Top 4 Warehouse Racking System Design Suppliers (And How to Choose)

Introduction: Navigating the Global Market for warehouse racking system design

In today’s competitive landscape, sourcing effective warehouse racking system designs is crucial for optimizing inventory management and maximizing storage efficiency. With the complexities of varying warehouse needs across regions—from the bustling supply chains in Brazil to the high-tech operations in Germany—international B2B buyers face the challenge of selecting the right racking solutions that align with their specific operational goals. This comprehensive guide delves into the diverse types of racking systems available, their applications, and essential design considerations tailored to enhance storage capabilities.

Buyers will gain insights into the benefits and drawbacks of various racking solutions, including selective pallet racking, automated systems, and mobile racking options, allowing for informed decision-making. Additionally, the guide covers critical aspects of supplier vetting, cost analysis, and maintenance strategies, ensuring that stakeholders can navigate the complexities of the global market with confidence.

By empowering B2B buyers from Africa, South America, the Middle East, and Europe with actionable insights, this guide serves as an essential resource for optimizing warehouse operations, ultimately leading to improved efficiency and reduced overhead costs. Whether you are looking to expand your storage capacity or streamline your logistics processes, understanding warehouse racking system design is the key to unlocking your operational potential.

Understanding warehouse racking system design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Selective Pallet Racking | Direct access to each pallet; standard forklift compatibility. | General warehousing, varied SKUs. | Pros: High accessibility, low cost per pallet. Cons: Lower storage density, more aisle space needed. |

| Drive-In Racking | Forklifts drive into deep lanes; LIFO system. | Bulk storage of homogeneous products. | Pros: High-density storage; cost-effective. Cons: Limited selectivity, slow access. |

| Gravity Flow Racking | FIFO system with sloped roller conveyors for automatic flow. | Perishable goods, high-volume items. | Pros: High storage density; automated stock rotation. Cons: High installation costs, ongoing maintenance required. |

| Push-Back Racking | Pallets stored on inclined rails, LIFO retrieval. | Warehouses with moderate SKU variety. | Pros: Better accessibility than drive-in; good density. Cons: Higher cost, LIFO only. |

| Automated Racking Systems | Uses cranes or shuttles for automated pallet movement. | High-volume, fast-paced operations. | Pros: Maximizes density and speed; improves accuracy. Cons: High initial cost, complex maintenance. |

