Top 4 Komatsu Pc01 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for komatsu pc01

The global market for the Komatsu PC01 mini excavator presents unique opportunities and challenges for B2B buyers navigating procurement in a competitive landscape. Sourcing a compact and efficient excavator like the PC01 can be daunting, especially when considering factors such as machine specifications, pricing, and supplier reliability. This guide aims to demystify the process by providing a comprehensive overview of the Komatsu PC01, including its diverse applications across various industries, from construction to landscaping, and highlighting its suitability for projects in confined spaces.

In the following sections, we will delve into the specifications of the PC01, explore its operational benefits, and outline crucial considerations for vetting suppliers. Understanding the typical costs associated with purchasing new and used models will also be covered, ensuring that buyers can make informed financial decisions. Additionally, this guide will address logistical concerns specific to international markets, particularly for buyers from Africa, South America, the Middle East, and Europe, including Germany and Vietnam.

By equipping B2B buyers with actionable insights and best practices, this guide empowers them to confidently navigate the complexities of sourcing the Komatsu PC01. Whether you are looking for optimal performance in tight urban environments or require a reliable machine for rural projects, this resource is designed to enhance your purchasing strategy and ensure you make the best investment for your operational needs.

Understanding komatsu pc01 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PC01-1 | Compact design, 1-ton operating weight, 0.008m³ bucket capacity | Urban construction, landscaping | Pros: Ideal for tight spaces; low operating costs. Cons: Limited power for heavy-duty tasks. |

| PC01 Micro | Extremely lightweight (300 kg), versatile for indoor use | Home renovations, small site work | Pros: Easily transportable; minimal ground disturbance. Cons: Limited bucket capacity may require more cycles. |

| PC01 with Gasoline Engine | Powered by gasoline, suitable for smaller jobs | Residential projects, utility work | Pros: Lower fuel costs; easier maintenance. Cons: Less powerful than diesel variants; not ideal for extensive use. |

| PC01-1A | Enhanced hydraulic system, improved digging force | Excavation in confined areas | Pros: Increased efficiency; robust design. Cons: Higher initial investment may deter budget-conscious buyers. |

| PC01-1C | Advanced control systems, greater maneuverability | Demolition, trenching | Pros: Superior handling; suitable for complex projects. Cons: More complex systems may require specialized training. |

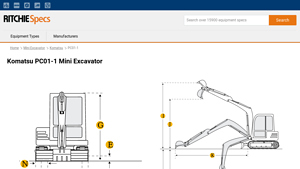

What are the distinguishing features of the Komatsu PC01-1?

The Komatsu PC01-1 is renowned for its compact structure, making it a preferred choice for urban construction and landscaping projects. With an operating weight of 1 ton and a bucket capacity of 0.008m³, it excels in tight spaces where larger excavators cannot operate efficiently. B2B buyers should consider its low operating costs and versatility, although its limited power may not suffice for heavy-duty tasks.

How does the PC01 Micro cater to specific business needs?

Weighing only 300 kg, the PC01 Micro is designed for indoor applications, such as home renovations and small site work. Its lightweight nature allows for easy transportation and minimal ground disturbance, making it ideal for sensitive environments. However, businesses should note that its limited bucket capacity may necessitate more cycles to complete tasks, impacting overall efficiency.

Illustrative image related to komatsu pc01

What are the advantages of the PC01 with a gasoline engine?

The PC01 with a gasoline engine is particularly suited for residential projects and utility work, offering lower fuel costs and simpler maintenance compared to diesel models. This makes it an attractive option for small contractors or businesses focused on cost-efficiency. However, potential buyers should be aware that this variant may lack the power needed for extensive or heavy-duty operations.

What improvements does the PC01-1A offer for B2B buyers?

The PC01-1A features an enhanced hydraulic system that provides improved digging force, making it suitable for excavation tasks in confined areas. This model is favored for its increased efficiency and robust design, ensuring durability on the job site. However, the higher initial investment may be a concern for budget-conscious buyers, necessitating a careful cost-benefit analysis.

How does the PC01-1C enhance operational capabilities?

The PC01-1C stands out with its advanced control systems and greater maneuverability, making it ideal for complex tasks such as demolition and trenching. This model provides superior handling, allowing operators to navigate challenging work environments effectively. However, its complexity may require specialized training for operators, which can be a consideration for companies looking to maximize workforce efficiency.

Key Industrial Applications of komatsu pc01

| Industry/Sector | Specific Application of komatsu pc01 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Excavating in confined spaces and urban environments | Enhances productivity in tight job sites, reducing labor costs | Ensure machine’s compact size and weight specifications meet project requirements. |

| Landscaping | Site preparation and landscaping in residential areas | Provides precision in small-scale earth-moving tasks, improving project quality | Verify compatibility with various attachments for different landscaping tasks. |

| Demolition | Selective demolition in urban settings | Minimizes collateral damage while maximizing efficiency in debris removal | Check for machine durability and maintenance history to ensure reliability. |

| Utility Installation | Trenching for utility lines (water, gas, electricity) | Facilitates quick and efficient installation, reducing downtime | Assess hydraulic performance and power output for varied soil conditions. |

| Agriculture | Land clearing and preparation for agricultural use | Increases arable land availability, enhancing productivity | Consider machine’s weight and track width for soil compaction and crop safety. |

How is the Komatsu PC01 Used in Construction Projects?

