Top 4 Friction Hinges Marine Suppliers (And How to Choose)

Introduction: Navigating the Global Market for friction hinges marine

In today’s rapidly evolving marine industry, sourcing reliable friction hinges that meet specific operational needs poses a significant challenge for international B2B buyers. These hinges play a pivotal role in enhancing the functionality of marine applications, from hatches to storage compartments, ensuring durability and ease of use in demanding environments. This guide provides a comprehensive overview of marine friction hinges, detailing various types, their applications, and the crucial factors to consider when making purchasing decisions.

Navigating the complexities of supplier vetting, understanding cost implications, and evaluating product quality are essential for buyers, particularly those in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam. This guide empowers decision-makers by offering actionable insights into the selection process, enabling them to make informed choices that align with their operational requirements and budget constraints.

By delving into this resource, B2B buyers will gain a deeper understanding of the friction hinge landscape, equipping themselves with the knowledge necessary to secure high-quality products that enhance their marine operations. Whether you are looking to upgrade existing equipment or invest in new projects, this guide serves as your essential tool for navigating the global market for marine friction hinges.

Understanding friction hinges marine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Top Mounted Friction Hinges | Mounted on top surfaces, offering easy installation | Boat hatches, console doors | Pros: Simple installation; Cons: May require more space above the mounting surface. |

| Flush Mounted Friction Hinges | Installed flush with the surface for a sleek look | Cabinet doors, storage compartments | Pros: Aesthetically pleasing; Cons: More complex installation. |

| Swaged Down Friction Hinges | Features a swaged design for enhanced strength | Heavy-duty applications, marine doors | Pros: Superior strength; Cons: Heavier than standard hinges. |

| Light Duty Friction Hinges | Designed for lighter applications | Small compartments, lightweight doors | Pros: Cost-effective; Cons: Limited load capacity. |

| Specialty Friction Hinges | Custom designs for unique applications | Ratcheting seat backs, bimini tops | Pros: Tailored solutions; Cons: Higher cost and longer lead times. |

What Are the Characteristics of Top Mounted Friction Hinges?

Top mounted friction hinges are designed for ease of installation, allowing them to be affixed directly to the top surface of doors or hatches. This type is particularly favored in marine applications such as boat hatches and console doors. When considering a purchase, B2B buyers should assess the hinge’s load capacity and the space available above the mounting surface, as this can affect functionality and aesthetics.

How Do Flush Mounted Friction Hinges Differ from Other Types?

Flush mounted friction hinges provide a clean, unobtrusive look by sitting level with the surface of the door or hatch. This style is ideal for applications where visual appeal is paramount, such as cabinet doors and storage compartments. Buyers should consider the complexity of installation, as flush mounts often require precise alignment and may be less forgiving if adjustments are needed post-installation.

Why Choose Swaged Down Friction Hinges for Heavy-Duty Applications?

Swaged down friction hinges are engineered for enhanced strength, making them suitable for heavy-duty applications like marine doors that experience significant wear and tear. The swaged design allows for greater durability and load-bearing capacity. B2B buyers should evaluate the specific weight requirements of their projects and consider the hinge’s material composition to ensure longevity in harsh marine environments.

What Are the Benefits of Light Duty Friction Hinges?

Light duty friction hinges are optimized for smaller, lighter applications, making them a cost-effective choice for items like small compartments and lightweight doors. Their affordability and ease of use make them appealing for budget-conscious projects. However, buyers must be cautious about their limited load capacity, ensuring they match the hinge type to the intended application to avoid premature failure.

How Do Specialty Friction Hinges Cater to Unique Applications?

Specialty friction hinges are tailored for specific uses, such as securing ratcheting seat backs or attaching bimini tops. These hinges are often custom-designed, allowing for innovative solutions in marine environments. While they provide unique benefits, B2B buyers should be prepared for potentially higher costs and longer lead times, making it essential to plan ahead when incorporating these hinges into their projects.

Key Industrial Applications of friction hinges marine

| Industry/Sector | Specific Application of friction hinges marine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Maritime Transportation | Access doors and hatches on vessels | Enhanced safety and operational efficiency | Durability against marine conditions and corrosion resistance |

| Recreational Boating | Console doors and storage compartments | Improved user experience with smooth operation | Weight capacity and ease of installation |

| Commercial Fishing | Livewell lids and gear storage | Increased reliability and reduced maintenance costs | Material compatibility and resistance to saltwater |

| Marine Construction | Windows and ventilation systems | Enhanced airflow and temperature control | Custom sizing and load-bearing capacity |

| Shipbuilding | Machinery access panels | Streamlined access for maintenance and repairs | Compliance with industry standards and certifications |

How Are Friction Hinges Used in Maritime Transportation?

In the maritime transportation sector, friction hinges are crucial for access doors and hatches on vessels. They provide a reliable means of securing compartments while allowing easy opening and closing, which enhances both safety and operational efficiency. For international buyers, particularly from regions like Africa and South America, sourcing hinges that withstand harsh marine environments is essential. Buyers should prioritize durability and corrosion resistance to ensure long-term functionality.