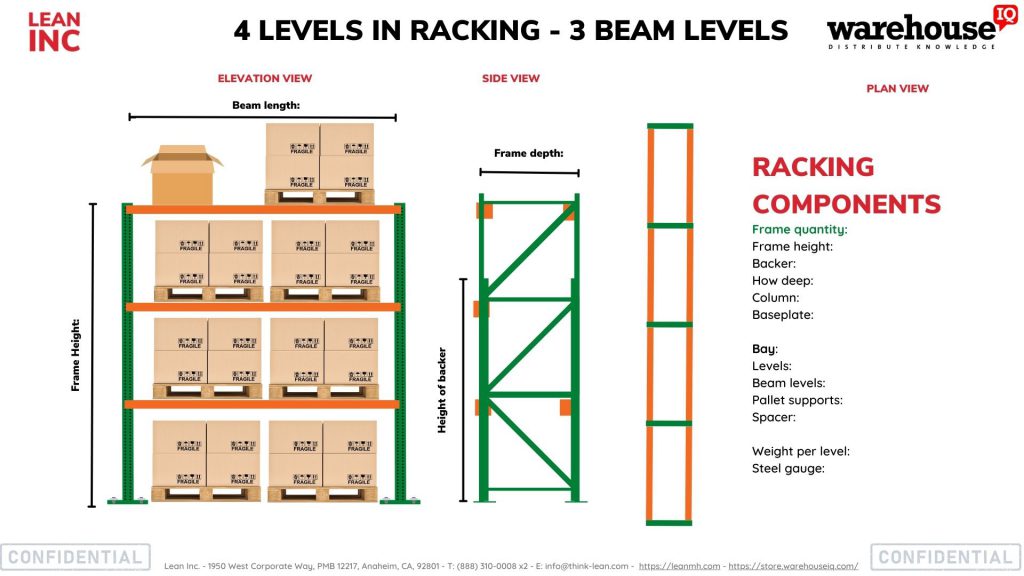

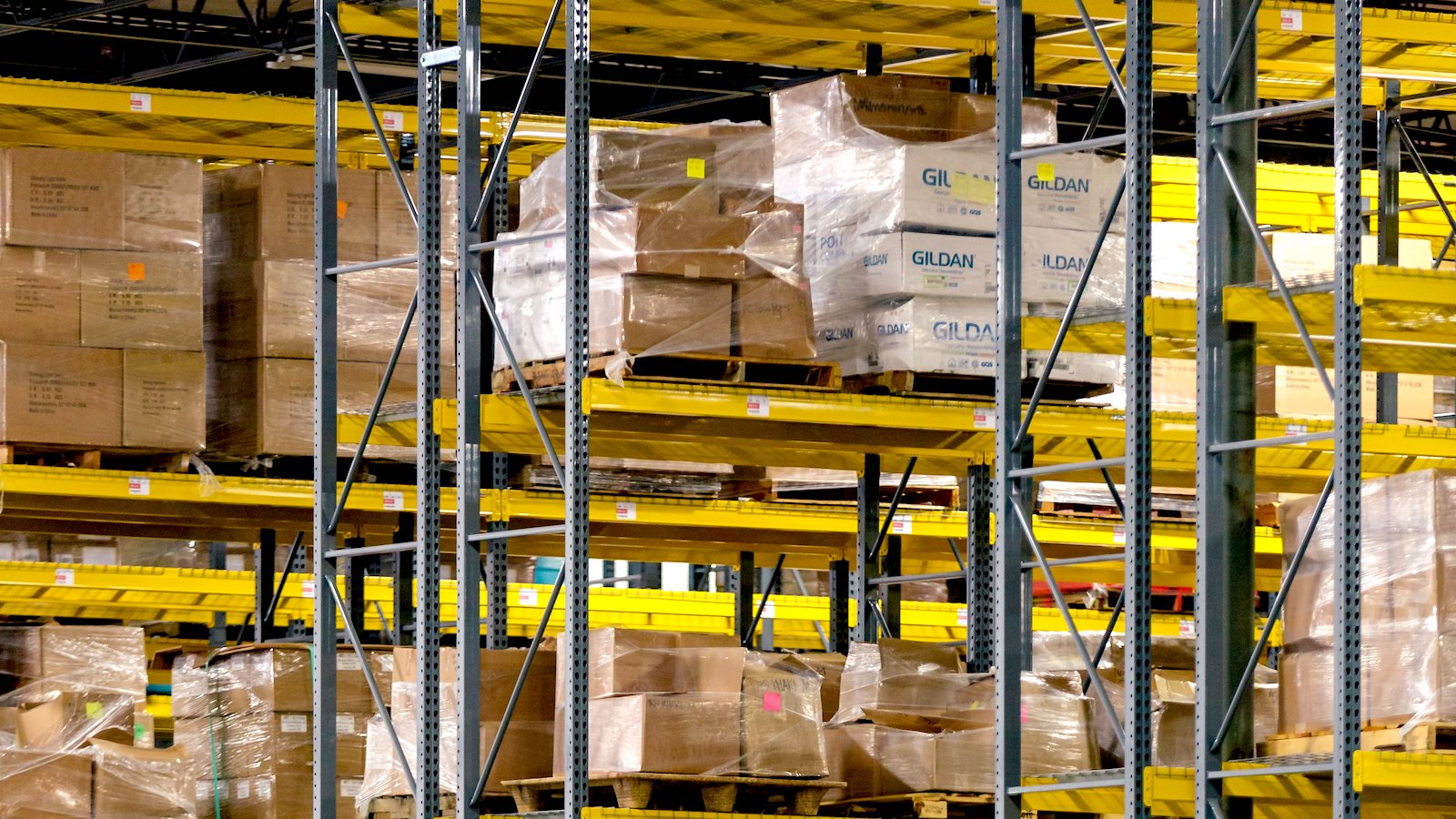

What Are the Key Characteristics of Selective Pallet Racking?

Selective pallet racking is the most widely used system due to its straightforward design and functionality. It allows for direct access to every pallet, making it ideal for warehouses with diverse inventory and frequent stock rotation. This type of racking is best suited for operations that require quick access to a variety of SKUs. When considering this option, buyers should evaluate their space layout, as this system requires more aisle space compared to high-density alternatives.

Illustrative image related to warehouse racking system design

How Does Drive-In Racking Enhance Storage Efficiency?

Drive-in racking systems are designed for high-density storage, allowing forklifts to drive directly into the racking lanes. This system is particularly effective for storing large quantities of the same SKU, as it employs a Last-In, First-Out (LIFO) retrieval method. Buyers should assess their inventory turnover rates and product variety, as this system may limit selectivity and speed of retrieval, which could affect operational efficiency.

Why Choose Gravity Flow Racking for Perishable Goods?

Gravity flow racking utilizes sloped roller conveyors, enabling a First-In, First-Out (FIFO) inventory management system, which is particularly beneficial for perishable goods. This system automates stock rotation, minimizing the risk of spoilage and ensuring optimal inventory freshness. B2B buyers should consider the initial investment and ongoing maintenance costs, along with the need for high-quality pallets to maintain functionality.

What Are the Advantages of Push-Back Racking?

Push-back racking systems combine high-density storage with improved accessibility by utilizing inclined rails that allow pallets to slide back during loading. This system supports LIFO retrieval and is suitable for warehouses that handle a moderate variety of SKUs. Buyers should weigh the initial cost against the benefits of better accessibility compared to drive-in systems, as well as the implications of LIFO inventory management.

Illustrative image related to warehouse racking system design

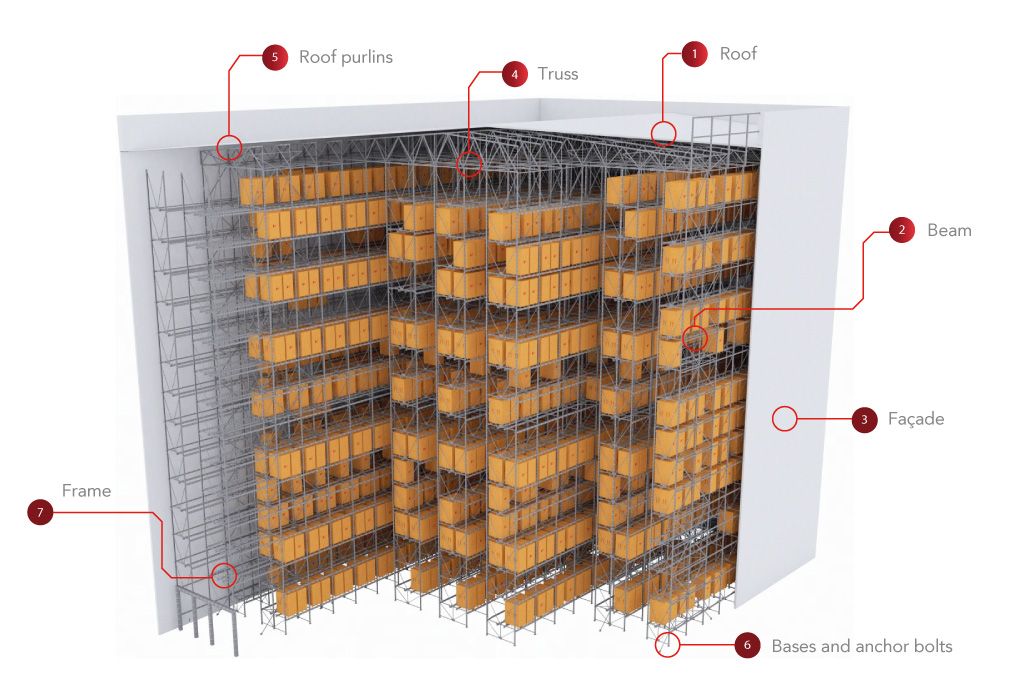

How Do Automated Racking Systems Transform Warehouse Operations?

Automated racking systems employ advanced technology such as cranes or shuttle carts for efficient pallet movement, significantly enhancing storage density and operational speed. These systems are particularly advantageous for high-volume operations requiring minimal labor input. However, buyers must consider the substantial upfront costs and the complexity of maintenance, as well as how these systems align with their operational goals and flexibility needs.

Key Industrial Applications of warehouse racking system design

| Industry/Sector | Specific Application of warehouse racking system design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and E-commerce | High-density shelving for diverse product ranges | Maximizes storage capacity and improves order fulfillment speed | Flexibility in design, ease of access, and integration with inventory management systems |

| Manufacturing | Custom racking for raw materials and finished goods | Streamlines production flow and reduces material handling time | Durability under heavy loads, compliance with safety regulations, and space optimization |

| Food and Beverage | FIFO racking systems for perishable goods | Ensures product freshness and minimizes waste | Temperature control features, compliance with health standards, and ease of cleaning |

| Pharmaceuticals | Automated racking systems for inventory management | Enhances accuracy in order picking and reduces labor costs | High precision, regulatory compliance, and integration with supply chain systems |

| Construction and Lumber | Cantilever racking for long and bulky items | Facilitates easy access and maximizes storage for irregular shapes | Robust construction, weather resistance, and load capacity considerations |

How is Warehouse Racking System Design Applied in Retail and E-commerce?

In the retail and e-commerce sectors, warehouse racking system design is crucial for managing a diverse range of products efficiently. High-density shelving solutions allow businesses to maximize storage space while ensuring quick access to items for faster order fulfillment. This is particularly important for companies operating in regions with limited warehousing space, such as urban areas in Europe or densely populated regions in Africa. Buyers should prioritize flexibility in design to accommodate varying product sizes and the ability to integrate with existing inventory management systems for optimal efficiency.

