Top 4 Electric Cord Parts Suppliers (And How to Choose)

Introduction: Navigating the Global Market for electric cord parts

In today’s interconnected world, sourcing electric cord parts can pose significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Whether you’re looking to procure extension cords, power adapters, or specialized connectors, understanding the nuances of quality, compliance, and supplier reliability is crucial for ensuring operational efficiency. This guide serves as a comprehensive resource, equipping buyers with essential insights into the various types of electric cord components, their applications across different industries, and the critical factors to consider when vetting suppliers.

As you navigate this complex landscape, you’ll discover how to evaluate product specifications, such as gauge ratings and amperage capacities, which are vital for matching the right cord to your needs. Furthermore, we will delve into the cost structures associated with these components, providing transparency that empowers you to make informed purchasing decisions. By addressing common pitfalls and offering actionable strategies, this guide aims to enhance your procurement process, enabling you to select high-quality electric cord parts that meet your operational requirements and compliance standards. With the right knowledge at your disposal, you can confidently engage with suppliers, ensuring that your sourcing efforts yield the best possible results in today’s competitive global market.

Understanding electric cord parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Extension Cords | Multiple lengths, various gauges, indoor/outdoor use | Construction sites, office setups | Pros: Versatile, portable; Cons: Risk of overload if not matched to amperage. |

| Power Cords | Fixed length, often appliance-specific, varying gauge sizes | Home appliances, industrial machinery | Pros: Designed for specific devices; Cons: Limited adaptability across devices. |

| Generator Cords | Heavy-duty, often weather-resistant, high amperage ratings | Emergency services, outdoor events | Pros: Durable, reliable for high power; Cons: Bulkier and may require specific outlets. |

| Appliance Cords | Typically shorter, designed for specific appliances, various plug types | Consumer electronics, kitchen equipment | Pros: Tailored for specific appliances; Cons: Limited reach may necessitate additional cords. |

| Custom Cords | Tailored specifications, unique lengths and connectors | Specialized machinery, unique setups | Pros: Perfect fit for specific needs; Cons: Longer lead times and potentially higher costs. |

What are the Key Characteristics of Extension Cords for B2B Use?

Extension cords are versatile tools that allow for increased flexibility in electrical setups. They come in various lengths and gauges, making them suitable for both indoor and outdoor applications. B2B buyers should consider the amperage rating and wire gauge to prevent overloads, as using a cord that cannot handle the required power can lead to hazards. They are particularly valuable in construction sites and office setups where temporary power solutions are needed.

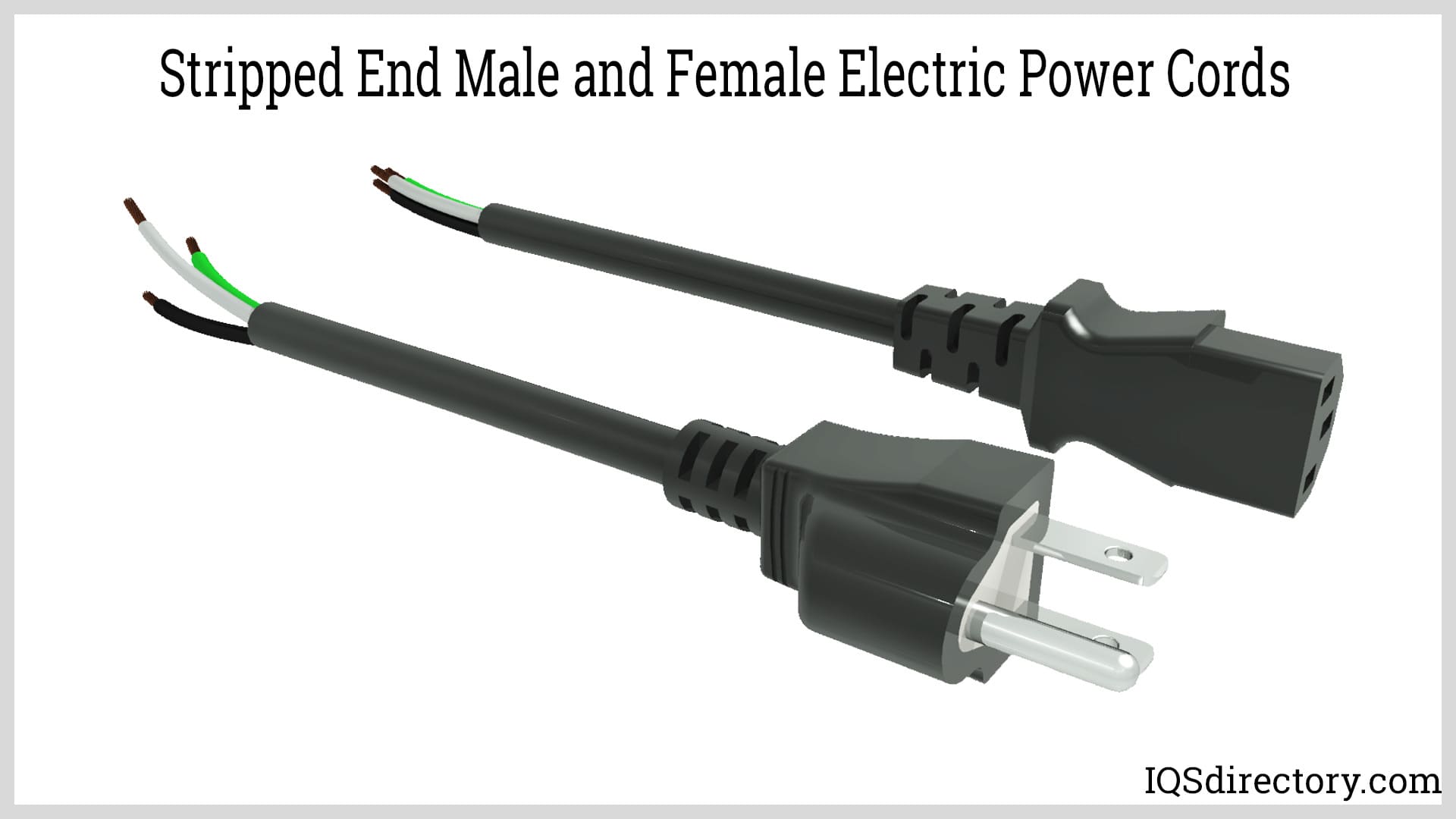

How Do Power Cords Differ in Their Applications?

