Top 4 Conveyor Manufacturers Near Me Suppliers (And How to Choose)

Introduction: Navigating the Global Market for conveyor manufacturers near me

In the complex landscape of global manufacturing, sourcing reliable conveyor manufacturers near you can present a formidable challenge for international B2B buyers. The need for efficient material handling solutions is paramount, as businesses seek to optimize operations and enhance productivity. This guide aims to demystify the process of selecting the right conveyor systems by providing a comprehensive overview of various types, applications, and essential considerations when vetting suppliers.

From belt and roller conveyors to specialized pneumatic systems, understanding the breadth of options available is crucial for making informed decisions. This resource not only outlines the different types of conveyor systems but also delves into their specific applications across various industries, ensuring that you can find solutions tailored to your operational needs.

Moreover, we offer insights into the supplier selection process, including factors such as cost, quality, and customer support, which are vital for establishing long-term partnerships. By leveraging the information contained within this guide, B2B buyers from Africa, South America, the Middle East, and Europe—countries like Vietnam and Brazil—will be empowered to navigate the global market confidently. Equip yourself with the knowledge necessary to make strategic purchasing decisions that enhance your supply chain and drive business success.

Understanding conveyor manufacturers near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Belt Conveyors | Continuous loop of material-handling belts | Warehousing, manufacturing, food processing | Pros: Versatile, easy to maintain. Cons: Limited incline capability. |

| Roller Conveyors | Uses rollers to facilitate movement of goods | Distribution centers, assembly lines | Pros: High load capacity, low friction. Cons: Requires more space. |

| Vertical Conveyors | Moves items vertically between levels | Multi-level warehouses, manufacturing facilities | Pros: Space-saving, efficient for high-rise operations. Cons: Higher initial cost. |

| Bucket Elevators | Transports bulk materials using buckets | Agriculture, mining, recycling | Pros: Efficient for bulk materials. Cons: Limited to specific materials. |

| Pneumatic Conveyors | Utilizes air pressure to move materials through tubes | Food processing, pharmaceuticals, chemicals | Pros: Good for fine powders, enclosed system. Cons: Potential for high energy use. |

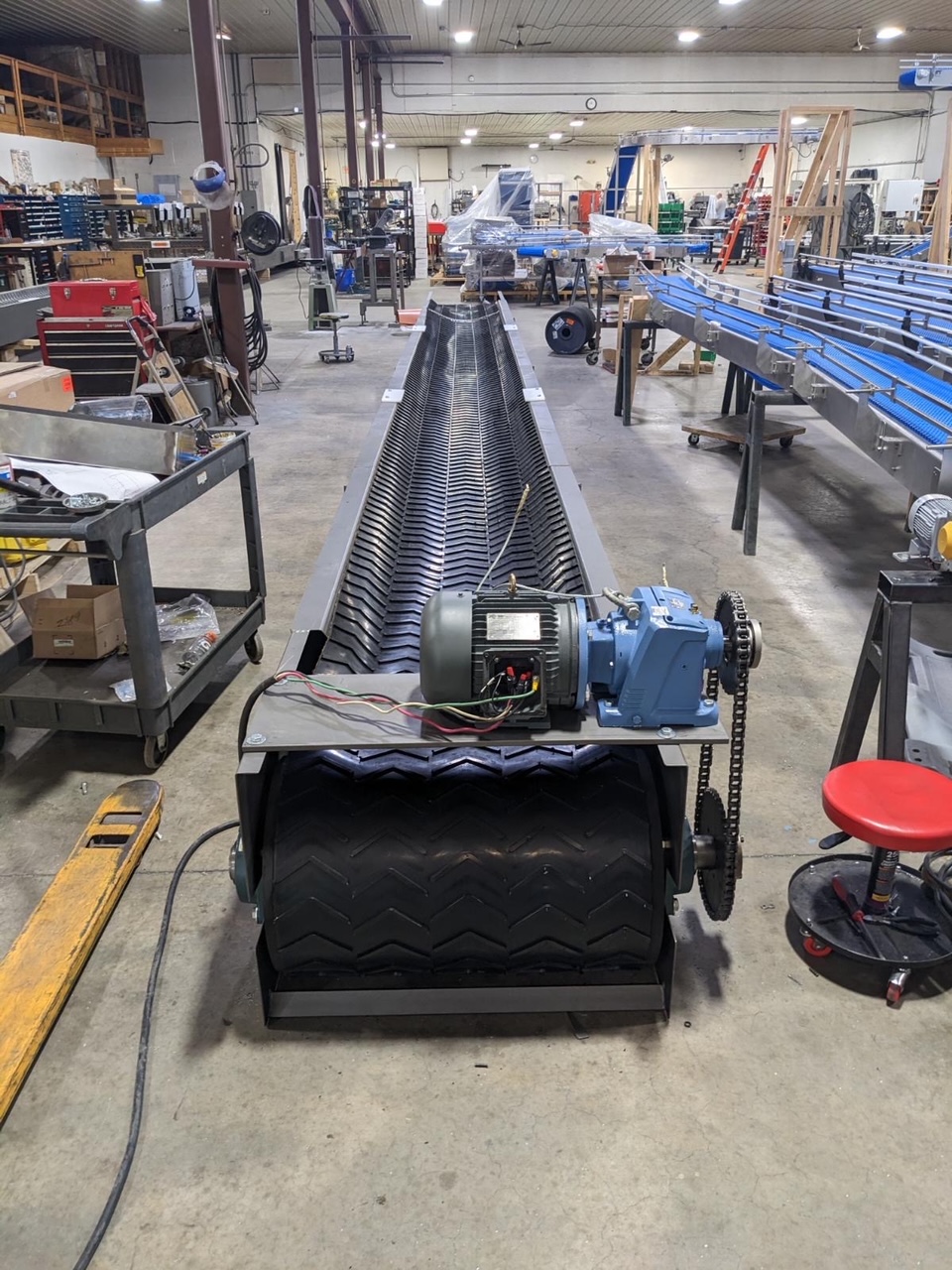

What Are the Characteristics and Suitability of Belt Conveyors for B2B Buyers?

