Top 3 Drift Tires Suppliers (And How to Choose)

Introduction: Navigating the Global Market for drift tires

In the fast-evolving world of motorsport, sourcing high-performance drift tires presents a unique challenge for international B2B buyers. With diverse markets spanning Africa, South America, the Middle East, and Europe, understanding the nuances of drift tire specifications, applications, and supplier reliability is crucial for making informed purchasing decisions. This comprehensive guide delves into the various types of drift tires available, their specific applications—from grassroots events to competitive racing—and the critical factors to consider when vetting suppliers.

With insights into pricing structures, including bulk purchase discounts, and tire performance characteristics, this guide empowers buyers to navigate the complexities of the global drift tire market. Whether you’re a distributor looking to expand your product offerings or a racing team seeking the best grip and durability, our resource equips you with the knowledge to optimize your procurement strategy. By addressing the common pain points associated with sourcing drift tires, we aim to facilitate smooth transactions and foster long-term partnerships in this dynamic industry.

Investing in the right drift tires can significantly impact performance and safety on the track. This guide is designed to ensure you have all the tools needed to make the best decisions for your business and enhance your competitive edge in the global market.

Understanding drift tires Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Semi-Slick Drift Tires | Street-legal, high grip, designed for mixed-use (track and street) | Grassroots drifting, amateur racing | Pros: Versatile, good balance of grip and durability. Cons: May wear faster on rough surfaces. |

| Competition Drift Tires | Optimized for maximum grip, softer rubber compounds | Professional racing, competitive drifting | Pros: Superior performance, quick heat-up times. Cons: Higher cost, shorter lifespan. |

| All-Weather Drift Tires | Designed to perform in various weather conditions | Year-round use, diverse climates | Pros: Versatile, reliable in different conditions. Cons: Less grip in dry conditions compared to specialized tires. |

| Low-Profile Drift Tires | Features a smaller sidewall, enhancing response and handling | Street racing, performance-oriented applications | Pros: Improved handling, aesthetic appeal. Cons: Rougher ride quality, potential for damage on potholes. |

| Hard Compound Drift Tires | Designed for extended tire life, with a focus on durability | Budget racing, practice sessions | Pros: Longer lifespan, cost-effective. Cons: Reduced grip and performance compared to softer options. |

What Are the Characteristics of Semi-Slick Drift Tires?

Semi-slick drift tires are engineered for versatility, making them suitable for both street and track use. They possess a unique tread pattern that balances grip and durability, allowing drivers to enjoy spirited driving without sacrificing performance. B2B buyers should consider their application; these tires are ideal for grassroots drifting and amateur racing, as they offer a good compromise between performance and cost. However, they may wear more quickly on rough surfaces, which is a consideration for budget-conscious buyers.

Why Choose Competition Drift Tires for Professional Racing?

Competition drift tires are crafted from softer rubber compounds that provide maximum grip, essential for high-stakes racing environments. Their design allows for quick heating, enabling drivers to achieve optimal performance almost immediately. These tires are primarily used in professional racing and competitive drifting, where every fraction of a second counts. B2B buyers should weigh the benefits of superior performance against the higher cost and shorter lifespan, as these tires are designed for maximum performance rather than longevity.

How Do All-Weather Drift Tires Benefit Diverse Climates?

All-weather drift tires are designed to perform reliably across various weather conditions, making them an excellent choice for regions with unpredictable climates. They offer a balanced performance that ensures safety and control in both wet and dry conditions. B2B buyers can leverage these tires for year-round applications, appealing to a broader customer base. However, while they are versatile, they may not provide the same level of grip in dry conditions as specialized tires, which could impact performance in competitive settings.

What Advantages Do Low-Profile Drift Tires Offer?

Low-profile drift tires feature a smaller sidewall, which enhances vehicle response and handling. This design is particularly appealing for street racing and performance-oriented applications, as it can improve the overall aesthetics of the vehicle while providing better cornering capabilities. B2B buyers should be aware that while these tires enhance handling, they can result in a rougher ride quality and may be more susceptible to damage from road imperfections, making them a less ideal choice for everyday driving.

Why Consider Hard Compound Drift Tires for Budget Racing?

