Top 4 Industrial Safety Guards Suppliers (And How to Choose)

Introduction: Navigating the Global Market for industrial safety guards

In today’s fast-paced industrial landscape, the importance of sourcing reliable industrial safety guards cannot be overstated. With increasing global competition, businesses face the dual challenge of ensuring worker safety while maximizing operational efficiency. Industrial safety guards serve as essential barriers that protect employees from hazardous machinery, thereby reducing workplace accidents and enhancing productivity. This comprehensive guide delves into various types of safety guards, their applications across different industries, and the critical factors to consider when selecting the right solutions for your specific needs.

From machine guards and safety barriers to specialized shields, this resource covers a broad spectrum of products designed to meet diverse safety requirements. Buyers will gain insights into the vetting process for suppliers, ensuring that they partner with manufacturers who adhere to global safety standards. Additionally, we will address the cost implications of different guarding solutions, helping businesses make informed financial decisions that align with their safety objectives.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Germany, will find this guide particularly beneficial. By empowering decision-makers with actionable insights and expert recommendations, we aim to facilitate safer work environments and foster a culture of compliance and efficiency in industrial operations worldwide.

Understanding industrial safety guards Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Machine Guards | Physical barriers that prevent access to dangerous machine parts. | Manufacturing, metalworking, woodworking | Pros: Enhances worker safety; Cons: May require customization for specific machines. |

| Safety Shields | Transparent barriers protecting against flying debris and chemicals. | Assembly lines, chemical processing | Pros: Allows visibility while ensuring safety; Cons: May require regular maintenance. |

| Safety Barriers | Flexible barriers that absorb impact and separate work areas. | Warehousing, logistics, construction | Pros: Reduces risk of accidents; Cons: May not be suitable for all environments. |

| Perimeter Fencing | Enclosures that secure hazardous areas and restrict access. | Outdoor storage, construction sites | Pros: Provides robust security; Cons: Installation can be complex and costly. |

| Modular Guarding Systems | Customizable systems that can be adjusted for different applications. | Automated production lines, robotics | Pros: Highly adaptable; Cons: Initial investment can be significant. |

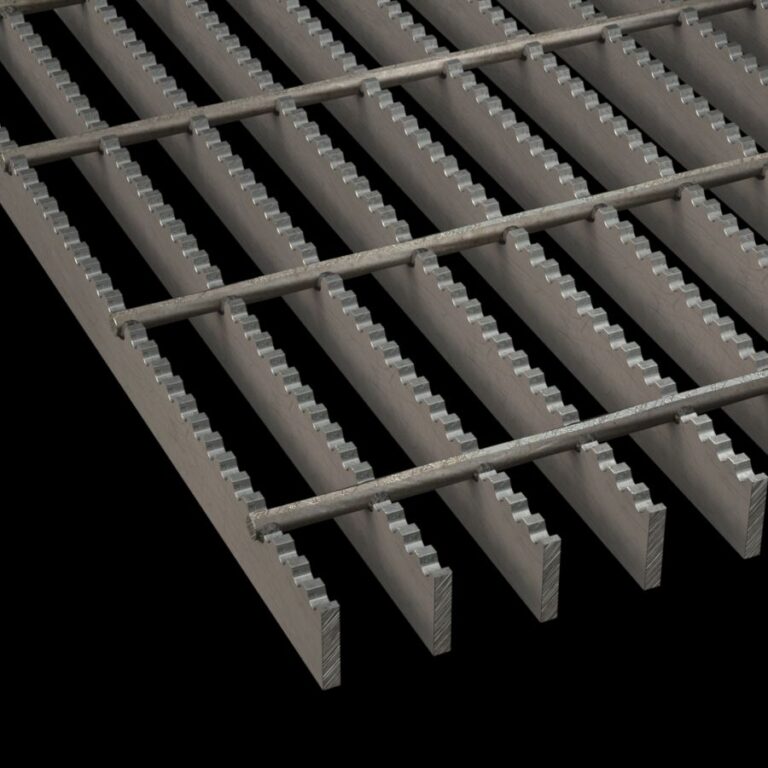

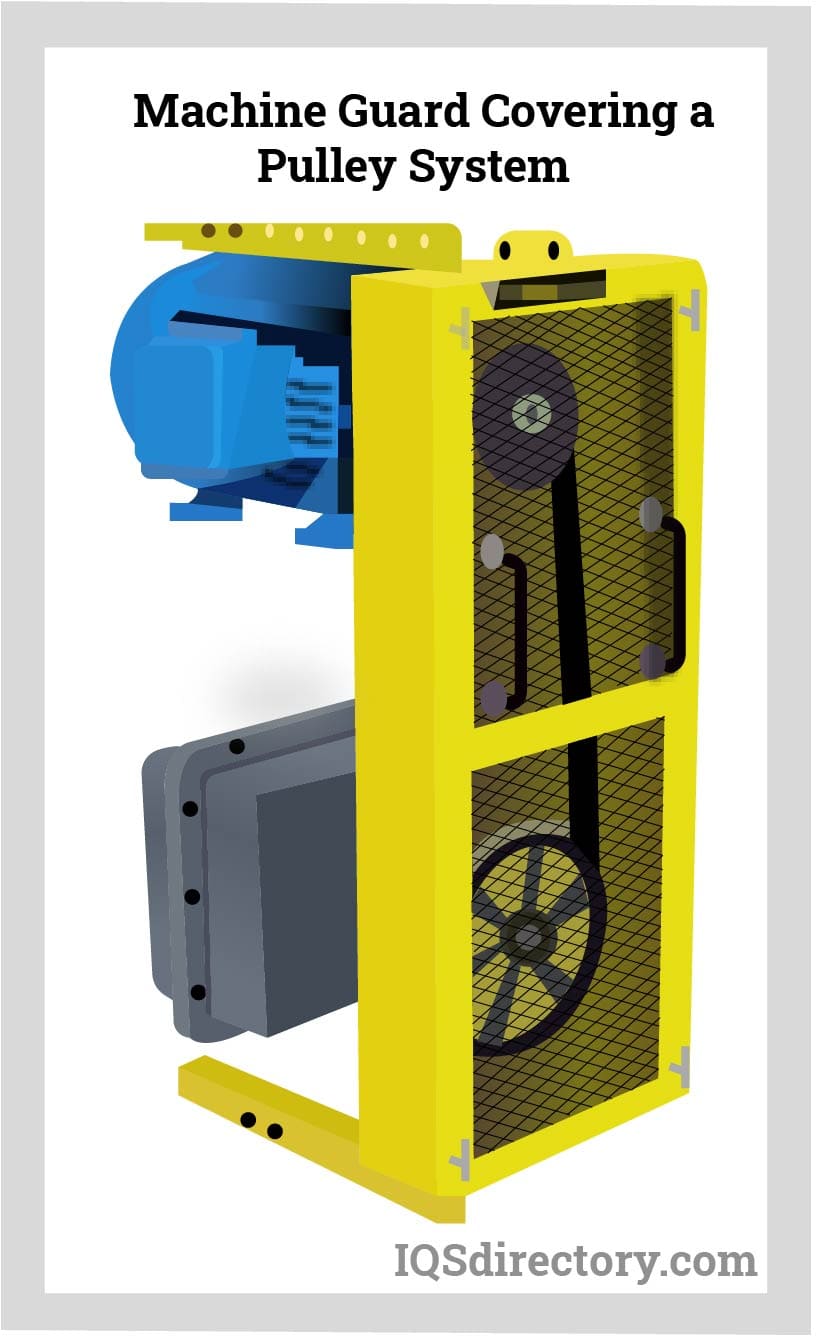

What Are Machine Guards and Their Key Features?

Machine guards serve as essential protective barriers around equipment, effectively preventing worker access to hazardous areas. These guards can be tailored to fit various machines, ensuring compliance with safety regulations. When purchasing, consider the specific machinery involved and the potential need for customization to meet your operational demands. Their robust design promotes workplace safety but may require additional investment for tailored solutions.