In the construction sector, the Komatsu PC01 is invaluable for excavating in confined spaces, particularly in urban environments. Its compact size allows it to maneuver through narrow pathways and doorways, making it ideal for residential projects where space is limited. By optimizing productivity in tight job sites, businesses can reduce labor costs and improve project timelines. When sourcing this equipment, buyers should ensure that the machine’s specifications align with their specific project requirements, especially regarding weight and size.

What Role Does the Komatsu PC01 Play in Landscaping?

The landscaping industry utilizes the Komatsu PC01 for site preparation and earth-moving tasks in residential areas. Its precision and compact design enable operators to perform delicate work without disturbing surrounding landscapes. This capability not only enhances project quality but also contributes to customer satisfaction. Buyers in this sector should verify the machine’s compatibility with various attachments, ensuring versatility for different landscaping applications.

Illustrative image related to komatsu pc01

How is the Komatsu PC01 Effective in Demolition?

In demolition scenarios, the Komatsu PC01 excels in selective demolition within urban settings. Its small footprint allows for efficient debris removal while minimizing collateral damage to adjacent structures. This efficiency is crucial for maintaining project timelines and reducing costs associated with unintended damages. Prospective buyers should check the machine’s durability and maintenance history to ensure it can withstand the rigors of demolition work.

How Does the Komatsu PC01 Facilitate Utility Installation?

The utility installation sector benefits from the Komatsu PC01’s ability to trench for water, gas, and electricity lines. Its powerful hydraulic system allows for quick and efficient installations, significantly reducing downtime for utility projects. When considering sourcing this equipment, buyers must assess the hydraulic performance and power output to ensure it can handle various soil conditions effectively.

In What Ways Can the Komatsu PC01 Support Agricultural Activities?

In agriculture, the Komatsu PC01 is used for land clearing and preparation, making previously unusable land arable. This capability enhances agricultural productivity by increasing land availability. Buyers should consider the machine’s weight and track width to ensure it does not compact the soil excessively, which could harm future crop yields. Proper sourcing will ensure that the equipment meets the specific needs of agricultural tasks in diverse environments.

Illustrative image related to komatsu pc01

3 Common User Pain Points for ‘komatsu pc01’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Used Komatsu PC01 Excavators

The Problem: For international B2B buyers, especially those in emerging markets like Africa and South America, finding reliable used Komatsu PC01 excavators can be a daunting task. Many sellers may lack transparency regarding the machine’s condition, maintenance history, or previous usage, leading to potential pitfalls in procurement. Buyers often face challenges such as inflated prices, misrepresented specifications, and concerns about the availability of spare parts, which can significantly impact project timelines and budgets.

The Solution: To mitigate these risks, buyers should prioritize sourcing from reputable dealers with proven track records in the used machinery market. Conduct thorough due diligence by requesting detailed documentation, including maintenance records and original purchase invoices. Using platforms that provide verified seller ratings and customer feedback can also help buyers make informed decisions. Additionally, buyers should consider investing in an independent inspection service to evaluate the condition of the excavator before purchase. Establishing a relationship with local service providers can also ensure that spare parts and maintenance support are readily available, thereby enhancing the longevity and reliability of the equipment.

Scenario 2: Challenges with Compact Size and Operational Limitations

The Problem: While the compact design of the Komatsu PC01 makes it ideal for working in confined spaces, some B2B buyers may find its operational limitations frustrating. For instance, projects requiring heavy lifting or extensive excavation might lead to inefficiencies if the machine’s capabilities are overestimated. Buyers might also struggle with understanding the optimal applications for the excavator, which can lead to suboptimal usage and increased operational costs.

The Solution: To address this challenge, buyers should invest time in understanding the specific operational capabilities of the Komatsu PC01. Familiarizing themselves with the machine’s specifications—such as its weight capacity, bucket size, and hydraulic power—can help buyers set realistic expectations and application scenarios. Additionally, training operators on the best practices for using the excavator in confined spaces will maximize productivity. Collaborating with Komatsu’s local distributors or service centers can also provide valuable insights into the machine’s capabilities and limitations, allowing for better planning and execution of projects.

Scenario 3: Maintenance and Repair Issues Over Time

The Problem: As with any machinery, the Komatsu PC01 may require maintenance and repairs over its lifecycle. B2B buyers might face difficulties in accessing genuine spare parts or qualified technicians, particularly in regions where the presence of Komatsu’s service network is limited. This can lead to prolonged downtimes, increased operational costs, and ultimately, project delays, which are critical in competitive markets.

