Top 3 Dynamometer Lab Suppliers (And How to Choose)

Introduction: Navigating the Global Market for dynamometer lab

In today’s competitive landscape, sourcing reliable dynamometer lab services is a critical challenge for international B2B buyers, especially those operating in diverse industries across Africa, South America, the Middle East, and Europe. As companies strive to enhance product performance and ensure compliance with rigorous quality standards, the need for comprehensive dynamometer testing has never been more pressing. This guide aims to navigate the complexities of the global market for dynamometer labs, offering insights into various types of testing services, their applications in different sectors, and the essential criteria for supplier selection.

The scope of this guide encompasses a wide array of dynamometer testing solutions, including engine, chassis, and component testing, tailored to meet the unique demands of each buyer’s operational context. Additionally, we delve into cost considerations, enabling businesses to evaluate their investment against potential returns in performance and compliance. By providing actionable insights and strategic recommendations, this guide empowers decision-makers to make informed purchasing choices that align with their specific needs and industry standards.

For B2B buyers from regions such as Germany and Brazil, this resource serves as a vital tool in understanding the landscape of dynamometer labs, ensuring they can effectively vet suppliers and select the right testing services to drive their business success. Whether you are assessing local providers or exploring global options, this guide will equip you with the knowledge necessary to navigate the dynamometer testing market with confidence.

Understanding dynamometer lab Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Dynamometer Lab | Specialized cells for testing various engine types, including calibration and emissions testing. | Automotive development, emissions certification, engine mapping. | Pros: High accuracy, compliance with regulations. Cons: High initial investment, specialized knowledge required. |

| Chassis Dynamometer Lab | Tests entire vehicles for performance metrics under real-world conditions. | Vehicle performance validation, durability testing, R&D. | Pros: Comprehensive data on vehicle dynamics. Cons: Space-intensive, can be costly to operate. |

| Component Dynamometer Lab | Focuses on individual components like gearboxes and axles, assessing efficiency and durability. | Quality control, R&D for specific parts, performance testing. | Pros: Specific insights into component performance. Cons: Limited to parts, not entire systems. |

| Specialty Dynamometer Lab | Custom setups tailored for unique testing scenarios, including extreme environmental conditions. | Research and development, niche applications in various industries. | Pros: Highly adaptable to specific testing needs. Cons: Potentially higher costs for customization. |

| Heavy-Duty Dynamometer Lab | Designed for testing large machinery and equipment, capable of handling high torque and power. | Heavy equipment testing, off-road vehicle performance, industrial applications. | Pros: Robust testing for heavy-duty applications. Cons: May require specialized facilities and expertise. |

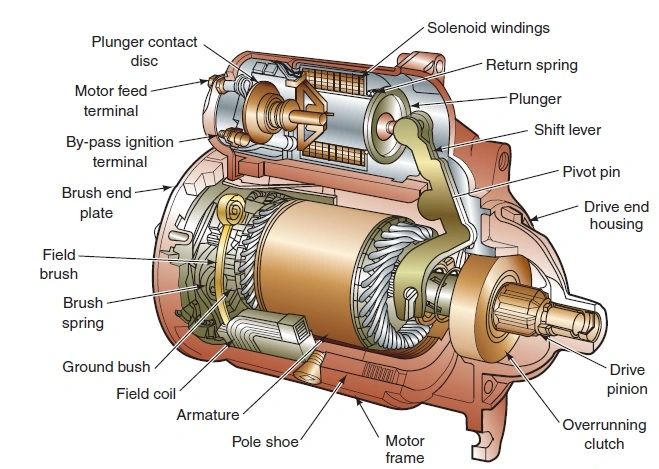

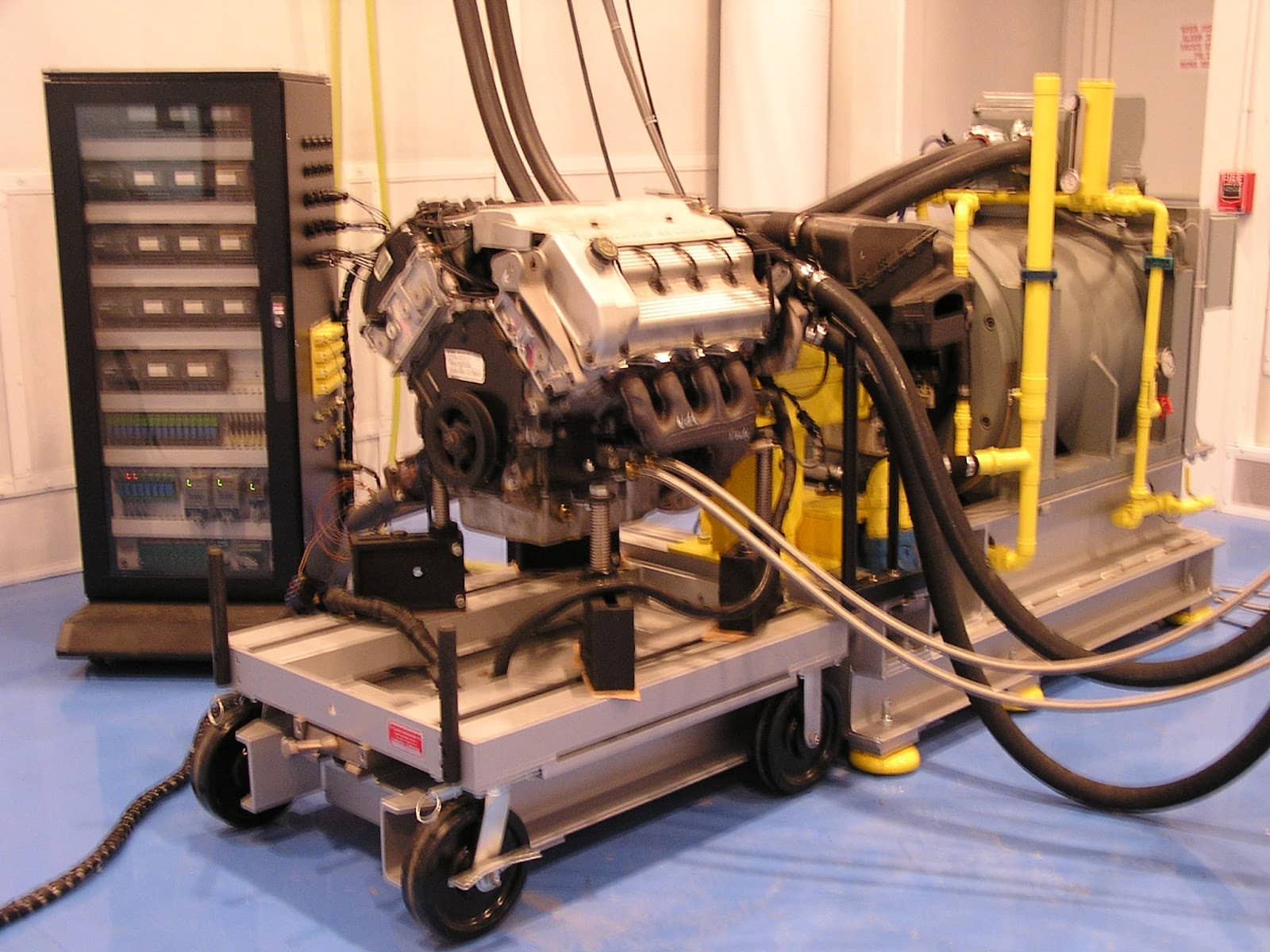

What Are the Characteristics of Engine Dynamometer Labs?

Engine dynamometer labs are equipped with specialized test cells that facilitate the comprehensive assessment of various engine types. These labs are essential for automotive manufacturers focusing on engine development, emissions testing, and compliance with regulatory standards. Key B2B purchasing considerations include the lab’s capability to simulate varying environmental conditions, which is crucial for accurate testing. Buyers should evaluate the lab’s adherence to international testing protocols and its ability to handle diverse engine sizes, from small handheld engines to large industrial engines.

How Do Chassis Dynamometer Labs Differ from Other Types?

