Top 4 Live Roller Conveyor Suppliers (And How to Choose)

Introduction: Navigating the Global Market for live roller conveyor

The global market for live roller conveyors presents a unique opportunity for businesses seeking efficient material handling solutions. As international B2B buyers grapple with the challenge of sourcing reliable equipment that enhances productivity while minimizing operational costs, understanding the nuances of live roller conveyors becomes essential. These systems are engineered to transport boxed and palletized products seamlessly, offering significant advantages in industries such as warehousing, manufacturing, food and beverage distribution, and e-commerce.

This comprehensive guide delves into the various types of live roller conveyors, including chain-driven and belt-driven models, as well as their diverse applications. It also addresses critical considerations such as supplier vetting, cost factors, and customization options to meet specific operational needs. By equipping buyers with actionable insights, this guide empowers decision-makers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Brazil—to make informed purchasing decisions.

With an emphasis on maximizing efficiency and reducing labor costs through automation, this resource highlights how live roller conveyors can transform material handling processes. Ultimately, understanding these systems will not only enhance operational workflows but also provide a competitive edge in the increasingly globalized market landscape.

Understanding live roller conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chain Driven Live Roller (CDLR) | Positively driven rollers; robust construction; high load capacity | Heavy-duty applications, manufacturing, and distribution | Pros: High durability, suitable for heavy loads. Cons: More expensive upfront costs. |

| Belt Driven Live Roller (BDLR) | Versatile design; low back pressure accumulation; various drive options | E-commerce, food and beverage, general warehousing | Pros: Flexible applications, low maintenance. Cons: Limited load capacity compared to CDLR. |

| 24-Volt Live Roller Conveyor | Energy-efficient; low-voltage operation; modular design | Small to medium-sized product handling and assembly lines | Pros: Energy-efficient, easy to integrate. Cons: Lower load capacity than traditional systems. |

| Lineshaft Live Roller Conveyor | Utilizes a shaft to drive rollers; cost-effective for long runs | Package handling, sorting systems, and distribution centers | Pros: Economical for large systems, minimal maintenance. Cons: Limited speed control. |

| Gravity Live Roller Conveyor | Non-powered; relies on gravity for movement; simple design | Shipping and receiving docks, temporary setups | Pros: Low cost, easy installation. Cons: Limited to gravity-fed applications, less control over speed. |

What Are the Characteristics of Chain Driven Live Roller Conveyors?

Chain Driven Live Roller (CDLR) conveyors are characterized by their robust construction and positive drive mechanism, making them ideal for heavy-duty applications. They feature steel rollers that are driven by a chain system, allowing for high load capacities—up to 15,000 lbs for shorter runs. This type of conveyor is particularly suitable for manufacturing and distribution environments where durability and reliability are paramount. Buyers should consider the initial investment cost, as CDLR systems tend to be more expensive but offer long-term savings through reduced maintenance and increased efficiency.

How Do Belt Driven Live Roller Conveyors Offer Versatility?

Belt Driven Live Roller (BDLR) conveyors are known for their versatility in handling a variety of product shapes and sizes. They can be configured for accumulation, merging, and transportation, making them suitable for e-commerce, food and beverage distribution, and general warehousing. The BDLR design allows for low back pressure, which is beneficial in operations requiring precise product placement. When purchasing, businesses should evaluate their specific application needs, as BDLRs can be customized with various drive options but may have limitations in load capacity compared to CDLR systems.