The Solution: To preemptively tackle maintenance issues, buyers should establish a comprehensive maintenance plan that includes regular servicing and inspections. Partnering with local or regional authorized Komatsu service centers can ensure access to genuine parts and skilled technicians. Buyers should also consider investing in a maintenance training program for their staff to perform basic upkeep and troubleshooting. Furthermore, keeping a stock of commonly needed spare parts can minimize downtime during critical operations. Engaging with online forums and communities of Komatsu users can also provide insights into common maintenance challenges and effective solutions, thereby fostering a proactive maintenance culture.

Strategic Material Selection Guide for komatsu pc01

What Are the Key Materials Used in the Komatsu PC01 Excavator?

The Komatsu PC01 mini excavator is designed for performance in confined spaces, making material selection critical for durability and functionality. Below, we analyze several common materials used in the construction of the PC01, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Steel: The Backbone of the Komatsu PC01

Key Properties: Steel is known for its high tensile strength and durability, capable of withstanding significant pressure and stress. Its corrosion resistance can be enhanced through galvanization or coatings.

Pros & Cons: Steel provides excellent durability and is relatively cost-effective, making it a popular choice for structural components. However, it can be heavy, which may affect the overall weight and maneuverability of the excavator. Additionally, the manufacturing complexity increases if advanced alloys or treatments are required.

Impact on Application: Steel components are essential for the frame and structural integrity of the PC01. The material’s compatibility with hydraulic systems is crucial, as it must endure high pressure without deforming.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 10025 for structural steel. In contrast, buyers in Africa and South America may prioritize cost-effectiveness and local sourcing.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with good corrosion resistance and thermal conductivity, making it suitable for various components.

Illustrative image related to komatsu pc01

Pros & Cons: The primary advantage of aluminum is its reduced weight, which enhances the PC01’s maneuverability and efficiency. However, it is generally less durable than steel and may not withstand heavy loads as effectively, leading to potential long-term performance issues.

Impact on Application: Aluminum is often used in non-structural components such as covers and panels, where weight savings are essential. Its corrosion resistance is beneficial in humid environments, which is a consideration for buyers from tropical regions.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 for aluminum extrusions is vital. Buyers should also consider the availability of aluminum in their region, as sourcing can vary significantly.

Illustrative image related to komatsu pc01

Rubber: Essential for Mobility and Vibration Dampening

Key Properties: Rubber is flexible, resilient, and provides excellent vibration dampening, which is crucial for the comfort and stability of the excavator.

Pros & Cons: The primary advantage of rubber is its ability to absorb shocks and vibrations, enhancing operator comfort. However, its lifespan can be shorter than that of metals, especially in harsh environments, leading to increased maintenance costs.

Impact on Application: Rubber components are critical for tracks and seals, ensuring smooth operation and preventing leaks in hydraulic systems. The material’s compatibility with various environmental conditions makes it a versatile choice.

Illustrative image related to komatsu pc01

Considerations for International Buyers: Buyers should ensure that rubber components meet relevant standards, such as ISO 9001 for quality management. In regions with extreme temperatures, rubber formulations may need to be tailored to prevent degradation.

Plastic: Versatile and Cost-Effective

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, making them ideal for various applications.

Pros & Cons: The versatility and low cost of plastics are significant advantages, allowing for innovative designs and reduced manufacturing costs. However, plastics may not offer the same strength or durability as metals, which can limit their use in high-stress applications.

Impact on Application: Plastics are often used for housings, covers, and non-load-bearing components, providing protection and insulation. Their chemical resistance is beneficial in environments where exposure to various substances is common.

Illustrative image related to komatsu pc01

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties of plastics is essential. Buyers should also consider the environmental impact and recyclability of plastic components, which may be a concern in regions with stringent environmental regulations.

Summary Table of Material Selection for Komatsu PC01

| Material | Typical Use Case for komatsu pc01 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High durability and strength | Heavy, can affect maneuverability | Medium |

| Aluminum | Non-structural components | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Rubber | Tracks and seals | Excellent vibration dampening | Shorter lifespan in harsh conditions | Low |

| Plastic | Housings and covers | Versatile and cost-effective | Limited strength compared to metals | Low |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions when sourcing components for the Komatsu PC01 excavator.

In-depth Look: Manufacturing Processes and Quality Assurance for komatsu pc01

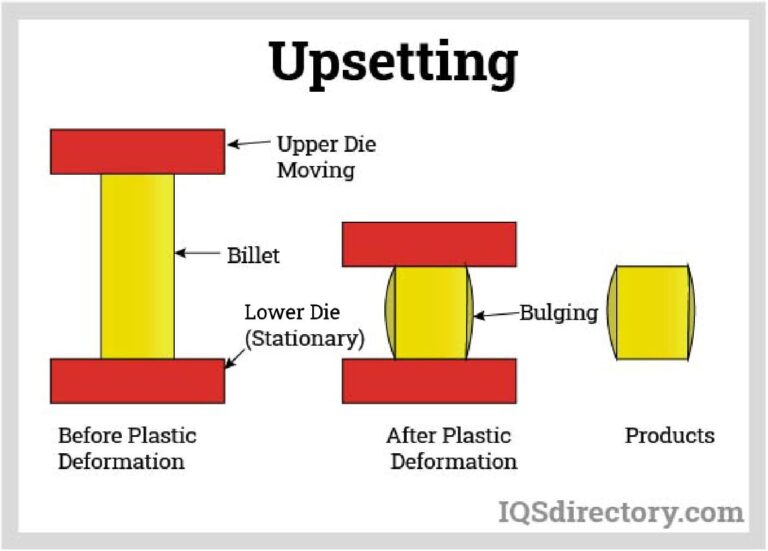

What Are the Key Stages in the Manufacturing Process of the Komatsu PC01?