What Role Do Friction Hinges Play in Recreational Boating?

Recreational boating applications often utilize friction hinges in console doors and storage compartments. These hinges facilitate smooth operation, allowing boaters easy access to essential equipment while maintaining a streamlined appearance. For buyers from Europe, especially Germany and Vietnam, it is important to consider weight capacity and ease of installation to ensure that the hinges meet the specific requirements of various boat designs.

How Are Friction Hinges Beneficial in Commercial Fishing?

In the commercial fishing industry, friction hinges are commonly found on livewell lids and gear storage. They provide increased reliability, ensuring that lids stay open when needed and close securely to maintain optimal conditions for caught fish. For businesses sourcing these hinges, material compatibility and resistance to saltwater are vital considerations to minimize maintenance costs and enhance the longevity of their equipment.

How Do Friction Hinges Enhance Marine Construction?

Friction hinges are integral to windows and ventilation systems in marine construction, allowing for effective airflow and temperature control. This is particularly important in tropical climates where heat buildup can be a concern. Buyers should focus on custom sizing and load-bearing capacities to ensure that the hinges can support the specific designs and requirements of marine structures.

Why Are Friction Hinges Important in Shipbuilding?

In shipbuilding, friction hinges are used for machinery access panels, facilitating streamlined access for maintenance and repairs. This efficiency is crucial for minimizing downtime and ensuring operational readiness. Buyers should ensure that their sourced hinges comply with industry standards and certifications to guarantee safety and reliability in their applications.

3 Common User Pain Points for ‘friction hinges marine’ & Their Solutions

Scenario 1: Inconsistent Performance Under Marine Conditions

The Problem: Many B2B buyers in the marine industry face the challenge of friction hinges failing to perform consistently in harsh marine environments. Factors such as saltwater exposure, temperature fluctuations, and heavy loads can lead to corrosion, decreased functionality, and even hinge failure. This inconsistency can result in costly repairs and safety issues, affecting the overall reliability of marine equipment and installations.

The Solution: To combat these challenges, it’s crucial to source friction hinges specifically designed for marine applications. Look for hinges made from marine-grade materials such as stainless steel or bronze, which offer superior resistance to corrosion and wear. Additionally, select hinges with protective coatings that enhance durability. When specifying hinges, consider the weight they need to support and ensure the friction adjustment is suitable for your application. Regular maintenance, including cleaning and lubrication, can also prolong the life of your hinges and maintain consistent performance. Partnering with reputable suppliers who understand marine requirements can further ensure you receive products that meet industry standards.

Scenario 2: Difficulty in Selecting the Right Hinge Type

The Problem: B2B buyers often struggle with selecting the appropriate type of friction hinge for specific marine applications. With various options available—such as top mount, flush mount, and specialty hinges—choosing the right one can be overwhelming. Incorrect selections can lead to installation issues, compromised functionality, and potential safety hazards, which can be detrimental to projects and client relationships.

The Solution: Start by clearly defining the requirements of your application, including load capacity, mounting style, and environmental conditions. Conduct thorough research or consult with hinge manufacturers to understand the specifications and performance characteristics of different hinge types. For instance, if you’re dealing with heavy lids or doors, a top mount friction hinge may provide better stability and ease of operation. Additionally, consider the installation process and whether your chosen hinge type can accommodate the existing design of your marine equipment. Utilizing design tools or CAD software can help visualize how different hinges will fit into your project, ensuring a more informed decision.

Scenario 3: Friction Adjustment Challenges Leading to User Frustration

The Problem: Users often experience frustration when friction hinges do not hold their position as intended, either being too loose or too tight. This can lead to operational inefficiencies, where doors or lids fail to stay open or are difficult to operate. In a marine environment, this can pose safety risks and hinder the efficient use of space, particularly in tight quarters on boats or vessels.

The Solution: To address friction adjustment challenges, ensure you select hinges with adjustable friction mechanisms. When sourcing hinges, inquire about models that allow for easy adjustments without requiring specialized tools. Regularly review the adjustment settings based on usage patterns and environmental changes to maintain optimal performance. Additionally, provide users with clear instructions on how to adjust the hinges correctly. Training personnel on the proper use and maintenance of friction hinges can significantly reduce frustration and enhance overall user experience. By integrating user feedback into the hinge selection process, you can ensure that the chosen products meet the practical needs of your operations, leading to improved satisfaction and efficiency.

Strategic Material Selection Guide for friction hinges marine

What Materials Are Commonly Used for Marine Friction Hinges?

Selecting the right material for marine friction hinges is crucial for ensuring performance, durability, and compliance with industry standards. Here, we analyze four common materials used in the manufacturing of these hinges, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Marine Applications?