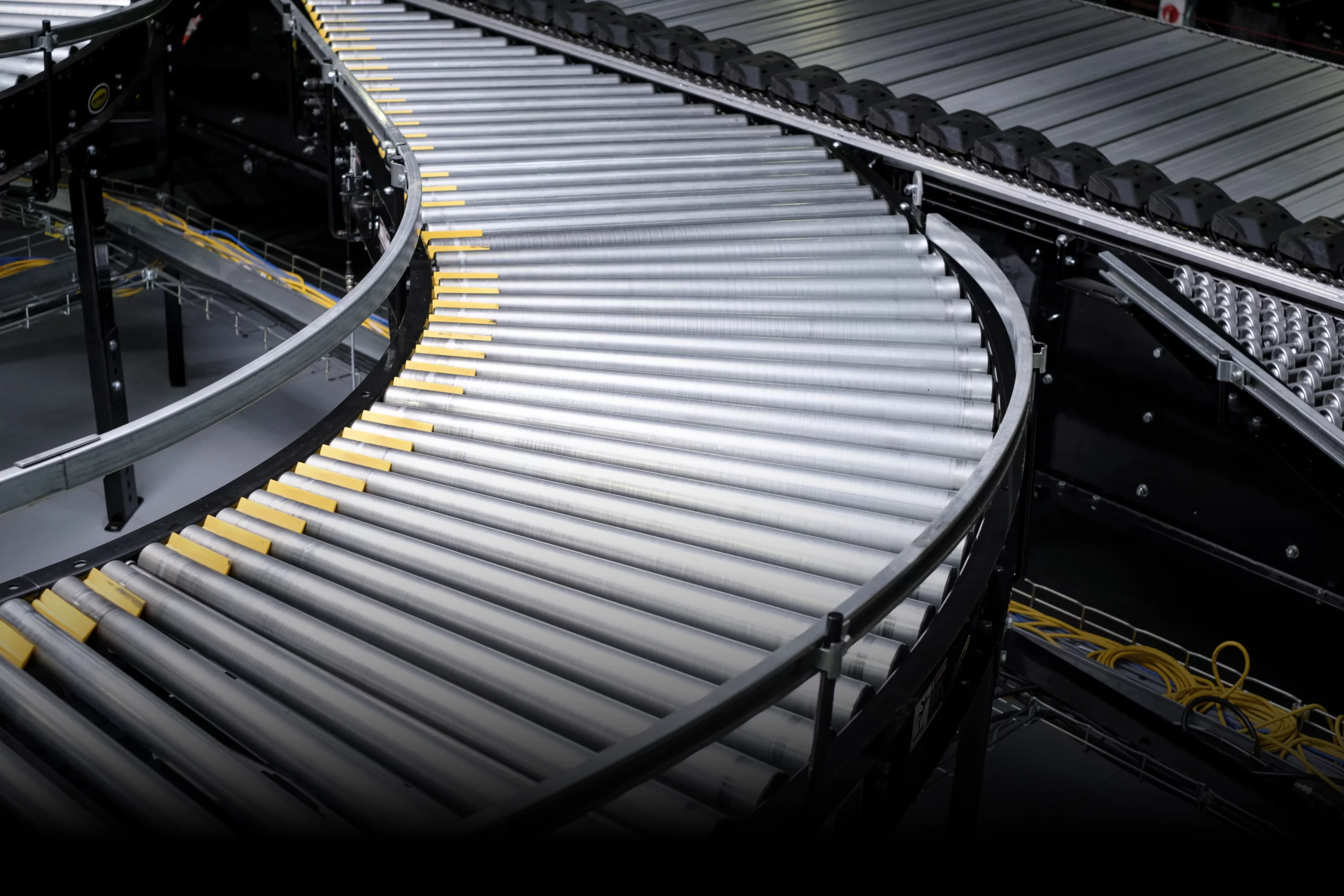

Illustrative image related to live roller conveyor

What Are the Benefits of 24-Volt Live Roller Conveyors?

The 24-Volt Live Roller Conveyor stands out for its energy-efficient operation and modular design, making it a great fit for small to medium-sized product handling. These conveyors are designed for easy integration into existing systems and can be used in assembly lines where low voltage is advantageous. While they provide significant energy savings, buyers should be aware that their load capacity is generally lower than that of traditional live roller systems, making them more suitable for lighter products.

Why Choose Lineshaft Live Roller Conveyors for Cost Efficiency?

Lineshaft Live Roller Conveyors utilize a shaft to drive the rollers, allowing for a cost-effective solution for long runs in package handling and sorting applications. This design minimizes maintenance needs and provides a straightforward installation process. However, buyers should consider that lineshaft systems may have limited speed control, which could affect operational efficiency in certain applications. Their economical nature makes them a popular choice for businesses looking to optimize large-scale operations without excessive capital expenditure.

How Do Gravity Live Roller Conveyors Function in Material Handling?

Gravity Live Roller Conveyors operate without power, relying on gravity to move products along the conveyor line. This simple design is ideal for shipping and receiving docks or temporary setups where low cost and quick installation are critical. While they are budget-friendly, buyers should note that gravity conveyors are limited to specific applications where gravity can be effectively utilized, and they lack the speed control features that powered systems offer.

Key Industrial Applications of live roller conveyor

| Industry/Sector | Specific Application of live roller conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Warehousing and Distribution | Sorting and transporting packages in distribution centers | Increased efficiency and reduced handling time | Reliability, load capacity, and integration with existing systems |

| Manufacturing | Moving components along assembly lines | Streamlined production processes and reduced labor costs | Customization options for layout and product types |

| Food and Beverage | Transporting packaged food products | Compliance with hygiene standards and safe handling | Material durability, sanitation features, and ease of cleaning |

| E-Commerce | Automating order fulfillment and package sorting | Enhanced speed and accuracy in order processing | Flexibility for varying package sizes and integration capabilities |

| Automotive | Conveying parts in assembly plants | Improved workflow and reduced bottlenecks | Heavy load capacity and customization for specific parts |

How Are Live Roller Conveyors Used in Warehousing and Distribution?

In warehousing and distribution, live roller conveyors are essential for sorting and transporting packages efficiently. They facilitate the movement of goods from receiving areas to storage and shipping zones, significantly reducing manual handling. This automation leads to faster processing times and lower labor costs. International buyers should consider sourcing conveyors that offer high reliability and the ability to integrate seamlessly with existing warehouse management systems to optimize their operations.

What Role Do Live Roller Conveyors Play in Manufacturing?

In the manufacturing sector, live roller conveyors are employed to move components along assembly lines, enhancing productivity. By automating material handling, these conveyors minimize downtime and labor costs, allowing workers to focus on value-added tasks. Buyers should prioritize custom solutions that can accommodate various product sizes and layouts, ensuring that the conveyor system aligns with their specific production processes.