Chassis dynamometer labs are designed to test complete vehicles, providing insights into performance metrics under simulated real-world conditions. These labs are particularly beneficial for automotive manufacturers and researchers seeking to validate vehicle performance, conduct durability testing, and enhance R&D efforts. When purchasing, businesses should consider the lab’s ability to simulate different driving scenarios, the maximum weight it can accommodate, and the data analysis capabilities. Although they provide comprehensive insights, the operational costs and space requirements can be significant.

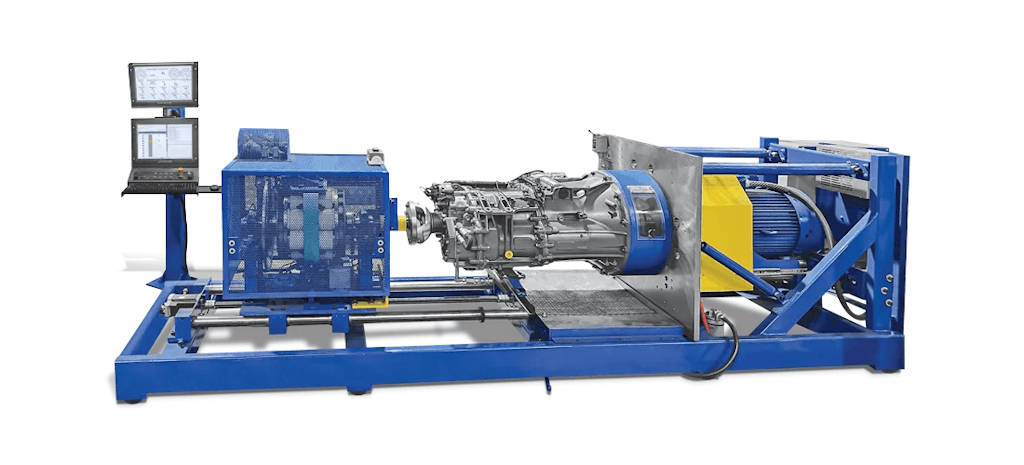

What Are the Advantages of Component Dynamometer Labs?

Component dynamometer labs focus on testing individual components such as gearboxes, axles, and transmissions. These labs are crucial for manufacturers looking to ensure the quality and performance of specific parts before they are integrated into larger systems. Key considerations for B2B buyers include the lab’s testing accuracy, the range of components it can assess, and its ability to provide detailed performance analytics. While these labs offer in-depth insights, they do not evaluate entire systems, which may necessitate additional testing in other lab types.

How Are Specialty Dynamometer Labs Tailored for Unique Needs?

Specialty dynamometer labs are designed to accommodate unique testing requirements, including extreme environmental conditions or specific industry needs. These labs are particularly valuable for companies involved in R&D or those needing to conduct niche testing that standard labs cannot provide. Buyers should assess the lab’s flexibility, customization options, and previous experience with similar projects. While these labs offer tailored solutions, they often come with higher costs and may require more time to set up for specific tests.

What Makes Heavy-Duty Dynamometer Labs Unique?

Heavy-duty dynamometer labs are specifically built to test large machinery and equipment, accommodating high torque and power levels. These labs are essential for industries such as construction, mining, and agriculture, where performance validation of heavy equipment is critical. B2B buyers should focus on the lab’s capacity for handling large-scale equipment, the robustness of its testing systems, and the expertise of the personnel involved. While they provide essential testing for demanding applications, the specialized nature of these labs can lead to increased costs and operational complexities.

Key Industrial Applications of dynamometer lab

| Industry/Sector | Specific Application of dynamometer lab | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine performance testing | Ensures compliance with emissions standards and optimizes fuel efficiency | Look for labs with ISO/IEC 17025 accreditation for quality assurance |

| Heavy Equipment | Durability testing for off-road machinery | Validates performance under extreme conditions, reducing downtime | Consider facilities that can simulate various environmental conditions |

| Marine | Propulsion system testing | Enhances reliability and efficiency of marine engines | Ensure the lab can accommodate various engine sizes and configurations |

| Aerospace | Engine calibration and emissions testing | Meets stringent regulatory requirements for air travel | Seek providers with advanced control systems for precise data acquisition |

| Industrial Manufacturing | Testing of motors and pumps | Improves operational efficiency and reliability of equipment | Choose labs with comprehensive testing capabilities for diverse components |

How is Dynamometer Lab Used in the Automotive Sector?

In the automotive industry, dynamometer labs are essential for engine performance testing. They help manufacturers validate that engines meet emissions regulations and optimize fuel efficiency. This is particularly crucial for international B2B buyers, especially in regions with stringent environmental laws like Europe. Buyers should prioritize labs with ISO/IEC 17025 accreditation to ensure compliance with international testing standards.

What Role Does Dynamometer Lab Play in Heavy Equipment Testing?

Heavy equipment manufacturers utilize dynamometer labs for durability testing of off-road machinery. These labs simulate extreme operational conditions to assess the performance and longevity of components such as transmissions and axles. For businesses in Africa and South America, where heavy machinery operates in harsh environments, selecting a lab that can replicate these conditions is vital for reducing equipment downtime and enhancing reliability.

How is Dynamometer Lab Beneficial for Marine Applications?

In the marine sector, dynamometer labs are used for testing propulsion systems, ensuring that marine engines operate efficiently and reliably. This testing is crucial for compliance with environmental regulations and for optimizing performance in different sea conditions. International buyers from the Middle East and Europe should look for labs equipped to handle various engine sizes and configurations to cater to the diverse needs of the marine industry.

