Top 3 Single Sided Foam Tape Suppliers (And How to Choose)

Introduction: Navigating the Global Market for single sided foam tape

In today’s dynamic global marketplace, sourcing single sided foam tape presents unique challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including markets like Vietnam and Brazil. As industries increasingly rely on versatile adhesive solutions for applications ranging from automotive assembly to construction, understanding the specifications, types, and suppliers of single sided foam tape becomes critical for maintaining competitive advantage.

This comprehensive guide delves into the various types of single sided foam tapes available, exploring their applications across different sectors, including insulation, cushioning, and mounting. We also provide insights into the supplier vetting process, cost considerations, and market trends, ensuring that buyers can make informed decisions tailored to their specific needs. By equipping international B2B buyers with the knowledge required to navigate the complexities of the foam tape market, this guide empowers them to enhance their procurement strategies and optimize their operational efficiency.

Whether you are a seasoned buyer or new to the foam tape landscape, the insights contained within this guide are designed to facilitate smarter purchasing decisions, ensuring that your business has access to the best materials for your projects. As you embark on this journey, you will find actionable information that not only addresses your immediate sourcing needs but also sets the foundation for long-term partnerships with reliable suppliers.

Understanding single sided foam tape Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Foam Tape | Durable, weather-resistant, available in various densities | Automotive, construction, HVAC systems | Pros: Strong adhesion; Cons: Limited flexibility. |

| Polyethylene (PE) Foam Tape | Lightweight, moisture-resistant, often comes in rolls | Packaging, insulation, window glazing | Pros: Cost-effective; Cons: Not suitable for heavy loads. |

| EPDM Foam Tape | Excellent UV resistance, good for outdoor applications | Roofing, outdoor signage, sealing gaps | Pros: Long-lasting outdoors; Cons: More expensive. |

| Neoprene Foam Tape | High elasticity, resistant to oils and chemicals | Industrial applications, automotive sealing | Pros: Versatile in harsh environments; Cons: Higher cost. |

| Acrylic Foam Tape | High bonding strength, available in double-sided variants | Signage, mounting applications | Pros: Superior adhesion; Cons: Requires surface preparation. |

What are the characteristics and applications of PVC Foam Tape?

PVC foam tape is known for its durability and resistance to various environmental factors, making it ideal for applications in automotive, construction, and HVAC systems. This tape typically comes in different densities, allowing for selection based on specific project requirements. When purchasing PVC foam tape, B2B buyers should consider the tape’s adhesion strength and its ability to withstand temperature fluctuations, as these factors can significantly impact performance in demanding environments.

How does Polyethylene (PE) Foam Tape suit B2B needs?

Polyethylene (PE) foam tape is lightweight and moisture-resistant, making it a popular choice for packaging and insulation tasks. It is commonly used in window glazing applications due to its ability to seal effectively without adding significant weight. Buyers should evaluate the thickness and adhesive properties of PE foam tape to ensure it meets their specific needs, especially when considering cost-effectiveness for large-scale projects.

What makes EPDM Foam Tape a preferred choice for outdoor applications?

EPDM foam tape is particularly valued for its exceptional UV resistance, making it suitable for outdoor applications such as roofing and sealing gaps in outdoor signage. Its longevity in harsh weather conditions is a significant advantage for B2B buyers looking for reliable sealing solutions. However, the higher cost compared to other foam tapes may require justification based on the expected lifespan and performance in outdoor environments.

Why is Neoprene Foam Tape versatile for industrial applications?

Neoprene foam tape offers high elasticity and resistance to oils and chemicals, making it highly versatile for various industrial applications, including automotive sealing and manufacturing processes. Its ability to perform under harsh conditions is a key selling point. B2B buyers should consider the specific chemical exposures and temperature ranges of their applications when selecting neoprene foam tape to ensure optimal performance.

What advantages does Acrylic Foam Tape offer for mounting applications?

Acrylic foam tape is known for its high bonding strength and is often available in double-sided variants, making it ideal for signage and mounting applications. Its superior adhesion can provide a long-lasting bond, but it may require careful surface preparation to maximize effectiveness. Buyers should assess the surface materials and environmental conditions where the tape will be used to ensure compatibility and performance.

Key Industrial Applications of single sided foam tape

| Industry/Sector | Specific Application of single sided foam tape | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sealing and insulating components in vehicles | Enhances durability and reduces noise in vehicles | Ensure high-temperature resistance and adhesion strength |

| Electronics | Mounting electronic components and insulation | Provides reliable insulation and protects sensitive parts | Look for conductive or non-conductive options as needed |

| Construction and Building | Glazing applications for windows and doors | Improves energy efficiency and reduces air leaks | Consider UV resistance and compatibility with various substrates |

| HVAC Systems | Insulating ductwork and sealing joints | Increases energy efficiency and reduces operational costs | Evaluate thickness and adhesive quality for specific environments |

| Signage and Displays | Attaching signage to surfaces without damage | Enables clean removal and repositioning of displays | Ensure tape is compatible with various surface materials |

How is Single Sided Foam Tape Used in the Automotive Industry?

In the automotive sector, single sided foam tape is essential for sealing and insulating various components, such as windows, doors, and trunk lids. This tape helps to minimize noise, vibrations, and water ingress, enhancing the overall durability and comfort of vehicles. For international buyers, especially from regions like Africa and the Middle East, it is crucial to source tapes that can withstand extreme temperatures and environmental conditions, ensuring long-term performance and reliability.

What Role Does Single Sided Foam Tape Play in Electronics?

Single sided foam tape is widely used in the electronics industry for mounting components and providing insulation. It effectively cushions sensitive electronic parts, protecting them from shock and vibration while also preventing dust and moisture ingress. B2B buyers in South America and Europe should prioritize sourcing tapes with specific conductive or non-conductive properties to suit their applications, as well as ensuring compatibility with diverse manufacturing processes.