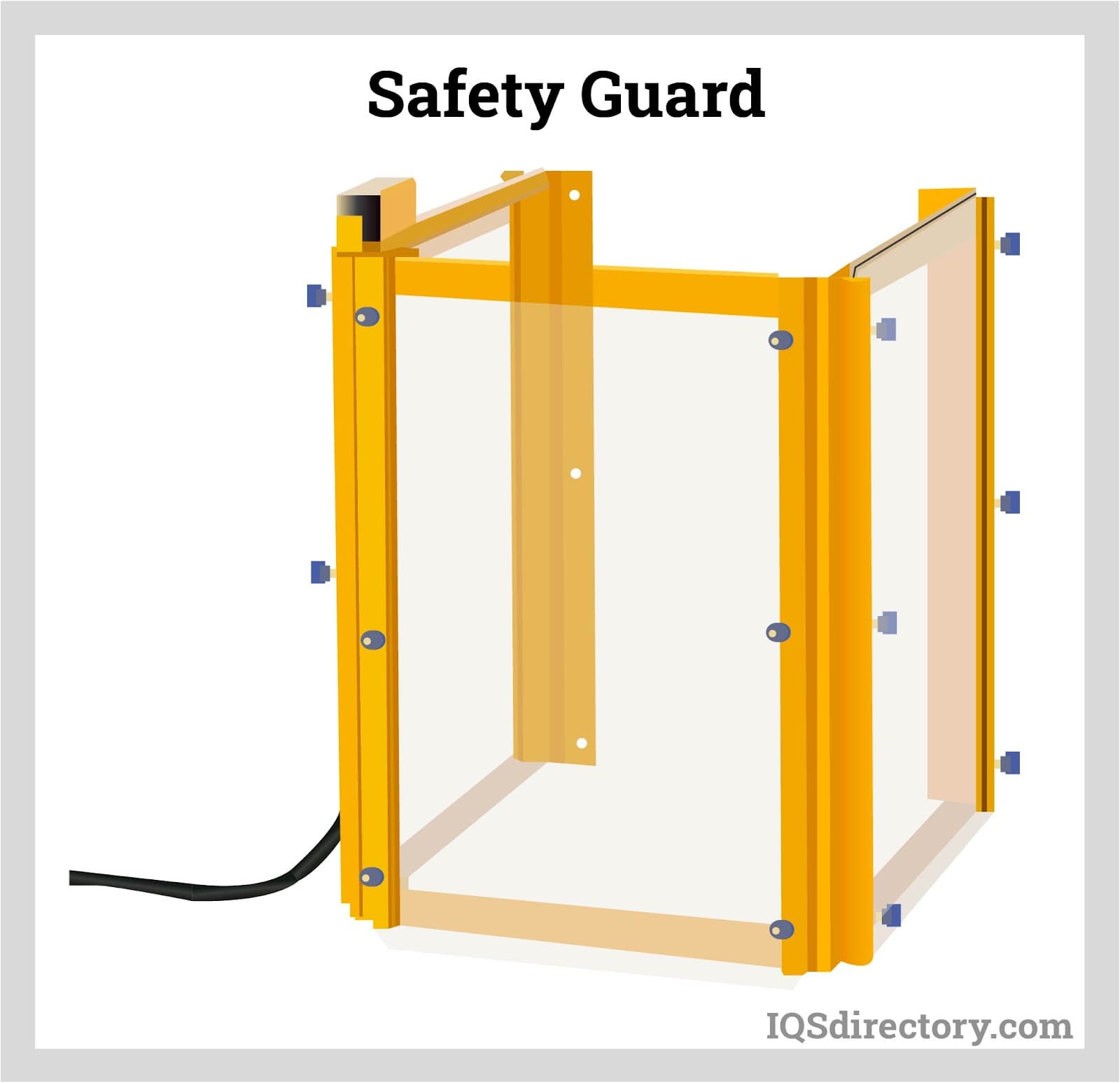

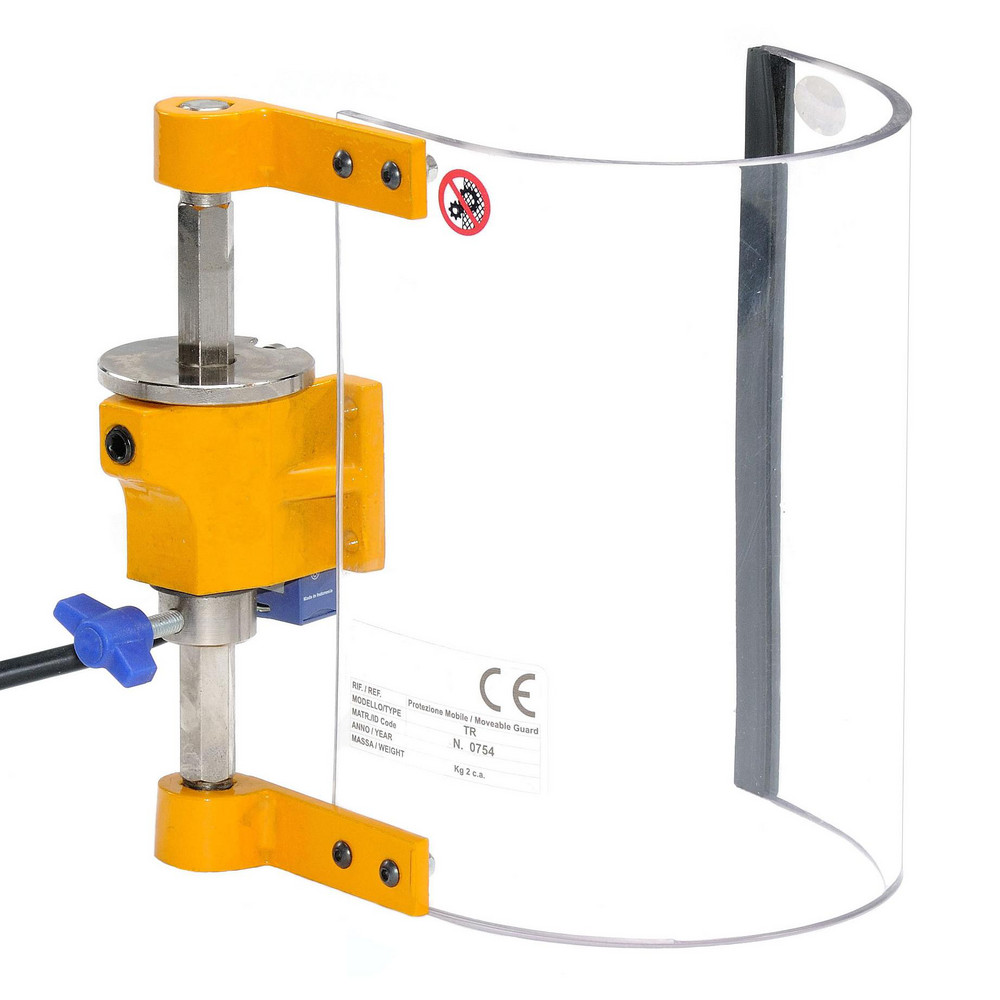

How Do Safety Shields Enhance Workplace Safety?

Safety shields are designed to protect workers from flying debris and hazardous substances while allowing visibility of the work area. They are particularly useful in environments such as assembly lines and chemical processing plants where risks are prevalent. Buyers should evaluate the material’s durability and maintenance requirements, as regular inspections may be necessary to ensure ongoing effectiveness.