Hard compound drift tires are built for durability and extended tire life, making them a cost-effective option for budget racing and practice sessions. These tires prioritize longevity over grip, allowing racers to practice more frequently without incurring high costs. B2B buyers should evaluate the trade-off between performance and lifespan; while these tires are economical, they do not offer the same level of grip as softer options, which can be a significant factor for serious competitors.

Key Industrial Applications of drift tires

| Industry/Sector | Specific Application of drift tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorsports | Professional drifting events and competitions | Enhanced vehicle control and performance during races | Supplier reliability, tire durability, and performance reviews |

| Automotive Retail | Retail sales for drifting enthusiasts | Increased sales through specialized tire offerings | Bulk purchasing options, tire variety, and competitive pricing |

| Automotive Education | Drift training programs and driving schools | Improved training outcomes and safety for students | Quality assurance, compliance with safety standards, and pricing |

| Entertainment | Drift shows and exhibitions | Engaging audiences with thrilling performances | Custom tire designs, availability for bulk orders, and pricing |

| Motorsports Marketing | Promotional events featuring drifting demonstrations | Enhanced brand visibility and customer engagement | Sponsorship opportunities, tire performance data, and pricing |

How Are Drift Tires Used in Motorsports and What Problems Do They Solve?

In the motorsports industry, drift tires are crucial for professional drifting events and competitions. These tires are engineered to provide optimal grip while allowing controlled slip, enabling drivers to maintain high-speed slides around corners. The specific requirements for these tires include a balance of durability and performance, as they must withstand the extreme conditions of competitive racing. For international buyers, especially from regions like Europe and the Middle East, sourcing high-quality drift tires from reputable manufacturers is essential to ensure safety and performance during races.

What Role Do Drift Tires Play in Automotive Retail?

In automotive retail, drift tires cater to a growing market of drifting enthusiasts. Retailers can boost sales by offering specialized tire options that appeal to this niche audience. The key to success in this sector lies in providing a variety of tire models that suit different driving styles and vehicle types. Buyers should consider bulk purchasing options to maximize profit margins, as well as competitive pricing strategies to attract customers. Additionally, building relationships with reliable suppliers ensures consistent product availability.

How Are Drift Tires Utilized in Automotive Education?

Drift tires are increasingly used in automotive education, particularly in drift training programs and driving schools. These tires help students learn the art of drifting while prioritizing safety and control. By using high-performance drift tires, educational institutions can enhance training outcomes, allowing students to gain hands-on experience in a controlled environment. Buyers from educational sectors should focus on sourcing tires that meet safety standards and offer good performance metrics, as this directly impacts the quality of training provided.

Why Are Drift Tires Important for Entertainment Events?

In the entertainment industry, drift tires are vital for drift shows and exhibitions that aim to captivate audiences. These events rely on the spectacle of controlled drifting, which requires tires that can perform under high-stress conditions while still delivering a thrilling experience. Businesses involved in organizing such events must consider custom tire designs to enhance visual appeal and performance. Additionally, sourcing tires in bulk can help manage costs effectively, ensuring that events remain profitable while delivering an unforgettable experience for attendees.

How Can Drift Tires Benefit Motorsports Marketing?

Drift tires are also significant in motorsports marketing, particularly for promotional events featuring drifting demonstrations. These tires enhance brand visibility by showcasing a company’s commitment to quality and performance in a high-octane environment. Businesses looking to leverage drift tires for marketing purposes should consider sponsorship opportunities that align with their brand values. Moreover, having access to performance data and competitive pricing can help in crafting effective marketing strategies that resonate with target audiences in various regions, including Africa and South America.

3 Common User Pain Points for ‘drift tires’ & Their Solutions

Scenario 1: The Challenge of Limited Tire Life for Competitive Drifting

The Problem: B2B buyers, especially those managing fleets for competitive drifting events, often face the challenge of tires wearing out quickly due to the extreme conditions associated with drifting. The high-speed slides and sharp turns can lead to rapid degradation, resulting in increased costs and the need for frequent replacements. This not only strains the budget but also complicates inventory management, as buyers must constantly ensure they have enough tires on hand to meet demand.

The Solution: To mitigate the issue of tire longevity, buyers should focus on sourcing high-performance drift tires specifically engineered for endurance. Tires like the Accelera 351 GD, known for their longer tread life, can be a viable option. Additionally, establishing a bulk purchasing agreement with suppliers can lead to significant cost savings. Buyers should also consider implementing a tire rotation strategy during events to evenly distribute wear and prolong the life of their tires. Regularly monitoring tire performance and adjusting driving techniques can also help manage wear rates more effectively.

