Top 4 Fluidized Bed Powder Coating Suppliers (And How to Choose)

Introduction: Navigating the Global Market for fluidized bed powder coating

In the quest for robust and durable metal products, sourcing fluidized bed powder coating solutions presents a critical challenge for B2B buyers across diverse industries. This innovative coating technique offers superior protection against corrosion, wear, and environmental factors, making it an attractive option for manufacturers looking to enhance the longevity and performance of their metal components. As the global market for fluidized bed powder coating continues to evolve, understanding its intricacies becomes essential for informed purchasing decisions.

This comprehensive guide delves into the various types of fluidized bed powder coatings available, their applications across sectors such as automotive, aerospace, and construction, and the benefits they provide over traditional coating methods. Additionally, we will explore effective supplier vetting processes, cost considerations, and the unique challenges faced by buyers in regions like Africa, South America, the Middle East, and Europe.

By equipping international B2B buyers with actionable insights and in-depth knowledge, this guide empowers them to navigate the complexities of sourcing fluidized bed powder coating solutions effectively. Understanding these dynamics not only enhances product quality but also drives competitive advantage in an increasingly globalized marketplace, ensuring that your business remains at the forefront of innovation and quality.

Understanding fluidized bed powder coating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermoplastic Coatings | Made from materials like PVC or nylon; can be remelted. | Automotive, Aerospace, Electronics | Pros: High durability, remeltability. Cons: Limited heat resistance compared to thermoset. |

| Thermoset Coatings | Hardens permanently upon curing; excellent chemical resistance. | Industrial Equipment, Agriculture | Pros: Superior hardness, chemical resistance. Cons: Not remeltable, more complex application. |

| Rilsan Coatings | Made from polyamide; offers flexibility and impact resistance. | Food Processing, Medical Devices | Pros: Excellent adhesion, impact resistance. Cons: Higher cost due to specialized formulation. |

| Epoxy Coatings | Known for strong adhesion and corrosion resistance. | Marine, Oil & Gas | Pros: Exceptional durability, ideal for harsh environments. Cons: Longer curing times, potential for yellowing. |

| Custom Blends | Tailored formulations to meet specific performance needs. | Diverse Industries | Pros: Versatility in application, targeted performance. Cons: Potentially higher costs and longer lead times. |

What Are the Characteristics of Thermoplastic Coatings in Fluidized Bed Powder Coating?

Thermoplastic coatings are characterized by their ability to be remelted and reshaped upon heating, making them versatile for various applications. Commonly made from materials like PVC or nylon, these coatings provide a robust layer that offers both flexibility and durability. They are particularly suitable for industries such as automotive and aerospace, where parts may need to withstand mechanical stress. When considering thermoplastic coatings, buyers should evaluate the specific temperature and environmental conditions their products will face, as these factors can impact performance.

How Do Thermoset Coatings Differ from Other Fluidized Bed Options?

Thermoset coatings undergo a chemical change during the curing process, resulting in a permanent bond that provides exceptional hardness and chemical resistance. Ideal for industrial equipment and agricultural applications, these coatings are less likely to chip or wear under harsh conditions. However, they cannot be remelted, which limits repair options. Buyers should consider the long-term durability and resistance to environmental factors when choosing thermoset coatings, as these attributes can significantly affect the lifespan of their products.

What Advantages Do Rilsan Coatings Offer for Specific Industries?

Rilsan coatings, made from polyamide, are known for their flexibility and impact resistance, making them an excellent choice for applications in food processing and medical devices. They provide strong adhesion and can withstand rigorous cleaning processes, which is crucial in these industries. While the benefits are substantial, the higher cost associated with Rilsan coatings should be justified by the performance requirements of the application. B2B buyers should assess the balance between cost and the specific performance features needed for their products.

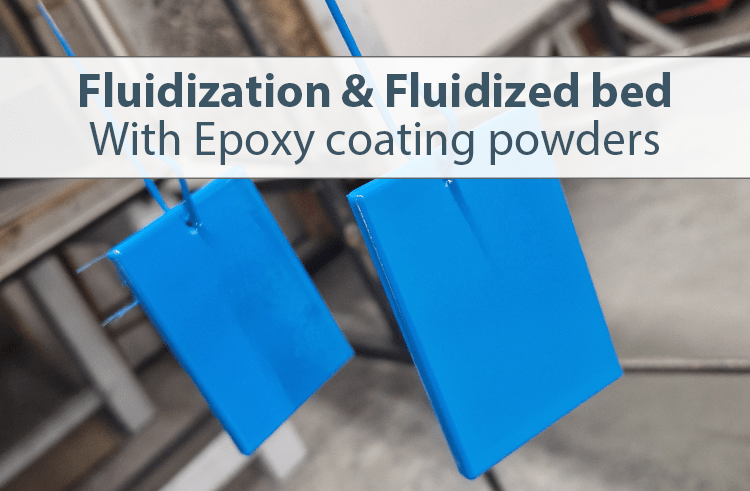

Why Are Epoxy Coatings Preferred in Marine and Oil & Gas Applications?

Epoxy coatings are favored in marine and oil & gas industries due to their strong adhesion and outstanding corrosion resistance. These coatings can endure harsh environmental conditions, making them ideal for equipment exposed to water and chemicals. However, they often require longer curing times and may be prone to yellowing over time. Buyers in these sectors should prioritize long-term performance and maintenance considerations when selecting epoxy coatings, as the initial investment can lead to significant savings in durability and repair costs.

How Can Custom Blends of Fluidized Bed Coatings Address Diverse Needs?

Custom blends of fluidized bed coatings offer tailored solutions designed to meet specific performance requirements across various industries. By combining different materials and properties, manufacturers can create coatings that excel in adhesion, flexibility, or chemical resistance, depending on the application. While these tailored solutions can incur higher costs and longer lead times, the benefits of improved performance often outweigh these considerations. B2B buyers should engage closely with suppliers to define their needs, ensuring that the custom blend aligns with their operational goals and product specifications.

