Top 3 Hinge Latch Suppliers (And How to Choose)

Introduction: Navigating the Global Market for hinge latch

In today’s global marketplace, sourcing reliable hinge latches can pose a significant challenge for international B2B buyers, especially those in diverse regions like Africa, South America, the Middle East, and Europe. The need for durable, efficient, and cost-effective hinge latches is critical across various industries—from construction and manufacturing to automotive and marine applications. This comprehensive guide aims to address these challenges by providing insights into the different types of hinge latches available, their specific applications, and the importance of selecting the right materials, such as stainless steel or plain steel.

Navigating the complexities of supplier vetting is another crucial aspect this guide covers. With a multitude of manufacturers vying for attention, understanding how to assess supplier credibility, product quality, and compliance with international standards can empower B2B buyers to make informed purchasing decisions. Furthermore, we will delve into cost considerations, helping you balance quality and budget effectively.

This guide is designed to equip international buyers with the knowledge they need to confidently source hinge latches that meet their operational demands. By understanding the nuances of hinge latch options and supplier dynamics, you can streamline your procurement process and enhance your competitive edge in the global market.

Understanding hinge latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Combination Latch Hinge | Integrates hinge and latch in a single unit; spring-loaded pin for quick release. | Industrial equipment, trailers, storage solutions. | Pros: Easy installation and operation; reduces component count. Cons: May require specific alignment for optimal function. |

| Heavy-Duty Latch Hinge | Constructed from robust materials; designed to withstand high stress and frequent use. | Shipping containers, heavy lids, industrial doors. | Pros: High durability; ideal for demanding environments. Cons: Higher cost may deter budget-conscious buyers. |

| Stainless Steel Latch Hinge | Corrosion-resistant; suitable for outdoor and marine applications. | Marine hardware, outdoor furniture, food processing. | Pros: Long lifespan; excellent resistance to rust and wear. Cons: Higher initial investment compared to plain steel options. |

| Spring-Loaded Latch Hinge | Automatically engages and disengages; offers quick access. | Access panels, maintenance doors, machinery covers. | Pros: Enhanced safety and convenience; minimizes manual handling. Cons: Spring mechanism may wear over time, requiring maintenance. |

| Custom Latch Hinge | Tailored specifications to meet unique operational needs; available in various materials and finishes. | Specialized industrial applications, bespoke projects. | Pros: Perfect fit for unique applications; flexibility in design. Cons: Longer lead times and potentially higher costs. |

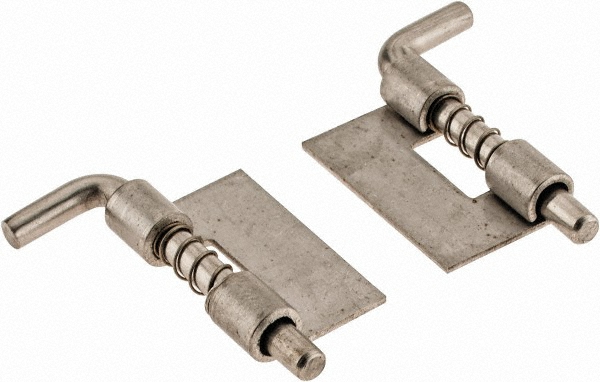

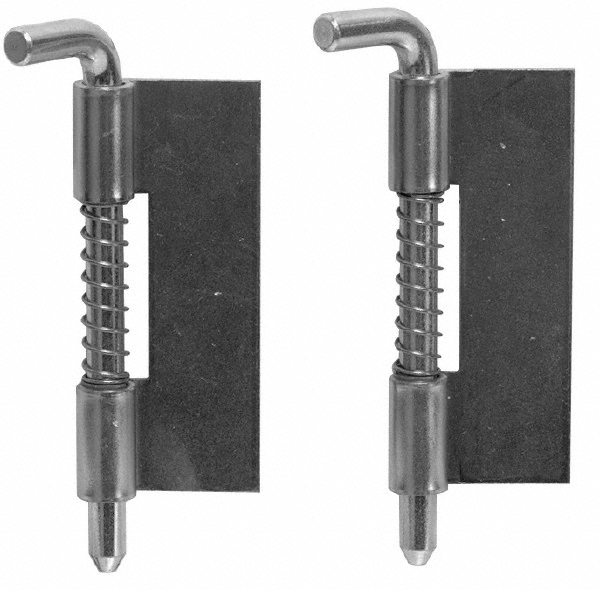

What are the characteristics of Combination Latch Hinges?

Combination latch hinges uniquely merge the functionality of hinges and latches into a single component. This design features a spring-loaded pin that allows for quick disengagement, making it ideal for applications requiring frequent access. Industries such as transportation, manufacturing, and storage benefit from their ease of use and installation. When purchasing, consider the specific alignment requirements to ensure optimal performance.

How do Heavy-Duty Latch Hinges perform in demanding environments?

