Top 3 Extrusions Fort Scott Ks Suppliers (And How to Choose)

Introduction: Navigating the Global Market for extrusions fort scott ks

Navigating the global market for aluminum extrusions from Fort Scott, KS, presents a unique challenge for international B2B buyers. Sourcing high-quality, custom aluminum extrusions that meet specific project requirements can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, such as those in Nigeria and Germany. This comprehensive guide aims to demystify the process by providing insights into the diverse types of extrusions available, their applications across various industries, and key factors to consider when selecting suppliers.

As you explore this guide, you will gain a deeper understanding of the intricate details involved in sourcing aluminum extrusions. From recognizing the importance of material quality and manufacturing processes to evaluating supplier capabilities and cost structures, each section is designed to equip you with the knowledge necessary for informed purchasing decisions.

Additionally, we will cover the essential aspects of supplier vetting, including quality control measures and the significance of customer service in the extrusion industry. By leveraging this guide, B2B buyers can confidently navigate the complexities of sourcing aluminum extrusions, ensuring that their projects are supported by reliable, high-quality products tailored to their specific needs. Let’s embark on this journey to streamline your procurement process and enhance your competitive edge in the global marketplace.

Understanding extrusions fort scott ks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Extrusions | Pre-designed profiles, widely available, cost-effective | General manufacturing, construction | Pros: Affordable, readily available. Cons: Limited customization options. |

| Custom Profiles | Tailored shapes based on specific client specifications | Specialized machinery, architectural | Pros: High adaptability, meets unique needs. Cons: Longer lead times, potentially higher costs. |

| Tubes and Pipes | Hollow structures for fluid transport or structural applications | HVAC systems, plumbing, automotive | Pros: Lightweight, versatile. Cons: May require additional processing for specific applications. |

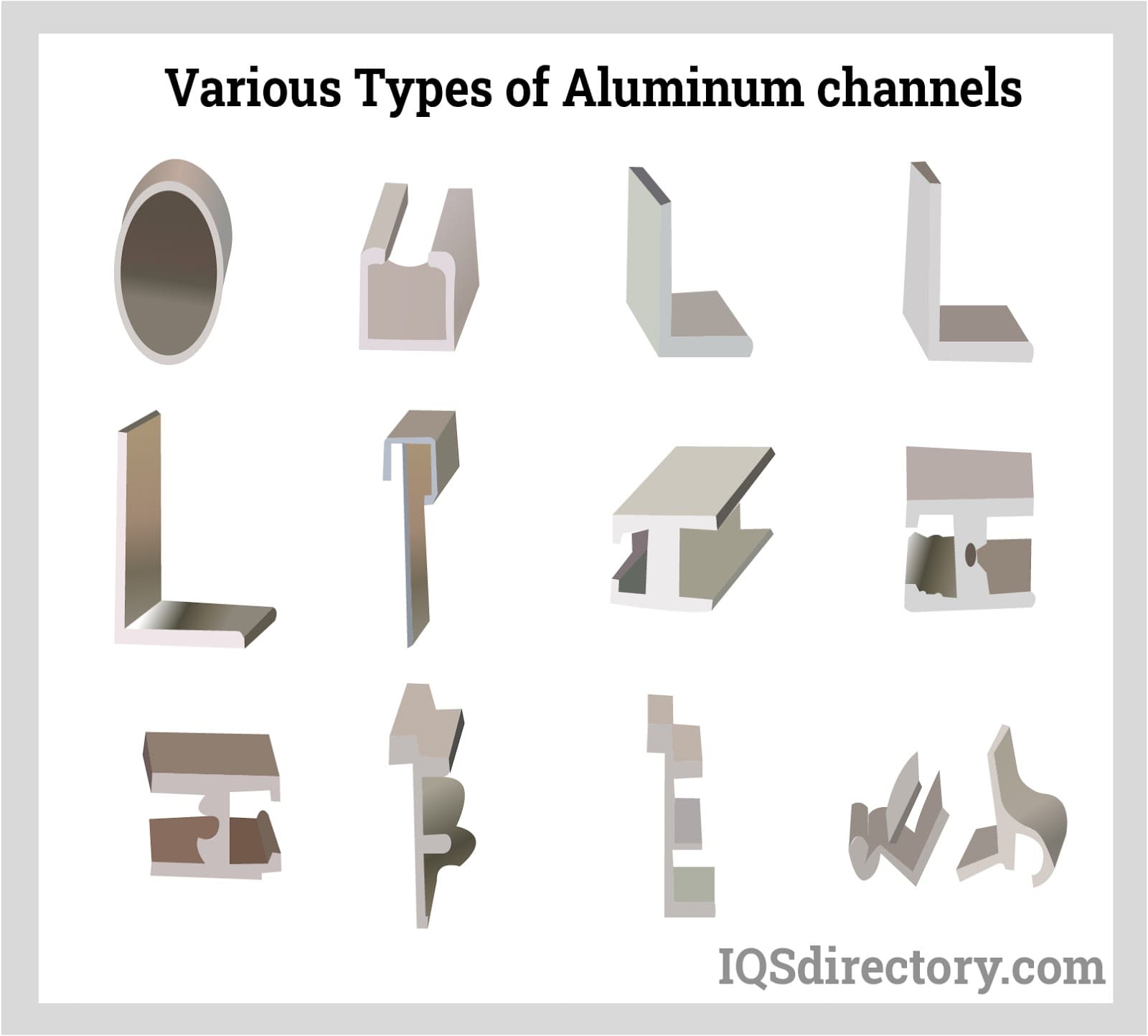

| Angles and Channels | L-shaped and U-shaped profiles for support and framing | Structural support, frames, brackets | Pros: Strong and stable, easy to work with. Cons: Less aesthetic appeal for visible applications. |

| Bars and Rods | Solid profiles for various industrial uses | Manufacturing, fabrication, tooling | Pros: Durable, versatile. Cons: Heavier than hollow profiles, may require more material. |

What Are Standard Extrusions and Their Applications?