The manufacturing process of the Komatsu PC01 mini excavator involves several critical stages, each contributing to the overall quality and performance of the machine. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-grade materials that meet stringent engineering specifications. Steel and other alloys are sourced from reputable suppliers, ensuring they comply with international standards for durability and strength. Materials undergo thorough inspections to guarantee they are free from defects before moving on to the next stage.

-

Forming: The forming stage employs advanced techniques such as precision cutting, bending, and welding. Computer Numerical Control (CNC) machines are often utilized to ensure accuracy in creating components like the excavator’s chassis and arm. This precision is essential for the structural integrity of the PC01, particularly given its compact design that necessitates a robust yet lightweight framework.

-

Assembly: During assembly, skilled technicians follow detailed engineering drawings to construct the excavator. Components such as the hydraulic systems, engine, and electrical systems are integrated into the structure. This stage is critical as it determines the operational efficiency and reliability of the excavator. A systematic approach is used to ensure that all parts fit together seamlessly.

-

Finishing: The finishing stage involves surface treatments such as painting and coating, which not only enhance aesthetics but also protect against corrosion and wear. Quality checks are conducted to ensure that the finish meets Komatsu’s high standards, which are crucial for maintaining the machine’s longevity in various working environments.

How Is Quality Assurance Implemented in the Production of Komatsu PC01?

Quality assurance (QA) is an integral part of the manufacturing process for the Komatsu PC01, ensuring that every unit produced meets both company standards and international regulations.

-

International Standards Compliance: Komatsu adheres to international quality standards, notably ISO 9001, which outlines requirements for a quality management system. This certification demonstrates a commitment to consistent quality and continuous improvement. In addition, industry-specific certifications such as CE (Conformité Européenne) for compliance with European safety standards and API (American Petroleum Institute) standards for equipment used in the petroleum industry are also crucial.

-

Quality Control Checkpoints: The QA process includes multiple checkpoints throughout production:

– Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Conducts inspections during the manufacturing process to identify defects early.

– Final Quality Control (FQC): Involves comprehensive testing and inspection of the final product to ensure it operates correctly and meets all design specifications. -

Common Testing Methods: Various testing methods are employed to evaluate the functionality and safety of the PC01. These may include hydraulic pressure tests, performance tests, and stress analysis to ensure all components function effectively under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical to ensuring a reliable purchase. Here are some actionable steps:

Illustrative image related to komatsu pc01

-

Conduct Supplier Audits: A thorough audit of the supplier’s manufacturing facilities can provide insights into their quality assurance practices. Buyers should look for adherence to international standards and the presence of a robust quality management system.

-

Request Quality Assurance Reports: Suppliers should provide detailed QA reports that outline their processes and results from quality checks. These reports can reveal how often defects occur and the measures taken to address them.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These inspections can be particularly useful in verifying compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing the Komatsu PC01, international buyers must be aware of certain nuances in quality control that could affect their purchasing decisions:

-

Cultural and Regional Differences: Quality standards and expectations may vary significantly across regions. Buyers from Europe, for instance, may have stricter expectations regarding compliance with environmental and safety regulations compared to buyers from other regions. Understanding these differences can help buyers negotiate better and ensure they receive a product that meets their needs.

-

Documentation and Certification: Ensure that the supplier provides all necessary documentation, including compliance certificates and warranty information. This is particularly important for buyers in regions with stringent import regulations.

-

Communication and Support: Establishing clear lines of communication with suppliers is essential for addressing any quality concerns that may arise post-purchase. Suppliers should offer ongoing support and be willing to engage in dialogue about any issues that may affect product performance.

Conclusion

The manufacturing processes and quality assurance protocols for the Komatsu PC01 mini excavator are designed to ensure that the final product meets the highest standards of quality and performance. By understanding these processes, international B2B buyers can make informed decisions and establish trust with suppliers, ultimately leading to successful partnerships and reliable equipment for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘komatsu pc01’

To assist international B2B buyers in sourcing the Komatsu PC01 mini excavator, this practical guide outlines essential steps to ensure a successful procurement process. The Komatsu PC01 is known for its compact design and powerful performance, making it an ideal choice for various construction tasks, particularly in tight spaces. Follow the checklist below to navigate your sourcing journey effectively.

