Top 3 Phone Cooling Pad Suppliers (And How to Choose)

Introduction: Navigating the Global Market for phone cooling pad

In today’s fast-paced digital landscape, sourcing an effective phone cooling pad has become crucial for businesses aiming to enhance device performance and user satisfaction. As mobile technology continues to evolve, the demand for reliable accessories that mitigate overheating issues has surged, particularly in regions such as Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource for international B2B buyers, providing insights into the diverse types of phone cooling pads available, their various applications, and essential factors to consider when vetting suppliers.

Navigating the global market can be challenging, especially when it comes to understanding the nuances of product specifications, pricing structures, and regional demand trends. This guide will empower you with actionable insights, allowing you to make informed purchasing decisions. We will delve into the critical aspects of selecting the right cooling pad for your needs, from evaluating material quality to understanding the implications of shipping and logistics in your region. Additionally, we will explore cost considerations, ensuring you are equipped to negotiate effectively with suppliers.

By leveraging the knowledge and strategies presented in this guide, B2B buyers will not only enhance their procurement processes but also position themselves competitively in their respective markets. Whether you are looking to bulk purchase for retail or enhance your product lineup, this resource is designed to streamline your sourcing efforts and elevate your business potential.

Understanding phone cooling pad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Active Cooling Pads | Utilize fans or liquid cooling systems | Tech manufacturers, gaming centers | Pros: Highly effective cooling; customizable. Cons: Noisy; potential for mechanical failure. |

| Passive Cooling Pads | Made from materials with high thermal conductivity | Retailers, mobile device repair shops | Pros: Silent operation; lightweight. Cons: Less effective in high heat; no adjustable cooling. |

| Gel Cooling Pads | Contain gel that absorbs and dissipates heat | E-commerce, consumer electronics | Pros: Good heat absorption; affordable. Cons: Limited longevity; may require replacement. |

| Smart Cooling Pads | Feature integrated sensors and smart technology | IoT device manufacturers | Pros: Real-time temperature monitoring; energy-efficient. Cons: Higher cost; complex technology integration. |

| Multi-Device Cooling Pads | Designed to cool multiple devices simultaneously | Tech hubs, educational institutions | Pros: Versatile; saves space. Cons: May not cool as effectively as single-device pads; higher initial investment. |

What Are the Characteristics of Active Cooling Pads and Their B2B Suitability?

Active cooling pads are characterized by their use of fans or advanced liquid cooling systems to enhance heat dissipation. These pads are particularly suitable for businesses involved in technology manufacturing or gaming, where devices often experience high operational temperatures. When considering purchasing active cooling pads, B2B buyers should evaluate factors like noise levels, energy consumption, and the potential need for maintenance due to mechanical components.

Why Choose Passive Cooling Pads for Your Business Needs?

Passive cooling pads are constructed from materials that naturally dissipate heat without the use of fans or electricity. This makes them ideal for retailers and mobile device repair shops that prioritize silent operation and lightweight designs. B2B buyers should assess the thermal conductivity of materials used and how well these pads can perform under varying environmental conditions, especially in hotter climates.

How Do Gel Cooling Pads Function and What Are Their Business Applications?

Gel cooling pads utilize a gel material that absorbs heat, providing a cooling effect without mechanical components. They are commonly used in e-commerce and consumer electronics sectors due to their affordability and ease of use. However, B2B buyers must consider the longevity of gel pads, as they may need replacement after extensive use, which can impact long-term cost-effectiveness.

What Advantages Do Smart Cooling Pads Offer to B2B Buyers?

Smart cooling pads integrate sensors and smart technology to monitor device temperatures in real time. These pads are particularly beneficial for IoT device manufacturers who require precise thermal management. When purchasing smart cooling pads, businesses should weigh the benefits of energy efficiency and advanced features against the higher upfront costs and the complexity of integrating such technologies into existing systems.

How Do Multi-Device Cooling Pads Enhance Efficiency for Businesses?

Multi-device cooling pads are designed to manage the heat of several devices simultaneously, making them ideal for tech hubs and educational institutions that utilize multiple gadgets. These pads offer versatility and space-saving solutions. However, B2B buyers should be aware that while they provide a broader cooling solution, they may not perform as efficiently as dedicated single-device cooling systems, necessitating a careful evaluation of specific cooling needs and budget constraints.

Key Industrial Applications of phone cooling pad

| Industry/Sector | Specific Application of Phone Cooling Pad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Used in mobile network operations to maintain device performance | Enhances network reliability and reduces downtime | Consider compatibility with various device models and heat dissipation efficiency. |

| Gaming | Employed in gaming lounges and eSports events to cool devices | Improves gaming performance and user experience | Look for portability and ease of use in high-traffic environments. |

| Field Services | Utilized by technicians in remote locations for device cooling | Ensures operational efficiency in harsh conditions | Assess durability and battery life for extended use in the field. |

| Automotive | Integrated in vehicle infotainment systems to prevent overheating | Enhances user satisfaction and system longevity | Evaluate compatibility with existing vehicle systems and environmental resilience. |

| Manufacturing | Applied in production lines where mobile devices are used | Reduces device failure rates and maintenance costs | Focus on bulk purchasing options and reliability under industrial conditions. |

How is a Phone Cooling Pad Used in Telecommunications?