Standard extrusions are pre-designed aluminum profiles that are mass-produced, making them a cost-effective choice for many businesses. They are typically available in various lengths and thicknesses, suited for a range of applications such as general manufacturing and construction. Buyers appreciate the quick turnaround and affordability, though the trade-off is limited customization, which may not fit specialized project requirements.

How Do Custom Profiles Enhance Project Flexibility?

Custom profiles are designed specifically to meet unique client specifications, allowing for high adaptability in projects. These extrusions can accommodate intricate designs and specific functional needs, making them ideal for specialized machinery and architectural applications. While they provide tailored solutions, buyers should consider longer lead times and potentially higher costs compared to standard options. Ensuring clear communication of requirements during the design phase is essential for optimal results.

What Are the Key Uses of Tubes and Pipes in Industry?

Tubes and pipes are hollow aluminum structures that serve critical roles in fluid transport and structural applications. They are lightweight yet strong, making them suitable for HVAC systems, plumbing, and automotive components. Buyers benefit from their versatility; however, additional processing may be required for certain applications, which could affect project timelines and costs. Understanding the specific requirements for fluid dynamics or structural integrity is crucial when selecting these extrusions.

Why Choose Angles and Channels for Structural Support?

Angles and channels are L-shaped and U-shaped profiles used primarily for support and framing in various constructions. Their robust design offers stability for structural applications such as frames and brackets. Buyers appreciate their ease of use and strength, but they may lack aesthetic appeal for projects where visibility is a concern. It’s important to balance functional requirements with design considerations when incorporating these profiles into projects.

What Advantages Do Bars and Rods Offer for Manufacturing?

Bars and rods are solid aluminum profiles utilized across various industrial applications, including manufacturing, fabrication, and tooling. Their durability and versatility make them a reliable choice for many projects. However, they tend to be heavier than hollow profiles, which may increase material costs. Buyers should weigh the benefits of strength and durability against the logistical considerations of handling and transportation when opting for these extrusions.

Key Industrial Applications of extrusions fort scott ks

| Industry/Sector | Specific Application of extrusions fort scott ks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural frameworks for buildings and facades | Enhanced strength-to-weight ratio and design flexibility | Compliance with local building codes and standards |

| Automotive | Lightweight components for vehicles | Improved fuel efficiency and performance | Material certification and adherence to automotive standards |

| Renewable Energy | Solar panel frames and mounting systems | Durability and corrosion resistance | Customization for specific solar panel designs |

| Electronics | Heat sinks and enclosures for electronic devices | Efficient thermal management and protection | Precision in dimensions and surface finish requirements |

| Transportation & Logistics | Rail and truck chassis components | Increased load capacity and reduced wear | Supply chain reliability and lead time considerations |

How Are Extrusions Used in the Construction Industry?

In the construction sector, extrusions from Fort Scott, KS, are extensively used to create structural frameworks and facades for buildings. The lightweight nature of aluminum extrusions allows for innovative architectural designs while providing the necessary strength and stability. International buyers, particularly from regions like Europe and the Middle East, must ensure that the extrusions comply with local building codes and standards to avoid project delays and regulatory issues.

What Role Do Extrusions Play in the Automotive Sector?

Aluminum extrusions are vital in the automotive industry, where they are used to manufacture lightweight components that enhance fuel efficiency and vehicle performance. With the global push towards sustainability, automakers are increasingly relying on these materials to reduce overall vehicle weight. Buyers from Africa and South America should prioritize sourcing suppliers who can provide certified materials that meet automotive standards to ensure product safety and compliance.

How Are Extrusions Beneficial in Renewable Energy Applications?

In the renewable energy sector, particularly in solar energy, extrusions are utilized to create frames and mounting systems for solar panels. These extrusions offer durability and resistance to environmental factors, ensuring long-lasting performance. Buyers must consider customization options to fit specific solar panel designs and ensure that the extrusions can withstand local weather conditions, which varies significantly across regions like Africa and Europe.

Why Are Extrusions Important in Electronics Manufacturing?

Extrusions are critical in the electronics industry, where they are used for heat sinks and enclosures that protect sensitive components. The efficient thermal management provided by aluminum extrusions is essential for maintaining device performance and longevity. When sourcing extrusions for electronics, international buyers should focus on precision in dimensions and surface finish, as these factors directly impact the efficiency of heat dissipation.

How Do Extrusions Enhance Transportation and Logistics?

In transportation and logistics, extrusions are used to manufacture components for rail and truck chassis, providing increased load capacity and reducing wear over time. The lightweight yet robust nature of aluminum helps in optimizing fuel consumption and enhancing overall vehicle performance. Buyers should evaluate the reliability of the supply chain and lead times when sourcing these components to ensure timely delivery and operational efficiency.

3 Common User Pain Points for ‘extrusions fort scott ks’ & Their Solutions

Scenario 1: Navigating Complex Customization Requests for Aluminum Extrusions

The Problem: In many industries, the need for customized aluminum extrusions is critical. B2B buyers often face the challenge of articulating their unique specifications to suppliers, which can lead to miscommunication and ultimately result in products that do not meet their needs. This scenario is especially prevalent when dealing with intricate designs or specific functional requirements. Buyers may struggle to convey the precise dimensions, tolerances, and finishes required, leading to delays in production and additional costs.

The Solution: To mitigate this issue, B2B buyers should take a proactive approach by developing a detailed specification document that outlines all critical parameters of the aluminum extrusions needed. This should include dimensions, tolerances, alloy types, surface finishes, and any secondary operations such as machining or anodizing. Furthermore, collaborating closely with the engineering team at the extrusion provider, such as Extrusions Inc. in Fort Scott, KS, can facilitate a more straightforward communication process. Utilizing 3D modeling software to create visual representations of the desired product can bridge the gap between the buyer’s needs and the manufacturer’s capabilities. This level of detail not only ensures clarity but also fosters a collaborative relationship with the supplier, leading to a more successful outcome.