How is Single Sided Foam Tape Applied in Construction and Building?

In construction, single sided foam tape is commonly utilized for glazing applications, sealing windows and doors to enhance energy efficiency. This tape reduces air leaks, contributing to better insulation and lower energy costs for buildings. Buyers from regions like Europe and Africa should focus on sourcing UV-resistant tapes to ensure longevity and performance in outdoor applications, as well as compatibility with various building materials.

Why is Single Sided Foam Tape Important for HVAC Systems?

Single sided foam tape plays a critical role in HVAC systems by insulating ductwork and sealing joints. This application not only improves energy efficiency but also reduces operational costs associated with heating and cooling systems. When sourcing for HVAC applications, international buyers should consider the tape’s thickness and adhesive quality to ensure optimal performance in varying environmental conditions.

How is Single Sided Foam Tape Beneficial for Signage and Displays?

In the signage and displays sector, single sided foam tape allows for the secure attachment of signs to various surfaces without causing damage. This tape enables easy removal and repositioning, making it an ideal choice for temporary or promotional displays. B2B buyers should ensure that the tape is compatible with different surface materials and adheres well in diverse environmental conditions, particularly in regions with varying climates like Brazil and Vietnam.

3 Common User Pain Points for ‘single sided foam tape’ & Their Solutions

Scenario 1: Sourcing the Right Adhesive for Specific Applications

The Problem: B2B buyers often struggle with selecting the appropriate adhesive for their specific applications when using single sided foam tape. Different projects may require varying levels of adhesion strength, temperature resistance, and environmental considerations. For instance, a manufacturer in the automotive industry may need a tape that can withstand high temperatures and vibrations, while a construction firm might require a tape that adheres well to wet surfaces. Failing to choose the right adhesive can lead to product failures, costly reworks, and customer dissatisfaction.