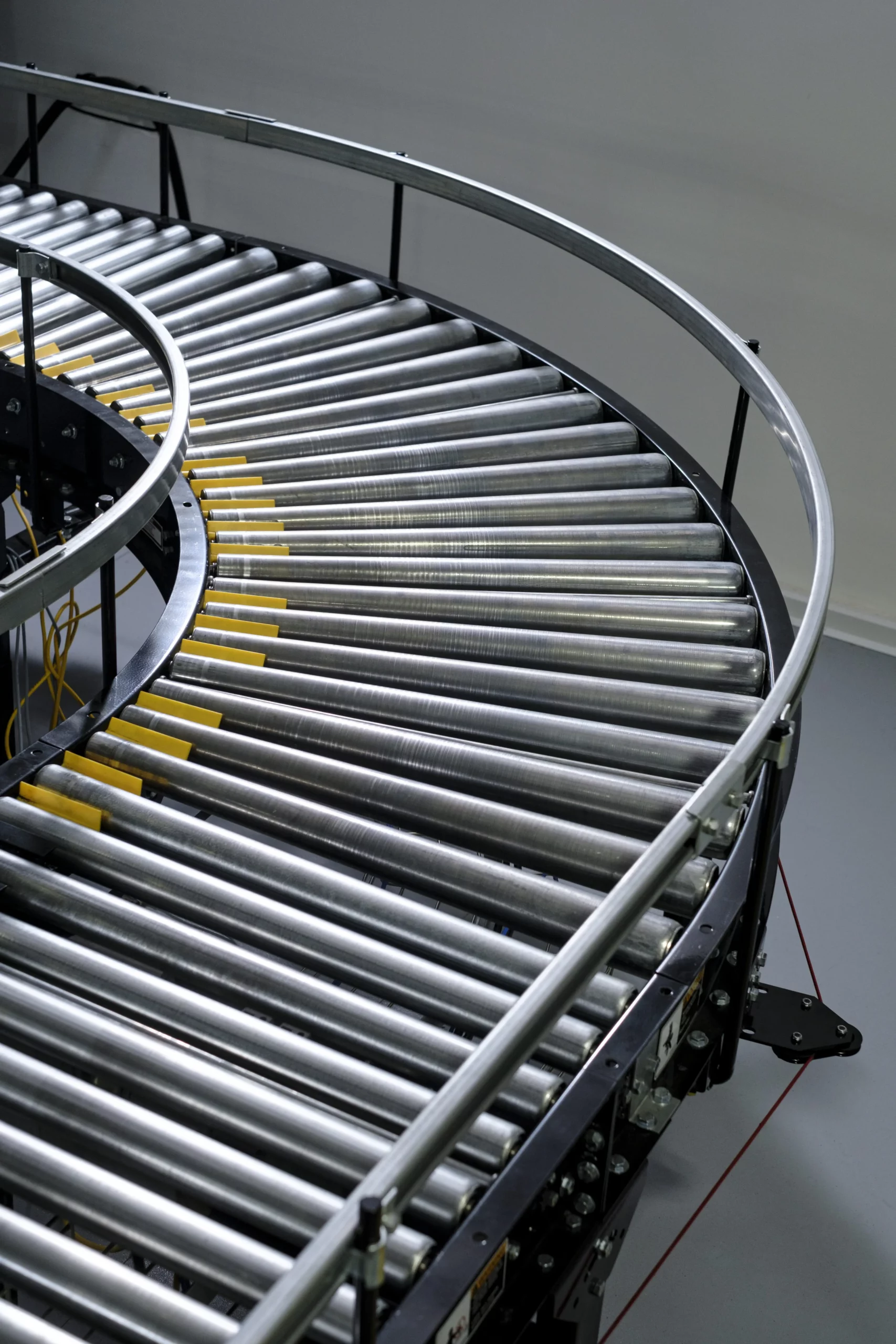

Illustrative image related to live roller conveyor

Why Are Live Roller Conveyors Important in the Food and Beverage Industry?

Live roller conveyors are crucial in the food and beverage industry for safely transporting packaged products while adhering to strict hygiene standards. These systems are designed to minimize contamination risks and facilitate easy cleaning. When sourcing conveyors for this sector, businesses should look for durable materials that comply with food safety regulations, as well as features that ensure ease of maintenance and sanitation.

How Do Live Roller Conveyors Enhance E-Commerce Operations?

In the fast-paced world of e-commerce, live roller conveyors play a pivotal role in automating order fulfillment and package sorting. They enable quick and accurate processing of orders, which is vital for maintaining customer satisfaction. For international buyers, it is essential to select conveyors that can handle a wide range of package sizes and integrate with automated sorting systems to streamline operations and improve throughput.

What Benefits Do Live Roller Conveyors Offer in Automotive Manufacturing?

In the automotive industry, live roller conveyors are utilized for the efficient conveyance of parts in assembly plants. These systems help maintain a smooth workflow and reduce bottlenecks, which is critical in high-volume production environments. Buyers should focus on sourcing conveyors with high load capacities and customizable configurations to meet the specific requirements of automotive parts, ensuring optimal performance and reliability.

3 Common User Pain Points for ‘live roller conveyor’ & Their Solutions

Scenario 1: Inefficient Workflow Due to Manual Handling

The Problem: Many businesses face significant inefficiencies in their material handling processes due to reliance on manual labor. For instance, in a busy warehouse, employees may spend excessive time moving boxed products from one area to another, leading to bottlenecks in workflow. This not only slows down operations but also increases labor costs and raises the risk of workplace injuries. The challenge lies in finding a solution that can automate these processes without incurring excessive costs or requiring extensive modifications to existing systems.

The Solution: Implementing live roller conveyors can dramatically enhance workflow efficiency by automating the movement of boxed products. When sourcing live roller conveyors, it’s essential to evaluate your specific operational needs, including the types of products being transported and the layout of your facility. Collaborate with a reputable provider to customize a conveyor system that seamlessly integrates with your existing infrastructure. Features like variable speed control and the ability to handle different product sizes will allow for precise handling and optimized throughput. Investing in a high-quality conveyor system will not only reduce the need for manual labor but also minimize product damage, ultimately leading to cost savings and increased productivity.

Illustrative image related to live roller conveyor

Scenario 2: High Maintenance Costs and Downtime

The Problem: Frequent breakdowns and high maintenance costs can plague businesses using outdated or low-quality conveyor systems. For example, a manufacturer relying on a poorly designed live roller conveyor may experience unexpected downtimes, which disrupts production schedules and can lead to lost revenue. The frustration of dealing with maintenance issues can also distract management from focusing on core business operations, creating a cascading effect on overall efficiency.

The Solution: To mitigate maintenance costs and reduce downtime, businesses should consider investing in robust, durable live roller conveyors designed for longevity. Look for systems constructed with high-quality materials that require minimal maintenance, such as galvanized steel frames and heavy-duty rollers. Additionally, select conveyors that come with warranties and reliable customer support. When implementing a new system, prioritize models that allow for easy access to components for routine inspections and repairs. Regular maintenance schedules should be established to ensure optimal performance and longevity of the system. By making informed choices when sourcing equipment, businesses can significantly reduce operational disruptions and enhance productivity.

Scenario 3: Difficulty in Customizing Conveyor Systems for Unique Needs

The Problem: B2B buyers often struggle to find live roller conveyor systems that can be tailored to meet their unique operational requirements. For instance, a company in the food and beverage industry may require conveyors that can handle varying product sizes and weights while ensuring compliance with safety regulations. Without the right customization options, businesses may resort to suboptimal solutions that can lead to inefficiencies and potential regulatory issues.

