Top 4 Greg Smith Equipment Suppliers (And How to Choose)

Introduction: Navigating the Global Market for greg smith equipment

In the dynamic world of automotive equipment, sourcing reliable and high-quality Greg Smith equipment can pose significant challenges for international B2B buyers. Whether you are a dealer in Brazil seeking robust car lifts or a service center in Nigeria looking for tire changers, the need for dependable suppliers is paramount. This guide serves as an essential resource, providing a thorough exploration of the types of Greg Smith equipment available, their applications, and strategic insights into supplier vetting processes.

Understanding the nuances of the global market is critical for decision-makers in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide addresses key factors such as equipment specifications, pricing comparisons, and logistical considerations. By equipping buyers with actionable insights, we aim to enhance their ability to make informed purchasing decisions that align with their operational needs and budget constraints.

Through detailed analysis and expert recommendations, this guide empowers businesses to navigate the complexities of sourcing Greg Smith equipment confidently. From assessing product quality to understanding warranty options, B2B buyers will gain the knowledge necessary to optimize their procurement strategies and ensure they invest in equipment that delivers both performance and value. Prepare to enhance your operations with the right tools for success in the competitive automotive landscape.

Understanding greg smith equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Post Lifts | Simple design, cost-effective, suitable for light to medium vehicles | Automotive repair shops, dealerships | Pros: Affordable, easy to install; Cons: Limited height and weight capacity. |

| Four-Post Lifts | Greater weight capacity, ideal for heavier vehicles, often includes rolling jacks | Heavy-duty automotive service centers | Pros: Versatile for various vehicle types; Cons: Requires more space. |

| Scissor Lifts | Compact design, portable, ideal for limited space environments | Small garages, mobile repair services | Pros: Space-saving, easy to maneuver; Cons: Lower lifting capacity compared to other lifts. |

| Tire Changers | Automated features, various sizes for different tire types | Tire shops, automotive repair facilities | Pros: Increases efficiency, reduces manual labor; Cons: Higher initial investment. |

| Wheel Balancers | Advanced technology for precision balancing, available in manual and automatic models | Auto service shops, tire retailers | Pros: Enhances tire longevity, improves vehicle performance; Cons: Maintenance can be complex. |

What are the Characteristics of Two-Post Lifts and Their B2B Suitability?

Two-post lifts are characterized by their straightforward design, which allows for easy access to the undercarriage of vehicles. They typically accommodate light to medium vehicles, making them ideal for automotive repair shops and dealerships. When considering a purchase, B2B buyers should evaluate the lift’s weight capacity and installation requirements, as these factors can impact operational efficiency and safety.

How Do Four-Post Lifts Differ and What Are Their Key Applications?

Four-post lifts offer a more robust solution for heavier vehicles, featuring a design that supports greater weight capacities. They often come with rolling jacks, which enhance their versatility for various service tasks. These lifts are suitable for heavy-duty automotive service centers that handle a range of vehicles, from cars to trucks. Buyers must consider the space requirements and installation complexity, as these lifts require more floor area compared to two-post options.

What Advantages Do Scissor Lifts Provide for B2B Buyers?

Scissor lifts are compact and portable, making them an excellent choice for businesses with limited space. Their design allows for easy maneuverability, which is particularly beneficial for small garages and mobile repair services. While they are advantageous for space-saving, B2B buyers should be aware that scissor lifts typically have lower lifting capacities than their two- and four-post counterparts, which may limit their application for heavier vehicles.

Why Are Tire Changers Essential for Automotive Service Providers?

Tire changers are designed to automate the tire replacement process, significantly enhancing efficiency in tire shops and automotive repair facilities. With various models available, buyers can select machines that suit different tire sizes and types. While the initial investment can be higher, the reduction in manual labor and time savings make tire changers a valuable asset for businesses looking to improve service speed and customer satisfaction.

What Role Do Wheel Balancers Play in Vehicle Maintenance?

Wheel balancers are crucial for ensuring the longevity and performance of tires by providing precise balancing. Available in both manual and automatic models, these machines are essential for auto service shops and tire retailers. B2B buyers should consider the technology used in the balancers, as advanced features can enhance accuracy but may also increase maintenance complexity. Investing in a quality wheel balancer can lead to improved customer satisfaction and repeat business.

Key Industrial Applications of greg smith equipment

| Industry/Sector | Specific Application of greg smith equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Car Lifts (2-Post and 4-Post) | Increased efficiency in vehicle servicing and repair | Capacity requirements, compliance with local regulations, and warranty support |

| Tire Retailers | Tire Changers and Wheel Balancers | Enhanced productivity and accuracy in tire services | Equipment compatibility with various tire sizes, ease of use, and training availability |

| Fleet Maintenance | Alignment Machines | Improved vehicle performance and reduced tire wear | Durability for heavy usage, calibration standards, and after-sales service |

| Motorcycle Dealerships | Specialty Lifts for Motorcycles | Safe and efficient servicing of motorcycles | Load capacity, space considerations, and brand reputation |

| Construction Equipment Rentals | Scissor Lifts | Safe access to elevated work areas | Compliance with safety standards, mobility features, and maintenance requirements |

How Does Greg Smith Equipment Serve Automotive Repair Shops?