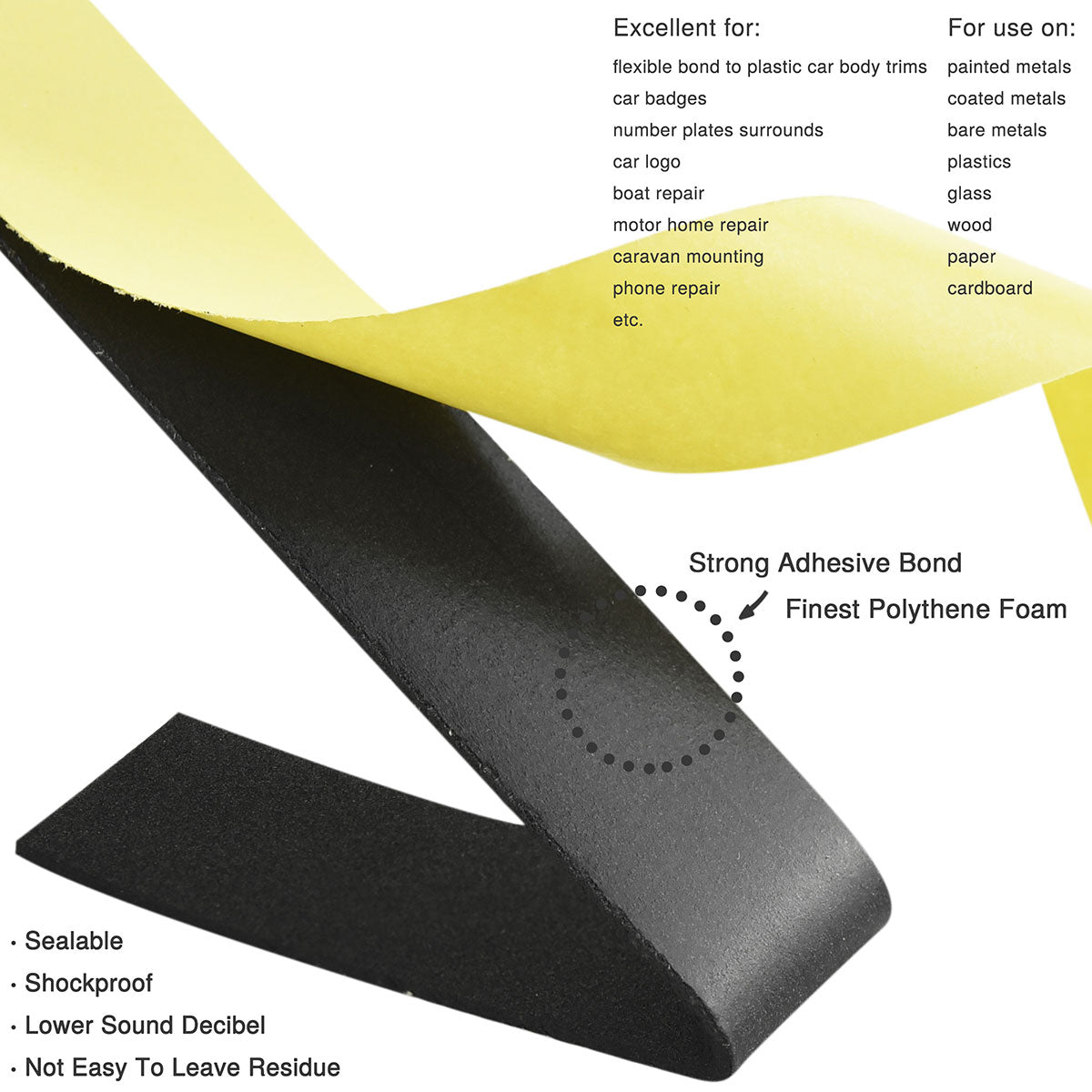

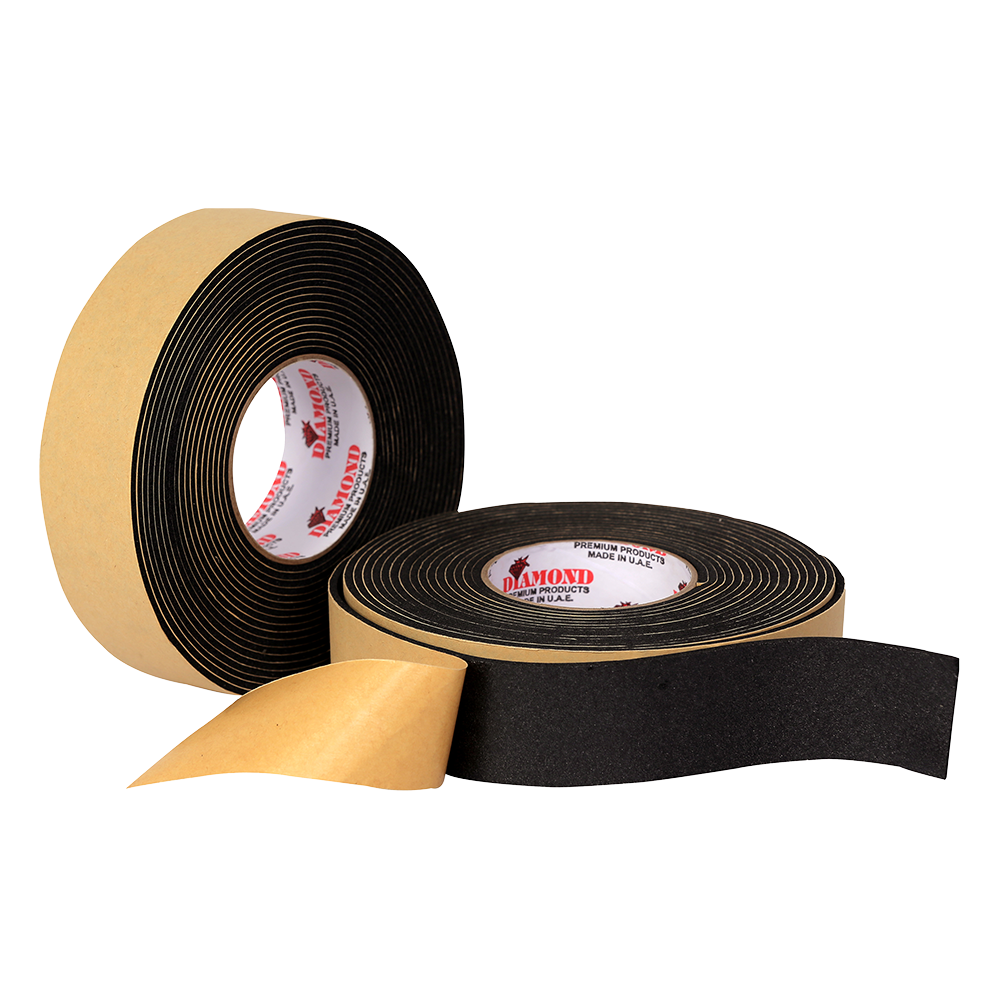

Illustrative image related to single sided foam tape

The Solution: To effectively source the right single sided foam tape, buyers should begin by conducting a thorough needs assessment for their specific applications. Create a checklist that includes the required adhesion strength, temperature range, and environmental conditions. Engage with suppliers who can provide technical data sheets that detail the performance characteristics of different foam tapes. Additionally, consider ordering samples to test under actual conditions before committing to a bulk purchase. This hands-on evaluation can help ensure that the selected tape meets the operational requirements and minimizes the risk of product failures.

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem: International B2B buyers frequently face challenges related to inventory management and supply chain disruptions, especially in regions like Africa and South America, where logistical issues can be prevalent. Fluctuations in demand can lead to overstocking or stockouts of single sided foam tape, causing delays in production or project completions. This not only affects cash flow but can also damage supplier relationships and overall business reputation.

The Solution: To mitigate these challenges, companies should implement a just-in-time (JIT) inventory management system that aligns closely with production schedules. Utilize inventory management software that tracks usage patterns and forecasts demand based on historical data. Establish strong relationships with multiple suppliers to create a diversified sourcing strategy, which can provide alternative options in case of disruptions. Regularly communicate with suppliers about lead times and potential delays, allowing for proactive adjustments in procurement plans. By optimizing inventory levels and maintaining open lines of communication, businesses can better navigate supply chain challenges.

Scenario 3: Ensuring Proper Application Techniques

The Problem: Incorrect application of single sided foam tape can lead to inadequate bonding, resulting in product failures or diminished performance. B2B buyers may encounter issues such as bubbles or uneven adhesion when applying the tape, particularly in high-stress environments. This not only leads to wasted materials but can also result in costly repairs and operational downtime.

