Top 4 Blackout Fabric For Projector Screen Suppliers (And How to Choose)

Introduction: Navigating the Global Market for blackout fabric for projector screen

Navigating the global market for blackout fabric for projector screens presents a unique set of challenges for international B2B buyers. Sourcing the right blackout fabric can be daunting, especially considering the diverse requirements across regions like Africa, South America, the Middle East, and Europe. Buyers often grapple with factors such as material quality, flame retardancy, color options, and pricing, which can significantly impact the effectiveness of their projection setups. This guide aims to demystify the complexities involved in selecting blackout fabric, offering valuable insights into various types, applications, and specifications.

Throughout this comprehensive resource, we will explore key considerations for evaluating suppliers, understanding market trends, and making cost-effective purchasing decisions. From the technical aspects of fabric composition to the nuances of performance in different environments, each section is designed to empower B2B buyers with the knowledge needed to make informed choices.

Whether you’re a procurement specialist in Germany seeking high-quality materials or a project manager in Vietnam looking to optimize your audiovisual solutions, this guide provides the necessary tools to ensure successful sourcing. As you delve into the intricacies of blackout fabrics, you’ll be better equipped to enhance your projects, ensuring optimal visual experiences while navigating the diverse global market landscape.

Understanding blackout fabric for projector screen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Blackout Fabric | Typically white on one side, prevents light bleed | Home theaters, conference rooms | Pros: Cost-effective, easy to source. Cons: Limited size options. |

| Flame-Retardant Blackout Fabric | Meets fire safety standards, often double-sided | Theatrical productions, events | Pros: Safety compliant, versatile. Cons: Higher cost. |

| High-Gain Blackout Fabric | Enhanced reflectivity, usually coated for better image quality | Commercial cinemas, large venues | Pros: Superior image quality, ideal for large screens. Cons: More expensive. |

| Stretchable Blackout Fabric | Flexible material that can be stretched over frames | Custom screen setups, portable screens | Pros: Customizable, easy to transport. Cons: May require additional framing. |

| Blackout Lining Fabric | Wider widths available, often less expensive | DIY projector screens, temporary setups | Pros: Economical, can be easily combined. Cons: May not provide high reflectivity. |

What are the Characteristics of Standard Blackout Fabric?

Standard blackout fabric is widely used for projector screens due to its light-blocking capabilities. Typically white on one side, this fabric prevents light bleed, making it suitable for home theaters and conference rooms. When sourcing this type, B2B buyers should consider the width and length available, as many fabrics are limited to specific dimensions. Additionally, cost-effectiveness is a major advantage, but buyers should be aware of the challenges in achieving larger screen sizes without seams.

Why Choose Flame-Retardant Blackout Fabric for Safety Compliance?

Flame-retardant blackout fabric is essential for applications where safety standards must be met, such as theatrical productions and large events. This type of fabric not only blocks light but also adheres to fire safety regulations, making it a preferred choice in public venues. When purchasing, buyers should verify compliance with local safety standards and consider the added cost, which reflects the enhanced safety features. This fabric offers versatility across various applications but may require a higher budget.

How Does High-Gain Blackout Fabric Enhance Image Quality?

High-gain blackout fabric is designed to enhance reflectivity, providing superior image quality for commercial cinemas and large venues. This type of fabric is often coated to improve brightness and contrast, making it ideal for high-performance projection systems. B2B buyers should assess the specific gain ratings and compatibility with their projectors, as this fabric is generally more expensive but can significantly elevate the viewing experience.

What Benefits Does Stretchable Blackout Fabric Offer for Custom Setups?

Stretchable blackout fabric is a flexible solution that allows for customization in screen setups, making it suitable for portable screens and unique installations. This material can easily be stretched over frames, facilitating the creation of tailored projector screens. Buyers should consider the ease of transport and installation, although they may need additional framing to ensure a taut surface. This type of fabric is particularly appealing for businesses that frequently relocate or require adaptable solutions.

Why Consider Blackout Lining Fabric for Economical DIY Projects?

Blackout lining fabric provides an economical option for businesses looking to create DIY projector screens or temporary setups. With wider widths available, this fabric can reduce the number of seams needed for larger screens. Buyers should evaluate the cost-effectiveness of this fabric, as it is typically less expensive than specialized projector screen materials. However, it may not offer the same level of reflectivity, so understanding the intended application is crucial for achieving desired results.

Key Industrial Applications of blackout fabric for projector screen

| Industry/Sector | Specific Application of blackout fabric for projector screen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Events | Theater and performance venues utilizing projection screens | Enhances visual clarity and audience engagement | Need for flame-retardant materials, large width options, durability |

| Education | Classrooms and auditoriums with multimedia presentations | Improves learning experience through better image quality | Considerations for light absorption, ease of installation, and maintenance |

| Corporate & Business | Conference rooms with video presentations | Facilitates effective communication and professional image | Requirements for custom sizes, portability, and professional aesthetics |

| Hospitality | Hotels and event spaces hosting conferences and exhibitions | Attracts clients with high-quality visual setups | Sourcing for bulk quantities, variety in colors, and easy cleaning options |

| Film Production | Film sets requiring controlled lighting environments | Provides optimal conditions for filming and projection | Need for large fabric sizes, light-blocking capabilities, and cost-effectiveness |

In the entertainment and events sector, blackout fabric is crucial for theater and performance venues where projection screens are employed. The fabric enhances visual clarity, ensuring that images are vivid and engaging for the audience. This application requires materials that are flame-retardant, available in large widths to accommodate various screen sizes, and durable enough to withstand repeated use. Buyers in regions like Africa and South America should prioritize suppliers who can meet local safety regulations and provide reliable shipping options.

In educational environments, classrooms and auditoriums often utilize blackout fabric for projector screens to facilitate multimedia presentations. This fabric significantly improves the learning experience by providing better image quality, allowing students to engage more effectively with the content. Buyers must consider the fabric’s ability to absorb light, ease of installation, and maintenance requirements, particularly in regions with fluctuating temperatures and humidity levels, which can affect material performance.

For the corporate sector, blackout fabric is essential in conference rooms where video presentations are common. The use of high-quality projection screens enhances communication and reflects a professional image. Businesses should focus on sourcing custom sizes that fit their specific room dimensions, ensuring portability for different setups, and maintaining a polished appearance. This is particularly important for B2B buyers in Europe and the Middle East, where corporate standards can be stringent.

In the hospitality industry, hotels and event spaces utilize blackout fabric to create stunning visual environments for conferences and exhibitions. High-quality visuals attract clients and enhance their overall experience. When sourcing, companies should look for bulk purchasing options, a variety of colors to match their branding, and easy-to-clean materials to maintain a pristine appearance.