In the telecommunications sector, phone cooling pads are essential for maintaining optimal device performance during network operations. High-demand environments, such as data centers and mobile network stations, generate significant heat, which can lead to device failures. By integrating cooling pads, companies can enhance network reliability and minimize downtime, ensuring uninterrupted service. When sourcing, it’s crucial to consider the compatibility of cooling pads with various device models and their efficiency in heat dissipation.

What Role Do Phone Cooling Pads Play in Gaming?

In gaming lounges and eSports events, phone cooling pads are vital for maintaining device performance during intense gaming sessions. High-performance gaming generates considerable heat, which can throttle performance and degrade user experience. Cooling pads help maintain optimal temperatures, allowing for smoother gameplay and longer device lifespan. Buyers should prioritize portability and ease of use, as these environments often require quick setup and teardown.

How Do Field Services Benefit from Phone Cooling Pads?

Field service technicians frequently operate in remote and harsh environments where mobile devices are crucial for communication and data access. Phone cooling pads are used to prevent overheating, which can lead to device failure and operational inefficiencies. By ensuring that devices remain functional in extreme conditions, businesses can maintain high productivity levels. When sourcing cooling pads for field services, durability and battery life are key considerations, as they must withstand rugged use.

Why Are Phone Cooling Pads Important in the Automotive Sector?

In the automotive industry, phone cooling pads are increasingly integrated into vehicle infotainment systems to prevent overheating. As vehicles become more technologically advanced, the demand for reliable, cool-running devices is paramount. Cooling pads enhance user satisfaction by ensuring that infotainment systems operate smoothly without interruption. Buyers should evaluate the compatibility of cooling pads with existing vehicle systems and their ability to withstand various environmental conditions.

How Do Manufacturing Companies Utilize Phone Cooling Pads?

Manufacturing environments often rely on mobile devices for real-time data collection and communication. Phone cooling pads are applied in production lines to minimize the risk of device overheating, which can lead to failures and increased maintenance costs. By using cooling pads, companies can enhance device reliability and efficiency. When sourcing for manufacturing applications, it’s beneficial to focus on bulk purchasing options and the reliability of cooling pads under industrial conditions.

3 Common User Pain Points for ‘phone cooling pad’ & Their Solutions

Scenario 1: Overheating Issues During High Usage

The Problem: B2B buyers in regions with high ambient temperatures, such as Africa and the Middle East, often encounter issues with smartphones overheating during prolonged use. This is particularly problematic for businesses relying on mobile devices for tasks like customer service, logistics, or field operations. Overheating can lead to device malfunctions, reduced performance, and ultimately, operational downtime, resulting in lost productivity and revenue.

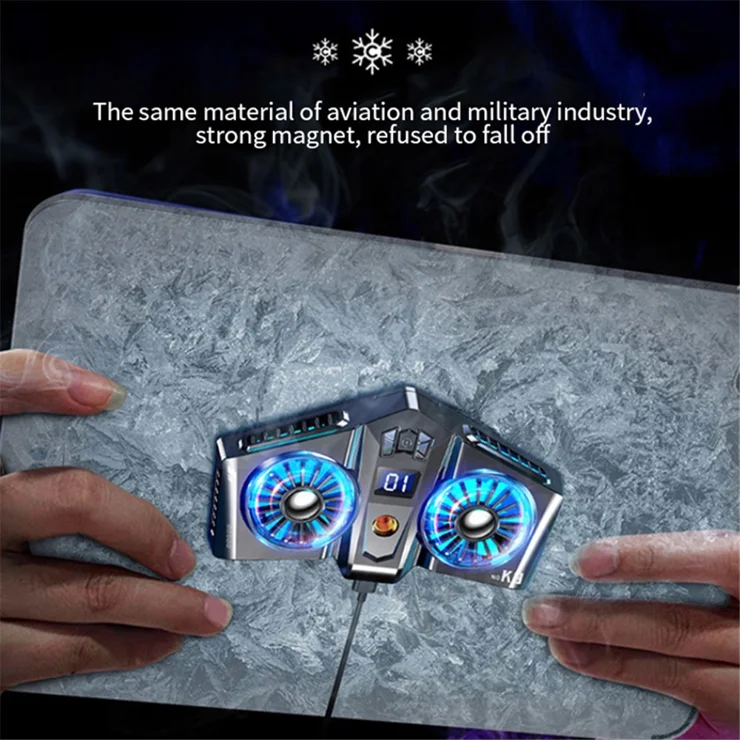

Illustrative image related to phone cooling pad

The Solution: To mitigate overheating, B2B buyers should consider sourcing high-quality phone cooling pads specifically designed for prolonged use in hot environments. When selecting a cooling pad, look for features like adjustable fan speeds and ergonomic designs to enhance airflow. Additionally, suppliers should ensure that the cooling pads have compatibility with a range of phone models, allowing for flexibility within the workforce. Regularly training staff on the importance of using these cooling pads during intensive tasks can further enhance their effectiveness and prolong device life.