Illustrative image related to komatsu pc01

Step 1: Define Your Technical Specifications

Before beginning your search, clarify your operational needs and technical requirements for the Komatsu PC01. Consider factors such as operating weight, bucket capacity, and engine type, as these will impact the excavator’s performance in your specific applications.

– Key Specifications to Consider:

– Operating weight: Aim for a model that meets your job site constraints.

– Bucket capacity: Ensure it aligns with the volume of work required.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers of used Komatsu PC01 excavators. Utilize platforms like Machinio and Machineryline to gather information about available models and suppliers’ credibility.

– What to Look For:

– Supplier reviews and ratings from previous customers.

– Established track records in your region or industry.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers rigorously. Request detailed company profiles, customer testimonials, and references from buyers in similar industries or regions to ensure they have a solid reputation.

– Important Considerations:

– Verify the supplier’s experience with used machinery.

– Ask for case studies that demonstrate successful transactions.

Step 4: Inspect Equipment Thoroughly

Once you’ve narrowed down your options, arrange for an inspection of the excavators. This step is critical to assess the machine’s condition, operational capabilities, and any potential issues.

– Inspection Checklist:

– Check for oil leaks, rust, and overall wear and tear.

– Test operational functions such as the hydraulic systems and controls.

Step 5: Request Documentation

Ensure you receive all necessary documentation related to the Komatsu PC01 before finalizing your purchase. This includes maintenance records, warranty information, and compliance certifications.

– Why This Matters:

– Documentation helps verify the machine’s history and condition.

– It provides essential information for future maintenance and resale.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with your chosen supplier to finalize pricing and payment terms. Be transparent about your budget and any financial constraints to facilitate a mutually beneficial agreement.

– Negotiation Tips:

– Consider factors like shipping costs and after-sales support.

– Don’t hesitate to discuss warranties or return policies.

Step 7: Plan for Logistics and Delivery

Once the deal is closed, coordinate logistics for transporting the excavator to your site. Factor in shipping timelines, customs regulations, and any import duties applicable in your region.

– Logistics Considerations:

– Choose a reliable shipping partner experienced in heavy machinery transport.

– Ensure compliance with local regulations to avoid delays.

By following this checklist, B2B buyers can navigate the procurement process for the Komatsu PC01 with confidence, ensuring they acquire a machine that meets their operational needs and contributes to their project success.

Comprehensive Cost and Pricing Analysis for komatsu pc01 Sourcing

What Are the Key Cost Components in Sourcing a Komatsu PC01 Excavator?

When sourcing a Komatsu PC01 excavator, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to komatsu pc01

-

Materials: The Komatsu PC01 is constructed using high-quality materials, including steel and hydraulic components sourced from reputable suppliers. The choice of materials directly impacts both the durability and performance of the excavator, which is crucial for buyers in harsh working environments.

-

Labor and Manufacturing Overhead: Labor costs vary significantly by region. In countries with lower labor costs, manufacturing may be cheaper, but it’s essential to ensure that quality standards are maintained. Overhead costs, including facility maintenance and administrative expenses, also contribute to the overall price.

-

Tooling and QC: Specialized tooling is necessary for the production of excavators, which can be a significant investment. Furthermore, rigorous quality control processes ensure that each machine meets Komatsu’s high standards, which can influence pricing.

-

Logistics: Transportation costs can fluctuate based on the shipping method and distance from the supplier to the buyer’s location. Buyers should consider shipping costs in addition to the purchase price when evaluating overall expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s reputation, the demand for the equipment, and market conditions.

How Do Price Influencers Affect the Sourcing of Komatsu PC01 Excavators?

Several factors can influence the pricing of the Komatsu PC01, making it essential for buyers to understand these nuances:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Suppliers may offer lower prices per unit for larger orders, making it beneficial for companies looking to equip multiple projects.

-

Specifications and Customization: Customizing features or specifications can lead to increased costs. Buyers must balance their needs with budget constraints when considering optional features.

-

Quality and Certifications: Equipment that meets specific certifications or quality standards may command higher prices. Buyers should weigh the importance of certification against potential savings from lower-quality options.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more due to their quality assurance and after-sales service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can impact the final cost significantly.

What Negotiation Strategies Can Buyers Employ to Ensure Cost-Efficiency?

To achieve the best possible price and terms when sourcing the Komatsu PC01, buyers should consider the following negotiation strategies:

-

Conduct Market Research: Understanding the market rates for the Komatsu PC01 across different regions can provide leverage during negotiations. Buyers should be aware of average prices and competitor offerings.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield favorable conditions, including priority service and preferential pricing.

-

Focus on Total Cost of Ownership (TCO): Buyers should evaluate the TCO rather than just the upfront price. This includes maintenance, fuel efficiency, and potential resale value, which can significantly affect long-term costs.

-

Be Flexible with Payment Terms: Offering flexibility in payment terms can incentivize suppliers to offer better pricing. For example, upfront payments may yield discounts, while extended payment terms can help with cash flow management.

-

Explore Financing Options: Many suppliers offer financing solutions that can make the purchase more manageable. Buyers should inquire about available financing options that may include lower interest rates or deferred payments.