Finally, in film production, blackout fabric is used on sets to control lighting conditions, ensuring optimal environments for filming and projection. This application requires large fabric sizes with excellent light-blocking capabilities to eliminate unwanted reflections. Buyers should seek cost-effective solutions that do not compromise on quality, especially in competitive markets like Germany and Vietnam, where production budgets can be tight.

3 Common User Pain Points for ‘blackout fabric for projector screen’ & Their Solutions

Scenario 1: Sizing Challenges for Large Screens

The Problem:

B2B buyers often face difficulties in sourcing blackout fabric that meets the size requirements for large projector screens. Many fabrics come in limited widths, typically around 54 inches, which can restrict the ability to create a seamless projection surface for larger setups. This can be especially frustrating for event planners or companies setting up large venues, as they may find that the fabric needs to be pieced together, resulting in visible seams that detract from the overall viewing experience.

The Solution:

To effectively address sizing challenges, B2B buyers should seek out suppliers that offer blackout fabric in wider formats, such as 110 inches or more. When sourcing, it’s essential to inquire about custom fabric options or bulk purchasing agreements that allow for larger rolls. Additionally, consider collaborating with manufacturers that can provide tailored solutions, such as custom cutting or finishing services. Utilizing a high-quality fabric that maintains its integrity when stretched or sewn can also minimize the risk of visible seams. For those needing specific dimensions, working with a reliable fabricator can ensure that the blackout material is delivered to precise specifications, providing a professional finish for any large-scale projection setup.

Scenario 2: Light Leakage and Image Quality Concerns

The Problem:

One of the prevalent issues faced by B2B buyers is light leakage, which can severely impact the quality of the projected image. In environments with ambient light, such as conference rooms or outdoor settings, using inadequate blackout fabric can lead to washed-out images or color distortion. This is particularly problematic for businesses that rely on high-quality presentations, as it can diminish the impact of their visual content.

The Solution:

To combat light leakage, it’s crucial to select blackout fabric with a proven ability to block out ambient light effectively. Look for materials with a minimum opacity rating, which indicates their ability to prevent light from passing through. Additionally, ensure the fabric is specifically designed for projection use, as this will enhance image quality through better light reflection and color accuracy. Testing the fabric in the intended environment before finalizing the purchase can also help identify potential issues. For optimal results, consider layering the blackout fabric with additional light-blocking materials or using light-absorbing borders to further enhance image clarity.