Scenario 2: Finding the Right Balance Between Grip and Slip

The Problem: Many buyers struggle to find drift tires that offer the perfect balance between grip and slip. This is crucial for maintaining control while executing high-speed maneuvers. Tires that provide too much grip can hinder the ability to drift effectively, while those with insufficient grip can lead to loss of control. This dilemma can frustrate teams and drivers, impacting their performance and overall event outcomes.

The Solution: Buyers should conduct thorough research on tire compounds and tread patterns that cater to their specific drifting styles. For instance, tires like the Accelera 651 Sport are designed to deliver maximum versatility, making them suitable for various drifting scenarios. Testing different tire types in controlled environments before major events can help buyers identify which tires best suit their needs. Collaborating with experienced drivers to gather feedback on tire performance can also provide invaluable insights, enabling teams to make informed purchasing decisions.

Scenario 3: Navigating Import Regulations and Sourcing Challenges

The Problem: International B2B buyers, particularly in regions like Africa and the Middle East, often encounter challenges related to sourcing drift tires due to import regulations, tariffs, and logistical issues. These hurdles can lead to delays in receiving products, increased costs, and potential disruptions in their operations. Additionally, navigating the complexities of customs can be overwhelming, especially for businesses not accustomed to international trade.

The Solution: To effectively navigate these challenges, buyers should partner with reliable suppliers who have experience in international shipping and understand the regulatory landscape of their respective regions. Establishing a direct line of communication with suppliers can help clarify shipping timelines and potential customs issues. Additionally, buyers should stay informed about local import regulations and consider engaging a freight forwarder to streamline the process. Creating a buffer stock of tires in anticipation of delays can also mitigate the impact of unforeseen logistical challenges, ensuring that operations remain uninterrupted.

Strategic Material Selection Guide for drift tires

When selecting drift tires, the choice of material is crucial for optimizing performance, durability, and safety. Here, we analyze four common materials used in drift tire construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Rubber in Drift Tires?

Rubber is the primary material used in drift tires, specifically formulated for performance driving. It exhibits excellent grip due to its high coefficient of friction, which is essential for maintaining control during drifts. The rubber compound is often softer, allowing for better traction and heat dissipation during high-speed maneuvers. The temperature resistance of rubber can vary, but specialized compounds can withstand the elevated temperatures generated during drifting.

Pros & Cons: The advantages of rubber include its superior grip and ability to conform to road surfaces, which enhances performance. However, softer rubber tends to wear out faster, leading to higher replacement costs. Additionally, the manufacturing process can be complex, requiring precise formulations to balance performance and durability.

How Does Nylon Reinforcement Impact Drift Tire Performance?

Nylon is often used as a reinforcement material in drift tires, enhancing structural integrity and performance. This synthetic fiber provides excellent tensile strength, which helps the tire maintain its shape under extreme conditions. Nylon also contributes to the tire’s resistance to deformation, ensuring consistent performance during high-speed drifting.

Pros & Cons: The key advantage of nylon reinforcement is its ability to improve durability without significantly increasing weight. However, the cost of incorporating nylon can raise the overall price of the tire, which may not be ideal for budget-conscious buyers. Additionally, the manufacturing complexity increases, as it requires specialized techniques to integrate nylon effectively.

What Role Does Carbon Black Play in Drift Tire Composition?

Carbon black is a common additive in tire manufacturing that enhances various properties of drift tires. It improves the tire’s wear resistance and contributes to better traction and heat resistance. The incorporation of carbon black allows for a more durable tire that can withstand the rigors of drifting while maintaining performance.