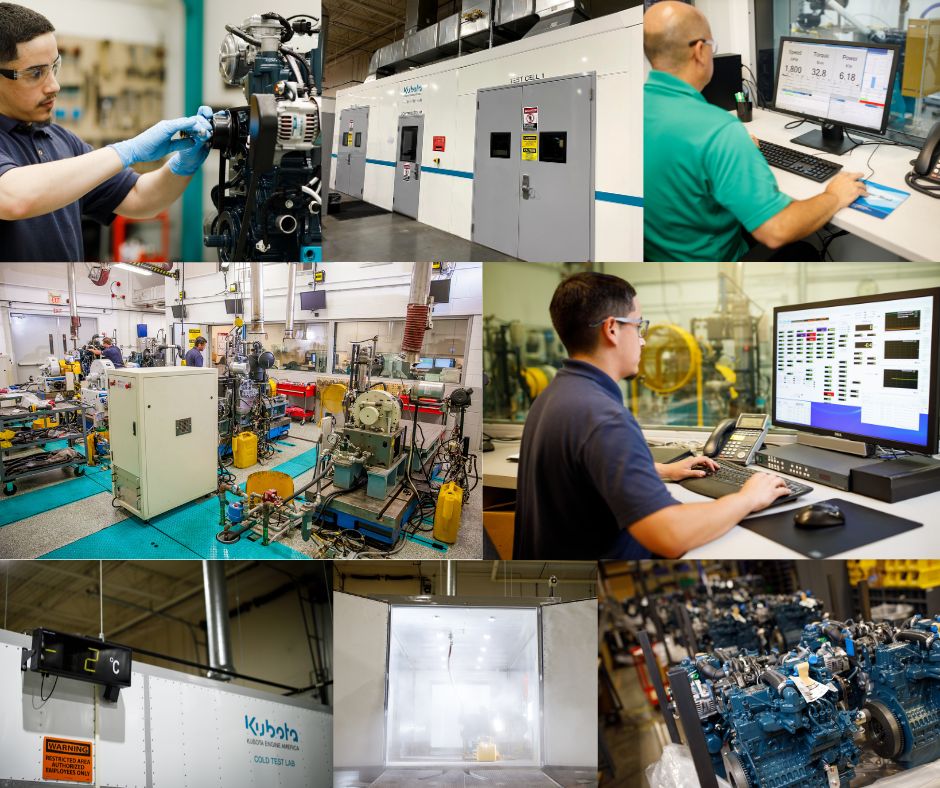

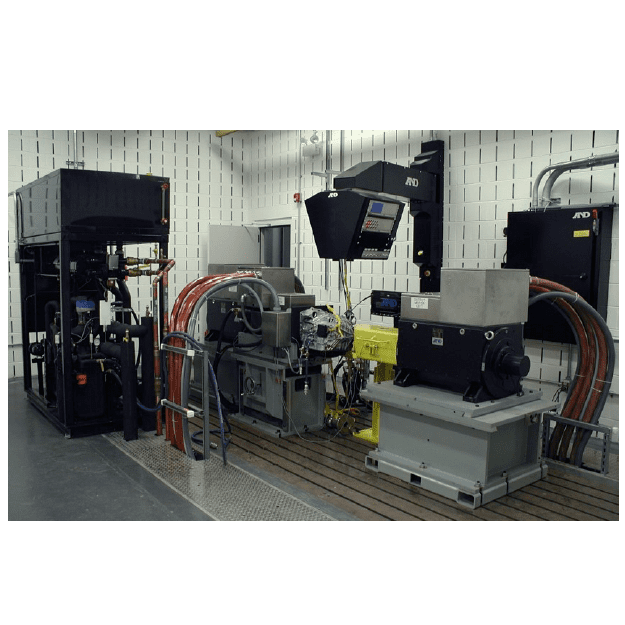

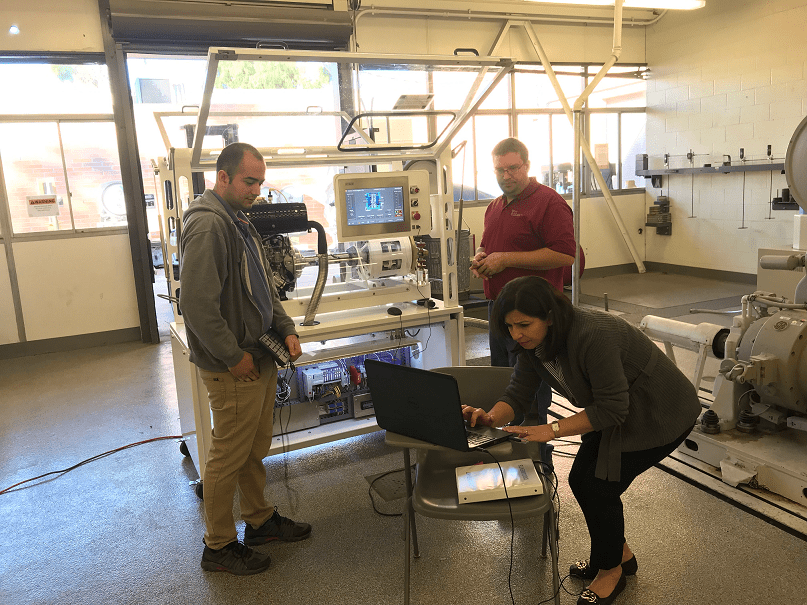

Illustrative image related to dynamometer lab

What are the Applications of Dynamometer Lab in Aerospace Testing?

Dynamometer labs play a critical role in aerospace by providing engine calibration and emissions testing. These labs help manufacturers meet the stringent regulatory requirements necessary for air travel. For B2B buyers in the aerospace sector, it’s essential to work with labs that possess advanced control systems for precise data acquisition, ensuring the accuracy and reliability of testing results.

How Does Dynamometer Lab Improve Efficiency in Industrial Manufacturing?

In industrial manufacturing, dynamometer labs are employed to test motors and pumps, improving their operational efficiency and reliability. This testing allows manufacturers to identify potential issues before products reach the market, thereby reducing the risk of failures. Buyers should choose labs that offer comprehensive testing capabilities for diverse components, ensuring that all aspects of performance are thoroughly evaluated.

3 Common User Pain Points for ‘dynamometer lab’ & Their Solutions

Scenario 1: Inconsistent Testing Results Leading to Production Delays

The Problem: Many B2B buyers face challenges with inconsistent testing results when using dynamometer labs, which can lead to significant production delays. This inconsistency often arises from variations in testing environments, equipment calibration, and the complexity of the components being tested. For instance, a manufacturer of heavy-duty engines might encounter discrepancies in torque measurements, causing them to question the reliability of the data. Such uncertainties can stall product launches and strain relationships with clients who rely on timely deliveries.

The Solution: To mitigate this issue, buyers should prioritize the selection of dynamometer labs that adhere to stringent quality control protocols and have ISO/IEC 17025 accreditation. When sourcing a lab, ask for detailed documentation of their calibration procedures and environmental controls. Additionally, consider establishing a regular communication line with the lab’s engineers to discuss specific testing parameters and any observed anomalies. Implementing a feedback loop where the lab can adjust testing methods based on real-time data will enhance consistency. Investing in labs that utilize advanced data acquisition systems can also provide more reliable results by minimizing human error and ensuring precise measurements.

Scenario 2: Difficulty in Complying with Regulatory Standards

The Problem: B2B buyers often struggle to ensure that their products comply with regulatory standards, particularly in industries with stringent emissions and performance requirements. For example, an automotive parts manufacturer may face challenges in passing emissions tests for new engine designs, leading to costly redesigns and delays in market entry. The complexity of various regulations across different regions, such as those in Europe and the United States, adds another layer of difficulty.

The Solution: To address compliance challenges, buyers should partner with dynamometer labs that have extensive experience in regulatory testing and certifications specific to their industry. When selecting a lab, inquire about their familiarity with local and international regulations, and whether they have the capability to perform tests for multiple markets. Furthermore, utilizing labs that offer comprehensive pre-testing consultations can help identify potential compliance issues early in the design process. This proactive approach will save time and resources, ensuring that products meet regulatory standards before they reach the testing stage.

Scenario 3: Limited Understanding of Data Analysis for Performance Optimization

The Problem: A common pain point for B2B buyers is the limited understanding of how to interpret dynamometer test data effectively for performance optimization. For instance, an engineering team may receive a wealth of data from a dynamometer test but lack the expertise to analyze it meaningfully. This gap can prevent companies from making informed decisions about product improvements, ultimately hindering their competitive edge in the market.

The Solution: To overcome this hurdle, buyers should seek dynamometer labs that offer comprehensive data analysis services along with testing. When engaging with a lab, ask about their ability to provide detailed reports that include not only raw data but also insights and recommendations for performance improvements. Additionally, consider requesting training sessions for your engineering team focused on data interpretation and application. This knowledge transfer will empower your team to leverage test results effectively, enabling them to make data-driven decisions that enhance product performance and efficiency. Collaborating with labs that utilize advanced software for data visualization can also facilitate a better understanding of complex data sets, leading to actionable insights.

Strategic Material Selection Guide for dynamometer lab

What Materials Are Commonly Used in Dynamometer Labs?

When selecting materials for dynamometer labs, it is essential to consider their properties, advantages, disadvantages, and how they align with specific applications. Here, we analyze four common materials: steel, aluminum, composites, and plastics.