In automotive repair shops, Greg Smith Equipment’s car lifts, particularly the 2-post and 4-post lifts, are essential tools that enhance vehicle servicing efficiency. These lifts allow mechanics to work on vehicles at a comfortable height, improving ergonomics and reducing the risk of injury. For international buyers, especially from regions like Africa and South America, it is crucial to consider the lift’s load capacity and compliance with local safety regulations. Additionally, warranty support and the availability of spare parts are significant factors that can influence purchasing decisions.

What Benefits Do Tire Retailers Gain from Using Tire Changers and Wheel Balancers?

Tire retailers benefit significantly from incorporating Greg Smith Equipment’s tire changers and wheel balancers into their operations. These machines streamline the process of changing and balancing tires, which is crucial for maintaining customer satisfaction and operational efficiency. Retailers in regions such as the Middle East must focus on equipment compatibility with a variety of tire sizes and types. Furthermore, ease of use and training options for staff can enhance productivity and reduce service times, making these factors vital for sourcing decisions.

How Can Fleet Maintenance Operations Leverage Alignment Machines?

Fleet maintenance operations can significantly enhance vehicle performance and longevity by utilizing Greg Smith Equipment’s alignment machines. Proper alignment reduces tire wear and improves fuel efficiency, which is critical for fleet operators looking to minimize operational costs. Buyers from Europe and Africa should prioritize machines that can withstand heavy usage and adhere to calibration standards. Additionally, after-sales service and support are essential to ensure that the equipment remains operational, reducing downtime for fleet vehicles.

Why Are Specialty Lifts Important for Motorcycle Dealerships?

Motorcycle dealerships find Greg Smith Equipment’s specialty lifts indispensable for servicing bikes safely and effectively. These lifts provide the necessary height and stability to work on various motorcycle models, ensuring mechanics can perform maintenance without risk. International buyers must consider load capacity and the specific requirements of different motorcycle types when sourcing these lifts. Reputation and reliability of the brand also play a crucial role in purchasing decisions, particularly in competitive markets.

What Role Do Scissor Lifts Play in Construction Equipment Rentals?

In the construction equipment rental sector, Greg Smith Equipment’s scissor lifts are vital for providing safe access to elevated work areas. These lifts enable workers to perform tasks at heights without compromising safety. For companies in regions like Brazil, compliance with local safety standards and mobility features are key considerations when sourcing scissor lifts. Additionally, understanding maintenance requirements and the availability of parts can ensure the longevity and reliability of the equipment in demanding rental environments.

3 Common User Pain Points for ‘greg smith equipment’ & Their Solutions

Scenario 1: Difficulty in Product Availability and Stock Issues

The Problem: B2B buyers often encounter frustration when they find that the specific equipment they need, such as car lifts or tire changers, is out of stock or unavailable. This situation is particularly challenging for automotive service centers that rely on timely access to equipment to meet customer demands. The inability to procure necessary tools can lead to lost business opportunities, delays in service, and decreased customer satisfaction. Additionally, unclear communication regarding stock levels can further exacerbate these issues, leaving buyers feeling unsupported and uncertain.

The Solution: To mitigate issues related to product availability, B2B buyers should establish direct lines of communication with Greg Smith Equipment’s sales representatives. It’s advisable to inquire about stock levels before making a purchasing decision and to ask for estimated lead times for items that are currently unavailable. Buyers can also consider alternative products that may meet their operational needs while waiting for specific items to become available. Furthermore, leveraging the option of placing orders in advance or signing up for restock notifications can help ensure that they are among the first to know when items are back in stock. This proactive approach will not only streamline the purchasing process but also strengthen the relationship with the supplier.

Scenario 2: Lack of Technical Support and After-Sales Service

The Problem: After purchasing equipment from Greg Smith Equipment, some buyers report challenges in obtaining technical support or warranty services. This lack of support can be particularly concerning for B2B buyers who require ongoing maintenance and troubleshooting assistance to keep their operations running smoothly. When equipment malfunctions or requires repairs, the absence of responsive customer service can lead to prolonged downtimes, negatively impacting business productivity and profitability.

The Solution: To address concerns about after-sales support, buyers should ask detailed questions about warranty terms and available customer service channels before finalizing their purchase. It’s crucial to clarify how to access technical support and what the expected response times are for service requests. Additionally, buyers should document all communications regarding equipment issues and maintain records of any warranty claims. Building a strong relationship with the sales team can also facilitate better access to support when needed. Engaging in training sessions provided by the supplier can empower staff with knowledge about the equipment, thereby reducing reliance on external support for minor issues.

Scenario 3: Confusion Over Product Specifications and Compatibility

The Problem: Another common pain point for B2B buyers is the confusion surrounding the specifications and compatibility of equipment. With a diverse product range, buyers may struggle to determine which car lift or alignment machine is best suited for their specific needs. This confusion can lead to purchasing errors, resulting in equipment that does not meet operational requirements or is incompatible with existing tools. Such missteps can not only incur additional costs but can also hinder service efficiency.