Belt conveyors are designed to transport materials continuously along a loop of flexible material. They are widely used in various industries, including warehousing and food processing, due to their adaptability and ease of maintenance. When considering a belt conveyor, B2B buyers should evaluate factors such as load capacity, belt material, and the operational environment. Belt conveyors are particularly effective for horizontal transport but may struggle with steep inclines, making them less suitable for vertical movement without additional systems.

Illustrative image related to conveyor manufacturers near me

How Do Roller Conveyors Stand Out in Material Handling?

Roller conveyors are characterized by their use of cylindrical rollers, which allow for easy movement of goods without requiring additional power. This type of conveyor is ideal for distribution centers and assembly lines where heavy loads need to be moved efficiently. B2B buyers should consider the spacing and diameter of the rollers, as these factors influence load capacity and operational efficiency. While roller conveyors offer low friction and high durability, they do require more floor space compared to other conveyor types, which can be a consideration for space-constrained facilities.

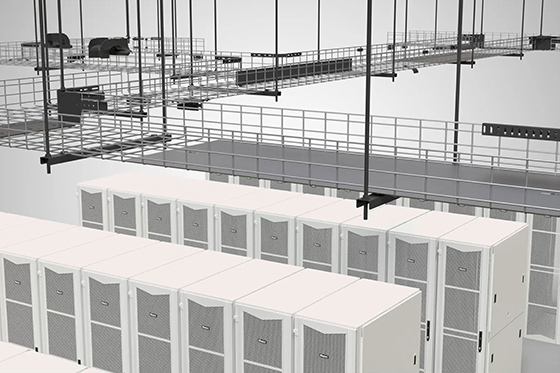

Why Choose Vertical Conveyors for Multi-Level Operations?

Vertical conveyors are specifically engineered to transport goods between different levels, making them essential for multi-story warehouses and manufacturing plants. They save valuable floor space while increasing operational efficiency. B2B buyers should assess the vertical lift capacity and speed of the system, as well as safety features to prevent accidents. Although vertical conveyors can have higher upfront costs, their ability to streamline operations in high-rise settings often justifies the investment.

What Are the Advantages of Bucket Elevators for Bulk Material Handling?

Bucket elevators are designed to move bulk materials using attached buckets, making them a go-to solution in industries like agriculture and mining. They excel in transporting materials vertically and can handle a wide range of materials, from grains to recycling products. Buyers should consider the material of the buckets and the overall design for specific applications. While bucket elevators are efficient for bulk handling, they are limited to specific types of materials and may not be suitable for smaller items.

How Do Pneumatic Conveyors Benefit Industries Requiring Hygiene?

Pneumatic conveyors employ air pressure to move materials through an enclosed system, making them ideal for industries such as food processing and pharmaceuticals that prioritize hygiene. Their design minimizes contamination risks while efficiently transporting fine powders and granules. B2B buyers should focus on the system’s pressure capabilities and energy efficiency. Although pneumatic systems can consume significant energy, their effectiveness in maintaining product integrity and cleanliness often outweighs this drawback.

Key Industrial Applications of conveyor manufacturers near me

| Industry/Sector | Specific Application of conveyor manufacturers near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated food processing and packaging conveyors | Increases production efficiency and maintains hygiene standards | Compliance with food safety regulations, material durability |

| Pharmaceuticals | Conveyor systems for drug manufacturing and packaging | Enhances accuracy in dosage and reduces contamination risks | Precision engineering, cleanroom compatibility |

| Mining and Agriculture | Bulk material handling conveyors | Optimizes transport of heavy materials, reducing manual labor | Robust design, resistance to harsh environments |

| E-commerce and Retail | Sorting and fulfillment conveyor systems | Speeds up order processing and improves accuracy in shipments | Flexibility in design, scalability, and integration with existing systems |

| Manufacturing | Assembly line conveyors for product assembly | Streamlines production processes and reduces bottlenecks | Customization options, reliability, and maintenance support |

How Are Conveyor Manufacturers Near Me Used in the Food and Beverage Industry?

Conveyor manufacturers near me provide automated systems crucial for food processing and packaging. These conveyors facilitate the seamless movement of products through various stages—from raw material handling to final packaging—while ensuring adherence to strict hygiene standards. International buyers need to consider compliance with local food safety regulations and the durability of materials used in conveyor construction, especially in regions like Africa and South America where environmental conditions can vary significantly.