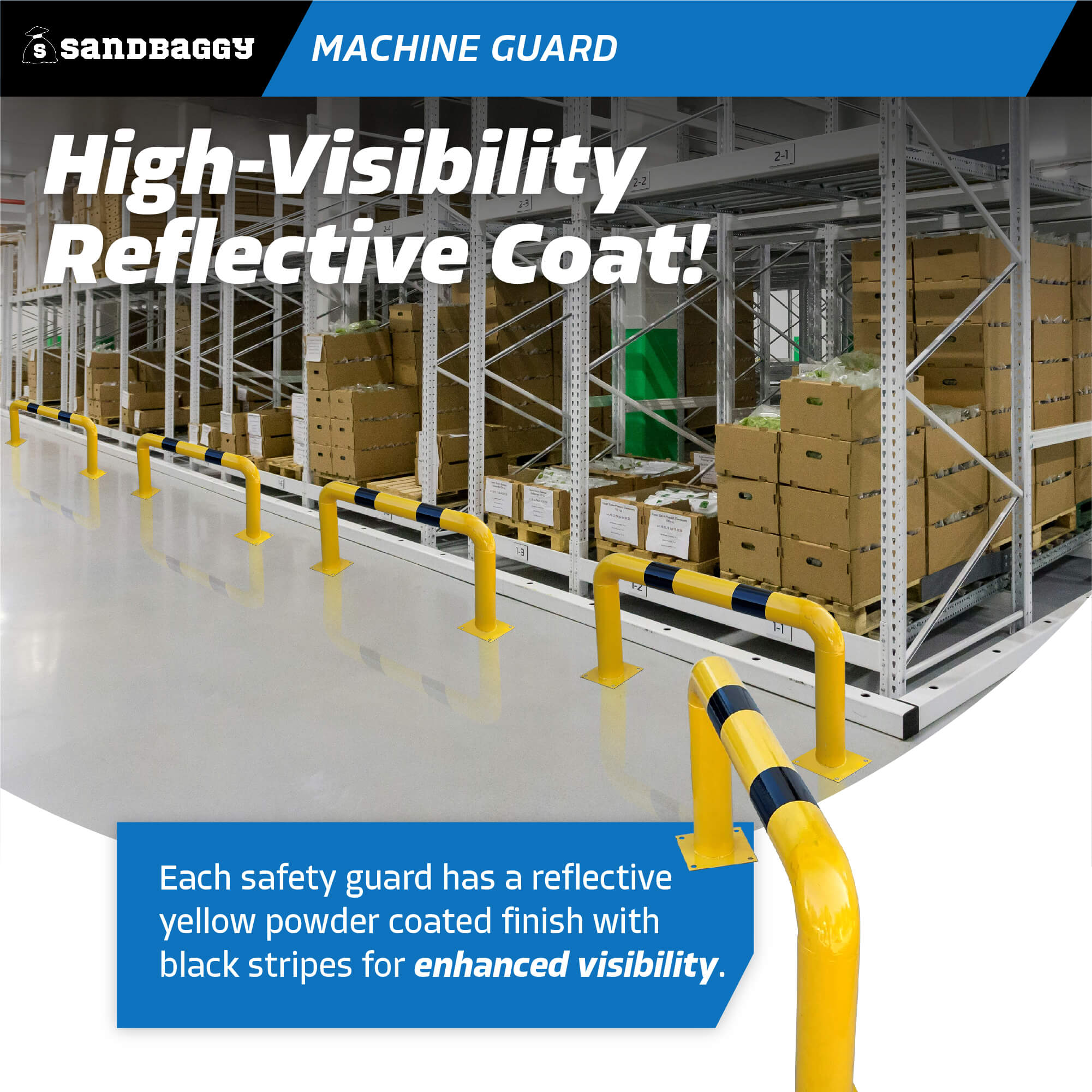

What Are the Benefits of Safety Barriers?

Safety barriers are flexible structures that protect personnel and equipment by absorbing impacts. They are ideal for environments like warehouses and construction sites where moving vehicles pose a risk. When considering safety barriers, assess their ability to withstand various impacts and their ease of installation. While they significantly reduce accident risks, their effectiveness may vary based on the specific operational context.

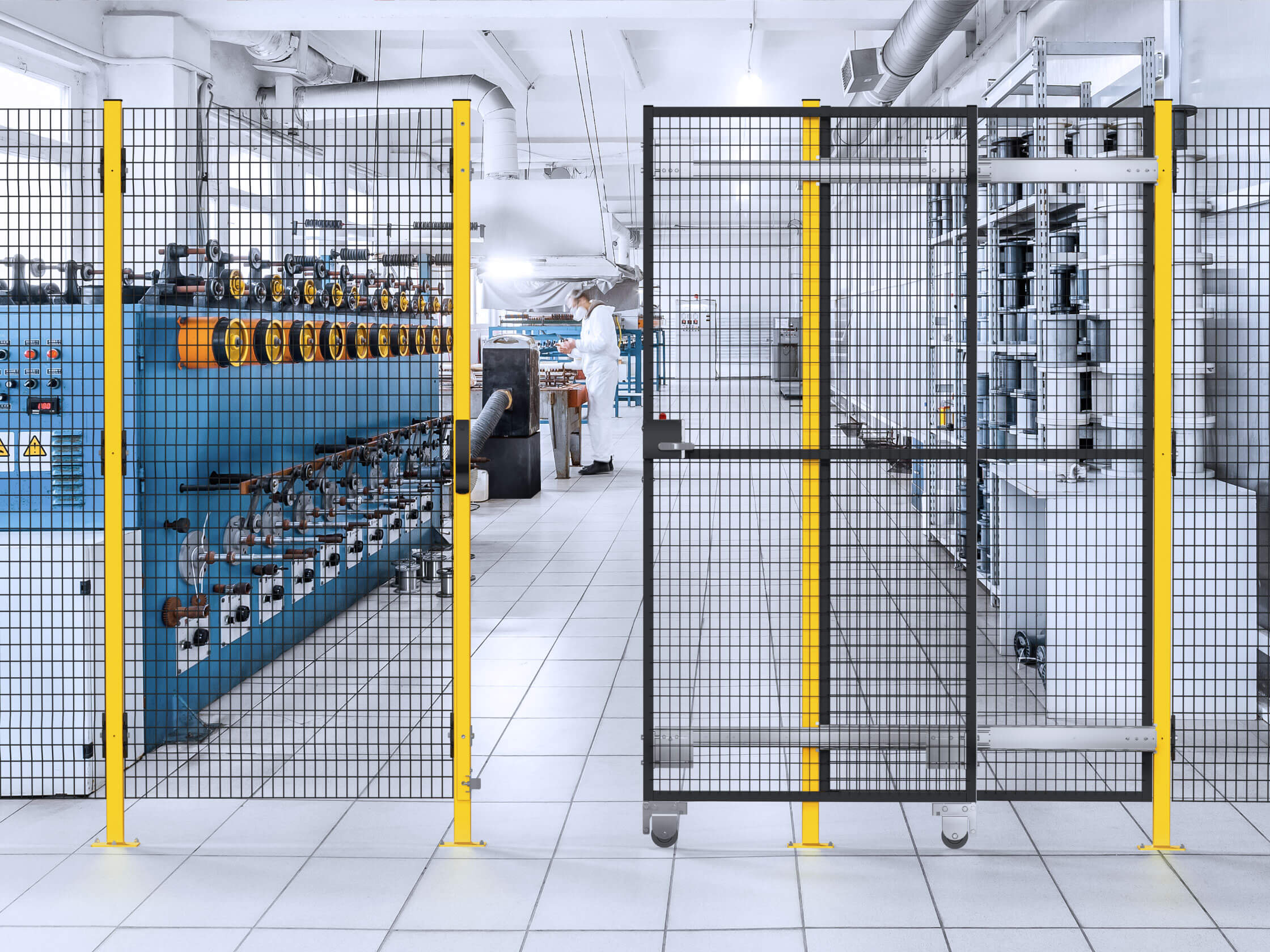

How Does Perimeter Fencing Secure Hazardous Areas?