Power cords are typically fixed in length and designed for specific appliances, ranging from consumer electronics to industrial machinery. They come in various gauge sizes, which determine the amount of current they can safely carry. For B2B buyers, understanding the compatibility of power cords with specific devices is crucial, as using the wrong type can result in inefficiencies or equipment damage. These cords are essential in environments where equipment is permanently installed, offering a reliable power source.

What Makes Generator Cords Essential for Certain Industries?

Generator cords are built to withstand harsh conditions and high power demands, making them indispensable in emergency services and outdoor events. They often feature weather-resistant materials and higher amperage ratings to handle the significant power output from generators. B2B buyers should prioritize durability and safety ratings when selecting generator cords, as these factors directly influence the reliability of power supply during critical operations.

Why Are Appliance Cords Important in Commercial Settings?

Appliance cords are designed specifically for certain devices, ensuring optimal performance and safety. They are typically shorter in length and come with various plug types to match different appliances. B2B buyers should evaluate the compatibility of appliance cords with their equipment to avoid operational disruptions. While they provide a tailored solution for specific appliances, their limited length may require additional extension cords for larger setups.

What Should B2B Buyers Know About Custom Cords?

Custom cords offer a tailored solution for businesses with unique electrical needs. These cords can be designed to specific lengths, gauges, and connector types, making them ideal for specialized machinery or unique setups. However, B2B buyers should be aware that custom cords may involve longer lead times and higher costs compared to standard options. When purchasing custom cords, businesses should consider their long-term electrical needs to ensure they invest wisely in the right solutions.

Key Industrial Applications of electric cord parts

| Industry/Sector | Specific Application of electric cord parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and tools | Ensures operational efficiency and minimizes downtime | Gauge requirements, environmental resistance, safety standards |

| Construction | Temporary power supply for tools and equipment | Facilitates construction activities in remote locations | Durability, length, and amperage capacity |

| Agriculture | Connecting irrigation systems and equipment | Enhances productivity and reduces labor costs | Weather resistance, length, and compatibility with equipment |

| Telecommunications | Connecting network infrastructure and devices | Supports reliable communication and data transfer | Voltage ratings, cable flexibility, and insulation quality |

| Event Management | Powering lighting and sound systems at events | Ensures seamless operation and enhances guest experience | Portability, safety ratings, and load capacity |

How Are Electric Cord Parts Used in Manufacturing?

In the manufacturing sector, electric cord parts are essential for powering machinery and tools. These cords connect equipment to electrical outlets, ensuring that production lines run smoothly. A critical requirement for buyers in this sector is the gauge and amperage rating of the cords, as thicker wires can carry more current safely. International buyers, particularly in regions like Africa and South America, must also consider the environmental conditions, such as humidity and temperature, which can affect cord longevity and performance.

What Role Do Electric Cord Parts Play in Construction?

In construction, electric cord parts are used to provide temporary power to tools and heavy equipment, especially in remote locations lacking permanent electrical infrastructure. This flexibility allows construction teams to operate efficiently, reducing delays. Buyers need to focus on the durability and length of cords, ensuring they can withstand the rigors of outdoor use and meet specific amperage requirements for various tools. Safety is paramount, as improper cords can lead to hazards on job sites.

How Are Electric Cord Parts Essential in Agriculture?

Electric cord parts are integral to connecting irrigation systems and various agricultural equipment, such as pumps and generators. By facilitating reliable power supply, these cords enhance productivity and help reduce labor costs through automation. Buyers in the agricultural sector must prioritize weather-resistant materials and appropriate lengths to accommodate expansive fields. Additionally, compatibility with existing equipment is crucial to ensure seamless integration into farming operations.

How Do Electric Cord Parts Support Telecommunications?

In the telecommunications industry, electric cord parts connect network infrastructure and devices, ensuring reliable communication and data transfer. These cords are vital for powering routers, switches, and other essential equipment. Key considerations for buyers include voltage ratings and cable flexibility, as installations often require navigating tight spaces. Quality insulation is also critical to prevent signal interference, making it essential for international buyers to source cords that meet regional electrical standards.

Why Are Electric Cord Parts Important in Event Management?

Electric cord parts are indispensable for powering lighting, sound systems, and other equipment during events. They ensure that all electrical devices operate seamlessly, contributing to a positive experience for attendees. When sourcing these cords, event managers need to consider portability, safety ratings, and load capacity to accommodate varying power needs. In regions like the Middle East and Europe, where events may be held in diverse environments, the ability to quickly set up and dismantle electrical systems is crucial for operational success.

3 Common User Pain Points for ‘electric cord parts’ & Their Solutions

Scenario 1: Ensuring Compliance with International Standards for Electric Cord Parts

The Problem: B2B buyers, particularly in regions like Africa and South America, often face challenges in sourcing electric cord parts that comply with local and international safety standards. The lack of standardization can lead to serious safety issues, including electrical fires and equipment failures. Buyers may not be fully aware of the specific standards required for their region, causing them to purchase unsuitable products. This not only jeopardizes safety but can also lead to costly legal repercussions and damage to brand reputation.

The Solution: To mitigate these risks, buyers should conduct thorough research on the regulatory requirements in their respective markets. Engaging with local regulatory bodies or industry associations can provide clarity on the necessary certifications and standards. Additionally, when sourcing electric cord parts, opt for suppliers who can provide documentation proving compliance with relevant safety standards (e.g., IEC, UL, CE). It’s advisable to prioritize suppliers with a proven track record in your industry, as their products are more likely to meet the required specifications. Implementing a quality assurance process that includes regular audits of suppliers can further ensure ongoing compliance and safety.

Scenario 2: Dealing with Supply Chain Disruptions for Electric Cord Components

The Problem: Global supply chain disruptions have become increasingly common, affecting the availability of essential electric cord components. Buyers may find themselves facing unexpected delays in receiving critical parts, which can halt production lines or delay project timelines. This issue is particularly pronounced for companies that rely on just-in-time inventory systems, leaving them vulnerable to shortages and increased costs due to expedited shipping or the need to source from secondary suppliers.

The Solution: To combat this challenge, companies should diversify their supplier base by establishing relationships with multiple vendors across different regions. This approach not only mitigates the risk of supply chain disruptions but also fosters competitive pricing. Implementing a robust inventory management system can help anticipate demand fluctuations and maintain buffer stock for critical components. Additionally, consider investing in technology for better visibility across the supply chain, allowing for proactive adjustments based on market conditions. Engaging in long-term contracts with key suppliers can also provide more stability and predictability in sourcing.

Scenario 3: Addressing Performance and Compatibility Issues with Electric Cord Parts

The Problem: B2B buyers often face compatibility issues when integrating new electric cord parts with existing equipment or systems. Variability in wire gauge, connector types, and insulation materials can lead to performance failures, inefficient power transfer, or even equipment damage. This situation can be frustrating, especially when buyers are unaware of the specific requirements for their applications or the potential implications of using incompatible components.