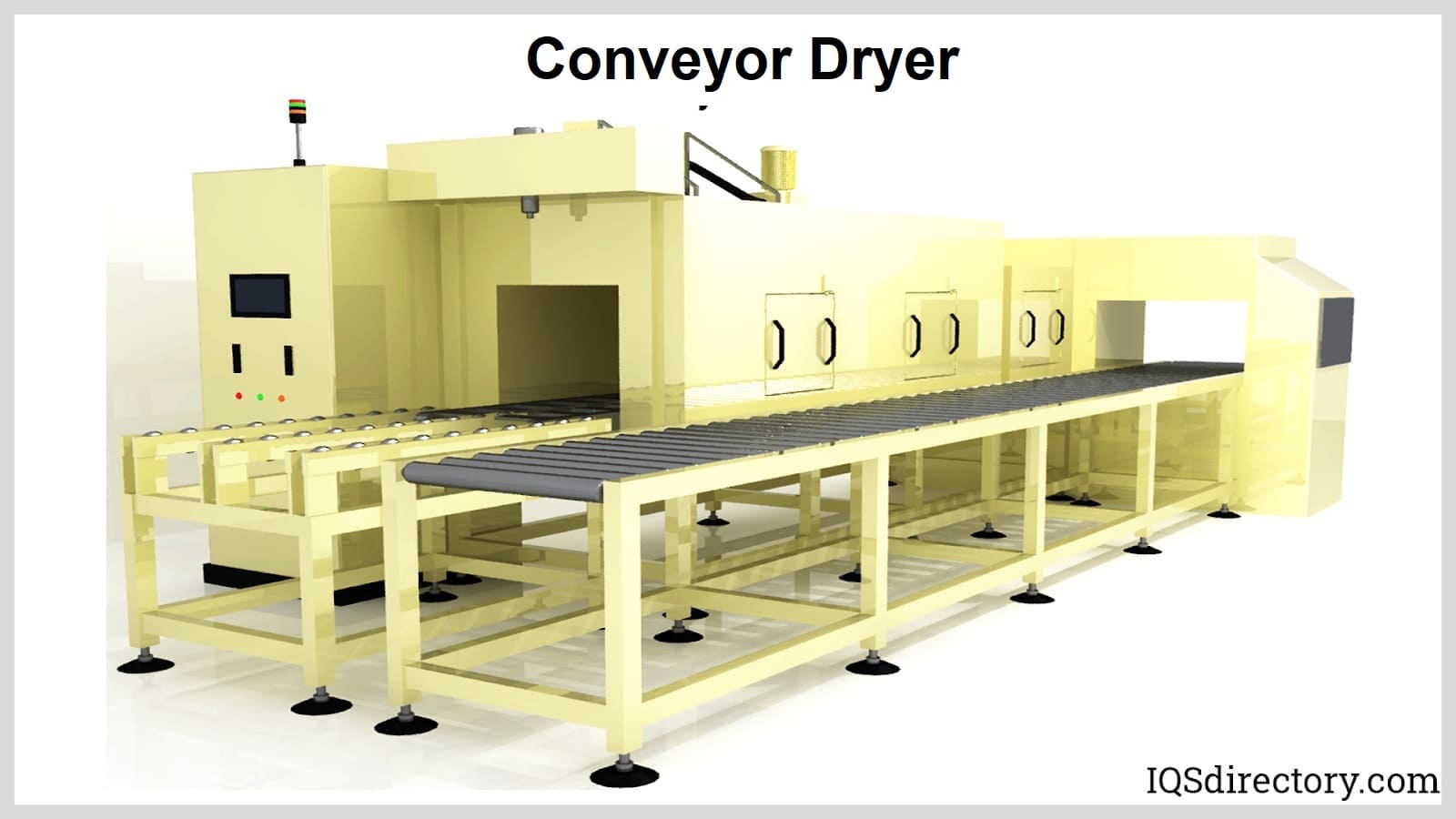

Illustrative image related to conveyor manufacturers near me

What Role Do Conveyor Systems Play in the Pharmaceutical Sector?

In the pharmaceutical industry, conveyor systems are essential for the precise manufacturing and packaging of medications. These systems help maintain high levels of accuracy in dosage while minimizing contamination risks during production. For international buyers, sourcing conveyors that meet cleanroom standards and provide precision engineering is vital. Additionally, understanding the local regulatory landscape is crucial for ensuring compliance with pharmaceutical manufacturing standards.

How Do Conveyor Manufacturers Support Mining and Agriculture?

In mining and agriculture, bulk material handling conveyors are indispensable for transporting heavy materials efficiently. These conveyors reduce the need for manual labor, thus enhancing safety and productivity. Buyers from regions like the Middle East and Europe should look for robust designs that can withstand harsh operational environments, as well as conveyors that offer easy maintenance and high durability to ensure long-term operation without frequent downtime.

Why Are Sorting and Fulfillment Conveyors Critical for E-commerce and Retail?

Conveyor systems designed for sorting and fulfillment are pivotal in the e-commerce and retail sectors. They accelerate order processing and enhance accuracy in shipments, which is critical for customer satisfaction. International B2B buyers should prioritize flexibility in design and scalability, ensuring that the conveyor systems can adapt to changing business needs and integrate smoothly with existing logistics frameworks.

What Advantages Do Assembly Line Conveyors Offer in Manufacturing?

In manufacturing, assembly line conveyors streamline production processes by facilitating the efficient flow of materials and components. This reduces bottlenecks and enhances overall operational efficiency. Buyers should focus on customization options that meet their specific production requirements, as well as the reliability and maintenance support offered by conveyor manufacturers. This is particularly important for businesses looking to scale operations in competitive markets across various continents.

Illustrative image related to conveyor manufacturers near me

3 Common User Pain Points for ‘conveyor manufacturers near me’ & Their Solutions

Scenario 1: Delayed Production Due to Inefficient Conveyor Systems

The Problem: A manufacturing company in Brazil faces significant delays in its production line due to outdated conveyor systems. The existing equipment struggles to handle the increased volume of goods, resulting in bottlenecks and missed deadlines. This inefficiency not only affects output but also escalates operational costs and diminishes customer satisfaction. The B2B buyer is frustrated, as they need a reliable conveyor manufacturer that can deliver a tailored solution quickly.

The Solution: To address this issue, the buyer should begin by conducting a thorough needs assessment. This involves analyzing current production workflows and identifying specific pain points within the existing system. Once these details are clarified, the buyer should research local conveyor manufacturers who specialize in custom solutions. They can utilize online directories and industry forums to find reputable manufacturers near them. When reaching out, it’s essential to provide comprehensive information about production requirements, including load capacities and desired throughput rates. Furthermore, requesting a free consultation can help the buyer understand potential upgrades or new systems that can be implemented without extensive downtime. Ultimately, choosing a manufacturer with a solid track record in providing rapid installation and maintenance services can minimize disruptions and enhance overall productivity.

Scenario 2: High Maintenance Costs for Conveyor Systems

The Problem: A company in the Middle East struggles with escalating maintenance costs associated with its conveyor systems. Frequent breakdowns and the need for specialized parts have led to unplanned downtime, which hampers production efficiency and strains the budget. The buyer is concerned about the sustainability of these costs and is seeking a more reliable and cost-effective solution.

The Solution: The buyer should engage with conveyor manufacturers who emphasize durability and low maintenance in their product offerings. It’s crucial to inquire about the materials used and the technology integrated into the conveyor systems. For instance, opting for conveyors made from high-quality stainless steel or featuring advanced automation technology can reduce wear and tear, leading to lower maintenance needs. Additionally, the buyer should ask about extended warranties and service agreements that cover maintenance and repairs. Establishing a long-term partnership with a manufacturer can also provide insights into best practices for system upkeep, further reducing costs. By prioritizing manufacturers with a reputation for reliability and customer support, the buyer can mitigate the risk of high maintenance expenses while ensuring smooth operations.