Heavy-duty latch hinges are engineered from robust materials, making them suitable for applications that experience high stress and frequent use, such as shipping containers and industrial doors. Their durability ensures they can withstand harsh conditions, which is essential for businesses looking for longevity in their hardware. Buyers should weigh the higher upfront costs against the long-term benefits of reduced maintenance and replacement needs.

Why are Stainless Steel Latch Hinges preferred in outdoor applications?

Stainless steel latch hinges offer exceptional resistance to corrosion, making them ideal for marine hardware and outdoor furniture. Their durability in harsh environments contributes to a longer lifespan, which is a significant consideration for businesses in sectors like food processing and construction. While they may come with a higher initial cost, the investment often pays off in reduced maintenance and replacement frequency.

What advantages do Spring-Loaded Latch Hinges provide?

Spring-loaded latch hinges automatically engage and disengage, providing quick access to equipment and access panels. This feature enhances safety and convenience, particularly in environments where rapid access is critical. While they offer substantial operational benefits, buyers should account for the potential wear of the spring mechanism over time, which may necessitate periodic maintenance.

How can Custom Latch Hinges cater to specialized needs?

Custom latch hinges are designed to meet specific operational requirements, available in various materials and finishes to suit unique applications. These hinges are particularly beneficial for businesses with bespoke projects or specialized industrial needs. While they provide a perfect fit, buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing.

Key Industrial Applications of hinge latch

| Industry/Sector | Specific Application of hinge latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing machine access panels | Enhances safety and accessibility for maintenance tasks | Material durability (stainless steel vs. plain steel), custom sizes for specific machinery |

| Transportation | Latching trailer doors and hatches | Ensures cargo security and ease of access | Weather resistance, load capacity, and compliance with local regulations |

| Construction | Attaching gates and access doors | Provides reliable security and operational efficiency | Sizing for heavy-duty applications, resistance to corrosion, and custom options available |

| Marine | Securing hatches and compartments on vessels | Protects against water ingress and enhances safety | Saltwater resistance, material choice, and adaptability to various boat designs |

| Agriculture | Latching equipment covers and storage units | Safeguards machinery and prevents unauthorized access | Weatherproofing, ease of use in field conditions, and compatibility with existing equipment |

How Are Hinge Latches Used in Manufacturing?

In the manufacturing sector, hinge latches are crucial for securing access panels on machinery. By providing a reliable locking mechanism, these latches ensure that maintenance personnel can safely access components while preventing unauthorized entry. Buyers in this sector should consider the durability of materials, such as stainless steel for high-wear environments, and the need for custom sizes to fit specific machinery designs.

What Role Do Hinge Latches Play in Transportation?

In the transportation industry, hinge latches are essential for securing trailer doors and hatches. They ensure that cargo remains safe during transit while allowing for quick access when needed. When sourcing hinge latches for trailers, businesses should prioritize weather resistance and load capacity, ensuring compliance with local regulations to maintain safety standards.

How Are Hinge Latches Utilized in Construction Projects?

In construction, hinge latches are commonly used to attach gates and access doors, providing both security and operational efficiency. These latches help secure job sites and allow for easy access for workers and equipment. Buyers should focus on heavy-duty options that resist corrosion and consider custom solutions tailored to specific project requirements.

Why Are Hinge Latches Important in Marine Applications?

Marine applications often rely on hinge latches to secure hatches and compartments on vessels. These latches protect against water ingress, enhancing safety and preserving the integrity of onboard equipment. When sourcing for marine use, businesses should prioritize materials that resist saltwater corrosion and ensure that the latches can adapt to various boat designs.

How Do Hinge Latches Benefit Agricultural Equipment?

In agriculture, hinge latches are vital for securing equipment covers and storage units. They help protect machinery from environmental elements while preventing unauthorized access. Buyers in this sector should seek weatherproof options that are easy to operate in field conditions, ensuring compatibility with existing agricultural equipment for seamless integration.

3 Common User Pain Points for ‘hinge latch’ & Their Solutions

Scenario 1: Struggling with Inconsistent Quality in Hinge Latches

The Problem:

B2B buyers often face significant challenges in maintaining quality standards for hinge latches. Inconsistent product quality can lead to premature failures, resulting in costly repairs and replacements. This issue is particularly pronounced when sourcing from multiple suppliers, especially for buyers in regions with varying manufacturing standards. For example, a manufacturer in Nigeria may experience discrepancies in latch performance compared to those sourced from Europe, leading to operational inefficiencies and customer dissatisfaction.

The Solution:

To overcome quality inconsistency, it is essential for buyers to establish strong relationships with reputable suppliers who adhere to international quality standards. When sourcing hinge latches, conduct thorough due diligence by requesting certifications such as ISO 9001 or industry-specific standards that guarantee product reliability. Additionally, consider suppliers who offer samples for testing prior to bulk orders. Implementing a rigorous quality control process during the procurement stage can help ensure that only high-quality latches are used in production. Regular communication with suppliers to discuss quality expectations and feedback can also foster improvements and align standards across different regions.