The Solution: To avoid these issues, buyers should conduct a comprehensive assessment of their current equipment and its specifications before sourcing new electric cord parts. This includes understanding the required gauge, amperage ratings, and connector types. When selecting parts, it’s beneficial to work closely with manufacturers or suppliers who can provide expert guidance tailored to your specific applications. Utilizing sample testing for new components can help identify any performance issues before full-scale implementation. Additionally, consider investing in training for procurement teams to better understand electrical specifications and compatibility, ensuring informed decision-making in future purchases.

Strategic Material Selection Guide for electric cord parts

What Are the Key Materials Used in Electric Cord Parts?

When selecting materials for electric cord parts, it is essential to consider their properties, advantages, and limitations. The right material can significantly influence the performance, safety, and cost-effectiveness of the final product. Below, we analyze four common materials used in electric cord components.

How Does PVC Contribute to Electric Cord Performance?

Polyvinyl Chloride (PVC) is widely used in the insulation of electric cords due to its excellent durability and flexibility. It has a high resistance to moisture, chemicals, and abrasion, making it suitable for both indoor and outdoor applications. PVC can withstand temperatures ranging from -20°C to 60°C, which is adequate for most general-purpose electric cords.

Pros: PVC is cost-effective and easy to manufacture, allowing for mass production. It also provides good electrical insulation properties.

Cons: However, PVC can become brittle over time, especially when exposed to extreme temperatures. It is also less environmentally friendly compared to other materials.

Impact on Application: PVC is compatible with a wide range of electrical applications but may not be suitable for high-temperature environments or where chemical exposure is significant.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local electrical safety standards, such as IEC standards, which may dictate specific requirements for PVC insulation.

Why is Rubber a Preferred Material for Electric Cords?

Rubber is another common material used in electric cord construction, particularly for its excellent flexibility and resilience. It can handle a wide temperature range, typically from -40°C to 90°C, making it ideal for outdoor and heavy-duty applications.

Pros: Rubber provides superior protection against moisture and mechanical stress, enhancing the durability of electric cords.

Cons: The primary drawback is its higher cost compared to PVC and potential degradation from UV light exposure.

Impact on Application: Rubber is particularly suitable for environments where cords may be exposed to harsh weather conditions or mechanical wear.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of the need for UV-resistant rubber formulations to meet local standards and ensure long-term performance.

How Does Copper Compare to Aluminum in Conductivity?

Copper is the standard choice for conductors in electric cords due to its excellent electrical conductivity and thermal properties. It can handle high currents with minimal energy loss, making it suitable for applications requiring high power.

Pros: Copper wires are highly durable and resistant to corrosion, ensuring long-term reliability.

Cons: The main disadvantage is the higher cost compared to aluminum, which can be a significant factor for large-scale purchases.

Impact on Application: Copper is ideal for applications requiring high performance, such as industrial machinery or high-power devices.

Considerations for International Buyers: Buyers should consider the availability and cost of copper in their region, especially in areas like Africa and South America, where copper prices can fluctuate significantly.

What Role Does Aluminum Play in Electric Cord Manufacturing?

Aluminum is often used as a more affordable alternative to copper, particularly in lower-power applications. It is lighter and easier to handle, which can reduce shipping costs.

Pros: Aluminum is cost-effective and can be used in applications where weight is a concern, such as portable devices.

Cons: However, aluminum has lower conductivity than copper, requiring thicker wires to carry the same current, which can affect the overall design.

