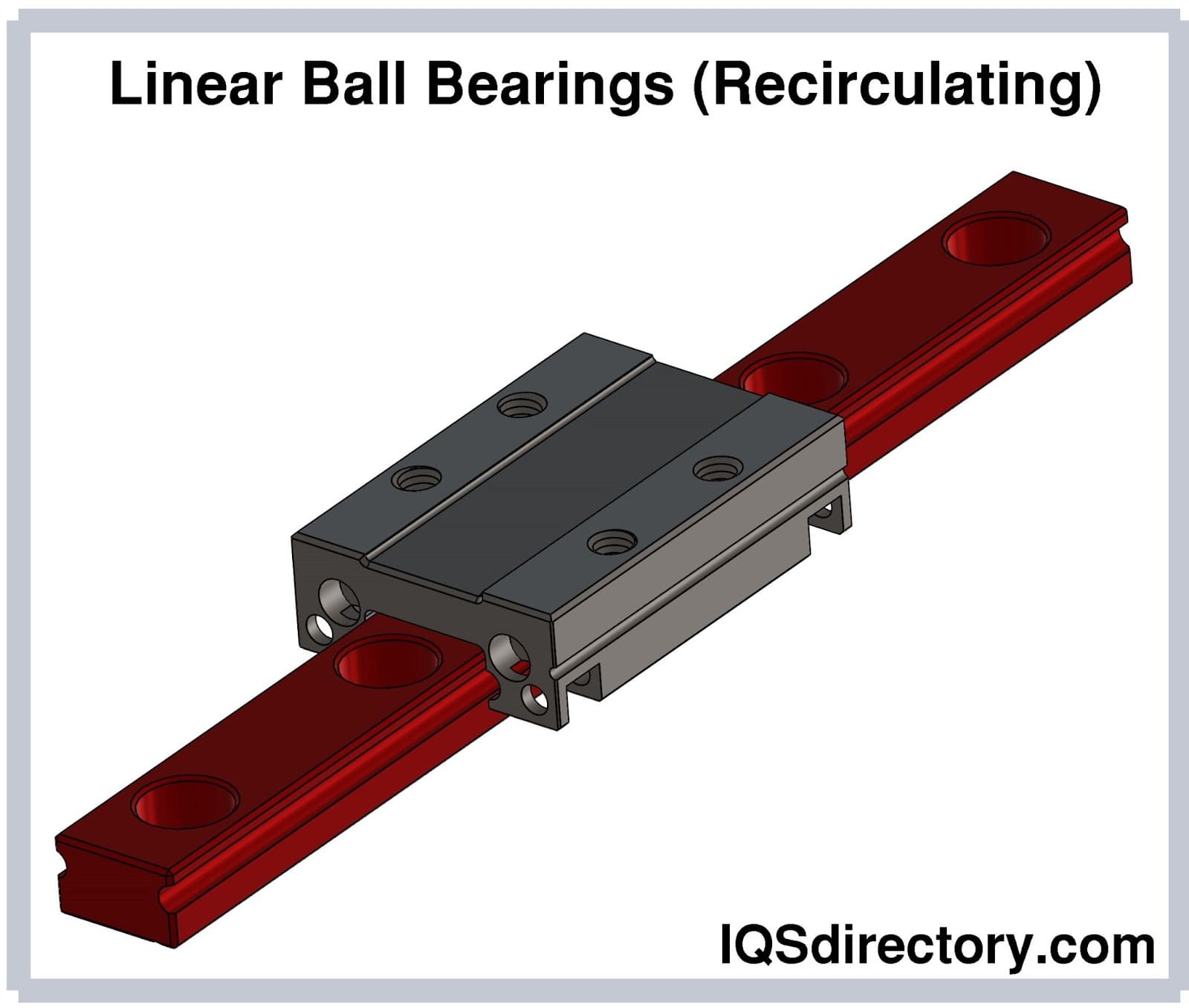

Recirculation Mechanism

This refers to how the rolling elements (e.g., balls or rollers) are arranged within the bearing. Options include open and closed designs, which influence friction and load distribution. Understanding the recirculation mechanism is vital for optimizing performance in specific applications, as it can affect both wear rates and the efficiency of linear motion.