The Solution: To effectively navigate product specifications, B2B buyers should conduct thorough research before making a purchase. This includes understanding the operational needs of their service center and how specific equipment features align with those needs. Engaging with knowledgeable sales representatives at Greg Smith Equipment can provide valuable insights and recommendations tailored to the buyer’s operational context. Buyers should prepare a list of questions regarding load capacities, dimensions, and compatibility with existing tools before discussions. Additionally, requesting product demonstrations or seeking peer reviews can aid in making informed decisions. By taking these steps, buyers can ensure they select equipment that optimally supports their business operations.

Strategic Material Selection Guide for greg smith equipment

When selecting materials for automotive equipment, such as those offered by Greg Smith Equipment, it is crucial to consider various factors that affect performance, durability, and cost. Here, we analyze four common materials used in automotive equipment, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Steel in Automotive Equipment?

Steel is a widely used material in automotive equipment due to its high strength and durability. Key properties include excellent tensile strength, temperature tolerance, and resistance to deformation under load. Steel can withstand high pressures, making it suitable for hydraulic systems and heavy-duty applications.

Pros & Cons: The advantages of steel include its cost-effectiveness and ease of manufacturing, allowing for a wide range of shapes and sizes. However, steel is susceptible to corrosion if not properly treated, which can limit its lifespan in humid or corrosive environments.

Impact on Application: In automotive lifts and other equipment, steel’s strength allows for the safe lifting of heavy vehicles. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings.

How Does Aluminum Compare in Terms of Performance and Cost?

Aluminum is another common material, known for its lightweight properties and corrosion resistance. It is ideal for applications where weight reduction is crucial, such as in portable lifts or equipment designed for ease of transport.

Pros & Cons: Aluminum offers excellent resistance to corrosion and is easier to handle due to its lower weight. However, it is generally more expensive than steel and may not provide the same level of strength for heavy-duty applications.

Impact on Application: In environments where weight is a concern, aluminum can enhance mobility and ease of use. International buyers should be aware of the higher costs associated with aluminum products, which may influence purchasing decisions.

What Role Does Composite Material Play in Automotive Equipment?

Composite materials, often a combination of resin and fibers, are increasingly used in automotive applications due to their high strength-to-weight ratio and resistance to environmental factors.

Pros & Cons: Composites are lightweight and resistant to corrosion and chemical exposure, making them suitable for various automotive applications. However, they can be more complex to manufacture and repair, potentially leading to higher costs.

Impact on Application: Composites are particularly useful in specialized equipment that requires both strength and lightweight properties. Buyers should consider the manufacturing capabilities of suppliers in their region, as not all manufacturers may have the technology to produce or repair composite materials effectively.

What Are the Benefits of Using Cast Iron in Automotive Equipment?

Cast iron is often used in automotive equipment due to its excellent wear resistance and ability to dampen vibrations. It is particularly suitable for components that endure significant stress and wear over time.

Pros & Cons: The durability of cast iron makes it a reliable choice for heavy-duty applications. However, it is heavier than steel and aluminum, which can be a disadvantage in applications where weight is a concern. Additionally, cast iron can be brittle, making it susceptible to cracking under extreme conditions.

Impact on Application: In automotive lifts and machinery, cast iron can provide stability and longevity. Buyers in regions prone to extreme temperatures should consider how cast iron will perform under their specific environmental conditions.

Summary Table of Material Selection for Greg Smith Equipment

| Material | Typical Use Case for greg smith equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Car lifts, hydraulic systems | High strength and durability | Susceptible to corrosion | Low |

| Aluminum | Portable lifts, lightweight equipment | Lightweight and corrosion-resistant | Higher cost than steel | Med |

| Composite | Specialized automotive components | High strength-to-weight ratio | Complex manufacturing and repair | High |

| Cast Iron | Heavy-duty machinery, stability components | Excellent wear resistance | Heavier and brittle | Med |

This analysis provides B2B buyers with a comprehensive understanding of material properties and their implications for automotive equipment. By considering these factors, businesses can make informed decisions that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for greg smith equipment

What Are the Main Stages of Manufacturing Processes for Greg Smith Equipment?

The manufacturing process for Greg Smith Equipment, particularly in automotive lifts and related machinery, can be broken down into several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets quality and performance standards.

Material Preparation

This initial stage involves selecting high-quality raw materials, such as steel and aluminum, which are vital for the structural integrity of automotive lifts. Suppliers are often evaluated based on their ability to deliver materials that meet specific standards. The materials undergo testing to check for strength and durability before being approved for use.

Forming

In the forming stage, raw materials are shaped into usable parts through various techniques such as cutting, bending, and welding. Advanced machinery is typically employed to ensure precision. For example, laser cutting technology may be used to achieve intricate designs with minimal material waste, while robotic welding ensures consistent quality and reduces human error.

Assembly

The assembly stage involves bringing together all components, including hydraulic systems, electrical wiring, and safety features. Trained technicians follow strict protocols to ensure that each lift is assembled correctly. This stage may also involve the use of jigs and fixtures to maintain alignment and accuracy throughout the process.