Key Industrial Applications of fluidized bed powder coating

| Industry/Sector | Specific Application of fluidized bed powder coating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Coating of structural components and parts | Enhanced durability and resistance to corrosion | Ensure compliance with aerospace standards and certifications. |

| Agricultural Equipment | Coating of machinery parts and tools | Improved resistance to wear and environmental factors | Look for coatings compatible with harsh chemicals and UV exposure. |

| Marine | Coating of boat hulls and marine hardware | Protection against saltwater corrosion | Consider the coating’s adhesion properties in marine environments. |

| Medical Devices | Coating of surgical instruments and implants | Biocompatibility and enhanced durability | Verify the coating’s compliance with medical regulations. |

| Transportation | Coating of automotive and public transport parts | Increased longevity and reduced maintenance costs | Evaluate the coating’s performance under varying weather conditions. |

How Is Fluidized Bed Powder Coating Used in Aerospace Applications?

In the aerospace sector, fluidized bed powder coating is crucial for protecting structural components and parts against extreme conditions. The high durability and corrosion resistance of the coating ensure that components can withstand the rigors of flight, including exposure to harsh weather and environmental conditions. For international buyers, especially in regions like Europe and the Middle East, it’s essential to source coatings that meet strict aerospace standards and certifications, ensuring both safety and performance.

What Are the Benefits of Fluidized Bed Powder Coating for Agricultural Equipment?

Agricultural equipment often faces challenging conditions, including exposure to chemicals, dirt, and varying weather. Fluidized bed powder coating provides a robust protective layer that enhances the wear resistance of machinery parts and tools. This application helps farmers and agricultural businesses reduce maintenance costs and extend the lifespan of their equipment. Buyers in South America and Africa should prioritize coatings that are compatible with harsh chemicals and UV exposure to meet their specific operational needs.

Why Is Fluidized Bed Powder Coating Essential for Marine Applications?

In the marine industry, fluidized bed powder coating is employed to protect boat hulls and marine hardware from the corrosive effects of saltwater. The coating’s ability to create a thick, uniform layer ensures long-lasting protection against corrosion, which is vital for maintaining the integrity of marine vessels. For buyers in regions like Africa and Europe, it’s important to consider the coating’s adhesion properties, especially in challenging marine environments, to ensure optimal performance and longevity.

How Does Fluidized Bed Powder Coating Benefit Medical Device Manufacturing?

Medical devices require coatings that are not only durable but also biocompatible. Fluidized bed powder coating is used to coat surgical instruments and implants, providing a smooth, protective finish that enhances durability while ensuring safety for patients. International buyers, particularly in Europe and the Middle East, must ensure that the coatings comply with stringent medical regulations to guarantee that the products meet health and safety standards.

What Advantages Does Fluidized Bed Powder Coating Offer in Transportation?

In the transportation sector, fluidized bed powder coating is applied to automotive and public transport parts to enhance durability and reduce maintenance costs. The thick coating protects against corrosion and wear, which is crucial for parts exposed to various weather conditions. Buyers in regions like Brazil and Nigeria should evaluate the coating’s performance under diverse environmental conditions to ensure that it meets their operational requirements and provides long-term value.

Illustrative image related to fluidized bed powder coating

3 Common User Pain Points for ‘fluidized bed powder coating’ & Their Solutions

Scenario 1: Inconsistent Coating Thickness Leading to Product Rework

The Problem: A manufacturer of agricultural equipment faces issues with inconsistent coating thickness on their metal components due to the variability in the fluidized bed powder coating process. Some parts are overly thick, while others have bare spots, leading to premature corrosion and wear. This inconsistency not only affects the product’s durability but also increases production costs due to the need for rework and additional quality checks. As a result, the company struggles to maintain customer satisfaction and faces delays in fulfilling orders.

The Solution: To mitigate these issues, the manufacturer should prioritize the preheating process of the metal components. Ensuring that the metal parts are uniformly heated to the optimal temperature (ideally between 400 to 450 degrees Fahrenheit) before dipping into the fluidized bed can significantly enhance coating consistency. Additionally, investing in a temperature monitoring system can provide real-time data to adjust heating protocols as needed. Furthermore, incorporating a rigorous pre-coating inspection and cleaning process, such as sandblasting, will ensure that all surfaces are adequately prepared for coating, promoting better adhesion and uniformity. Collaborating with experienced coating service providers who can offer technical insights on optimal material handling will also streamline operations.

Scenario 2: Environmental Compliance Challenges with Powder Coatings

The Problem: A company in Brazil that specializes in manufacturing automotive parts is struggling to meet stringent environmental regulations regarding volatile organic compounds (VOCs) emissions. Although fluidized bed powder coating is generally more environmentally friendly than liquid coatings, some suppliers’ products still contain VOCs that can lead to compliance issues. This situation poses a risk of fines and could damage the company’s reputation in an increasingly eco-conscious market.

Illustrative image related to fluidized bed powder coating

The Solution: To navigate these environmental compliance challenges, the company should conduct thorough research on suppliers that offer low-VOC or zero-VOC fluidized bed powder coatings. Establishing a partnership with a coating manufacturer that specializes in environmentally friendly solutions can help ensure compliance with local regulations. Additionally, the company can invest in air quality monitoring systems to track emissions during the coating process. This proactive approach not only aids in compliance but also demonstrates the company’s commitment to sustainability, potentially attracting eco-conscious clients. Regular training for staff on best practices in handling and applying powder coatings will further enhance compliance and operational efficiency.

Scenario 3: Incompatibility of Coatings with Diverse Substrates

The Problem: A metal fabrication business in Nigeria faces difficulties when attempting to use fluidized bed powder coating on a variety of substrates, including aluminum, steel, and certain plastics. The coatings often do not adhere properly, resulting in chipping and peeling, which leads to increased warranty claims and customer dissatisfaction. The complexity of managing different materials without a standardized approach adds to the operational headache and impacts overall productivity.