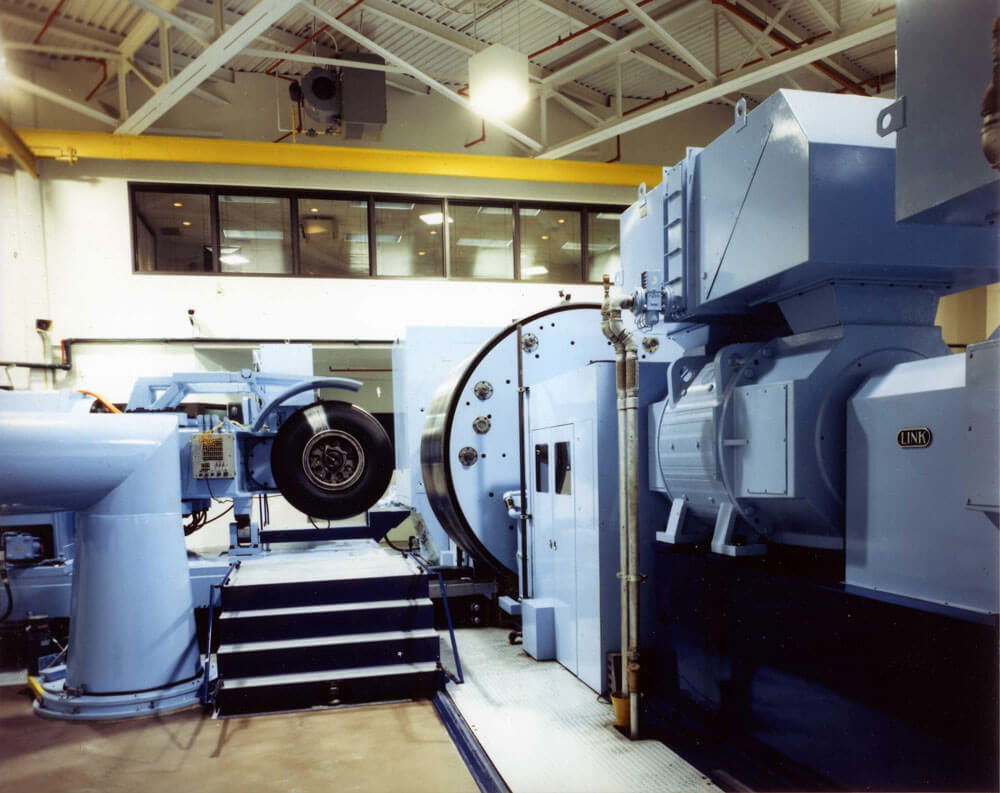

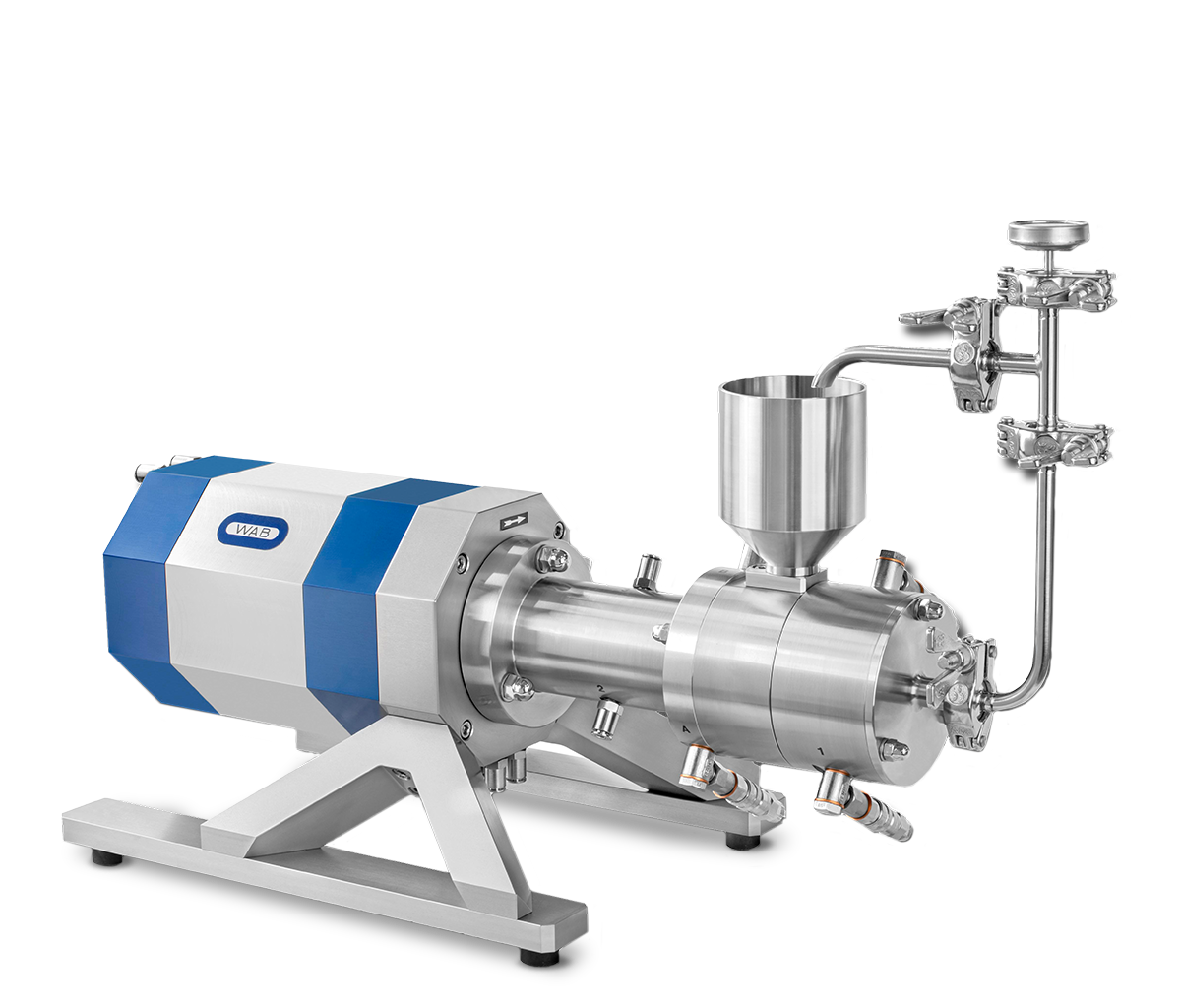

Illustrative image related to dynamometer lab

How Does Steel Perform in Dynamometer Applications?

Steel is a primary material used in dynamometer construction due to its strength and durability. It typically exhibits excellent temperature and pressure ratings, making it suitable for high-torque applications. Steel’s corrosion resistance can vary based on the alloy used; stainless steel offers better resistance compared to carbon steel.

Pros: Steel is highly durable, cost-effective, and widely available. Its manufacturing processes are well-established, allowing for easy fabrication into various components.

Cons: The weight of steel can be a disadvantage in applications requiring lightweight materials. Additionally, while it can be treated for corrosion resistance, it may still require protective coatings in harsh environments.

Impact on Application: Steel components are compatible with a wide range of media, making them versatile for different dynamometer tests.

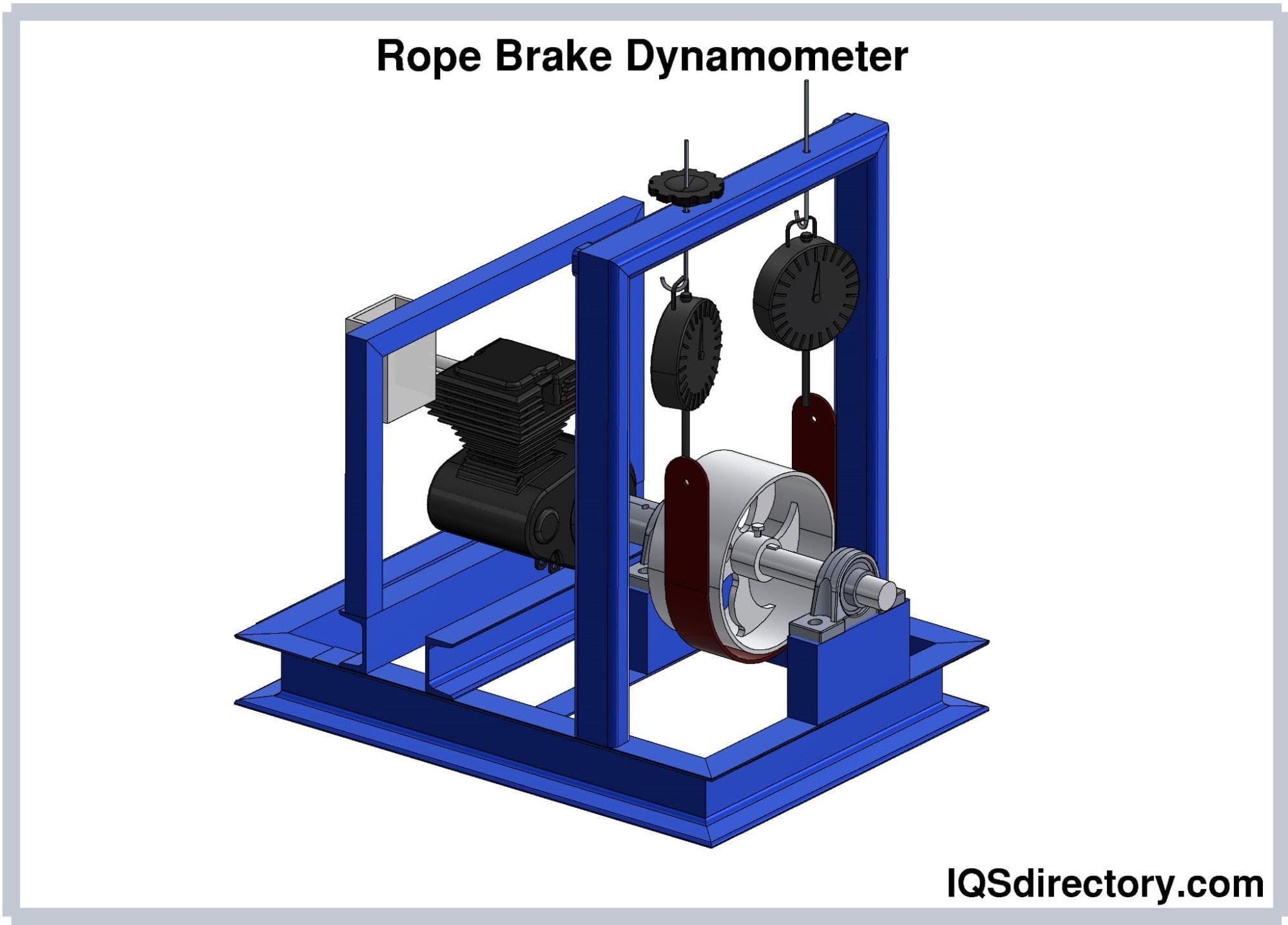

Illustrative image related to dynamometer lab

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers from regions like Europe and the Middle East may prefer specific steel grades that meet these standards.