What Role Does Racking System Design Play in Manufacturing?

Manufacturing facilities utilize customized racking systems to store raw materials and finished goods, significantly streamlining production workflows. By reducing the time spent on material handling, businesses can increase output and efficiency. For international buyers, especially in South America and the Middle East, sourcing durable racks that comply with safety regulations is critical. Additionally, optimizing space through effective racking can lead to substantial cost savings, making it a vital consideration for manufacturers looking to enhance their operational capabilities.

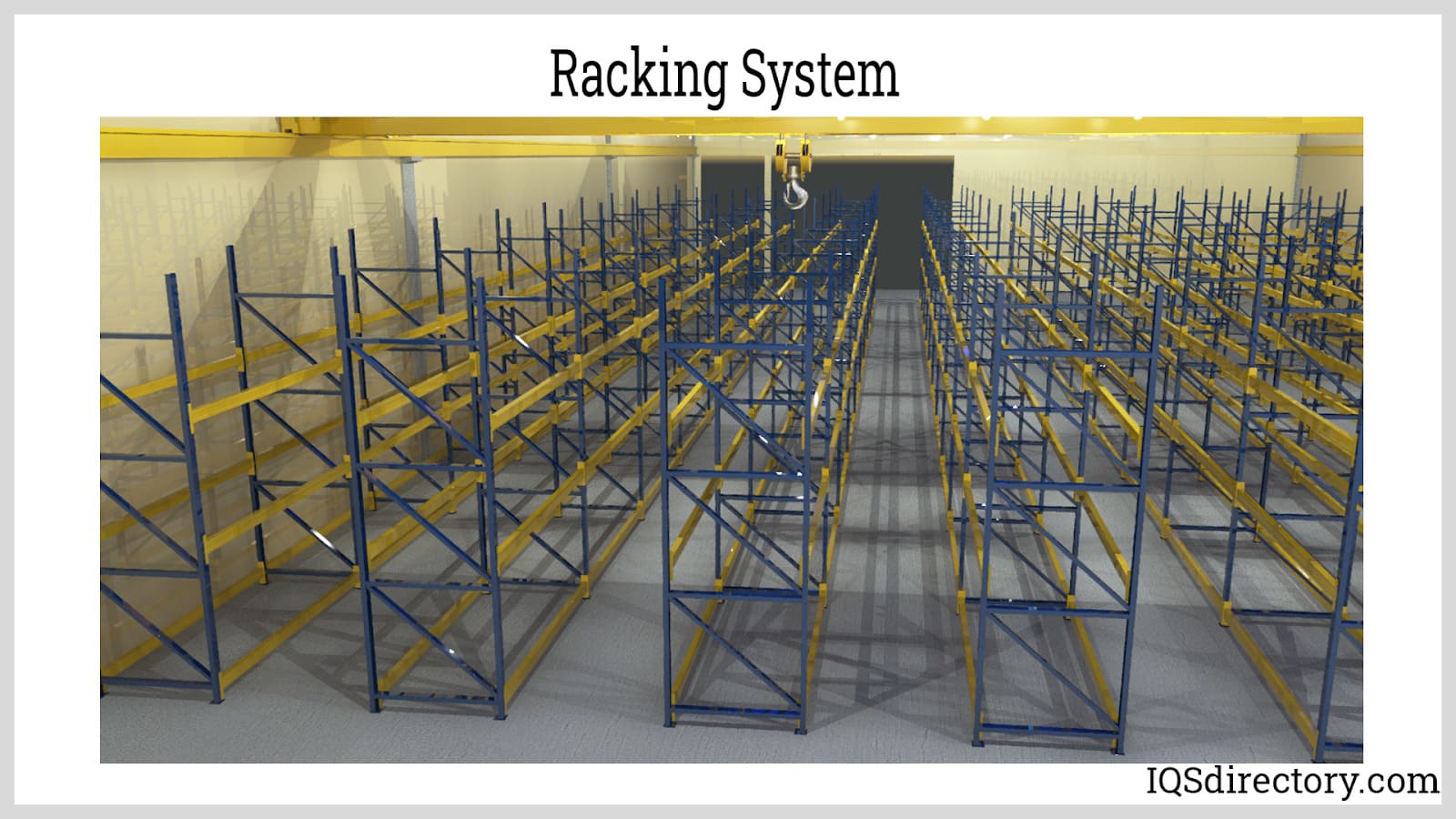

Illustrative image related to warehouse racking system design

Why is Racking System Design Important for Food and Beverage Industries?

In the food and beverage industry, FIFO (First-In, First-Out) racking systems are essential for managing perishable goods. These systems help maintain product freshness and minimize waste by ensuring older stock is sold before newer stock. For buyers in this sector, particularly in regions with strict health regulations, sourcing racking solutions that comply with safety and hygiene standards is paramount. Features such as temperature control and ease of cleaning are also critical considerations for maintaining product integrity.

How Does Warehouse Racking System Design Benefit the Pharmaceutical Sector?

Pharmaceutical companies benefit from automated racking systems that enhance inventory management and accuracy in order picking. This is crucial for reducing labor costs and ensuring compliance with stringent regulations. Buyers from regions with advanced pharmaceutical markets, such as Germany, should focus on sourcing high-precision racking solutions that integrate seamlessly with existing supply chain systems. The ability to maintain accurate inventory levels is vital for ensuring product availability and compliance with health standards.

What Are the Key Considerations for Racking Systems in Construction and Lumber?

In the construction and lumber industries, cantilever racking systems are specifically designed to store long and bulky items like lumber and piping. These systems facilitate easy access and maximize storage efficiency for irregularly shaped products. Buyers in this sector must consider the robustness of the racking system to withstand heavy loads and environmental factors, particularly in outdoor storage scenarios. Weather resistance and proper load capacity are vital to ensure safety and operational efficiency in construction-related applications.

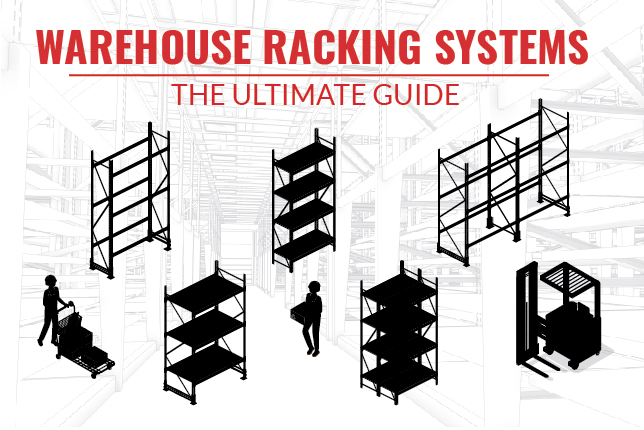

Illustrative image related to warehouse racking system design

3 Common User Pain Points for ‘warehouse racking system design’ & Their Solutions

Scenario 1: Inefficient Space Utilization in Diverse Warehousing Needs

The Problem: Many B2B buyers encounter challenges when their warehouse space is not fully optimized for their specific inventory types. This can lead to wasted space, increased operational costs, and a backlog in order fulfillment. For example, a company that handles both heavy pallets and small items might struggle to find a racking system that accommodates both without compromising efficiency. The mismatch between racking solutions and the nature of the products stored can lead to a chaotic warehouse environment, making it difficult to locate items quickly.