Perimeter fencing is crucial for securing hazardous areas and preventing unauthorized access. Commonly used in outdoor storage and construction sites, these fences offer a robust solution for protecting both personnel and equipment. Buyers should consider the installation complexity and the materials used, as these factors can influence long-term durability and maintenance costs.

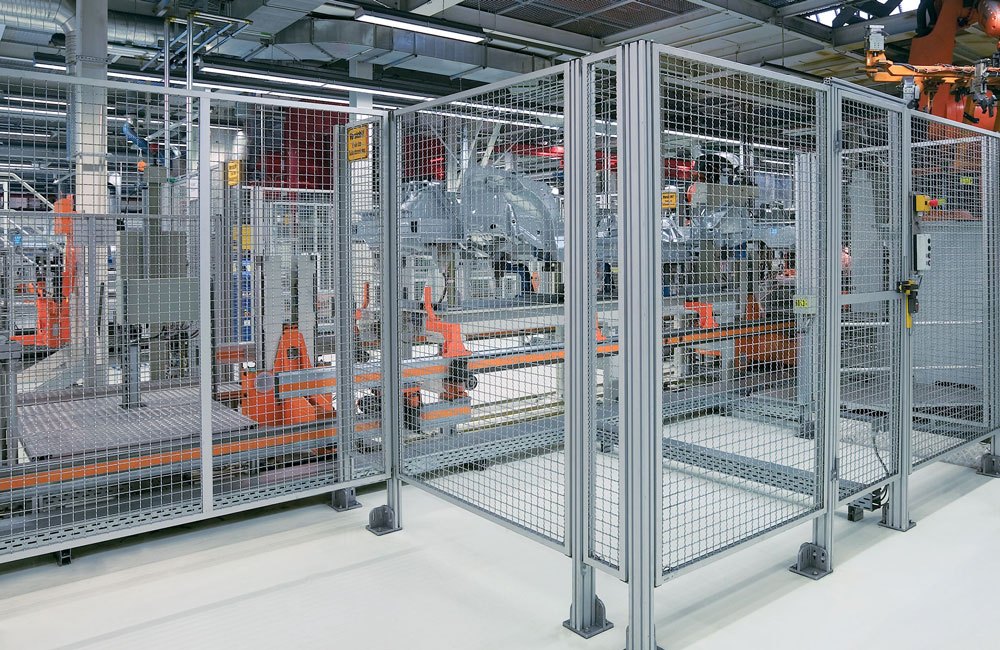

What Are Modular Guarding Systems and Their Advantages?

Modular guarding systems provide a versatile safety solution that can be customized for different applications, such as automated production lines and robotics. Their adaptability allows businesses to modify configurations as needs change, making them a long-term investment. However, buyers should be prepared for a potentially higher initial cost and assess the system’s compatibility with existing machinery and workflows to ensure optimal safety and efficiency.

Key Industrial Applications of industrial safety guards

| Industry/Sector | Specific Application of Industrial Safety Guards | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machine Guarding for Lathes and Milling Machines | Enhanced worker safety, reduced downtime | Compliance with local safety regulations, material durability |

| Food Processing | Hygiene-focused Safety Guards for Food Machinery | Improved hygiene standards, reduced contamination risk | Stainless steel options, easy-to-clean designs |

| Construction | Safety Barriers and Guardrails for Work Zones | Protection against falls, reduced liability | Weather resistance, visibility features |

| Mining | Heavy-duty Guards for Conveyor Systems | Increased equipment lifespan, minimized accidents | Impact resistance, compatibility with harsh environments |

| Warehousing | Safety Barriers for Racking Systems | Enhanced inventory protection, injury reduction | Customizable sizes, high visibility colors |

How Are Industrial Safety Guards Used in Manufacturing?

In the manufacturing sector, industrial safety guards are crucial for machine safeguarding, particularly for lathes and milling machines. These guards prevent accidental contact with moving parts, significantly reducing the risk of injuries. Compliance with safety regulations, such as those set by OSHA, is vital for manufacturers, especially in regions like Europe where regulations are stringent. Buyers should consider guards made from durable materials that withstand heavy use and ensure easy access for maintenance.

What Role Do Safety Guards Play in Food Processing Facilities?

In the food processing industry, hygiene is paramount. Safety guards designed specifically for food machinery not only protect workers but also enhance hygiene by preventing contaminants from entering the production line. Stainless steel safety guards are preferred due to their corrosion resistance and ease of cleaning. International buyers should ensure that the guards meet local health regulations and can withstand cleaning processes without degrading.

Why Are Safety Barriers Essential in Construction?

Safety barriers and guardrails are essential in construction zones to prevent falls and protect workers from hazards. These barriers delineate safe working areas and provide visual warnings to avoid accidents. In regions with diverse weather conditions, sourcing barriers that are weather-resistant and provide high visibility is crucial. Companies must also consider the ease of installation and maintenance when selecting these safety solutions.

How Do Industrial Safety Guards Enhance Mining Operations?

In mining operations, heavy-duty guards for conveyor systems are vital for ensuring worker safety and protecting equipment from damage. These guards help minimize the risk of accidents by preventing unauthorized access to hazardous areas. Buyers in the mining sector should prioritize sourcing guards that are impact-resistant and suitable for harsh environments, ensuring they can withstand the rigors of mining operations.

What Benefits Do Safety Barriers Provide in Warehousing?

In warehousing, safety barriers are used to protect racking systems and prevent damage to inventory. These barriers help reduce the risk of accidents involving forklifts and other equipment, enhancing overall safety. Buyers should look for customizable barrier solutions that fit their specific racking configurations and opt for high-visibility colors to ensure they are easily seen by all warehouse personnel.

3 Common User Pain Points for ‘industrial safety guards’ & Their Solutions

Scenario 1: Navigating Compliance and Safety Standards in Industrial Settings

The Problem: Many B2B buyers face the daunting challenge of ensuring that their industrial safety guards comply with local and international safety regulations. In regions like Africa and South America, where regulatory frameworks may be evolving, businesses often struggle to understand the specific requirements for safety guards. This lack of clarity can lead to costly fines, increased liability, and even injuries in the workplace. Buyers may find themselves overwhelmed by the need to balance compliance with operational efficiency, particularly when sourcing guards that meet diverse standards.

The Solution: To effectively navigate compliance, it is essential for buyers to invest in comprehensive training for their procurement teams. This training should focus on understanding relevant regulations, such as those set by OSHA in the U.S. or local health and safety administrations in their respective countries. Additionally, buyers should establish strong relationships with reputable suppliers who can provide documentation and certifications for their safety guards, ensuring they meet the required standards. When sourcing industrial safety guards, consider engaging a consultant familiar with local laws to help interpret regulations and recommend specific products tailored to your operational needs. Regular audits and updates of compliance status are also critical to maintaining adherence to safety standards.

Scenario 2: Customization Challenges for Unique Machinery

The Problem: A common pain point for B2B buyers is the difficulty in finding safety guards that fit unique or specialized machinery. Many industries utilize custom equipment that does not conform to standard sizes or shapes, which can lead to inadequate protection and increased risk of accidents. This scenario is especially prevalent in sectors such as manufacturing and mining, where bespoke machinery is the norm. Buyers often find themselves either settling for subpar solutions that compromise safety or facing lengthy lead times for custom orders, disrupting production schedules.

The Solution: To address customization challenges, buyers should engage in proactive design collaboration with their suppliers. When initiating the procurement process, provide detailed specifications and even 3D models of the machinery that requires guarding. This level of detail enables suppliers to propose tailored solutions that ensure optimal fit and functionality. Additionally, consider using modular guarding systems, which allow for flexibility and can be adjusted as machinery evolves. Establishing a feedback loop with the supplier post-installation can further refine the guard design to enhance safety and efficiency over time.