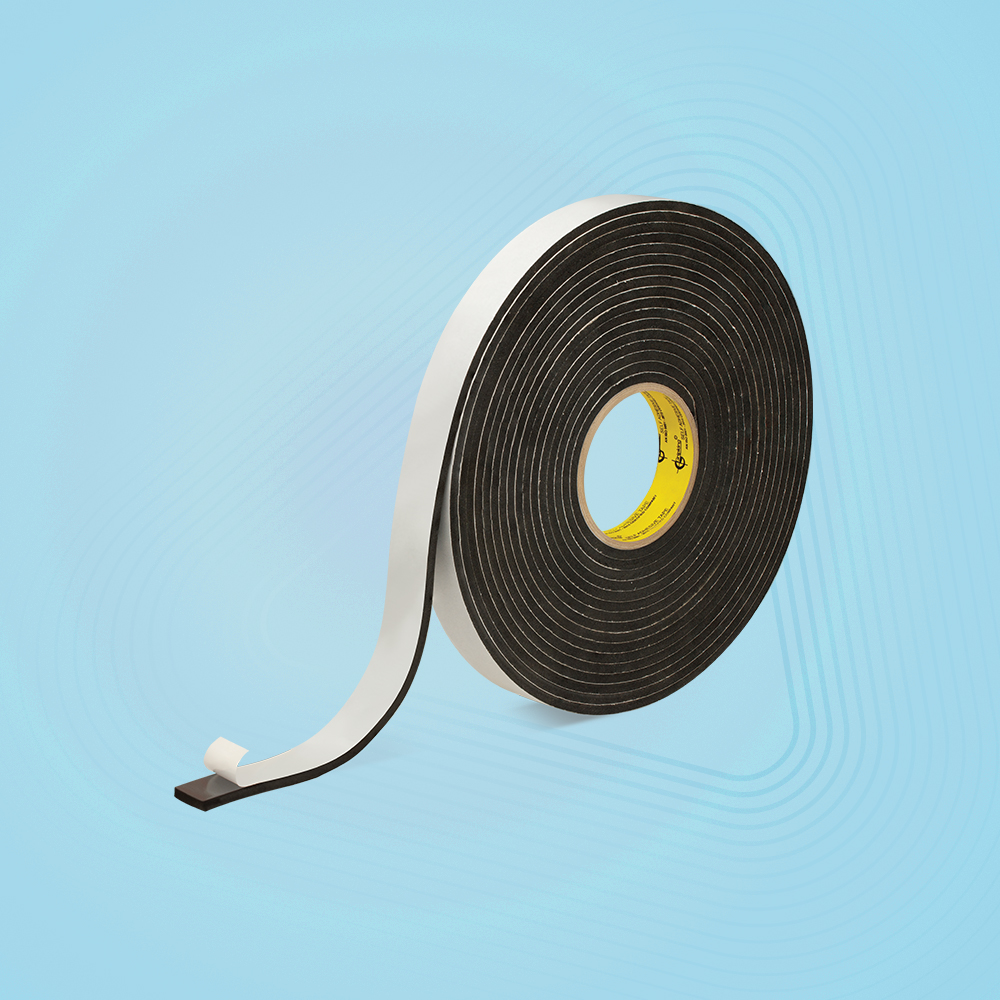

Illustrative image related to single sided foam tape

The Solution: To ensure proper application, it is crucial to educate staff on best practices for using single sided foam tape. Provide training sessions that cover surface preparation, application techniques, and environmental considerations. Emphasize the importance of cleaning surfaces thoroughly to remove dust, grease, and moisture before application. Additionally, advise using consistent pressure during application to achieve optimal adhesion. For projects requiring precise application, consider investing in applicator tools designed to apply uniform pressure and reduce the risk of air bubbles. By enhancing application techniques, businesses can improve the performance and longevity of their foam tape solutions, ultimately leading to better project outcomes.

Strategic Material Selection Guide for single sided foam tape

What Are the Common Materials Used in Single Sided Foam Tape?

Single sided foam tape is available in various materials, each with distinct properties and applications. Understanding these materials is crucial for B2B buyers looking to make informed purchasing decisions. Here, we analyze four common materials used in single sided foam tape: PVC, polyethylene (PE), polyurethane (PU), and acrylic foam.

How Does PVC Foam Tape Perform in Various Applications?

PVC foam tape is known for its excellent cushioning properties and resistance to moisture. It typically operates effectively within a temperature range of -30°C to 70°C. This material offers good adhesion to a variety of surfaces, making it suitable for indoor applications like sealing and insulation.

Illustrative image related to single sided foam tape

Pros: PVC foam tape is durable and cost-effective, making it a popular choice for many applications. Its manufacturing process is relatively straightforward, which keeps production costs low.

Cons: However, PVC foam can be less resistant to UV light and extreme temperatures, which may limit its outdoor applications. Additionally, it may not be suitable for use with certain chemicals, leading to degradation over time.

Impact on Application: Buyers should consider PVC foam tape for applications requiring moisture resistance but should be cautious about using it in environments exposed to direct sunlight or harsh chemicals.

Illustrative image related to single sided foam tape

What Advantages Does Polyethylene Foam Tape Offer?

Polyethylene (PE) foam tape is lightweight and flexible, making it ideal for applications requiring a strong yet adaptable adhesive. It can withstand temperatures from -40°C to 80°C, providing versatility in various environments. PE foam is also resistant to chemicals and moisture.

Pros: The flexibility of PE foam allows it to conform to irregular surfaces, enhancing its sealing capabilities. Its chemical resistance makes it suitable for industrial applications.

Cons: While PE foam tape is durable, it may not provide the same level of cushioning as other materials. Additionally, its adhesive strength may vary depending on the surface it is applied to.

Impact on Application: PE foam tape is a great choice for applications in industries such as automotive and electronics, where adaptability and moisture resistance are crucial.

How Does Polyurethane Foam Tape Compare?

Polyurethane (PU) foam tape is recognized for its high resilience and excellent thermal insulation properties. It can operate effectively in a temperature range of -40°C to 100°C, making it suitable for demanding environments.

Illustrative image related to single sided foam tape

Pros: PU foam tape offers superior durability and is resistant to UV light, making it suitable for outdoor applications. Its excellent bonding capabilities ensure a strong hold on various surfaces.

Cons: The primary drawback of PU foam tape is its higher cost compared to other materials, which may deter budget-conscious buyers. Additionally, the manufacturing process can be more complex, potentially leading to longer lead times.

Impact on Application: PU foam tape is ideal for applications in construction and automotive industries, where high-performance insulation and durability are essential.

What Are the Benefits of Acrylic Foam Tape?

Acrylic foam tape is known for its exceptional bonding strength and versatility. It can withstand extreme temperatures, ranging from -40°C to 120°C, and is resistant to moisture, UV light, and chemicals.

Pros: The strong adhesive properties of acrylic foam tape make it suitable for high-stress applications, including automotive and construction. Its durability ensures long-lasting performance.

Illustrative image related to single sided foam tape

Cons: However, acrylic foam tape can be more expensive than other options, which may not align with all budget constraints. Additionally, it requires careful surface preparation for optimal adhesion.