The Solution: To address this pain point, buyers should seek suppliers that offer a wide range of customization options for live roller conveyors. Engage with manufacturers who can provide tailored solutions based on your specific operational needs, including incline, decline, and curve capabilities. Discuss your requirements in detail, such as load capacities, roller materials, and any necessary safety features. Many suppliers also offer modular designs that allow for future adjustments as your business grows or changes. By prioritizing a supplier that understands your unique challenges and can deliver customized solutions, you can ensure that your live roller conveyor system enhances productivity while maintaining compliance with industry standards.

Strategic Material Selection Guide for live roller conveyor

When selecting materials for live roller conveyors, it is essential to consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in the construction of live roller conveyors: steel, aluminum, plastic, and stainless steel. Each material has unique characteristics that influence its suitability for different applications and environments, particularly for international B2B buyers.

Illustrative image related to live roller conveyor

What Are the Key Properties of Steel for Live Roller Conveyors?

Steel is a popular choice for live roller conveyor frames and rollers due to its strength and durability. It typically has a high-temperature rating and can withstand significant pressure, making it suitable for heavy-duty applications. Steel also offers excellent load-bearing capacity, which is crucial for industries that transport heavy products.

Pros: Steel is known for its robustness and longevity, providing a cost-effective solution for high-capacity applications. It is readily available and can be easily fabricated into various shapes and sizes.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can lead to increased maintenance costs over time. Additionally, its weight can make installation and handling more complex.

Impact on Application: Steel is ideal for environments where heavy loads are common, such as manufacturing and warehousing. Buyers must consider the need for protective coatings to ensure longevity, especially in humid or corrosive environments.

How Does Aluminum Compare as a Material for Live Roller Conveyors?

Aluminum is another common material used in live roller conveyors, particularly in applications where weight is a concern. It has a lower density compared to steel, making it easier to handle and install. Aluminum also has good corrosion resistance, which is beneficial in environments where moisture is present.

Pros: The lightweight nature of aluminum allows for easier installation and reduces the overall weight of the conveyor system. It also has a good strength-to-weight ratio, making it suitable for medium-duty applications.

Cons: On the downside, aluminum is generally less durable than steel and may not be suitable for very heavy loads. Its cost can also be higher compared to steel, especially for large-scale applications.

Impact on Application: Aluminum is well-suited for industries like food and beverage, where corrosion resistance is critical. International buyers should consider compliance with food safety standards when selecting aluminum components.

What Are the Benefits of Using Plastic for Live Roller Conveyors?

Plastic rollers are increasingly used in live roller conveyors, particularly in applications where noise reduction and lightweight construction are priorities. Plastic materials can be engineered to provide specific properties, such as impact resistance and flexibility.

Illustrative image related to live roller conveyor

Pros: The main advantages of plastic include its resistance to corrosion and ease of cleaning, making it suitable for hygienic applications. Plastic rollers are also quieter during operation, which can enhance workplace safety and comfort.

Cons: However, plastic may not support heavy loads as effectively as metal materials, limiting its use in heavy-duty applications. The cost of high-performance plastics can also be significant.

Impact on Application: Plastic is ideal for industries like pharmaceuticals and food processing, where cleanliness is paramount. Buyers should ensure that the selected plastic complies with relevant safety and health standards.

Why Is Stainless Steel a Preferred Material for Certain Applications?

Stainless steel is often chosen for live roller conveyors in environments that demand high corrosion resistance and hygiene, such as food processing and pharmaceuticals. It combines the strength of steel with enhanced resistance to rust and staining.

Illustrative image related to live roller conveyor

Pros: Stainless steel offers excellent durability and is easy to clean, making it suitable for applications where sanitation is critical. Its aesthetic appeal also makes it a preferred choice for visible installations.

Cons: The primary disadvantage is its higher cost compared to other materials, which may be a consideration for budget-conscious buyers. Additionally, stainless steel can be heavier, complicating installation.

Impact on Application: Stainless steel is essential in industries with strict hygiene requirements. Buyers in regions with stringent health regulations, such as Europe, should prioritize this material to ensure compliance.

Illustrative image related to live roller conveyor

Summary Table of Material Selection for Live Roller Conveyors

| Material | Typical Use Case for live roller conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in manufacturing | High strength and load capacity | Prone to corrosion without treatment | Medium |

| Aluminum | Medium-duty applications in food industry | Lightweight and corrosion-resistant | Less durable under heavy loads | High |

| Plastic | Hygienic applications in pharmaceuticals | Corrosion-resistant and quiet | Limited load capacity | Medium |

| Stainless Steel | Food processing and pharmaceuticals | Excellent hygiene and durability | Higher cost and weight | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in live roller conveyors, helping them make informed decisions tailored to their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for live roller conveyor

The manufacturing of live roller conveyors involves several critical processes and quality assurance measures to ensure that the final product meets the high standards required by various industries. For B2B buyers, especially those from diverse international markets such as Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

What Are the Main Stages of Manufacturing Live Roller Conveyors?

How Is Material Prepared for Live Roller Conveyor Production?

The first stage in the manufacturing process involves the preparation of raw materials. This typically includes high-quality steel, aluminum, or composite materials depending on the specific requirements of the conveyor system. Suppliers often source materials that comply with international standards for durability and strength. The materials undergo cutting, shaping, and sometimes pre-treatment processes to enhance their properties, such as corrosion resistance.

What Forming Techniques Are Used in Manufacturing Live Roller Conveyors?

Once the materials are prepared, they are subjected to various forming techniques. Common techniques include welding, bending, and machining. For instance, rollers may be welded onto frames to create a robust structure. Advanced manufacturers often use computer numerical control (CNC) machinery to ensure precision in forming components, which is crucial for the seamless operation of the conveyor system. This automation enhances consistency and reduces human error during production.