Illustrative image related to conveyor manufacturers near me

Scenario 3: Difficulty in Sourcing Specialized Conveyor Systems

The Problem: An international buyer from South America is seeking specialized conveyor systems for handling fragile products. However, they find it challenging to locate manufacturers that can provide the necessary expertise and customization options. This lack of available options leads to delays in sourcing and ultimately impacts their ability to meet market demands.

The Solution: To effectively source specialized conveyor systems, the buyer should leverage their network and industry connections. Engaging with trade shows, industry associations, and online B2B platforms can reveal manufacturers who specialize in niche applications. Furthermore, the buyer should prepare a detailed project brief that outlines the specific requirements for the fragile products, including handling methods, dimensions, and any unique features needed (like soft-touch conveyor belts). Once potential manufacturers are identified, the buyer should arrange meetings to discuss customization options and past projects similar to their needs. Asking for case studies or references can also help ensure that the chosen manufacturer has the requisite experience. By clearly communicating their specific requirements and engaging with multiple manufacturers, the buyer can find a conveyor solution that not only meets their needs but also enhances their operational capabilities.

Strategic Material Selection Guide for conveyor manufacturers near me

What Are the Key Materials Used in Conveyor Systems?

When selecting materials for conveyor systems, manufacturers often consider various factors such as durability, cost, and compatibility with the intended application. Here, we analyze four common materials used in conveyor manufacturing: steel, stainless steel, plastic, and aluminum. Each material has unique properties that influence its performance, making it essential for international B2B buyers to understand their implications.

How Does Steel Perform in Conveyor Systems?

Steel is a widely used material in conveyor systems due to its strength and durability. It can withstand high temperature and pressure ratings, making it suitable for heavy-duty applications. Steel’s resistance to wear and tear allows for long-lasting performance, especially in environments where heavy loads are common.

Illustrative image related to conveyor manufacturers near me

Pros: Steel is relatively inexpensive compared to other materials, making it a cost-effective option for many manufacturers. Its high tensile strength ensures that it can handle substantial loads without deforming.

Cons: However, steel is prone to corrosion if not properly treated, which can lead to reduced lifespan and increased maintenance costs. Additionally, its weight can complicate installation and increase shipping costs.

Impact on Application: Steel is ideal for applications involving heavy materials, such as mining or manufacturing. It is crucial for buyers in regions with high humidity or corrosive environments to consider protective coatings to enhance longevity.

Illustrative image related to conveyor manufacturers near me

What Advantages Does Stainless Steel Offer for Conveyor Systems?

Stainless steel is known for its excellent corrosion resistance, making it a preferred choice in food processing, pharmaceuticals, and other industries where hygiene is critical. It can withstand harsh chemicals and high temperatures, ensuring that it maintains structural integrity under demanding conditions.

Pros: The primary advantage of stainless steel is its durability and low maintenance requirements. Its aesthetic appeal also makes it suitable for visible applications.

Cons: The main drawback is its higher cost compared to regular steel. Additionally, stainless steel can be more challenging to machine and fabricate, which may lead to increased manufacturing complexity.

Impact on Application: For international buyers, compliance with food safety standards and regulations is crucial when selecting stainless steel. Familiarity with standards such as ASTM and FDA regulations is essential for ensuring product suitability.

Why Choose Plastic for Conveyor Systems?

Plastic materials, such as polyethylene and polypropylene, are increasingly used in conveyor systems due to their lightweight nature and resistance to chemicals. They are particularly useful in applications where corrosion is a concern, such as in the food and beverage industry.

Illustrative image related to conveyor manufacturers near me

Pros: The lightweight nature of plastic allows for easier installation and lower shipping costs. Additionally, plastics can be molded into various shapes, providing design flexibility.

Cons: However, plastics generally have lower strength compared to metals, which may limit their use in heavy-duty applications. They can also be susceptible to wear over time, especially under high loads.

Impact on Application: Buyers from regions with diverse climates should consider the temperature limits of plastic materials, as extreme heat or cold can affect their performance. Compliance with international standards for food safety is also a consideration.

Illustrative image related to conveyor manufacturers near me

What Are the Benefits of Using Aluminum in Conveyor Systems?

Aluminum is another popular material for conveyor systems, known for its lightweight and corrosion-resistant properties. It is often used in applications where weight savings are critical, such as in packaging and assembly lines.

Pros: Aluminum’s low weight facilitates easier handling and installation, reducing labor costs. It also offers good strength-to-weight ratios, making it suitable for moderate loads.

Cons: The primary disadvantage of aluminum is its cost, which can be higher than that of steel. Additionally, while it is resistant to corrosion, it may not be as durable as stainless steel in harsh environments.

Impact on Application: For international buyers, understanding the specific alloy grades and their properties is essential. Compliance with industry standards such as DIN and JIS can also affect material selection.

Summary Table of Material Selection for Conveyor Systems

| Material | Typical Use Case for conveyor manufacturers near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications (mining, manufacturing) | High strength and low cost | Prone to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Food and beverage, light-duty applications | Lightweight and design flexibility | Lower strength and wear susceptibility | Medium |

| Aluminum | Packaging, assembly lines | Lightweight and good strength-to-weight | Higher cost and less durability | Medium |

Understanding these materials and their properties will help international B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor manufacturers near me

What Are the Key Stages in the Manufacturing Process for Conveyor Systems?

The manufacturing process of conveyor systems typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the capabilities and reliability of conveyor manufacturers.

Material Preparation: How Is Raw Material Processed?

The first step in conveyor manufacturing is material preparation, where raw materials such as metals, plastics, and rubber are sourced and processed. For example, steel is often cut and shaped into the desired dimensions for components like frames and rollers. This preparation phase may also involve surface treatments to enhance durability and corrosion resistance, particularly important for industries such as food processing and pharmaceuticals.

Forming: What Techniques Are Commonly Used?