What Role Does Aluminum Play in Dynamometer Labs?

Aluminum is another popular choice due to its lightweight nature and good corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for less demanding applications.

Pros: The primary advantage of aluminum is its reduced weight, which can enhance the efficiency of dynamometer systems. Its natural corrosion resistance minimizes maintenance needs.

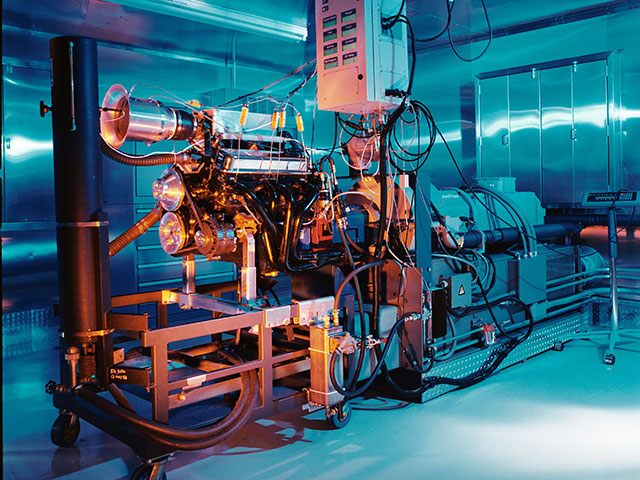

Illustrative image related to dynamometer lab

Cons: Aluminum is generally more expensive than steel and may not perform as well under extreme conditions. It also has lower tensile strength, which may limit its application in high-load scenarios.

Impact on Application: Aluminum is often used for components that require weight savings, such as housings and enclosures.

Considerations for International Buyers: Buyers should ensure compliance with local standards and consider the availability of aluminum grades that meet specific performance criteria.

How Do Composites Enhance Dynamometer Testing?

Composite materials, such as carbon fiber reinforced polymers, are increasingly used in dynamometer labs. They offer high strength-to-weight ratios and excellent resistance to environmental factors.

Pros: Composites are lightweight and can be tailored for specific applications, providing flexibility in design. They also exhibit superior corrosion resistance.

Illustrative image related to dynamometer lab

Cons: The manufacturing process for composites can be complex and costly. Additionally, they may not be suitable for high-temperature applications unless specifically engineered.

Impact on Application: Composites are ideal for components that require both strength and reduced weight, such as drive shafts and housings.

Considerations for International Buyers: Compliance with international standards for composites is essential, especially in regions with stringent regulations. Buyers should also consider the availability of composite materials in their local markets.

Illustrative image related to dynamometer lab

What Advantages Do Plastics Offer in Dynamometer Labs?

Plastics, particularly engineering-grade thermoplastics, are used for non-structural components in dynamometer labs. They offer good chemical resistance and can perform well in various temperature ranges.

Pros: Plastics are lightweight, cost-effective, and easy to mold into complex shapes. They also provide excellent electrical insulation.

Cons: Plastics generally have lower mechanical strength compared to metals and may degrade under extreme temperatures or pressures.

Illustrative image related to dynamometer lab

Impact on Application: Plastics are suitable for components such as seals, gaskets, and housings that do not bear heavy loads.

Considerations for International Buyers: Buyers should ensure that the selected plastics meet relevant industry standards for performance and safety, especially in regions with specific regulatory requirements.

Summary Table of Material Selection for Dynamometer Labs

| Material | Typical Use Case for dynamometer lab | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, frames | High durability and strength | Heavier than other materials | Medium |

| Aluminum | Lightweight housings, enclosures | Reduced weight and good corrosion resistance | More expensive, lower tensile strength | High |

| Composites | Drive shafts, specialized components | High strength-to-weight ratio | Complex manufacturing process | High |

| Plastics | Seals, gaskets, non-structural components | Cost-effective and easy to mold | Lower mechanical strength | Low |

This strategic material selection guide provides essential insights for international B2B buyers in the dynamometer lab sector, helping them make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dynamometer lab

What Are the Key Stages in the Manufacturing Process of Dynamometers?

The manufacturing process of dynamometers involves several critical stages, each designed to ensure that the final product meets the rigorous standards required by various industries. Here’s a breakdown of the main stages:

Material Preparation

The first step in manufacturing dynamometers is the careful selection and preparation of materials. High-quality metals, such as steel and aluminum, are often used due to their strength and durability. Material preparation includes processes like cutting, machining, and surface treatment to ensure that the components meet precise specifications. Suppliers should look for manufacturers that employ advanced techniques like laser cutting and CNC machining, which enhance precision and minimize waste.

Forming

Once the materials are prepared, the next step is forming. This can involve processes such as forging, casting, or stamping, depending on the component’s design requirements. For dynamometers, components like frames, shafts, and gear systems must be formed to exact tolerances to ensure optimal performance. Advanced forming techniques, such as hydroforming or die-casting, can be employed to create complex shapes while maintaining structural integrity.

Assembly

After forming, the components are assembled. This is a critical stage that requires skilled labor to ensure that all parts fit together seamlessly. Modern assembly lines may utilize automated systems for efficiency, but human oversight is essential for quality assurance. Key components, such as sensors, motors, and control systems, are integrated during this phase. Manufacturers should utilize lean manufacturing principles to minimize assembly time while ensuring that each unit is thoroughly tested before moving on to the next stage.

Finishing

The final stage of manufacturing involves finishing processes, which enhance the product’s durability and aesthetics. Finishing techniques may include painting, coating, or anodizing to protect against corrosion and wear. Quality control is paramount in this phase, as any flaws can affect the dynamometer’s performance. Manufacturers often employ rigorous testing methods to ensure that the finished product meets all operational and environmental standards.

How Is Quality Control Implemented in Dynamometer Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, ensuring that each dynamometer meets international and industry-specific standards. Here’s how QC is typically implemented:

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistency and reliability in manufacturing processes. For dynamometer manufacturers, adherence to these standards signals a commitment to quality. Additionally, industry-specific certifications like CE marking and API (American Petroleum Institute) certifications are crucial for ensuring that products meet safety and performance standards relevant to specific markets.

What Are the Common Quality Control Checkpoints?

Quality control in dynamometer manufacturing typically involves multiple checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should verify that suppliers conduct thorough inspections and maintain records of material certifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are crucial to catch defects early. This may involve monitoring dimensional tolerances, operational parameters, and assembly techniques.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection is conducted. This includes testing for performance metrics such as torque, power, and emissions, ensuring that the dynamometer operates within acceptable limits.