Scenario 2: Difficulty in Finding the Right Specifications for Heavy-Duty Applications

The Problem:

In industries requiring heavy-duty hinge latches, such as construction or manufacturing, buyers often struggle to find components that meet specific load-bearing requirements. Inadequate specifications can lead to hinge failures under stress, posing safety risks and operational downtime. For instance, a construction firm in South America may need latches that can withstand harsh environmental conditions while supporting heavy doors, yet they find it challenging to identify the right product specifications.

The Solution:

To effectively source hinge latches for heavy-duty applications, buyers should engage with manufacturers that specialize in custom solutions. Start by clearly defining the operational parameters, including load capacity, environmental factors, and usage frequency. Reach out to suppliers with expertise in engineering and ask for detailed product specifications, including material composition and testing certifications. Additionally, consider utilizing online tools and resources to calculate load requirements and match them with appropriate latch options. Partnering with suppliers who offer engineering support can further assist in selecting the right hinge latches tailored to specific applications, ensuring safety and durability.

Illustrative image related to hinge latch

Scenario 3: Challenges in Integrating Latch Hinges into Existing Systems

The Problem:

Buyers often encounter integration issues when trying to fit new hinge latches into existing systems or machinery. This challenge can lead to delays in production and increased costs if modifications are necessary. For example, a company in Germany may have legacy equipment that requires specific hinge designs, yet they find that contemporary latches do not align with their needs, resulting in compatibility issues.

The Solution:

To address integration challenges, it is crucial to conduct a thorough assessment of existing systems before sourcing new hinge latches. Begin by documenting the current hinge specifications, including dimensions, materials, and any unique features that are critical for compatibility. Engage with suppliers who offer customization options to create latches that align with your existing requirements. Many manufacturers provide CAD models and technical drawings that can help visualize how new latches will fit into current systems. Moreover, collaborating with engineering teams during the selection process can ensure that the chosen hinge latches not only fit but also enhance overall functionality, minimizing the risk of operational disruptions.

Strategic Material Selection Guide for hinge latch

What Are the Key Properties of Common Materials Used in Hinge Latches?

When selecting materials for hinge latches, it is essential to consider properties that directly impact performance, including temperature and pressure ratings, corrosion resistance, and overall durability. Here, we analyze four common materials used in hinge latch production: plain steel, stainless steel, aluminum, and plastic.

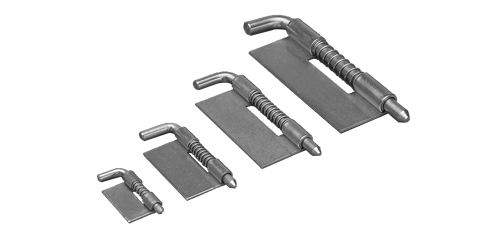

Illustrative image related to hinge latch

How Does Plain Steel Perform as a Material for Hinge Latches?

Plain steel is a widely used material for hinge latches due to its strength and availability. It typically has a good temperature tolerance but can be susceptible to corrosion if not treated.

Pros: Plain steel is generally cost-effective and easy to manufacture, making it suitable for high-volume applications. It offers high load-bearing capacity, making it ideal for heavy-duty applications.

Cons: The primary drawback is its susceptibility to rust and corrosion, especially in humid or outdoor environments. Additionally, it may require protective coatings to enhance its durability.

Illustrative image related to hinge latch

Impact on Application: Plain steel hinge latches are best suited for applications where exposure to moisture is minimal. They are commonly used in industrial settings, but care must be taken to ensure they are not exposed to corrosive environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local environmental conditions that may affect the longevity of plain steel latches. Compliance with local standards, such as ASTM or DIN, should also be considered.

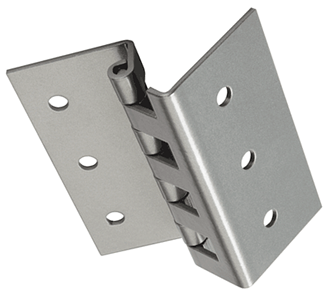

What Advantages Does Stainless Steel Offer for Hinge Latches?

Stainless steel is renowned for its corrosion resistance and durability, making it a preferred choice for hinge latches in various applications.

Pros: Stainless steel latches can withstand harsh environmental conditions, including exposure to moisture and chemicals. They also have a high aesthetic appeal, which is beneficial for consumer-facing products.

Cons: The primary limitation is cost; stainless steel is generally more expensive than plain steel. Additionally, manufacturing processes may be more complex due to its hardness.

Impact on Application: Stainless steel hinge latches are ideal for marine applications, outdoor furniture, and food processing equipment where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Buyers in Europe, particularly Germany, often prefer stainless steel due to stringent quality standards. Compliance with regulations like RoHS and DIN is crucial for market acceptance.

How Does Aluminum Compare as a Material for Hinge Latches?