Stainless steel is a popular choice for marine friction hinges due to its excellent corrosion resistance and strength. The most commonly used grades are 304 and 316, with 316 offering superior resistance to saltwater environments. These hinges can typically withstand high temperatures and pressures, making them suitable for various marine applications.

Illustrative image related to friction hinges marine

Pros: Stainless steel offers high durability and longevity, making it ideal for harsh marine conditions. It is also relatively easy to manufacture and can be polished for aesthetic appeal.

Cons: The primary drawback is cost; stainless steel is generally more expensive than other materials. Additionally, it can be prone to scratching and may require regular maintenance to prevent tarnishing.

Impact on Application: Stainless steel is compatible with a wide range of media, including seawater, making it suitable for boats and marine equipment exposed to harsh environments.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel, while those in Africa and South America may need to consider local sourcing options to mitigate costs.

What Role Does Aluminum Play in Marine Friction Hinges?

Aluminum is another widely used material for marine friction hinges, known for its lightweight nature and resistance to corrosion. Marine-grade aluminum alloys, such as 6061 and 5086, are commonly used due to their strength and durability.

Pros: Aluminum is lightweight, which reduces the overall weight of marine equipment. It also has good corrosion resistance, making it suitable for various marine environments.

Cons: While aluminum is durable, it is generally less strong than stainless steel and may not withstand heavy loads as effectively. It can also be more susceptible to denting and scratching.

Impact on Application: Aluminum hinges are ideal for applications where weight is a critical factor, such as on smaller boats or equipment that requires portability.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM B221 for aluminum alloys. In regions with a high demand for lightweight materials, aluminum may be preferred despite potential trade-offs in strength.

How Do Plastics Compare for Marine Friction Hinges?

Plastics, particularly high-performance polymers like nylon and acetal, are increasingly used in marine friction hinges due to their corrosion resistance and low weight. These materials can handle moderate temperatures and pressures, making them suitable for specific applications.

Pros: Plastic hinges are lightweight, resistant to corrosion, and often more cost-effective than metal options. They also offer good insulation properties.

Cons: The primary limitation is their lower strength compared to metals, making them unsuitable for high-load applications. They may also degrade over time when exposed to UV light unless specifically treated.

Impact on Application: Plastic hinges are ideal for non-structural applications, such as on storage compartments or lightweight lids.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with relevant standards, such as ASTM D638 for tensile properties. Markets in Africa and South America may find plastic hinges particularly appealing due to lower costs.

What About Bronze as a Material for Marine Friction Hinges?

Bronze, particularly marine-grade bronze, is another option for friction hinges in marine applications. This alloy is known for its excellent corrosion resistance, particularly in saltwater environments.

Pros: Bronze offers high strength and durability, making it suitable for heavy-duty applications. It also has a pleasing aesthetic that many boat builders appreciate.

Cons: The cost of bronze can be significantly higher than aluminum or plastic. Additionally, it may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Bronze is particularly effective in applications requiring high strength and resistance to corrosion, such as on larger vessels or in areas with high wear.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM B150 for bronze alloys. In Europe, particularly in Germany, there may be a preference for bronze due to its traditional use in marine applications.

Summary Table of Material Selection for Marine Friction Hinges

| Material | Typical Use Case for Friction Hinges Marine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty marine applications | Excellent corrosion resistance | Higher cost, prone to scratching | High |

| Aluminum | Lightweight marine equipment | Lightweight and corrosion-resistant | Less strength than stainless steel | Medium |

| Plastic | Non-structural applications | Cost-effective and lightweight | Lower strength, UV degradation | Low |

| Bronze | Heavy-duty marine applications | High strength and durability | High cost, complex manufacturing | High |

This strategic material selection guide provides insights for B2B buyers to make informed decisions when sourcing marine friction hinges, ensuring optimal performance and compliance with industry standards.

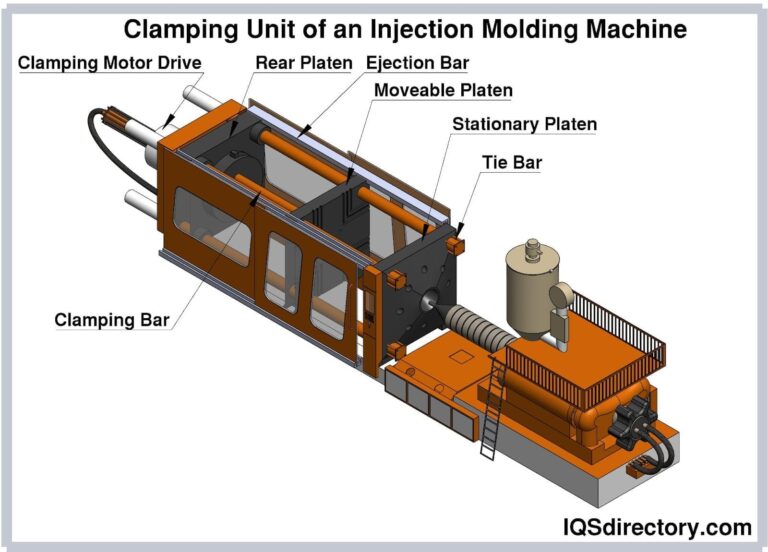

In-depth Look: Manufacturing Processes and Quality Assurance for friction hinges marine

What Are the Main Stages in the Manufacturing Process of Marine Friction Hinges?