The Solution: Conduct a thorough assessment of your product types and warehouse layout before selecting a racking system. A mixed-use racking solution, such as a combination of selective pallet racks for heavy items and shelving systems for smaller items, can maximize space utilization. Additionally, consider implementing modular racking systems that can be adjusted as inventory needs change. Partnering with a racking design consultant who specializes in tailored solutions can also help you create an efficient layout that meets both current and future demands.

Scenario 2: Safety Risks and Compliance Issues in Racking Systems

The Problem: Safety is a paramount concern in warehouses, and poorly designed racking systems can lead to accidents and compliance violations. B2B buyers often face the dilemma of balancing high-density storage needs with safety regulations. For instance, an improperly installed or overloaded racking system can result in pallet collapses, injury to workers, and significant financial liabilities. This issue is particularly pressing for companies operating in regions with stringent safety standards.

The Solution: Ensure that your racking system design adheres to local safety regulations by engaging with a certified racking system provider. Conduct regular safety audits to identify potential hazards, such as overloading racks or inadequate clearance for forklifts. Additionally, incorporating safety accessories like wire mesh backing, pallet support bars, and column protectors can mitigate risks. Training staff on safe racking practices and ensuring they understand load limits is crucial. By prioritizing safety in your design and operations, you can protect your workforce and comply with regulations, ultimately reducing liability.

Scenario 3: High Initial Costs and Long-Term ROI Concerns

The Problem: B2B buyers frequently struggle with the high initial costs associated with investing in a new racking system. Many companies hesitate to upgrade their warehouse racking due to the perceived financial burden, particularly when operating on tight budgets. This concern is amplified in regions where capital expenditures must be justified with clear long-term ROI. Without an effective racking solution, however, inefficiencies can lead to increased operational costs that outweigh the initial investment.

Illustrative image related to warehouse racking system design

The Solution: To address financial concerns, perform a comprehensive cost-benefit analysis comparing the initial investment in a new racking system against the potential savings and efficiency gains over time. Consider options like leasing racking systems or purchasing used equipment to reduce upfront costs. Additionally, focus on high-density storage solutions, such as drive-in or automated racking systems, which can drastically increase storage capacity and streamline operations. Investing in a racking system with a proven track record of durability and efficiency can lead to significant savings in labor, space, and inventory management, providing a clear ROI over time. Engaging with financial advisors or procurement specialists can also help navigate financing options that align with your budget constraints.

Strategic Material Selection Guide for warehouse racking system design

What Are the Key Materials for Warehouse Racking System Design?

Selecting the right materials for warehouse racking systems is crucial for ensuring durability, safety, and efficiency in storage operations. The choice of material impacts not only the performance of the racking system but also its cost, maintenance, and compliance with international standards. Below, we analyze four common materials used in warehouse racking systems, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Steel Perform as a Material for Warehouse Racking Systems?

Steel is the most prevalent material used in warehouse racking systems due to its exceptional strength and durability. It typically has a high temperature and pressure rating, making it suitable for various environments, including those with heavy loads or extreme conditions.

Pros: Steel racking systems are highly durable, with a lifespan of 10-20 years or more, and they can withstand significant weight without warping or bending. They are also relatively easy to manufacture and assemble, which can reduce installation costs.

Cons: However, steel is susceptible to corrosion if not properly treated or coated, which can be a concern in humid or corrosive environments. Additionally, the initial cost of steel racking can be high, impacting budget considerations for buyers.

Illustrative image related to warehouse racking system design

Impact on Application: Steel is compatible with a wide range of media, including pallets, boxes, and bulk items, making it a versatile choice for various warehouse operations.

Considerations for International Buyers: Compliance with standards like ASTM (American Society for Testing and Materials) and DIN (Deutsches Institut für Normung) is essential for ensuring safety and quality. Buyers in regions with high humidity, such as parts of Africa and the Middle East, should consider galvanized or powder-coated options to mitigate corrosion risks.

What Role Does Aluminum Play in Warehouse Racking Systems?

Aluminum is increasingly being used in warehouse racking systems, particularly in environments where weight is a concern. It is lightweight and corrosion-resistant, making it ideal for applications in cold storage or areas with high moisture levels.

Pros: The primary advantage of aluminum is its lightweight nature, which simplifies installation and reduces labor costs. It also offers excellent corrosion resistance, making it suitable for food storage or chemical handling.

Cons: On the downside, aluminum has a lower load-bearing capacity compared to steel, which may limit its application in heavy-duty storage scenarios. Additionally, the cost of aluminum can be significantly higher than that of steel, which may deter budget-conscious buyers.

Illustrative image related to warehouse racking system design

Impact on Application: Aluminum is particularly effective for storing smaller items or goods that require frequent access, as its lightweight nature allows for easy mobility.

Considerations for International Buyers: Buyers in Europe and South America should be aware of local aluminum standards and certifications to ensure compliance with safety regulations. The higher cost may be justified in environments where corrosion is a significant concern.

How Does Wood Compare as a Material for Racking Systems?

Wood is a traditional material used in warehouse racking, especially for lighter loads or in environments where aesthetics are important. It is often used in combination with metal components to create hybrid systems.

Illustrative image related to warehouse racking system design

Pros: Wood is a sustainable and cost-effective option, offering good load capacity for lighter items. Its natural appearance can also enhance the visual appeal of retail or showroom environments.

Cons: However, wood is less durable than metal and can be susceptible to warping, rot, and insect damage, particularly in humid climates. This can lead to increased maintenance costs over time.

Impact on Application: Wood is best suited for non-palletized storage, such as bins or boxes, and is often used in environments where aesthetics are prioritized over heavy-duty performance.

Considerations for International Buyers: Buyers should ensure that the wood used complies with local standards for sustainability and safety. In regions like Africa and South America, where humidity can be high, treated wood may be necessary to enhance durability.

What Are the Benefits of Composite Materials in Racking Systems?

Composite materials, which combine various substances to enhance performance, are becoming popular in warehouse racking systems. These materials often include a mix of plastics and metals, designed to provide specific benefits.

Pros: Composite materials are lightweight, resistant to corrosion, and can be designed to meet specific load requirements. They also offer flexibility in design, allowing for customized solutions.

Cons: The primary disadvantage is that composite materials can be more expensive than traditional options. Additionally, their load-bearing capacity may not match that of steel or aluminum, limiting their application in heavy-duty environments.