Finishing

Finally, the finishing stage includes surface treatments such as powder coating or painting to protect the equipment from corrosion and wear. This not only enhances the aesthetic appeal but also extends the lifespan of the equipment. Quality checks are conducted at this stage to ensure that the finish meets industry standards.

How Is Quality Assurance Implemented in Manufacturing Processes?

Quality assurance (QA) is critical in the manufacturing of Greg Smith Equipment to ensure that products meet international and industry-specific standards. The QA process includes several checkpoints and testing methods that help maintain high quality throughout production.

Illustrative image related to greg smith equipment

Relevant International Standards

For B2B buyers, understanding the certifications that Greg Smith Equipment adheres to is essential. ISO 9001, an internationally recognized standard for quality management systems, ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain industrial equipment signify compliance with safety and quality standards.

Quality Checkpoints

Quality assurance involves multiple checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Materials must meet predefined specifications to be accepted.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor compliance with quality standards. This may involve checking dimensions, material properties, and assembly accuracy.

-

Final Quality Control (FQC): Once the equipment is fully assembled, a comprehensive inspection is performed. This includes functional testing, load testing, and safety evaluations to ensure the equipment operates as intended.

What Testing Methods Are Commonly Used for Quality Assurance?

To maintain high standards, various testing methods are employed throughout the manufacturing process:

-

Load Testing: This test simulates the maximum load that the equipment will handle during operation. For automotive lifts, this might involve lifting weights that exceed the rated capacity to ensure safety and performance.

-

Hydraulic Testing: For hydraulic lifts, pressure tests are conducted to ensure there are no leaks and that the system operates efficiently under pressure.

-

Electrical Testing: For equipment with electrical components, tests are performed to check for proper functionality and safety compliance, including insulation resistance and continuity testing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital to ensure they receive high-quality products. Here are several strategies:

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s quality control practices. Buyers can assess the processes, equipment, and personnel involved in production.

-

Quality Reports: Requesting detailed quality reports from the supplier can help buyers understand the results of various tests and inspections conducted throughout the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection agencies to verify compliance with international standards can provide an unbiased assessment of the supplier’s quality assurance efforts. This is particularly important for buyers unfamiliar with local standards or practices.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of certain nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulatory requirements. For instance, equipment sold in Europe must comply with CE marking requirements, while equipment in the U.S. may need to adhere to ANSI standards. Understanding these regulations is crucial for compliance and safety.

-

Cultural Differences: Business practices and quality perceptions can differ significantly across cultures. Buyers should take the time to understand these differences to facilitate smoother negotiations and ensure that quality expectations are clearly communicated.

-

Supply Chain Transparency: Buyers should seek suppliers who are transparent about their sourcing and manufacturing processes. This transparency can help ensure that materials are ethically sourced and that labor practices meet international standards.

By understanding the manufacturing processes and quality assurance practices of Greg Smith Equipment, international B2B buyers can make informed decisions that align with their operational needs and quality expectations. This knowledge not only helps in selecting the right supplier but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘greg smith equipment’

In this guide, we present a practical checklist for B2B buyers aiming to procure equipment from Greg Smith Equipment. Whether you are sourcing automotive lifts, tire changers, or alignment machines, following these steps will ensure a successful purchase that meets your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial for a successful procurement process. Determine the types of equipment you need, including weight capacities, features, and any specific certifications (e.g., ALI certification for lifts). This clarity will streamline your search and help suppliers provide you with the most suitable options.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers like Greg Smith Equipment. Look for companies with a solid reputation in the industry and positive customer feedback. Utilize platforms such as trade shows, online reviews, and industry forums to gather insights on reliability and service quality.

Step 3: Evaluate Supplier Credentials and Experience

Before making a commitment, vet the suppliers by checking their credentials and industry experience. Look for certifications, such as ISO or ALI, that demonstrate adherence to quality and safety standards. Additionally, consider the supplier’s history in the market—experience often correlates with reliability and expertise.

Step 4: Request Detailed Quotes

Once you have a shortlist, request detailed quotes from each supplier. Ensure that the quotes include all costs, such as shipping, installation, and any additional fees. Comparing comprehensive quotes will help you identify the best overall value rather than just the lowest price.

Step 5: Assess Customer Support and Warranty Options

Quality customer support can significantly impact your experience with the equipment. Inquire about warranty terms and post-purchase support services. A supplier that offers robust support can save you time and money in the long run, especially for equipment that requires maintenance or troubleshooting.

Step 6: Check Shipping and Delivery Terms

Understanding shipping logistics is essential, especially for international buyers. Confirm the delivery timelines, shipping methods, and whether the supplier offers free shipping for larger orders. Be mindful of potential customs duties and regulations that could affect the delivery process to your region.

Step 7: Finalize Your Purchase and Review Terms

Once you have selected a supplier, carefully review all purchase terms before finalizing the order. Pay attention to payment terms, return policies, and any conditions related to warranty claims. A clear understanding of these terms will help prevent misunderstandings and ensure a smoother transaction.

By following this checklist, you can effectively navigate the procurement process for Greg Smith Equipment, ensuring that you select the right products from a reliable supplier while minimizing risks associated with international purchasing.

Comprehensive Cost and Pricing Analysis for greg smith equipment Sourcing

What Are the Key Cost Components in Sourcing Greg Smith Equipment?