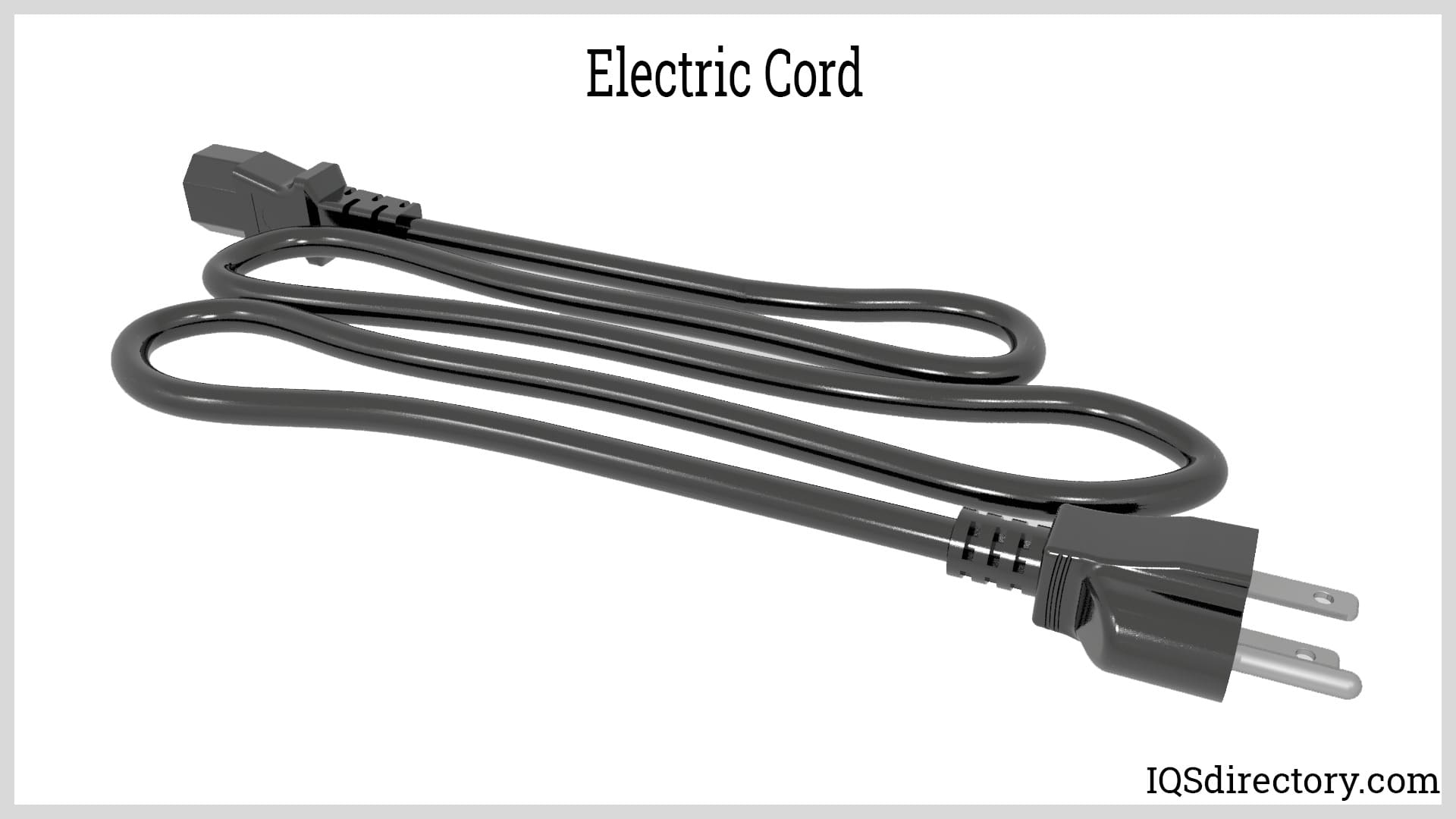

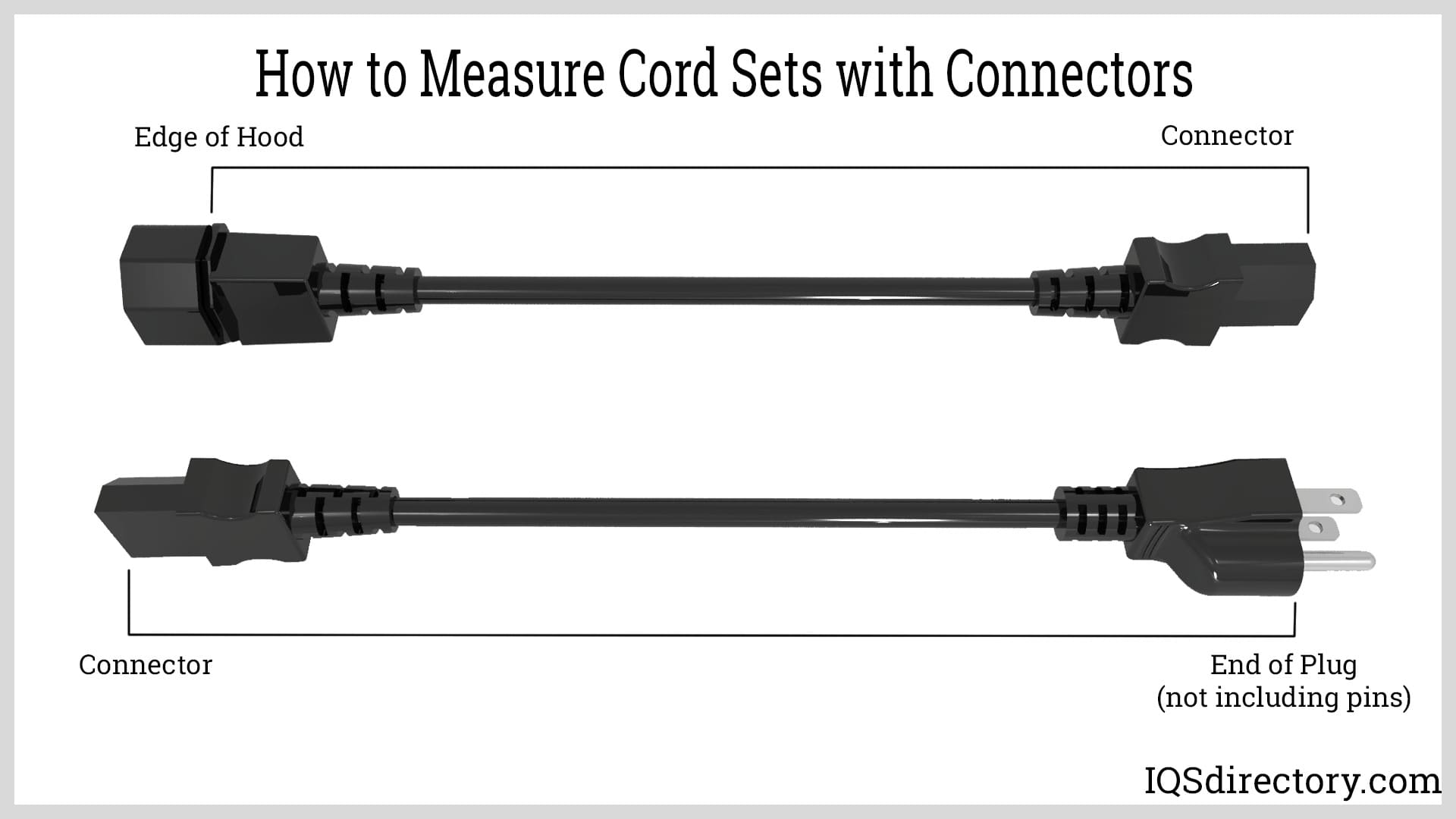

Illustrative image related to electric cord parts

Impact on Application: Aluminum is suitable for applications where weight and cost are critical, but it may not be suitable for high-performance requirements.

Considerations for International Buyers: Buyers should ensure that aluminum cords meet local safety standards, as they may have different requirements compared to copper cords.

Summary Table of Material Properties for Electric Cord Parts

| Material | Typical Use Case for electric cord parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose extension cords | Cost-effective and durable | Becomes brittle over time | Low |

| Rubber | Heavy-duty and outdoor cords | Excellent flexibility and durability | Higher cost, UV degradation | Medium |

| Copper | High-power applications | Superior conductivity and durability | Higher cost compared to aluminum | High |

| Aluminum | Lightweight and cost-sensitive applications | Lightweight and affordable | Lower conductivity, requires thicker wire | Medium |

This strategic material selection guide provides insights into the properties and considerations necessary for making informed decisions about electric cord parts. By understanding the advantages and limitations of each material, international B2B buyers can better align their purchases with their specific operational needs and local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cord parts

What Are the Main Stages of Manufacturing Electric Cord Parts?

The manufacturing of electric cord parts involves several critical stages, each designed to ensure quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Cord Manufacturing?

Material preparation begins with sourcing high-quality raw materials, which typically include copper or copper-clad aluminum for wires, along with durable plastics such as PVC or rubber for insulation and connectors. Manufacturers often choose materials based on their electrical conductivity, durability, and resistance to environmental factors.

Once sourced, the materials undergo testing to confirm they meet specified standards. This initial quality control (QC) step is crucial for ensuring that all components will perform reliably throughout their intended lifespan.

What Techniques Are Used in the Forming Stage of Electric Cord Parts?