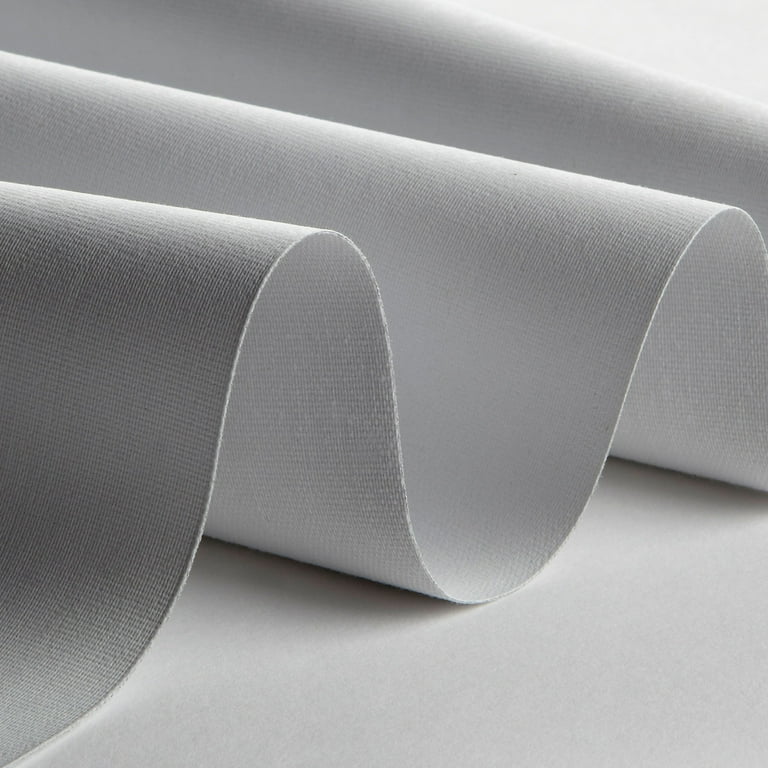

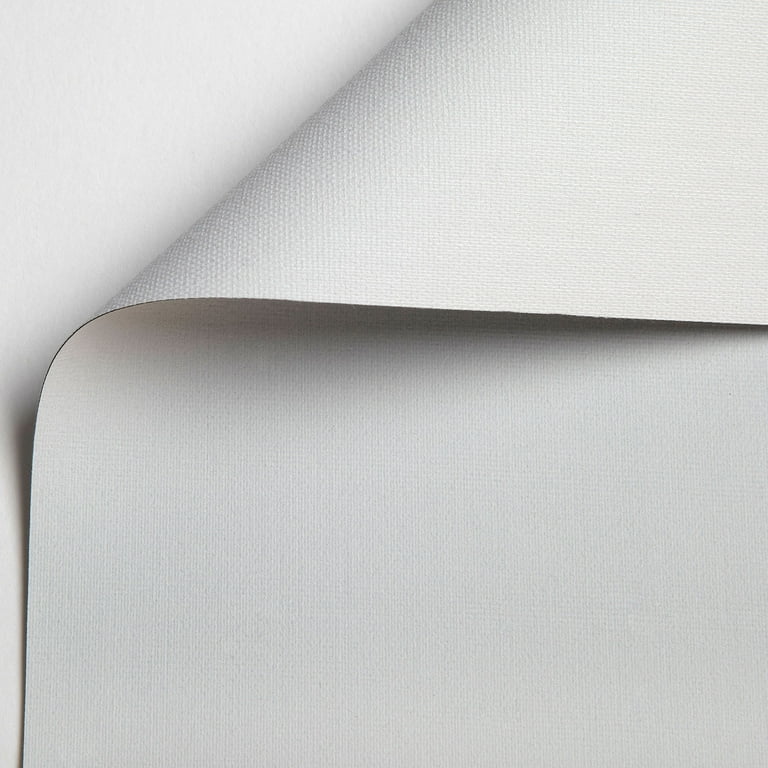

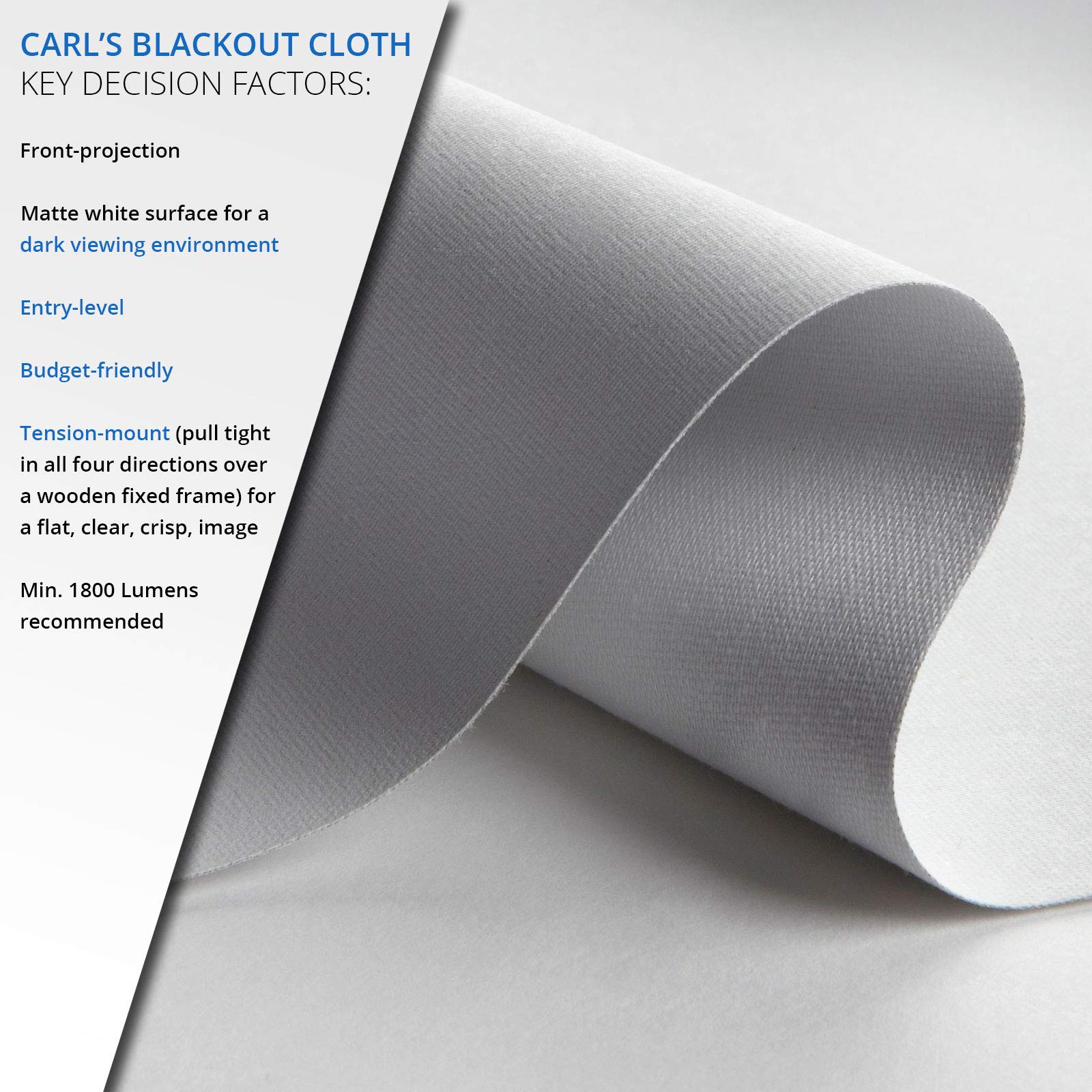

Illustrative image related to blackout fabric for projector screen

Scenario 3: Budget Constraints with Quality Expectations

The Problem:

Budget constraints are a common pain point for B2B buyers looking to procure blackout fabric for projector screens. Many may find themselves torn between the desire for high-quality materials and the need to stay within budget. This dilemma often leads to the compromise of image quality or durability, which can have long-term repercussions on business presentations and events.

The Solution:

Buyers should adopt a strategic approach to procurement by prioritizing long-term value over initial costs. Start by researching suppliers that offer high-quality blackout fabrics at competitive prices, potentially through bulk purchasing or long-term contracts. Additionally, consider alternative materials that provide similar benefits at a lower cost, such as specialized coated fabrics or innovative blends that enhance performance without breaking the bank. Investing in proper installation and maintenance will also extend the lifespan of the fabric, providing better returns on investment. Lastly, keep an eye on industry trends and innovations that may offer new, cost-effective solutions for high-quality blackout materials.

Strategic Material Selection Guide for blackout fabric for projector screen

When selecting blackout fabric for projector screens, understanding the properties and performance of various materials is crucial for B2B buyers. This guide analyzes several common materials used in blackout fabrics, highlighting their key properties, advantages, disadvantages, and considerations for international markets.

What are the Key Properties of Polyester Blackout Fabric?

Polyester is a widely used material for blackout fabrics due to its excellent light-blocking capabilities and durability. Typically, polyester blackout fabric has a weight of around 200-300 g/m², providing a good balance between thickness and flexibility. It is resistant to wrinkling and fading, making it suitable for long-term use in various environments.

Pros: Polyester is relatively inexpensive and easy to manufacture, which makes it a cost-effective option for large-scale production. It also offers good flame-retardant properties and is often compliant with international safety standards.