Scenario 2: Overcoming Lead Time Challenges in Global Supply Chains

The Problem: B2B buyers often operate under tight deadlines, and lead time can be a significant concern, particularly when sourcing aluminum extrusions from suppliers like those in Fort Scott, KS. Delays in production or shipping can disrupt entire project timelines, resulting in missed deadlines and financial penalties. This is especially true for international buyers who must account for additional shipping times, customs clearance, and potential delays at ports.

Illustrative image related to extrusions fort scott ks

The Solution: To address lead time issues, buyers should engage in proactive supply chain management. This involves establishing clear timelines with the supplier, discussing production capabilities, and understanding their capacity for handling urgent orders. It is beneficial to maintain open lines of communication regarding any potential delays and to explore options for expedited shipping if necessary. Additionally, building a long-term relationship with a reliable supplier can enhance responsiveness and flexibility. Buyers should also consider maintaining a buffer stock of critical extrusions to mitigate the impact of unexpected delays. Implementing these strategies can significantly enhance the reliability of the supply chain and help maintain project schedules.

Scenario 3: Ensuring Quality and Compliance in Aluminum Extrusions

The Problem: Quality assurance is paramount when sourcing aluminum extrusions, as subpar materials can lead to product failures and significant liability issues. B2B buyers must ensure that their suppliers adhere to industry standards and regulations, particularly when exporting products to markets in Europe, Africa, or the Middle East, where compliance requirements can vary significantly. The challenge lies in verifying that the supplier’s manufacturing processes meet these stringent standards.

The Solution: Buyers should conduct thorough due diligence on potential suppliers, including reviewing their quality control processes and certifications. Asking for documentation regarding material specifications, testing protocols, and compliance with relevant industry standards (such as ISO certifications) is essential. Additionally, buyers may consider visiting the manufacturing facility in Fort Scott, KS, to observe operations firsthand and assess quality control measures. Establishing a clear agreement on quality expectations and conducting routine audits can further ensure compliance and performance. Utilizing third-party inspection services can also provide an additional layer of assurance, helping to safeguard against quality issues before products are shipped. By prioritizing quality and compliance from the outset, B2B buyers can significantly reduce the risk of costly errors and enhance their overall supply chain reliability.

Strategic Material Selection Guide for extrusions fort scott ks

What Are the Key Materials for Aluminum Extrusions in Fort Scott, KS?

When selecting materials for aluminum extrusions, it is essential to consider the specific properties, advantages, and limitations of various aluminum alloys. This analysis focuses on four common materials used in aluminum extrusions, providing insights that are particularly relevant to international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Which Aluminum Alloys Are Commonly Used for Extrusions?

6061 Aluminum Alloy

Key Properties:

6061 aluminum alloy is known for its excellent mechanical properties and good corrosion resistance. It has a temperature rating of up to 150°C (302°F) and can withstand moderate pressure, making it suitable for a variety of applications.

Illustrative image related to extrusions fort scott ks

Pros & Cons:

This alloy is versatile, offering good weldability and machinability. However, it can be more expensive than other alloys and may require additional finishing processes, which can increase manufacturing complexity.

Impact on Application:

6061 is ideal for structural applications, automotive components, and marine environments due to its corrosion resistance. It is compatible with various media, including water and mild chemicals.

Considerations for International Buyers:

Compliance with ASTM standards is crucial, as many countries have specific regulations regarding material properties. Buyers in Europe may prefer materials that meet DIN standards, while those in Africa and South America should ensure compliance with local regulations.

Illustrative image related to extrusions fort scott ks

6063 Aluminum Alloy

Key Properties:

6063 aluminum alloy is characterized by its excellent extrudability and surface finish. It has a lower strength compared to 6061 but offers superior corrosion resistance and a temperature rating of up to 100°C (212°F).

Pros & Cons:

The primary advantage of 6063 is its aesthetic appeal, making it suitable for architectural applications. However, its lower strength may limit its use in high-stress environments, and it can be more costly due to its finishing requirements.

Impact on Application:

This alloy is commonly used in window frames, door frames, and other architectural applications. It is particularly compatible with coatings and anodizing processes, enhancing its durability.

Considerations for International Buyers:

Buyers should be aware of the varying standards for architectural applications in different regions. Compliance with local building codes and standards, such as JIS in Japan, may be necessary.

Illustrative image related to extrusions fort scott ks

7075 Aluminum Alloy

Key Properties:

7075 aluminum alloy is known for its high strength-to-weight ratio and is often used in aerospace and military applications. It has a temperature rating of up to 120°C (248°F) and excellent fatigue resistance.

Pros & Cons:

While 7075 offers superior strength, it is more challenging to work with and has lower corrosion resistance compared to other alloys. This can lead to higher manufacturing costs and complexity.

Impact on Application:

This alloy is ideal for applications requiring high strength, such as aircraft components and high-stress structural parts. However, it may not be suitable for environments with high corrosion potential.

Illustrative image related to extrusions fort scott ks

Considerations for International Buyers:

Compliance with aerospace standards is critical for buyers in this sector. Buyers should ensure that suppliers can meet stringent quality control measures, particularly in regions with rigorous aerospace regulations.

5005 Aluminum Alloy

Key Properties:

5005 aluminum alloy is known for its excellent anodizing response and good corrosion resistance. It has a temperature rating of up to 150°C (302°F) and is suitable for various applications.

Pros & Cons:

The alloy offers good weldability and is less expensive than high-strength alloys. However, it may not provide the same level of strength as 6061 or 7075, which could limit its use in demanding applications.

Impact on Application:

5005 is often used in decorative applications, signage, and architectural features due to its aesthetic qualities. It is compatible with a range of media, including water and mild chemicals.

Illustrative image related to extrusions fort scott ks

Considerations for International Buyers:

International buyers should check for compliance with local anodizing standards and ensure that the alloy meets the requirements for their specific applications.