During the forming stage, the raw materials are shaped into their final forms. Wires are drawn to specific gauges, ensuring they can handle the required amperage. The gauge size is a critical specification that B2B buyers should pay attention to, as it determines the wire’s current-carrying capacity.

For plugs and sockets, molding techniques are employed, where the thermoplastic materials are heated and then molded into shape. The precision of these molds directly influences the fit and electrical contact between components, which are essential for safety and functionality.

How Are Electric Cord Parts Assembled?

The assembly process involves connecting the wires to the plugs and sockets. This stage is often where quality can vary significantly among manufacturers. Proper crimping and soldering techniques are employed to ensure that electrical connections are secure and reliable.

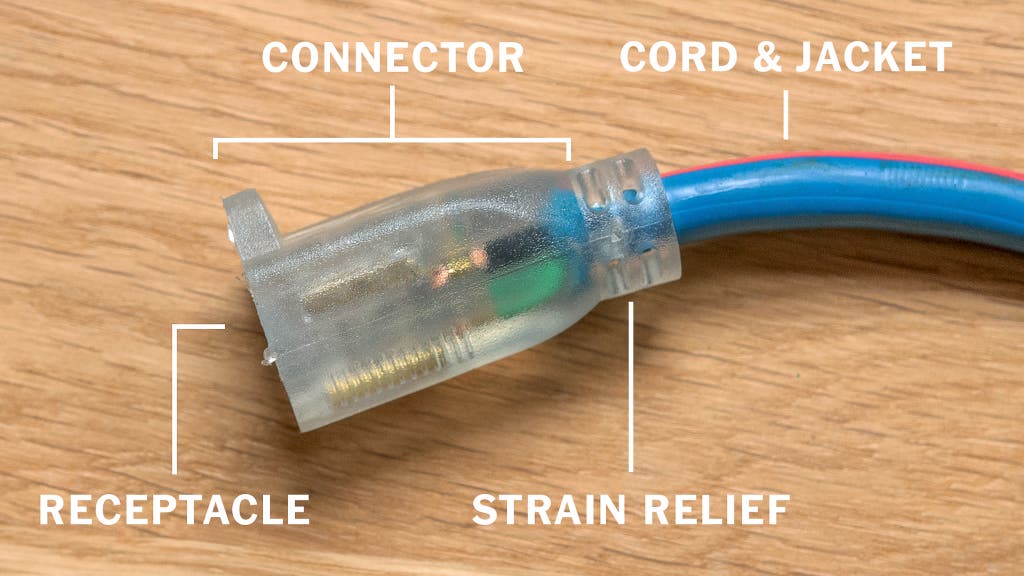

Illustrative image related to electric cord parts

Additionally, assembly lines should be equipped with automated machinery to enhance precision and reduce human error. This is particularly important for large-scale production, where maintaining consistent quality across thousands of units is crucial.

What Finishing Processes Are Applied to Electric Cord Parts?

Finishing processes include applying insulation to the wires and assembling the final products. Insulation is critical for preventing electrical shorts and ensuring user safety. Manufacturers often use nylon or PVC coatings, which provide both protection and flexibility.

Furthermore, products may undergo additional treatments, such as weatherproofing for outdoor cables. The final step typically includes quality checks before packaging, ensuring that all products meet the established standards.

What International Standards Should B2B Buyers Be Aware Of for Electric Cord Parts?

Quality assurance in manufacturing electric cord parts is guided by several international standards. ISO 9001 is a foundational quality management system standard that emphasizes consistent quality in products and services. Manufacturers aiming to sell internationally should be certified to this standard to enhance their credibility.

Illustrative image related to electric cord parts

In addition to ISO standards, electric cord parts must often comply with industry-specific regulations such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards. For buyers in the Middle East and Africa, understanding the local compliance requirements, such as GCC (Gulf Cooperation Council) standards, is also crucial.

What Quality Control Checkpoints Are Essential in Electric Cord Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps catch defects early. This includes checking wire gauge, insulation integrity, and assembly accuracy.

-

Final Quality Control (FQC): Before products are packaged and shipped, they undergo final inspections to ensure they meet all quality standards and specifications.

Which Testing Methods Are Commonly Used to Ensure Quality?

Testing methods for electric cord parts vary but commonly include:

-

Electrical Testing: Ensures that wires can handle the specified amperage without overheating or failing.

-

Mechanical Testing: Assesses the physical durability of the cords, including stress tests for pulling and bending.

-

Environmental Testing: Evaluates how well cords withstand various environmental conditions, including humidity, temperature fluctuations, and exposure to UV light.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to rigorous quality control standards, B2B buyers can take several steps:

Illustrative image related to electric cord parts

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider both announced and unannounced audits.

-

Request Quality Reports: Suppliers should be able to provide documentation detailing their QC processes, including results from various testing stages.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can offer an unbiased view of a supplier’s adherence to quality standards.

-

Check Certifications: Buyers should verify that suppliers hold relevant certifications (e.g., ISO, CE) and understand the implications of these certifications on product quality.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, must navigate a complex landscape of compliance and quality assurance. Understanding the specific standards required in each target market is vital.

For example, buyers in Europe might prioritize CE marking, while those in Africa may focus on local regulatory compliance. Additionally, cultural differences in business practices can affect expectations around quality and communication. Establishing clear channels for feedback and quality expectations is essential to foster strong supplier relationships.

By understanding the manufacturing processes and quality assurance measures for electric cord parts, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cord parts’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure electric cord parts, including plugs, sockets, and wiring. With the increasing demand for electrical components across various industries, it’s essential to approach sourcing strategically. This guide outlines key steps to ensure you select high-quality products that meet your specifications and compliance standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the electric cord parts you need. This includes specifications like wire gauge, voltage ratings, insulation type, and environmental considerations (e.g., indoor vs. outdoor use). Defining these parameters early on helps streamline supplier searches and ensures that the products meet operational needs.

- Wire Gauge and Amperage: Determine the appropriate wire gauge based on the current requirements of your applications.

- Material Requirements: Identify whether you need copper, aluminum, or copper-clad aluminum (CCA) wires based on conductivity and cost considerations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in electric cord parts. Look for manufacturers with a proven track record in your specific industry. Utilize online directories, trade shows, and industry associations to compile a list of potential suppliers.

- Supplier Reputation: Check online reviews and testimonials from other B2B buyers.

- Market Presence: Consider suppliers who have a strong presence in your target regions, such as Africa or South America.

Step 3: Evaluate Supplier Certifications

Before committing to any supplier, it’s crucial to verify their certifications and compliance with international standards. This step helps mitigate risks associated with product quality and safety.

- ISO Certifications: Look for suppliers with ISO 9001 certification, indicating a commitment to quality management.