In the forming stage, manufacturers employ various techniques to shape materials into functional components. Common methods include:

- Metal Stamping: Utilized for creating precise metal parts, this technique involves using a die to cut and shape material.

- Welding: Essential for joining different components together, welding ensures that the structural integrity of the conveyor system is maintained.

- Injection Molding: Used predominantly for plastic parts, this method allows for complex shapes and designs, catering to specific operational needs.

The choice of technique often depends on the type of conveyor system being manufactured—be it belt, roller, or overhead conveyors.

Assembly: How Are Components Integrated?

Once components are formed, the assembly stage begins. This involves bringing together various parts, such as motors, belts, and control systems, into a cohesive unit. Manufacturers may utilize automated assembly lines to enhance efficiency and precision. During this stage, attention to detail is critical, as misalignments can lead to operational failures.

What Quality Assurance Practices Should B2B Buyers Expect from Conveyor Manufacturers?

Quality assurance (QA) is essential in the conveyor manufacturing process to ensure that products meet industry standards and customer expectations. B2B buyers should be aware of the following aspects of QA.

Which International Standards Are Relevant for Conveyor Manufacturers?

Conveyor manufacturers often adhere to international standards to ensure product quality and safety. Notable standards include:

- ISO 9001: This standard focuses on quality management systems and is critical for ensuring that manufacturers maintain consistent quality in their products and services.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers supplying conveyor systems to the oil and gas industry, API standards ensure that products can withstand harsh operational conditions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring the production process to identify and rectify any deviations from quality standards in real-time.

- Final Quality Control (FQC): At the end of the manufacturing process, FQC ensures that the finished product meets all specifications before shipping.

These checkpoints are vital for maintaining quality and consistency in conveyor systems.

How Are Common Testing Methods Implemented?

Manufacturers employ various testing methods to validate the performance and durability of conveyor systems. Common tests include:

- Load Testing: Assessing how much weight a conveyor can handle without failure.

- Operational Testing: Running the conveyor system under normal operating conditions to ensure efficiency and performance.

- Durability Testing: Subjecting components to extreme conditions to evaluate their longevity and resilience.

These tests help manufacturers confirm that their products can withstand the rigors of industrial environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial for ensuring reliable partnerships.

What Auditing and Reporting Options Are Available?

One effective way to verify a manufacturer’s QC practices is through audits. Buyers can request audits of the manufacturer’s facilities to assess their compliance with quality standards. Additionally, manufacturers should provide detailed QC reports that outline their testing methods, results, and any corrective actions taken.

Are Third-Party Inspections Beneficial?

Engaging third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control measures. These inspections can help identify potential risks and ensure that the manufacturer adheres to international standards, giving buyers greater confidence in their supplier’s capabilities.

Illustrative image related to conveyor manufacturers near me

What QC and Certification Nuances Should International Buyers Consider?

When dealing with international suppliers, buyers should be aware of specific QC and certification nuances that may affect their procurement process. Different countries may have varying standards and regulations that impact the quality and compliance of conveyor systems.

For example, while ISO 9001 is recognized globally, regional standards may also apply, necessitating additional certifications for specific markets. Buyers should research these requirements and ensure that their suppliers can meet them to avoid potential compliance issues.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

In summary, understanding the manufacturing processes and quality assurance practices of conveyor manufacturers is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust QC measures, buyers can make informed decisions when selecting suppliers. Verifying compliance with international standards and conducting thorough audits and inspections will further ensure that the conveyor systems purchased meet operational requirements and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor manufacturers near me’

When sourcing conveyor manufacturers, particularly in your vicinity, it’s vital to follow a structured approach to ensure you select the best partner for your business needs. This guide outlines essential steps for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe, to streamline their procurement process effectively.

Illustrative image related to conveyor manufacturers near me

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements. Consider the type of conveyor system you need—belt, roller, vertical, or specialized types. Specify dimensions, load capacities, and industry standards that must be met. This clarity will help manufacturers understand your needs and provide accurate solutions.

Step 2: Research Local and International Manufacturers

Conduct thorough research to identify conveyor manufacturers near you. Utilize online directories, industry publications, and trade shows to compile a list of potential suppliers. Pay attention to their geographical presence, as local manufacturers may offer quicker service and support, while international ones might provide advanced technology or specialized products.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for evidence of their experience in your specific application, as well as their ability to deliver on time and within budget.

- Check for Industry Experience: Suppliers with a proven track record in your sector will likely understand your unique challenges and requirements better.

- Assess Customer Reviews: Look for testimonials and ratings from previous clients to gauge reliability and service quality.

Step 4: Verify Certifications and Compliance

Ensure that the manufacturers you consider comply with relevant industry standards and certifications. This may include ISO certifications or specific safety and quality standards applicable to your region. Compliance ensures that the products you receive meet necessary safety and operational guidelines, reducing the risk of operational issues.

Illustrative image related to conveyor manufacturers near me

Step 5: Request Quotes and Proposals

Once you have shortlisted potential suppliers, request detailed quotes and proposals. This should include pricing, lead times, warranty information, and after-sales support. Compare these factors to make an informed decision, considering not just cost but also value for money.

- Consider Total Cost of Ownership: Look beyond the initial purchase price to include installation, maintenance, and operational costs over time.

- Review Service Agreements: Ensure clarity on support services, including maintenance and repairs, which can significantly impact long-term operational efficiency.

Step 6: Conduct Site Visits if Possible

If feasible, arrange site visits to the manufacturers’ facilities. Observing their operations can provide insights into their production capabilities, quality control processes, and overall professionalism. This step can also help build a personal relationship, which is crucial in B2B transactions.

Step 7: Finalize Contracts and Terms

Once you’ve selected a supplier, carefully review and finalize the contract. Ensure all terms, including delivery schedules, payment terms, and service agreements, are clearly defined. This step is critical to avoid misunderstandings and ensure both parties are aligned on expectations.

By following these steps, you can streamline your sourcing process for conveyor manufacturers, ensuring you find a reliable partner that meets your specific needs and enhances your operational efficiency.

Comprehensive Cost and Pricing Analysis for conveyor manufacturers near me Sourcing

What are the Key Cost Components for Conveyor Manufacturers?