Summary Table of Material Selection for Extrusions in Fort Scott, KS

| Material | Typical Use Case for extrusions fort scott ks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 | Structural components, automotive parts | Good mechanical properties | Higher cost and complexity | Medium |

| 6063 | Architectural applications, window frames | Excellent surface finish | Lower strength than 6061 | Medium |

| 7075 | Aerospace and military applications | High strength-to-weight ratio | Difficult to work with, lower corrosion | High |

| 5005 | Decorative applications, signage | Excellent anodizing response | Lower strength compared to others | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various aluminum alloys, helping them make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for extrusions fort scott ks

What Are the Main Stages of the Manufacturing Process for Aluminum Extrusions?

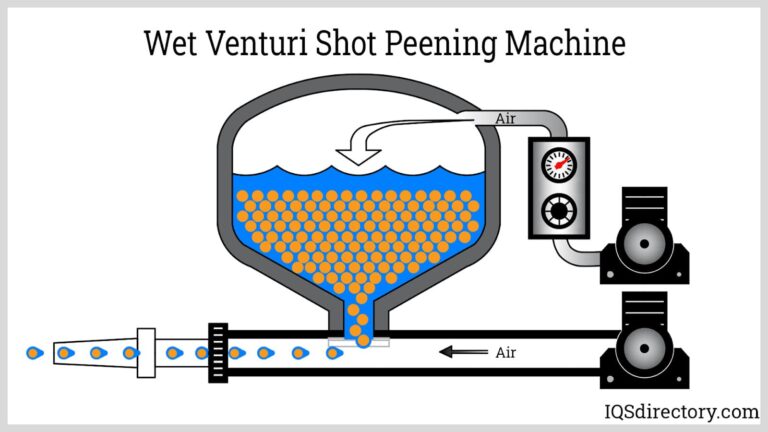

The manufacturing process for aluminum extrusions involves several critical stages, each designed to ensure the highest quality and precision. This process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality aluminum alloys that meet specific mechanical properties and performance requirements. These alloys are usually sourced from certified suppliers to ensure consistency. The aluminum billets are then heated to a precise temperature, making them malleable for the extrusion process.

-

Forming: Once the billets are ready, they are placed into an extrusion press, where they are forced through a die to create the desired shape. This forming stage is crucial as it directly influences the final product’s dimensions and surface finish. Advanced techniques, such as using a fully automated extrusion press, enhance the accuracy and efficiency of this process.

-

Assembly: After the extrusions are formed, they may undergo additional assembly processes. This could include cutting, drilling, or punching to meet specific customer requirements. The use of CNC machines during this stage allows for precise machining, ensuring that the extrusions fit seamlessly into the customer’s applications.

-

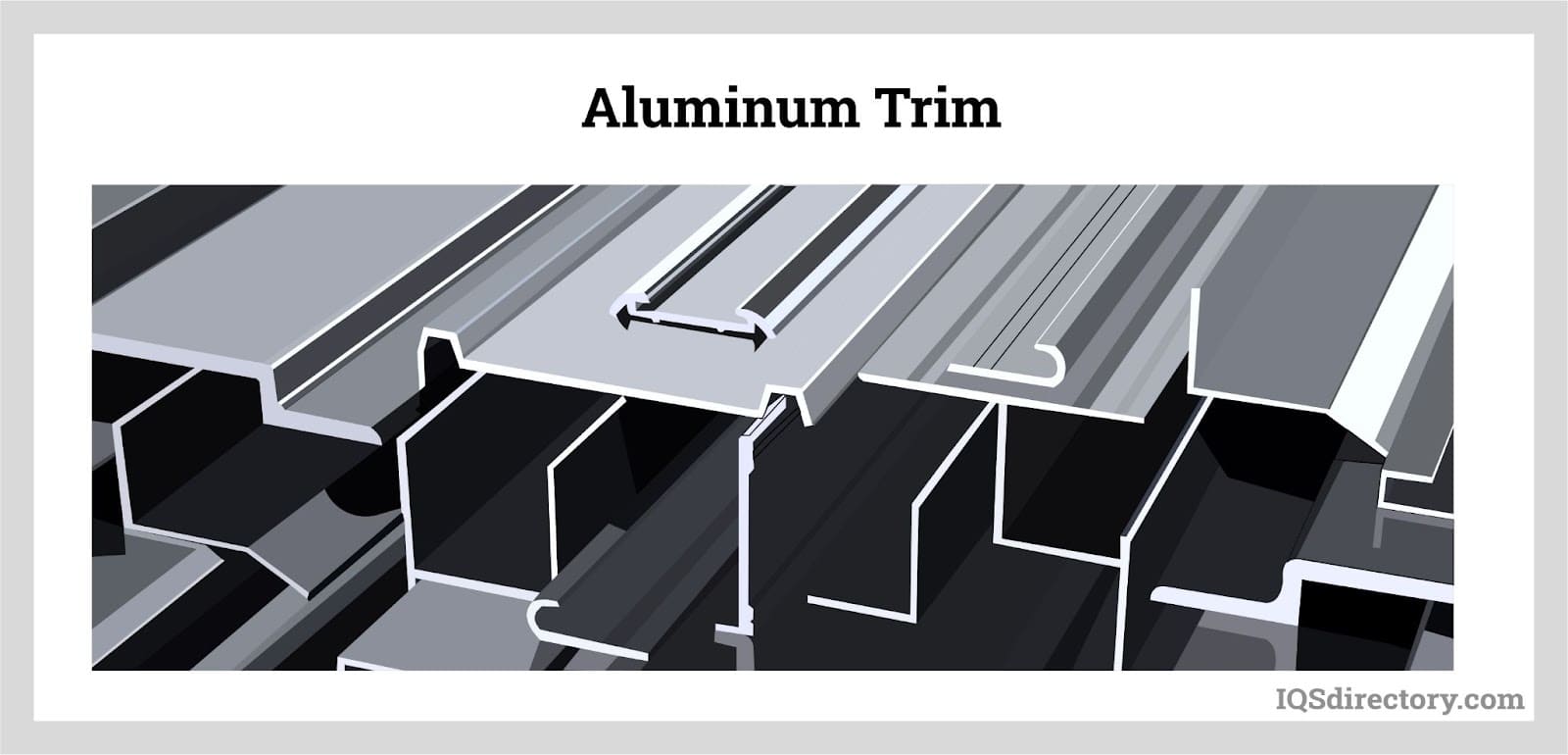

Finishing: The final stage involves surface treatments such as anodizing, powder coating, or other finishing processes to enhance durability and aesthetics. These treatments not only improve the visual appeal of the extrusions but also provide protection against corrosion and wear, which is particularly important for applications in demanding environments.