What Are Common Trade Terms Related to Linear Bearings?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are several common trade terms relevant to linear bearings:

Illustrative image related to what is a linear bearing

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in another company’s end products. In the context of linear bearings, OEMs may require custom specifications to meet particular machinery requirements. Understanding this term is vital for buyers seeking tailored solutions. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to sell. This term is significant for B2B buyers as it impacts budgeting and inventory management. Knowing the MOQ can help companies plan their purchases effectively, especially when scaling operations. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to solicit price proposals from suppliers for specific products or services. When purchasing linear bearings, issuing an RFQ allows companies to compare pricing, lead times, and specifications from different manufacturers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risks associated with international procurement of linear bearings. -

Lead Time

This term refers to the time taken from placing an order to the delivery of the product. In industries with tight production schedules, understanding lead times for linear bearings can help businesses plan their operations more effectively, ensuring minimal downtime. -

Precision Engineering

This phrase describes the design and manufacturing processes that ensure components meet strict tolerances and specifications. In the context of linear bearings, precision engineering is critical for applications that demand high reliability and performance, such as in aerospace and medical devices. Understanding this concept can guide buyers in selecting high-quality bearings for their specific needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding linear bearings, ultimately enhancing operational efficiency and productivity.

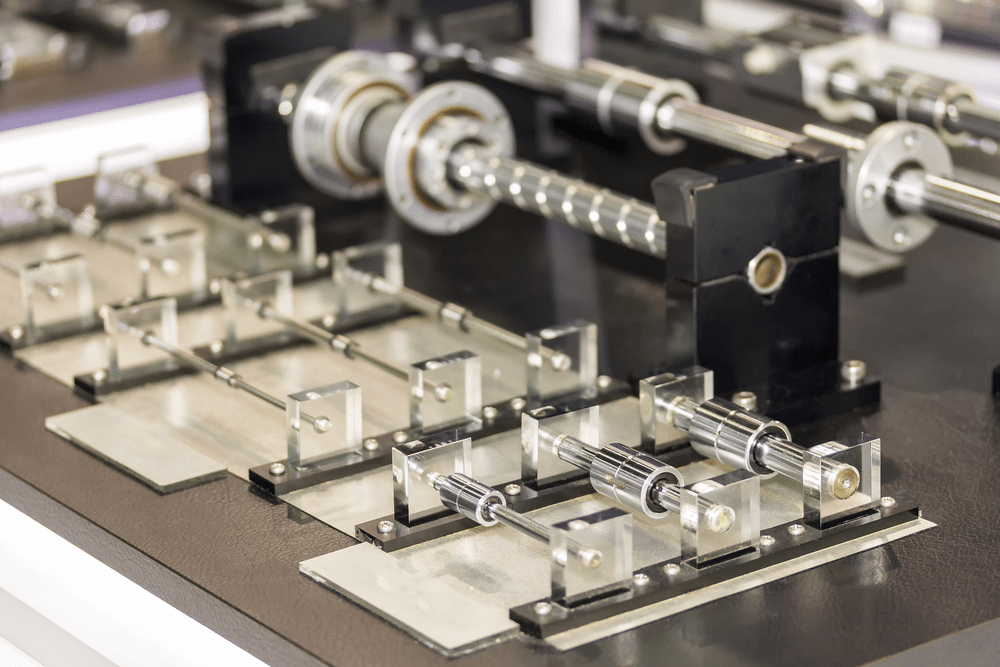

Navigating Market Dynamics and Sourcing Trends in the what is a linear bearing Sector

What Are the Current Market Dynamics and Key Trends in the Linear Bearing Sector?

The global linear bearing market is witnessing substantial growth, driven by increasing automation across various industries, including manufacturing, automotive, and aerospace. The demand for precision and efficiency in operations is pushing companies to invest in advanced linear motion technologies. Notably, emerging markets in Africa, South America, and the Middle East are ramping up their industrial capabilities, creating a burgeoning demand for high-quality linear bearings. Countries like Nigeria and Vietnam are particularly notable for their focus on enhancing manufacturing processes, which often incorporate linear motion systems.

In terms of technology and sourcing trends, the integration of smart manufacturing solutions and Industry 4.0 concepts is transforming how linear bearings are designed and utilized. The adoption of IoT-enabled devices allows for real-time monitoring of linear bearing performance, which can significantly reduce maintenance costs and downtime. Furthermore, the trend towards customization is gaining traction, with manufacturers offering tailored solutions that meet specific application requirements. This shift is particularly beneficial for B2B buyers who seek to optimize their machinery for unique operational conditions.