Impact on Application: B2B buyers in sectors requiring robust bonding solutions, such as construction and manufacturing, will find acrylic foam tape to be an excellent choice.

Summary Table of Material Properties

| Material | Typical Use Case for single sided foam tape | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor sealing and insulation | Cost-effective and durable | Limited UV resistance | Low |

| Polyethylene | Automotive and electronics applications | Flexible and moisture-resistant | Lower cushioning capability | Medium |

| Polyurethane | High-performance insulation in construction | Excellent durability and insulation | Higher cost and complex manufacturing | High |

| Acrylic | Automotive and construction bonding | Exceptional bonding strength | Requires careful surface prep | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various single sided foam tape materials, helping them make informed decisions that align with their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for single sided foam tape

What Are the Key Stages in the Manufacturing Process of Single-Sided Foam Tape?

The manufacturing of single-sided foam tape involves several critical stages that ensure the final product meets the necessary specifications for quality and performance. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials used in single-sided foam tape include polyethylene (PE), polyurethane (PU), and PVC. Each material is chosen based on its adhesive properties, density, and intended application.

Illustrative image related to single sided foam tape

Once selected, the materials undergo a cleaning and drying process to remove any contaminants that could affect adhesion. This step is crucial, as impurities can lead to product failure in the field.

2. Forming

Following material preparation, the foam is formed into sheets or rolls. This is typically achieved through methods like extrusion or compression molding.

-

Extrusion: In this method, raw foam material is heated and forced through a die to create a continuous sheet. This process allows for uniform thickness and density, which is essential for consistent adhesive performance.

-

Compression Molding: This technique involves placing pre-measured foam material into a mold and applying heat and pressure to shape it. This method is often used for custom shapes or specific thickness requirements.

3. Assembly

After forming, the foam sheets or rolls are coated with a suitable adhesive. The adhesive can vary based on the intended application and the required bond strength.

- Coating Techniques: Common techniques include roll coating and spray coating. Roll coating is often preferred for uniform adhesive distribution, while spray coating may be used for specialized applications.

Once coated, the adhesive is cured, allowing it to bond securely to the foam. This step is vital, as improper curing can lead to weak adhesion.

4. Finishing

The final stage involves cutting the foam tape to specified dimensions and packaging it for distribution. Quality checks are performed throughout the process to ensure that the product meets industry standards.

Illustrative image related to single sided foam tape

How Is Quality Assurance Implemented in Single-Sided Foam Tape Production?

Quality assurance (QA) in the manufacturing of single-sided foam tape is critical to ensuring that the product meets international standards and customer expectations.

1. What International Standards Apply to Single-Sided Foam Tape?

Manufacturers often comply with internationally recognized standards such as ISO 9001, which outlines criteria for a quality management system. Achieving ISO certification demonstrates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for applications in the oil and gas sector may also apply. These certifications ensure that the tape meets specific performance and safety requirements.

2. What Are the Key Quality Control Checkpoints?

Quality control is integrated into various stages of the manufacturing process, with specific checkpoints established to monitor quality at critical phases:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards in real-time. This can include testing adhesive viscosity, foam density, and dimensions.

-

Final Quality Control (FQC): Before packaging, the finished product undergoes thorough testing, which may include peel strength tests, shear tests, and environmental resistance tests to evaluate performance under different conditions.

What Common Testing Methods Are Used for Quality Assurance?

To ensure that single-sided foam tape meets quality and performance standards, several testing methods are commonly employed:

-

Peel Strength Testing: Measures the adhesive’s ability to hold under stress. This test is essential for applications requiring strong, durable bonds.

-

Shear Strength Testing: Assesses the adhesive’s resistance to sliding forces, ensuring that the tape remains securely in place under pressure.

-

Environmental Testing: Evaluates the tape’s performance under various environmental conditions, such as heat, moisture, and UV exposure. This testing is crucial for products intended for outdoor use or in extreme conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

1. Conducting Supplier Audits

One effective way to verify quality control practices is through supplier audits. These audits can be scheduled or surprise visits, allowing buyers to assess the manufacturing environment, quality control measures, and compliance with international standards firsthand.

2. Reviewing Quality Assurance Reports

Requesting detailed quality assurance reports can provide insights into the supplier’s QA processes. These reports should outline testing methodologies, results, and any corrective actions taken in response to quality issues.

3. Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing process, conduct tests, and verify compliance with international standards, providing an unbiased assessment of the supplier’s quality control.

Illustrative image related to single sided foam tape

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

B2B buyers from different regions may face unique challenges when it comes to quality control. Understanding these nuances is vital for successful procurement:

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should ensure that suppliers are compliant with local laws and international standards relevant to their market.

-

Cultural Differences: Attitudes towards quality and manufacturing processes can differ by region. Establishing clear communication and expectations with suppliers is essential to mitigate misunderstandings.

-

Supply Chain Dynamics: Buyers should be aware of the entire supply chain, as disruptions can affect product quality. Ensuring that all suppliers and subcontractors adhere to the same quality standards is crucial.

In summary, understanding the manufacturing processes and quality assurance practices for single-sided foam tape is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘single sided foam tape’

In the world of B2B procurement, sourcing single-sided foam tape requires a structured approach to ensure quality, compatibility, and cost-effectiveness. This checklist is designed to guide international buyers through the essential steps to effectively source single-sided foam tape tailored to their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to outline the technical requirements for your foam tape. This includes thickness, width, density, and adhesive type. Properly defining these specifications helps in identifying products that meet your application needs, ensuring you don’t waste time on unsuitable options.

- Consider application requirements: Different applications, such as insulation, cushioning, or soundproofing, may require varying properties.

- Identify environmental factors: Consider exposure to temperature extremes, moisture, or chemicals, which could affect performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in single-sided foam tape. Look for companies with a proven track record and strong market presence.