How Is Quality Assurance Implemented in the Manufacturing of Extrusions?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final products meet international and industry-specific standards. For B2B buyers, understanding the QA measures in place can provide confidence in the reliability and performance of the products.

-

International Standards: Many manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. Compliance with ISO 9001 signifies that the manufacturer has established processes to ensure consistent quality in their products and services. Additionally, industry-specific certifications such as CE marking or API standards may apply, depending on the intended use of the extrusions.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage verifies the quality of raw materials upon arrival, ensuring they meet the specified standards before production begins.

– In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the extrusion process, checking for dimensional accuracy and surface quality.

– Final Quality Control (FQC): Once the extrusions are completed, a thorough inspection is performed to ensure that all specifications have been met before shipment. -

Common Testing Methods: Various testing methods are employed to assess the quality of aluminum extrusions. These may include:

– Dimensional Inspection: Using calipers and gauges to measure the extrusions against specified tolerances.

– Mechanical Testing: Conducting tensile, yield, and hardness tests to ensure the extrusions meet strength requirements.

– Surface Finish Testing: Evaluating the surface treatment for uniformity and adherence.

How Can B2B Buyers Verify a Supplier’s Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product reliability.

-

Supplier Audits: Conducting on-site audits can provide invaluable insights into a supplier’s manufacturing processes and quality control practices. During these audits, buyers can assess the facility’s capabilities, review quality management systems, and observe production processes firsthand.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the testing methods used, results achieved, and any corrective actions taken in case of non-compliance. These reports should ideally align with international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s processes and product quality. This is particularly useful for buyers who may not have the resources to conduct audits themselves.

-

Certifications and Accreditations: Buyers should verify that suppliers hold relevant certifications that demonstrate compliance with international quality standards. This not only ensures product quality but also reflects the supplier’s commitment to maintaining high standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

Navigating the quality control landscape can be complex for international buyers, particularly those from diverse markets. Here are key nuances to consider:

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding product quality and compliance. Understanding these cultural nuances can aid in setting realistic expectations and fostering better communication with suppliers.

-

Regulatory Compliance: Different countries may have specific regulations that affect the manufacturing and importation of aluminum extrusions. Buyers should ensure that their suppliers are compliant with both local and international regulations to avoid legal complications.

-

Shipping and Handling: Quality assurance does not end at manufacturing; proper handling during shipping is crucial. Buyers should discuss packaging and transportation methods with suppliers to ensure that products arrive in pristine condition.

-

Post-Sale Support: Establishing a relationship with suppliers that includes robust post-sale support can help address any quality issues that arise after delivery. This may include warranty programs, return policies, and customer service support.

By understanding the manufacturing processes and quality assurance measures for aluminum extrusions in Fort Scott, KS, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their specific needs and standards.

Illustrative image related to extrusions fort scott ks

Practical Sourcing Guide: A Step-by-Step Checklist for ‘extrusions fort scott ks’

To assist B2B buyers in sourcing aluminum extrusions from Fort Scott, KS, this guide provides a structured checklist designed to streamline the procurement process. By following these steps, you can ensure that you partner with a reliable supplier that meets your specific needs for quality, customization, and service.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your aluminum extrusions is the first critical step. This includes dimensions, tolerances, alloy types, and any specific surface treatments required. A well-defined specification aids suppliers in providing accurate quotes and ensures that the final product meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers located in Fort Scott, KS, that specialize in aluminum extrusions. Look for companies with a strong reputation and extensive experience in the industry. Utilize online resources, trade directories, and industry associations to compile a list of potential candidates.

- Tip: Prioritize suppliers with a focus on custom solutions, as they are more likely to meet unique project requirements.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, evaluate the capabilities of each supplier. Inquire about their extrusion presses, fabrication services, and finishing options. A vertically integrated supplier, like Extrusions, Inc., can handle everything from extrusion to finishing in-house, which often leads to better quality control and shorter lead times.

- Consider: The range of services offered, such as CNC machining, anodizing, and powder coating, which can streamline your supply chain.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold relevant industry certifications and adhere to quality standards. Certifications such as ISO 9001 can provide assurance of their commitment to quality management. Additionally, check for compliance with environmental standards, particularly if sustainability is a priority for your organization.

- Action Item: Request copies of certifications and any quality assurance documentation.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the extrusions. This step allows you to assess the quality, finish, and overall suitability of the product for your application. It also provides an opportunity to verify the supplier’s responsiveness and willingness to collaborate on adjustments.

- Important: Ensure that samples align closely with your specified requirements to avoid discrepancies.

Step 6: Discuss Lead Times and Pricing

Engage in discussions regarding lead times and pricing structures with your shortlisted suppliers. Understand their production capacities and how they handle bulk orders versus one-time requests. Transparent communication about costs, including any additional fees for custom work or expedited shipping, is essential for budgeting.

Illustrative image related to extrusions fort scott ks

- Tip: Compare quotes from multiple suppliers to ensure competitive pricing without compromising quality.

Step 7: Establish Communication Protocols

Finally, establish clear communication protocols with your chosen supplier. Define points of contact, preferred communication channels, and response times. Effective communication is vital for addressing any issues that may arise during production or delivery, ensuring a smooth and successful partnership.