The manufacturing of marine friction hinges involves several critical stages, each designed to ensure that the final product meets the rigorous demands of marine environments.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in the manufacturing process is the preparation of materials. Marine friction hinges are typically constructed from high-grade stainless steel or marine-grade aluminum, chosen for their corrosion resistance and durability. The materials undergo rigorous quality checks upon arrival at the manufacturing facility. This includes verifying the chemical composition and physical properties to ensure they meet industry standards.

Once verified, the materials are cut into precise dimensions using advanced CNC (Computer Numerical Control) machines. This ensures that each component of the hinge is uniform, which is essential for the functionality and longevity of the product.

How Are Friction Hinges Formed?

Following material preparation, the forming process begins. This involves bending, stamping, or forging the components into their required shapes. Techniques such as die casting may also be employed, particularly for complex designs that require intricate features.

During this stage, manufacturers utilize hydraulic presses and specialized tooling to create the necessary contours in the hinge. Precision in this step is crucial, as any deviation can affect the performance of the hinge, particularly its ability to hold position under load.

What Assembly Techniques Are Commonly Used?

Once the components are formed, they proceed to the assembly stage. This typically involves the installation of the friction mechanism, which may include springs and friction pads. Automated assembly lines are often used to enhance efficiency and ensure consistent quality.

Quality control checks during assembly involve ensuring that all parts fit together seamlessly and that the friction mechanism operates smoothly. For instance, the amount of resistance provided by the hinge is tested to ensure it aligns with design specifications.

What Finishing Processes Enhance Durability?

The final stage in the manufacturing process is finishing, which enhances both the appearance and durability of the hinges. Common finishing techniques include anodizing for aluminum parts and passivation for stainless steel components. These processes increase resistance to corrosion, which is essential for marine applications.

Additionally, surface treatments such as powder coating or plating may be applied for aesthetic purposes and further protection against environmental factors.

How Is Quality Assurance Implemented in Marine Friction Hinge Manufacturing?

Quality assurance (QA) is critical in ensuring that marine friction hinges are safe and effective. The QA process typically adheres to several international standards and industry-specific regulations.

What International Standards Apply to Marine Friction Hinges?

One of the primary international standards governing quality assurance in manufacturing is ISO 9001. This standard outlines criteria for a quality management system, ensuring that companies consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, marine friction hinges may also need to comply with specific certifications such as CE marking for products sold in Europe, and API standards for products used in the oil and gas industry.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. These checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): QC measures during production, including inspections after forming and assembly stages, ensure that any defects are identified and rectified immediately.

-

Final Quality Control (FQC): The final inspection stage checks the complete assembly of the hinge, assessing functionality, aesthetics, and compliance with specifications.

What Common Testing Methods Ensure Quality?

Common testing methods for marine friction hinges include:

-

Load Testing: This assesses the hinge’s ability to withstand specified weights and forces.

-

Corrosion Resistance Testing: Exposing hinges to saltwater or saline environments simulates marine conditions, ensuring longevity.

-

Fatigue Testing: This tests the hinge’s performance over repeated cycles to assess durability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital.

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits can provide insights into the manufacturer’s QA processes. Buyers should request documentation that outlines the supplier’s compliance with ISO 9001 and any relevant industry standards.

Additionally, asking for records of previous inspections, certifications, and test results can help verify the quality of the products being offered.

How Important Are Third-Party Inspections?

Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing processes. These inspections can verify compliance with both international and industry-specific standards, giving buyers peace of mind regarding the quality and reliability of the hinges.

What Nuances Should International Buyers Consider?

International B2B buyers should be aware of specific nuances in quality control and certification that may vary by region. For instance, regulations in Europe may differ significantly from those in the Middle East or Africa. Understanding these differences is crucial for ensuring compliance and successful market entry.

Moreover, language barriers and varying interpretations of quality standards can pose challenges. Establishing clear communication channels with suppliers and utilizing translation services for technical documents can mitigate these issues.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing marine friction hinges, ensuring they receive products that meet their specific needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘friction hinges marine’

To successfully procure marine friction hinges, a structured approach ensures that you select products that meet your operational needs while maintaining quality and compliance. This checklist provides a clear pathway for B2B buyers to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for your friction hinges. Consider factors such as size, load capacity, material (e.g., stainless steel for corrosion resistance), and mounting style. This clarity will help you communicate effectively with potential suppliers and ensure that the products you receive are fit for purpose.