The Solution: To address the compatibility issues, the business should standardize its approach by categorizing substrates and matching them with appropriate powder coatings. Conducting compatibility tests for each substrate type before committing to a large production run is crucial. Additionally, sourcing fluidized bed powders that are specifically formulated for diverse materials can enhance adhesion and performance. Training staff on substrate-specific preparation techniques, such as surface treatments or priming, will ensure better bonding of the powder coating. Lastly, working closely with suppliers who can provide technical support and advice on the best practices for each substrate will help optimize the coating process and reduce the risk of defects.

Illustrative image related to fluidized bed powder coating

Strategic Material Selection Guide for fluidized bed powder coating

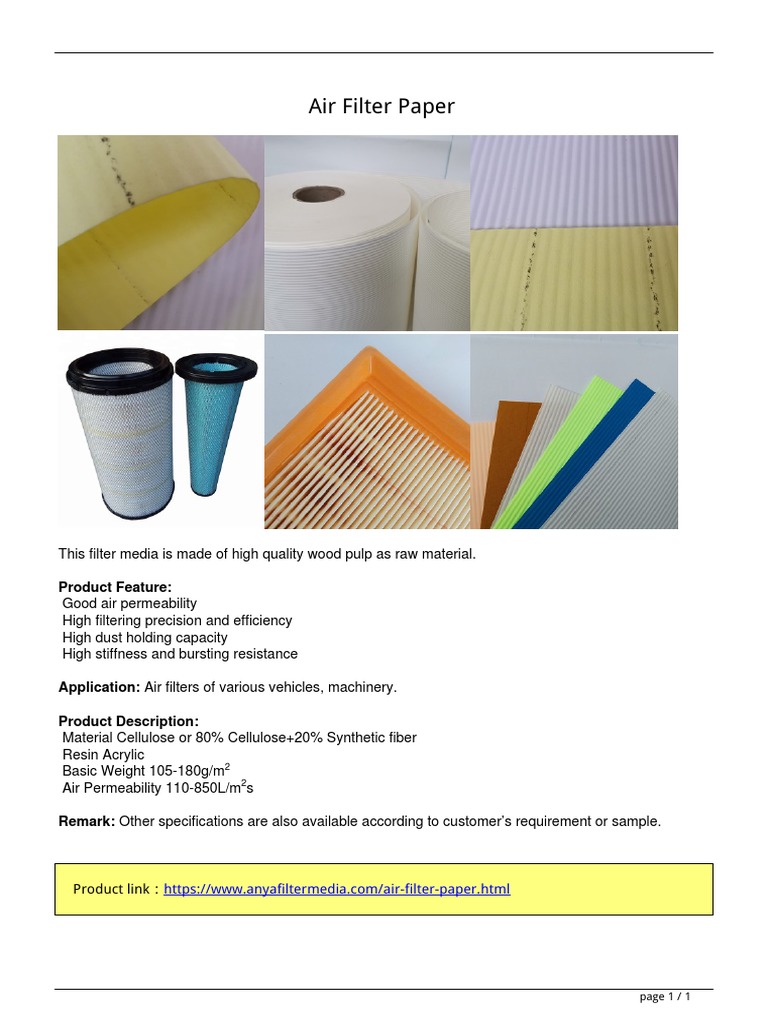

What Are the Key Materials Used in Fluidized Bed Powder Coating?

When selecting materials for fluidized bed powder coating, it is essential to consider various factors that influence product performance and suitability for specific applications. Here, we analyze four common materials used in this process: Polyvinyl Chloride (PVC), Nylon, Polyethylene, and Thermoplastic Elastomers (TPE). Each material has unique properties, advantages, and limitations that can significantly affect the final product’s performance.

How Does Polyvinyl Chloride (PVC) Perform in Fluidized Bed Powder Coating?

PVC is a widely used thermoplastic in fluidized bed powder coating due to its excellent chemical resistance and durability. It has a temperature rating of up to 140°C (284°F) and is resistant to a variety of corrosive chemicals, making it suitable for applications in harsh environments.

Pros: PVC offers good adhesion properties and a smooth finish, which enhances the aesthetic appeal of coated products. It is also relatively cost-effective, making it a popular choice among manufacturers.

Cons: However, PVC can be less durable than other materials when exposed to UV light, leading to potential degradation over time. Its processing temperature is lower than some alternatives, which can limit its application in high-temperature environments.

Illustrative image related to fluidized bed powder coating

Impact on Application: PVC is compatible with various media, including water and oils, but may not be suitable for applications involving high temperatures or prolonged UV exposure.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local environmental regulations regarding PVC, as it can release harmful substances during processing.

What Are the Benefits of Using Nylon in Fluidized Bed Powder Coating?

Nylon is another popular choice for fluidized bed powder coating, known for its high strength and excellent wear resistance. It can withstand temperatures up to 200°C (392°F), making it suitable for applications that encounter high thermal stress.

Pros: Nylon’s toughness and flexibility allow it to absorb impacts without cracking, making it ideal for industrial applications. It also provides good chemical resistance, particularly against oils and fuels.

Cons: On the downside, nylon can be more expensive than PVC and may require more complex processing techniques, which can increase manufacturing costs.

Impact on Application: Nylon is particularly effective for applications requiring high durability and resistance to abrasion, such as automotive and industrial components.

Considerations for International Buyers: Buyers should be aware of the varying standards for nylon coatings in different regions, including ASTM and DIN, to ensure compliance.

Why Choose Polyethylene for Fluidized Bed Powder Coating?

Polyethylene is a versatile thermoplastic that offers excellent impact resistance and low friction properties. It has a temperature rating of up to 80°C (176°F), making it suitable for a range of applications, though it is not as heat-resistant as PVC or nylon.

Pros: Polyethylene is lightweight and cost-effective, making it an attractive option for manufacturers looking to reduce production costs while maintaining quality.

Cons: Its lower temperature resistance limits its use in high-heat applications, and it may not adhere as well to certain substrates compared to PVC or nylon.

Impact on Application: Polyethylene is often used in consumer goods and packaging applications where impact resistance is essential.