By following this checklist, B2B buyers can effectively navigate the sourcing process for aluminum extrusions in Fort Scott, KS, ensuring they make informed decisions that align with their operational goals and requirements.

Comprehensive Cost and Pricing Analysis for extrusions fort scott ks Sourcing

What Are the Key Cost Components for Sourcing Aluminum Extrusions in Fort Scott, KS?

When considering sourcing aluminum extrusions from Fort Scott, KS, it is essential to understand the various cost components that contribute to the overall pricing structure. These components include:

-

Materials: The primary cost driver is the aluminum alloy itself. Prices can fluctuate based on global aluminum market trends and local supply chain conditions. Choosing high-grade alloys may increase costs but can enhance durability and performance.

-

Labor: Skilled labor is necessary for both the extrusion process and subsequent fabrication tasks. Labor costs can vary depending on local wage rates and the complexity of the required operations.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and equipment depreciation. A vertically integrated supplier like Extrusions, Inc. can often manage these costs more effectively due to their in-house capabilities.

-

Tooling: Custom dies and tooling are critical for producing specific extrusion profiles. The initial investment in tooling can be significant, but these costs can be amortized over larger production runs.

-

Quality Control (QC): Rigorous quality control measures are vital to ensure that the extrusions meet industry standards. The costs associated with QC processes are essential for maintaining product integrity and can influence final pricing.

-

Logistics: Shipping costs, including freight and handling, can impact the overall cost structure, especially for international buyers. Factors such as distance, shipping method, and Incoterms can significantly affect these expenses.

-

Margin: Suppliers will include a margin in their pricing to cover risks and provide profit. This margin can vary based on the supplier’s market position and the complexity of the order.

How Do Volume and Customization Affect Pricing for Aluminum Extrusions?

Price influencers play a crucial role in determining the final costs of aluminum extrusions. Key factors include:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders when feasible.

-

Specifications and Customization: Custom profiles and specific dimensions can increase costs due to the need for unique tooling and additional design work. Clear communication of specifications upfront can help avoid unexpected costs later in the process.

-

Quality and Certifications: Extrusions that meet specific industry certifications may carry a premium. Buyers should assess their needs against the value provided by certified products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may command higher prices but can also offer more assurance in terms of delivery and product consistency.

-

Incoterms: The choice of Incoterms impacts logistics costs and responsibilities. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for calculating total landed costs for international shipments.

What Are Effective Negotiation Strategies for International Buyers of Aluminum Extrusions?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies are crucial to achieving cost efficiency:

-

Understanding Total Cost of Ownership (TCO): Buyers should consider all costs associated with procurement, including maintenance and operational costs, not just the upfront price. This holistic view can lead to better long-term value.

-

Leveraging Relationships: Building strong relationships with suppliers can provide leverage in negotiations. Regular communication and a collaborative approach can lead to better terms and pricing.

-

Market Research: Understanding local market conditions and trends can empower buyers during negotiations. Knowledge about competitors’ pricing and capabilities can help in securing favorable terms.

-

Flexibility in Specifications: Being open to alternative materials or designs can lead to cost savings. Suppliers may have existing tooling that can be utilized, reducing initial setup costs.

-

Exploring Payment Terms: Negotiating favorable payment terms can help manage cash flow and reduce financial risk. Options such as partial payments or extended terms can be beneficial.

Conclusion: What Should Buyers Keep in Mind?

When sourcing aluminum extrusions from Fort Scott, KS, buyers should approach pricing with a comprehensive understanding of the cost structure and key influencers. Engaging in strategic negotiations while considering the Total Cost of Ownership will help in securing the best possible deal. It is advisable to remain informed about market dynamics, supplier capabilities, and logistical considerations to maximize value from every transaction. Keep in mind that prices can vary widely based on individual project requirements and market conditions, so always seek multiple quotes for a well-rounded perspective.

Alternatives Analysis: Comparing extrusions fort scott ks With Other Solutions

Understanding Alternative Solutions to Extrusions in Fort Scott, KS

In the competitive landscape of aluminum extrusion manufacturing, it is essential for B2B buyers to explore various solutions that meet their specific project needs. While Extrusions, Inc. in Fort Scott, KS, offers a comprehensive range of services and products, other alternatives can provide unique benefits depending on the application, budget, and operational requirements. Below, we compare Extrusions Fort Scott, KS, with two viable alternatives: 3D Aluminum Printing and Offshore Aluminum Extrusions.

Comparison Table

| Comparison Aspect | Extrusions Fort Scott, KS | 3D Aluminum Printing | Offshore Aluminum Extrusions |

|---|---|---|---|

| Performance | High-quality, custom profiles with precise tolerances | Excellent for complex geometries but limited in size | Variable quality; often lower than local options |

| Cost | Competitive pricing with potential for bulk discounts | Higher initial costs; cost-effective for small runs | Generally lower due to reduced labor and overhead |

| Ease of Implementation | Streamlined process with in-house capabilities | Requires specialized equipment and expertise | Longer lead times due to shipping and customs |

| Maintenance | Minimal; local support available | Regular maintenance of 3D printers required | Varies by supplier; potential for quality issues |

| Best Use Case | Large volume, custom projects requiring quick turnaround | Prototyping and small-batch production of complex designs | Cost-sensitive projects where price is the primary concern |

Detailed Breakdown of Alternatives

3D Aluminum Printing

3D aluminum printing has emerged as a game-changer in the manufacturing industry, particularly for projects requiring intricate designs that traditional extrusion methods cannot accommodate. This technology allows for rapid prototyping and customization, making it ideal for innovative applications. However, the initial investment in equipment can be high, and the printing process may not be suitable for large-scale production due to size constraints. Additionally, while it offers flexibility, the mechanical properties of printed parts may not always match those of extruded aluminum.