Impact on Application: Composites are suitable for environments that require resistance to chemicals or moisture, making them ideal for specialized storage applications.

Illustrative image related to warehouse racking system design

Considerations for International Buyers: Buyers should evaluate compliance with international standards, particularly in industries where safety and material performance are critical. The higher initial investment may be offset by lower maintenance costs in corrosive environments.

Summary Table of Material Selection for Warehouse Racking Systems

| Material | Typical Use Case for warehouse racking system design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty storage for pallets and bulk items | High durability and load capacity | Susceptible to corrosion | High |

| Aluminum | Lightweight storage for cold or humid environments | Corrosion-resistant and lightweight | Lower load capacity than steel | High |

| Wood | Non-palletized storage and aesthetic applications | Cost-effective and sustainable | Susceptible to damage and wear | Medium |

| Composite | Specialized storage requiring chemical resistance | Lightweight and customizable | Higher cost and limited load capacity | High |

This material selection guide provides essential insights for international B2B buyers, helping them make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for warehouse racking system design

What Are the Main Stages of Manufacturing Warehouse Racking Systems?

The manufacturing process of warehouse racking systems involves several crucial stages, each designed to ensure that the final product meets the rigorous demands of modern storage solutions. Understanding these stages is essential for B2B buyers looking to invest in durable and efficient racking systems.

How Is Material Prepared for Warehouse Racking Systems?

The first stage in the manufacturing process is material preparation. Steel is the most commonly used material due to its strength and durability. Suppliers often source high-quality steel from reputable mills, which undergoes rigorous quality checks to ensure it meets specific standards.

Illustrative image related to warehouse racking system design

Once sourced, the steel is cut into appropriate dimensions using advanced cutting techniques such as laser cutting or plasma cutting. This precision ensures that the components will fit together seamlessly during assembly. Additionally, the cut pieces are subjected to surface treatments, such as shot blasting, to remove any impurities and enhance adhesion for subsequent coatings.

What Forming Techniques Are Used in Racking System Production?

After material preparation, the next stage is forming. This involves shaping the steel into the desired profiles for the racking system. Common techniques include:

-

Roll Forming: This method involves feeding flat steel into a series of rollers that gradually shape it into the desired cross-section. It’s efficient for producing long runs of racking components like upright frames and beams.

-

Welding: Critical for assembling various parts, welding techniques such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are employed to join components securely. Automated welding machines enhance consistency and reduce labor costs.

-

Punching and Notching: These processes are used to create holes and cutouts in the steel components, allowing for the attachment of beams and safety features.

How Is Assembly Carried Out in Racking System Manufacturing?

The assembly stage is where individual components come together to form a complete racking system. This process can be manual or automated, depending on the production scale.

During assembly, parts such as upright frames, horizontal beams, and safety accessories are connected using bolts, clips, and other fasteners. Quality control checkpoints are crucial at this stage to ensure that all components are correctly aligned and securely fastened.

Efficient assembly techniques not only speed up production but also ensure that the final product adheres to safety standards and customer specifications.

What Finishing Processes Are Involved in Racking Systems?

Once assembled, the racking systems undergo finishing processes to enhance durability and aesthetics. Common finishing techniques include:

-

Painting: A powder coating process is often used to apply a durable and corrosion-resistant finish. This involves electrostatically applying powder paint, which is then cured in an oven.

-

Galvanization: For environments with high humidity or corrosive substances, galvanization provides additional protection. This process involves coating steel with a layer of zinc to prevent rust.

-

Inspection: After finishing, each racking system is inspected for visual defects and compliance with specifications. This step is crucial for ensuring the longevity and safety of the racking system.

What Quality Assurance Measures Are Essential for Warehouse Racking Systems?

Quality assurance (QA) in the manufacturing of warehouse racking systems is vital for ensuring product safety and reliability. B2B buyers should be aware of various international and industry-specific standards that govern the quality of these systems.

Which International Standards Should B2B Buyers Consider?

One of the most recognized standards in manufacturing is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer follows systematic processes to enhance customer satisfaction through consistent quality.

Additionally, CE marking is crucial for products sold in the European market, demonstrating compliance with health, safety, and environmental protection standards. For racking systems, adherence to relevant standards ensures that products can withstand the rigors of warehouse environments.

Illustrative image related to warehouse racking system design

What Are the Key Quality Control Checkpoints in Racking System Manufacturing?

Quality control in racking system manufacturing is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. This is critical for preventing defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to ensure that all processes comply with quality standards. This includes checking dimensions, weld quality, and surface treatments.

-

Final Quality Control (FQC): Before shipping, each racking system undergoes a final inspection to verify that it meets all specifications and quality standards. This includes load testing and ensuring that all safety features are in place.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s adherence to quality standards. This can be done in collaboration with third-party inspection agencies.

-

Request Quality Reports: Suppliers should provide documentation that outlines their quality control procedures, inspection results, and compliance with international standards.

-

Engage Third-Party Inspectors: Independent inspectors can assess the manufacturing process and the final product, providing an unbiased evaluation of quality.

What Are the Nuances of Quality Control for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential.

-

Cultural and Regulatory Differences: Buyers must navigate varying regulations and cultural expectations regarding product quality. Familiarizing themselves with local standards and practices is crucial for successful procurement.

-

Shipping and Logistics Considerations: Quality assurance doesn’t end at the manufacturing facility. Buyers should ensure that products are protected during shipping to prevent damage. This may include specifying packaging standards and conducting inspections upon arrival.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and any necessary adjustments to manufacturing processes.

In summary, understanding the manufacturing processes and quality assurance practices of warehouse racking systems equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on these critical aspects, businesses can ensure they invest in reliable and efficient storage solutions tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘warehouse racking system design’

Introduction

Designing an effective warehouse racking system is crucial for optimizing storage capacity and improving operational efficiency. This practical sourcing guide outlines essential steps for B2B buyers looking to procure or design warehouse racking systems tailored to their specific needs. By following this checklist, you can ensure a strategic approach to sourcing the right solutions for your warehouse environment.

Step 1: Assess Your Warehouse Space

Begin by thoroughly measuring your warehouse dimensions, including height, width, and depth. Understanding your available space will help you determine the type and configuration of racking systems that can be implemented. Pay attention to obstacles such as columns, doors, and ventilation systems, as these will influence the layout and design of your racking system.

Step 2: Define Your Inventory Needs

Evaluate the types of products you will store, including their size, weight, and turnover rates. Different racking systems are designed for specific inventory types, such as pallets, cartons, or long items. For instance, high-density racking may be suitable for bulk items, while selective racking may be ideal for a diverse range of SKUs.

Illustrative image related to warehouse racking system design

Step 3: Determine Load Capacities and Safety Requirements

Calculate the load capacities required for your racking system based on your inventory assessment. Safety is paramount; ensure that the racking system complies with local regulations and safety standards. Look for certifications and testing reports that validate the structural integrity and load-bearing capabilities of the racking components.