Aluminum is a lightweight alternative that offers good corrosion resistance and is often used in applications where weight is a concern.

Pros: Aluminum latches are lightweight, making them easy to handle and install. They also resist corrosion well and can be anodized for additional protection.

Cons: While aluminum is strong for its weight, it may not bear as much load as steel options. It can also be more expensive than plain steel.

Impact on Application: Aluminum hinge latches are commonly used in aerospace, automotive, and portable equipment applications where weight reduction is critical.

Considerations for International Buyers: In regions like the Middle East, where temperatures can be extreme, aluminum’s lightweight and corrosion-resistant properties are beneficial. Compliance with international standards ensures compatibility with various applications.

What Role Does Plastic Play in Hinge Latch Manufacturing?

Plastic is increasingly used in hinge latches, particularly in applications requiring lightweight and non-corrosive materials.

Pros: Plastic latches are resistant to corrosion and can be produced in various colors and designs. They are also lightweight and often less expensive than metal options.

Cons: The primary drawback is that plastic may not provide the same strength as metal, limiting its use in heavy-duty applications. Additionally, temperature sensitivity can affect performance.

Impact on Application: Plastic hinge latches are suitable for household items, lightweight enclosures, and applications where aesthetics are important.

Considerations for International Buyers: Buyers from regions with varying climatic conditions, such as Africa, should consider the specific type of plastic used, as some may degrade under UV exposure. Compliance with standards such as ASTM for plastics is essential.

Summary Table of Material Selection for Hinge Latches

| Material | Typical Use Case for hinge latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plain Steel | Industrial applications | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Marine and outdoor applications | Excellent corrosion resistance | Higher cost and complex to manufacture | High |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower load-bearing capacity | Medium |

| Plastic | Household items and lightweight enclosures | Corrosion-resistant and aesthetic | Limited strength and temperature sensitivity | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for hinge latch

What Are the Key Stages in the Manufacturing Process of Hinge Latches?

The manufacturing of hinge latches involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can help B2B buyers assess the reliability and performance of their suppliers.

Material Preparation: What Materials Are Commonly Used?

The primary materials for hinge latches include plain steel and stainless steel, with variations available in zinc-plated finishes for corrosion resistance. Material selection is essential, as the choice between plain and stainless steel affects the hinge latch’s strength, durability, and resistance to environmental factors. Suppliers often source materials compliant with international standards, ensuring that they meet the specifications required for different applications.

Illustrative image related to hinge latch

How Are Hinge Latches Formed?

The forming process typically involves techniques such as stamping, forging, and machining. Stamping is often used to create the hinge’s basic shape from metal sheets, while forging enhances strength through the application of heat and pressure. Precision machining is employed to achieve the necessary tolerances for pin holes and other critical dimensions. The forming stage is vital in ensuring that the hinge latches function correctly and fit seamlessly into their intended applications.

What Does the Assembly Process Entail?

Once the components are formed, the assembly stage follows. This process may involve inserting the pivot pins and springs into the hinge body, ensuring smooth operation. For latch hinges with holdback features, additional components are integrated to allow the pin to lock in place when needed. Quality assurance checks during assembly ensure that each component fits correctly and operates as intended.

How Important Is the Finishing Stage?

The finishing stage involves applying protective coatings, such as zinc plating or powder coating, to enhance corrosion resistance and aesthetic appeal. This step is crucial, especially for products intended for outdoor use or in humid environments. Finishing not only improves durability but also affects the overall appearance of the hinge latch, which can be an important factor for end-users.

What Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance is critical in the hinge latch manufacturing process, ensuring that the final product meets international standards and customer specifications. Here’s what B2B buyers should know:

Which International Standards Apply to Hinge Latches?

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with industry-specific certifications, such as CE marking in Europe or API standards in the oil and gas sector, may also be relevant depending on the application. These certifications ensure that manufacturers have established processes that guarantee product quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control in hinge latch manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, various checks are conducted to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly and finishing, final inspections ensure that the hinge latches meet all specifications before they are shipped.

These checkpoints help maintain high-quality standards throughout the manufacturing process.

What Testing Methods Are Commonly Used?

Common testing methods for hinge latches include tensile testing, corrosion resistance testing, and functional testing. Tensile testing measures the strength of materials, while corrosion tests evaluate how well the finish holds up under various environmental conditions. Functional testing ensures that the latch operates smoothly and reliably under intended use conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable strategies:

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is an effective way to assess quality control processes. Buyers should request documentation of past audits, including results and corrective actions taken by the supplier. This transparency helps buyers understand the supplier’s commitment to maintaining quality standards.

How Can Buyers Utilize Quality Control Reports?

Requesting regular quality control reports can provide insights into the supplier’s performance over time. These reports should detail inspection results, non-conformance issues, and resolutions, allowing buyers to evaluate the supplier’s reliability and responsiveness to quality concerns.