Offshore Aluminum Extrusions

Offshore aluminum extrusions can present a cost-effective alternative for businesses looking to minimize expenses. Companies in countries with lower labor costs can often provide extrusions at a significantly reduced price. However, buyers must be cautious of potential quality inconsistencies and longer lead times associated with international shipping and customs clearance. Furthermore, communication barriers and time zone differences may complicate project management. This option is best suited for large-scale orders where cost is the primary driver and quality control measures are firmly established.

Conclusion: How to Choose the Right Aluminum Extrusion Solution

When selecting the right aluminum extrusion solution, B2B buyers should consider their specific project requirements, including volume, complexity, and budget. Extrusions Fort Scott, KS, offers a robust and reliable option for custom profiles with a strong emphasis on customer service and quality control. Conversely, 3D aluminum printing is ideal for innovative projects with complex geometries but may come with higher costs and limitations on scale. Offshore aluminum extrusions provide a lower-cost alternative but require careful management to ensure quality and timely delivery. By assessing these factors, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for extrusions fort scott ks

What Are the Key Technical Properties of Aluminum Extrusions?

When evaluating aluminum extrusions, understanding their technical properties is essential for making informed purchasing decisions. Here are several critical specifications:

-

Material Grade: The material grade of aluminum extrusions defines the alloy composition, which affects strength, corrosion resistance, and weight. Common grades include 6061 and 6063, with 6061 offering higher strength and 6063 being more malleable and easier to extrude. Selecting the right grade ensures that the extrusions will meet the performance requirements of specific applications, such as structural components or decorative finishes.

-

Tolerance: Tolerance refers to the allowable deviation from a specified dimension. In the context of extrusions, tighter tolerances are crucial for applications requiring precision, such as in automotive or aerospace industries. Standard tolerances range from ±0.005 inches to ±0.015 inches, depending on the profile complexity. Maintaining proper tolerances ensures parts fit together correctly and function as intended.

-

Surface Finish: The surface finish of an extrusion can significantly impact its aesthetic appeal and resistance to environmental factors. Options include anodizing, powder coating, and mill finish. Anodizing enhances corrosion resistance and durability, making it suitable for outdoor applications, while powder coating provides a wide range of colors and textures for decorative purposes.

-

Mechanical Properties: These include yield strength, tensile strength, and elongation, which indicate how the material behaves under stress. For instance, a higher yield strength means the material can withstand greater forces without deforming. Understanding these properties helps businesses choose extrusions that can endure operational stresses in their specific applications.

-

Thermal Conductivity: This property indicates how well the material can conduct heat. Aluminum has excellent thermal conductivity, making it ideal for heat exchangers and electronic housings. Knowing the thermal properties of the extrusion is vital for industries that require efficient heat dissipation.

What Are Common Trade Terms Used in Aluminum Extrusions?

Familiarity with industry jargon can streamline communication and negotiations. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that are sold under another company’s brand. Understanding OEM relationships is crucial for buyers looking to integrate aluminum extrusions into existing products or systems.

-

MOQ (Minimum Order Quantity): MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in planning inventory and managing costs effectively. Smaller businesses should seek suppliers with flexible MOQs to accommodate various project sizes.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request price quotes from suppliers. This document typically includes specifications, quantities, and delivery timelines. Crafting a detailed RFQ ensures accurate responses and aids in comparing supplier offerings.

-

Incoterms: Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international transactions. Key terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify shipping responsibilities and risk transfer, which is vital for global procurement of extrusions.

-

Lead Time: This term refers to the time taken from placing an order to receiving the product. Understanding lead times helps businesses plan their projects and manage supply chain logistics effectively. Suppliers with shorter lead times can provide a competitive edge in fast-paced markets.

By grasping these essential properties and terminologies, international B2B buyers can navigate the complexities of aluminum extrusions more effectively, leading to better procurement decisions and successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the extrusions fort scott ks Sector

What Are the Key Market Dynamics and Trends Influencing the Extrusions Sector in Fort Scott, KS?

The global aluminum extrusions market is witnessing significant growth driven by increasing demand across various sectors, including construction, automotive, and consumer goods. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable sources for high-quality aluminum products. The rise of e-commerce and digital platforms is transforming the sourcing landscape, enabling buyers to access suppliers more efficiently and facilitating easier price comparisons. Additionally, advancements in technology, such as automation and artificial intelligence, are enhancing production capabilities and improving quality control, thereby boosting overall efficiency.

Emerging trends such as customization and flexibility in manufacturing are vital in meeting the unique needs of global customers. Buyers are leaning towards suppliers that offer tailored solutions, which is where companies like Extrusions, Inc. excel. Their ability to collaborate closely with clients, offering bespoke designs and swift turnaround times, positions them as a competitive player in the market. Moreover, the focus on operational excellence and innovation continues to shape the market dynamics, as suppliers strive to maintain a competitive edge through improved product offerings and customer service.

How Is Sustainability and Ethical Sourcing Impacting the Extrusions Market?

Sustainability has become a cornerstone of purchasing decisions in the B2B space, particularly for international buyers who are increasingly conscious of environmental impact. In the extrusions sector, companies are adopting sustainable practices by utilizing recycled aluminum and adhering to green certifications. This not only minimizes environmental footprints but also appeals to buyers looking for ethical sourcing options. Extrusions, Inc., for instance, emphasizes its commitment to eco-friendly operations, which aligns with the values of many global customers.

Ethical supply chains are critical for building trust and long-term relationships with buyers. Companies that prioritize transparency, fair labor practices, and environmentally responsible sourcing are more likely to attract and retain clients. Certifications such as LEED (Leadership in Energy and Environmental Design) provide assurance to buyers that suppliers are committed to sustainable practices. As the global market continues to evolve, the importance of integrating sustainability into business strategies will only increase, making it essential for suppliers to adapt and innovate accordingly.

Illustrative image related to extrusions fort scott ks

What Is the Historical Context of the Extrusions Industry in Fort Scott, KS?