Sourcing dynamics are also evolving, with an increasing emphasis on local suppliers to mitigate supply chain risks and reduce lead times. International buyers are encouraged to establish relationships with local manufacturers who can offer competitive pricing and quicker delivery. Additionally, as businesses strive for greater efficiency, the focus on reducing friction and enhancing load capacities in linear bearings is driving innovation and product development in the sector.

How Is Sustainability and Ethical Sourcing Shaping the Linear Bearing Industry?

Sustainability is becoming a core consideration in the linear bearing sector, driven by both regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to adopt greener technologies. For B2B buyers, this means sourcing linear bearings that are produced through sustainable methods, such as using recyclable materials and reducing carbon footprints.

Ethical supply chains are equally important. Businesses are increasingly aware of their suppliers’ practices, insisting on transparency and ethical labor conditions. Buyers should look for suppliers that have obtained green certifications, which often indicate adherence to environmental standards and responsible sourcing practices. Certifications such as ISO 14001 or the use of eco-friendly materials in the production of linear bearings can enhance a company’s reputation while contributing to sustainability goals.

Moreover, the trend towards circular economy practices is influencing sourcing strategies in the linear bearing sector. Companies are exploring ways to recycle and repurpose materials, ensuring that products have longer lifecycles and are less harmful to the environment. By prioritizing sustainable and ethical sourcing, B2B buyers can not only comply with regulations but also align their operations with global sustainability goals.

What Is the Brief Evolution and History of Linear Bearings in the B2B Context?

The evolution of linear bearings can be traced back to the early 20th century when the need for precise linear motion became apparent with the rise of industrial automation. Initially, simple sliding bearings were employed, but as manufacturing processes advanced, the demand for more efficient and reliable solutions grew. The introduction of ball bearings in the mid-20th century marked a significant breakthrough, allowing for smoother motion with reduced friction.

Illustrative image related to what is a linear bearing

With technological advancements, linear bearings have evolved to incorporate sophisticated designs and materials, leading to the development of various types such as closed-type and open-type linear bearings. These innovations have expanded their applications across diverse sectors, including automotive assembly lines, robotics, and medical devices. Today, linear bearings are integral to modern machinery, reflecting a rich history of engineering innovation that continues to shape industrial practices globally. B2B buyers can leverage this historical context to make informed purchasing decisions, ensuring they select products that meet contemporary demands for precision and reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a linear bearing

-

How do I select the right linear bearing for my application?

Selecting the right linear bearing involves evaluating several factors, including load capacity, speed, and environmental conditions. Assess your specific application requirements, such as the type of motion needed, the weight of the components, and the operating environment (e.g., exposure to dust or moisture). Additionally, consider the bearing type—closed, open, or super linear—and the material composition for durability. Collaborating with suppliers who can provide technical support and customization options can also ensure optimal performance in your application. -

What are the key benefits of using linear bearings in industrial applications?

Linear bearings provide numerous advantages, including reduced friction, improved precision, and enhanced load handling capabilities. They enable smooth and efficient motion along linear paths, which is crucial in high-speed applications. Their design minimizes wear and tear on components, leading to lower maintenance costs and longer operational lifespans. Industries such as automotive, aerospace, and manufacturing benefit significantly from these attributes, making linear bearings an essential choice for applications requiring accuracy and reliability. -

What customization options are available for linear bearings?

Many manufacturers offer customization options for linear bearings to meet specific application needs. Customizations may include adjusting the bearing size, material selection, and load ratings. Suppliers can also provide modifications such as special coatings for corrosion resistance or seals for environmental protection. Discussing your requirements with potential suppliers is essential to ensure they can deliver the tailored solutions that will optimize performance in your unique operational context. -

What are the minimum order quantities (MOQs) for linear bearings?

Minimum order quantities for linear bearings can vary significantly among suppliers. Some may offer low MOQs for standard products, while others may require larger quantities for custom designs. When sourcing, inquire about MOQs upfront to align your purchasing strategy with your production needs. For smaller businesses, consider working with suppliers who provide flexibility in order sizes or those that specialize in low-volume manufacturing to avoid excess inventory costs. -

How can I vet suppliers for linear bearings?