Scenario 2: Compatibility Concerns with Various Devices

The Problem: Many B2B buyers struggle with sourcing phone cooling pads that are compatible with multiple device brands and models. This is particularly crucial for companies that manage diverse fleets of mobile devices. Incompatibility can lead to wasted resources on products that do not effectively serve the intended purpose, leading to frustration among employees and potential delays in operations.

The Solution: To address compatibility issues, buyers should prioritize suppliers that offer versatile and adjustable cooling pads. It’s essential to request detailed specifications regarding the dimensions and compatibility range of the cooling pads before purchasing. Engage with suppliers who provide customization options, allowing the cooling pads to accommodate various models. Furthermore, conducting a pilot program with a small selection of devices can help assess the effectiveness of the cooling pads before a larger roll-out, ensuring that the entire fleet is adequately supported.

Scenario 3: Insufficient Cooling Efficiency

The Problem: B2B buyers often find that some cooling pads do not provide adequate cooling efficiency, especially during intensive applications such as gaming or data processing. This can be particularly concerning for businesses in the tech and gaming sectors, where device performance is critical. Inadequate cooling can lead to thermal throttling, which negatively impacts user experience and productivity.

The Solution: To ensure optimal cooling efficiency, buyers should focus on sourcing phone cooling pads equipped with advanced cooling technologies, such as heat dissipation materials and high-performance fans. It’s advisable to seek out reviews and case studies from other businesses that have tested the cooling pads in similar environments. Additionally, consider implementing a feedback mechanism where employees can report on the performance of the cooling pads over time. This approach allows for continuous improvement and can help in making informed purchasing decisions for future needs. Furthermore, integrating these cooling solutions into standard operating procedures can ensure consistent use, enhancing device longevity and performance.

Strategic Material Selection Guide for phone cooling pad

What Are the Key Materials Used in Phone Cooling Pads?

When selecting materials for phone cooling pads, it is essential to consider how these choices affect performance, durability, and compatibility with various applications. Below, we analyze four common materials used in the production of phone cooling pads, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Aluminum Perform as a Material for Phone Cooling Pads?

Aluminum is a popular choice for phone cooling pads due to its excellent thermal conductivity, which allows for efficient heat dissipation. It typically has a temperature rating of up to 150°C and exhibits good corrosion resistance when anodized.

Pros: Aluminum is lightweight, making it easy to transport and handle. It also has a relatively low manufacturing complexity, allowing for cost-effective production.

Cons: While durable, aluminum can be prone to scratches and dents, which may affect aesthetics over time. Additionally, its cost can be higher than some plastic alternatives.

Impact on Application: Aluminum’s compatibility with various cooling mediums makes it suitable for high-performance applications. However, it may require special coatings or treatments to enhance corrosion resistance in humid environments, particularly in regions like South America and the Middle East.

What Are the Benefits of Using Plastic in Phone Cooling Pads?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is often used in phone cooling pads due to its versatility and lower cost. These materials generally have good temperature resistance, withstanding temperatures up to 80°C.

Pros: Plastics are lightweight and can be molded into complex shapes, providing design flexibility. They are also resistant to corrosion and chemicals, making them suitable for various environments.

Cons: Plastics may not dissipate heat as effectively as metals, potentially limiting their performance in high-heat situations. They can also be less durable over time, especially under mechanical stress.

Impact on Application: Plastic cooling pads are often preferred for consumer-grade products where cost is a significant factor. However, international buyers should ensure that the selected plastic complies with local regulations regarding environmental impact and recycling.

Why Choose Copper for Phone Cooling Pads?

Copper is renowned for its superior thermal conductivity, making it an excellent choice for high-performance cooling pads. It can handle temperatures up to 200°C and is highly resistant to corrosion when properly treated.

Pros: The thermal efficiency of copper is unmatched, leading to quicker cooling times. Its durability ensures a long lifespan, even under demanding conditions.

Cons: Copper is heavier than aluminum and plastic, which may affect portability. Additionally, its higher cost can be a barrier for budget-conscious buyers.

Impact on Application: Copper cooling pads are ideal for high-end smartphones and gaming devices that generate substantial heat. However, international buyers should be aware of the material’s weight when considering shipping and logistics.

Illustrative image related to phone cooling pad

What Role Does Graphene Play in Phone Cooling Pads?

Graphene is an emerging material in the tech industry, known for its remarkable thermal conductivity and strength. It can handle extreme temperatures and is resistant to corrosion.

Pros: Graphene is incredibly lightweight and can be integrated into various designs without adding bulk. Its high thermal conductivity allows for efficient heat management.

Cons: The manufacturing process for graphene can be complex and expensive, which may limit its use in lower-cost products. Additionally, its long-term durability in consumer applications is still being evaluated.