When evaluating conveyor manufacturers, understanding the cost structure is essential for making informed purchasing decisions. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to conveyor manufacturers near me

-

Materials: The type of materials used can significantly affect the overall cost. For example, stainless steel conveyors may be more expensive than those made from aluminum or plastic due to material costs and the durability they offer.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Skilled labor may demand higher wages, impacting the final price of the conveyor system.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance that are necessary for production but not directly tied to a specific product.

-

Tooling: Custom tooling for specialized conveyor systems adds to upfront costs. Manufacturers may pass these costs onto buyers, particularly for bespoke solutions.

-

Quality Control: Ensuring that conveyor systems meet industry standards requires investment in QC processes, which can influence pricing.

-

Logistics: Shipping costs, especially for international orders, can vary widely based on distance, shipping method, and packaging requirements.

-

Margin: Manufacturers will add a profit margin to cover their operational costs and provide a return on investment.

How Do Price Influencers Affect Conveyor Manufacturing Costs?

Several factors can influence the pricing of conveyor systems, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger volumes often leads to lower per-unit costs. Understanding the manufacturer’s minimum order quantities (MOQs) can help negotiate better pricing.

-

Specifications and Customization: Customized solutions tailored to specific operational needs will generally incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: High-quality materials and industry certifications (like ISO) can increase costs but may be necessary for compliance and durability, especially in regulated industries.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may command higher prices due to perceived value.

-

Incoterms: Understanding Incoterms is vital for international transactions. Different terms (like FOB, CIF, DDP) can affect the total cost of ownership by determining who bears shipping costs, insurance, and other logistical expenses.

What Tips Should Buyers Consider for Effective Negotiation?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it’s crucial to consider several strategies to ensure cost-efficiency:

-

Negotiation: Engage in negotiations with manufacturers regarding pricing, especially for larger orders. Don’t hesitate to ask for discounts or better payment terms.

-

Total Cost of Ownership: Look beyond the initial purchase price. Consider long-term costs including maintenance, downtime, and energy efficiency when evaluating conveyor systems.

-

Pricing Nuances: Be aware that international shipping and tariffs can add unexpected costs. It’s advisable to factor these into the overall budget early in the procurement process.

-

Local Partnerships: Establishing relationships with local suppliers or distributors can reduce logistics costs and provide better support services, ultimately lowering the total cost.

Disclaimer on Indicative Prices

Pricing for conveyor systems can vary widely based on the factors mentioned above. It is essential to request quotes from multiple manufacturers to obtain a clear understanding of the market rates and to ensure that you are making a cost-effective decision. Always consider the unique requirements of your operation when evaluating the total costs associated with conveyor systems.

Alternatives Analysis: Comparing conveyor manufacturers near me With Other Solutions

When considering conveyor solutions, B2B buyers must evaluate various options available in the market. While local conveyor manufacturers offer tailored products and services, alternative technologies can also meet material handling needs effectively. This section provides a comparative analysis of ‘conveyor manufacturers near me’ against two viable alternatives: Automated Guided Vehicles (AGVs) and Manual Handling Solutions.

| Comparison Aspect | Conveyor Manufacturers Near Me | Automated Guided Vehicles (AGVs) | Manual Handling Solutions |

|---|---|---|---|

| Performance | High efficiency in material transport; customizable to specific needs. | Good for flexible routing; can handle various loads. | Limited by human capacity; performance varies based on workforce. |

| Cost | Initial investment can be high, but ROI is realized through efficiency. | Moderate to high; dependent on technology and integration needs. | Low initial cost, but long-term costs can accumulate due to labor. |

| Ease of Implementation | Requires professional installation and integration, potentially time-consuming. | Can be complex to set up; requires infrastructure assessment and training. | Simple and straightforward; minimal setup required. |

| Maintenance | Regular maintenance needed; manufacturers often provide support. | Requires ongoing software updates and hardware maintenance. | Minimal maintenance; dependent on workforce training and management. |

| Best Use Case | Ideal for large-scale operations needing reliable, continuous material transport. | Best for environments requiring flexibility and dynamic routing of materials. | Suitable for smaller operations or where automation is not feasible. |

What Are the Advantages and Disadvantages of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) provide a flexible and efficient solution for material handling, particularly in environments with varying layouts. Their ability to navigate complex paths autonomously makes them ideal for warehouses and manufacturing facilities that frequently change configurations. However, the implementation of AGVs can be costly, requiring significant upfront investment in technology and infrastructure. Moreover, AGVs necessitate ongoing maintenance and software updates, which can add to operational costs over time.

How Do Manual Handling Solutions Compare?

Manual handling solutions involve human labor to transport materials and products. While these methods have low initial costs and can be easily implemented without specialized equipment, they come with significant downsides. The efficiency and speed of manual handling depend heavily on the workforce’s capability and availability, which can fluctuate. Additionally, relying on manual labor can lead to higher long-term costs due to potential injuries, worker turnover, and the need for ongoing training.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a conveyor system or an alternative, B2B buyers should carefully assess their operational requirements, budget constraints, and future growth plans. Conveyor manufacturers near your location can provide tailored solutions that enhance efficiency and reduce handling costs over time. On the other hand, AGVs offer flexibility and adaptability, making them suitable for dynamic environments. For smaller operations, manual handling may be a practical choice, though it may not be as efficient in the long term. Ultimately, the decision should align with the company’s specific operational goals and financial capacities.

Essential Technical Properties and Trade Terminology for conveyor manufacturers near me

What Are the Key Technical Properties of Conveyor Systems for B2B Buyers?