Considerations for International Buyers: Buyers should consider local preferences for polyethylene grades and ensure compliance with safety standards, particularly in food-related applications.

What Advantages Do Thermoplastic Elastomers (TPE) Offer?

Thermoplastic elastomers combine the properties of rubber and plastic, offering flexibility and durability. They can withstand temperatures up to 120°C (248°F) and provide excellent resistance to abrasion and chemicals.

Pros: TPEs are highly versatile and can be formulated to meet specific performance requirements, making them suitable for a wide range of applications, from automotive to consumer products.

Cons: The primary drawback is their higher cost compared to other materials, which may deter some manufacturers from using them in price-sensitive markets.

Impact on Application: TPEs are particularly effective for applications requiring a soft touch or enhanced grip, making them ideal for handles and grips.

Considerations for International Buyers: Buyers should evaluate local market demands for TPE products and ensure compliance with relevant standards.

Summary Table of Material Selection for Fluidized Bed Powder Coating

| Material | Typical Use Case for fluidized bed powder coating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Chemical-resistant coatings for industrial parts | Cost-effective and good adhesion | Less durable under UV exposure | Low |

| Nylon | High-strength components in automotive applications | Excellent wear resistance | More complex processing | Medium |

| Polyethylene | Packaging and consumer goods | Lightweight and cost-effective | Limited heat resistance | Low |

| Thermoplastic Elastomers (TPE) | Soft-touch applications like grips | Highly versatile and flexible | Higher cost compared to alternatives | High |

This analysis provides a comprehensive overview of the key materials used in fluidized bed powder coating, allowing international B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fluidized bed powder coating

What Are the Key Stages in the Manufacturing Process of Fluidized Bed Powder Coating?

Fluidized bed powder coating is a sophisticated process designed to enhance the durability and aesthetics of metal products. Understanding the stages involved in manufacturing can help B2B buyers ensure they are partnering with the right suppliers. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fluidized Bed Powder Coating?

The first step in the fluidized bed powder coating process is material preparation. This stage involves cleaning the metal parts to remove any contaminants that could affect adhesion. Techniques such as sandblasting or chemical cleaning are commonly employed to ensure a pristine surface. After cleaning, the metal parts may be pre-treated with a primer to further enhance the bond between the powder coating and the substrate.

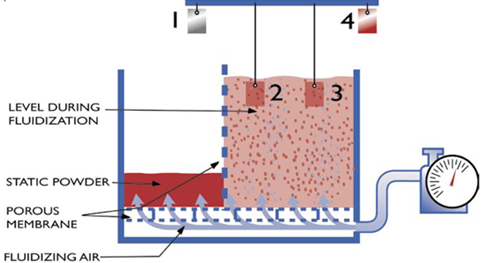

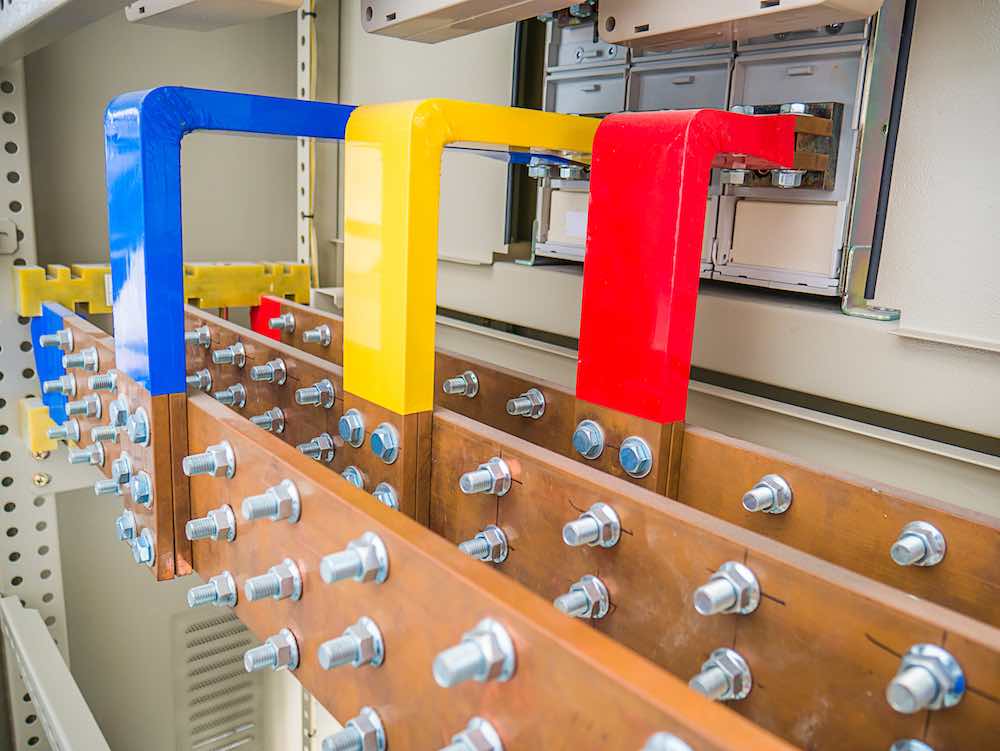

What Techniques Are Used in Forming and Coating?

Once the material is prepared, the next stage is forming, which typically involves preheating the metal parts to a specific temperature, usually between 350°F and 450°F. This step is crucial as it allows the fluidized powder to melt upon contact, ensuring a uniform coating.

Illustrative image related to fluidized bed powder coating

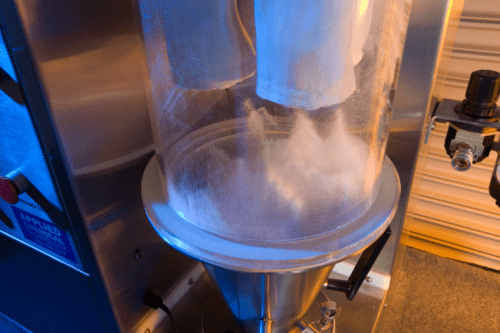

The fluidized bed coating technique itself involves a specialized apparatus where finely ground powder particles are suspended in a chamber. Air is forced through a porous membrane at the bottom, creating a fluid-like state. The preheated metal parts are then immersed in this fluidized powder, ensuring that they are coated evenly. The thickness of the coating can be adjusted by controlling the immersion time and the temperature of the metal parts.