Impact on Application: Graphene is suitable for cutting-edge technology and premium products. Buyers in Europe, particularly in tech-forward markets like Germany, may find this material appealing due to its innovative properties.

Summary Table of Material Selection for Phone Cooling Pads

| Material | Typical Use Case for Phone Cooling Pad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | High-performance consumer devices | Excellent thermal conductivity | Susceptible to scratches | Medium |

| Plastic | Budget-friendly consumer products | Lightweight and moldable | Limited heat dissipation | Low |

| Copper | Gaming and high-end smartphones | Superior thermal efficiency | Heavier and more expensive | High |

| Graphene | Premium and innovative tech products | Lightweight with high conductivity | Complex manufacturing process | High |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for phone cooling pad

What Are the Main Stages of Manufacturing a Phone Cooling Pad?

The manufacturing process of a phone cooling pad involves several critical stages, each contributing to the overall functionality and quality of the final product. Understanding these stages is essential for B2B buyers who are sourcing products from international manufacturers.

Material Preparation: What Materials Are Used in Phone Cooling Pads?

The first step in manufacturing a phone cooling pad is material preparation. High-quality materials are crucial for effective heat dissipation. Common materials include:

- Thermal Conductive Materials: Aluminum and copper are often utilized for their excellent thermal conductivity.

- Plastic Components: High-density polyethylene (HDPE) or acrylonitrile butadiene styrene (ABS) are frequently used for the body of the cooling pad, providing durability and resistance to heat.

- Cooling Mechanisms: Some pads incorporate fans or gel-based cooling systems, which require specific components like small electric motors or gel-filled chambers.

Ensuring the quality of these materials is vital; therefore, B2B buyers should prioritize suppliers who source their materials from reputable vendors with certifications.

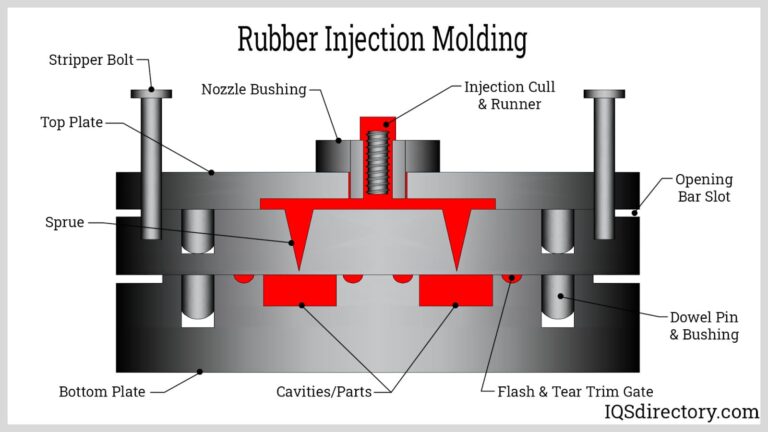

How Are Phone Cooling Pads Formed and Assembled?

Once materials are prepared, the next stage is forming and assembling the components. This process typically involves:

- Injection Molding: For plastic parts, injection molding is a common technique. It involves injecting molten plastic into a mold to create the desired shapes.

- Metal Fabrication: For metal components, processes like stamping, cutting, and machining are employed to form parts accurately.

- Assembly: After forming, the various components are assembled. This may involve mechanical fastening or adhesive bonding, depending on the design specifications.

During this stage, manufacturers often implement automated assembly lines to increase efficiency and reduce human error.

What Finishing Techniques Are Commonly Used?

Finishing processes are critical for enhancing the aesthetic appeal and durability of phone cooling pads. Common finishing techniques include:

- Surface Coating: Application of powder coating or painting to prevent corrosion and improve appearance.

- Quality Polishing: Polishing metal surfaces to enhance heat dissipation properties and improve visual appeal.

- Final Assembly: Ensuring that all components fit together seamlessly and function as intended.

Attention to detail in the finishing stage can significantly impact product performance, making it an essential consideration for B2B buyers.

What Quality Assurance Practices Should B2B Buyers Consider?

Quality assurance (QA) is integral to ensuring that the final product meets international standards and customer expectations. For B2B buyers, understanding the QA processes can help in selecting reliable suppliers.

Which International Standards Apply to Phone Cooling Pads?

Several international quality standards are relevant for phone cooling pads, including:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- RoHS Compliance: This directive restricts the use of certain hazardous substances in electrical and electronic equipment.

For buyers in regions such as Africa and South America, understanding these certifications can help in selecting suppliers who adhere to global quality standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) processes typically include several checkpoints throughout the manufacturing process:

Illustrative image related to phone cooling pad

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The final inspection ensures that the finished product meets all quality and regulatory standards before shipment.

These checkpoints are crucial for maintaining product integrity and reducing the risk of defects.

What Testing Methods Are Commonly Used in Quality Control?

Quality assurance for phone cooling pads involves various testing methods to evaluate performance and safety. Common testing methods include:

- Thermal Performance Testing: Evaluating how effectively a cooling pad dissipates heat under various conditions.