When evaluating conveyor systems, understanding their technical properties is crucial for making informed purchasing decisions. Here are several key specifications that buyers should consider:

-

Material Grade

The material grade of conveyor components (such as belts, frames, and rollers) directly impacts durability, load capacity, and resistance to environmental conditions. Common materials include stainless steel for its corrosion resistance, aluminum for its lightweight properties, and various plastics for specific applications. Selecting the right material ensures longevity and reliability in operations, especially in industries like food processing or pharmaceuticals, where hygiene is paramount. -

Load Capacity

This specification indicates the maximum weight a conveyor system can safely transport. Load capacities can vary significantly based on design and materials used. Understanding load capacity is essential for ensuring that the conveyor can handle the specific demands of your operations, thus preventing potential breakdowns and enhancing productivity. -

Belt Speed

Measured in feet per minute (FPM), belt speed determines how quickly materials can be transported. Selecting the right speed is critical for optimizing workflow efficiency and ensuring that your operations align with production schedules. Too slow can lead to bottlenecks, while too fast may cause product damage. -

Tolerance Levels

Tolerance levels refer to the acceptable deviation from specified dimensions in conveyor components. High tolerance levels are vital in applications requiring precision, such as electronics assembly or packaging. This ensures that parts fit together correctly and operate smoothly, reducing downtime and maintenance costs. -

Power Requirements

This specification includes the type and amount of power needed to operate the conveyor system. It is essential to assess the electrical requirements to ensure compatibility with existing infrastructure. Understanding power requirements helps in estimating operational costs and ensuring compliance with local regulations. -

Safety Features

Safety features, such as emergency stop buttons, guards, and sensors, are critical for protecting workers and ensuring compliance with workplace safety standards. Evaluating these features can help mitigate risks associated with conveyor operation, thus fostering a safer work environment.

What Common Trade Terms Should B2B Buyers Know When Dealing with Conveyor Manufacturers?

Familiarity with industry jargon can facilitate smoother negotiations and clearer communication with conveyor manufacturers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the conveyor industry, OEMs provide components that fit specific systems, ensuring compatibility and quality. Buyers should inquire about OEM partnerships to ensure they are getting reliable parts. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, as it can affect purchasing decisions, especially for smaller operations that may not require large quantities. -

RFQ (Request for Quote)

An RFQ is a formal document requesting pricing and other information from suppliers for specific products or services. Submitting an RFQ allows buyers to compare costs and capabilities among different conveyor manufacturers, aiding in the selection process. -

Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which is particularly important for international transactions. -

Lead Time

Lead time refers to the period between the initiation of an order and the delivery of the product. Understanding lead times is essential for planning and inventory management, as extended lead times can impact production schedules. -

Custom Solutions

Many conveyor manufacturers offer custom solutions tailored to specific operational needs. Knowing the options available for customization can help buyers design a system that maximizes efficiency and meets unique material handling challenges.

In summary, a solid grasp of technical properties and trade terminology not only empowers B2B buyers to make informed decisions but also enhances collaboration with conveyor manufacturers, ultimately leading to optimized operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the conveyor manufacturers near me Sector

What Are the Current Market Dynamics and Key Trends in the Conveyor Manufacturing Sector?

The conveyor manufacturing sector is witnessing significant transformation driven by globalization, technological advancements, and shifting consumer demands. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, the market is increasingly characterized by automation and smart technologies. The integration of IoT (Internet of Things) in conveyor systems allows for real-time monitoring and enhanced operational efficiency, making it essential for manufacturers to adopt these innovations to remain competitive.

Moreover, there is a growing trend toward customization. Buyers are seeking conveyor systems tailored to their specific operational needs, which drives manufacturers to offer modular designs and flexible solutions. This customization not only enhances productivity but also optimizes space utilization in warehouses and production facilities. Additionally, sustainability is becoming a core focus, with manufacturers exploring eco-friendly materials and energy-efficient designs to meet both regulatory requirements and consumer preferences.

As international supply chains become more complex, buyers must navigate various sourcing challenges, including fluctuating material costs and the need for reliable suppliers. Engaging with local manufacturers can mitigate risks associated with shipping delays and tariffs, while also fostering regional economic growth. Establishing strong relationships with suppliers who understand local market dynamics can be a strategic advantage for B2B buyers seeking to streamline their operations.

How Is Sustainability Influencing Sourcing Decisions in the Conveyor Manufacturing Sector?

Sustainability is a critical consideration for B2B buyers in the conveyor manufacturing sector. The environmental impact of manufacturing processes and the importance of ethical supply chains are increasingly influencing purchasing decisions. Buyers are now more inclined to partner with manufacturers that prioritize sustainable practices, such as using recyclable materials, reducing waste, and implementing energy-efficient technologies in their conveyor systems.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming vital in the selection process. Manufacturers that possess these certifications signal their commitment to sustainability and ethical sourcing. Additionally, buyers are looking for suppliers who can demonstrate a transparent supply chain, ensuring that all materials are sourced responsibly and ethically.

As global awareness of environmental issues rises, the demand for “green” conveyor systems is expected to increase. These systems often incorporate renewable energy sources and environmentally friendly materials, appealing to companies that prioritize corporate social responsibility. For international buyers, aligning procurement strategies with sustainability goals not only enhances brand reputation but also meets the growing consumer demand for environmentally conscious products.

How Has the Conveyor Manufacturing Industry Evolved Over Time?

The conveyor manufacturing industry has undergone a remarkable evolution, shaped by technological advancements and changing market demands. Initially, conveyors were simple mechanical systems designed for basic material handling. However, as industries expanded and production processes became more complex, the need for more sophisticated conveyor solutions emerged.

In the late 20th century, the introduction of automation revolutionized the sector. Manufacturers began integrating electric motors, sensors, and programmable logic controllers (PLCs) into conveyor systems, significantly enhancing their functionality and efficiency. The rise of e-commerce in the 21st century further accelerated this evolution, as businesses sought faster and more reliable ways to handle logistics and distribution.

Today, conveyor systems are not only integral to manufacturing and warehousing but also play a crucial role in various sectors, including food processing, pharmaceuticals, and recycling. The trend toward automation and smart technology continues to drive innovation, ensuring that the conveyor manufacturing industry remains at the forefront of operational efficiency and productivity in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor manufacturers near me

-

How do I choose the right conveyor manufacturer for my business needs?

Selecting the right conveyor manufacturer involves assessing your specific operational requirements. Consider factors such as the type of materials you need to transport, the layout of your facility, and any special features you may require, such as automation or customization. Research potential suppliers’ experience in your industry, their product range, and their ability to provide technical support. Request quotes and compare them to ensure you are getting the best value for your investment. -

What types of conveyor systems are available for industrial applications?