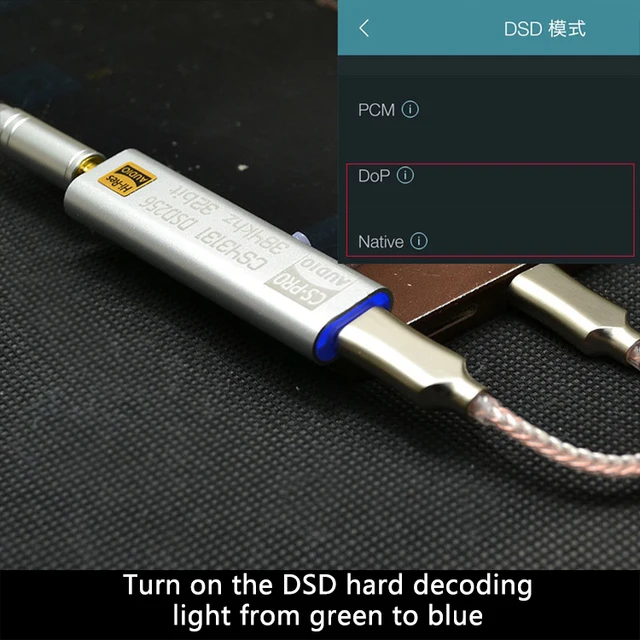

Illustrative image related to drift tires

Pros & Cons: The primary advantage of carbon black is its cost-effectiveness in enhancing tire longevity and performance. However, excessive use can lead to a stiffer tire, which may compromise grip. Additionally, sourcing high-quality carbon black may be challenging in certain regions, impacting supply chains for international buyers.

Why Is the Tread Pattern Important for Drift Tire Selection?

The tread pattern is a critical aspect of drift tire design, influencing grip and performance. Drift tires typically feature a specialized tread pattern that allows for controlled slippage while maximizing surface contact. This design helps channel water away, reducing hydroplaning risks during wet conditions.

Pros & Cons: A well-designed tread pattern enhances performance and safety, making it a significant selling point. However, developing unique tread designs can complicate manufacturing and increase costs. Moreover, tread patterns must comply with regional regulations, which may vary across markets in Africa, South America, the Middle East, and Europe.

Summary Table of Material Selection for Drift Tires

| Material | Typical Use Case for drift tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General performance drifting | Excellent grip and heat dissipation | Faster wear rate | Medium |

| Nylon | High-performance applications | Enhanced durability and shape retention | Higher manufacturing costs | High |

| Carbon Black | All drift tire applications | Cost-effective durability improvement | Can stiffen tire if overused | Low |

| Tread Pattern | Specialized drifting conditions | Optimized grip and water channeling | Complex manufacturing and regulatory compliance | Medium |

This comprehensive analysis of materials used in drift tires provides international B2B buyers with actionable insights to make informed purchasing decisions. Understanding the properties and implications of each material will aid in selecting the most suitable drift tires for specific applications and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for drift tires

What Are the Key Stages in the Manufacturing Process of Drift Tires?

The manufacturing of drift tires is a sophisticated process that involves several crucial stages, ensuring the final product meets the high-performance demands of motorsport enthusiasts and professional drivers alike. Understanding these stages helps B2B buyers assess the quality and reliability of potential suppliers.

Material Preparation: What Materials Are Used in Drift Tire Manufacturing?

The foundation of any high-quality drift tire lies in the selection of materials. Typically, manufacturers utilize a specialized blend of natural and synthetic rubber, which is crucial for achieving the desired grip and durability. Along with rubber, additives such as carbon black, silica, and various curing agents are used to enhance performance characteristics, including heat resistance and traction.

During the material preparation phase, raw materials undergo rigorous quality checks to ensure compliance with industry standards. This initial inspection is critical as it sets the tone for the entire manufacturing process. Any subpar materials can compromise the tire’s performance, leading to safety concerns on the racetrack.

Illustrative image related to drift tires

How Are Drift Tires Formed and Assembled?

Once the materials are prepared, the next step is forming the tire components. This involves mixing the rubber compounds in large industrial mixers to ensure uniform distribution of additives. The blended material is then extruded into sheets or strips that will form the tire’s tread and sidewalls.

The assembly stage follows, where the tire’s components are layered and shaped. This includes fitting the inner lining, belts, and beads, which provide structural integrity and maintain the tire’s shape. Advanced techniques like mold curing are employed to bond these components effectively, ensuring a strong, cohesive tire.

What Finishing Techniques Are Applied to Drift Tires?

After assembly, the tires undergo a finishing process that includes trimming excess rubber, applying surface treatments, and inspecting for defects. This step is essential to enhance the tire’s performance and appearance. Manufacturers may also apply a specific tread pattern that optimizes grip and control during drifting maneuvers.

Additionally, final inspections are performed to ensure that each tire meets stringent quality standards before packaging and shipping. This thorough approach minimizes the risk of defects that could affect performance.