- Durability Testing: Assessing the product’s resistance to wear and tear over time, including stress tests and impact tests.

- Electrical Safety Testing: For pads with electronic components, ensuring that they comply with safety standards to prevent electrical hazards.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure they meet their quality expectations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality standards, B2B buyers can take several steps:

- Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices.

- Request Quality Assurance Reports: Suppliers should provide documentation of their QC processes, including test results and certifications.

- Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control measures and product quality.

These practices can help mitigate risks and ensure that B2B buyers receive products that meet their specifications.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers should be aware of certain nuances when it comes to quality control:

- Regulatory Variations: Different regions may have unique regulatory requirements, making it essential for buyers to understand local standards.

- Cultural Differences: Communication barriers and cultural differences may affect quality expectations and manufacturing practices.

- Logistics and Supply Chain Challenges: Transportation and customs regulations can impact the timely delivery of quality products, necessitating close collaboration with suppliers.

Understanding these factors can help B2B buyers navigate the complexities of international sourcing and ensure they are selecting the best manufacturers for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘phone cooling pad’

Introduction

In the fast-paced world of mobile technology, a reliable phone cooling pad can significantly enhance device performance and longevity. This sourcing guide is designed for international B2B buyers looking to procure phone cooling pads, providing a systematic approach to ensure you make informed purchasing decisions. By following this checklist, you can streamline your procurement process and secure high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Understanding the requirements for your cooling pad is crucial. Identify the specific technical features you need, such as size compatibility, cooling efficiency, and power source (USB-powered vs. battery-operated). Knowing these specifications helps narrow down your options and ensures you select a product that integrates seamlessly with your existing devices.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in phone cooling technology. Investigate new materials, designs, and functionalities that enhance cooling performance. Understanding market trends not only helps you identify innovative products but also positions your business as a forward-thinking entity in the eyes of your customers.

Step 3: Evaluate Potential Suppliers

Thorough vetting of suppliers is essential before making a commitment. Request company profiles, case studies, and references from existing clients to gauge their reliability and product quality. It’s also beneficial to check if suppliers have experience dealing with businesses in your region, as this can affect shipping times and customer support.

- Look for suppliers with a solid reputation and positive reviews.

- Ensure they have relevant certifications, such as ISO standards, which indicate adherence to quality management practices.

Step 4: Compare Pricing and Payment Terms

Cost-effectiveness is a key consideration in B2B procurement. Gather quotes from multiple suppliers to compare pricing structures and payment terms. Be sure to clarify what is included in the price—such as shipping, warranties, and after-sales support—to avoid unexpected costs later on.

Illustrative image related to phone cooling pad

- Consider bulk purchase discounts or long-term partnership pricing.

- Assess the total cost of ownership, including maintenance and replacement parts.

Step 5: Request Product Samples

Before finalizing your order, obtain samples of the cooling pads. Testing samples allows you to evaluate the product’s performance and quality firsthand. Check for features like noise levels, durability, and ease of use, which can significantly impact customer satisfaction.

- Ask for samples that meet your defined specifications.

- Consider testing the samples in various environments to assess performance under different conditions.

Step 6: Review Shipping and Logistics Options

Logistics can significantly impact your supply chain efficiency. Discuss shipping options with your chosen supplier, ensuring they can meet your delivery timelines. Evaluate factors such as shipping costs, potential tariffs, and customs regulations, especially when sourcing internationally.

- Confirm the supplier’s ability to handle logistics and provide tracking information.

- Consider local warehousing options if frequent replenishment is necessary.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Ensure you establish clear lines of communication with your supplier for order updates, issue resolution, and feedback. Regular check-ins can help maintain a strong relationship and facilitate smoother transactions.

- Designate a point of contact for any inquiries or concerns.

- Use collaborative tools to streamline communication and documentation.

By following this checklist, B2B buyers can confidently navigate the procurement of phone cooling pads, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for phone cooling pad Sourcing

What Are the Key Cost Components in Phone Cooling Pad Manufacturing?

When sourcing phone cooling pads, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to phone cooling pad

-

Materials: The choice of materials significantly influences the cost. Common materials include plastics, metals, and electronic components. Buyers should evaluate the trade-off between cost and durability, especially for high-quality pads that require better thermal management.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs might offer attractive pricing, but this can sometimes impact product quality. It’s crucial to assess labor skill levels in the supplier’s region.

-

Manufacturing Overhead: This encompasses utilities, rent, and other operational costs incurred during production. Suppliers in regions with high operational costs may need to price their products higher to maintain profitability.

-

Tooling: Initial tooling costs for molds or production setups can be substantial, especially for custom designs. Buyers should consider these costs as part of the overall investment, particularly for bespoke solutions.

-

Quality Control: Effective QC processes ensure product reliability and compliance with international standards. Investing in stringent QC measures may raise costs but can lead to significant savings by reducing returns and enhancing customer satisfaction.