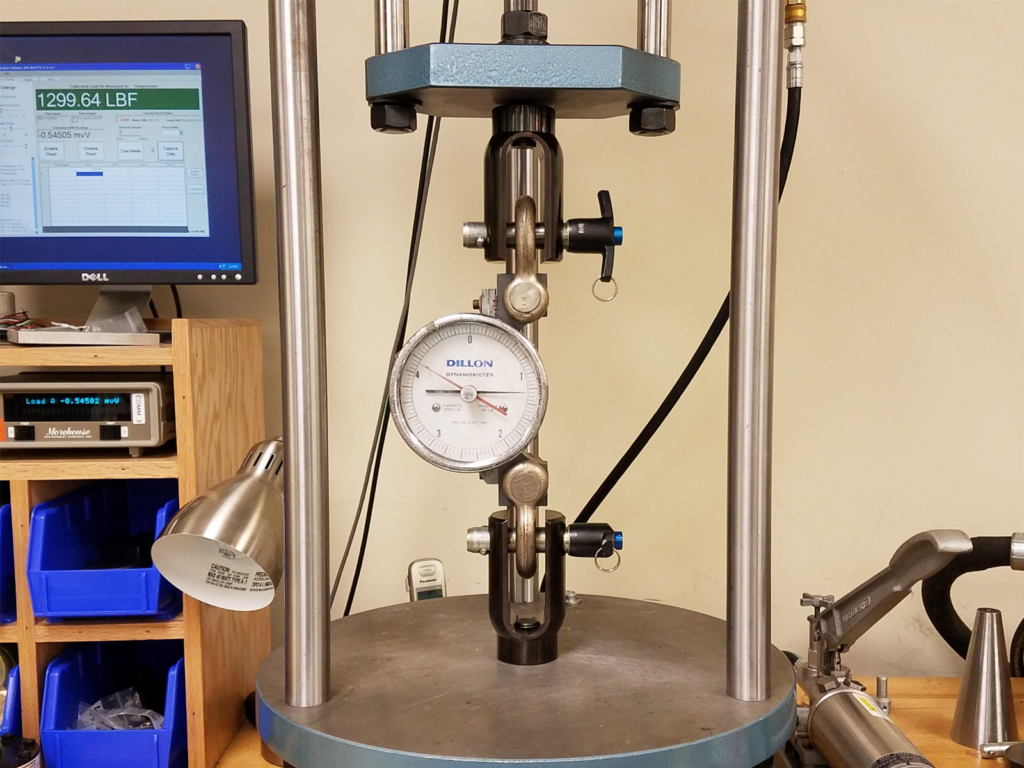

What Common Testing Methods Are Used for Quality Assurance?

Dynamometers are subjected to a variety of testing methods to ensure their reliability and performance:

-

Performance Testing: This includes measuring torque, power output, and RPM under various load conditions. It is essential for validating that the dynamometer can operate under real-world conditions.

-

Endurance Testing: Dynamometers may undergo prolonged testing to assess their durability and identify potential failure points. This is crucial for applications where reliability is paramount.

-

Environmental Testing: For applications in harsh conditions, dynamometers can be tested under extreme temperatures, humidity, and corrosive environments to ensure functionality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing dynamometers, B2B buyers should take proactive steps to verify a supplier’s quality control practices:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should seek manufacturers that welcome audits and provide transparency in their operations.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methods, results, and compliance with international standards. This documentation is vital for buyers to assess the reliability of the products.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. This is especially important for international buyers to ensure compliance with local regulations and standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality control. Understanding local regulations, import standards, and market expectations is crucial.

Illustrative image related to dynamometer lab

-

Regulatory Compliance: Different regions may have specific regulations governing the import of industrial equipment. Buyers should be aware of these regulations to avoid penalties and ensure smooth operations.

-

Cultural Considerations: Building relationships with suppliers can facilitate better communication and understanding of quality standards. Engaging with local partners who understand the market can enhance the sourcing process.

-

Logistics and Supply Chain Management: International shipping can introduce additional risks to product quality. Buyers should ensure that suppliers have robust logistics strategies that minimize the risk of damage during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting dynamometer suppliers, ultimately leading to enhanced operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dynamometer lab’

To assist B2B buyers in sourcing a dynamometer lab, this guide outlines a structured approach to ensure that your procurement process is effective and aligned with your technical requirements. By following this checklist, you will be able to identify reliable suppliers and make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your dynamometer lab, including the types of tests needed (e.g., engine, chassis, or component testing) and performance metrics (e.g., torque, horsepower, and speed). This step is crucial as it helps narrow down potential suppliers who can meet your specific testing needs. Be specific about environmental conditions, load capacities, and any regulatory compliance that must be adhered to.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in dynamometer testing. Look for companies with industry certifications, experience, and positive client testimonials. Utilize trade shows, industry publications, and online platforms to gather information. This step ensures that you are considering reputable suppliers who can deliver high-quality services.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request detailed information about their testing capabilities, including the types of dynamometers they use and their testing methodologies. Pay attention to:

– Flexibility in Testing: Can they accommodate custom test setups?

– Equipment Specifications: Are their dynamometers capable of handling your required power and torque ranges?

Step 4: Verify Supplier Certifications

Check for relevant certifications and compliance with international standards, such as ISO/IEC 17025 for testing and calibration laboratories. These certifications ensure that the supplier adheres to quality management systems and can provide reliable results. Also, inquire about their experience with local regulations in your target markets, as this can impact the validity of test results.

Step 5: Request Sample Tests

Before making a final decision, ask potential suppliers to conduct sample tests on your equipment or components. This will give you insight into their testing processes, accuracy, and turnaround times. Evaluate the reporting format and data presentation, as clear and comprehensive reports are essential for decision-making.

Step 6: Assess Customer Support and Maintenance Services

Evaluate the level of customer support and maintenance services offered by the supplier. Reliable support is vital for ongoing operations, especially if issues arise with testing equipment. Look for:

– Training Programs: Do they provide training for your staff on using their equipment?

– Technical Support: Is there a dedicated support team available for troubleshooting?

Step 7: Review Pricing and Contract Terms

Finally, analyze the pricing structure and contract terms offered by suppliers. Ensure that the pricing aligns with your budget while still offering value for the services rendered. Pay attention to contract details regarding service level agreements (SLAs), confidentiality, and liability clauses. A clear understanding of these terms will protect your interests throughout the partnership.

By following this step-by-step checklist, you will be well-equipped to source a dynamometer lab that meets your specific needs and ensures high-quality testing for your equipment.

Comprehensive Cost and Pricing Analysis for dynamometer lab Sourcing

What Are the Key Cost Components in Dynamometer Lab Sourcing?

When sourcing dynamometer lab services, understanding the cost structure is crucial for international B2B buyers. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: This encompasses the raw materials needed for the dynamometers, including metals, electronic components, and testing fluids. High-quality materials often lead to higher costs but can enhance the longevity and performance of the equipment.

-

Labor: Skilled labor is essential for the design, assembly, and testing of dynamometers. Labor costs can vary significantly by region, with developed markets like Germany typically having higher labor costs compared to emerging markets in Africa or South America.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and administrative expenses. Buyers should consider suppliers with optimized overhead to reduce overall costs.

-

Tooling: Custom tooling may be required for specialized dynamometer configurations. The cost of tooling can be substantial, particularly for bespoke solutions.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure the reliability of dynamometer systems. Higher QC standards often translate to increased costs but are essential for compliance and performance.

-

Logistics: Shipping and handling costs must be factored in, especially for international buyers. Understanding Incoterms is vital for clarifying who is responsible for shipping costs and risks during transit.

-

Margin: Supplier profit margins can vary widely based on competition, brand reputation, and perceived value. Buyers should seek transparency regarding pricing structures to ensure fair margins.

How Do Price Influencers Affect Dynamometer Lab Costs?

Several factors influence the pricing of dynamometer lab services, impacting the total cost for buyers:

-

Volume/MOQ: Suppliers often offer discounts for bulk orders. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom-built dynamometers tailored to specific needs typically incur higher costs. Buyers should evaluate whether off-the-shelf solutions could meet their requirements more cost-effectively.

-

Materials and Quality/Certifications: The choice of materials significantly impacts pricing. Additionally, certifications (such as ISO standards) can affect costs, with certified products often being priced higher due to the added assurance of quality.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their expertise and reliability, while newer companies might offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms is essential. Different Incoterms can shift costs and responsibilities, affecting the final price paid by the buyer.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

To navigate the complexities of dynamometer lab sourcing, buyers can adopt several strategies:

-

Negotiate Effectively: Building a strong relationship with suppliers can facilitate better pricing. Consider discussing long-term partnerships, which may yield more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Assessing the TCO rather than just the initial purchase price can lead to better investment decisions. Consider aspects like maintenance, operational efficiency, and potential downtime costs.