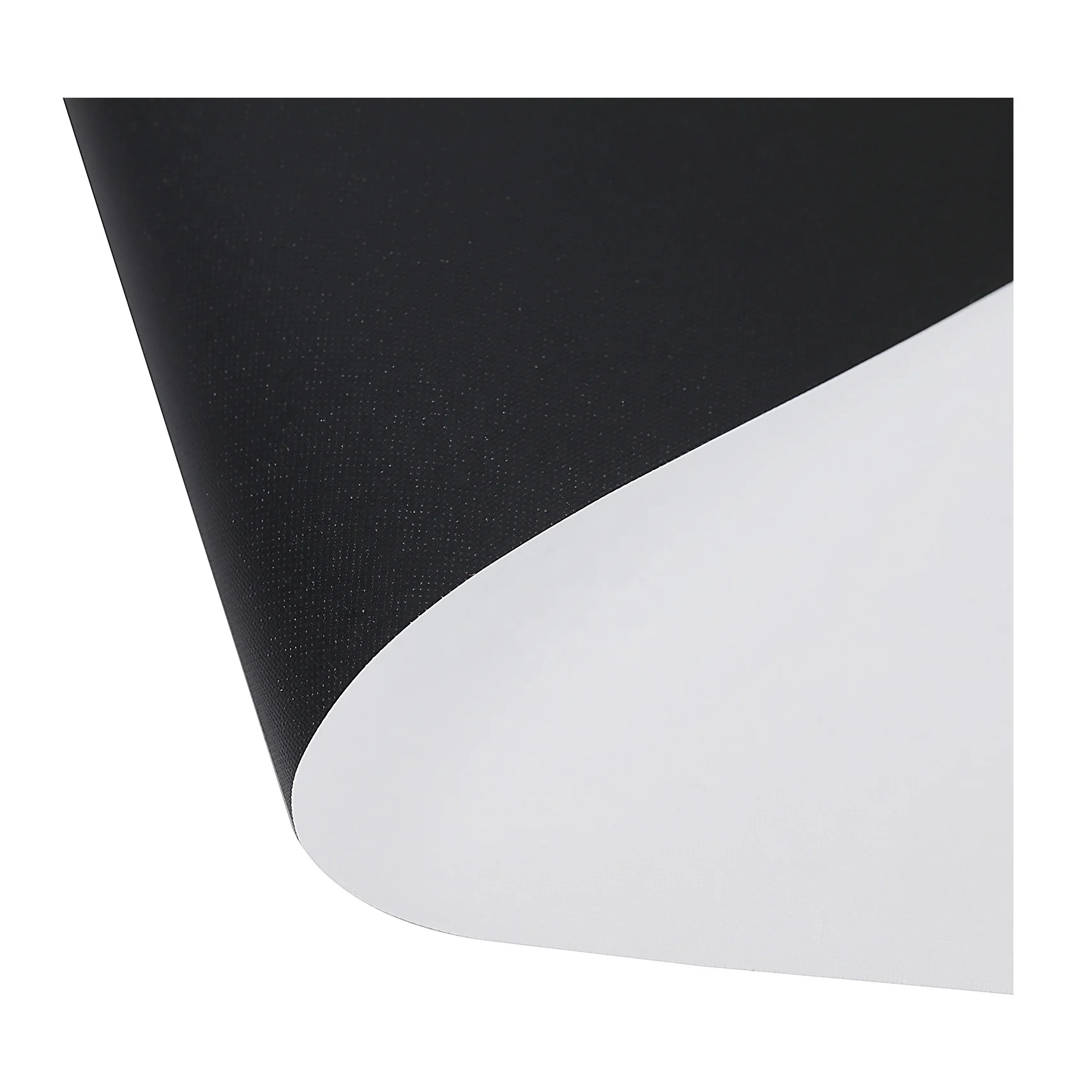

Illustrative image related to blackout fabric for projector screen

Cons: While durable, polyester can be less effective in extreme temperatures, which might affect its performance in regions with high heat or humidity. Additionally, some polyester fabrics may not provide the highest level of opacity compared to other materials.

Impact on Application: Polyester is compatible with a wide range of projectors and is commonly used in both commercial and residential settings.

How Does PVC Blackout Fabric Compare?

PVC (polyvinyl chloride) blackout fabric is known for its exceptional light-blocking capabilities and durability. This material is often heavier than polyester, typically weighing around 300-400 g/m², and is highly resistant to moisture and mildew.

Pros: PVC blackout fabric provides superior opacity and is ideal for environments requiring complete darkness, such as theaters and conference rooms. Its resistance to moisture makes it suitable for humid climates.

Cons: The manufacturing process for PVC can be more complex and costly, which may lead to higher prices. Additionally, PVC is less environmentally friendly, raising concerns about sustainability in regions with strict environmental regulations.

Impact on Application: PVC is highly effective for high-end projector systems, ensuring vibrant image quality even in challenging lighting conditions.

What Advantages Does Cotton Blackout Fabric Offer?

Cotton blackout fabric is a natural alternative that appeals to buyers looking for eco-friendly options. Typically weighing between 200-300 g/m², cotton provides a soft texture while still blocking light effectively.

Pros: Cotton is breathable and can help regulate temperature, making it suitable for various climates. It is also biodegradable, aligning with sustainability goals.

Cons: Cotton may require additional treatments to enhance its flame resistance and durability, which can complicate manufacturing. It is also more susceptible to mold and mildew in humid environments.

Impact on Application: Cotton blackout fabric is best suited for residential applications where aesthetics and environmental considerations are paramount.

What is the Role of Blended Fabrics in Blackout Solutions?

Blended fabrics, often combining polyester and cotton, leverage the benefits of both materials. These fabrics typically weigh around 250-350 g/m², offering a balance of durability and comfort.

Pros: Blended fabrics provide improved durability and light-blocking capabilities while maintaining a softer feel. They are often more cost-effective than pure cotton while still being environmentally friendly.