-

Logistics: Shipping and handling costs should not be overlooked. Factors like distance, shipping method, and customs duties can dramatically affect the final price. Buyers should factor in these costs when evaluating supplier quotes.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical margins in the industry can help buyers negotiate more effectively.

How Do Price Influencers Affect Phone Cooling Pad Sourcing?

Several factors can influence the pricing of phone cooling pads in the international market:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often lead to discounts, so buyers should consider their inventory needs and potential for bulk purchasing.

-

Specifications/Customization: Customized designs or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses during production.

-

Materials Quality/Certifications: Premium materials and certifications (like CE, FCC, or RoHS) can raise prices but are often necessary for compliance in certain markets, particularly in Europe and North America.

-

Supplier Factors: The supplier’s reputation, reliability, and experience can influence pricing. Established suppliers may charge more for their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is crucial for determining who bears responsibility for shipping, insurance, and customs clearance. Different terms can lead to variations in total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always approach negotiations with a clear understanding of the market rates and your budget constraints. Building a relationship with suppliers can lead to better terms and pricing.

-

Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like durability, warranty, and potential for returns. A higher upfront cost may result in lower lifetime costs.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, products sourced from Asia might have lower base costs but can incur higher shipping fees for buyers in Europe or Africa.

-

Supplier Diversification: Avoid reliance on a single supplier. Diversifying your supplier base can lead to better pricing and reduce the risk of supply chain disruptions.

Disclaimer on Indicative Prices

It is essential to note that prices for phone cooling pads can vary significantly based on numerous factors mentioned above. Buyers should conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing phone cooling pad With Other Solutions

Understanding Alternative Cooling Solutions for Phones

In the competitive landscape of mobile technology, ensuring optimal device performance is crucial for businesses. Phone cooling pads are one solution that helps manage device temperatures during heavy usage. However, other alternatives exist that may better fit specific operational needs. This analysis explores how phone cooling pads stack up against two viable alternatives: active cooling systems and thermal paste application.

Comparison Table

| Comparison Aspect | Phone Cooling Pad | Active Cooling System | Thermal Paste Application |

|---|---|---|---|

| Performance | Effectively reduces heat | Provides superior cooling | Improves internal heat dissipation |

| Cost | Moderate initial investment | Higher upfront costs | Low-cost, but labor-intensive |

| Ease of Implementation | Plug-and-play convenience | Requires installation and expertise | Requires technical knowledge |

| Maintenance | Minimal maintenance required | Regular checks needed | Long-lasting but may need reapplication |

| Best Use Case | Casual gaming and streaming | High-performance gaming or intensive tasks | Overheating devices needing internal repair |

What Are the Advantages and Disadvantages of Active Cooling Systems?

Active cooling systems, which often use fans or liquid cooling mechanisms, provide a high level of cooling efficiency. They can significantly lower device temperatures, making them ideal for high-performance gaming or intensive applications. However, they come with a higher initial investment and require installation expertise, which can deter some users. Moreover, regular maintenance is necessary to ensure optimal performance, increasing the total cost of ownership.

How Does Thermal Paste Application Compare?

Thermal paste application is a cost-effective solution for improving heat transfer between the device’s CPU/GPU and its cooler. This method can significantly enhance the internal cooling of devices and is particularly useful for addressing overheating issues in older phones. However, it requires technical knowledge for proper application and may not be suitable for all users. Additionally, while it can provide long-lasting results, there may be a need for reapplication over time.

Choosing the Right Cooling Solution for Your Business Needs

When selecting the appropriate cooling solution for phones, B2B buyers must consider various factors such as performance requirements, budget constraints, and ease of implementation. Phone cooling pads offer a balance of performance and convenience, making them suitable for casual users. On the other hand, businesses focused on high-performance applications may find active cooling systems or thermal paste application to be more effective, albeit at a higher cost or complexity. Assessing the specific operational context and user needs will help in determining the best solution for maintaining optimal device performance.

Essential Technical Properties and Trade Terminology for phone cooling pad

What Are the Key Technical Properties of a Phone Cooling Pad?

1. Material Grade

The material used in manufacturing phone cooling pads significantly influences their thermal conductivity and durability. Common materials include aluminum, which offers excellent heat dissipation, and high-grade plastics, which provide lightweight options. Understanding material properties helps buyers evaluate the longevity and performance of cooling pads, ensuring they select products that meet their operational requirements.

2. Cooling Efficiency

This specification refers to the ability of the cooling pad to lower the temperature of the phone. Cooling efficiency is often measured in degrees Celsius (°C) per watt. For B2B buyers, selecting a cooling pad with high efficiency ensures that devices remain operational during prolonged use, particularly in high-temperature environments typical in regions like Africa and the Middle East.

3. Noise Level

Noise generated by cooling pads can affect user experience, especially in quiet environments. The noise level is typically measured in decibels (dB). Buyers should consider the acceptable noise threshold for their target market, as products marketed in professional settings may require lower noise levels to maintain a conducive work atmosphere.