When sourcing equipment from Greg Smith, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of raw materials directly impacts the performance and longevity of automotive equipment. High-quality steel and advanced components in lifts and other machinery contribute to higher upfront costs but can lead to lower maintenance expenses over time.

-

Labor: Labor costs encompass both the manufacturing workforce and assembly teams. Skilled labor is essential for ensuring that equipment is built to high standards, which may influence the overall pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Manufacturers often distribute these costs across all products, affecting the unit price.

-

Tooling: Specialized tools and machinery required for production can significantly impact costs. If custom tooling is necessary for specific equipment, this can lead to increased prices.

-

Quality Control (QC): Rigorous QC processes ensure that equipment meets industry standards and certifications. The costs associated with these processes are factored into the final pricing.

-

Logistics: Shipping and handling fees, especially for international orders, can add to the total cost. It’s important to consider the logistics involved in transporting heavy machinery to various global locations.

-

Margin: The profit margin set by Greg Smith Equipment also plays a role in the final price. Understanding this margin can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing Costs?

Several factors influence the pricing of Greg Smith equipment, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts. Buyers should evaluate their needs and consider bulk purchasing to optimize costs.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the need for customization against standard options that may be more cost-effective.

-

Materials and Quality Certifications: Equipment that meets higher quality standards or certifications may come with a premium price. However, investing in certified equipment can lead to lower Total Cost of Ownership (TCO) through reduced failures and maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers like Greg Smith may charge higher prices due to their brand equity and customer service standards.

-

Incoterms: Understanding the agreed terms of shipment (Incoterms) is vital. Different Incoterms can significantly influence shipping costs and responsibilities, impacting the total landed cost of the equipment.

What Are Effective Buyer Tips for Negotiating Equipment Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic negotiation and cost-efficiency can lead to significant savings:

-

Research and Compare: Investigate similar products from different suppliers. Understanding the market landscape can empower buyers to negotiate better terms.

-

Leverage Total Cost of Ownership (TCO): When discussing prices, emphasize the long-term savings from lower maintenance and higher quality. This perspective can justify a higher initial investment.

-

Negotiate Terms and Conditions: Don’t hesitate to discuss payment terms, warranties, and after-sales support. Favorable terms can enhance the overall value of the purchase.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations and regional economic conditions that may affect pricing. It’s essential to account for these factors when budgeting.

-

Seek Volume Discounts: If planning to make repeat purchases, communicate this to the supplier. Establishing a long-term relationship can lead to better pricing and support.

Disclaimer on Indicative Prices

Prices for Greg Smith equipment are subject to change based on market conditions, availability, and individual buyer negotiations. It is advisable for buyers to request quotes directly from suppliers to obtain the most accurate and current pricing.

Alternatives Analysis: Comparing greg smith equipment With Other Solutions

Understanding the Importance of Evaluating Alternatives in Equipment Solutions

When it comes to selecting automotive equipment, B2B buyers often face a plethora of choices. Evaluating alternatives to ‘Greg Smith Equipment’ can provide valuable insights into which solution best meets the unique needs of automotive service centers and dealerships. This analysis focuses on comparing Greg Smith Equipment with two viable alternatives: Atlas Automotive Equipment and BendPak. Each option has distinct characteristics that can influence a buyer’s decision based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Greg Smith Equipment | Atlas Automotive Equipment | BendPak |

|---|---|---|---|

| Performance | Limited product range; mixed reviews on quality and support | High-quality lifts; strong reputation for reliability | Premium builds; excellent durability and performance |

| Cost | Competitive pricing; average cost for average quality | Cost-effective with good value for quality | Higher price point; premium features justify cost |

| Ease of Implementation | Challenging; inconsistent customer support reported | Straightforward ordering process; responsive customer service | Smooth installation process; user-friendly |

| Maintenance | Mixed reviews on after-sales support and warranty handling | Good maintenance support; knowledgeable staff | Excellent warranty service and robust support system |

| Best Use Case | Small-scale operations needing budget solutions | General automotive service centers looking for reliability | High-volume shops requiring heavy-duty equipment |

Analyzing Alternatives in Detail

Atlas Automotive Equipment

Atlas offers a robust lineup of automotive equipment, including car lifts, wheel balancers, and tire changers. The performance of Atlas products is generally well-reviewed, with a strong emphasis on quality and durability. Their pricing structure is competitive, often providing a better value compared to more expensive brands. The ordering and support process is user-friendly, making it easier for buyers to obtain the necessary equipment without hassle. However, while Atlas is a reliable choice, it may not cater to niche requirements that specific high-performance operations might demand.

BendPak

BendPak is recognized for its premium automotive equipment, particularly in the lift category. Their products are engineered for durability, making them suitable for high-volume automotive service shops. Although BendPak’s pricing is on the higher end, the investment is often justified by the long-term reliability and superior performance of their equipment. Buyers can expect excellent customer support and maintenance services, ensuring that equipment downtime is minimized. However, for smaller operations or those with tight budgets, BendPak’s higher costs may be a barrier to entry.