- Use industry directories and trade shows: These platforms can provide insights into reputable suppliers.

- Check online reviews and testimonials: Feedback from other businesses can give you an idea of product reliability and customer service.

Step 3: Evaluate Product Quality

Request samples of the foam tape you are considering. Evaluating the product firsthand allows you to assess the quality and suitability for your specific applications.

- Test adhesive strength: Ensure it meets your requirements for durability and adhesion.

- Check for certifications: Look for compliance with international standards, such as ISO or ASTM, which can assure quality.

Step 4: Verify Supplier Certifications

It is essential to confirm that your selected suppliers hold relevant certifications that reflect their commitment to quality and safety standards.

- Request documentation: Ask for copies of ISO certifications or safety data sheets.

- Confirm manufacturing processes: Ensure they adhere to industry best practices in production.

Step 5: Assess Pricing and Payment Terms

Once you have shortlisted suppliers, compare pricing structures while considering the total cost of ownership. This includes shipping, duties, and potential tariffs.

- Negotiate payment terms: Discuss credit terms and bulk purchase discounts, which can significantly affect your cash flow.

- Consider long-term partnerships: Establishing a relationship with a supplier can lead to better pricing and service in the future.

Step 6: Understand Shipping and Delivery Options

Shipping logistics can significantly impact your procurement process, especially for international buyers.

Illustrative image related to single sided foam tape

- Evaluate lead times: Ensure the supplier can meet your timelines without compromising quality.

- Explore shipping methods: Consider the costs and reliability of different shipping options, including air freight versus sea freight.

Step 7: Establish a Communication Plan

Effective communication is key to a successful procurement process. Establish a plan for regular updates and feedback during the sourcing process.

- Designate points of contact: Ensure that there are clear lines of communication between your team and the supplier.

- Set expectations for responses: Agree on timelines for inquiries and updates to avoid misunderstandings.

Following these steps will help you streamline the sourcing process for single-sided foam tape, ensuring that you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for single sided foam tape Sourcing

When sourcing single-sided foam tape, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers to make informed decisions. This analysis will break down the key cost components, price influencers, and provide actionable buyer tips, particularly relevant for international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Single-Sided Foam Tape?

-

Materials: The primary cost driver for single-sided foam tape is the raw materials used in production, which typically include polyethylene (PE), polyurethane (PU), or PVC foam. The choice of material significantly impacts pricing due to variations in quality, density, and adhesive properties. Higher quality materials often lead to better performance and durability but at a higher cost.

-

Labor: Labor costs encompass the workforce involved in manufacturing the tape. This includes direct labor for production as well as indirect labor for administrative and support roles. Regions with lower labor costs can offer more competitive pricing, which is particularly relevant for buyers sourcing from emerging markets.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, equipment depreciation, and management salaries. Efficient production processes can help mitigate overhead costs, thereby reducing the overall price of the tape.

-

Tooling: Tooling costs are associated with the creation and maintenance of molds and machinery used in the manufacturing process. Custom tooling for specialized tape specifications can add to the initial costs but may be necessary for specific applications.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product reliability and compliance with industry standards. While this can increase costs, it ultimately protects the buyer from potential losses due to defective products.

-

Logistics: Transportation and shipping costs can vary significantly based on distance, mode of transport, and Incoterms. For international buyers, understanding these logistics costs is critical for accurate pricing assessments.

-

Margin: Suppliers will add a profit margin to cover their operational costs and desired profit. This margin can vary based on market demand, competition, and the supplier’s positioning.

What Influences Pricing for Single-Sided Foam Tape?

-

Volume and Minimum Order Quantity (MOQ): Pricing often becomes more favorable with larger order volumes. Suppliers may offer discounts for bulk purchases, making it crucial for buyers to assess their needs accurately.

-

Specifications and Customization: Customized tapes tailored to specific applications or industry standards may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Tapes with higher specifications or certifications (e.g., ISO, ASTM) typically command higher prices. Buyers should weigh the importance of these certifications against their budget constraints.

-

Supplier Factors: Established suppliers with a strong reputation may charge premium prices due to perceived reliability and quality assurance. Conversely, newer or less recognized suppliers may offer lower prices to attract business.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential, as they dictate who bears the cost and risk during transport. This can significantly affect the total landed cost of the product.

What Tips Should Buyers Consider for Cost-Efficiency?

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the tape, including installation, maintenance, and potential replacement. Higher upfront costs may be justified by lower lifecycle costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that may affect pricing when sourcing from different countries. It’s advisable to work with suppliers who have experience in international transactions.

-

Market Research: Conduct thorough market research to identify competitive pricing and supplier options. Understanding the landscape can empower buyers to make more strategic sourcing decisions.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic buying tips will enable international B2B buyers to optimize their sourcing of single-sided foam tape. This approach not only aids in achieving cost efficiencies but also ensures that the chosen product meets their quality and performance requirements.

Alternatives Analysis: Comparing single sided foam tape With Other Solutions

When selecting the right adhesive solution for various applications, understanding the alternatives to single sided foam tape is crucial. This section provides a comparative analysis of single sided foam tape against other viable solutions, helping international B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Single Sided Foam Tape | Double Sided Foam Tape | Adhesive Sealants |

|---|---|---|---|

| Performance | Good for cushioning and sealing | Excellent for mounting and bonding | Superior for permanent sealing |

| Cost | Moderate | Higher than single sided | Variable, often higher |

| Ease of Implementation | Easy to apply | Requires careful alignment | Requires mixing/application |

| Maintenance | Low maintenance | Low maintenance | Can require reapplication |

| Best Use Case | Weather stripping, cushioning | Mounting signs, panels | Sealing gaps in structures |

What Are the Advantages and Disadvantages of Double Sided Foam Tape Compared to Single Sided Foam Tape?