Final Thoughts on Sourcing the Komatsu PC01 Excavator

While sourcing the Komatsu PC01, buyers should remain aware that prices can vary widely based on numerous factors, including location, supplier, and market conditions. It is advisable to obtain multiple quotes and conduct thorough due diligence to ensure a fair deal. Always remember to factor in the total cost of ownership to gauge the true value of the investment. Prices noted in this guide are indicative and should be verified with suppliers for accuracy.

Alternatives Analysis: Comparing komatsu pc01 With Other Solutions

When evaluating equipment for construction and excavation projects, businesses often seek alternatives to the Komatsu PC01 mini excavator. Understanding the strengths and weaknesses of various options can help B2B buyers make informed decisions that align with their operational needs. Below, we compare the Komatsu PC01 against two viable alternatives: the Bobcat E10 and the Caterpillar 300.9D.

| Comparison Aspect | Komatsu PC01 | Bobcat E10 | Caterpillar 300.9D |

|---|---|---|---|

| Performance | 1 ton operating weight, compact design, effective in tight spaces | 1 ton operating weight, powerful hydraulic system, versatile attachments | 1 ton operating weight, strong digging force, stability on uneven terrain |

| Cost | Approx. $7,000 – $18,000 (used) | Approx. $15,000 – $20,000 (new) | Approx. $18,000 – $25,000 (new) |

| Ease of Implementation | Simple operation, low learning curve | User-friendly controls, quick attachment changes | More complex operation, requires operator training |

| Maintenance | Moderate; parts readily available | Low; strong durability and service support | Moderate; reliable but parts can be costlier |

| Best Use Case | Indoor projects, landscaping, utility work | Residential projects, tight urban areas | Construction sites, landscaping, and utility work |

What Are the Pros and Cons of the Bobcat E10 as an Alternative?

The Bobcat E10 is a strong competitor in the mini excavator market. Its user-friendly design and powerful hydraulic system make it an excellent choice for residential projects and tight urban environments. The E10 can accommodate a variety of attachments, enhancing its versatility. However, its higher price point—approximately $15,000 to $20,000 for new models—may deter budget-conscious buyers. Additionally, while maintenance costs are generally low due to its durability, the investment upfront is considerably higher than that of the Komatsu PC01.

How Does the Caterpillar 300.9D Compare?

The Caterpillar 300.9D offers robust performance with a strong digging force, making it suitable for construction sites and landscaping tasks. Its stability on uneven terrain is a significant advantage, especially in more challenging work environments. However, the complexity of its operation means that operators may require training, increasing the initial investment in terms of time and resources. Additionally, while the Caterpillar is a reliable machine, the cost of parts and maintenance can be higher compared to the Komatsu PC01, which may affect long-term operational costs.

How Can B2B Buyers Choose the Right Solution?

When selecting the right mini excavator, B2B buyers should consider their specific operational needs, budget constraints, and the types of projects they will undertake. The Komatsu PC01 excels in compactness and affordability, making it ideal for indoor and tight-space applications. Conversely, for buyers focused on versatility and robust performance in varied conditions, the Bobcat E10 or Caterpillar 300.9D may provide better long-term value despite the higher initial cost. Ultimately, evaluating these factors will ensure that businesses invest in the equipment that best supports their operational goals and enhances productivity.

Essential Technical Properties and Trade Terminology for komatsu pc01

What Are the Key Technical Properties of the Komatsu PC01 Excavator?

Understanding the technical specifications of the Komatsu PC01 is crucial for B2B buyers, especially when considering the equipment’s suitability for specific projects. Here are some critical specs to consider:

-

Operating Weight (1 Ton)

– The operating weight of the Komatsu PC01 is approximately 1 ton. This lightweight design enables the machine to maneuver easily in confined spaces, making it ideal for indoor and urban construction projects. For international buyers, particularly in regions with limited access roads, a compact excavator like the PC01 can significantly reduce logistical challenges. -

Bucket Capacity (0.008 m³)

– With a bucket capacity of 0.008 cubic meters, the PC01 is designed for precise digging and material handling tasks. This specification is vital for buyers who need to understand the volume of material the excavator can handle per load, impacting project timelines and efficiency. -

Hydraulic System Components

– The PC01 features original hydraulic components, including cylinders, pumps, and valves, all branded by Komatsu. These parts are critical for ensuring reliable performance and reducing maintenance costs. For B2B buyers, the assurance of original components can enhance the machine’s resale value and longevity. -

Engine Power (2.5 kW)

– The excavator is equipped with a powerful engine that produces approximately 2.5 kW of output. This specification determines the machine’s performance capabilities, including its digging force and speed. Buyers should consider engine specifications to ensure they meet the demands of their specific applications. -

Machine Weight (300 kg)

– At a weight of just 300 kg, the Komatsu PC01 is one of the smallest mini excavators on the market. This weight allows for greater versatility, enabling the machine to be transported easily and operated in areas where larger excavators cannot fit, such as residential construction sites.