How Does the Assembly Process Work for Live Roller Conveyors?

The assembly stage involves combining all individual components into a complete conveyor system. This can include the integration of motors, rollers, and control systems. Skilled technicians oversee this process to ensure proper alignment and functionality. During assembly, manufacturers may also implement modular designs, allowing for easier upgrades and maintenance in the future. This flexibility is particularly attractive to B2B buyers looking for long-term solutions.

What Are the Finishing Techniques Applied to Live Roller Conveyors?

Finishing processes are critical for enhancing the durability and aesthetic appeal of live roller conveyors. Techniques such as powder coating, galvanization, or anodizing are commonly employed to protect against wear and corrosion. These finishes not only extend the life of the product but also contribute to its overall appearance, which can be an important consideration for buyers in retail or consumer-facing industries.

What Quality Control Measures Are Essential in Live Roller Conveyor Manufacturing?

Which International Standards Should B2B Buyers Consider?

Quality assurance in manufacturing live roller conveyors often adheres to international standards such as ISO 9001, which focuses on quality management systems. This certification ensures that manufacturers have established processes for maintaining quality throughout the production cycle. For specific industries, additional certifications like CE (for compliance with European safety standards) or API (for oil and gas applications) may also be relevant.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor for deviations from design specifications. This may involve testing the functionality of components as they are assembled.

- Final Quality Control (FQC): After assembly, a thorough inspection of the completed conveyor is performed. This includes functionality tests, load testing, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality control measures, B2B buyers can implement several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance protocols firsthand.

- Requesting Quality Reports: Buyers should ask for documentation that outlines the QC processes and results. This can include inspection reports, test results, and certifications.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased evaluation of the supplier’s quality assurance practices.

What Are the Nuances of Quality Control for International B2B Buyers?

How Do Regional Standards Affect Quality Assurance in Manufacturing?

For international buyers, understanding regional standards is crucial. In Europe, for example, CE marking is mandatory for many products, indicating compliance with EU regulations. In contrast, buyers in Africa or South America may encounter varying standards based on local regulations. It’s essential for buyers to communicate their quality requirements clearly to suppliers and ensure that the products meet both local and international standards.

Illustrative image related to live roller conveyor

What Should Buyers Know About Warranty and Support?

When purchasing live roller conveyors, understanding the warranty and support options is vital. Buyers should inquire about warranty terms, including what is covered and the duration of the coverage. Additionally, evaluating the supplier’s support services for maintenance and repairs can significantly impact the long-term performance of the conveyor system.

In conclusion, the manufacturing processes and quality assurance measures for live roller conveyors are intricate and require a detailed understanding by B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside rigorous quality control, manufacturers can deliver high-quality products that meet the diverse needs of global markets. Buyers who prioritize these aspects in their procurement strategy will be better equipped to select reliable suppliers that contribute to their operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘live roller conveyor’

When sourcing a live roller conveyor, it’s crucial to have a structured approach to ensure you select the right equipment for your operations. This checklist provides B2B buyers with a practical guide to navigate the procurement process effectively, ensuring you meet your operational needs while optimizing efficiency and cost.

1. Define Your Technical Specifications

Before initiating the procurement process, it’s essential to clearly outline your technical requirements. Consider factors such as the types of products you will be transporting, their sizes, weights, and any specific handling requirements.

– Product Characteristics: Identify if you need to move boxed items, pallets, or irregular shapes.

– Operational Constraints: Account for available space, incline/decline requirements, and integration with existing systems.

2. Evaluate Supplier Certifications

Verification of supplier certifications is crucial for ensuring compliance with industry standards and regulations. Look for suppliers who hold relevant certifications such as ISO 9001, which indicates a commitment to quality management.

– Quality Assurance: Certifications can also reflect the supplier’s adherence to safety and performance standards.

– Regional Compliance: Ensure that the supplier meets local regulations applicable in your country or region.

3. Assess Customization Options

Live roller conveyors often require customization to fit specific operational needs. When evaluating suppliers, inquire about their ability to provide tailored solutions.

– Variety of Configurations: Check if they offer different roller sizes, materials, and drive options (e.g., belt-driven vs. chain-driven).

– Integration Capabilities: Ensure that the conveyor can seamlessly integrate with other equipment, such as sortation or packaging systems.

Illustrative image related to live roller conveyor

4. Request Detailed Quotations

Once you have identified potential suppliers, request detailed quotations that outline all costs involved. This should include not just the purchase price but also installation, maintenance, and any potential customization costs.

– Transparent Pricing: Look for clarity on pricing structures to avoid hidden fees.

– Comparative Analysis: Use these quotations to compare the value offered by different suppliers effectively.

5. Verify Lead Times and Support Services

Understanding lead times is essential for planning your operations. Ask suppliers about their production and delivery timelines, especially if you have a tight schedule.

– Timeliness: Ensure that the supplier can meet your deadlines without compromising on quality.

– After-Sales Support: Inquire about warranty terms, maintenance services, and availability of spare parts to ensure long-term operational reliability.

6. Conduct Site Visits or Virtual Tours

If possible, arrange site visits to the supplier’s facilities or request virtual tours. This allows you to see their manufacturing processes, quality control measures, and overall operational capabilities.

– Quality Control Insight: Observing their processes can give you confidence in their product quality.

– Relationship Building: Meeting suppliers in person can enhance communication and build a stronger business relationship.

7. Check References and Case Studies

Before finalizing your decision, ask for references from other clients, particularly those within your industry or region. Reviewing case studies can provide insights into the supplier’s performance and reliability.

– Real-World Performance: Understanding how similar businesses have benefited can validate your choice.

– Feedback on Support: Insights into post-purchase support can help you gauge the supplier’s commitment to customer satisfaction.