Making the Right Choice for Your Business

In conclusion, selecting the right equipment solution requires careful consideration of your specific needs and operational capacity. B2B buyers should weigh the performance and support aspects of each alternative against their budget constraints and the nature of their operations. While Greg Smith Equipment might offer competitive pricing, alternatives like Atlas Automotive Equipment and BendPak present compelling options with better performance and customer support. Ultimately, the best choice will align with your operational goals, ensuring that you invest in equipment that enhances productivity and service quality.

Essential Technical Properties and Trade Terminology for greg smith equipment

What Are the Key Technical Properties of Greg Smith Equipment?

When considering Greg Smith Equipment for automotive needs, understanding the critical specifications is essential for B2B buyers. Here are some vital technical properties to be aware of:

-

Load Capacity

This specification indicates the maximum weight that a piece of equipment can safely lift or support. For instance, Greg Smith offers lifts with capacities ranging from 8,000 lbs to 15,000 lbs. Knowing the load capacity is crucial for buyers to ensure the equipment meets the demands of their specific automotive services, helping to prevent accidents and equipment failure. -

Material Grade

The material used in manufacturing equipment significantly affects durability and performance. For instance, high-grade steel is commonly used in lifts for its strength and resilience. Understanding material grades helps B2B buyers assess the longevity and reliability of their investment, ensuring that they choose equipment that can withstand the rigors of daily use. -

Certifications (e.g., ALI Certification)

Equipment that is certified by organizations such as the Automotive Lift Institute (ALI) meets rigorous safety and performance standards. This is particularly important for B2B buyers who want assurance that the equipment is safe and reliable for their operations. Certification can also influence insurance and liability considerations. -

Footprint Dimensions

The physical dimensions of equipment, such as lifts, determine how much space it will occupy in a workshop. Buyers need to assess their available space to ensure that the equipment fits without disrupting workflow. Understanding footprint dimensions helps in maximizing operational efficiency and optimizing shop layout. -

Adjustability Features

Many automotive lifts offer adjustable heights or widths to accommodate various vehicle types. This adaptability is essential for service centers that handle a diverse range of vehicles. Knowing the adjustability features allows buyers to select equipment that can cater to their specific service requirements, enhancing versatility.

What Are Common Trade Terms in the Greg Smith Equipment Industry?

Understanding the jargon used in the automotive equipment industry can facilitate smoother transactions and communication. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that are used in the assembly of vehicles. In the context of Greg Smith Equipment, knowing whether parts are OEM or aftermarket can impact the quality and compatibility of the equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budget planning and inventory management, particularly for equipment purchases that require significant upfront investment. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific equipment or services. For buyers considering Greg Smith Equipment, submitting an RFQ can lead to competitive pricing and tailored offers, ensuring that they receive the best possible deal. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. For international buyers from regions like Africa or South America, understanding Incoterms is essential to navigate shipping costs, risks, and delivery terms. -

Warranty Period

This term refers to the length of time that a product is guaranteed against defects. Knowing the warranty period can provide peace of mind and protect against potential future costs. B2B buyers should inquire about warranty terms for Greg Smith Equipment to ensure they are covered for a reasonable duration after purchase. -

Lead Time

Lead time is the time it takes from placing an order to receiving the equipment. Understanding lead times is crucial for B2B buyers to manage their operations effectively and plan for any disruptions in service due to equipment installation or replacement.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when selecting Greg Smith Equipment, ensuring that they invest wisely in their automotive service capabilities.

Navigating Market Dynamics and Sourcing Trends in the greg smith equipment Sector

What Are the Key Drivers Influencing the Greg Smith Equipment Market?

The global market for automotive equipment, including brands like Greg Smith Equipment, is influenced by several key drivers. First, the increasing demand for automotive services in emerging markets, particularly in Africa and South America, is propelling growth. Countries like Brazil and Nigeria are experiencing a surge in vehicle ownership, leading to a higher demand for quality automotive service equipment. This trend is further bolstered by advancements in technology, such as automation and smart equipment, which are becoming essential for efficient operations.

Moreover, the ongoing digital transformation across industries has led to the rise of e-commerce platforms for B2B transactions. Buyers are increasingly leveraging online resources to compare products, prices, and specifications, which enhances their purchasing power and decision-making capabilities. Companies that offer seamless online purchasing experiences, like Atlas Automotive Equipment, are well-positioned to capture this market segment.

Another emerging trend is the focus on high-quality products at competitive prices. As B2B buyers become more discerning, they seek equipment that not only meets their operational needs but also offers long-term value. This shift is prompting manufacturers to innovate and improve product offerings while maintaining affordability.

How Is Sustainability and Ethical Sourcing Impacting the Greg Smith Equipment Sector?

Sustainability and ethical sourcing are increasingly becoming non-negotiable factors for B2B buyers in the automotive equipment sector. Companies are now expected to demonstrate a commitment to environmental stewardship, which includes minimizing their carbon footprint and ensuring that their supply chains are ethically sound. For instance, manufacturers of Greg Smith Equipment can adopt eco-friendly materials and processes, enhancing their appeal to environmentally conscious buyers.