Scenario 3: Balancing Cost with Quality in Safety Solutions

The Problem: B2B buyers often grapple with the dilemma of balancing cost with the quality of industrial safety guards. In a competitive market, there is pressure to minimize expenses, which can lead to the temptation to opt for lower-cost options that may not provide adequate protection. This cost-cutting approach can result in higher long-term expenses due to increased injury rates, equipment damage, and potential legal liabilities. Buyers may feel uncertain about how to justify higher investments in quality safety guards while also achieving their budgetary goals.

The Solution: To strike the right balance between cost and quality, buyers should conduct a thorough cost-benefit analysis that evaluates the long-term implications of their purchasing decisions. This analysis should include potential savings from reduced injury claims, lower insurance premiums, and decreased downtime from equipment failures. Moreover, investing in high-quality safety guards can enhance employee morale and productivity by fostering a safer working environment. Buyers should also explore volume discounts with suppliers or consider leasing options for high-quality guards, which can alleviate upfront costs while ensuring compliance with safety standards. By prioritizing quality in their procurement strategy, businesses can achieve a more sustainable and cost-effective safety solution.

Illustrative image related to industrial safety guards

Strategic Material Selection Guide for industrial safety guards

When selecting materials for industrial safety guards, it is vital to consider the specific properties of each material in relation to their application, performance, and the operational environment. This analysis will explore four common materials used in the manufacturing of industrial safety guards: steel, aluminum, polycarbonate, and heavy-duty polymers. Each material has unique characteristics that can influence their suitability for various industrial applications.

What Are the Key Properties of Steel for Industrial Safety Guards?

Steel is renowned for its strength and durability, making it a popular choice for safety guards in heavy-duty applications. It typically has a high temperature and pressure rating, which is crucial in environments where machinery operates under extreme conditions. Steel’s excellent corrosion resistance can be enhanced through galvanization or powder coating, extending its lifespan in harsh environments.

Pros and Cons of Steel:

While steel offers exceptional durability and structural integrity, it can also be heavy and may require additional support in installation. The manufacturing complexity can increase costs, especially when custom designs are needed. However, its suitability for high-impact applications often justifies the investment.

Illustrative image related to industrial safety guards

Impact on Application:

Steel guards are ideal for environments with heavy machinery, such as manufacturing plants and construction sites. They can withstand significant impacts, making them suitable for high-risk areas.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local corrosion factors, such as humidity and chemical exposure. Compliance with international standards like ASTM for material quality is essential, particularly in Europe, where regulations are stringent.

How Does Aluminum Compare as a Material for Safety Guards?

Aluminum is lightweight and resistant to corrosion, making it an excellent alternative to steel for safety guards. It typically has a moderate temperature rating and is suitable for various industrial environments. Its natural resistance to oxidation allows it to maintain its appearance over time without the need for extensive maintenance.

Illustrative image related to industrial safety guards

Pros and Cons of Aluminum:

The lightweight nature of aluminum facilitates easier installation and reduces shipping costs. However, it may not be as strong as steel and can be more susceptible to denting under high impact. This trade-off makes it less suitable for heavy-duty applications.

Impact on Application:

Aluminum guards are commonly used in environments where weight savings are critical, such as in aerospace or automotive industries. They are also effective in applications requiring frequent relocation or adjustments.

Considerations for International Buyers:

In markets like Germany, where precision engineering is paramount, aluminum’s lightweight properties can be advantageous. However, compliance with DIN standards is crucial for ensuring safety and performance.

What Are the Advantages of Polycarbonate for Safety Guards?

Polycarbonate is a transparent thermoplastic known for its high impact resistance and lightweight properties. It can withstand a wide range of temperatures and is often used in environments where visibility is important, such as in food processing or pharmaceutical industries.

Pros and Cons of Polycarbonate:

The primary advantage of polycarbonate is its ability to provide visibility while ensuring safety. However, it is more expensive than traditional materials like steel or aluminum and may require specialized manufacturing processes.

Impact on Application:

Polycarbonate guards are ideal for applications where monitoring processes is necessary without compromising safety. They are often used in environments where chemical exposure is a concern, given their chemical resistance.

Considerations for International Buyers:

For buyers in the Middle East, where extreme temperatures can be a factor, polycarbonate’s temperature resilience is a key advantage. Compliance with international safety standards is essential to ensure the material’s effectiveness.

How Do Heavy-Duty Polymers Enhance Safety Guard Performance?

Heavy-duty polymers are increasingly popular due to their flexibility and impact resistance. They are often used in environments where traditional materials may corrode or degrade. These polymers can be engineered to meet specific performance requirements, including UV resistance and chemical compatibility.

Pros and Cons of Heavy-Duty Polymers:

The primary advantage of heavy-duty polymers is their lightweight nature and resistance to corrosion, which reduces maintenance costs. However, they may not offer the same structural strength as metals, making them less suitable for high-impact applications.

Illustrative image related to industrial safety guards

Impact on Application:

Polymers are ideal for applications in chemical processing and food industries, where corrosion and contamination are concerns. Their flexibility allows for innovative designs that can adapt to various industrial needs.

Considerations for International Buyers:

In regions like Africa, where environmental conditions can vary widely, selecting polymers that are specifically designed for local conditions is crucial. Compliance with local and international safety standards is necessary to ensure reliability.

Summary Table of Material Selection for Industrial Safety Guards

| Material | Typical Use Case for Industrial Safety Guards | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery protection | High strength and durability | Heavy and may require additional support | High |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Less strong than steel, susceptible to denting | Medium |

| Polycarbonate | Visibility-critical environments | High impact resistance and transparency | More expensive, requires specialized manufacturing | High |

| Heavy-Duty Polymers | Chemical processing and food industries | Corrosion-resistant and flexible | Less structural strength than metals | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for industrial safety guards

What Are the Main Stages of Manufacturing Industrial Safety Guards?

The manufacturing process for industrial safety guards typically consists of several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets safety standards and performance expectations.

How Is Material Prepared for Industrial Safety Guards?

Material preparation is the foundation of the manufacturing process. Common materials used for safety guards include steel, aluminum, and advanced polymers. The selection of material depends on the specific application and the environment in which the guards will be used. For instance, stainless steel is often preferred for its corrosion resistance in food processing environments, while durable polymers may be chosen for impact resistance in high-traffic areas.

Illustrative image related to industrial safety guards

During this stage, raw materials are sourced from reputable suppliers who comply with international quality standards. After procurement, materials undergo inspection and testing for quality assurance. This may include checking for tensile strength, corrosion resistance, and other relevant properties to ensure they meet the required specifications.

What Forming Techniques Are Commonly Used in Manufacturing Safety Guards?

Once the materials are prepared, they move into the forming stage. This involves various techniques such as cutting, bending, welding, and machining.

- Cutting: Materials are cut to specific dimensions using laser cutting or plasma cutting technologies, which provide high precision.

- Bending: Sheet metal is often bent into shape using CNC press brakes, which allow for intricate designs that enhance safety features.

- Welding: For assembly, components are frequently welded together to create robust structures. Techniques such as MIG and TIG welding are commonly used for their strength and durability.

- Machining: Precision machining may be employed to create custom fittings or brackets that are integral to the assembly of the guards.

Each of these techniques must adhere to strict tolerances to ensure the safety guards function as intended.

Illustrative image related to industrial safety guards

How Are Industrial Safety Guards Assembled?

The assembly phase brings together all formed components into a final product. This process often includes:

- Integration of Safety Features: Guards may include interlocking mechanisms or safety switches that prevent machine operation when guards are removed.

- Quality Checks: Each assembly undergoes initial quality checks (IQC) to ensure all components meet specifications before moving to the next stage.

- Final Assembly: The guards are assembled with careful attention to detail, ensuring that all safety features are correctly installed and functional.