Illustrative image related to live roller conveyor

By following this checklist, B2B buyers can ensure a comprehensive evaluation of live roller conveyor options, leading to informed purchasing decisions that enhance operational efficiency and effectiveness.

Comprehensive Cost and Pricing Analysis for live roller conveyor Sourcing

What Are the Key Cost Components of Live Roller Conveyors?

When sourcing live roller conveyors, understanding the detailed cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly affects the cost. High-quality steel and durable components increase the initial price but can reduce long-term maintenance costs. Variants like galvanized or stainless steel may offer additional corrosion resistance, which is crucial for specific industries like food and beverage.

-

Labor: Labor costs encompass the workforce required for assembly, installation, and maintenance. This can vary significantly by region, with labor rates differing across Africa, South America, the Middle East, and Europe. Investing in training can enhance efficiency and reduce future labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling may be necessary for specific designs, influencing overall costs. Investing in versatile tooling can lead to long-term savings, particularly for suppliers that offer a range of conveyor models.

-

Quality Control (QC): Rigorous QC processes ensure the reliability and safety of the conveyors. While this may increase initial costs, it can minimize warranty claims and product failures, leading to cost savings over time.

-

Logistics: Shipping costs can vary based on the geographical distance from the supplier to the buyer, mode of transport, and the chosen Incoterms. Understanding these logistics can help optimize total expenditure.

-

Margin: Supplier margins vary based on brand reputation, product quality, and market competition. Established brands may command higher prices due to perceived reliability and superior service.

How Do Pricing Influencers Affect Live Roller Conveyor Costs?

Several factors influence the pricing of live roller conveyors, and buyers should consider these when sourcing:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases can significantly reduce the unit cost. Suppliers often provide discounts for larger orders, making it advantageous for businesses with high throughput needs.

-

Specifications and Customization: Customized features such as variable speed controls, roller sizes, or specific material types can add to the cost. Buyers should weigh the benefits of customization against the additional expense.

-

Quality and Certifications: Products meeting international quality standards or possessing certifications can cost more upfront but may offer better long-term reliability and fewer compliance issues in regulated markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may have higher prices but provide better support and warranty terms.

-

Incoterms: Different shipping terms can impact overall costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers negotiate better shipping arrangements.

What Buyer Tips Can Help Optimize Costs in Live Roller Conveyor Sourcing?

To ensure cost-effective procurement, international buyers should consider the following strategies:

-

Negotiation: Engage in open negotiations with suppliers. Discussing volume discounts, payment terms, and potential for future orders can lead to favorable pricing arrangements.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and operational costs over the conveyor’s lifecycle. A lower initial price may not always translate to overall savings.

-

Understand Pricing Nuances in Different Regions: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market conditions that affect pricing. Economic factors, tariffs, and import duties can all influence the final cost.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various manufacturers can provide insights into the market rate and help identify competitive pricing.

-

Be Mindful of Lead Times: Longer lead times can impact inventory management and operational efficiency. Assessing suppliers’ capabilities to meet delivery timelines is crucial.

Disclaimer on Pricing

Pricing for live roller conveyors can fluctuate based on market conditions, supplier pricing strategies, and global economic factors. The figures mentioned in this analysis are indicative and should be verified through direct consultation with suppliers for accurate and current pricing.

Alternatives Analysis: Comparing live roller conveyor With Other Solutions

When considering material handling solutions, businesses often explore various options to determine the most efficient and cost-effective approach for their operations. Among these options, live roller conveyors stand out due to their versatility and efficiency. However, it is essential to evaluate alternative systems to make an informed decision. This analysis will compare live roller conveyors with two other viable options: belt-driven conveyors and automated guided vehicles (AGVs).

| Comparison Aspect | Live Roller Conveyor | Belt-Driven Conveyor | Automated Guided Vehicle (AGV) |

|---|---|---|---|

| Performance | High efficiency for transporting boxed or palletized products | Versatile; suitable for various shapes and sizes | Highly flexible; can navigate complex environments |

| Cost | Moderate initial investment; low maintenance costs | Varies based on design; can be economical for heavy loads | Higher initial investment; operational costs depend on battery life and maintenance |

| Ease of Implementation | Requires space for installation; integration with existing systems | Generally straightforward; modular designs facilitate quick setup | Requires navigation system setup and programming |

| Maintenance | Low maintenance; durable and reliable | Moderate; depends on belt wear and motor upkeep | Requires regular maintenance and software updates |

| Best Use Case | Warehousing, manufacturing, and e-commerce | Handling diverse products in distribution centers | Complex environments needing flexible routing and automation |

What Are the Pros and Cons of Belt-Driven Conveyors?

Belt-driven conveyors are a popular alternative to live roller conveyors. They excel in handling various product shapes and sizes, making them versatile for different applications, from light to heavy loads. Their modular designs allow for easy customization and integration into existing systems. However, they may require more frequent maintenance due to belt wear, which can lead to increased operational costs over time. Additionally, their performance can be limited in heavy-duty applications compared to live roller systems.

How Do Automated Guided Vehicles (AGVs) Compare?

Automated Guided Vehicles (AGVs) represent a cutting-edge solution for material handling. They offer unmatched flexibility, capable of navigating through complex environments without the need for fixed infrastructure. AGVs can be programmed to perform various tasks, including transporting materials between different locations. However, they come with a higher initial investment and require a robust navigation system. Maintenance can also be more demanding, as software updates and battery management are crucial for optimal performance.

Illustrative image related to live roller conveyor

Conclusion: How to Choose the Right Material Handling Solution?

Selecting the appropriate material handling solution involves assessing your specific operational needs, budget constraints, and desired efficiency levels. Live roller conveyors are ideal for businesses focused on high-volume transport of boxed or palletized goods with low maintenance requirements. Belt-driven conveyors offer flexibility for varying product types but may incur higher upkeep costs. In contrast, AGVs provide advanced automation and routing capabilities, suitable for dynamic environments but at a greater investment. By evaluating these factors, B2B buyers can make informed decisions that align with their strategic goals and operational efficiencies.