Conveyor systems come in various types tailored for different industrial applications. Common types include belt conveyors, roller conveyors, bucket elevators, and pneumatic conveyors. Each type serves distinct functions; for example, belt conveyors are ideal for transporting bulk materials, while roller conveyors are effective for handling items with a flat bottom. Understanding your material handling needs will help you select the most suitable conveyor system for your operations. -

What customization options are available for conveyor systems?

Many conveyor manufacturers offer customization options to meet specific business needs. Customization can include adjustments to conveyor length, width, and speed, as well as the integration of additional components such as sensors and controls for automation. Discuss your requirements with potential suppliers to explore their capabilities in designing tailored solutions that enhance efficiency and productivity in your operations. -

What are the typical minimum order quantities (MOQs) for conveyor systems?

Minimum order quantities (MOQs) can vary significantly between manufacturers and the type of conveyor system required. Some suppliers may have no MOQ for standard products, while custom solutions may require larger orders. It’s crucial to discuss MOQs upfront with potential suppliers to ensure they align with your project needs and budget, especially if you are sourcing for large-scale operations or multiple facilities. -

How can I ensure quality assurance when sourcing conveyor systems?

Quality assurance is vital when sourcing conveyor systems. Look for manufacturers with established quality control processes, certifications (like ISO 9001), and a track record of delivering reliable products. Request samples or case studies from previous clients to assess performance. Additionally, inquire about warranty policies and after-sales support, as these can be indicative of a manufacturer’s commitment to quality. -

What payment terms should I expect when purchasing conveyor systems internationally?

Payment terms for international purchases can vary widely depending on the manufacturer and your relationship with them. Common terms include upfront payments, progress payments, or payment upon delivery. It’s essential to clarify these terms before finalizing the agreement. Additionally, consider using secure payment methods and consult with your financial institution about any currency exchange implications to avoid unexpected costs. -

What logistics considerations should I keep in mind when sourcing conveyor systems?

Logistics play a crucial role in the procurement of conveyor systems, especially for international buyers. Consider shipping methods, lead times, and customs regulations in your country. Work with your supplier to establish a clear timeline for delivery and ensure that all necessary documentation, such as bills of lading and import permits, are prepared in advance. Collaborating with a logistics provider experienced in international shipping can also streamline the process. -

How do I evaluate the reliability of a conveyor manufacturer?

To evaluate the reliability of a conveyor manufacturer, research their reputation in the industry through customer reviews and testimonials. Look for manufacturers with a long-standing presence in the market and a solid history of delivering quality products. Additionally, consider their customer service responsiveness, warranty offerings, and after-sales support. Engaging in direct communication with their sales and technical teams can also provide insights into their reliability and commitment to customer satisfaction.

Top 4 Conveyor Manufacturers Near Me Manufacturers & Suppliers List

1. Hytrol – Conveyor Solutions

Domain: hytrol.com

Registered: 1996 (29 years)

Introduction: Hytrol Conveyor Co. offers a range of conveyor products including: Transport conveyors for moving products, Accumulation conveyors with zero and minimum-pressure solutions, Sortation systems that include high-speed powerhouses and cost-effective pushers and transfers, Pallet Handling solutions designed for tough jobs, Conveyor Controls for smarter conveying, and Accessories to complement their sys…

2. Ashland Conveyor – ProFlex & Conveyor Rollers

Domain: ashlandconveyor.com

Registered: 1999 (26 years)

Introduction: ProFlex: A flexible, extendable powered conveyance system engineered for longer service life, ultra-low maintenance, and excellent ROI. Operating modes include Accumulation or Transportation.

Conveyor Rollers: Replacement rollers made from galvanized steel, stainless steel, aluminum, plain steel, and PVC. High capacity and quiet bearings available, along with vinyl and polyurethane sleeves.

Fl…

3. Ultimation – Conveyor Systems

Domain: ultimationinc.com

Registered: 1998 (27 years)

Introduction: Ultimation offers a wide range of conveyor systems and material handling solutions, including: 1. Belt Conveyors 2. Gravity Roller Conveyors 3. Gravity Flowrail and Skatewheel Conveyors 4. Powered Roller Conveyors 5. Beam Trolleys and I Beam Tracks 6. Enclosed Track Conveyors 7. Chain Driven Live Roller (CDLR) Conveyors 8. Food Conveyors and Washdown Conveyors 9. Slat Conveyor Systems 10. Overhead…

4. Custom Conveyor & Equipment Corporation – Custom Conveyors

Domain: customconveyor.com

Registered: 2020 (5 years)

Introduction: Custom Conveyor & Equipment Corporation specializes in conveyor design and manufacturing, offering custom solutions for various industries including food manufacturing, glass processing, and material handling. Key products include:

– Custom Conveyors: Tailored to specific needs, no two conveyors are identical.

– Plate Glass Breakers: Available in in-floor or above-floor models to enhance productiv…

Strategic Sourcing Conclusion and Outlook for conveyor manufacturers near me

In today’s competitive landscape, strategic sourcing for conveyor systems is essential for optimizing supply chain efficiencies and enhancing operational capabilities. Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should prioritize collaboration with reputable conveyor manufacturers who offer tailored solutions, such as belt, roller, and pneumatic conveyors. By leveraging local expertise and the latest technologies, businesses can ensure that their material handling processes are not only efficient but also scalable to meet future demands.

Investing in high-quality conveyor systems can significantly reduce operational costs and improve throughput, making it a crucial consideration for international buyers. Furthermore, the emphasis on customization allows for the alignment of solutions with specific industry needs, whether in food processing, pharmaceuticals, or manufacturing.

Looking ahead, the evolution of conveyor technology and the increasing demand for automation present a wealth of opportunities. B2B buyers are encouraged to engage with local manufacturers and suppliers to explore innovative solutions that can propel their businesses forward. Start your journey towards enhanced efficiency and growth by connecting with trusted conveyor manufacturers today.

Illustrative image related to conveyor manufacturers near me

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.