Should Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages, including material sourcing, in-process checks, and final inspections, ensuring that the product meets the necessary specifications before shipment.

What Are the Unique Challenges for International B2B Buyers?

International B2B buyers face specific challenges when sourcing hinge latches. Understanding regional standards, regulations, and potential language barriers can complicate the procurement process. Buyers should familiarize themselves with local market conditions and compliance requirements to navigate these challenges effectively.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for hinge latches enables B2B buyers to make informed purchasing decisions. By assessing the manufacturing stages, quality standards, and verification methods, buyers can ensure they select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge latch’

Introduction

Sourcing hinge latches can be a complex task, especially for international B2B buyers. This guide aims to simplify the procurement process by outlining essential steps to ensure you select the right products for your business needs. Following this checklist will help you make informed decisions, reduce risks, and establish strong supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for hinge latches. Consider factors such as size, material (e.g., stainless steel or plain steel), and load capacity. Specificity in your requirements will help you communicate effectively with suppliers and ensure the products meet your operational standards.

- Consider application: Identify whether the hinge latches will be used in heavy-duty applications or light-duty scenarios.

- Include standards: Reference any industry standards or certifications that the hinge latches must comply with.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in hinge latches. Utilize online directories, trade shows, and industry associations to compile a list of candidates.

- Evaluate reputation: Look for suppliers with positive reviews and a strong track record in the industry.

- Check product range: Ensure they offer a variety of hinge latch options that align with your specifications.

Step 3: Evaluate Supplier Certifications

Before finalizing your choice, verify the certifications and quality standards of your potential suppliers. Certifications such as ISO 9001 indicate a commitment to quality management.

Illustrative image related to hinge latch

- Request documentation: Ask suppliers for copies of their certifications and quality assurance processes.

- Assess compliance: Ensure their products comply with relevant safety and environmental regulations in your target market.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the hinge latches you are interested in. Testing samples allows you to assess the quality and performance of the products before making a bulk purchase.

- Conduct performance tests: Evaluate the durability, ease of installation, and functionality of the samples in real-world conditions.

- Gather feedback: Involve your engineering or maintenance teams in the testing process to gain insights on usability.

Step 5: Compare Pricing and Terms

After testing the samples, compare the pricing and terms offered by different suppliers. Consider not only the unit price but also factors such as shipping costs, payment terms, and bulk order discounts.

- Negotiate pricing: Don’t hesitate to negotiate terms to achieve the best possible deal.

- Assess total cost of ownership: Factor in long-term costs, including maintenance and potential replacements, when evaluating pricing.

Step 6: Establish Clear Communication Channels

Effective communication is key to successful procurement. Establish clear lines of communication with your chosen supplier to facilitate smooth transactions.

- Define points of contact: Identify key personnel on both sides responsible for order management and issue resolution.

- Set expectations: Clearly outline timelines for delivery, order changes, and responses to inquiries to avoid misunderstandings.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with the supplier and terms, finalize the purchase agreement. Ensure that all specifications, pricing, and delivery timelines are clearly documented.

- Review legal terms: Consider having legal counsel review the agreement to protect your interests.

- Confirm order details: Double-check all details before placing the order to prevent costly errors.

By following these steps, B2B buyers can streamline the sourcing process for hinge latches, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for hinge latch Sourcing

What Are the Key Cost Components in Hinge Latch Sourcing?

When sourcing hinge latches, several cost components must be taken into account. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice between plain steel and stainless steel significantly affects costs. Stainless steel latches, known for their durability and corrosion resistance, are typically more expensive than their plain steel counterparts. Custom finishes, such as zinc plating, also add to the material costs.

-

Labor: Labor costs vary based on the production location and the complexity of the latch design. Regions with lower labor costs may offer more competitive pricing, but this could come at the expense of quality or lead time.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. High overhead can lead to increased unit prices, particularly in regions with stringent labor laws or environmental regulations.

-

Tooling: Custom tooling for unique latch designs can be a significant upfront cost. Buyers should be prepared for these costs, especially if ordering specialized or bespoke products.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to overall costs. Certifications such as ISO can further increase prices but provide assurance regarding product reliability.

-

Logistics: Shipping costs can vary dramatically based on distance, shipping methods, and the terms of delivery (Incoterms). International buyers should factor in potential tariffs and customs fees, which can significantly impact the final cost.

-

Margin: Suppliers typically include a profit margin that can vary based on their market positioning, reputation, and the competitiveness of their offerings.

How Do Price Influencers Impact Hinge Latch Costs?

Several factors influence the pricing of hinge latches in the B2B market:

-

Volume/MOQ: Bulk orders often lead to discounts due to economies of scale. Suppliers may have Minimum Order Quantities (MOQs) that can affect pricing strategies, especially for international buyers who may face higher shipping costs on smaller orders.

-

Specifications and Customization: Custom designs or specific performance specifications can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses during production.