4. Power Consumption

Power consumption indicates how much energy the cooling pad uses during operation, usually measured in watts (W). Low power consumption is a vital selling point for buyers looking to reduce energy costs and promote eco-friendly products. Understanding this metric can help businesses align their offerings with sustainability goals and attract environmentally conscious customers.

5. Size and Compatibility

Phone cooling pads come in various sizes, and compatibility with different phone models is crucial. Buyers must consider the dimensions of the cooling pad to ensure it accommodates various phone sizes without compromising cooling efficiency. Providing detailed specifications for compatibility can enhance the product’s appeal and reduce the likelihood of returns.

What Are Common Trade Terms Related to Phone Cooling Pads?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are branded and sold by another company. In the context of phone cooling pads, understanding OEM relationships can help buyers navigate supply chains and identify opportunities for customized products that meet specific market demands.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. Suppliers often set MOQs to ensure production efficiency, and understanding these thresholds can help buyers negotiate better pricing and terms.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. Utilizing RFQs can help B2B buyers compare prices and terms from multiple suppliers, ensuring they secure the best deal for phone cooling pads while fostering competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B transactions. They clarify cost responsibilities and risk management, helping buyers avoid disputes during the shipping process.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is critical for planning inventory and managing customer expectations. Factors influencing lead times include production schedules, shipping methods, and supplier reliability.

6. Warranty and After-Sales Service

Warranties provide assurance regarding product quality and performance. Understanding warranty terms is essential for buyers to mitigate risks associated with product defects or failures. After-sales service, including support and maintenance, can also influence purchasing decisions, as strong support can enhance customer satisfaction and loyalty.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their investments in phone cooling pads align with their operational goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the phone cooling pad Sector

What Are the Key Market Drivers and Trends in the Phone Cooling Pad Sector?

The phone cooling pad market is experiencing significant growth, driven by the increasing demand for mobile devices and their accessories. As smartphones become more powerful, the risk of overheating during prolonged use has prompted consumers and businesses alike to seek effective cooling solutions. This trend is particularly pronounced in regions such as Africa and South America, where rapid urbanization and mobile penetration are leading to higher smartphone usage rates. Moreover, in Europe, particularly Germany and Vietnam, technological advancements in materials and design are enhancing product efficiency and user experience.

Emerging B2B tech trends include the integration of smart technologies into cooling pads, such as temperature sensors and automated cooling systems. These innovations not only improve performance but also appeal to tech-savvy consumers looking for advanced solutions. Additionally, the rise of e-commerce platforms has transformed sourcing strategies, allowing international buyers to access a wider range of products and suppliers, thereby fostering competition and innovation within the market.

How Can Sustainability and Ethical Sourcing Impact the Phone Cooling Pad Market?

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers. Environmental concerns surrounding the manufacturing processes and materials used in phone cooling pads necessitate a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials. This includes the use of recyclable plastics and biodegradable components, which can significantly lower the environmental impact of products.

Ethical sourcing is equally important, as businesses seek to ensure that their supply chains adhere to fair labor practices and responsible sourcing standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as key indicators of a supplier’s commitment to sustainability and ethical practices. By aligning with suppliers who prioritize these values, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally-conscious consumers.

What Is the Evolution of the Phone Cooling Pad Market?

The phone cooling pad market has evolved significantly over the past decade, transitioning from simple passive cooling solutions to more sophisticated, active cooling systems. Initially, cooling pads were primarily designed to enhance airflow through basic ventilation. However, with advancements in technology, manufacturers have developed products that incorporate features like liquid cooling systems and advanced thermal materials.

This evolution has been driven by the increasing complexity and heat generation of modern smartphones, as well as the growing consumer expectation for performance and durability. As a result, the market has expanded to cater to a diverse range of applications, from casual gaming to professional use, solidifying the phone cooling pad’s role as an essential accessory in today’s mobile ecosystem.

Frequently Asked Questions (FAQs) for B2B Buyers of phone cooling pad

-

How do I solve overheating issues for my mobile devices in a commercial setting?

To address overheating issues for mobile devices, investing in high-quality phone cooling pads is essential. Look for pads with efficient heat dissipation technology, such as active cooling fans or advanced thermal materials. Ensure that the cooling pads are compatible with various phone models and sizes, which can be crucial for businesses with diverse device inventories. Regular maintenance of the cooling pads, including cleaning dust from vents and ensuring fans are operational, will also enhance their effectiveness and longevity. -

What is the best phone cooling pad for high-performance gaming?

For high-performance gaming, select a cooling pad that offers robust airflow and adjustable fan speeds. Look for models equipped with dual or triple fan systems, as they provide better heat management during intensive gaming sessions. Additionally, ensure that the cooling pad has a non-slip surface to securely hold the device in place. Brands that focus on gaming accessories often have specialized features designed for prolonged use, making them ideal for gaming environments. -

What customization options are available for bulk orders of phone cooling pads?