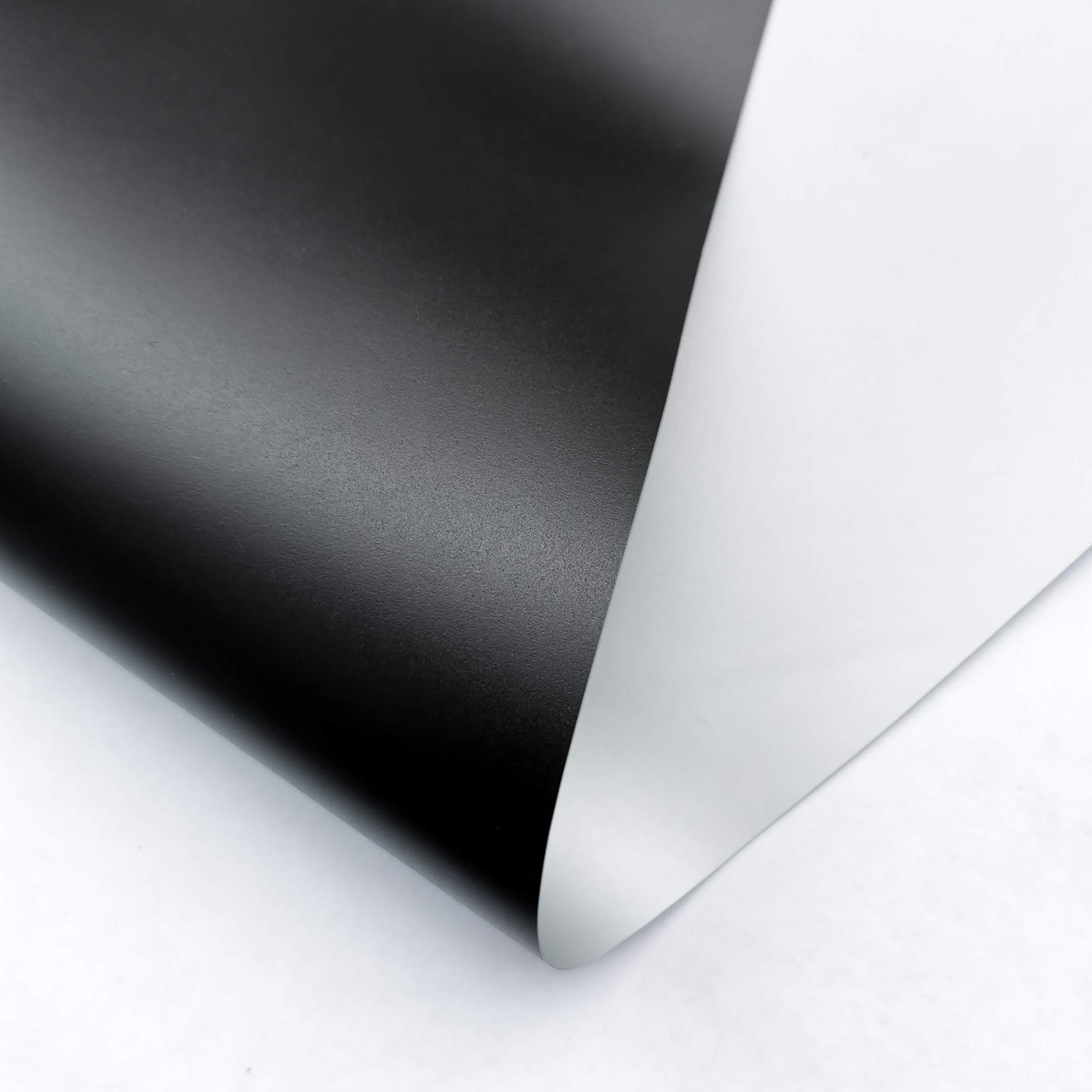

Illustrative image related to blackout fabric for projector screen

Cons: The performance of blended fabrics can vary significantly based on the proportions of each material, which may lead to inconsistencies in opacity and durability.

Impact on Application: Blended fabrics are versatile and can be used in both commercial and residential settings, appealing to a wide range of buyers.

Summary Table of Blackout Fabric Materials

| Material | Typical Use Case for blackout fabric for projector screen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Residential and commercial projector screens | Cost-effective and durable | Less effective in extreme temperatures | Low |

| PVC | Theaters and conference rooms | Superior opacity and moisture resistance | Higher cost and less environmentally friendly | High |

| Cotton | Residential applications | Eco-friendly and breathable | Requires treatments for durability | Medium |

| Blended Fabrics | Versatile use in various settings | Balanced properties of durability and feel | Variable performance based on material blend | Medium |

This analysis provides B2B buyers with actionable insights into the various materials available for blackout fabrics, enabling informed decisions that meet their specific needs and compliance requirements in international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for blackout fabric for projector screen

What Are the Key Stages in the Manufacturing Process of Blackout Fabric for Projector Screens?

Manufacturing blackout fabric involves several critical stages, each designed to ensure that the final product meets the high standards required for effective projection. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Raw Materials Are Used?

The process begins with the selection of high-quality raw materials, typically a blend of polyester (PES) and polyacrylonitrile (PAN). The fabric composition is crucial, as it directly impacts the blackout capability, durability, and flame retardancy of the final product. For instance, a common composition might be 23% PES and 77% PAN, providing a balance of strength and light-blocking properties.

Illustrative image related to blackout fabric for projector screen

During this stage, the raw materials are tested for quality and consistency. This involves checking for defects in the fabric, ensuring that the fibers are of the appropriate length and thickness, and verifying that the materials meet necessary safety standards.

How Is the Fabric Formed and Assembled?

Once the materials are prepared, they undergo a forming process. This typically involves weaving or knitting the fibers together to create a fabric that is dense enough to block light effectively. Techniques such as warp-knitting can be employed, as this allows for greater flexibility in the fabric’s final properties.

After forming, the fabric is cut to specific dimensions based on the requirements of the end user. This assembly stage may involve sewing or bonding multiple pieces of fabric together, especially for larger screens. Precision is key here, as any misalignment can lead to light leakage and affect the performance of the projector screen.

What Finishing Processes Are Essential for Quality?

The finishing stage is where the fabric is treated to enhance its properties. This may include processes such as coating the fabric with a flame retardant, which is essential for compliance with safety regulations in various markets. Additionally, the fabric may undergo treatments to improve its resistance to wear, fading, and staining.

Quality assurance checks are performed throughout these manufacturing stages to ensure that the fabric meets the required specifications. This includes verifying the weight, width, and overall quality of the fabric, as well as ensuring that it complies with international standards.

Illustrative image related to blackout fabric for projector screen

How Is Quality Assurance Managed During Blackout Fabric Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for blackout fabric, ensuring that the final product meets the expectations of B2B buyers. Various international standards, such as ISO 9001, guide manufacturers in establishing effective QA processes.

Which International Standards Are Relevant for Blackout Fabric?

For blackout fabric manufacturers, compliance with international standards is crucial. ISO 9001 provides a framework for quality management systems, ensuring consistent quality across production processes. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, and flame retardancy standards like EN 13773 and NFPA 701, help to assure buyers that the fabric meets safety requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This initial check involves inspecting raw materials upon arrival to ensure they meet predefined quality standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to monitor the quality of the fabric at different stages. This includes assessing the fabric’s texture, color consistency, and overall integrity.

-

Final Quality Control (FQC): Before the fabric is shipped, a final inspection is conducted to ensure it meets all specifications and standards. This includes checking for defects, ensuring that the dimensions are accurate, and confirming that the fabric performs well in light-blocking tests.

What Testing Methods Are Commonly Used?

Common testing methods for blackout fabric include:

- Light Blockage Tests: These assess the fabric’s ability to prevent light from passing through, ensuring it meets the required standards for projection.

- Flame Retardancy Tests: Conducted to confirm that the fabric complies with safety regulations for fire resistance.

- Durability Tests: These involve subjecting the fabric to wear and tear to ensure it can withstand regular use without significant degradation.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality is paramount. Here are several actionable steps to ensure suppliers meet quality standards:

Illustrative image related to blackout fabric for projector screen

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should establish a schedule for these audits to ensure ongoing compliance.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports that outline their QC processes, testing methods, and results. These documents should be transparent and easily accessible.

-

Engage Third-Party Inspectors: In many cases, employing third-party inspection services can help verify that the products meet the required quality standards. This is particularly important for buyers in regions with varying standards and regulations.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware that quality assurance and certification processes may vary by region. For instance, European buyers may require CE marking, while those in the Middle East might focus on local standards. Buyers should familiarize themselves with the specific requirements in their target markets to ensure compliance and avoid potential issues with imports.

Additionally, understanding the nuances of local regulations, such as flame retardancy standards, can help buyers make informed decisions when selecting suppliers.