Step 4: Evaluate Supplier Experience and Reputation

Research potential suppliers to assess their experience in the industry. Look for companies with a proven track record in warehouse racking system design and installation. Request case studies or testimonials from previous clients, particularly those in similar industries or geographic regions, to gauge their reliability and customer service.

Step 5: Explore Customization Options

Consider whether you need a standard racking solution or a customized design. Customization can address specific operational needs or unique warehouse layouts. Discuss options with suppliers and inquire about their ability to tailor racking systems to fit your specific requirements, including size, configuration, and materials used.

Step 6: Review Cost vs. Value

Analyze the cost of various racking solutions and compare them against the value they provide. While lower upfront costs may be appealing, consider the long-term benefits such as durability, efficiency, and maintenance needs. A higher-quality racking system may result in lower operational costs over time, so weigh the initial investment against potential savings.

Step 7: Plan for Installation and Maintenance

Ensure that your procurement plan includes installation and ongoing maintenance considerations. Discuss installation timelines, procedures, and any required training for staff. Additionally, inquire about maintenance services offered by the supplier, as regular inspections and upkeep are essential for ensuring safety and longevity of your racking system.

Illustrative image related to warehouse racking system design

By following this checklist, you can make informed decisions that enhance your warehouse operations and align with your business objectives.

Comprehensive Cost and Pricing Analysis for warehouse racking system design Sourcing

What Are the Key Cost Components for Warehouse Racking System Design?

When sourcing warehouse racking systems, understanding the cost structure is essential for informed decision-making. The primary cost components include:

-

Materials: The bulk of costs is derived from the materials used, predominantly steel due to its strength and durability. Other materials like aluminum or wood may be considered depending on specific needs and budgets.

-

Labor: Installation labor costs can vary significantly based on local wage standards and the complexity of the installation process. Highly skilled labor may be necessary for specialized systems, adding to overall expenses.

-

Manufacturing Overhead: This includes costs related to the production process, such as utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead, impacting the final price.

-

Tooling: Custom racking solutions may require specialized tooling, which can increase initial costs. Standardized solutions, however, may allow for reduced tooling expenses.

-

Quality Control (QC): Ensuring that racking systems meet safety and performance standards is crucial. QC costs can vary based on the manufacturer’s processes and certifications.

-

Logistics: Transport costs can fluctuate based on the distance between the supplier and the buyer, as well as the chosen Incoterms. International shipping can introduce additional complexities and expenses.

-

Margin: Suppliers typically include a margin to cover risks and ensure profitability. Understanding the margin structure can help in negotiating better prices.

How Do Price Influencers Affect Warehouse Racking System Costs?

Several factors influence the pricing of warehouse racking systems:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should assess their needs carefully to optimize order quantities and negotiate volume pricing.

-

Specifications and Customization: Custom-designed systems will invariably cost more than off-the-shelf solutions. While customization can enhance functionality, it is essential to weigh the benefits against the costs.

-

Material Quality and Certifications: Higher quality materials and compliance with safety certifications can increase costs but may lead to long-term savings through durability and safety.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a history of quality may charge a premium, but they often provide better support and reliability.

-

Incoterms: Understanding the terms of shipping and delivery is crucial for international buyers. Different Incoterms can significantly impact the final landed cost of the racking systems.

What Negotiation Strategies Can Buyers Use to Optimize Costs?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial savings:

-

Research Market Prices: Having a thorough understanding of market prices for various racking systems can provide leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and potential resale value. A higher initial investment in a quality system may lead to lower TCO.

-

Leverage Competition: Obtain quotes from multiple suppliers to create competitive pressure, which can lead to better pricing and terms.

-

Discuss Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce immediate financial pressure.

What Are the Pricing Nuances for International B2B Buyers?

International buyers must consider additional nuances when sourcing warehouse racking systems:

-

Currency Fluctuations: Exchange rates can impact pricing. Locking in rates through forward contracts might mitigate risks.

-

Import Duties and Taxes: Be aware of the potential tariffs and taxes that may apply to imported racking systems, as these can significantly impact the total cost.

-

Cultural Differences: Understanding local business practices and negotiation styles can facilitate smoother transactions.

Disclaimer on Indicative Prices

It is important to note that pricing for warehouse racking systems can vary widely based on the factors discussed above. Prospective buyers should seek multiple quotes and conduct thorough market research to establish a price baseline tailored to their specific needs and circumstances.

Illustrative image related to warehouse racking system design

Alternatives Analysis: Comparing warehouse racking system design With Other Solutions

Introduction to Alternatives in Warehouse Storage Solutions

In the rapidly evolving landscape of logistics and supply chain management, businesses are constantly seeking efficient and cost-effective solutions for inventory storage. While warehouse racking systems are a popular choice for optimizing space and improving accessibility, several alternative solutions exist that may better suit specific operational needs or budget constraints. This analysis will compare warehouse racking systems with alternative storage solutions, helping B2B buyers make informed decisions tailored to their unique requirements.

Comparison Table

| Comparison Aspect | Warehouse Racking System Design | Automated Storage and Retrieval Systems (AS/RS) | Mobile Racking Systems |

|---|---|---|---|

| Performance | High storage density, direct access to pallets | Maximizes density, speed, and accuracy | Flexible space usage, full selectivity |

| Cost | Moderate initial investment, variable ongoing costs | High initial investment, lower ongoing costs | High installation cost, moderate maintenance |

| Ease of Implementation | Requires planning and space allocation | Complex setup, requires integration with existing systems | Requires space for movement, moderate complexity |

| Maintenance | Regular inspections needed | Requires specialized maintenance | Regular checks for moving parts |

| Best Use Case | General warehousing needs, diverse inventory | High-volume, repetitive storage needs | Cold storage, small warehouses |

Detailed Breakdown of Alternatives

Automated Storage and Retrieval Systems (AS/RS)

AS/RS solutions utilize advanced robotics and automated systems to manage inventory storage and retrieval. This technology offers exceptional performance by significantly increasing storage density and reducing labor costs through automation. However, the initial investment is substantially higher than traditional racking systems, which may deter some businesses. Maintenance of AS/RS can be complex and requires specialized knowledge, making it essential for companies to have the right technical support in place. Ideal use cases include high-volume warehouses that handle repetitive tasks, where the investment can be justified through efficiency gains.

Mobile Racking Systems

Mobile racking systems consist of pallet racks mounted on mobile bases that can be moved to create access aisles as needed. This solution maximizes storage capacity while maintaining full pallet selectivity, making it particularly useful in environments where space is limited. While the installation costs are high, the ongoing maintenance is relatively moderate, as it primarily involves ensuring the mechanical components are in good working order. These systems are particularly suited for cold storage facilities or smaller warehouses where maximizing space is crucial, but they do require careful planning to ensure ease of access.