The aluminum extrusions industry in Fort Scott, KS, has evolved significantly since its inception. Established in 1962, Extrusions, Inc. has been at the forefront of innovation and service in this sector. Initially focused on basic extrusion processes, the company has expanded its capabilities to include advanced fabrication and finishing services. This evolution reflects the broader trends in the industry towards vertical integration and customization, allowing suppliers to offer comprehensive solutions that cater to the specific needs of B2B clients.

Over the decades, the company has built a reputation for quality and reliability, securing long-lasting partnerships with various businesses across different sectors. This historical foundation, combined with a commitment to innovation and customer service, positions Fort Scott as a key player in the aluminum extrusions market, making it an attractive sourcing option for international buyers seeking high-quality materials and exceptional service.

Frequently Asked Questions (FAQs) for B2B Buyers of extrusions fort scott ks

-

How do I ensure the quality of aluminum extrusions from Fort Scott, KS?

To ensure high-quality aluminum extrusions, it is essential to partner with a reputable supplier like Extrusions, Inc. They implement rigorous quality control measures throughout the manufacturing process, including sourcing premium aluminum alloys and conducting thorough inspections. Request certifications that demonstrate compliance with industry standards, such as ISO or ASTM. Additionally, consider visiting the facility if possible or asking for samples to evaluate the quality firsthand before placing a larger order. -

What customization options are available for aluminum extrusions?

Extrusions, Inc. offers extensive customization options to meet specific project needs. This includes custom shapes, sizes, and profiles tailored to your specifications. Their team of engineers and designers collaborates closely with clients to develop unique solutions, from concept through to production. Be sure to communicate your requirements clearly and ask about their capabilities in terms of machining and finishing to ensure you receive the desired product. -

What are the minimum order quantities (MOQs) for aluminum extrusions?

Minimum order quantities (MOQs) can vary based on the supplier and the complexity of the extrusion design. At Extrusions, Inc., they are capable of accommodating both high-volume orders and smaller, one-time requests. It’s advisable to discuss your project requirements with the sales team to understand the MOQ for your specific needs, as this flexibility is a key advantage for international buyers looking to test the market or fulfill smaller projects. -

What payment terms are typically offered for international buyers?

Payment terms for international buyers can differ among suppliers. Common options include upfront payment, net 30 or net 60 days, and letters of credit for larger orders. It’s crucial to clarify payment options with the supplier to find a mutually beneficial agreement. Additionally, consider the impact of currency exchange rates and any potential transaction fees that may apply when dealing with international payments. -

How can I vet a supplier of aluminum extrusions effectively?

To vet a supplier, start by researching their reputation and experience in the industry. Look for customer testimonials, case studies, and reviews from previous international clients. Request certifications and compliance documents to ensure they meet quality standards. Establish communication to assess responsiveness and willingness to collaborate on projects. If feasible, visiting the facility or arranging a video call can provide valuable insights into their operations and capabilities. -

What logistics considerations should I be aware of when importing extrusions?

When importing aluminum extrusions, consider factors such as shipping methods, lead times, and customs regulations. Work with your supplier to determine the best shipping options based on your timeline and budget. Understand the import duties and tariffs applicable in your country, as these can significantly impact total costs. Establish a clear logistics plan that includes tracking shipments and managing any potential delays in customs clearance. -

How does Extrusions, Inc. support sustainability in their operations?

Extrusions, Inc. is committed to environmentally friendly practices, which is increasingly important for international buyers. They focus on sustainable manufacturing processes, including efficient energy use and waste reduction initiatives. Inquire about their LEED certification and other sustainability measures to ensure that your procurement aligns with your corporate social responsibility goals. This commitment not only benefits the environment but can also enhance your brand’s reputation in the marketplace. -

What are the typical turnaround times for custom aluminum extrusions?

Turnaround times for custom aluminum extrusions can vary based on the complexity of the design and current production schedules. At Extrusions, Inc., they pride themselves on competitive lead times due to their vertically integrated operations. Typically, you can expect initial prototypes within a few weeks, with full production following shortly after approval. It’s advisable to discuss your timeline during the initial consultation to ensure your project deadlines are met.

Top 3 Extrusions Fort Scott Ks Manufacturers & Suppliers List

1. Extrusions, Inc. – Aluminum Extrusions

Domain: aluminumextrusions.com

Registered: 1998 (27 years)

Introduction: Extrusions, Inc. is a full-service aluminum extruder with a large inventory of stock dies and thousands of custom shapes. They operate a 1850-ton fully automated 7″ extrusion press, have two extrusion presses, a fabrication department, three CNC machines, a state-of-the-art powder coat paint line, pour and debridge machinery, polyamide strut insertion machinery, and in-house anodizing. They offer …

2. Extrusions, Inc. – Accounting Services

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Extrusions, Inc. – Accounting Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Facebook – Job Opportunities

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Job Opportunities, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for extrusions fort scott ks

In navigating the competitive landscape of aluminum extrusions, strategic sourcing from Extrusions, Inc. in Fort Scott, KS, offers significant advantages for international buyers. With a robust inventory of stock dies and the ability to create custom profiles, businesses can access high-quality extruded products tailored to their unique specifications. The company’s vertical integration ensures efficient production processes, enabling faster turnaround times without compromising quality.

For B2B buyers from Africa, South America, the Middle East, and Europe, the commitment to sustainability and operational excellence at Extrusions, Inc. further enhances its appeal. Leveraging their advanced manufacturing capabilities and experienced workforce, clients can expect not only superior products but also exceptional customer service that prioritizes collaboration and innovation.

Looking ahead, there is a growing demand for customized aluminum solutions across various industries. As global markets continue to evolve, forming a strategic partnership with Extrusions, Inc. can provide businesses with a competitive edge. Take the next step in optimizing your supply chain by reaching out for a consultation or quote—discover how Extrusions, Inc. can elevate your projects with their comprehensive aluminum extrusion solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.