- Safety Compliance: Ensure that products meet relevant safety standards, such as UL or CE certifications, depending on your target market.

Step 4: Request Samples for Testing

Once you have narrowed down your supplier options, request samples of the electric cord parts you intend to procure. Testing samples allows you to evaluate quality, performance, and compatibility with your existing systems.

Illustrative image related to electric cord parts

- Quality Assurance: Inspect samples for durability, insulation integrity, and overall construction quality.

- Compatibility Testing: Test samples with your devices to ensure they meet performance expectations.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with your chosen suppliers to finalize pricing, payment terms, and delivery schedules. This is a critical step to ensure that you secure favorable terms that align with your budget and project timelines.

- Volume Discounts: Inquire about discounts for bulk orders, which can significantly reduce costs.

- Lead Times: Clarify delivery timelines and ensure they meet your operational needs.

Step 6: Establish a Quality Control Process

Implement a quality control process to monitor the performance of electric cord parts after procurement. This ensures that any issues are identified early and addressed promptly.

- Regular Inspections: Schedule periodic inspections of the cords during their use to detect any wear or damage.

- Feedback Loop: Create a system for gathering feedback from your team on the performance of the parts to inform future procurement decisions.

Step 7: Build Long-Term Supplier Relationships

Finally, focus on building long-term relationships with your suppliers. Strong partnerships can lead to better pricing, priority service, and access to new products and technologies.

- Open Communication: Maintain regular communication to discuss future needs and any concerns that may arise.

- Collaborative Development: Engage suppliers in discussions about product improvements and innovations that could benefit both parties.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing electric cord parts effectively, ensuring they make informed decisions that align with their operational goals.

Illustrative image related to electric cord parts

Comprehensive Cost and Pricing Analysis for electric cord parts Sourcing

What Are the Key Cost Components for Electric Cord Parts?

When sourcing electric cord parts, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The type of materials used significantly influences costs. Common materials include copper or copper-clad aluminum for wires, PVC for insulation, and plastic or rubber for plugs and sockets. The choice between standard and high-grade materials can affect not only the upfront costs but also the long-term performance and safety of the cords.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the assembly process. Regions with lower labor costs can provide competitive pricing, but it’s essential to consider the skill level required for quality assembly, especially for cords that require precise electrical standards.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help lower overhead costs, making it essential to evaluate suppliers on their production efficiency.

-

Tooling: The cost of tooling can be significant, especially for custom or high-volume orders. Investing in quality tooling can enhance production efficiency and reduce long-term costs.

-

Quality Control (QC): Ensuring compliance with international safety standards is crucial. QC processes can add to the cost but are necessary to mitigate risks associated with faulty products, especially in regions with stringent regulations.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the delivery method. Understanding the logistics involved, including potential tariffs and taxes for international shipping, is essential for accurate cost assessment.

-

Margin: Suppliers typically add a margin to cover their operating expenses and profit. This margin can vary based on market demand, supplier reputation, and the level of service provided.

How Do Price Influencers Affect Electric Cord Parts Sourcing?

Several factors can influence the pricing of electric cord parts, particularly in the international B2B landscape:

-

Volume/MOQ: Bulk orders often lead to better pricing due to economies of scale. However, minimum order quantities (MOQs) can vary significantly among suppliers, impacting your total procurement costs.

-

Specifications and Customization: Custom specifications can drive up costs due to the need for specialized materials or manufacturing processes. Clearly defining your requirements can help suppliers provide more accurate quotes.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as UL or CE marks) can significantly impact pricing. Buyers should weigh the importance of certifications against cost when selecting suppliers.

-

Supplier Factors: Supplier reliability, reputation, and the ability to meet delivery timelines can influence pricing. Building a strong relationship with suppliers can lead to better pricing and terms over time.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing shipping responsibilities and costs. Different terms can lead to varying cost implications, affecting the total landed cost of products.

What Buyer Tips Can Enhance Cost Efficiency in Electric Cord Parts Sourcing?

-

Negotiation: Engage suppliers in open discussions about pricing, especially for larger orders. Many suppliers are willing to negotiate terms, particularly if you can assure them of repeat business.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate the TCO, which includes maintenance, operational efficiency, and potential replacement costs over the product’s lifecycle.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should consider currency fluctuations and regional market dynamics. Understanding local economic conditions can provide leverage in negotiations.

-

Supplier Evaluation: Regularly assess suppliers based on their performance, quality, and pricing. This ongoing evaluation can help identify opportunities for cost savings and ensure you are getting the best value.

-

Stay Informed: Keeping abreast of market trends, material costs, and technological advancements can provide insights into pricing strategies and help you make informed sourcing decisions.

Disclaimer

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific order requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing electric cord parts With Other Solutions

Exploring Alternatives to Electric Cord Parts in Power Solutions

In the realm of electrical connectivity, electric cord parts are a widely used solution for transferring power from outlets to devices. However, various alternatives exist that can also meet power distribution needs. This analysis will compare electric cord parts with two viable alternatives: wireless power transmission and hardwired systems. Each solution has its unique features, advantages, and limitations, which are essential for B2B buyers to consider.

| Comparison Aspect | Electric Cord Parts | Wireless Power Transmission | Hardwired Systems |

|---|---|---|---|

| Performance | High reliability with minimal power loss | Limited by distance and device compatibility | Very high reliability, ideal for permanent installations |

| Cost | Generally low cost for materials and installation | Higher initial investment; ongoing R&D costs | Higher upfront costs for installation and materials |

| Ease of Implementation | Simple to install and replace | Complex setup; requires specialized equipment | Requires professional installation, can be disruptive |

| Maintenance | Low maintenance; replace cords as needed | Requires monitoring for efficiency; technology upgrades | Low maintenance once installed, but difficult to upgrade |

| Best Use Case | Temporary setups, home and office use | Mobile devices, consumer electronics, and specific industrial applications | Permanent installations in commercial and industrial settings |

In-Depth Analysis of Alternatives

What are the Pros and Cons of Wireless Power Transmission?

Wireless power transmission utilizes electromagnetic fields to transfer energy without physical connections. This technology is particularly beneficial for charging mobile devices and powering small electronics. Its major advantage is convenience; there are no cords to manage, making it ideal for consumer electronics and mobile applications. However, the technology is still evolving, and challenges include efficiency loss over longer distances and compatibility issues with various devices. Additionally, the initial investment can be significantly higher compared to traditional electric cord parts.

How Do Hardwired Systems Compare?