What Finishing Processes Are Involved in Fluidized Bed Powder Coating?

After coating, the parts undergo a post-fusing process, where they are placed in a curing oven at a lower temperature. This step solidifies the powder into a durable finish, providing excellent resistance to corrosion, wear, and environmental factors. The entire process is designed to produce a consistent, high-quality finish that meets the rigorous demands of various industries.

How Is Quality Assurance Managed in Fluidized Bed Powder Coating?

Quality assurance (QA) is critical in the fluidized bed powder coating process, as it directly impacts the performance and longevity of the coated products. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers adhere to best practices.

Illustrative image related to fluidized bed powder coating

What Are the Relevant International Standards for Fluidized Bed Powder Coating?

B2B buyers should look for suppliers that comply with relevant international standards, such as ISO 9001 for quality management and CE marking for products sold in the European market. Additionally, industry-specific certifications like API (American Petroleum Institute) may be necessary for sectors such as oil and gas. Understanding these standards can help buyers assess the credibility and reliability of potential suppliers.

What Are the Key QC Checkpoints in Fluidized Bed Powder Coating?

Quality control (QC) in fluidized bed powder coating typically involves several key checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials and components to ensure they meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, various parameters such as temperature, coating thickness, and adhesion are monitored to ensure they remain within acceptable limits.

-

Final Quality Control (FQC): After the coating process, the finished products undergo comprehensive testing to verify that they meet all quality specifications.

What Common Testing Methods Are Used to Ensure Quality?

To maintain high-quality standards, manufacturers employ a variety of testing methods, including:

-

Adhesion Testing: Ensures that the powder coating adheres effectively to the substrate.

-

Thickness Measurement: Uses tools such as micrometers or ultrasonic thickness gauges to measure the coating’s thickness accurately.

-

Corrosion Resistance Testing: Evaluates the coated parts’ ability to withstand corrosive environments, often using salt spray tests.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is essential to mitigate risks. Here are some actionable steps:

Illustrative image related to fluidized bed powder coating

-

Conduct Supplier Audits: Regular audits can help assess the supplier’s adherence to quality standards and processes. Consider scheduling both announced and unannounced audits to get a comprehensive view.

-

Request Quality Reports: Ask suppliers for detailed quality reports that outline their QC processes, results of tests conducted, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality management practices and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing fluidized bed powder coating services from international suppliers, especially in regions like Africa, South America, the Middle East, and Europe, it’s vital to understand the specific quality control nuances. Different regions may have varying standards and regulations, which can impact product quality.

For instance, buyers should be aware of local regulations that may affect the sourcing of raw materials or the environmental impact of coating processes. Additionally, cultural differences can influence the approach to quality assurance; thus, establishing clear communication and expectations is crucial.

In summary, understanding the manufacturing processes and quality assurance mechanisms for fluidized bed powder coating is essential for B2B buyers. By focusing on the key stages of production, relevant international standards, and effective verification methods, businesses can ensure they partner with reliable suppliers that deliver high-quality coated products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fluidized bed powder coating’

To effectively source fluidized bed powder coating services, B2B buyers must navigate a variety of considerations that ensure they select a supplier that meets their specific needs. This guide provides a step-by-step checklist to help you make informed procurement decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clarify your product requirements. Consider factors such as the type of metal, the desired thickness of the coating, and any specific environmental resistance needed. Defining these parameters early will streamline the selection process and help suppliers provide accurate proposals.

Step 2: Research Potential Suppliers

Conduct thorough research to identify qualified suppliers specializing in fluidized bed powder coating. Look for companies with a proven track record in your industry, and ensure they have the capacity to handle your volume needs. Utilize industry directories, trade shows, and online platforms to compile a list of potential partners.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications that demonstrate compliance with industry standards. Certifications such as ISO 9001 or environmental management certifications indicate a commitment to quality and sustainability. This step is crucial to ensure that the coatings used are safe, effective, and environmentally friendly.

Step 4: Request Samples and Case Studies

Before making a commitment, ask for samples of the coatings and case studies of similar projects. This will allow you to assess the quality and performance of the coating under real-world conditions. Pay attention to the finish, durability, and resistance to wear and corrosion.

Step 5: Assess Production Capabilities

Inquire about the supplier’s production capabilities, including their equipment and technology used in the fluidized bed process. A supplier with modern, efficient machinery will be able to produce consistent quality coatings. Additionally, check their lead times and flexibility in handling urgent orders or varying batch sizes.

Step 6: Review Pricing and Terms

Obtain detailed pricing from shortlisted suppliers, ensuring that all costs are transparent, including setup fees and shipping. Compare these costs against the quality of service and materials offered. Look for terms that provide flexibility and security, such as warranties on the coatings and clear return policies.

Step 7: Establish Communication and Support

Effective communication is vital for a successful partnership. Assess the supplier’s responsiveness and willingness to provide ongoing support. Establish a clear point of contact for any questions or issues that may arise during the coating process. A supplier who prioritizes customer service can greatly enhance your procurement experience.

By following these steps, B2B buyers can navigate the complexities of sourcing fluidized bed powder coating services, ensuring they choose a partner who meets their technical needs and business goals.

Comprehensive Cost and Pricing Analysis for fluidized bed powder coating Sourcing

What Are the Key Cost Components in Fluidized Bed Powder Coating?

When considering fluidized bed powder coating, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to fluidized bed powder coating

-

Materials: The cost of thermoplastic powders, such as PVC or nylon, forms a significant part of the overall expense. The price can vary based on the quality and specific formulations required for different applications.