Illustrative image related to warehouse racking system design

Conclusion: How to Choose the Right Warehouse Storage Solution

When selecting the most appropriate storage solution, B2B buyers must consider their specific operational needs, budget constraints, and the nature of their inventory. Warehouse racking systems provide versatility and cost-effectiveness for general warehousing needs, while AS/RS solutions are ideal for high-volume operations demanding speed and efficiency. Conversely, mobile racking systems offer flexibility for smaller spaces, particularly in cold storage environments. By thoroughly evaluating these alternatives against their operational requirements, businesses can make a strategic investment that enhances their inventory management and overall efficiency.

Essential Technical Properties and Trade Terminology for warehouse racking system design

What Are the Key Technical Properties in Warehouse Racking System Design?

When designing a warehouse racking system, understanding the technical properties is crucial for ensuring safety, efficiency, and compliance with industry standards. Here are some of the essential specifications to consider:

1. Material Grade

The material grade of racking systems, typically steel, is a critical property. Common grades include ASTM A36 for structural steel, which offers a good balance of strength and ductility. High-quality materials ensure that the racking can support the intended loads without deformation or failure, which is essential for operational safety and longevity. For B2B buyers, selecting the right material grade can reduce long-term costs associated with repairs and replacements.

2. Load Capacity

Load capacity refers to the maximum weight a racking system can safely support. This specification is vital in determining the appropriate racking type for specific warehouse operations. Load capacity must account for both static and dynamic loads, especially in high-traffic environments. For international buyers, understanding load capacities helps in compliance with local regulations and standards, ensuring safe storage practices.

3. Tolerance Levels

Tolerance levels define the acceptable deviations in the dimensions of racking components. High tolerance levels ensure that parts fit together correctly, which enhances the overall stability and safety of the racking system. In B2B contexts, precise tolerances can minimize installation time and costs, as well as reduce the likelihood of maintenance issues down the line.

4. Dimensions and Configurations

Understanding the various dimensions and configurations of racking components, such as upright frames and beams, is essential for optimizing warehouse space. Specific dimensions can impact the system’s overall height, depth, and width, which can affect both storage density and accessibility. For buyers, this knowledge aids in designing layouts that maximize space while accommodating necessary equipment.

5. Fire Safety Ratings

Fire safety ratings indicate how well a racking system can withstand fire conditions. Compliance with fire safety regulations is mandatory in many regions, and racking systems must often be designed with fire-resistant materials or coatings. For B2B buyers, ensuring that racking systems meet these ratings is critical for protecting inventory and complying with local safety laws.

Illustrative image related to warehouse racking system design

What Are the Common Trade Terms in Warehouse Racking Systems?

Familiarity with industry terminology can greatly enhance communication and negotiation processes in B2B transactions. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of warehouse racking, an OEM may provide specialized components tailored to specific client needs. Understanding OEM relationships can help buyers navigate supplier networks and ensure they receive high-quality, compatible parts.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For warehouse racking systems, MOQs can significantly impact budget and inventory management. B2B buyers should consider their storage needs and operational capacity when negotiating MOQs to avoid excess inventory or insufficient supply.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotations for specific products or services. In the context of warehouse racking, an RFQ can help buyers compare prices and features across different suppliers. Crafting a detailed RFQ ensures that all necessary specifications are communicated, leading to more accurate quotes.

Illustrative image related to warehouse racking system design

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade that define the responsibilities of buyers and sellers. Understanding these terms is crucial for B2B transactions, particularly when dealing with international suppliers of warehouse racking systems. They help clarify who is responsible for shipping, insurance, and tariffs, minimizing misunderstandings and disputes.

5. CAD (Computer-Aided Design)

CAD refers to the software used to create detailed design plans and layouts for racking systems. Utilizing CAD allows for precise modeling of warehouse space, making it easier for buyers to visualize their setups and make informed decisions. In B2B contexts, CAD can facilitate collaboration between designers and buyers, ensuring that the final product meets operational requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance warehouse efficiency, safety, and compliance.

Navigating Market Dynamics and Sourcing Trends in the warehouse racking system design Sector

What Are the Current Market Dynamics Influencing Warehouse Racking System Design?

The global warehouse racking system market is experiencing significant growth, driven by the rapid expansion of e-commerce, increased demand for efficient inventory management, and the need for space optimization. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly focused on racking solutions that enhance operational efficiency and reduce overhead costs. Emerging technologies, such as automated storage and retrieval systems (AS/RS), are transforming traditional warehousing, enabling higher storage densities and faster retrieval times.

Illustrative image related to warehouse racking system design

Moreover, the rise of Industry 4.0 has spurred the adoption of smart racking solutions that integrate IoT devices for real-time inventory tracking and management. This technological advancement is particularly valuable for businesses looking to streamline operations and reduce errors. As markets evolve, there is also a noticeable shift towards modular and customizable racking systems that can adapt to varying warehouse layouts and product types.

Buyers should be aware of regional variations in market demand. For example, Latin America may prioritize cost-effective solutions due to budget constraints, while European buyers may seek advanced technology and sustainability. Understanding these dynamics can help businesses align their sourcing strategies with market needs.

How Is Sustainability Shaping Sourcing Trends in Warehouse Racking System Design?

Sustainability has become a critical factor in the sourcing of warehouse racking systems. International buyers are increasingly concerned about the environmental impact of their supply chains and are looking for suppliers who prioritize sustainable practices. This includes the use of recyclable materials, such as high-strength steel and aluminum, which not only reduce waste but also enhance the durability of racking systems.

Illustrative image related to warehouse racking system design

Ethical sourcing is equally important, as companies strive to ensure that their suppliers adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and FSC for sustainable forestry can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, innovative designs that reduce material usage without compromising strength are gaining traction. For instance, lightweight racking systems that utilize advanced engineering techniques can significantly lower carbon footprints. B2B buyers should seek partnerships with manufacturers who demonstrate a commitment to sustainability and can provide transparent information about their sourcing practices.

What Is the Historical Context Behind Warehouse Racking System Design?

The evolution of warehouse racking system design has been shaped by the changing needs of inventory management and advancements in technology. Initially, warehouses utilized basic shelving and pallet systems that offered limited space optimization. The introduction of selective pallet racking in the mid-20th century revolutionized the industry by allowing direct access to every pallet, significantly improving efficiency.

As businesses began to recognize the importance of maximizing storage density, more sophisticated systems emerged, including drive-in and push-back racking. The late 20th century saw the advent of automated systems, which further enhanced operational efficiency.

Today, the focus is on integrating technology with traditional designs to create smart racking systems that not only save space but also improve inventory accuracy. Understanding this historical context can help international B2B buyers appreciate the ongoing innovations in racking solutions and make informed decisions that align with their operational goals.

Illustrative image related to warehouse racking system design

Frequently Asked Questions (FAQs) for B2B Buyers of warehouse racking system design

-

How do I choose the right warehouse racking system for my facility?