Step 2: Research Supplier Credentials

Take the time to evaluate potential suppliers’ credentials. Look for certifications that indicate compliance with international standards, such as ISO or ASTM. Verified certifications not only reflect quality assurance but also ensure that the products meet safety and performance benchmarks relevant to marine applications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Examine their track record for reliability, delivery times, and customer service. This evaluation will help you identify suppliers who are capable of meeting your specific needs.

Step 4: Request Samples and Specifications

Ask for samples of the friction hinges you are considering. This allows you to assess the quality, functionality, and suitability for your application firsthand. Additionally, request detailed specifications, including load ratings and installation guidelines, to ensure that the hinges will perform as required in your marine environment.

Step 5: Compare Pricing and Payment Terms

Once you have identified suitable suppliers, compare their pricing structures and payment terms. Understand what is included in the pricing—such as shipping costs, warranties, and after-sales support. This comparison will help you determine the best overall value rather than simply the lowest price.

Step 6: Review Shipping and Delivery Options

Shipping logistics can significantly impact your procurement timeline. Discuss delivery options and lead times with potential suppliers, especially if you are sourcing from international locations. Ensure that they can meet your deadlines, and inquire about their policies regarding customs clearance and handling.

Step 7: Negotiate Contracts and Terms of Service

Before finalizing your purchase, negotiate the terms of service and contracts. Pay attention to warranty provisions, return policies, and support services. Clear agreements will help mitigate risks and provide recourse in case of product issues, ensuring a smoother procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing marine friction hinges with confidence, ensuring that they select the right products to enhance their operations while maintaining quality and compliance.

Comprehensive Cost and Pricing Analysis for friction hinges marine Sourcing

What Are the Key Cost Components in Sourcing Marine Friction Hinges?

When analyzing the cost structure of marine friction hinges, several components play a critical role in determining the final price. These include:

-

Materials: The choice of materials significantly impacts cost. Marine-grade stainless steel or aluminum is preferred for its corrosion resistance, but these materials are often more expensive than standard options. Buyers should consider the specific marine environment in which the hinges will be used to select the appropriate material.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs can offer more competitive pricing, but quality may vary. Understanding the labor market of the supplier’s country can help buyers gauge the labor component of the cost.

-

Manufacturing Overhead: This encompasses utilities, rent, and salaries of non-production staff. Efficient manufacturing processes can reduce overhead, which is beneficial for the overall pricing.

-

Tooling: The initial setup for manufacturing hinges, including molds and dies, can be a substantial upfront investment. Suppliers may pass these costs onto buyers, particularly for custom orders.

-

Quality Control (QC): Ensuring that each batch of hinges meets the required standards incurs additional costs. Certifications like ISO can also add to the price, but they are essential for ensuring product reliability, especially in critical marine applications.

-

Logistics: Transportation costs can vary widely depending on the shipping method, distance, and any associated tariffs or duties. Buyers should account for these costs in their total sourcing price.

-

Margin: Suppliers typically build in a profit margin that can vary based on market conditions and competition. Understanding typical margins in the industry can assist buyers in negotiating better terms.

What Factors Influence the Pricing of Marine Friction Hinges?

Pricing is not just a reflection of cost; it is also influenced by various factors:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Buyers should consider consolidating orders to benefit from economies of scale.

-

Specifications and Customization: Unique specifications or custom designs can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The higher the quality of materials and certifications, the higher the price. Buyers need to balance quality and cost based on their specific application needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record but may provide better quality assurance and service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is crucial. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total landed cost.

How Can Buyers Negotiate Better Prices on Marine Friction Hinges?

Buyers can take several steps to negotiate better pricing on marine friction hinges:

-

Research Market Prices: Understanding the current market rates for various types of friction hinges allows buyers to negotiate from an informed position.

-

Leverage Volume Discounts: Consolidating orders or committing to long-term contracts can lead to significant savings.

-

Explore Multiple Suppliers: Engaging with multiple suppliers can create competition, leading to better pricing and terms.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term value rather than just the initial purchase price. Factors such as durability, maintenance, and reliability can significantly affect TCO.

-

Stay Informed About Pricing Nuances: International buyers should be aware of additional costs associated with importing, such as customs duties and currency fluctuations, which can impact the overall pricing strategy.

Conclusion

While indicative pricing for marine friction hinges can range widely based on the factors discussed, understanding the cost structure and price influencers equips international B2B buyers with the knowledge needed to make informed purchasing decisions. By carefully considering these elements, buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing strategies and achieve cost-effective solutions that meet their operational needs.