Quality assurance during assembly is crucial, as any oversight can compromise the effectiveness of the safety guard.

What Finishing Processes Are Essential for Industrial Safety Guards?

Finishing processes are vital for enhancing the durability and appearance of safety guards. Common finishing techniques include:

Illustrative image related to industrial safety guards

- Painting or Coating: Guards are often coated with powder paint or other protective finishes to prevent corrosion and improve aesthetics. This is particularly important in harsh environments.

- Surface Treatment: Processes such as anodizing or galvanizing may be employed to increase resistance to wear and corrosion.

- Final Inspection: A thorough final quality check (FQC) is performed to ensure that the finished product meets all safety standards and specifications.

These finishing processes not only improve the longevity of the guards but also ensure compliance with industry regulations.

What International Standards Should Buyers Be Aware Of?

For B2B buyers, understanding the relevant international standards and certifications is crucial when sourcing industrial safety guards. These standards ensure that the products meet safety and quality benchmarks.

Which International Standards Are Most Relevant?

- ISO 9001: This standard focuses on quality management systems and is essential for any manufacturer aiming to ensure consistent quality in their products.

- CE Marking: In Europe, CE marking indicates that the product complies with EU safety, health, and environmental protection standards. This is particularly relevant for safety guards used in industrial settings.

- API Standards: For buyers in sectors like oil and gas, adhering to American Petroleum Institute (API) standards ensures that the products are fit for purpose in potentially hazardous environments.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control is integrated throughout the manufacturing process, with specific checkpoints established to maintain product integrity.

- Incoming Quality Control (IQC): This initial check assesses the quality of materials upon arrival. It ensures that only materials that meet specified standards are used in production.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor compliance with quality standards. This includes checking dimensions, weld quality, and assembly accuracy.

- Final Quality Control (FQC): Before shipping, a comprehensive inspection is performed to verify that the final product meets all specifications and regulatory requirements.

Implementing these checkpoints helps mitigate risks and ensures that the final products are safe for use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers.

What Steps Can Buyers Take for Supplier Verification?

- Audits: Conducting on-site audits of the manufacturing facility allows buyers to evaluate the supplier’s quality control processes firsthand.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control procedures, including IQC, IPQC, and FQC reports.

- Third-party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s manufacturing and quality control processes.

- Certifications and Compliance: Buyers should verify that suppliers hold relevant certifications (ISO, CE, etc.) and comply with international standards. This adds an additional layer of assurance regarding product quality.

What Nuances Should International Buyers Consider?

For international buyers, understanding the nuances of sourcing industrial safety guards can make a significant difference in the procurement process.

- Cultural Differences: Communication styles and business practices can vary widely across regions. It’s essential to establish clear expectations and maintain open lines of communication with suppliers.

- Regulatory Compliance: Different regions may have varying safety regulations and standards. Buyers should be aware of local requirements in their markets to ensure compliance.

- Lead Times and Logistics: Consideration of lead times, shipping logistics, and potential tariffs or duties is crucial for international procurement. Planning ahead can prevent delays and additional costs.

By considering these factors, B2B buyers can make informed decisions when sourcing industrial safety guards, ensuring both compliance and safety in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘industrial safety guards’

Introduction

Sourcing industrial safety guards is a critical task for businesses aiming to enhance workplace safety while complying with regulatory standards. This guide provides a step-by-step checklist for B2B buyers to ensure they select the most suitable products and suppliers for their specific needs. By following these steps, you can streamline the procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it is essential to clearly define your technical requirements. Consider the types of machines you operate and the specific safety risks associated with them.

Illustrative image related to industrial safety guards

- Identify machine types: Different machines require different guarding solutions, such as lathe guards or milling machine shields.

- Assess risk factors: Evaluate the potential hazards your employees face, including moving parts and flying debris.

Step 2: Research Regulatory Compliance Requirements

Understanding local and international safety regulations is crucial for compliance and to avoid potential liabilities.

- Familiarize yourself with standards: Research regulations from organizations like OSHA or local equivalents in your region to ensure your guards meet safety standards.

- Document compliance: Request documentation from suppliers to verify that their products adhere to these regulations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your safety and quality standards.

- Request company profiles: Obtain information about their history, experience, and expertise in manufacturing safety guards.

- Check references: Ask for case studies or references from other businesses in similar industries or regions to validate their reliability.

Step 4: Assess Product Quality and Durability

The effectiveness of safety guards directly impacts employee safety and operational efficiency.

- Review material specifications: Look for high-quality materials that are resistant to wear and tear, such as heavy-duty polymers or stainless steel.

- Inquire about testing: Ensure the products have undergone rigorous testing for impact resistance and durability.

Step 5: Compare Pricing and Value

While cost is a significant factor, it should not be the only consideration.

- Obtain multiple quotes: Reach out to several suppliers to compare prices and ensure you are getting a competitive rate.

- Evaluate total cost of ownership: Consider installation, maintenance, and potential downtime costs when assessing overall value.

Step 6: Confirm Availability and Lead Times

Understanding supplier capacity and lead times is vital for effective project planning.

- Check stock levels: Ensure the supplier can meet your demand without significant delays.

- Inquire about customization: If you need specific modifications, ask about the timeline and feasibility for custom orders.

Step 7: Finalize Terms and Conditions

Before proceeding with a purchase, clarify all terms and conditions to avoid misunderstandings.

- Review warranty and support policies: Ensure you understand the warranty coverage and what support is available post-purchase.

- Negotiate payment terms: Establish clear payment terms that work for both parties to foster a positive supplier relationship.

By following this comprehensive checklist, B2B buyers can effectively navigate the procurement process for industrial safety guards, ensuring both compliance and enhanced workplace safety.

Comprehensive Cost and Pricing Analysis for industrial safety guards Sourcing

What Are the Key Cost Components for Sourcing Industrial Safety Guards?

When sourcing industrial safety guards, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to industrial safety guards

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for safety guards include steel, aluminum, and polymers. Each material’s durability, weight, and resistance to environmental factors can affect pricing.

-

Labor: Labor costs include the wages of workers involved in manufacturing, assembling, and installing safety guards. Variations in labor costs across different regions can influence the total price, especially when sourcing from countries with lower labor rates.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Understanding these costs can help buyers identify manufacturers that operate efficiently.

-

Tooling: Custom designs may require specialized tooling, which adds to the initial investment. Buyers should evaluate whether a supplier can absorb these costs or if they will be passed on.

-

Quality Control (QC): Ensuring that safety guards meet regulatory standards involves rigorous QC processes. Certifications from recognized bodies can add to costs but are essential for ensuring compliance and safety.

-

Logistics: Shipping costs vary based on the distance, mode of transport, and volume. Buyers should consider the total logistics cost, including customs duties and taxes, when calculating the total price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can provide leverage during negotiations.

What Factors Influence Pricing for Industrial Safety Guards?

Several factors can influence the pricing of industrial safety guards:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk often leads to discounts. Suppliers may have a MOQ that can affect initial purchasing decisions.

-

Specifications and Customization: Custom safety guards tailored to specific machinery or operational needs will generally incur higher costs due to the additional design and production efforts.

-

Materials and Quality Certifications: High-quality materials and certifications for safety standards can increase costs. Buyers should weigh the benefits of investing in superior products against budget constraints.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can impact pricing. Established suppliers with proven track records may charge a premium.

-

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) is essential, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

How Can B2B Buyers Negotiate Cost-Efficiency for Industrial Safety Guards?

To ensure cost-efficiency and maximize value, B2B buyers can employ several strategies:

-

Negotiate Terms: Engage suppliers in discussions regarding pricing, payment terms, and delivery schedules. Building a strong relationship can lead to better deals over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and potential downtime associated with the safety guards. A higher upfront investment may yield lower TCO.