Conclusion: Ensuring Quality in Blackout Fabric for Projector Screens

In summary, the manufacturing processes for blackout fabric involve meticulous attention to detail at every stage, from material preparation to finishing. Quality assurance is equally critical, ensuring that the fabric not only meets industry standards but also satisfies the specific needs of B2B buyers. By understanding the manufacturing and QC processes, international buyers can make informed decisions and forge successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blackout fabric for projector screen’

To assist B2B buyers in sourcing blackout fabric for projector screens effectively, this guide outlines essential steps to ensure informed procurement decisions. Blackout fabric is critical for achieving optimal projection quality, and understanding the nuances of selection and supplier evaluation will streamline the process.

Illustrative image related to blackout fabric for projector screen

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as the required dimensions, weight, and material composition of the blackout fabric. For example, a fabric that is 290 cm wide and weighs 275 g/m² may be ideal for large installations, while lighter options might be suitable for portable screens.

Step 2: Research Material Options

Understanding the different types of blackout fabrics available is crucial. Look for materials that offer specific benefits, such as flame retardancy and Oeko-Tex certification for safety and environmental considerations. Common options include polyester blends and specialized coatings that enhance light blocking and reflectivity, which can significantly affect image quality.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s important to vet potential suppliers thoroughly. Request company profiles, case studies, and references from other buyers in similar industries. Consider suppliers that have established credibility in the market, especially those specializing in theater and event materials, as they often have the necessary expertise in blackout fabrics.

Illustrative image related to blackout fabric for projector screen

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications to guarantee product quality and safety. Look for compliance with international standards, such as EN 13773 for flame retardancy and Oeko-Tex Standard 100. These certifications not only provide peace of mind but also demonstrate the supplier’s commitment to quality and safety.

Step 5: Request Samples

Requesting samples before placing a bulk order is a critical step in the sourcing process. This allows you to evaluate the fabric’s texture, opacity, and overall quality. Check for any imperfections, and assess how the fabric performs with your specific projector setup to ensure it meets your performance expectations.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier and product, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the pricing aligns with your budget while also considering long-term partnerships for future needs. Establish clear terms to avoid any misunderstandings later in the procurement process.

Step 7: Finalize Your Order and Plan Installation

After agreeing on terms, finalize your order and discuss installation options if applicable. Consider the logistics of delivery and installation, especially if the fabric is for large-scale projects. Collaborate with your supplier to ensure that all aspects of the procurement and installation process are clearly outlined, reducing the risk of complications during execution.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing blackout fabric for projector screens, ensuring optimal product selection and supplier reliability.

Comprehensive Cost and Pricing Analysis for blackout fabric for projector screen Sourcing

What Are the Key Cost Components for Blackout Fabric for Projector Screens?

When sourcing blackout fabric for projector screens, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The fabric composition significantly affects pricing. For instance, high-quality blackout fabrics may include polyester and acrylic blends, which offer superior light-blocking capabilities and durability. Prices can vary widely based on the raw materials, with specialty fabrics costing more.

-

Labor: Labor costs encompass the workforce involved in manufacturing, cutting, and finishing the fabric. Skilled labor is essential for ensuring quality, especially in custom orders, which can increase overall costs.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can lower these overheads, allowing suppliers to offer more competitive pricing.

-

Tooling: For custom sizes or designs, tooling costs can be a significant factor. This includes the cost of molds or dies required for production, which can lead to higher initial costs but may decrease with larger order volumes.

-

Quality Control (QC): Ensuring the fabric meets specified standards incurs costs in inspection and testing. Compliance with certifications such as Oeko-Tex or flame retardancy standards adds to the QC expenses.

-

Logistics: Shipping and handling are vital components of the total cost. Depending on the distance and method of transport, logistics can significantly impact pricing, especially for international buyers.

-

Margin: Finally, suppliers will include their profit margin in the final price. This can vary based on market demand and competition.

How Do Price Influencers Impact Blackout Fabric Sourcing?

Several factors influence the pricing of blackout fabric, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Suppliers may set a MOQ that, if met, can significantly reduce costs, making it more economical for larger projects.

-

Specifications and Customization: Custom sizes or specific fabric characteristics (e.g., color, weight, flame retardancy) can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Fabrics with certifications (like Oeko-Tex) or superior performance characteristics often command higher prices. Buyers should consider the long-term value of investing in higher-quality materials.

-

Supplier Factors: Supplier reputation, reliability, and service level can influence pricing. Established suppliers with a track record may offer better quality assurance, which can justify higher costs.

-

Incoterms: Understanding shipping terms can greatly affect the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, which can significantly impact the final price.

What Buyer Tips Can Help Negotiate Better Prices for Blackout Fabric?

B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, can benefit from several strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate prices based on order volume, payment terms, and delivery timelines. Building a good relationship can lead to better pricing and terms.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes initial purchase price, shipping, and potential long-term savings from durability and performance. Sometimes, a higher upfront cost may lead to lower overall expenses.

-

Pricing Nuances for International Buyers: Be aware of regional market conditions that can affect pricing, such as tariffs or currency fluctuations. Local suppliers may offer more favorable terms than international counterparts.

-

Research and Benchmarking: Conduct market research to understand average pricing and specifications. This knowledge can empower buyers during negotiations and ensure they are getting competitive rates.

Disclaimer on Indicative Prices

Pricing for blackout fabric can vary significantly based on specifications, supplier relationships, and market conditions. The information provided should be used as a guideline, and buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they secure the best deal.

Alternatives Analysis: Comparing blackout fabric for projector screen With Other Solutions

Exploring Alternatives for Projector Screen Solutions

When considering the best solution for a projector screen, it’s essential to explore alternatives to blackout fabric. While blackout fabric is a popular choice due to its light-blocking properties and affordability, there are other viable options available. Each alternative comes with its own set of advantages and drawbacks that can influence your decision based on specific needs and contexts.

| Comparison Aspect | Blackout Fabric For Projector Screen | Paint-on Projection Screen | Rigid Projection Screen |

|---|---|---|---|

| Performance | Excellent light blocking; 0.9 gain | Variable gain; can be customized | High reflectivity; can exceed 1.0 gain |

| Cost | Moderate; typically $6-$26 per yard | Low to moderate; paint costs vary | High; often $200+ depending on size |

| Ease of Implementation | Moderate; requires framing | High; requires proper application | Low; often needs professional installation |

| Maintenance | Low; wipe clean if needed | Moderate; may need repainting | Low; durable and easy to clean |

| Best Use Case | Home theaters, budget setups | DIY projects, customizable displays | Professional venues, high-quality settings |

What Are the Pros and Cons of Paint-on Projection Screens?

Paint-on projection screens offer a cost-effective alternative to traditional screens. They allow users to customize the gain and color based on their specific projector and room conditions. However, the performance can be inconsistent, and achieving a perfectly smooth finish requires skill and patience during application. Maintenance can also be a concern, as the paint may need touch-ups or complete reapplications over time. This option is best for DIY enthusiasts or those looking for tailored solutions in informal settings.