Double sided foam tape is a robust alternative that excels in mounting applications. Its adhesive properties allow for bonding two surfaces together seamlessly, making it ideal for applications where aesthetics are important. However, it can be more expensive and requires precise alignment during installation, which may pose challenges in high-volume production environments.

How Do Adhesive Sealants Compare in Performance and Cost to Single Sided Foam Tape?

Adhesive sealants, such as silicone or polyurethane, provide a strong, permanent bond and are often used in applications requiring waterproofing or sealing against environmental elements. They are typically more expensive and involve a more complex application process, including mixing components or ensuring proper curing times. While they offer excellent durability, they may not be suitable for applications where temporary adhesion is preferred.

How to Choose the Right Adhesive Solution for Your Needs?

For B2B buyers, the choice between single sided foam tape and its alternatives hinges on specific application requirements. If the project involves temporary or less demanding bonding, single sided foam tape is an efficient and cost-effective choice. For tasks requiring stronger bonding capabilities or permanent solutions, double sided foam tape or adhesive sealants may be more appropriate. Consider factors like the intended use, environmental conditions, and budget constraints to select the most suitable adhesive solution.

Essential Technical Properties and Trade Terminology for single sided foam tape

Single-sided foam tape is a versatile adhesive solution used in various industries, including construction, automotive, and electronics. Understanding its technical properties and trade terminology is essential for international B2B buyers seeking reliable and effective tape solutions.

What Are the Key Technical Properties of Single-Sided Foam Tape?

1. Material Grade

Single-sided foam tape is available in various materials, including polyethylene (PE), polyurethane (PU), and PVC. The choice of material affects the tape’s durability, adhesion strength, and resistance to environmental factors like moisture and temperature. For instance, PVC foam is often preferred for its excellent weather resistance, making it suitable for outdoor applications.

2. Thickness

The thickness of foam tape typically ranges from 1/16 inch to 1 inch. Thicker tapes provide greater cushioning and insulation properties, which are essential in applications requiring impact resistance or noise reduction. Understanding the appropriate thickness for specific applications is crucial for ensuring optimal performance and longevity.

3. Adhesive Type

The adhesive used in single-sided foam tape can be acrylic, rubber, or silicone-based, each offering distinct bonding characteristics. Acrylic adhesives, for example, provide strong adhesion and UV resistance, making them ideal for long-term outdoor use. Selecting the right adhesive type is vital for achieving the desired bonding strength and application suitability.

Illustrative image related to single sided foam tape

4. Density

Foam density impacts the tape’s compressibility and durability. High-density foam tapes are often used in heavy-duty applications where resistance to deformation is critical. In contrast, lower-density options may be suitable for lighter applications. Assessing the required density helps buyers match the tape to their specific operational needs.

5. Temperature Resistance

Single-sided foam tapes can withstand varying temperature ranges, typically from -40°F to 200°F (-40°C to 93°C). This property is essential for applications exposed to extreme conditions, such as automotive and industrial environments. Ensuring that the tape can handle the specific temperature requirements of an application is crucial for maintaining its integrity.

What Are Common Trade Terms Related to Single-Sided Foam Tape?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of foam tape, OEMs often require specific tape solutions tailored to their products, emphasizing the need for customized specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can impact purchasing decisions and inventory management. Buyers should negotiate MOQs that align with their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific product or service. In the foam tape industry, submitting an RFQ allows buyers to obtain competitive pricing and understand the supplier’s capabilities. It is an essential step in the procurement process.

Illustrative image related to single sided foam tape

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risk transfers, and delivery obligations associated with their purchases.

5. Adhesion Testing

Adhesion testing measures the tape’s ability to stick to various surfaces. This testing is critical for ensuring that the selected foam tape will perform effectively in its intended application. Buyers should inquire about adhesion testing results to verify product reliability.

Understanding these technical properties and trade terms not only aids in selecting the right single-sided foam tape but also enhances communication with suppliers, ensuring a smoother procurement process and better alignment with business needs.

Illustrative image related to single sided foam tape

Navigating Market Dynamics and Sourcing Trends in the single sided foam tape Sector

What Are the Key Market Dynamics and Trends Affecting Single Sided Foam Tape?

The global market for single sided foam tape is experiencing significant growth, driven by increased demand across various industries, including automotive, electronics, and construction. In regions such as Africa, South America, the Middle East, and Europe, there is a notable surge in infrastructure development and manufacturing activities. This trend is further fueled by the push for lightweight and efficient materials in product design. Notably, the adoption of advanced adhesive technologies is reshaping the competitive landscape, with companies investing in research and development to enhance product performance and versatility.

Emerging B2B tech trends, such as automation in manufacturing processes and digital procurement platforms, are streamlining the sourcing of single sided foam tape. These technologies enable buyers to gain real-time insights into inventory levels, pricing, and supplier reliability, facilitating informed purchasing decisions. Furthermore, the rise of e-commerce in industrial supplies is making it easier for international buyers to access a diverse range of products, fostering competition and driving down prices.

How Can Sustainability and Ethical Sourcing Impact Your Sourcing Decisions for Single Sided Foam Tape?

Sustainability is becoming a critical consideration for B2B buyers in the single sided foam tape sector. The environmental impact of materials used in production, such as PVC and polyurethane, is drawing scrutiny from consumers and regulators alike. As a result, companies are increasingly seeking suppliers who prioritize eco-friendly practices. This includes using recycled materials, minimizing waste during production, and adhering to stringent environmental regulations.

Ethical sourcing is also gaining traction, with buyers looking for suppliers who demonstrate transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and Green Seal can help buyers identify manufacturers committed to sustainable practices. By prioritizing suppliers with these credentials, businesses can enhance their corporate social responsibility profiles while also meeting consumer demands for greener products.

What Is the Historical Context of Single Sided Foam Tape Development?