-

Leverage Volume Discounts: If possible, consolidate orders or collaborate with other companies to meet MOQ thresholds for bulk discounts.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide insights into market pricing and help identify competitive offers.

-

Understand Pricing Nuances for International Sourcing: For buyers from regions like Africa, South America, the Middle East, and Europe, be aware of local regulations, tariffs, and logistical challenges that may affect pricing.

Disclaimer on Pricing

Prices for industrial safety guards can vary widely based on the factors discussed. The information provided here is for guidance only and does not represent specific quotations. Always consult suppliers for precise pricing tailored to your specific needs and circumstances.

Alternatives Analysis: Comparing industrial safety guards With Other Solutions

Exploring Alternative Solutions to Industrial Safety Guards

In today’s industrial environments, ensuring worker safety is paramount. While industrial safety guards are a widely adopted solution, various alternative methods and technologies can achieve similar safety objectives. Understanding these alternatives can empower B2B buyers to make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Industrial Safety Guards | Automated Safety Sensors | Safety Training Programs |

|---|---|---|---|

| Performance | Highly effective at preventing physical access to hazardous areas. | Can detect and alert operators of unsafe conditions in real-time. | Improves worker awareness and reduces risk through education. |

| Cost | Initial investment can be high, but long-term savings on injuries. | Moderate cost with ongoing maintenance for sensors. | Generally low-cost, but requires time investment for training. |

| Ease of Implementation | Requires installation, which may involve downtime. | Can be integrated with existing machinery but may need technical expertise. | Straightforward to implement but requires ongoing sessions and updates. |

| Maintenance | Low maintenance if properly installed; occasional inspections needed. | Requires regular calibration and updates to software/hardware. | No maintenance required, but refresher courses are beneficial. |

| Best Use Case | Ideal for high-risk areas with stationary machinery. | Best suited for dynamic environments with moving equipment. | Effective across all industries to cultivate a safety culture. |

What Are the Benefits and Drawbacks of Automated Safety Sensors?

Automated safety sensors offer a modern alternative to traditional industrial safety guards. These systems utilize advanced technology to monitor the environment continuously, detecting hazards and alerting personnel before accidents occur. The pros include real-time alerts and flexibility in various environments, but they may require substantial upfront investment and ongoing maintenance, which could be a drawback for some organizations.

Illustrative image related to industrial safety guards

How Do Safety Training Programs Compare in Effectiveness?

Safety training programs focus on educating employees about potential hazards and safe practices within the workplace. The primary advantage of this method is its low cost and ability to empower employees to recognize and address risks. However, the effectiveness of training can diminish over time without regular updates and refresher courses, leading to a potential gap in safety awareness.

Conclusion: How to Choose the Right Safety Solution for Your Business

Selecting the appropriate safety solution requires a comprehensive analysis of your specific operational needs, budget constraints, and the nature of your work environment. While industrial safety guards provide robust physical protection, alternatives like automated safety sensors and safety training programs can complement or even replace them, depending on your operational dynamics. B2B buyers should assess the unique risks associated with their machinery and workforce to determine the most effective and sustainable safety measures, ensuring compliance with industry regulations while fostering a culture of safety.

Essential Technical Properties and Trade Terminology for industrial safety guards

What Are the Key Technical Properties of Industrial Safety Guards?

When selecting industrial safety guards, understanding their technical specifications is essential for ensuring worker safety and regulatory compliance. Here are some critical specifications to consider:

1. Material Grade

The material grade of safety guards significantly impacts their durability and effectiveness. Common materials include steel, aluminum, and polycarbonate. Steel offers high strength and resistance to impacts, making it ideal for heavy machinery. Aluminum is lighter and corrosion-resistant, suitable for environments requiring mobility. Polycarbonate provides transparency and impact resistance, often used in areas where visibility is crucial. Selecting the right material ensures long-term performance and compliance with safety standards.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing of safety guards. This is particularly important in applications where precise fit is critical for safety and functionality. Tighter tolerances generally indicate higher manufacturing quality, reducing the risk of equipment failure or worker injury. In B2B contexts, understanding tolerances can help buyers ensure that the guards fit correctly with existing machinery, enhancing overall operational safety.

3. Impact Resistance

Impact resistance indicates how well a safety guard can withstand physical forces without deforming or breaking. This is crucial in environments with moving machinery or vehicles. Safety guards with high impact resistance protect workers from potential hazards, thereby reducing the risk of accidents and liability. When evaluating products, buyers should consider the impact resistance ratings to ensure they meet industry-specific safety requirements.

4. Compliance Standards

Safety guards must comply with various international safety standards, such as OSHA in the U.S. or the European Machinery Directive. These standards dictate the minimum safety requirements for equipment and materials used in industrial applications. Buyers should verify that the safety guards they purchase are certified to comply with relevant regulations, ensuring not only safety but also legal compliance.

5. Customization Options

Customization options allow buyers to tailor safety guards to specific applications or machinery. This can include modifications in size, shape, or additional features like access doors or interlocking systems. Customized solutions can enhance safety and efficiency by ensuring that the guards fit seamlessly into existing workflows and equipment. Understanding available customization options can help buyers make informed decisions that meet their specific operational needs.

What Are Common Trade Terms in the Industrial Safety Guard Sector?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of industrial safety guards, understanding whether a supplier is an OEM can affect product quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is important for buyers to understand, as it can impact inventory costs and supply chain management. Knowing the MOQ can help companies plan their purchasing strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and negotiate better terms. Crafting a detailed RFQ can lead to more favorable pricing and delivery terms.

Illustrative image related to industrial safety guards

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in the shipping process. These terms clarify who is responsible for shipping costs, insurance, and risk during transportation. Understanding Incoterms is vital for international transactions, as they can significantly affect overall costs and logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. This is a key consideration for buyers, as longer lead times can disrupt production schedules. Clear communication regarding lead times can help manage expectations and ensure timely delivery of safety guards.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing industrial safety guards, enhancing both safety and operational efficiency in their workplaces.

Illustrative image related to industrial safety guards

Navigating Market Dynamics and Sourcing Trends in the industrial safety guards Sector

What are the Current Market Dynamics and Key Trends in Industrial Safety Guards?

The industrial safety guards sector is witnessing significant transformation driven by various global factors. Increasing regulatory pressures, particularly from organizations such as OSHA, are compelling manufacturers across regions like Africa, South America, the Middle East, and Europe to invest in advanced safety solutions. In regions like Nigeria, where industrialization is rapidly evolving, the demand for effective safety guards is surging to mitigate workplace hazards. Similarly, European countries such as Germany are prioritizing innovative safety technologies to enhance operational efficiency and compliance.

Emerging technologies are reshaping sourcing trends in this sector. The integration of smart safety solutions, such as IoT-enabled monitoring systems, provides real-time data on equipment safety, allowing businesses to proactively manage risks. Additionally, modular and customizable safety guard systems are gaining traction, enabling companies to adapt quickly to changing operational needs without significant capital investment. As B2B buyers increasingly focus on total cost of ownership, suppliers offering durable materials and low-maintenance products are likely to gain a competitive edge.

Sourcing practices are also evolving, with a marked shift towards direct sourcing from manufacturers to reduce costs and enhance supply chain transparency. This trend is particularly relevant for international buyers seeking reliable partnerships to ensure consistent quality and timely delivery of safety solutions. As the market continues to expand, understanding local regulations and safety standards will be crucial for B2B buyers looking to navigate these dynamics effectively.

Illustrative image related to industrial safety guards

How Important is Sustainability and Ethical Sourcing in the Industrial Safety Guards Sector?

Sustainability and ethical sourcing are becoming paramount in the industrial safety guards sector, driven by growing environmental concerns and consumer demand for responsible practices. The production of safety guards often involves materials that can have significant environmental impacts, such as plastics and metals. As a result, companies are increasingly seeking suppliers that prioritize eco-friendly materials and sustainable manufacturing processes. For instance, sourcing safety guards made from recycled or biodegradable materials can significantly reduce a company’s carbon footprint.