Alternatives Analysis: Comparing friction hinges marine With Other Solutions

Exploring Alternatives to Friction Hinges Marine

In the marine industry, the choice of hardware can significantly impact the functionality and durability of equipment. While friction hinges marine are popular for their ability to maintain a desired position without additional support, there are alternative solutions worth considering. This section compares friction hinges marine against two viable alternatives: traditional butt hinges and gas struts. Each option offers unique advantages and potential drawbacks, making it essential for B2B buyers to evaluate their specific requirements before making a selection.

| Comparison Aspect | Friction Hinges Marine | Butt Hinges | Gas Struts |

|---|---|---|---|

| Performance | Allows controlled movement; holds position without additional support | Provides basic support and movement; may sag over time | Offers smooth, assisted movement; can hold heavy loads |

| Cost | Moderate ($37 – $44 each) | Lower ($10 – $30 each) | Higher ($50 – $100 each) |

| Ease of Implementation | Requires precise installation; needs compatible surfaces | Simple installation; versatile in applications | Requires careful measurements; may need brackets |

| Maintenance | Low maintenance; corrosion-resistant options available | Moderate maintenance; can rust if not stainless | Low maintenance; durable but may need replacement after wear |

| Best Use Case | Ideal for compartments needing stable positioning (e.g., doors, lids) | Common for general access points (e.g., hatches) | Best for heavy lids or doors needing lifting assistance |

Detailed Breakdown of Alternatives

Butt Hinges

Butt hinges are among the most commonly used hinges in marine applications. They are straightforward to install and provide reliable movement for a variety of doors and hatches. However, while they are generally more cost-effective than friction hinges, they may not hold positions as securely, which can lead to sagging over time. They are suitable for applications where precise positioning is less critical, making them a good choice for general access points.

Gas Struts

Gas struts provide an innovative solution for applications requiring smooth and controlled movement, particularly for heavier doors and compartments. They utilize gas pressure to assist in lifting and lowering, making them ideal for larger hatches that would otherwise be cumbersome to operate. However, gas struts come at a higher cost and require careful installation to ensure proper functioning. They are particularly beneficial in environments where ease of access is paramount, but they may not be the best choice for situations where stability in a fixed position is essential.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting hardware for marine applications, it is crucial to consider the specific requirements of your project. Friction hinges marine excel in scenarios where maintaining a fixed position is vital, while butt hinges offer cost-effective solutions for general access. Gas struts, on the other hand, provide enhanced lifting capabilities for heavier applications. By evaluating performance, cost, ease of implementation, and maintenance needs, B2B buyers can make informed decisions that align with their operational demands and budget constraints. Assessing these factors will lead to optimal hardware choices that enhance functionality and longevity in marine environments.

Essential Technical Properties and Trade Terminology for friction hinges marine

What Are the Key Technical Properties of Marine Friction Hinges?

Marine friction hinges play a vital role in the functionality and longevity of various marine applications, such as doors, hatches, and storage compartments. Understanding their essential technical specifications can significantly influence purchasing decisions for B2B buyers.

1. Material Grade

The material grade is critical for ensuring durability and resistance to corrosion in marine environments. Common materials include stainless steel, aluminum, and plastic composites. Stainless steel, particularly marine-grade (e.g., 316 stainless), is favored for its superior resistance to saltwater corrosion. Buyers should prioritize hinges made from high-grade materials to ensure longevity and performance in harsh marine conditions.

2. Load Capacity

The load capacity defines the maximum weight a hinge can support without failure. This property is essential for ensuring that the hinge can adequately handle the weight of doors or lids it is meant to support. Buyers must match the load capacity of the hinge with the expected weight of the application to prevent premature wear or breakage.

3. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the hinge. Precise tolerances are crucial for ensuring proper fit and function, especially in applications where space is limited. For B2B buyers, understanding tolerance specifications helps in selecting hinges that will integrate seamlessly with existing designs or equipment.

Illustrative image related to friction hinges marine

4. Friction Adjustment Mechanism

This property allows users to adjust the resistance of the hinge, providing control over how easily a door or lid opens and stays in position. A well-designed friction adjustment mechanism enhances user experience and ensures that the hinge can be tailored to specific operational needs. This feature is particularly beneficial in environments where conditions can change frequently.

5. Mounting Style

Different mounting styles (top mount, flush mount, etc.) determine how the hinge is installed on the application. The choice of mounting style affects aesthetics, functionality, and ease of installation. Buyers should consider the compatibility of the hinge with their specific installation needs to ensure an efficient setup.

What Common Trade Terms Should B2B Buyers Know About Marine Friction Hinges?

Navigating the B2B marketplace for marine friction hinges involves familiarity with specific industry jargon. Understanding these terms can facilitate smoother transactions and clearer communications.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of marine hinges, an OEM may provide custom solutions tailored to specific vessel designs. Buyers often seek OEM products to ensure compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and budget effectively. Larger orders often lead to better pricing, making it important to balance needs with purchasing capacity.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers should utilize RFQs to gather competitive pricing and terms from multiple suppliers, ensuring they make informed decisions based on comprehensive market data.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities, risk management, and cost implications in global trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is essential for project planning and ensuring that timelines are met. Buyers should inquire about lead times to avoid delays in their operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting marine friction hinges, ultimately enhancing the performance and reliability of their marine applications.

Illustrative image related to friction hinges marine

Navigating Market Dynamics and Sourcing Trends in the friction hinges marine Sector

What Are the Current Market Dynamics and Key Trends in the Marine Friction Hinges Sector?