Choosing the right warehouse racking system involves assessing your specific storage needs, including the types of products you handle, the volume of inventory, and your operational workflow. Begin by evaluating the dimensions of your warehouse space and considering factors like aisle width, pallet sizes, and the weight of the items. Additionally, consider the retrieval methods you’ll use—whether FIFO (First In, First Out) or LIFO (Last In, First Out)—as this impacts the racking type you should select. Consulting with a racking specialist can provide tailored insights based on your requirements. -

What are the key design considerations when planning a racking system?

When designing a racking system, consider factors such as warehouse layout, product turnover rates, and safety regulations. Measure the space accurately, account for any obstacles, and determine the optimal placement for fast-moving items. Additionally, assess the type of handling equipment you will use, as this influences aisle width and racking height. Compliance with local safety standards is also essential to ensure a safe working environment. Consulting with an experienced designer can help align your racking system with operational efficiency. -

What are the benefits of customizing my warehouse racking system?

Customizing your warehouse racking system allows you to tailor the design to your specific operational needs, maximizing efficiency and space utilization. Custom solutions can accommodate unique product dimensions, improve accessibility, and enhance safety measures. Additionally, a customized system can adapt to future changes in your inventory or operations, providing flexibility as your business grows. Engaging with a supplier who offers bespoke solutions ensures that you receive a racking system optimized for your unique requirements. -

What are the typical minimum order quantities (MOQ) for warehouse racking systems?

Minimum order quantities for warehouse racking systems can vary significantly depending on the supplier and the type of racking you require. Generally, MOQs can range from a few units for standard systems to larger quantities for customized solutions. It’s important to discuss your specific needs with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility, especially for first-time buyers or ongoing partnerships, so it’s worth negotiating terms that align with your inventory management strategy. -

How can I ensure quality assurance (QA) for my racking systems?

To ensure quality assurance for your racking systems, start by selecting reputable suppliers with a proven track record in the industry. Request certifications that demonstrate compliance with international safety and quality standards, such as ISO certifications. Additionally, inquire about the materials used in construction and their durability. Regular inspections during installation and periodic audits post-installation can help maintain safety and operational efficiency. Establishing a clear communication channel with your supplier for ongoing support is also crucial for addressing any potential quality concerns. -

What payment terms should I expect when sourcing racking systems internationally?

Payment terms for sourcing warehouse racking systems can vary widely based on the supplier and the nature of the transaction. Common arrangements include advance payments, net 30 or 60 terms, or letters of credit, particularly for international transactions. Ensure that you clarify payment terms upfront and consider using secure payment methods that offer buyer protection. Negotiating favorable terms can help manage cash flow, especially for larger orders. Always review contracts carefully to understand the implications of the payment terms. -

What logistics considerations should I keep in mind when importing racking systems?

When importing warehouse racking systems, consider factors such as shipping costs, lead times, and customs regulations. Research the most efficient shipping methods based on your timeline and budget—options may include sea freight for cost-effectiveness or air freight for quicker delivery. Ensure compliance with local customs laws and tariffs, as these can significantly affect total costs. Collaborating with a logistics partner experienced in international shipping can streamline the process and help mitigate potential delays or issues. -

How do I vet suppliers for warehouse racking systems?

To effectively vet suppliers for warehouse racking systems, begin by researching their reputation and experience in the industry. Look for reviews and testimonials from previous clients, and verify their certifications and compliance with safety standards. Request case studies or examples of past projects that align with your needs. Additionally, engage in direct communication to assess their responsiveness and willingness to provide customized solutions. Establishing a strong relationship with a reliable supplier can lead to better service and support in the long run.

Top 4 Warehouse Racking System Design Manufacturers & Suppliers List

1. Storcoor – Warehouse Racking Systems

Domain: storcoor.com

Registered: 2000 (25 years)

Introduction: Warehouse racking systems include various types such as Block Stacking, Selective Pallet Rack (Single-Deep and Double-Deep), Push Back Pallet Rack, Flow Through Pallet Rack, Drive In Pallet Rack, Carton Flow Pallet Rack, Cantilever Rack, and Pallet Shuttle Systems. Block Stacking is economical and maximizes space but has height limitations and risks of damage. Selective Pallet Rack offers easy acc…

2. Malin USA – Customized Warehouse Racking Solutions

Domain: malinusa.com

Registered: 2005 (20 years)

Introduction: Storage Solutions include customized warehouse racking systems designed to fit specific space and storage requirements. Key offerings include: 1. Cantilever Rack – Multi-level storage for bulky or long products without interference from uprights. 2. Drive-In/Drive-Through Rack – Allows forklifts to enter the rack, providing more storage space than standard racks. 3. Pallet Flow Rack – Utilizes gra…

3. Exotec – Warehouse Racking Solutions

Domain: exotec.com

Registered: 1996 (29 years)

Introduction: Types of Warehouse Racking: 1. Selective Racking: Most popular, allows access to individual pallets, easy loading/unloading. 2. Drive-In/Drive-Thru Racking: Space-efficient, LIFO (Drive-In) and FIFO (Drive-Thru) inventory systems. 3. Pallet Flow Racking: Automates stock rotation using gravity, ideal for perishable goods. 4. Push Back Racking: Stores pallets 2-5 deep, accessible from the same aisle…

4. Mazzella Companies – Pallet Racking Essentials

Domain: mazzellacompanies.com

Registered: 1998 (27 years)

Introduction: 1. Pallet Size and Type: Standard pallet size is 40″ x 48″; important for determining rack dimensions. 2. Order of Inventory Retrieval: LIFO (last-in-first-out) vs. FIFO (first-in-first-out) affects system type. 3. SKU / Pallet Count: Number of SKUs and pallets per SKU influences racking system choice. 4. Warehouse Environment: Cold, controlled, or ambient environments affect pricing and design. 5…

Strategic Sourcing Conclusion and Outlook for warehouse racking system design

Why Is Strategic Sourcing Essential for Warehouse Racking Systems?

In conclusion, the strategic sourcing of warehouse racking systems is vital for optimizing inventory management and enhancing operational efficiency. As highlighted throughout this guide, selecting the appropriate racking solution—be it selective pallet racking, mobile systems, or automated solutions—directly impacts storage capacity, workflow, and overall cost-effectiveness. Buyers must consider their unique requirements and regional factors, such as local regulations and supply chain dynamics, to make informed decisions that align with their business objectives.

What Should International B2B Buyers Focus On Moving Forward?

As international buyers from regions like Africa, South America, the Middle East, and Europe evaluate their warehouse needs, they should prioritize flexibility and scalability in racking systems. With the increasing demand for efficient logistics and supply chain management, investing in advanced racking solutions can provide a competitive edge.

How Can You Take Action Today?

We encourage you to assess your current warehouse setup and explore innovative racking options that suit your operational needs. By leveraging strategic sourcing practices, you can enhance efficiency, reduce overhead, and position your business for future growth in a rapidly evolving market. Engage with suppliers who understand your regional challenges and can offer tailored solutions that meet your specific demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to warehouse racking system design

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.