Hardwired systems involve permanently installed electrical wiring that connects directly to devices. This solution is highly reliable, making it suitable for industrial applications where consistent power supply is critical. Hardwired systems also provide a cleaner aesthetic and eliminate the risk of tripping hazards associated with cords. However, they come with higher installation costs and can be disruptive to set up, as they often require wall modifications. Moreover, upgrades or repairs can be challenging, making them less flexible than other options.

Conclusion: How Can B2B Buyers Choose the Right Power Solution?

When evaluating power solutions, B2B buyers must consider their specific needs, including the nature of the application, budget constraints, and installation capabilities. Electric cord parts offer a straightforward, cost-effective solution for temporary or flexible setups, making them ideal for offices and homes. Conversely, wireless power transmission is best suited for environments where mobility and convenience are paramount, while hardwired systems excel in permanent installations that require high reliability. Ultimately, the decision should align with the operational requirements and long-term strategy of the business, ensuring that the chosen solution provides optimal performance and value.

Essential Technical Properties and Trade Terminology for electric cord parts

What Are the Key Technical Properties of Electric Cord Parts?

When sourcing electric cord parts, understanding specific technical properties is crucial for ensuring quality and compliance with industry standards. Here are some critical specifications to consider:

1. Material Composition

Electric cord parts are typically made from various materials, including PVC (polyvinyl chloride), TPR (thermoplastic rubber), or silicone. Each material has its unique properties; for instance, PVC is known for its durability and resistance to chemicals, while silicone offers excellent flexibility and temperature resistance. Selecting the right material is vital for the cord’s application, especially in environments that may expose it to harsh conditions.

2. Wire Gauge

The wire gauge indicates the thickness of the wire and is measured in American Wire Gauge (AWG). A lower gauge number represents a thicker wire, which can handle more electrical current. For example, a 12-gauge wire can safely carry more amperage than a 14-gauge wire. Understanding wire gauge is essential for ensuring that the cords can support the electrical load without overheating, which is particularly important in industrial settings.

3. Amperage Rating

This specification denotes the maximum current that a cord can carry safely. Common ratings for extension cords are 15 or 20 amps. Knowing the amperage rating helps in selecting cords suitable for specific devices, ensuring they operate efficiently without risk of failure or fire hazards. This is particularly relevant for B2B buyers looking to standardize their operations with reliable equipment.

4. Temperature Rating

Electric cords have defined temperature ratings that indicate the maximum and minimum temperatures they can endure. For example, some cords are rated for use in extreme conditions, while others are designed for indoor use only. Understanding these ratings ensures that the cords will function safely and effectively in their intended environment.

5. Length and Number of Conductors

The length of the cord and the number of conductors are also critical specifications. Longer cords can lead to voltage drop, which may affect performance, while the number of conductors indicates how many circuits the cord can handle. This information is essential for B2B buyers who need to match cords with specific applications or installations.

What Are Common Trade Terms in the Electric Cord Parts Industry?

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the electric cord industry, understanding OEM relationships can help buyers find reliable suppliers who provide high-quality components that meet specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units that a supplier is willing to sell. This term is important for B2B buyers, as it can affect inventory management and cost-effectiveness. Knowing the MOQ helps businesses plan their purchases more strategically.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products or services. In the context of electric cord parts, issuing an RFQ allows buyers to compare offers and negotiate better deals, ensuring they receive quality products at competitive prices.

4. Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers engaged in cross-border trade, as they define who is responsible for shipping costs, insurance, and risks.

5. Certification Standards

Certification standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), are critical in ensuring that electric cord parts meet safety and performance regulations. Familiarity with these standards helps buyers ensure compliance and minimize risks associated with product failures.

Illustrative image related to electric cord parts

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ultimately enhancing their operational efficiency and safety in using electric cord parts.

Navigating Market Dynamics and Sourcing Trends in the electric cord parts Sector

What Are the Current Market Dynamics Driving the Electric Cord Parts Sector?

The electric cord parts sector is experiencing robust growth, driven by several global factors. The surge in consumer electronics, industrial automation, and the growing demand for renewable energy solutions are significant market drivers. International B2B buyers are increasingly seeking high-quality electric cord components to support their manufacturing processes and meet rising consumer expectations. Emerging trends in the sector include the integration of smart technology in power cords, which allows for enhanced safety features and energy efficiency. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, enabling buyers from regions like Africa, South America, the Middle East, and Europe to access a broader range of suppliers and products.

The demand for customized solutions is also on the rise. As businesses look to differentiate themselves in competitive markets, they increasingly require electric cord parts that meet specific technical and aesthetic requirements. This trend is particularly relevant in regions such as Nigeria and Vietnam, where local manufacturing capabilities are expanding. Furthermore, the emphasis on speed and flexibility in supply chains is prompting buyers to adopt just-in-time inventory practices, thus enhancing their operational efficiency.

How Can Sustainability and Ethical Sourcing Impact Your Procurement Strategy?

Sustainability and ethical sourcing are becoming paramount in the electric cord parts sector, influencing procurement decisions across the globe. The environmental impact of manufacturing processes, including waste generation and resource depletion, is under scrutiny. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using recyclable materials and minimizing carbon footprints.

The importance of ethical supply chains cannot be overstated. As regulatory frameworks tighten globally, companies are being held accountable for their sourcing practices. Buyers are encouraged to seek suppliers with certifications like ISO 14001 (Environmental Management) or those utilizing green materials such as PVC alternatives that are less harmful to the environment. By aligning with ethical suppliers, businesses not only mitigate risks but also enhance their brand reputation, appealing to a growing base of environmentally-conscious consumers.

In regions like South America and the Middle East, where economic development is closely tied to environmental sustainability, ethical sourcing is not just a compliance issue but a competitive advantage. Buyers who prioritize sustainable practices can differentiate themselves in the market, potentially leading to increased customer loyalty and market share.

What Is the Historical Context of Electric Cord Parts and Its Relevance Today?

The evolution of electric cord parts can be traced back to the early 20th century when the proliferation of electrical appliances began to reshape consumer behavior and industrial practices. Initially, these cords were rudimentary, primarily made from rubber and cloth. However, advancements in materials science led to the development of more durable and safer options, such as PVC and thermoplastic elastomers.

This historical context is critical for B2B buyers today as it informs current product standards and regulatory compliance requirements. Understanding the evolution of electric cord technology enables buyers to make informed decisions about the types of materials and safety features they need to consider when sourcing components. Additionally, awareness of historical trends can guide buyers in anticipating future innovations, such as the integration of smart technology and enhanced safety features in electric cord designs.