The environmental impact of manufacturing processes, including waste management and energy consumption, is under scrutiny. Buyers are more likely to engage with companies that have transparent practices and can provide certifications such as ISO 14001, which indicates a robust environmental management system. Additionally, the use of recyclable materials and energy-efficient technologies in equipment production not only reduces environmental harm but also attracts a growing segment of eco-conscious consumers.

Furthermore, ethical supply chains are crucial for building trust and credibility. B2B buyers are increasingly considering the ethical implications of their purchases, including labor practices and sourcing transparency. Companies that proactively address these concerns often find themselves at a competitive advantage, as they can foster long-term relationships with buyers who prioritize ethical considerations.

How Has the Greg Smith Equipment Brand Evolved Over Time?

The evolution of Greg Smith Equipment reflects broader trends in the automotive service industry. Established over three decades ago, the brand has consistently focused on providing quality automotive equipment, including car lifts, tire changers, and wheel balancers. This focus has positioned the brand as a reliable choice for both small and large automotive service centers.

In response to changing market dynamics, Greg Smith Equipment has adapted by forming partnerships with reputable suppliers, such as Atlas Automotive Equipment, to enhance its product offerings and streamline the purchasing process. This collaboration not only expands the product range but also improves customer service, a critical factor for B2B buyers.

As the industry evolves, Greg Smith Equipment continues to prioritize innovation and customer satisfaction, ensuring that it remains relevant in an increasingly competitive market. This commitment to quality and service has established the brand as a trusted name in the automotive equipment sector, making it an attractive option for international buyers seeking reliable and efficient solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of greg smith equipment

-

How do I solve equipment sourcing challenges when importing Greg Smith equipment?

When importing Greg Smith equipment, first, conduct thorough market research to understand local regulations and customs requirements in your region. Utilize reliable freight forwarders to navigate logistics and ensure compliance with import duties. Establish strong communication with suppliers to clarify product specifications, lead times, and warranty support. Additionally, consider forming partnerships with local distributors who can provide insights into market dynamics and assist in after-sales support. -

What is the best automotive equipment for starting a workshop in Africa?

For starting a workshop in Africa, the best automotive equipment includes reliable car lifts (both 2-post and 4-post), tire changers, and wheel balancers. These tools are essential for basic vehicle maintenance and repair services. Look for high-quality options from Greg Smith equipment that offer durability and ease of use. Prioritize equipment with robust warranties and support services to ensure long-term operational efficiency. -

What are the minimum order quantities (MOQ) for Greg Smith equipment?

Greg Smith typically has flexible MOQ policies, which can vary based on the specific equipment and your negotiation with the supplier. For larger orders, you may be able to negotiate lower MOQs. It’s advisable to discuss your requirements directly with Greg Smith representatives to find a solution that meets your business needs, especially if you are looking to import a diverse range of equipment. -

What payment terms can I expect when purchasing Greg Smith equipment?

Payment terms for purchasing Greg Smith equipment often include options such as upfront payment, installment plans, or letters of credit for international transactions. It’s essential to clarify these terms during negotiations to ensure they align with your cash flow management. Additionally, inquire about any available financing options or discounts for bulk purchases to optimize your investment. -

How can I ensure the quality of Greg Smith equipment before purchasing?

To ensure the quality of Greg Smith equipment, request detailed product specifications and certifications, such as ALI certification for lifts. Ask for references or case studies from existing customers, particularly those in your region. If possible, visit a local distributor or trade show where you can see the equipment in action. Consider arranging for a trial or demo if feasible, to evaluate performance and reliability. -

What logistics considerations should I keep in mind when importing Greg Smith equipment?

When importing Greg Smith equipment, consider shipping methods, transit times, and potential customs clearance delays. Work with logistics providers experienced in international trade to streamline the process. Ensure that you have all necessary documentation, such as invoices and packing lists, ready for customs. Additionally, consider local warehousing options to facilitate quicker distribution once the equipment arrives. -

How can I customize Greg Smith equipment to meet my specific needs?

Customization options for Greg Smith equipment may include modifications to fit specific workshop layouts or additional features tailored to your service offerings. Engage directly with the Greg Smith sales team to discuss your requirements and explore available options. Be prepared to provide details about your operational needs, as this will help them recommend suitable customizations that enhance functionality and efficiency. -

What after-sales support can I expect when buying Greg Smith equipment?

After purchasing Greg Smith equipment, you can typically expect comprehensive after-sales support, including installation assistance, training, and access to spare parts. Be sure to inquire about warranty terms and the process for claiming support if issues arise. Establishing a good relationship with your supplier will be beneficial, as it can lead to timely assistance and maintenance services, ensuring your equipment remains operational and effective.