How Do Rigid Projection Screens Compare?

Rigid projection screens, which are often made from specialized materials or coated boards, provide a high-quality viewing experience. They typically offer superior reflectivity and durability compared to fabric options. However, the initial investment is considerably higher, and installation can be complex, sometimes requiring professional help. Rigid screens are ideal for professional environments, such as conference rooms and cinemas, where image quality is paramount.

Conclusion: How to Choose the Right Projector Screen Solution for Your Needs

When selecting the appropriate projector screen solution, B2B buyers should consider their specific use cases, budget constraints, and desired performance levels. Blackout fabric is an excellent choice for businesses seeking a cost-effective, versatile option, especially for home theaters or temporary setups. Paint-on solutions may appeal to those looking for a DIY approach, while rigid screens will serve high-end applications where image quality is critical. By weighing the pros and cons of each alternative, buyers can make informed decisions that align with their operational goals and budgetary requirements.

Essential Technical Properties and Trade Terminology for blackout fabric for projector screen

What Are the Key Technical Properties of Blackout Fabric for Projector Screens?

When sourcing blackout fabric for projector screens, understanding its technical specifications is crucial for ensuring quality and performance. Here are some essential properties to consider:

-

Material Composition

Blackout fabrics are typically made from polyester (PES) and polyacrylonitrile (PAN) blends, which enhance durability and light-blocking capabilities. A common composition is 23% PES and 77% PAN. Knowing the material helps buyers assess the fabric’s performance against environmental factors like humidity and temperature variations, which can impact its longevity and effectiveness. -

Weight

The weight of blackout fabric, often measured in grams per square meter (g/m²), typically ranges from 250 to 300 g/m². A heavier fabric usually provides better light-blocking properties and durability. For B2B buyers, selecting the right weight is essential for the intended application, as heavier fabrics are often more suited for permanent installations, while lighter options may be better for temporary setups. -

Flame Retardancy Standards

Compliance with flame retardancy standards, such as EN 13773 or NFPA 701, is critical for safety in public venues. Fabrics that meet these standards reduce fire hazards, making them suitable for theaters, schools, and corporate environments. Buyers should verify certifications to ensure compliance with local regulations, which can vary by region. -

Width and Length

Blackout fabrics come in various widths, typically ranging from 54 inches to 290 cm (approximately 114 inches). Understanding the dimensions is crucial for buyers planning to create custom screens or large installations. The ability to source wider rolls can minimize seams, which can be a source of light leakage and visual distraction. -

Color and Finish

While many blackout fabrics are black on one side, options that are white on both sides exist for specific applications. The color affects light absorption and reflection, influencing the overall picture quality. Buyers should consider the intended use—whether for home theaters or professional presentations—to choose the appropriate finish for optimal performance. -

Light Gain

Light gain refers to the reflective properties of the fabric, often expressed as a gain factor (e.g., 0.9 gain). This metric indicates how much light is reflected back to the audience. Understanding light gain is essential for buyers to ensure compatibility with their projector’s brightness and type, impacting the overall viewing experience.

What Are Common Trade Terms in the Blackout Fabric Industry?

Navigating the procurement of blackout fabric involves familiarizing oneself with industry jargon. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify potential suppliers and evaluate the quality and reliability of products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is essential for B2B buyers as it affects inventory costs and procurement strategies. Buyers should assess their needs against the MOQ to optimize their purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific products or services. Crafting a clear RFQ can help buyers receive competitive pricing and terms, facilitating better procurement outcomes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery timelines, ensuring smooth logistics. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times helps buyers plan their projects effectively and manage expectations regarding supply chain timelines. -

Customization Options

Many suppliers offer customization, allowing buyers to specify dimensions, colors, or other features. Knowing customization capabilities can help businesses meet specific project requirements and enhance their offerings in competitive markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing blackout fabric for projector screens, ensuring they achieve the best quality and value for their investments.

Navigating Market Dynamics and Sourcing Trends in the blackout fabric for projector screen Sector

What Are the Key Market Trends in the Blackout Fabric for Projector Screen Sector?

The global market for blackout fabric for projector screens is experiencing a transformative phase, driven by advancements in projection technology and an increasing demand for high-quality visual experiences in both residential and commercial settings. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are capitalizing on these trends to enhance their offerings. The rise of home theaters and multimedia presentations is fueling demand for diverse screen materials, including specialized blackout fabrics that provide superior light-blocking capabilities.

Emerging technologies such as digital printing and innovative textile compositions are reshaping the product landscape. Buyers are increasingly seeking customizable options, enabling them to cater to specific needs in various environments—from professional AV setups to educational institutions. Furthermore, there’s a noticeable shift toward lightweight and easily transportable fabrics that support outdoor events and temporary installations.

Supply chain dynamics are also evolving, with a growing emphasis on direct sourcing from manufacturers to ensure quality control and reduce lead times. As the market expands, buyers must remain vigilant about price fluctuations and availability, especially in regions with less established supply networks.

How Is Sustainability Shaping the Blackout Fabric Sourcing Process?

The importance of sustainability in sourcing blackout fabric for projector screens cannot be overstated. Environmental concerns are prompting B2B buyers to prioritize suppliers that demonstrate a commitment to ethical production practices and sustainable materials. Fabrics that are Oeko-Tex certified or made from recycled materials are gaining traction, as businesses seek to minimize their ecological footprint.

Moreover, the concept of circular economy is influencing sourcing strategies. Buyers are increasingly interested in suppliers who offer recycling programs or fabric take-back schemes, which can significantly reduce waste associated with event setups and screen replacements. This focus on sustainability not only aligns with global environmental goals but also resonates with end-users who are increasingly eco-conscious.

Ethical sourcing extends beyond materials; it encompasses fair labor practices and transparent supply chains. Buyers are encouraged to conduct due diligence on their suppliers, ensuring that they adhere to ethical standards throughout the production process. By selecting partners who prioritize social responsibility, businesses can enhance their brand reputation and appeal to a wider audience.

What Is the Historical Context of Blackout Fabric in the Projector Screen Industry?

The history of blackout fabric in the projector screen industry is marked by continuous innovation and adaptation to changing consumer needs. Initially, blackout fabrics were primarily used in theaters and professional AV setups, where controlling light was crucial for optimal viewing experiences. Over time, as home entertainment systems gained popularity, the demand for high-quality blackout materials expanded into residential markets.

In the early days, blackout fabrics were often heavy and cumbersome, limiting their application. However, advancements in textile technology have led to the development of lightweight, flexible options that provide enhanced performance without sacrificing portability. This evolution has made blackout fabric an essential component in a variety of settings, from corporate presentations to outdoor movie nights.