-

Labor: Skilled labor is essential for the application process, which includes preheating, dip-coating, and post-curing. Labor costs can fluctuate based on the local market and the level of expertise required.

-

Manufacturing Overhead: This encompasses the costs associated with operating the coating facility, including utilities, equipment maintenance, and facility rental. Overhead can be a significant factor, particularly in regions where energy costs are high.

-

Tooling: The initial setup costs for specialized equipment and molds can be substantial, especially for custom parts. Investment in high-quality tooling is crucial to ensure precision and efficiency.

-

Quality Control (QC): Rigorous quality checks are necessary to maintain standards and certifications. This can add to the cost but is essential for ensuring product reliability and customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly depending on the distance and mode of transportation. International buyers must consider customs duties and tariffs, which can impact overall pricing.

-

Margin: Suppliers typically mark up prices to cover their operational costs and ensure profitability. Margins can vary based on market competition and the uniqueness of the coating services offered.

What Influences Pricing for Fluidized Bed Powder Coating?

Several factors can influence the pricing of fluidized bed powder coating, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from bulk pricing. Buyers should negotiate MOQs to optimize costs while ensuring their production needs are met.

-

Specifications and Customization: Custom formulations or specific application requirements can increase costs. Buyers should clearly define specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials and compliance with industry certifications can raise prices. Buyers should weigh the benefits of premium materials against budget constraints.

-

Supplier Factors: The reputation, experience, and location of the supplier can influence pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: Understanding the terms of shipping and delivery can impact total costs. Different Incoterms can shift responsibilities and costs between buyers and sellers, affecting the final price.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, can employ several strategies to secure better pricing:

-

Effective Negotiation: Engaging in open discussions about pricing, volume discounts, and payment terms can yield favorable outcomes. Building a relationship with suppliers may also lead to better pricing over time.

-

Cost-Efficiency Analysis: Consider the total cost of ownership (TCO) rather than just the upfront price. Evaluating factors like durability and maintenance can provide a clearer picture of long-term value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping costs, which can all impact the final price. Conducting thorough market research can help in understanding local pricing dynamics.

-

Supplier Diversification: Engaging multiple suppliers can foster competition and lead to better pricing. It’s essential to assess their capabilities and reliability before making commitments.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can often result in more favorable pricing and priority service. Consistent orders can also lead to lower costs due to economies of scale.

Disclaimer

Prices for fluidized bed powder coating can vary widely based on numerous factors, including market conditions, supplier capabilities, and specific project requirements. Buyers should seek quotes from multiple suppliers to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing fluidized bed powder coating With Other Solutions

In the realm of industrial coatings, various methods exist to enhance the durability and aesthetic appeal of metal products. Fluidized bed powder coating is one such method, known for its robust performance and environmental benefits. However, it’s essential for B2B buyers to evaluate alternatives to determine the best fit for their specific needs. Below is a comparison of fluidized bed powder coating against two viable alternatives: electrostatic spray coating and traditional liquid paint.

| Comparison Aspect | Fluidized Bed Powder Coating | Electrostatic Spray Coating | Traditional Liquid Paint |

|---|---|---|---|

| Performance | Excellent adhesion and uniform thickness; ideal for thick coatings. | Good adhesion; can achieve fine detail but may have uneven thickness. | Variable adhesion; prone to drips and sags, leading to weak areas. |

| Cost | Moderate initial investment; low material waste leads to cost efficiency. | Moderate to high cost depending on equipment; some material waste. | Generally lower initial costs; high material waste can increase overall expenses. |

| Ease of Implementation | Requires specialized equipment and preheating process; more complex setup. | Easier to implement with portable systems; less equipment needed. | Simple application; no special equipment required. |

| Maintenance | Low maintenance once equipment is in place; requires cleaning of parts. | Moderate maintenance; regular cleaning of spray guns necessary. | High maintenance; equipment often needs frequent cleaning and repairs. |

| Best Use Case | Ideal for large, simple shapes needing thick, protective coatings. | Best for complex shapes and intricate designs requiring detail. | Suitable for projects with budget constraints or where durability is less critical. |

How Does Electrostatic Spray Coating Compare to Fluidized Bed Powder Coating?

Electrostatic spray coating utilizes charged powder particles that adhere to grounded surfaces, allowing for intricate designs and finishes. This method excels in versatility, accommodating various shapes and sizes. However, it may not achieve the same thickness as fluidized bed powder coating, which can compromise durability. Maintenance is a consideration, as spray guns require regular cleaning to prevent clogging, which can impact production efficiency.

What Are the Advantages of Traditional Liquid Paint Over Fluidized Bed Powder Coating?

Traditional liquid paint offers a straightforward application process, often requiring less specialized equipment than fluidized bed powder coating. It can be more cost-effective upfront, particularly for smaller projects or those with budget constraints. However, the downsides include a higher rate of material waste and potential for uneven finishes due to dripping or sagging. This can lead to increased rework and long-term costs, making it less ideal for high-durability applications.

How Should B2B Buyers Choose the Right Coating Solution?

When selecting a coating method, B2B buyers should consider several factors including performance requirements, budget constraints, and the specific characteristics of the products being coated. For items requiring substantial protection against wear and corrosion, fluidized bed powder coating is an excellent choice. Conversely, for projects with intricate designs or lower durability requirements, electrostatic spray coating or traditional liquid paint may suffice. Assessing these aspects can guide buyers toward a solution that aligns with their operational needs and product expectations.

Essential Technical Properties and Trade Terminology for fluidized bed powder coating

What Are the Key Technical Properties of Fluidized Bed Powder Coating?

Fluidized bed powder coating is a sophisticated process that requires an understanding of its essential technical properties. Here are some critical specifications that every B2B buyer should know:

Illustrative image related to fluidized bed powder coating

1. Material Grade

Material grade refers to the quality and type of powder used in the coating process. Common materials include thermoplastic powders such as polyvinyl chloride (PVC), nylon, and polyethylene. The choice of material affects the coating’s durability, resistance to chemicals, and overall finish. Selecting the right material grade is crucial for ensuring that the final product meets industry standards and customer expectations.