-

Understand Pricing Nuances for International Transactions: Different regions may have unique pricing structures due to labor costs, materials availability, and market demand. Buyers from Africa and South America should be particularly vigilant about currency fluctuations and import tariffs that can affect pricing.

-

Leverage Global Competition: As the dynamometer market is competitive, buyers should explore multiple suppliers globally. This can provide leverage in negotiations and ensure access to the best prices.

Disclaimer on Indicative Prices

Prices for dynamometer lab services can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes from multiple suppliers and conduct thorough market research to obtain accurate pricing information tailored to their specific needs.

Alternatives Analysis: Comparing dynamometer lab With Other Solutions

When evaluating options for performance testing and analysis of heavy-duty equipment, it’s essential to consider various methodologies and technologies that can serve similar purposes to dynamometer labs. This comparison aims to provide insight into how dynamometer labs stack up against alternative solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Dynamometer Lab | Engine Test Cells | Powertrain Simulation Software |

|---|---|---|---|

| Performance | High accuracy in real-world conditions | Excellent for emissions and performance testing | Good for theoretical modeling, less precise in real-world simulation |

| Cost | Moderate to high initial investment | High initial and operational costs | Lower initial costs, but potential for high software license fees |

| Ease of Implementation | Requires specialized installation and setup | Complex setup with high maintenance needs | Quick to deploy with minimal hardware requirements |

| Maintenance | Regular calibration and upkeep needed | Frequent maintenance and calibration | Minimal maintenance, mainly software updates |

| Best Use Case | Comprehensive performance testing across various components | Emissions testing and engine development | Early-stage design and optimization of powertrains |

What Are the Pros and Cons of Engine Test Cells as an Alternative?

Engine test cells are specialized facilities designed for engine calibration and emissions testing. Their primary advantage lies in their capability to simulate various environmental conditions, making them ideal for regulatory compliance and performance validation. However, the high costs associated with setup and operation can be a barrier for smaller businesses. Additionally, the complexity of these systems may require specialized personnel for operation and maintenance, which can add to ongoing operational costs.

How Does Powertrain Simulation Software Compare?

Powertrain simulation software offers a cost-effective alternative for early-stage design and optimization of powertrain systems. It allows engineers to model and simulate vehicle performance without the need for physical prototypes, making it an attractive option for businesses looking to save on initial investment. However, its limitations include less precision in replicating real-world conditions and the inability to conduct physical tests on components. As a result, while this software can provide valuable insights during the design phase, it cannot fully replace the comprehensive data obtained from a dynamometer lab.

Illustrative image related to dynamometer lab

Conclusion: How Should B2B Buyers Choose the Right Testing Solution?

Selecting the appropriate testing solution hinges on specific business needs and objectives. For companies focused on rigorous performance validation of heavy-duty equipment, a dynamometer lab is indispensable due to its high accuracy and ability to replicate real-world conditions. Conversely, businesses prioritizing cost-effectiveness and early design optimization might find powertrain simulation software more suitable. Engine test cells serve a niche market, particularly for regulatory compliance, but can be prohibitively expensive for many. Ultimately, B2B buyers must assess their budget, technical requirements, and the specific outcomes they aim to achieve to determine the best fit for their operations.

Essential Technical Properties and Trade Terminology for dynamometer lab

What Are the Key Technical Properties for Dynamometer Labs?

In the world of dynamometer testing, certain technical properties are crucial for ensuring accurate and reliable performance evaluations. Here are some essential specifications that B2B buyers should consider when selecting a dynamometer lab:

-

Power Rating (Horsepower)

The power rating of a dynamometer indicates the maximum load it can handle, typically measured in horsepower (HP). For heavy-duty applications, such as those found in industrial equipment, a dynamometer that can accommodate up to 1300 HP or more is essential. Understanding the power rating helps businesses ensure that their testing capabilities align with the demands of their equipment, thereby avoiding potential damage or inaccurate results. -

Torque Capacity (lb-ft)

Torque capacity measures the amount of rotational force a dynamometer can apply or absorb, usually expressed in pound-feet (lb-ft). High torque capacities (up to 200,000 lb-ft) are vital for testing heavy machinery and vehicles under extreme conditions. For B2B buyers, selecting a dynamometer with adequate torque capacity is crucial for validating the durability and performance of components like gearboxes and drivetrains. -

Speed Range (RPM)

The speed range indicates the operational limits of the dynamometer, often measured in revolutions per minute (RPM). A broad speed range (up to 14,000 RPM) allows for comprehensive testing across different operational scenarios. Businesses need to understand the required speed range for their specific applications to ensure accurate performance metrics and compliance with industry standards. -

Environmental Simulation Capabilities

Dynamometers equipped with environmental simulation features can replicate various conditions, such as temperature extremes and humidity levels. This capability is essential for testing equipment under real-world conditions, especially in industries like automotive and aerospace. Buyers should prioritize labs that offer advanced simulation capabilities to ensure their products meet rigorous performance standards. -

Data Acquisition Systems

Advanced data acquisition systems are integral for capturing and analyzing performance metrics during testing. These systems provide critical insights into parameters such as torque, speed, and emissions. B2B buyers should consider the sophistication of a lab’s data acquisition technology to ensure they receive detailed and accurate reports that inform design and operational decisions. -

Calibration Standards

Calibration is vital for ensuring the accuracy and reliability of test results. Labs should adhere to recognized calibration standards, such as ISO/IEC 17025, to provide confidence in their testing outcomes. Buyers should verify that the dynamometer lab they choose maintains these standards, as this will impact the credibility of their testing and validation processes.

What Are Common Trade Terms Used in Dynamometer Labs?

Understanding industry jargon is essential for effective communication and decision-making in the dynamometer testing space. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In dynamometer testing, understanding OEM specifications is crucial for ensuring that components meet the required performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For dynamometer testing services, knowing the MOQ helps buyers plan their budgets and avoid overcommitting to services that may exceed their immediate needs. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to submit price proposals for specific services or products. B2B buyers should issue RFQs when seeking competitive pricing for dynamometer testing services to ensure they receive comprehensive and comparable offers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers operating across borders, as it clarifies liability and reduces the risk of disputes. -

Calibration Certificate

A calibration certificate is a document that verifies that a device has been tested and meets specified accuracy standards. For dynamometer testing, obtaining this certificate is crucial for validating test results, especially in regulated industries. -

Benchmarking

Benchmarking refers to the process of comparing a company’s performance metrics to industry standards or best practices. In dynamometer labs, benchmarking is essential for assessing the performance of engines or components against competitive products, allowing companies to identify areas for improvement.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when selecting dynamometer lab services, ensuring their testing processes are robust, compliant, and conducive to achieving their operational goals.

Illustrative image related to dynamometer lab

Navigating Market Dynamics and Sourcing Trends in the dynamometer lab Sector

What Are the Current Market Dynamics and Key Trends in the Dynamometer Lab Sector?

The dynamometer lab sector is experiencing significant growth driven by the increasing demand for precision testing in automotive and heavy-duty machinery applications. Key global drivers include the rise of electric vehicles (EVs) and stringent emissions regulations that necessitate advanced testing capabilities. This shift is particularly evident in regions such as Europe, which is leading the charge in adopting new automotive technologies, and Africa and South America, where industrial growth is spurring investments in testing infrastructure.

Emerging B2B tech trends, such as the integration of IoT and AI into dynamometer testing processes, are enhancing data collection and analysis. These innovations enable real-time monitoring and predictive maintenance, allowing companies to optimize performance and reduce downtime. Furthermore, the demand for versatile testing environments is rising, as buyers seek labs capable of simulating various conditions—from extreme temperatures to different altitudes—ensuring that their products are robust and compliant with international standards.

International B2B buyers should also consider the importance of partnerships with labs that offer comprehensive testing solutions, such as those that combine engine and component testing in a single facility. This trend is particularly relevant for companies in the Middle East and Europe, where operational efficiency and compliance with regulatory frameworks are paramount. As the dynamometer lab landscape evolves, understanding these dynamics will enable businesses to make informed sourcing decisions that align with their strategic goals.

Illustrative image related to dynamometer lab

How Is Sustainability and Ethical Sourcing Impacting the Dynamometer Lab Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the dynamometer lab sector. The environmental impact of manufacturing and testing processes is under scrutiny, with stakeholders demanding transparency and accountability in supply chains. Buyers are increasingly favoring suppliers that prioritize sustainable practices, such as reducing waste and utilizing eco-friendly materials in their operations.