How Is Quality Assurance Maintained in Drift Tire Manufacturing?

Quality assurance (QA) is a pivotal aspect of drift tire manufacturing, ensuring that products not only meet but exceed industry standards. For B2B buyers, understanding the QA processes can help in selecting reliable suppliers.

Illustrative image related to drift tires

What International Standards Govern Drift Tire Quality?

Manufacturers often adhere to international quality standards, such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE and API may apply, depending on the market and geographic location.

For buyers in regions like Africa, South America, the Middle East, and Europe, verifying these certifications can provide assurance of product quality and safety.

What Are the QC Checkpoints in Drift Tire Production?

Quality control checkpoints are integrated throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This checkpoint assesses the quality of raw materials before production begins. It ensures that only compliant materials are used in tire manufacturing.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor the quality of production. This includes checking material mixing, curing processes, and assembly.

-

Final Quality Control (FQC): Before shipment, tires undergo a comprehensive final inspection to identify any defects and ensure they meet performance specifications. This step is crucial for maintaining brand reputation and customer trust.

What Testing Methods Are Commonly Used for Drift Tires?

Testing methods play a significant role in validating the performance and safety of drift tires. Common testing techniques include:

-

Dynamic Testing: Simulating real-world conditions to evaluate tire performance under various speeds and temperatures.

-

Grip Testing: Assessing how well tires maintain traction on different surfaces, which is critical for drifting performance.

-

Durability Testing: Subjecting tires to extreme conditions to determine their lifespan and resistance to wear and tear.

These tests help ensure that the tires perform as expected, allowing manufacturers to make informed adjustments to their processes or materials as needed.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for making informed purchasing decisions. Here are effective strategies to ensure supplier credibility:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting audits of potential suppliers can provide insights into their quality control processes and adherence to international standards. Buyers can request detailed reports on past audits, including any corrective actions taken to address deficiencies. This transparency fosters trust and ensures alignment with quality expectations.

How Can Third-Party Inspections Enhance Supplier Credibility?

Engaging third-party inspection services can further validate a supplier’s quality assurance practices. These independent entities can perform inspections at various stages of the manufacturing process, providing unbiased assessments of quality and compliance.

What Are the Unique QC Considerations for International Buyers?

International buyers must be aware of specific nuances in quality control that may vary by region. For example, certain certifications might be more recognized in Europe than in Africa or South America. Understanding these regional differences is crucial for ensuring that the tires meet local regulations and performance expectations.

Additionally, language barriers and cultural differences can impact communication regarding quality standards. Establishing clear lines of communication and documentation can mitigate these challenges, ensuring that all parties are aligned on quality expectations.

In conclusion, the manufacturing and quality assurance processes of drift tires are intricate and vital for ensuring performance and safety. B2B buyers must take a proactive approach in understanding these processes to select suppliers that align with their quality standards and business goals. By focusing on material selection, rigorous quality control checkpoints, and effective testing methods, buyers can ensure they procure high-quality drift tires that meet the demands of motorsport enthusiasts worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drift tires’

In the world of motorsports, particularly drifting, sourcing the right tires is crucial for performance and safety. This guide provides B2B buyers with a practical checklist to ensure that they procure high-quality drift tires that meet their specific needs. Follow these steps to navigate the sourcing process effectively.

Illustrative image related to drift tires

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before you start sourcing. Determine the type of drift tires that suit your requirements based on factors such as vehicle type, driving style, and surface conditions. Consider the tire’s tread pattern, rubber compound, and performance characteristics to ensure they align with your drifting goals.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reputable suppliers in the drift tire market. Look for companies with a proven track record and positive customer reviews. Utilize industry forums, trade shows, and online platforms to gather insights about potential suppliers and their offerings.

- Key considerations:

- Years of experience in the market

- Customer testimonials or case studies

Step 3: Evaluate Product Range

Assess the product range offered by potential suppliers. A diverse selection allows you to find the exact tire specifications you need. Check if they provide various models suited for different types of drifting, such as competition or grassroots levels.

- Look for:

- Specialty tires designed for specific conditions

- Availability of bulk purchasing options to save costs

Step 4: Verify Supplier Certifications

Confirm that your suppliers meet relevant industry certifications and standards. Certifications can indicate a supplier’s commitment to quality and safety. This is especially important for drift tires, which must withstand extreme driving conditions.