The global marine friction hinges market is experiencing a robust transformation, driven by increasing demand for lightweight, durable, and corrosion-resistant materials. This trend is particularly significant in regions like Africa, South America, the Middle East, and Europe, where the marine industry is expanding rapidly. The rise in recreational boating and commercial maritime activities is propelling the need for high-performance hinges that offer reliability and ease of use. Moreover, advancements in manufacturing technologies, such as CNC machining and precision casting, are enabling suppliers to produce custom friction hinges that meet specific application requirements.

Emerging technologies, including smart materials and IoT integration, are also influencing sourcing trends. Buyers are increasingly interested in friction hinges that can provide feedback on their operational status or environmental conditions, thus enhancing safety and performance. Additionally, the shift towards e-commerce platforms for procurement is revolutionizing how international B2B buyers source these components, allowing for a broader selection and competitive pricing.

Sourcing strategies are evolving as businesses seek to establish long-term partnerships with manufacturers who can ensure consistent quality and supply chain reliability. This is particularly vital in regions like Germany and Vietnam, where compliance with stringent regulations and quality standards is paramount. Overall, understanding these market dynamics is crucial for B2B buyers looking to make informed sourcing decisions.

How Is Sustainability Influencing Sourcing Practices in the Marine Friction Hinges Industry?

Sustainability has become a cornerstone of modern sourcing practices, significantly impacting the marine friction hinges market. The environmental implications of manufacturing and sourcing materials are prompting businesses to prioritize ethical supply chains. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste during production.

Incorporating ‘green’ certifications and materials into product lines is essential for manufacturers aiming to attract environmentally conscious buyers. Certifications such as ISO 14001 for environmental management systems or compliance with REACH regulations signal a supplier’s commitment to sustainability. Moreover, the use of eco-friendly coatings and finishes can enhance the longevity of friction hinges while minimizing their ecological footprint.

Illustrative image related to friction hinges marine

For B2B buyers, adopting sustainable sourcing practices not only aligns with corporate social responsibility goals but also enhances brand reputation and customer loyalty. As the marine industry faces growing scrutiny over its environmental impact, buyers who prioritize sustainability in their procurement strategies are likely to gain a competitive edge in the marketplace.

What Has Been the Evolution of Marine Friction Hinges Over Time?

The evolution of marine friction hinges reflects broader trends in technology and materials science. Initially, these hinges were primarily made from heavy metals, which, while durable, added unnecessary weight to boats and vessels. Over time, advancements in materials such as marine-grade stainless steel and composite materials have allowed manufacturers to produce lighter, more resilient hinges that can withstand harsh marine environments.

The introduction of friction hinges designed specifically for marine applications has further enhanced functionality, allowing for better control of door and hatch movements. These innovations have led to increased adoption in various marine sectors, including recreational boating, commercial shipping, and military applications. As the demand for efficiency and performance grows, the friction hinges of today are engineered for optimal strength, corrosion resistance, and user-friendly operation, catering to the diverse needs of the international marine industry.

By understanding these historical developments, B2B buyers can appreciate the technological advancements that inform current products and make more informed purchasing decisions that align with their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of friction hinges marine

1. How do I select the right friction hinge for my marine application?

Choosing the right friction hinge involves considering several factors such as the weight of the door or hatch, the frequency of use, and the environmental conditions it will face. Look for hinges made of marine-grade materials to ensure resistance to corrosion and wear. Additionally, assess the hinge’s load capacity and friction strength; a hinge that is too weak may not hold the position, while one that is too strong could damage the mounting material. It’s advisable to consult with suppliers about specific applications to ensure optimal performance.

2. What are the key features to look for in marine friction hinges?

Key features to consider include corrosion resistance, load capacity, and the type of mounting style. Marine friction hinges should ideally be made from stainless steel or high-grade plastics to withstand harsh marine environments. Additionally, the hinge should provide adjustable friction settings, allowing you to control the ease of movement and position hold. It’s also beneficial to choose hinges that have a proven track record in marine applications, ensuring reliability and longevity in demanding conditions.

3. How can I ensure the quality of friction hinges from international suppliers?

To ensure quality, start by vetting suppliers through their certifications, such as ISO 9001, which indicates a commitment to quality management. Request product samples to evaluate the hinge’s material, finish, and functionality. Additionally, inquire about their quality assurance processes, including testing methods for durability and load capacity. Engaging with suppliers that have positive reviews and established reputations in the marine industry can also provide confidence in their product quality.

4. What is the typical minimum order quantity (MOQ) for friction hinges in marine applications?

Minimum order quantities can vary significantly between suppliers, often ranging from 50 to 500 units. Factors influencing MOQ include the type of hinge, customization options, and the supplier’s production capabilities. For large-scale projects, negotiating lower MOQs might be possible, especially if you are willing to commit to future orders. Always clarify MOQs upfront to avoid misunderstandings during the procurement process.