Essential Technical Properties and Trade Terminology for live roller conveyor

What Are the Key Technical Properties of Live Roller Conveyors?

1. Material Grade

Live roller conveyors are typically constructed from various materials, including steel and aluminum. Steel is favored for its strength and durability, making it ideal for heavy-duty applications, while aluminum offers lightweight properties that are useful in environments where flexibility is required. The choice of material impacts the conveyor’s longevity, load capacity, and maintenance needs, which are critical factors for B2B buyers aiming to minimize operational costs.

2. Roller Diameter

The diameter of rollers on a live roller conveyor can vary significantly, commonly ranging from 1.9 inches to 2.5 inches. A larger diameter allows for a greater load capacity and smoother operation, particularly in high-speed applications. Understanding roller diameter is crucial for businesses that need to transport heavy or bulky items, as it directly affects the efficiency and effectiveness of the material handling process.

3. Load Capacity

Load capacity refers to the maximum weight a conveyor can handle safely. This specification can vary based on the conveyor’s design, length, and the materials used. For instance, a chain-driven live roller conveyor may support loads up to 15,000 lbs, whereas a belt-driven model might have a lower capacity. B2B buyers must assess their operational needs to select a conveyor that can meet their load requirements while ensuring safety and efficiency.

Illustrative image related to live roller conveyor

4. Speed Control

Variable speed control is a significant feature that allows the adjustment of roller speed according to the specific requirements of the products being transported. This capability is essential for minimizing product damage and optimizing throughput. Buyers should consider this feature if their operations involve delicate items or require precise handling to enhance overall productivity.

5. Drive Type

Live roller conveyors can be powered by various drive types, including belt-driven and chain-driven systems. Each type has its advantages; for instance, belt-driven systems are often quieter and more suitable for lighter loads, while chain-driven systems are robust and capable of handling heavier loads. Understanding the differences in drive types is essential for buyers looking to integrate conveyors into existing systems efficiently.

What Are Common Trade Terminology and Acronyms in the Live Roller Conveyor Industry?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of live roller conveyors, working with an OEM ensures that the equipment meets specific industry standards and quality expectations. B2B buyers often seek OEM partnerships to guarantee product reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers as it affects inventory management and budgeting. Suppliers with high MOQs may require businesses to purchase more than they need, impacting cash flow and storage capacities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for B2B buyers as it facilitates comparison between different suppliers, allowing them to make informed purchasing decisions based on price, lead time, and other critical factors.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for buyers sourcing live roller conveyors from overseas. Understanding Incoterms can help businesses avoid unexpected costs and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. In the context of live roller conveyors, lead times can vary significantly based on customizations and supplier capabilities. B2B buyers should factor in lead times when planning their operations to avoid disruptions in material handling processes.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding the procurement and integration of live roller conveyors into their operations, ultimately enhancing efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the live roller conveyor Sector

What Are the Key Market Dynamics Affecting Live Roller Conveyor Sourcing?

The live roller conveyor market is experiencing significant growth driven by the increasing demand for automation in material handling across various industries. Global shifts towards e-commerce, rapid urbanization, and the need for efficient supply chain solutions are pivotal forces propelling this sector. In regions such as Africa, South America, the Middle East, and Europe, businesses are increasingly adopting live roller conveyors to enhance efficiency and reduce operational costs. For instance, sectors like warehousing, manufacturing, and food distribution are leveraging these systems to streamline processes, improve throughput, and reduce labor intensity.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are reshaping the landscape of live roller conveyors, enabling smarter operational management. These technologies facilitate real-time monitoring and predictive maintenance, minimizing downtime and maximizing productivity. Moreover, B2B buyers are increasingly focusing on customization options that allow for integration with existing systems, such as automated sortation and packaging equipment. This adaptability is crucial for companies aiming to remain competitive in an ever-evolving marketplace.

How Is Sustainability Influencing the Live Roller Conveyor Supply Chain?

Sustainability has become a central consideration in the procurement of live roller conveyors, with buyers increasingly prioritizing environmental impact in their sourcing decisions. The production processes for these conveyors can have significant environmental footprints, making it essential for manufacturers to adopt sustainable practices. This includes using recyclable materials, reducing energy consumption during manufacturing, and ensuring that products are designed for longevity to minimize waste.

Ethical sourcing is also gaining traction among international buyers. Companies are now seeking suppliers who adhere to responsible sourcing practices, ensuring that raw materials are obtained in a manner that is environmentally sustainable and socially responsible. Certifications such as ISO 14001 for environmental management and other green certifications are becoming important indicators of a supplier’s commitment to sustainability. Buyers are encouraged to evaluate potential partners based on their sustainability credentials, as this not only aligns with corporate social responsibility goals but also meets the growing consumer demand for environmentally conscious products.

What Is the Historical Context of Live Roller Conveyors in B2B Operations?

The evolution of live roller conveyors can be traced back to the early 20th century when mechanization began to transform industrial operations. Initially, these systems were primarily used in manufacturing settings for transporting heavy loads. Over the decades, advancements in engineering and materials science have led to the development of more versatile and efficient designs, allowing live roller conveyors to be used in various sectors beyond manufacturing, including warehousing and e-commerce.

In recent years, the integration of automation and smart technologies has marked a significant turning point. Today, live roller conveyors are not just passive transport systems; they play a crucial role in automated logistics and supply chain solutions. As businesses continue to innovate and seek efficiencies, the role of live roller conveyors is expected to grow, adapting to the needs of modern industries and paving the way for future advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of live roller conveyor

-

How do I solve issues with live roller conveyor performance?

To address performance issues with live roller conveyors, first conduct a thorough inspection of the system, focusing on the rollers, motors, and controls. Ensure that all components are clean and free from debris that could impede movement. Regular maintenance schedules should be established to check for wear and tear, lubrication needs, and alignment of the rollers. If problems persist, consult with the supplier for technical support or consider upgrades to higher-capacity models to meet increased demands. -

What is the best live roller conveyor for heavy-duty applications?