-

Materials: The type and quality of materials chosen will directly impact the price. Buyers should evaluate the long-term benefits of investing in higher-quality materials against initial costs.

-

Quality and Certifications: Products with recognized certifications may command higher prices due to perceived reliability and performance. International buyers should verify the certifications relevant to their markets.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can also affect pricing. Established suppliers may charge a premium for their expertise and customer support.

-

Incoterms: Understanding the implications of Incoterms is crucial for international transactions. Different terms can affect who bears the shipping costs and risks, influencing the total landed cost of hinge latches.

What Are Effective Buyer Tips for Cost-Efficient Hinge Latch Sourcing?

To maximize cost-efficiency when sourcing hinge latches, buyers should consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Building a long-term relationship may also yield favorable terms.

-

Total Cost of Ownership (TCO): Analyze not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality products can reduce overall costs over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, shipping delays, and international tariffs that can affect pricing. Ensure that the total cost includes all potential charges to avoid surprises.

-

Research and Compare Suppliers: Take the time to evaluate multiple suppliers, considering not just price but also quality, service, and delivery capabilities.

Buyers should remain vigilant in understanding these cost components and pricing influencers to make informed decisions that align with their procurement strategies.

Alternatives Analysis: Comparing hinge latch With Other Solutions

Exploring Alternative Solutions to Hinge Latch Systems

When considering the best hardware solutions for doors, gates, or lids, hinge latches are a popular choice due to their versatility and ease of use. However, various alternatives may better suit specific applications, particularly for international B2B buyers seeking efficiency and cost-effectiveness. This section will delve into viable alternatives to hinge latches, comparing their performance, costs, ease of implementation, maintenance requirements, and ideal use cases.

| Comparison Aspect | Hinge Latch | Sliding Bolt Lock | Cam Lock |

|---|---|---|---|

| Performance | Reliable for quick access | Provides strong security | Quick locking mechanism |

| Cost | Moderate cost | Generally lower cost | Low cost |

| Ease of Implementation | Simple installation | Requires precise alignment | Easy to install |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | General use in varied environments | High-security applications | Furniture and cabinets |

What Are the Advantages and Disadvantages of Using Sliding Bolt Locks?

Sliding bolt locks offer a robust alternative to hinge latches, particularly in high-security applications. They provide an enhanced level of security by allowing a bolt to slide into a fixed position, thereby locking the door or gate securely. This mechanism is ideal for environments where unauthorized access must be restricted, such as warehouses or storage units. The initial cost of sliding bolt locks can be lower than hinge latches; however, they require precise alignment during installation and may demand more maintenance over time due to wear and tear on the sliding mechanism.

How Do Cam Locks Compare to Hinge Latches?

Cam locks are another alternative that provides a different locking mechanism than hinge latches. They are particularly suited for furniture and cabinets, offering a quick and efficient way to secure items without the bulk of larger locks. Cam locks are generally less expensive and easy to install, making them a popular choice for lighter applications. However, they may not provide the same level of security as hinge latches or sliding bolt locks, making them less suitable for high-risk environments. Their maintenance is also minimal, appealing to buyers looking for low-effort solutions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right hardware solution ultimately depends on the specific requirements of the application. B2B buyers should assess factors such as the level of security needed, the frequency of use, and the installation environment. For instance, if quick access and moderate security are priorities, hinge latches may be ideal. Conversely, for applications requiring high security, sliding bolt locks would be more suitable. Lastly, for furniture or cabinetry where ease of use and cost are paramount, cam locks present an attractive option. By weighing these considerations, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for hinge latch

What are the Key Technical Properties of Hinge Latches?

In the B2B sector, understanding the technical specifications of hinge latches is crucial for making informed purchasing decisions. Here are several essential properties to consider:

1. Material Composition

Hinge latches are commonly made from materials such as plain steel or stainless steel. Plain steel is often less expensive but may require additional coatings to resist corrosion, while stainless steel offers superior durability and resistance to rust, making it suitable for outdoor or marine applications. Choosing the right material ensures longevity and performance, especially in harsh environments.

2. Load Capacity

The load capacity of a hinge latch indicates the maximum weight it can support without failure. This specification is vital for applications involving heavy doors or lids. Buyers should assess the expected load to select a latch that can handle the demands of their specific use case, thereby avoiding potential failures and safety hazards.

3. Pin Diameter

The diameter of the pin used in the latch mechanism affects both strength and compatibility with existing hardware. A larger pin diameter generally provides better support and stability, while a smaller diameter may allow for easier installation in tight spaces. Understanding this measurement helps ensure that the chosen hinge latch integrates seamlessly with existing systems.

4. Thickness and Width

The thickness and width of a hinge latch influence its durability and application suitability. Thicker latches are often required for heavy-duty applications, while thinner variants may be suitable for lighter tasks. Buyers should match these dimensions with the specific requirements of their projects to ensure optimal functionality.