Which Trade Terminology Should B2B Buyers Understand When Purchasing a Komatsu PC01?

Familiarity with industry-specific jargon can facilitate smoother transactions and better decision-making for B2B buyers. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products or components that are used in another company’s end product. For buyers, understanding OEM can help in sourcing genuine parts for maintenance and repairs, ensuring compatibility and reliability in operations. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity a supplier is willing to sell. This is crucial for buyers looking to negotiate bulk purchases. Knowing the MOQ can help businesses plan their purchases and manage inventory costs effectively. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where a buyer requests pricing information from suppliers. For B2B buyers, issuing an RFQ for the Komatsu PC01 can help compare prices and terms, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs and ensure smooth logistics. -

Used Equipment Certification

– This refers to the verification of the condition and functionality of pre-owned machinery. For buyers interested in used Komatsu PC01 excavators, certifications provide assurance of quality and performance, which is essential for making informed purchasing decisions.

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions, ensuring they select the right equipment for their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the komatsu pc01 Sector

What Are the Key Market Trends Affecting the Komatsu PC01 Sector?

The global market for mini excavators, particularly the Komatsu PC01, is currently witnessing significant growth driven by urbanization, infrastructure development, and an increasing focus on compact machinery suitable for constrained spaces. Regions such as Africa and South America are investing heavily in construction and mining, with a notable demand for efficient and versatile machinery like the PC01. In Europe, especially in Germany and Vietnam, the trend is leaning towards more sophisticated, tech-integrated equipment that enhances productivity and reduces operational downtime.

Illustrative image related to komatsu pc01

Emerging B2B technology trends also play a crucial role in shaping the sourcing landscape. The use of digital marketplaces for equipment procurement is becoming prevalent, allowing international buyers to access a broader range of suppliers and competitive pricing. Additionally, advancements in telematics and IoT are enabling better tracking of equipment performance and maintenance, which enhances decision-making for buyers. As construction projects become more complex, the need for reliable, high-performance machinery like the Komatsu PC01 is paramount, emphasizing its compact size and robust capabilities in tight operational environments.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Komatsu PC01 Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the construction machinery sector. The environmental impact of machinery operations, including emissions and waste, is under scrutiny. As such, buyers are gravitating towards suppliers who adopt sustainable practices and offer machinery that is energy-efficient and built with recyclable materials. For the Komatsu PC01, this means sourcing from manufacturers who prioritize eco-friendly production methods and materials.

Ethical sourcing is equally critical. Buyers are now more aware of the supply chains involved in the manufacturing of construction equipment. They prefer suppliers who are transparent about their sourcing practices, ensuring that their machinery is produced in compliance with labor laws and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainable practices. Buyers can leverage these certifications to ensure they are making responsible purchasing decisions that align with their own corporate social responsibility goals.

What Is the Historical Context of the Komatsu PC01’s Development?

The Komatsu PC01 mini excavator has evolved significantly since its inception, reflecting the changing needs of the construction and landscaping industries. Originally designed for small-scale tasks, the PC01 has gained popularity due to its compact size, making it ideal for urban environments and projects with limited space. Over the years, enhancements in hydraulic technology and engine efficiency have improved its performance, allowing for greater digging power and operational versatility.

As the demand for mini excavators has surged globally, especially in developing markets across Africa and South America, the PC01 has solidified its position as a reliable choice for international buyers. Its durability and ease of maintenance continue to make it a preferred option for contractors looking for cost-effective solutions without compromising on quality. The ongoing advancements in the model reflect Komatsu’s commitment to meeting the evolving needs of the global market, ensuring that the PC01 remains relevant and competitive in an ever-changing landscape.

Illustrative image related to komatsu pc01

Frequently Asked Questions (FAQs) for B2B Buyers of komatsu pc01

-

How do I ensure the quality of a used Komatsu PC01 excavator before purchasing?

To ensure the quality of a used Komatsu PC01 excavator, it’s essential to conduct a thorough inspection. Request detailed maintenance records and inquire about any past repairs or issues. If possible, arrange for a pre-purchase inspection by a qualified technician who can assess the machine’s condition. Additionally, ask for video footage of the equipment in operation and verify the seller’s reputation through reviews or references. This approach helps mitigate risks and ensures that you invest in a reliable machine. -

What are the key specifications I should consider when sourcing a Komatsu PC01?

When sourcing a Komatsu PC01, focus on specifications like operating weight, bucket capacity, and engine power. The PC01 typically has an operating weight of around 1 ton, with a bucket capacity of approximately 0.008m³. Check the machine’s working hours, as lower hours generally indicate less wear. Additionally, consider the hydraulic system’s brand and condition, as it significantly impacts performance. These specifications will help you determine if the excavator meets your operational needs. -

What are common issues to look for in a used Komatsu PC01 excavator?

Common issues to look for in a used Komatsu PC01 include hydraulic leaks, engine performance problems, and wear on the tracks or undercarriage. Inspect for signs of oil leakage around hydraulic cylinders and joints, as this can indicate maintenance neglect. Additionally, check the condition of the bucket and any attachments for wear. Ensuring that the machine has been regularly serviced and maintained can prevent costly repairs down the line. -

What is the typical price range for a used Komatsu PC01 excavator?