As the market continues to evolve, understanding the historical context of blackout fabric offers valuable insights into current trends and future directions. B2B buyers can leverage this knowledge to make informed sourcing decisions, ensuring they align with market demands while capitalizing on emerging opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of blackout fabric for projector screen

-

How do I select the right blackout fabric for my projector screen?

Choosing the right blackout fabric involves considering several factors such as the fabric’s weight, texture, and light-blocking capabilities. Look for fabrics that are specifically designed for projection, such as those with a 0.9 gain or higher, to ensure optimal image quality. Additionally, assess the fabric’s width to avoid seams if you need larger sizes, and consider flame retardancy certifications if your application requires it. Consulting with suppliers about their product specifications can help you make an informed decision. -

What are the key benefits of using blackout fabric for projector screens?

Blackout fabric is engineered to prevent light from passing through, ensuring that projected images remain vibrant and clear. It minimizes ambient light interference, which is crucial for high-quality presentations in various environments, such as conference rooms or outdoor events. Additionally, many blackout fabrics are designed to be durable and easy to clean, making them a practical choice for frequent use. They also offer versatility in terms of color and finish, allowing customization to fit different aesthetic needs. -

What is the typical minimum order quantity (MOQ) for blackout fabric?

Minimum order quantities (MOQ) can vary significantly depending on the supplier and the specific fabric type. Generally, MOQs can range from 50 to 500 meters. It’s essential to communicate your project requirements directly with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility for smaller orders, especially for new business relationships, so don’t hesitate to negotiate or explore bulk purchasing options if needed. -

How can I ensure the quality of blackout fabric before purchasing?

To ensure quality, request samples from potential suppliers before placing a large order. This allows you to assess the fabric’s texture, thickness, and light-blocking efficiency firsthand. Additionally, inquire about the supplier’s quality assurance processes, certifications (such as Oeko-Tex or ISO), and any testing methods they employ to ensure their fabrics meet industry standards. Establishing a reliable communication channel with the supplier can also facilitate transparency regarding product quality. -

What are the payment terms typically offered by suppliers of blackout fabric?

Payment terms can vary widely among suppliers, but common arrangements include full payment upfront, a deposit followed by the balance upon delivery, or payment upon receipt. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Discussing payment terms early in negotiations can help establish a mutually beneficial agreement and ensure a smooth transaction process. -

How do I handle logistics and shipping for international orders of blackout fabric?

When sourcing blackout fabric internationally, it’s crucial to work with suppliers who have experience in export logistics. Discuss shipping options, including air freight and sea freight, to determine the most cost-effective method for your order size and urgency. Be aware of any customs regulations and import duties applicable in your country. Collaborating with a freight forwarder can streamline the shipping process and help manage any potential logistical challenges. -

What customization options are available for blackout fabric?

Many suppliers offer customization options, including fabric width, color, and weight. Some may also provide specific coatings or finishes to enhance light reflectivity or durability. When discussing customization, be clear about your requirements and ask for any additional costs associated with these modifications. Custom solutions can help ensure that the blackout fabric meets your specific project needs and enhances overall performance. -

How do I vet suppliers for blackout fabric in international markets?

Vetting suppliers involves researching their reputation, experience, and reliability in the industry. Start by checking for customer reviews and testimonials, and look for certifications that indicate adherence to quality standards. It’s advisable to ask for references from other clients who have ordered similar products. Engaging with suppliers through trade shows or industry networks can also provide insights into their capabilities and help establish trust before finalizing any agreements.

Top 4 Blackout Fabric For Projector Screen Manufacturers & Suppliers List

1. Carl’s Place – Golf Enclosure Kits

Domain: shop.carlofet.com

Registered: 2006 (19 years)

Introduction: Theater – Carl’s Place offers a range of golf simulators and accessories, including DIY curved golf enclosures, impact screens, and launch monitors. Key products include: 1. DIY Golf Enclosure Kit 2. Pro Golf Enclosure Kit 3. Curved Golf Enclosure Kit 4. Built-In Golf Room Kit 5. High Contrast Gray Golf Impact Screen 6. Premium Golf Impact Screen 7. Preferred Golf Impact Screen 8. Standard Golf Im…

2. Dazian – Blackout Cloth for Extra Large Screens

Domain: avsforum.com

Registered: 1999 (26 years)

Introduction: Blackout cloth for extra large screens; required dimensions: 122″x76.25″; available width: 54″; alternative options discussed include using two pieces of fabric or a king-sized bed sheet; Dazian fabrics offer 122″ wide options; blackout cloth is inexpensive, light-blocking, with a gain of 0.9 at best; other suggestions include foam board or plywood for a seamless screen.

3. eBay – Motorized and Manual Projection Screens

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Blackout Cloth Type: Motorized Screen, Manual Screen, Fixed Frame, Stand, Electrical Mount-Wall, Tripod, Rear Projection Screen. Sizes Available: 60 in, 72 in, 80 in, 84 in, 100 in, 110 in, 120 in, 130 in, 150 in, 200 in, 300 in. Best Selling Products: Double-Sided 20ft Inflatable Movie Screen, VEVOR 20 ft Inflatable Movie Screen, Epson Duet Ultra Portable Tripod Projector Screen, Elite Screens M1…

4. ShowTex – Blackout 270

Domain: showtex.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Blackout 270”, “description”: “White blackout fabric for theatres and events”, “technical_data”: {“article_code”: “1259 0290 0003”, “width”: “290 cm”, “length”: “± 35 m”, “weight”: “275 g/m²”, “composition”: “23% PES + 77% PAN”, “flame_retardancy_standard”: “EN 13773 / class 1, NFPA 701 / pass”, “certification”: “Oekotex 100 certified (Class 2)”}, “available_colours”: [“0003”]}

Strategic Sourcing Conclusion and Outlook for blackout fabric for projector screen

How Can Strategic Sourcing Enhance Your Procurement of Blackout Fabric?

In the competitive landscape of audiovisual solutions, strategic sourcing of blackout fabric for projector screens is paramount. By understanding the diverse options available, including various widths, compositions, and flame retardancy standards, international buyers can make informed decisions that align with their specific project needs. Sourcing high-quality blackout fabric not only ensures optimal projection quality but also enhances the durability and safety of installations, crucial for compliance with local regulations.

Investing in strategic sourcing allows businesses to leverage supplier relationships, negotiate better terms, and access innovative materials that can set them apart in the marketplace. As demand for high-quality projection solutions continues to grow across regions such as Africa, South America, the Middle East, and Europe, particularly in markets like Germany and Vietnam, the ability to procure the right materials will be essential for success.

As you explore your options, consider reaching out to multiple suppliers and evaluating their offerings against your project specifications. This proactive approach will enable you to secure the best value and quality in your blackout fabric procurement. Embrace the future of projection solutions by prioritizing strategic sourcing today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.