Many suppliers offer customization options for bulk orders, including branding, color choices, and specific design features tailored to your target market. You can request custom packaging to enhance brand visibility and align with your marketing strategy. Additionally, inquire about modifying dimensions or materials used in the cooling pads to meet specific user needs. Establishing clear communication with suppliers about your requirements will facilitate a smoother customization process. -

What is the typical minimum order quantity (MOQ) for phone cooling pads?

The minimum order quantity (MOQ) for phone cooling pads can vary significantly depending on the supplier and the specific product features. Generally, MOQs range from 100 to 1,000 units. Some manufacturers may offer lower MOQs for standard models, while custom designs typically require larger orders. It’s advisable to discuss MOQs during initial negotiations to align your purchasing strategy with supplier capabilities and avoid excess inventory. -

How can I vet suppliers for phone cooling pads effectively?

To vet suppliers, start by checking their business credentials, including industry certifications and customer reviews. Request samples to assess product quality and ensure they meet your specifications. Additionally, ask about their production capacity and lead times to ensure they can meet your demand. Engage with references or previous clients to gauge their reliability and responsiveness. Attending trade shows or industry expos can also provide firsthand insights into potential suppliers. -

What payment terms should I expect when sourcing phone cooling pads internationally?

Payment terms can vary widely among international suppliers. Common arrangements include a 30% deposit with the balance due upon shipment or a letter of credit. Some suppliers may offer payment through platforms like PayPal or escrow services for added security. It’s crucial to clarify terms before finalizing agreements to avoid misunderstandings. Additionally, understand any currency exchange implications and fees that may arise during the transaction. -

What quality assurance processes should I look for in phone cooling pad suppliers?

A reputable supplier should have a robust quality assurance process in place, including regular inspections during production and before shipment. Ask about their adherence to international quality standards such as ISO certifications. Inquire whether they conduct third-party testing for safety and performance, especially for electronic components. Establishing a clear quality control agreement can help ensure that you receive products that meet your expectations. -

What logistics considerations are important when importing phone cooling pads?

When importing phone cooling pads, consider shipping methods, costs, and delivery timelines. Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness, especially for larger orders. Be aware of customs regulations and duties in your destination country, as these can impact overall costs. Collaborating with a logistics partner experienced in international shipping can streamline the process, ensuring timely and compliant delivery of your products.

Top 3 Phone Cooling Pad Manufacturers & Suppliers List

1. Black Shark – Fun Cooler 2Pro

Domain: newegg.com

Registered: 2000 (25 years)

Introduction: Black Shark Cell Phone Cooler Fun Cooler 2Pro(White), Cellphone Radiator with LED Temperature Display/Sleep Timer/Fan Speed Settings for 2.63-3.46 inches iOS/Android Semiconductor Heatsink Cooling, Color: White, Supports Device: Universal version, Model #: BR30-BS White, Price: $44.99, Free Shipping Available. Portable Mobile Phone Radiator Phone Cooling Fan Case For ABS Phone Cooler, Model #: 220…

2. eBay – Phone Coolers

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Cooler for Phone available on eBay includes various types such as mobile phone coolers, gaming phone coolers, and USB cooling fans. Compatible brands include Apple, Samsung, Motorola, ASUS, LG, ZTE, and Xiaomi. Types of coolers include phone holders, car mounts, desktop holders, and magnetic coolers. Colors available are black, pink, white, blue, multicolor, red, clear, silver, green, and gold. Mo…

3. CyberNews – Best Phone Coolers in 2025

Domain: cybernews.com

Registered: 1997 (28 years)

Introduction: Best Phone Coolers in 2025:

1. Black Shark 4 Pro

– Best for: Overall best and quick cooldowns

– Dimensions: 3.9″ x 7.13″ x 1.71″

– Cooling time: 30s

– Material: Plastic

– Pros: Quick and efficient cool downs, compatible with multiple devices, app controlled, quiet operation, 12-month warranty

– Cons: May need the app for full customization

2. Nubia 5 Pro

– Best for: Gaming pe…

Strategic Sourcing Conclusion and Outlook for phone cooling pad

The landscape of phone cooling pads presents a unique opportunity for strategic sourcing that can significantly enhance product offerings in the global market. As smartphone usage continues to surge, particularly in emerging markets across Africa and South America, the demand for effective cooling solutions is becoming increasingly vital. International buyers are encouraged to leverage strategic sourcing to identify reliable suppliers who can deliver quality products that meet varying regional needs.

Illustrative image related to phone cooling pad

Key takeaways include the importance of assessing supplier capabilities, understanding local regulations, and recognizing consumer preferences that may differ by region. By prioritizing quality and innovation in sourcing, businesses can differentiate themselves in a competitive market, ensuring they meet the demands of tech-savvy consumers looking for reliable cooling solutions.

Looking ahead, the integration of advanced materials and technology in phone cooling pads is set to redefine the industry. B2B buyers should stay informed about emerging trends and innovations that could enhance product functionality. Engaging with suppliers who are committed to research and development can yield significant long-term benefits. Take action now to secure your position in this growing market and ensure your offerings remain relevant and competitive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to phone cooling pad

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.