5. Are customization options available for marine friction hinges?

Yes, many suppliers offer customization options for marine friction hinges, including size, material, and friction levels. Customization can ensure that the hinges fit specific applications or design requirements. When requesting custom products, provide detailed specifications and any applicable drawings to help the supplier understand your needs. Keep in mind that customization may affect lead times and pricing, so it’s essential to discuss these factors upfront.

6. What payment terms should I expect when sourcing friction hinges internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common terms include 30% upfront and 70% upon delivery, or full payment prior to shipment. Some suppliers may offer credit terms for established buyers. It’s advisable to clarify payment methods accepted (e.g., bank transfer, letter of credit) and any potential fees associated with international transactions. Ensure that the terms are clearly outlined in the purchase agreement to avoid disputes later.

7. How does logistics work when importing friction hinges from international suppliers?

Logistics for importing hinges involves coordinating shipping methods, customs clearance, and delivery schedules. Work with suppliers who have experience in international shipping to streamline the process. Typically, they will provide Incoterms that clarify the responsibilities of both parties regarding shipping costs and risks. It’s essential to factor in lead times for production and shipping when planning your project timeline, and consider engaging a freight forwarder to assist with customs regulations and documentation.

8. What are the common applications of marine friction hinges?

Marine friction hinges are widely used in various applications, including hatches, doors, and compartments on boats and yachts. They provide controlled movement and stability, allowing doors to remain open at desired angles without additional support. Common uses include livewell lids, console doors, and storage compartments. Understanding the specific requirements of your application can help in selecting the appropriate type and size of hinge, ensuring functionality and safety in marine environments.

Top 4 Friction Hinges Marine Manufacturers & Suppliers List

1. GEM – Marine Friction Hinges

Domain: gemlux.com

Registered: 1995 (30 years)

Introduction: Marine Friction Hinges are designed to eliminate the need for gas shocks or hatch springs in various applications. They hold open hatches, live well lids, radio boxes, and more. The hinges feature built-in friction technology from GEM, ensuring reliable performance. Key specifications include:

– Mounting Styles: Flush Mount (FM), Top Mount (TM), Swaged Down (SD), Swaged Up (SU)

– Various sizes a…

2. Boat Outfitters – Marine Hinges

Domain: boatoutfitters.com

Registered: 2002 (23 years)

Introduction: Boat Hinges – Best Marine Hinges | Boat Outfitters. Types of Hinges: Butt Hinges (common for livewell lids and hatches), Piano Hinges (used on console and storage center doors, available in standard and friction styles), Concealed Hinges (hidden look for cabinet doors), Glass Door Hinges (hold glass without drilling), Specialty Hinges (for applications like ratcheting seat backs and securing bimin…

3. Roca Industry – Friction and Lift-Off Hinges

Domain: rocaindustry.com

Registered: 1997 (28 years)

Introduction: Friction hinges, Lift-off hinges, Hatch hinges, Butt hinges, Piano hinges, Table hinges, Glass hinges, Heavy Duty Hatch hinges, Boat locks, Barrel bolts, Door holders, Eccentric latches, Latches, Lift handles, Marine vents, Folding brackets (Regal folding bracket, Rakego folding bracket, Robust folding bracket), Boat electrics (Boat horn, Cable outlets, Electric pumps, Switches), Windshield wiper …

4. MarineTown – Stainless Steel Hinges

Domain: marinetown.com

Registered: 2001 (24 years)

Introduction: Hinges: Friction Hinge (Stainless Steel 316, 40 x 75.3mm), Covered Friction Hinge (Stainless Steel 316, 39.6 x 77.4mm), Covered Seam Damping Hinge (Stainless Steel 316), Seam Hinge (Stainless Steel 316), Butterfly Hinge (various sizes and configurations in Stainless Steel 316), Covered Hinge (various sizes and configurations in Stainless Steel 316), Nylon Covered Hinge (Nylon, 41mm x 82.4mm), Cast…

Strategic Sourcing Conclusion and Outlook for friction hinges marine

As the demand for marine applications continues to rise, the importance of strategic sourcing for friction hinges cannot be overstated. By understanding the various types of hinges and their specific applications, international B2B buyers can make informed decisions that enhance product functionality and longevity. The effective selection of friction hinges not only ensures operational efficiency but also promotes safety and user satisfaction in marine environments.

Investing in quality marine-grade materials, such as stainless steel and corrosion-resistant alloys, is essential for ensuring durability against harsh marine conditions. Moreover, establishing strong relationships with reliable suppliers will facilitate better negotiation terms and access to innovative products that meet evolving market needs.

Looking ahead, the global marine industry is poised for growth, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers are encouraged to leverage this opportunity by exploring diverse sourcing options and staying abreast of technological advancements. By prioritizing strategic sourcing, businesses can enhance their competitive edge and contribute to a sustainable marine ecosystem. Engage with trusted suppliers today to secure the best friction hinges for your projects and ensure your operations thrive in the years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.