The evolution of single sided foam tape dates back to the early 20th century when it was initially used for simple sealing applications. Over the decades, advancements in adhesive technology and material science have transformed its applications. The introduction of high-performance foam materials has enabled the tape to be utilized in demanding environments, such as automotive and aerospace, where durability and strength are paramount.

As industries evolve, so too does the technology behind single sided foam tape. The transition from traditional rubber-based adhesives to modern acrylic formulations has improved adhesion properties and temperature resistance, making it suitable for a wider range of applications. This historical context highlights the adaptability of single sided foam tape in meeting the changing needs of various sectors, further solidifying its position as a staple in industrial applications.

Conclusion

As the single sided foam tape market continues to grow, international B2B buyers must remain vigilant in monitoring market dynamics and sourcing trends. Emphasizing sustainability and ethical sourcing will not only align with global initiatives but also enhance brand reputation and customer loyalty. Understanding the historical evolution of these products can provide valuable insights into future innovations and applications, ensuring that businesses remain competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of single sided foam tape

-

How do I select the right single sided foam tape for my application?

Choosing the right single sided foam tape involves understanding the specific requirements of your project. Consider factors such as the material compatibility (e.g., metal, plastic, glass), the intended use (indoor vs. outdoor), and environmental conditions (temperature, humidity). Additionally, evaluate the thickness, adhesive strength, and density of the foam. Engaging with suppliers who can provide samples or technical support can also help you make an informed decision. -

What is the best single sided foam tape for mounting applications?

For mounting applications, a high-density foam tape with a strong adhesive backing is ideal. Look for tapes specifically designed for mounting purposes, such as those with acrylic adhesives that offer high bond strength and durability. Ensure the tape can withstand the weight of the objects being mounted and is suitable for the surface materials. Testing different options on small samples can also help determine the best fit for your needs. -

How can I ensure the quality of single sided foam tape from suppliers?

To ensure quality, verify that suppliers adhere to industry standards and certifications. Request product specifications, material safety data sheets (MSDS), and samples for testing. It’s advisable to look for suppliers with a solid reputation and positive customer reviews. Additionally, visiting the supplier’s facility or conducting audits can provide insights into their manufacturing processes and quality control measures. -

What are the common minimum order quantities (MOQs) for single sided foam tape?

Minimum order quantities can vary widely among suppliers, typically ranging from a few hundred meters to several thousand. Some manufacturers may offer lower MOQs for certain product lines or allow for mixed orders of different types or sizes of tape. It’s beneficial to communicate your specific needs and negotiate MOQs to ensure they align with your purchasing capacity. -

What payment terms should I expect when sourcing single sided foam tape internationally?

Payment terms can differ based on the supplier and the nature of your agreement. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. For international transactions, options like Letters of Credit (LC) or escrow services may be advisable to mitigate risks. Always clarify payment methods, currencies accepted, and any potential fees associated with international transactions before proceeding. -

What should I consider regarding logistics and shipping for international orders?

When ordering single sided foam tape internationally, consider shipping costs, delivery times, and customs regulations in your country. Work with suppliers that offer reliable logistics options and have experience with international shipping. It’s also important to understand the Incoterms used in your contract, as they define responsibilities regarding shipping, insurance, and tariffs. -

Can I customize single sided foam tape for specific applications?

Many suppliers offer customization options, including varying dimensions, thicknesses, adhesive types, and even colors. If your application requires unique specifications, discuss your needs with potential suppliers early in the procurement process. Customization may involve additional costs and lead times, so it’s essential to plan accordingly. -

What certifications should I look for in single sided foam tape products?

Look for certifications relevant to your industry and region, such as ISO 9001 for quality management, RoHS for hazardous substances, or ASTM standards for specific material properties. These certifications help ensure that the products meet safety and performance requirements. Additionally, inquire about any environmental certifications if sustainability is a priority for your business.

Top 3 Single Sided Foam Tape Manufacturers & Suppliers List

1. Tape Providers – Foam Weather Stripping Tapes

Domain: tapeproviders.com

Registered: 2017 (8 years)

Introduction: Foam Weather Stripping Tapes – Single-Sided & Double-Sided

2. CR Laurence – Black Foam Glazing Tape

Domain: crlaurence.com

Registered: 1995 (30 years)

Introduction: CRL Black 1/8″ x 1/2″ Single Sided Foam Glazing Tape

3. 3M – General Purpose Foam Tapes

Domain: 3m.com

Registered: 1988 (37 years)

Introduction: 3M General Purpose Foam Tapes include 63 products with various options. Key details include:

– Industries: Manufacturing (42), Design & Construction (32), Transportation (32), Commercial Solutions (24), Automotive (21), Consumer (19), Communications (3), Electronics (3), Energy (3), Safety (3).

– Brands: Scotch (12).

– Number of Adhesive Sides: Double-sided (36), Single-sided (12).

– Backing M…

Strategic Sourcing Conclusion and Outlook for single sided foam tape

In navigating the complexities of sourcing single-sided foam tape, international buyers must prioritize quality, versatility, and reliability. The diverse applications of single-sided foam tape—ranging from insulation to cushioning—highlight its critical role in various industries, including construction, automotive, and electronics. By strategically sourcing these materials, businesses can enhance their operational efficiency and product durability.

Understanding the nuances of adhesive properties and material specifications is essential for selecting the right tape for specific applications. Buyers should engage with reputable suppliers who offer comprehensive product lines and can provide technical support and guidance. This not only ensures the right fit for your needs but also fosters long-term partnerships that can lead to cost savings and innovation.

Looking ahead, the demand for high-quality single-sided foam tape is expected to grow, driven by advancements in manufacturing processes and increasing applications across sectors. Buyers in Africa, South America, the Middle East, and Europe should seize the opportunity to leverage this growth by aligning their sourcing strategies with emerging market trends. Engaging with trusted suppliers and staying informed about industry innovations will be key to maintaining a competitive edge. Embrace the future of sourcing—maximize your potential with single-sided foam tape today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to single sided foam tape

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.