2. Coating Thickness

Coating thickness is a vital specification that typically ranges from 10 to 100 mils (0.25 to 2.5 mm). This thickness directly influences the coating’s durability and resistance to wear and corrosion. In B2B contexts, understanding the required coating thickness helps in determining the right equipment and process parameters, ensuring that the product is adequately protected while maintaining compliance with industry regulations.

3. Curing Temperature

Curing temperature is the heat required to properly fuse the powder coating to the substrate. Generally, fluidized bed coatings require a curing temperature of around 350°F to 450°F (175°C to 232°C). This specification is critical for achieving a uniform, durable finish. In B2B transactions, specifying the correct curing temperature ensures that both the supplier and the manufacturer are aligned in their expectations for product quality.

4. Adhesion Strength

Adhesion strength measures how well the powder coating adheres to the substrate post-curing. This property is essential for ensuring that the coating will withstand various environmental conditions without peeling or flaking. B2B buyers should evaluate adhesion strength through standardized tests to ensure that the coating will meet the durability requirements of their specific applications.

5. Transfer Efficiency

Transfer efficiency refers to the percentage of powder that adheres to the substrate versus what is wasted during the coating process. A high transfer efficiency (typically above 90%) is economically advantageous as it minimizes material costs and reduces waste. In B2B procurement, understanding transfer efficiency can lead to better pricing negotiations and more sustainable practices.

Illustrative image related to fluidized bed powder coating

6. Color Stability

Color stability is the resistance of the powder coating to fading or discoloration over time, particularly under UV exposure. This property is crucial for applications where aesthetic appearance is essential. B2B buyers need to ensure that the coatings they choose maintain their color integrity, aligning with branding and customer satisfaction.

What Are Common Trade Terms in Fluidized Bed Powder Coating?

Familiarizing yourself with industry jargon can facilitate smoother transactions and better communication. Here are some commonly used terms in the fluidized bed powder coating sector:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fluidized bed powder coating, OEMs often require specialized coatings for their components to meet specific performance standards. Understanding OEM specifications can help buyers ensure that their products are compatible with those of larger manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In fluidized bed powder coating, MOQs can affect inventory management and production planning. B2B buyers should be aware of MOQs to ensure they can meet their own production needs without incurring unnecessary costs.

Illustrative image related to fluidized bed powder coating

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request price quotations for specific products or services. In the fluidized bed powder coating industry, an RFQ can help buyers compare prices and terms from different suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in cross-border trade of powder coatings, as they determine who bears the risk and costs during shipping and delivery.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. In fluidized bed powder coating, lead time can vary based on factors like production capacity and material availability. B2B buyers should account for lead times in their planning to avoid production delays.

6. Post-Fusing Process

The post-fusing process is the final step in fluidized bed powder coating, where the coated item is cured at a lower temperature after being dipped. This ensures a smooth, durable finish. Understanding this term helps B2B buyers grasp the importance of the curing process in achieving product quality.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions in your procurement processes and enhance the quality of your products.

Navigating Market Dynamics and Sourcing Trends in the fluidized bed powder coating Sector

What Are the Current Market Dynamics and Key Trends in Fluidized Bed Powder Coating?

The fluidized bed powder coating sector is witnessing significant growth, driven by a surge in demand for durable and environmentally friendly coating solutions across various industries, including aerospace, automotive, and construction. The global market for powder coatings is expected to expand at a CAGR of over 6% through 2030, spurred by rising industrialization and the need for advanced surface protection. Emerging technologies, such as enhanced fluidization techniques and automated coating systems, are streamlining production processes, making them more efficient and reducing waste. This shift is particularly relevant for international B2B buyers in regions like Africa and South America, where manufacturing capabilities are evolving.

Key trends influencing the market include the increasing adoption of thermoplastic powders due to their recyclability and superior performance characteristics. Additionally, the focus on custom solutions is growing, with suppliers offering tailored powder formulations to meet specific industry requirements. For buyers in the Middle East and Europe, understanding regional regulations and preferences is crucial, as local standards for coatings can vary widely. The rise of e-commerce platforms for industrial supplies is also transforming sourcing strategies, allowing buyers to access a broader range of products and suppliers more easily.

How Is Sustainability and Ethical Sourcing Shaping the Fluidized Bed Powder Coating Industry?

Sustainability is at the forefront of procurement strategies in the fluidized bed powder coating sector. Traditional solvent-based coatings contribute significantly to environmental pollution through volatile organic compounds (VOCs), prompting a shift toward powder coatings that are not only eco-friendly but also compliant with stringent regulations. B2B buyers are increasingly prioritizing suppliers that offer sustainable solutions, including those with certifications such as ISO 14001 for environmental management and Green Seal for non-toxic products.

Illustrative image related to fluidized bed powder coating

Ethical sourcing is equally important, as businesses are held accountable for their supply chain practices. Buyers should seek suppliers who demonstrate transparency in their sourcing methods and adhere to fair labor practices. Additionally, the use of recycled materials in powder formulations is gaining traction, appealing to organizations focused on reducing their carbon footprint. By aligning with sustainable suppliers, companies can enhance their brand reputation while contributing to a more responsible manufacturing ecosystem.

What Is the Historical Context of Fluidized Bed Powder Coating in the B2B Landscape?

Fluidized bed powder coating has its roots in the mid-20th century when the need for more resilient coatings emerged alongside industrial advancements. Initially developed for use in the automotive sector, the technique has evolved to accommodate a wide array of applications, from military and aerospace to consumer goods. The method gained popularity due to its ability to provide a thick, uniform coating that enhances durability and resistance to corrosion.