- Important certifications may include:

- ISO certifications

- Compliance with regional safety standards

Step 5: Request Samples or Trial Periods

Before making a bulk purchase, request samples or inquire about trial periods. Many suppliers offer risk-free trials that allow you to test the tires under real conditions. This step is vital to ensure that the tires perform as expected and meet your quality standards.

Illustrative image related to drift tires

Step 6: Negotiate Pricing and Terms

Engage in negotiations to secure the best pricing and payment terms. Discuss bulk discounts, shipping costs, and payment plans that may be available. This is particularly beneficial for B2B buyers looking to make large-volume purchases.

- Consider:

- Discounts for larger orders

- Flexible payment options that suit your cash flow

Step 7: Establish a Reliable Communication Channel

Effective communication is critical throughout the sourcing process. Establish a direct line of communication with your suppliers for timely updates and support. This will help in addressing any concerns or adjustments needed during the procurement process.

By following this checklist, B2B buyers can streamline their drift tire sourcing process, ensuring they find the right products that align with their needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for drift tires Sourcing

What Are the Key Cost Components in Drift Tire Manufacturing?

Understanding the cost structure of drift tire sourcing is crucial for B2B buyers aiming for cost efficiency. The primary cost components include:

-

Materials: The choice of rubber compounds significantly affects pricing. Softer compounds are often preferred for drifting as they provide better grip but wear out faster, impacting lifecycle costs.

-

Labor: Labor costs vary by region and can influence the overall price. Countries with higher labor costs might offer better craftsmanship and quality assurance, which could justify a higher price point.

-

Manufacturing Overhead: This includes facility costs, utilities, and administrative expenses. Efficient factories with advanced technology may have lower overhead, allowing for competitive pricing.

-

Tooling: The initial investment in molds and manufacturing tools can be substantial, particularly for customized tires. This cost is often amortized over large production runs.

-

Quality Control (QC): Ensuring that drift tires meet safety and performance standards incurs costs. Effective QC processes can prevent costly returns and enhance brand reputation.

-

Logistics: Shipping and handling costs are especially critical for international buyers. Freight charges, import duties, and local taxes can substantially affect the final price.

-

Margin: Suppliers generally add a margin to cover risks and ensure profitability. This margin can vary widely based on market competition and demand.

How Do Price Influencers Impact Drift Tire Costs?

Several factors can influence the pricing of drift tires:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often come with significant discounts. Suppliers may offer tiered pricing structures where larger orders yield better per-unit costs.

-

Specifications and Customization: Custom tire designs or specifications can lead to higher costs due to additional tooling and material requirements. Standardized products are generally more cost-effective.

-

Materials: Premium materials that enhance performance, such as high-quality rubber compounds, can increase the price. Buyers should assess the trade-offs between cost and performance.

-

Quality and Certifications: Tires meeting international safety and performance certifications may command higher prices. Investing in certified products can reduce long-term risks associated with tire failures.

-

Supplier Factors: The reputation and reliability of the supplier play a role in pricing. Established brands may charge more for their reputation, while emerging suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is essential for buyers. These terms affect who bears the cost and risk during transport, impacting the overall price.

What Tips Can Buyers Use to Negotiate Better Prices for Drift Tires?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to drift tires

-

Leverage Bulk Buying: Engage suppliers in discussions about bulk purchasing options. Many suppliers provide discounts for larger orders, significantly reducing the cost per unit.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, performance, and potential warranty claims. A higher upfront cost may lead to lower long-term expenses.

-

Negotiate Payment Terms: Flexible payment options can improve cash flow. Discussing payment plans or discounts for early payments can lead to better pricing.

-

Explore Local Suppliers: Investigate local suppliers who may offer lower shipping costs and quicker turnaround times. Local partnerships can also facilitate easier negotiations and stronger relationships.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends and practices. Different markets may have varying expectations regarding quality and cost.

Disclaimer on Indicative Prices

Prices for drift tires can fluctuate based on market conditions, supplier pricing strategies, and currency exchange rates. The prices mentioned in this analysis are indicative and should be verified with suppliers for current and accurate quotes. Always consider additional costs such as shipping and taxes when calculating the total expenditure.