Ethical supply chains are equally important, as businesses strive to ensure that their suppliers adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurance to B2B buyers that their sourcing decisions align with their corporate social responsibility objectives. Additionally, companies that actively promote sustainability often see enhanced brand reputation and customer loyalty, which are critical in today’s competitive marketplace.

As international buyers increasingly prioritize sustainability, it is essential to engage with suppliers who can provide transparency regarding their sourcing practices and environmental impact. This not only helps in complying with local regulations but also positions companies favorably in markets that value ethical business practices.

Illustrative image related to industrial safety guards

What is the Brief Evolution and History of Industrial Safety Guards?

The evolution of industrial safety guards can be traced back to the early 20th century when workplace safety regulations began to take shape. Initially, safety measures were rudimentary, focusing primarily on basic barriers and shields to protect workers from hazards. Over the decades, advancements in technology and a deeper understanding of workplace safety led to the development of more sophisticated guarding systems.

By the mid-20th century, regulatory bodies began to enforce stricter safety standards, compelling industries to adopt comprehensive safety solutions. This period saw the introduction of machine-specific guards and barriers designed to address particular risks associated with various types of machinery. In recent years, the integration of smart technologies, such as IoT and automation, has further transformed the landscape, enabling real-time monitoring and enhanced safety measures.

Today, industrial safety guards are not just compliance tools but are integral to operational efficiency and risk management strategies for businesses worldwide. The focus has shifted towards creating adaptable, modular systems that can evolve with changing industry demands, ensuring that safety remains a top priority in the industrial sector.

Illustrative image related to industrial safety guards

Frequently Asked Questions (FAQs) for B2B Buyers of industrial safety guards

-

How do I solve safety compliance issues with industrial safety guards?

Ensuring compliance with local and international safety regulations is crucial when sourcing industrial safety guards. Start by researching the specific safety standards applicable to your region, such as OSHA in the U.S. or EU regulations in Europe. Collaborate with suppliers who provide certified products that meet these standards. Regular audits and employee training on the proper use of safety guards can further mitigate compliance issues. Additionally, consider consulting safety experts or legal advisors to align your safety measures with regulatory requirements. -

What is the best type of safety guard for protecting workers from machinery?

The best type of safety guard depends on the specific machinery and the associated risks. For example, fixed guards are ideal for machines with minimal access points, while interlocking guards are suitable for equipment requiring frequent access. For operations involving high-speed machinery, consider robust materials like polycarbonate or steel that can withstand impact. Evaluate your operational needs, conduct a risk assessment, and consult with safety specialists to choose the most effective guard for your environment. -

How can I ensure the quality of industrial safety guards when sourcing internationally?

To ensure quality when sourcing industrial safety guards internationally, start by vetting suppliers thoroughly. Look for manufacturers with ISO certifications and a proven track record in safety products. Request product samples and check for compliance with relevant safety standards. It’s also beneficial to read reviews and obtain references from other businesses. Establish clear quality assurance protocols and consider conducting factory visits or audits if feasible to assess manufacturing processes and materials firsthand. -

What are the typical minimum order quantities (MOQ) for industrial safety guards?

Minimum order quantities for industrial safety guards can vary significantly by supplier and product type. Some manufacturers may have MOQs as low as 50 units for standard products, while customized solutions might require higher quantities to justify production costs. When negotiating with suppliers, express your needs clearly and inquire about flexibility in MOQs, especially if you are a small to medium-sized enterprise. Many suppliers are willing to accommodate smaller orders for first-time customers to build long-term relationships. -

What payment terms should I expect when ordering industrial safety guards?

Payment terms for industrial safety guards often depend on the supplier’s policies and the size of your order. Common practices include a deposit (typically 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established customers. Always clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, and ensure that all terms are documented in the purchase agreement to avoid disputes. -

How long does it typically take for industrial safety guards to be delivered internationally?

Delivery times for industrial safety guards can vary based on the supplier’s location, manufacturing lead times, and shipping logistics. Generally, expect anywhere from 4 to 12 weeks for international shipments. Factors such as customs clearance, freight forwarding, and local delivery can also impact timelines. When placing an order, request a detailed shipping schedule from your supplier and consider using expedited shipping options if time is critical. Tracking shipments can help you stay informed about delivery progress. -

Can I customize industrial safety guards to fit my specific needs?

Yes, many manufacturers offer customization options for industrial safety guards to meet specific operational requirements. Customizations may include adjustments in size, material, color, and additional safety features like access points or visibility enhancements. When discussing your needs with potential suppliers, provide detailed specifications and any relevant safety standards to ensure compliance. Be prepared to discuss lead times and costs associated with custom orders, as these can differ from off-the-shelf products. -

What logistics considerations should I keep in mind when sourcing industrial safety guards?

Logistics play a vital role in sourcing industrial safety guards, particularly in international trade. Consider factors such as shipping costs, delivery timelines, and customs regulations in your target market. It’s essential to work with suppliers who have experience in handling international shipments and can provide support with documentation and customs clearance. Additionally, evaluate transportation options (air, sea, land) based on your budget and urgency. Establishing a reliable logistics plan will help ensure timely and cost-effective delivery of your safety equipment.

Top 4 Industrial Safety Guards Manufacturers & Suppliers List

1. Strongarm Store – Safety Barriers & Guards

Domain: strongarmstore.com

Registered: 2009 (16 years)

Introduction: Safety Barriers & Guards include various products such as Guard Rails, Machine Guards (Fixed), Machine Guard Fencing, Post Protectors, Column Guards, and Safety Bollards. These products are designed to enhance safety in industrial environments by providing physical barriers and protection for workers and equipment.

2. Parco – Heavy-Duty Machine Guarding Solutions

Domain: parco-inc.com

Registered: 2004 (21 years)

Introduction: Parco’s heavy-duty machine guarding solutions are designed to provide robust protection for both personnel and equipment in high-demand industrial environments. Constructed with T-slot aluminum framing and a variety of protective panels, including wire mesh, polycarbonate, and steel, these guards are built to withstand heavy impacts and ensure safety around machinery with moving parts. Fully custo…

3. Omega – Safety Barriers

Domain: omegaindl.com

Registered: 1997 (28 years)

Introduction: This company, Omega – Safety Barriers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Cascade Industrial Safety & Security – GuardianCoil® Coiled Wire Fabric Systems

Domain: cascade-safetyandsecurity.com

Registered: 2014 (11 years)

Introduction: Cascade Industrial Safety & Security specializes in GuardianCoil® coiled wire fabric systems for industrial safety applications. Key products include: 1. Press Guard Kits: Pre-engineered systems for machines 24″-72″ wide and 58″-87″ high, featuring adjustable steel pipe assembly, industrial safety hooks, and steel coiled wire fabric curtain in Safety Black finish. 2. Custom Press Guards: Tailored …

Strategic Sourcing Conclusion and Outlook for industrial safety guards

In the dynamic landscape of industrial safety, the strategic sourcing of safety guards is paramount for protecting personnel and enhancing operational efficiency. By investing in high-quality machine guards and barriers, companies can not only comply with safety regulations but also minimize the risk of accidents and equipment damage. This proactive approach fosters a safer work environment, which is essential for maintaining productivity and reducing downtime.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the choice of safety solutions must align with specific operational needs and regulatory frameworks. Prioritizing products that are rigorously tested and certified ensures that your investment yields long-term benefits in safety and compliance.

Looking ahead, the evolution of industrial safety solutions will continue to emphasize innovation and adaptability. As global standards evolve, so too should your sourcing strategies. Embrace advancements in materials and technology that offer enhanced durability and functionality. Now is the time to reassess your safety strategies, engage with trusted suppliers, and invest in solutions that will safeguard your workforce and operations for years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.