The price of a used Komatsu PC01 excavator typically ranges from $5,000 to $18,000, depending on factors such as age, condition, and operating hours. Newer models with fewer working hours generally command higher prices. It’s advisable to compare prices across multiple sellers and platforms to ensure you are getting a fair deal. Additionally, consider the inclusion of warranties or service agreements that may affect the overall value. -

How do I find reliable suppliers for Komatsu PC01 excavators internationally?

To find reliable international suppliers for Komatsu PC01 excavators, start by researching established dealers and marketplaces that specialize in construction machinery. Look for suppliers with a good reputation, verified customer reviews, and a history of exporting to your region. Networking at industry events or trade shows can also help connect you with trustworthy suppliers. Finally, consider using online platforms that offer buyer protection and transparency in transactions. -

What payment terms are commonly offered for purchasing excavators internationally?

Payment terms for international excavator purchases can vary widely among suppliers. Common options include full upfront payment, bank transfers, or payment through escrow services that protect both parties. Some suppliers may offer financing options, allowing you to pay in installments. It’s crucial to discuss and clarify payment terms before finalizing a deal to ensure both parties are comfortable with the arrangement. -

What logistics considerations should I keep in mind when importing a Komatsu PC01?

When importing a Komatsu PC01, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reputable freight forwarder experienced in handling heavy machinery to ensure safe transport. Be aware of import duties and taxes that may apply in your country, as these can significantly impact the overall cost. Additionally, plan for any necessary inspections or certifications required by local authorities upon arrival. -

Can I customize a Komatsu PC01 excavator to fit specific operational needs?

Yes, customization options are often available for the Komatsu PC01 excavator. Depending on the supplier, you may be able to request modifications such as different bucket sizes, specialized attachments, or enhanced hydraulic systems. Discuss your specific operational requirements with the supplier to explore available customization options. Keep in mind that customizations may affect lead times and pricing, so factor these into your decision-making process.

Top 4 Komatsu Pc01 Manufacturers & Suppliers List

1. Komatsu – PC01 Mini Excavator

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: Manufacturer: Komatsu

Model: PC01

Year: 2013, 2016, 2017, 2015, 2021, 2018

Operating Weight: 1 Ton

Machine Weight: 300 KG

Bucket Capacity: 0.008m³

Hours: 0-2000

Hydraulic Cylinder Brand: Original / Komatsu

Hydraulic Pump Brand: Original / Komatsu

Hydraulic Valve Brand: Original / Komatsu

Engine Brand: Original / Komatsu

Location: Shanghai, China

Price Range: $5,000 – $18,000 USD

Features: Compact …

2. Komatsu – PC01-1 Mini Excavator Specs

Domain: ritchiespecs.com

Registered: 2008 (17 years)

Introduction: This company, Komatsu – PC01-1 Mini Excavator Specs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Komatsu – PC01 Mini Excavator

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Mini excavator | Komatsu pc01 for sale

4. Komatsu – PC01 Mini Excavator

Domain: machineryline.com

Registered: 2005 (20 years)

Introduction: {“Brand”:”Komatsu”,”Model”:”PC01″,”Type”:”mini excavator”,”Year of manufacture”:”2016″,”Load capacity”:”2,205 lb”,”Net weight”:”661.4 lb”,”Location”:”China Shanghai”,”Placed on”:”Sep 7, 2025″,”Machineryline ID”:”YM30070″,”Bucket volume”:”282.5 ft³”,”Engine Brand”:”Original”,”Power”:”2.59 kW (3.53 HP)”,”Condition”:”used”,”Colour”:”golden”,”Place of Origin”:”Japan”,”Core Components”:”Motor, Pump, En…

Strategic Sourcing Conclusion and Outlook for komatsu pc01

As the global demand for compact and efficient construction equipment continues to rise, the Komatsu PC01 excavator stands out as a reliable choice for international B2B buyers. Its compact design, robust performance, and versatility make it ideal for diverse applications, particularly in urban environments where space is limited. By strategically sourcing the PC01, buyers can leverage its operational efficiency and lower maintenance costs, ensuring a high return on investment.

In regions such as Africa, South America, the Middle East, and Europe, the availability of used Komatsu PC01 excavators presents a unique opportunity to acquire high-quality machinery at competitive prices. Buyers should prioritize vendors who provide comprehensive details, including operational hours and maintenance records, to make informed purchasing decisions. Furthermore, establishing relationships with trusted suppliers can facilitate ongoing support and access to spare parts, enhancing long-term operational reliability.

Looking ahead, the demand for mini excavators like the Komatsu PC01 is expected to grow, driven by infrastructure development and urbanization. International buyers are encouraged to act decisively, capitalizing on current market conditions to secure their investments in this highly sought-after machinery. Embrace the future of construction with the Komatsu PC01 and position your business for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.