5. Finish Type

The finish of a hinge latch, such as zinc plating or powder coating, affects its resistance to corrosion and wear. A finish not only enhances aesthetic appeal but also extends the life of the latch. Buyers should consider environmental factors when selecting a finish, ensuring that it aligns with the operational setting of the latch.

What are Common Trade Terms Related to Hinge Latches?

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking custom hinge latches or components that fit specific machinery or systems.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is significant for businesses looking to manage inventory costs while ensuring they meet supplier requirements for purchase. Knowing the MOQ can help buyers plan their orders and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. It is an essential step in the procurement process, allowing buyers to compare pricing and terms from multiple vendors, ultimately aiding in cost-effective decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is crucial for avoiding disputes and ensuring smooth logistics, especially when sourcing hinge latches from different regions.

5. Lead Time

Lead time is the duration between placing an order and receiving the product. For businesses, understanding lead times is vital for project planning and inventory management. Suppliers that provide clear lead time information can help buyers align their procurement with production schedules.

Being informed about these technical properties and trade terms enables B2B buyers to make better purchasing decisions, ensuring that they select hinge latches that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the hinge latch Sector

What Are the Key Trends Influencing the Global Hinge Latch Market?

The global hinge latch market is experiencing notable growth driven by various factors, including rising demand for robust and versatile fastening solutions across multiple industries. Key sectors such as automotive, construction, and marine are increasingly adopting hinge latches for their durability and ease of use. In regions like Africa and South America, infrastructure development and urbanization are spurring demand, while in Europe and the Middle East, a shift towards high-quality materials, such as stainless steel, is evident.

Emerging technologies are also shaping sourcing trends. The integration of e-commerce platforms allows B2B buyers to access a broader range of suppliers and products, enhancing transparency and competitive pricing. Additionally, the use of digital tools for inventory management and supply chain optimization is becoming increasingly prevalent, enabling companies to respond quickly to market changes. The trend toward customization is growing, with suppliers offering bespoke solutions to meet specific client needs, thereby enhancing customer satisfaction.

International buyers must remain vigilant about market dynamics, including fluctuations in raw material costs and supply chain disruptions. Understanding regional market nuances, such as regulatory requirements and local consumer preferences, is critical for successful sourcing strategies.

How Is Sustainability Shaping Sourcing Decisions in the Hinge Latch Sector?

Sustainability is a pivotal consideration for B2B buyers in the hinge latch sector. The environmental impact of manufacturing processes and materials used in hinge latches is garnering increasing scrutiny. Buyers are now more inclined to partner with suppliers who prioritize sustainable practices, such as reducing waste, utilizing recyclable materials, and implementing energy-efficient manufacturing methods.

Ethical sourcing has become a key focus, with buyers seeking suppliers that adhere to fair labor practices and maintain transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming benchmarks for suppliers aiming to demonstrate their commitment to sustainability.

The demand for ‘green’ materials, including recycled metals and eco-friendly coatings, is on the rise. By opting for sustainable products, B2B buyers can enhance their brand reputation and meet the growing expectations of environmentally conscious consumers. This shift towards sustainability not only benefits the planet but also aligns with long-term business viability.

What Is the Historical Context of Hinge Latch Development Relevant to Today’s Market?

The hinge latch has evolved significantly since its inception, transitioning from simple mechanical devices to sophisticated components engineered for specific applications. Historically, hinge latches were primarily made from wood or basic metals, serving basic functions in domestic settings. However, as industrialization progressed, the demand for more durable and versatile latch solutions emerged.

The introduction of materials such as stainless steel and advanced composites in the late 20th century revolutionized the hinge latch market, offering enhanced strength, corrosion resistance, and aesthetic appeal. This evolution has been critical for sectors like automotive and marine, where performance and reliability are paramount.

In recent years, the focus has shifted towards customization and technological integration, allowing for the development of latch hinges with features like quick-disconnect mechanisms and spring-loaded designs. This historical context underscores the importance of innovation in meeting the diverse needs of today’s international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of hinge latch

-

How do I solve issues with hinge latch durability in extreme environments?

To ensure hinge latches withstand harsh conditions, consider materials like stainless steel or galvanized steel, which resist corrosion and wear. Additionally, assess the latch’s design for factors like load capacity and weather resistance. Regular maintenance, including lubrication and inspection for signs of wear, will also prolong the lifespan of the latches. When sourcing, inquire about the supplier’s quality assurance processes and any certifications that guarantee the product’s reliability in specific environmental conditions. -

What is the best type of hinge latch for heavy-duty applications?

For heavy-duty applications, look for latch hinges specifically designed for high load-bearing capacities. Heavy-duty latch hinges made from stainless steel or reinforced plain steel are ideal, as they provide superior strength and durability. Features such as holdback mechanisms can also enhance functionality by allowing the hinge to remain open securely. When selecting a supplier, ensure they offer a range of options and can provide data on load ratings to meet your specific needs. -

How can I ensure the quality of hinge latches before purchase?