Over the years, advancements in powder technology and application processes have made fluidized bed coating more accessible and efficient. The introduction of more sophisticated machinery and materials has enabled manufacturers to improve their coating quality while reducing operational costs. As a result, fluidized bed powder coating has become a preferred choice for businesses seeking reliable and environmentally friendly solutions in an increasingly competitive marketplace. This historical context underscores the importance of understanding both the technical and market evolution for B2B buyers seeking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of fluidized bed powder coating

-

How do I choose the right supplier for fluidized bed powder coating?

Selecting the right supplier involves evaluating their experience, industry reputation, and technical capabilities. Look for suppliers who specialize in fluidized bed powder coating and have a proven track record with your industry or product type. Request case studies or references from previous clients, particularly those in your region. It’s also essential to assess their quality control processes, certifications, and the technology they use to ensure they can meet your specific requirements. -

What is the minimum order quantity (MOQ) for fluidized bed powder coating services?

MOQs can vary significantly between suppliers and are often influenced by factors such as the complexity of your coating requirements and the type of materials being coated. Typically, for fluidized bed powder coating, MOQs may range from a few hundred to several thousand units. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that suit your production scale and budget. -

What are the payment terms I can expect when sourcing fluidized bed powder coating?

Payment terms for fluidized bed powder coating can differ based on supplier policies and your relationship with them. Common terms include upfront deposits (often 30-50%), with the remaining balance due upon completion or delivery. Some suppliers may offer net 30 or net 60 payment terms for established clients. Ensure to clarify payment terms during negotiations to avoid any misunderstandings later in the process. -

How does fluidized bed powder coating compare to traditional liquid coatings?

Fluidized bed powder coating offers several advantages over traditional liquid coatings, including superior durability, a thicker application, and less environmental impact due to lower VOC emissions. The coating process also results in a more uniform finish, reducing the risk of drips and sagging. For products requiring high wear and corrosion resistance, fluidized bed powder coating is often the preferred choice, particularly in industrial applications. -

What industries benefit the most from fluidized bed powder coating?

Fluidized bed powder coating is widely used across various industries, including aerospace, automotive, agricultural, and medical equipment manufacturing. Its ability to provide a robust, protective layer makes it ideal for components exposed to harsh environments. Additionally, industries focused on aesthetic quality, such as furniture and consumer goods, also leverage this coating method for its smooth and durable finish. -

What quality assurance measures should I look for in a fluidized bed powder coating supplier?

When vetting suppliers, inquire about their quality assurance (QA) processes. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Suppliers should conduct regular inspections and tests, such as adhesion tests and thickness measurements, to ensure the coatings meet specified standards. A transparent QA process demonstrates a supplier’s dedication to delivering high-quality products consistently. -

How can logistics impact my sourcing of fluidized bed powder coating?

Logistics play a crucial role in the timely delivery of coated products. Consider factors such as shipping times, customs regulations, and potential delays in your region. Choose suppliers who have experience with international shipping and can navigate customs efficiently. Additionally, discuss packaging methods to ensure your products arrive in pristine condition. Effective logistics management helps mitigate risks associated with supply chain disruptions. -

Can fluidized bed powder coating be customized to fit specific project needs?

Yes, fluidized bed powder coating can be tailored to meet specific project requirements, including color, finish, and thickness. Many suppliers offer a range of colors and textures, allowing for customization to match branding or design specifications. Discuss your needs with suppliers during the initial consultation to explore available options and ensure that the final product aligns with your expectations.

Top 4 Fluidized Bed Powder Coating Manufacturers & Suppliers List

1. Chempoint – Rilsan Coatings

Domain: chempoint.com

Registered: 1999 (26 years)

Introduction: Rilsan Coatings – Fluidized Bed is a powder coating solution that utilizes electrostatic spray application for precise surface thickness control and comprehensive coverage. The fluidized bed coating process involves preheating and dipping metal parts into a fluid bed of polyamide 11 thermoplastic powders, resulting in a consistent coating thickness. Key features include:

– Ideal for parts at leas…

2. Reddit – Powder Coating Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Powder Coating Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Finishing & Coating – Fluidization Solutions

Domain: finishingandcoating.com

Registered: 2020 (5 years)

Introduction: Fluidization is essential for successful powder coating applications, using air to turn powder into a liquid state for even application and smooth flow through guns. Common fluidization issues include: 1. Powder blowing out of the hopper due to high powder levels or fluidizing pressure, fine powder, blocked hoppers, or poor venting. Solutions include marking hopper levels, adjusting virgin to recl…

4. Simply Crappie – 2 Powder Coating Fluid Bed

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {‘title’: ‘2″ Powder Coating Fluid Bed’, ‘brand’: ‘Simply Crappie’, ‘condition’: ‘New’, ‘price’: ‘US $42.99’, ‘shipping_cost’: ‘US $9.99’, ‘location’: ‘Iberia, Missouri, United States’, ‘quantity_available’: ‘More than 10 available’, ‘quantity_sold’: ’15 sold’, ‘returns’: ’30 days returns, buyer pays for return shipping’, ‘payment_options’: ‘4 interest-free payments of $10.75’, ‘fishing_type’: ‘Fr…

Strategic Sourcing Conclusion and Outlook for fluidized bed powder coating

In the rapidly evolving landscape of manufacturing, fluidized bed powder coating stands out as a superior choice for businesses seeking durability and efficiency. This coating method offers substantial benefits, including enhanced corrosion resistance, environmental safety, and uniform application, making it ideal for diverse industries—from aerospace to transportation. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of fluidized bed powder coating solutions can lead to significant cost savings and improved product quality.

Investing in this technology not only maximizes the longevity of metal products but also aligns with global sustainability trends by minimizing waste and harmful emissions. As your business navigates sourcing decisions, consider partnering with established coating providers who understand regional market dynamics and can offer tailored solutions to meet your specific needs.

Looking ahead, the demand for high-quality coatings is set to rise, driven by increasing industrialization and environmental regulations. Now is the time to leverage fluidized bed powder coating as a strategic asset for your operations. Embrace this opportunity to enhance your product offerings and secure a competitive edge in the marketplace. Reach out to reliable suppliers today to explore how fluidized bed powder coating can transform your manufacturing processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.