Incorporating ‘green’ certifications, like ISO 14001 for environmental management, can enhance a supplier’s credibility and appeal to environmentally conscious buyers. Furthermore, the adoption of sustainable practices, such as energy-efficient testing equipment and recycling programs, not only reduces environmental footprints but can also lead to cost savings in the long run. As the global market shifts towards a more sustainable future, B2B buyers must actively seek out partners that align with these values to mitigate risks and enhance their brand reputation.

Moreover, demonstrating a commitment to ethical sourcing can enhance customer loyalty and attract new clients, particularly in regions where environmental regulations are becoming stricter. By prioritizing sustainability in their sourcing strategies, businesses can position themselves as leaders in the dynamometer lab sector, fostering innovation while contributing to a healthier planet.

What Is the Brief Evolution and History of the Dynamometer Lab Sector?

The dynamometer lab sector has evolved significantly over the last century, transitioning from rudimentary mechanical devices to sophisticated, computer-controlled systems capable of precise measurements and simulations. Initially used primarily for testing automotive engines, dynamometers have expanded their applications to include a wide range of industries, including aerospace, marine, and industrial manufacturing.

The development of electronic and digital technologies in the late 20th century revolutionized dynamometer testing, allowing for enhanced data acquisition and analysis. This evolution has been driven by the increasing complexity of powertrains and the need for rigorous testing to meet regulatory standards. Today, dynamometer labs are equipped with advanced capabilities that not only facilitate performance testing but also enable comprehensive assessments of emissions, durability, and efficiency.

Illustrative image related to dynamometer lab

As the industry continues to innovate, the focus is shifting towards integrating smart technologies that enhance testing capabilities and improve operational efficiency. This historical context underscores the importance of adaptability and innovation in the dynamometer lab sector, positioning it as a vital component of the broader automotive and industrial landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of dynamometer lab

1. How can I ensure the dynamometer lab meets my specific testing requirements?

To ensure a dynamometer lab meets your specific needs, start by outlining your testing objectives, including the type of equipment, environmental conditions, and performance parameters. Communicate these requirements with potential suppliers and ask for detailed capabilities, including their testing methodologies, equipment specifications, and past project examples. It’s also beneficial to request references or case studies from similar industries to gauge their experience. Finally, consider visiting the lab to assess their facilities and ensure they align with your expectations.

2. What factors should I consider when selecting a dynamometer testing provider?

When selecting a dynamometer testing provider, consider their industry experience, technological capabilities, and the range of services offered. Evaluate their compliance with international standards and certifications, as this ensures reliability and quality. Additionally, assess their flexibility in customizing tests to meet your specific needs and their ability to provide comprehensive data analysis. It’s also crucial to review their customer support, turnaround times, and logistical capabilities, particularly if you are sourcing from regions like Africa, South America, or the Middle East.

3. What customization options are typically available for dynamometer testing?

Many dynamometer labs offer customization options tailored to meet specific testing needs. These can include adjustments to testing parameters, such as torque and speed settings, as well as environmental conditions like temperature and humidity. Additionally, some labs may provide bespoke data reporting formats or specialized testing scenarios to accommodate unique applications. When discussing your project, ensure you articulate your specific requirements to find a lab that can provide the necessary flexibility in their testing setups.

4. What are the typical payment terms for engaging a dynamometer lab?

Payment terms can vary significantly between dynamometer labs, but common arrangements include upfront deposits, milestone payments based on project phases, or payment upon completion of services. Some providers may offer net payment terms ranging from 30 to 90 days after invoicing. It’s essential to clarify these terms before entering into an agreement to avoid any misunderstandings. Additionally, inquire about accepted payment methods, particularly if you’re dealing with international transactions, to ensure a smooth financial process.

5. What is the minimum order quantity (MOQ) for dynamometer testing services?

Minimum order quantities (MOQ) for dynamometer testing services can vary widely based on the provider and the complexity of the tests required. Some labs may have no MOQ, allowing you to test a single component, while others might require a minimum number of tests or projects to justify setup and operational costs. When discussing your needs with potential suppliers, be sure to ask about their MOQ policies to ensure they align with your project scale and budget.

6. How do I verify the quality assurance processes of a dynamometer lab?

To verify the quality assurance processes of a dynamometer lab, request documentation of their QA protocols, certifications, and testing standards. Look for labs that are ISO certified, as this indicates adherence to international quality standards. Additionally, ask about their calibration procedures for testing equipment and how they handle data accuracy and reliability. Engaging in a dialogue about their past quality control measures and any third-party audits can also provide insight into their commitment to quality.

7. What logistics should I consider when working with an international dynamometer lab?

When working with an international dynamometer lab, consider logistics such as shipping costs, import duties, and lead times for transporting equipment or components. It’s crucial to understand the lab’s capabilities regarding international shipping and whether they provide support for customs clearance. Additionally, assess how time zone differences may impact communication and project timelines. Establishing a clear logistics plan upfront can help mitigate potential delays and ensure a smoother collaboration.

Illustrative image related to dynamometer lab

8. What are common testing standards followed by dynamometer labs?

Dynamometer labs typically follow a range of testing standards depending on the industry and application. Common standards include those set by ISO (International Organization for Standardization), SAE (Society of Automotive Engineers), and ASTM (American Society for Testing and Materials). For engine testing, you may encounter standards such as ISO 8178 for emissions or specific OEM guidelines. It’s essential to confirm with your chosen lab which standards they adhere to, ensuring compliance with regulatory requirements relevant to your industry and location.

Top 3 Dynamometer Lab Manufacturers & Suppliers List

1. Clark Testing – Dynamometer Testing Services

Domain: clarktesting.com

Registered: 2005 (20 years)

Introduction: Dynamometer Testing Services for Heavy-Duty Industrial Equipment. Capabilities include: High-Power Testing (up to 1300 horsepower), Versatile Power Supply (up to 600 amps at 480 volts, 2300-volt options), Comprehensive Component Testing (powertrains, drivetrains, transmissions, transfer cases, axles, brakes, bearings, clutches, drive shafts, gearboxes), Advanced Control Systems (proprietary softwa…

2. SGS – Engine Dynamometer Testing

Domain: sgs.com

Registered: 1991 (34 years)

Introduction: Engine dynamometer testing from SGS offers comprehensive engine testing using specialized test cells for engine development, regulatory compliance, and automotive homologation. The services include testing for small handheld engines to large heavy-duty engines, including vehicle, marine, and aircraft engines. Key features include:

– Combustion air temperature and pressure controls for simulating e…

3. Dyno One – Advanced Dynamometer Solutions

Domain: dyno-one.com

Registered: 1999 (26 years)

Introduction: Dynamometers: AC, DC, EV, Hub, Water Brake and more. AccuDyne™ – AC Dynamometers, AccuBrake™ – Brake-Based Dynamometers, HEViDyne™ – Dynamometer Test System, MicroDyne™ – AC Dynamometers, AccuHD™ – Hub Dynamometers, DynoLAB GenV – Test Automation Controller, Motor Efficiency Test (MET) – Across International Standards and Motor Sizes, EV Battery Test Systems – High Voltage Battery Test Systems, Ba…

Strategic Sourcing Conclusion and Outlook for dynamometer lab

In conclusion, leveraging strategic sourcing for dynamometer lab services is vital for businesses aiming to enhance their product performance and compliance with international standards. By partnering with reputable testing facilities, companies can access cutting-edge technologies and expertise that ensure accurate assessments of engine performance, emissions, and durability. This not only aids in meeting regulatory requirements but also drives innovation in product development, particularly for heavy-duty and high-performance applications.

International B2B buyers from Africa, South America, the Middle East, and Europe should prioritize selecting partners who offer comprehensive testing capabilities tailored to their specific industry needs. The ability to simulate varied environmental conditions and conduct thorough evaluations can significantly impact the reliability and market competitiveness of their products.

As we look ahead, the dynamometer testing landscape will continue to evolve with advancements in technology and regulatory frameworks. Now is the time for businesses to invest in robust dynamometer testing solutions that can adapt to these changes and support their growth objectives. Engage with trusted dynamometer service providers today to ensure your equipment meets the highest standards of performance and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.