To verify the quality of hinge latches, request samples from potential suppliers before placing a bulk order. Review their quality assurance certifications and manufacturing processes. Additionally, ask for references or customer testimonials to gauge satisfaction from other B2B buyers. Consider third-party quality audits for larger orders, and ensure the supplier has a clear return policy to address any defects or issues that may arise post-purchase. -

What are the typical minimum order quantities (MOQs) for hinge latches?

Minimum order quantities for hinge latches can vary significantly by supplier, ranging from a few dozen to several thousand units. It’s essential to confirm MOQs when negotiating terms with suppliers, especially if you are testing a new product line or entering a market. Some suppliers may offer flexible MOQs for custom orders, while others might have strict policies based on their production capabilities. Discussing your specific needs can lead to more favorable terms. -

What payment terms should I expect when sourcing hinge latches internationally?

Payment terms can vary widely among international suppliers, but common options include advance payment, net 30, or net 60 days post-delivery. It is advisable to negotiate terms that balance your cash flow needs with the supplier’s requirements. Be cautious of suppliers demanding full payment upfront, especially if you are new to them. Utilizing secure payment methods, such as letters of credit or escrow services, can also protect your investment in international transactions. -

How can I vet suppliers for hinge latches in international markets?

To vet suppliers, conduct thorough research, including checking their business licenses, certifications, and customer reviews. Utilize platforms like Alibaba or ThomasNet for background checks. Request references and speak with previous clients about their experiences. Additionally, consider visiting the supplier’s facility if possible or using third-party inspection services to verify their production capabilities and quality standards before placing a significant order. -

What logistics considerations should I keep in mind when importing hinge latches?

When importing hinge latches, consider shipping methods, lead times, and customs regulations in your country. Opt for reliable freight forwarders who understand your target market’s import requirements. Be aware of tariffs or duties that may apply and factor these into your total cost. Additionally, ensure that the supplier provides appropriate documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. -

Can hinge latches be customized for specific applications?

Yes, many suppliers offer customization options for hinge latches, including variations in size, material, finish, and additional features like locking mechanisms or specific load capacities. When seeking customization, provide detailed specifications to the supplier to ensure that your requirements are met. Be prepared for potential lead times and costs associated with custom orders, and confirm that the supplier has experience in producing tailored solutions for similar applications.

Top 3 Hinge Latch Manufacturers & Suppliers List

1. Austin Hardware – Spring Hinge

Domain: austinhardware.com

Introduction: Products: Latch Hinges

Materials: 304 Stainless Steel, Cold Rolled Steel, Stainless Steel, Steel, Steel Zinc Plated

Hand: Left Hand, Right Hand

Pin Diameter: 0.5″, 0.18″, 0.25″, 0.375″

Mounting: Mounting holes, Weld-On

Finish: Zinc Plated

Product Listings:

1. Part# AH 1425R – Spring Hinge, Right Hand, Zinc – MSRP: $1.4500

2. Part# AH 1425L – Spring Hinge, Left Hand, Zinc – MSRP: $1.3200

3. Part# A…

2. Hinge and Latch – Key Product

Domain: hingeandlatch.com

Registered: 2010 (15 years)

Introduction: Key Product Details:

– Product Types: Gate Hardware, Gate Hinges, Gate Latches, Gate Hangers, Cane Bolts, Gate Stops, Gate Springs, Handles, Cabin Hooks, Hasps, Landscape Chain, Accessories.

– Designs: Antique, Traditional, Contemporary, European inspired.

– Materials: Steel, Aluminum, Grade 304 Stainless Steel, Marine Grade 316 Stainless Steel.

– Finishes: Hot Dipped Galvanized (HDG), Black P…

3. Fixtureworks – Custom Industrial Hinges & Latches

Domain: fixtureworks.com

Introduction: Custom Industrial Hinge & Latch Manufacturer – Fixtureworks

Strategic Sourcing Conclusion and Outlook for hinge latch

In the dynamic landscape of hinge latch procurement, strategic sourcing emerges as a critical factor for success. International B2B buyers must prioritize understanding the diverse range of latch hinge options available, including materials, sizes, and customizations that suit specific applications. Recognizing the differences between plain steel and stainless steel options can significantly impact durability and performance, especially in industries facing harsh environmental conditions.

Moreover, fostering relationships with reliable suppliers can enhance supply chain resilience, ensuring timely deliveries and competitive pricing. Engaging in strategic sourcing not only reduces costs but also aligns purchasing decisions with long-term operational goals, enabling businesses to adapt to market fluctuations efficiently.

As we look ahead, the demand for high-quality, versatile hinge latches will continue to rise, particularly in emerging markets across Africa and South America, as well as established sectors in Europe and the Middle East. Buyers are encouraged to leverage this opportunity by exploring innovative sourcing strategies, investing in supplier partnerships, and staying abreast of market trends. By doing so, they will position themselves to gain a competitive edge in their respective industries.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.