Vetting suppliers for linear bearings involves assessing their experience, reputation, and product quality. Start by researching their track record in the industry, including customer reviews and case studies. Request certifications that demonstrate compliance with international standards, such as ISO or ASTM. Establish communication to gauge their responsiveness and willingness to provide technical support. Additionally, consider visiting their facilities if possible, or request samples to evaluate product quality before committing to a larger order. -

What payment terms should I expect when sourcing linear bearings internationally?

Payment terms for international orders of linear bearings can vary based on the supplier and the transaction size. Common terms include advance payment, net 30, or letter of credit arrangements. It’s crucial to clarify these terms during negotiations to avoid misunderstandings later. Additionally, consider the impact of currency exchange rates and any potential tariffs or taxes that may apply to your order. Ensuring transparent communication about payment expectations can foster a more reliable supplier relationship. -

What quality assurance processes should I look for in linear bearing suppliers?

When sourcing linear bearings, inquire about the supplier’s quality assurance (QA) processes. Look for suppliers that implement rigorous testing protocols, such as performance testing under various loads and environmental conditions. Certifications like ISO 9001 can indicate a commitment to maintaining quality standards. Additionally, ask about their warranty policies and how they handle defects or failures. A robust QA process not only ensures product reliability but also minimizes risks associated with operational downtime. -

What logistics considerations should I keep in mind for importing linear bearings?

Logistics play a crucial role in the successful importation of linear bearings. Consider factors such as shipping methods, lead times, and customs clearance processes. Work with suppliers who have experience in international shipping to ensure compliance with regulations and timely delivery. It’s also advisable to assess potential shipping costs, including duties and taxes, which can significantly impact overall expenses. Establishing a clear logistics plan helps mitigate delays and ensures that your bearings arrive in optimal condition for use.

Top 4 What Is A Linear Bearing Manufacturers & Suppliers List

1. IQS Directory – Linear Bearings

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Linear bearings are designed to support the load of a carriage moving along a single axis, providing a low-friction interface for smooth sliding on guide rails. They are categorized into rolling linear bearings and plain linear bearings, with applications in 3D printers, sliding doors, CNC machines, and industrial robots. Rolling linear bearings use rolling elements (balls or rollers) to minimize …

2. Kiwimotion – Linear Bearings

Domain: kiwimotion.co.uk

Registered: 2023 (2 years)

Introduction: Linear bearings, also known as linear bushings, enable linear motion with minimal friction along straight paths. They are crucial for guiding objects along linear shafts or rails, providing smooth and efficient motion even under heavy loads or high speeds. Key features include:

– **Design**: Composed of an outer sleeve that houses ball bearings arranged in rows, enclosed within cages for smooth r…

3. THK – LM Guides

Domain: thk.com

Registered: 1995 (30 years)

Introduction: Linear guides (also known as linear motion guides) are machine elements that utilize bearings for linear motion, enabling the easy movement of heavy objects in a straight line. THK refers to its linear guides as LM Guides, which consist of three main components: a mobile carriage (LM block), a rail (LM rail), and recirculating balls. The history of linear guides dates back to 1944 with the develop…

4. Bearing Centre – Linear Bearings

Domain: bearingcentre.net

Registered: 2009 (16 years)

Introduction: This company, Bearing Centre – Linear Bearings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for what is a linear bearing

In summary, linear bearings are essential components that facilitate precise and efficient linear motion across various industries, including manufacturing, automation, and aerospace. By understanding the different types—such as closed, open, and super linear bearings—B2B buyers can make informed decisions that enhance operational efficiency and product reliability. The strategic sourcing of these components not only streamlines supply chains but also ensures that businesses are equipped with the best technology to meet evolving market demands.

As international buyers from regions like Africa, South America, the Middle East, and Europe navigate the complexities of sourcing linear bearings, it is crucial to prioritize quality and supplier reliability. Establishing strong partnerships with trusted manufacturers can lead to significant cost savings, reduced downtime, and improved product performance.

Illustrative image related to what is a linear bearing

Looking ahead, the demand for advanced linear motion solutions will continue to rise. B2B buyers should remain proactive in exploring innovative technologies and suppliers to stay competitive. Engage with industry experts, attend trade shows, and leverage digital platforms to expand your sourcing options and ensure your operations are equipped for future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.