By keeping abreast of these developments, international B2B buyers can better position themselves to leverage emerging opportunities and mitigate risks in the rapidly evolving electric cord parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cord parts

-

How do I solve issues with electric cord parts not functioning properly?

To troubleshoot non-functioning electric cord parts, first ensure the cord is properly connected to both the power source and the device. Check for visible damage such as fraying, cuts, or loose plugs. If the cord is intact, test it with a different device to rule out appliance issues. If problems persist, consider the gauge of the wire—thinner wires may not support higher amperages. Always prioritize safety; if you suspect internal damage or overheating, replace the cord immediately to prevent hazards. -

What is the best gauge for extension cords used in industrial settings?

For industrial applications, a 12-gauge extension cord is typically the best choice, as it can handle higher amperage (up to 20 amps) and is suited for heavy-duty equipment. Thicker wires reduce the risk of overheating and voltage drops over longer distances. If you are using the cord for lighter equipment, a 14-gauge may suffice, but always assess the specific power requirements of your devices. Ensure the cord is rated for outdoor or indoor use based on your operational environment. -

How can I verify the quality of electric cord parts from suppliers?

To assess the quality of electric cord parts, request product certifications and compliance with international standards such as UL, CE, or IEC. Conduct a supplier audit, focusing on their manufacturing processes, quality control measures, and customer reviews. Ask for samples to evaluate material durability, flexibility, and overall construction. Additionally, inquire about their warranty and return policies as indicators of their commitment to quality. -

What are common customization options for electric cord parts?

Customization options for electric cord parts often include length, gauge, plug type, and insulation material. Many manufacturers can also provide specific color coding or branding for easy identification. Discuss your unique requirements with suppliers, as they may offer tailored solutions that fit your operational needs. Ensure that any customizations comply with local electrical standards and safety regulations. -

What are typical minimum order quantities (MOQs) for electric cord parts?

Minimum order quantities for electric cord parts can vary widely by supplier and product type. Generally, MOQs range from 100 to 1,000 units, depending on the customization and manufacturing process involved. When negotiating with suppliers, consider your inventory needs and potential for future orders to find a balance that works for both parties. Always clarify MOQs early in the conversation to avoid misunderstandings. -

What payment terms should I expect when sourcing electric cord parts internationally?

Payment terms for international B2B purchases of electric cord parts typically include options such as advance payment, letter of credit, or net 30/60/90 days after delivery. Be aware that suppliers may offer discounts for bulk orders or early payments. Always negotiate terms that protect your cash flow while ensuring the supplier’s confidence in fulfilling the order. It’s advisable to use secure payment methods to mitigate risks associated with international transactions. -

How does logistics impact the sourcing of electric cord parts?

Logistics plays a critical role in the timely and cost-effective delivery of electric cord parts. When sourcing internationally, consider shipping methods (air vs. sea), transit times, and customs clearance procedures. Engage with suppliers who have reliable logistics partners and can provide transparent tracking information. Additionally, be aware of potential tariffs and import regulations that may affect your total costs and delivery schedules. -

What quality assurance measures should be in place when sourcing electric cord parts?

Effective quality assurance measures include regular inspections during production, third-party testing of materials, and final product assessments before shipment. Request certificates of compliance to ensure that the products meet relevant safety standards. Establish clear communication with your supplier regarding quality expectations and implement a returns policy for defective items. Building a partnership based on transparency and accountability will enhance the reliability of your sourcing strategy.

Top 4 Electric Cord Parts Manufacturers & Suppliers List

1. Superior Electric – Power Cord Replacements

Domain: dhcsupplies.com

Registered: 2003 (22 years)

Introduction: This company, Superior Electric – Power Cord Replacements, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reelcraft – 602353-50 Replacement Power Cord

Domain: fastoolnow.com

Registered: 2008 (17 years)

Introduction: [{‘name’: ‘Reelcraft 602353-50 – 12/3 x 50ft Replacement Flying Lead Ends Power Cord’, ‘msrp’: ‘$99.99’, ‘sale_price’: ‘$87.99’}, {‘name’: ‘Reelcraft 262570 – Locking Knife Terminal Lug for use w/ 10 AWG Power Cord Reels’, ‘msrp’: ‘$11.74’, ‘sale_price’: ‘$10.84’}, {‘name’: ‘Reelcraft 602687 – Slip Ring (700 Amp)’, ‘msrp’: ‘$972.67’, ‘sale_price’: ‘$897.84’}, {‘name’: ‘Reelcraft 602473-35 – LED Li…

3. Superior Electric – Replacement Electrical Cords

Domain: superiorelectric.us

Registered: 2012 (13 years)

Introduction: Replacement Electrical Cords from Superior Electric include various specifications: 10 Feet 14 AWG 2 Wire SOW NEMA 1-15P, 9 Feet 12 AWG SJO 3 Wire 125 Volt NEMA L5-20P, 9 Feet 16 AWG SJO 2 Wire 125 Volt with Quick Connect, 9 Feet 16 Gauge 3 Wire with Strain Relief, and more. Prices range from $5.29 to $97.84, with special prices listed for each item. Cords are available in lengths from 8.5 feet to…

4. Hunker – Extension Cords

Domain: hunker.com

Registered: 2001 (24 years)

Introduction: Extension cords consist of wires, wire sheathing, insulation, and plugs. Key components include: 1. Wires and Wire Gauge: Conducting wires are crucial; their thickness (gauge) and length affect current capacity. Larger gauge numbers indicate smaller wires. 2. Wire Sheathing: Determines indoor (plastic, often brown or white) vs. outdoor (waterproof rubber, often orange, white, green, or black) use….

Strategic Sourcing Conclusion and Outlook for electric cord parts

In navigating the complexities of sourcing electric cord parts, international B2B buyers must prioritize quality, compliance, and cost-effectiveness. Understanding the essential components—such as plugs, sockets, and wire types—enables businesses to make informed decisions that align with safety standards and market needs. The gauge and amperage ratings of cords are critical factors that can significantly influence performance, especially in diverse applications across different regions.

Strategic sourcing not only enhances operational efficiency but also fosters long-term relationships with reliable suppliers. For buyers in Africa, South America, the Middle East, and Europe, it’s imperative to conduct thorough market research and evaluate vendors based on their product offerings and service reliability. This approach mitigates risks associated with supply chain disruptions and quality inconsistencies.

Looking ahead, the demand for electric cord parts is expected to grow, driven by the increasing reliance on electrical appliances and technology across global markets. We encourage B2B buyers to take proactive steps in their sourcing strategies today, ensuring they are well-positioned to leverage emerging opportunities in this vital sector. By prioritizing quality and strategic partnerships, businesses can thrive in an ever-evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.