Top 4 Greg Smith Equipment Manufacturers & Suppliers List

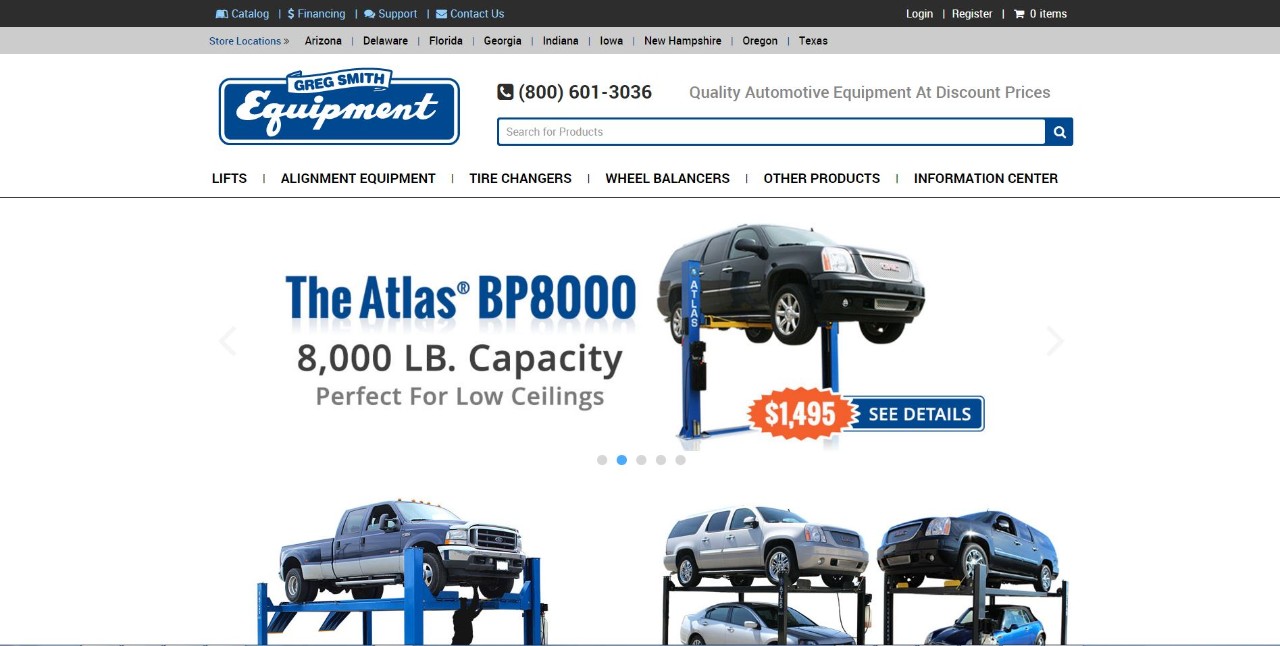

1. Atlas Auto Equipment – Automotive Lifts & Wheel Service Equipment

Domain: atlasautoequipment.com

Registered: 2009 (16 years)

Introduction: Greg Smith Equipment Lifts offers a variety of automotive lifts including 2 Post Lifts, 4 Post Lifts, Alignment Lifts, Scissor Lifts, Maxima® Mobile Column Lifts, Motorcycle/ATV Lifts, Specialty Lifts, and Rolling Jacks. Additionally, they provide Wheel Service Equipment such as Alignment Machines, Tire Changers, and Wheel Balancers. The company emphasizes knowledgeable industry experts with over …

2. Greg Smith Equipment Sales – Lifts and Lifting Equipment

Domain: vehicleservicepros.com

Registered: 2011 (14 years)

Introduction: Greg Smith Equipment Sales offers a variety of tools and equipment including:

1. **Lifts and Lifting Equipment**:

– Atlas mobile column lift system No. MC36K-KIT (9,000 lbs per column)

– Atlas alignment scissor lift No. 12AWFSL (built-in jack system)

– ATLAS NINE two-post asymmetric lift

– Pro 14K (14,000-pound capacity 4-post lift)

– Hanmecson Pro-6M (6,000 lb. capacity)

– DIREC…

3. Garage Journal – Key Products and Feedback

Domain: garagejournal.com

Registered: 2006 (19 years)

Introduction: 1. Robinair AC machine – $7000, noted for good customer service from Best Buy Automotive. 2. Atlas lifts from Greg Smith Equipment – concerns about proprietary bore size (1.57″), limited adapter availability, and customer service issues after company ownership change. 3. General feedback on Greg Smith Equipment indicates potential manufacturing quality issues, including uneven arm heights and poor…

4. Greg Smith Equipment – Industrial Equipment

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Greg Smith Equipment – Industrial Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for greg smith equipment

In today’s competitive landscape, strategic sourcing of automotive equipment, particularly from Greg Smith Equipment, offers significant advantages for international B2B buyers. With over three decades of experience, the transition to Atlas Automotive Equipment has streamlined access to a comprehensive range of high-quality products, including car lifts, tire changers, and alignment machines. Buyers can expect not only competitive pricing but also a commitment to exceptional customer service and support.

For businesses in Africa, South America, the Middle East, and Europe, leveraging the strengths of Greg Smith Equipment means gaining a partner that understands the nuances of the automotive market. The ease of online ordering, combined with free shipping on qualifying orders, enhances the purchasing experience, making it simpler to acquire essential equipment without compromising on quality.

Looking ahead, international buyers are encouraged to explore the diverse product offerings and take advantage of the expert knowledge available. This strategic sourcing approach not only ensures operational efficiency but also fosters long-term relationships that can drive business growth. Embrace the opportunity to partner with Greg Smith Equipment and optimize your automotive service capabilities today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.