For heavy-duty applications, a chain-driven live roller conveyor is often the best choice due to its robust construction and high load capacity. These systems can handle significant weights and are designed to withstand continuous operation in demanding environments. Look for models with heavy-gauge steel frames and rollers, and ensure that the motor specifications align with your operational requirements. Customization options such as variable speed control can further enhance performance. -

How can I customize a live roller conveyor for my specific needs?

Customization options for live roller conveyors are extensive. You can modify roller sizes, materials, and configurations to suit your product types and handling requirements. Features like variable speed controls, incline adjustments, and integration with existing systems can also be tailored. Consult with suppliers to discuss your specific needs, and they can provide solutions that align with your operational goals and enhance efficiency. -

What are the minimum order quantities (MOQs) for live roller conveyors?

Minimum order quantities for live roller conveyors vary by supplier and model. Typically, MOQs can range from a single unit for standard models to larger quantities for custom designs. It’s advisable to inquire directly with suppliers about their policies, as some may offer flexibility based on your specific project requirements. Bulk purchasing may also lead to discounted rates, making it beneficial for larger operations. -

What payment terms should I expect when purchasing live roller conveyors internationally?

Payment terms for international purchases of live roller conveyors usually include options like advance payment, letters of credit, or net payment terms (e.g., 30, 60, or 90 days post-delivery). It’s essential to discuss these terms upfront with your supplier to ensure clarity and alignment with your financial processes. Additionally, consider currency fluctuations and international transaction fees that may impact the total cost. -

How do I vet suppliers for live roller conveyors?

Vetting suppliers involves assessing their experience, reputation, and product quality. Look for suppliers with a proven track record in the industry, preferably with international experience in your region. Request references from previous clients and check online reviews. Additionally, evaluate their certifications and compliance with international quality standards, as this can impact the reliability and performance of the conveyors. -

What logistics considerations should I keep in mind when sourcing live roller conveyors?

Logistics is crucial when sourcing live roller conveyors, especially for international shipments. Consider shipping methods, lead times, and customs clearance processes. Ensure that the supplier can provide support in navigating these logistics, including packaging for safe transport. Additionally, factor in local regulations and any potential tariffs that may affect the overall cost of your purchase. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers of live roller conveyors should have robust quality assurance processes in place. This includes regular inspections during manufacturing, adherence to industry standards, and testing of the finished products before shipment. Request documentation of these processes, such as quality control certifications and test reports, to ensure that the conveyors meet your operational requirements and standards for reliability.

Top 4 Live Roller Conveyor Manufacturers & Suppliers List

1. Hytrol – Live Roller Conveyors

Domain: hytrol.com

Registered: 1996 (29 years)

Introduction: Live roller conveyors are transport roller conveyors used for moving boxed or palletized products. They utilize electric power to propel products down the line, making them an economical solution for various industries including warehousing, manufacturing, food and beverage distribution, and e-commerce. Key advantages include increased efficiency, reduced labor costs through automation, and custom…

2. Ashland Conveyor – CDLR16F10S Chain Driven Live Roller

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: {“Model”:”CDLR16F10S0551EW1A3ID30″,”Type”:”Chain Driven Live Roller”,”Construction”:”8 ga steel channel frame, 2-1/2\”x11 ga steel rollers on 5\” centers”,”Drive”:”1 HP motor, 240/480 VAC, 3 phase”,”Speed”:”30 FPM”,”Weight”:”810 lbs”,”Overall Length”:”10 ft”,”Effective Width”:”51 in”,”Between Frame”:”55 in”,”Capacity”:”Maximum live load of 7,000 lbs for 50 ft total length, 15,000 lbs for 30 ft tot…

3. Belt Power – Live Roller Belting

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: Live Roller Belting (LRB) is used in Live Roller Conveyors, commonly found in distribution centers and manufacturing plants. It drives gravity rollers in a Live Roller System. Belt Power offers various specifications for OEM equipment like Dematic, Intelligrated, Hytrol, and TGW. Popular drive options include Belt Driven Round Belt (O-Ring), Chain & Sprocket, Driver Pad, and Motorized Pulley. Live…

4. ConDrives – Hytrol Model ABLR Conveyor

Domain: condrives.com

Registered: 1998 (27 years)

Introduction: Hytrol Model ABLR Flat Belt Driven Live Roller Conveyor is designed for conveying cartons and tote boxes, particularly in warehouses and distribution centers. Key specifications include:

– Conveyor widths available: 16″, 18″, 20″, 22″, 24″, 26″, 28″, 30″, 34″, 36″, 40″, and 42″.

– Conveying speed: 65 feet per minute (constant).

– Motor: 1/2 HP (208/230/460/575/3/60 TEFC), with an optional upgra…

Strategic Sourcing Conclusion and Outlook for live roller conveyor

In the ever-evolving landscape of material handling, live roller conveyors stand out as a versatile and efficient solution for various industries, including warehousing, manufacturing, and e-commerce. Their ability to automate processes not only enhances productivity but also reduces labor costs, making them a strategic investment. When sourcing live roller conveyors, it is essential to consider customization options, integration capabilities, and the long-term reliability of the equipment to ensure it meets your specific operational requirements.

Strategic sourcing plays a crucial role in optimizing your supply chain, allowing you to partner with reputable manufacturers who provide high-quality products tailored to your needs. By prioritizing suppliers that offer robust customer support and comprehensive service, businesses can achieve seamless implementation and ongoing maintenance, thus maximizing their investment.

Looking ahead, the demand for efficient and automated material handling solutions will continue to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As you explore options for live roller conveyors, consider leveraging technology and innovation to enhance your operations. Connect with industry experts today to discover how live roller conveyors can transform your supply chain and drive success in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.