Alternatives Analysis: Comparing drift tires With Other Solutions

In the competitive landscape of motorsport, especially in drifting, selecting the right tires is crucial for performance and safety. However, buyers may consider alternatives to traditional drift tires that can also meet their specific needs. This analysis compares drift tires with two viable alternatives: performance street tires and specialized racing slicks.

| Comparison Aspect | Drift Tires | Performance Street Tires | Specialized Racing Slicks |

|---|---|---|---|

| Performance | Optimized for controlled slides; excellent grip during drifting | Good grip for high-speed cornering but may lack slip control | Maximum grip with minimal tread for dry conditions; excellent responsiveness |

| Cost | Moderate, generally ranging from $100 to $160 per tire | Typically lower, around $80 to $120 per tire | Higher cost, often exceeding $200 per tire due to advanced materials |

| Ease of Implementation | Requires specific setup and alignment for drifting | Easy to install on most vehicles; no special setup needed | Requires professional installation and setup for optimal performance |

| Maintenance | Moderate; wear may be faster due to softer compounds | Lower; longer lifespan under everyday driving conditions | High; frequent replacement needed due to rapid wear |

| Best Use Case | Ideal for dedicated drifting events and competitions | Suitable for street driving with occasional spirited use | Best for track use and competitive racing events under dry conditions |

What are the Pros and Cons of Performance Street Tires Compared to Drift Tires?

Performance street tires are designed for high-speed cornering and provide a balance between grip and longevity. Their construction allows for versatile use on public roads while still enabling spirited driving. The primary advantage is their cost-effectiveness, making them an attractive option for buyers looking for a budget-friendly solution. However, they may not provide the same level of controlled slip and grip as drift tires, which can be a disadvantage during competitive drifting scenarios.

How Do Specialized Racing Slicks Stack Up Against Drift Tires?

Specialized racing slicks are engineered for maximum grip and responsiveness on dry surfaces, making them the preferred choice for professional racing. These tires have no tread pattern, allowing for larger contact areas that enhance grip. While they deliver superior performance, the downsides include higher costs and rapid wear, necessitating frequent replacements. Additionally, they require careful setup and are not suitable for casual driving, making them less versatile than drift tires.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right tire solution depends on various factors, including the intended use, budget constraints, and performance requirements. For businesses focused on competitive drifting, investing in specialized drift tires may provide the best balance of performance and control. Conversely, those seeking cost-effective options for everyday use may benefit from performance street tires. Lastly, for high-level racing scenarios, specialized racing slicks could be justified despite their higher cost and maintenance needs. Ultimately, B2B buyers should assess their specific needs and operational context to make an informed decision that aligns with their performance goals and financial parameters.

Illustrative image related to drift tires

Essential Technical Properties and Trade Terminology for drift tires

What Are the Key Technical Properties of Drift Tires?

When considering drift tires for purchase, it’s crucial to understand the specific technical properties that influence performance. Here are several key specifications that should be on every B2B buyer’s radar:

1. Rubber Compound

The rubber compound is critical in determining the tire’s grip and durability. Drift tires are typically manufactured with softer rubber, which provides superior traction and allows for controlled slippage during drifting. This softer compound also wears out faster, making it essential for buyers to consider the balance between performance and longevity when selecting tires.

2. Tread Design

The tread pattern of drift tires is specifically engineered to optimize grip while allowing for controlled slides. Unique designs help channel water away from the contact patch to maintain traction in wet conditions. For buyers, understanding the tread design can help in selecting tires suitable for various track conditions and styles of drifting.

3. Tire Width

Tire width affects both grip and handling. Wider tires generally offer more surface area for traction, enhancing stability during high-speed maneuvers. However, they can also increase drag, which might not be ideal for all drifting scenarios. Buyers must assess their vehicle specifications and intended use to select the appropriate width.

4. Aspect Ratio

The aspect ratio is the ratio of the tire’s height to its width. A lower aspect ratio typically results in better handling and responsiveness, which is vital for drift performance. Buyers should take into account how aspect ratios affect vehicle dynamics, especially in competitive environments where precision is key.

5. Load Index and Speed Rating

The load index indicates the maximum weight a tire can support, while the speed rating denotes the maximum speed capability. Both are critical for ensuring that drift tires can handle the stresses of competitive driving. Buyers should verify that the load index and speed rating align with their vehicle’s specifications to prevent performance issues.

What Are Common Trade Terms Used in the Drift Tire Industry?

Understanding industry jargon is equally important for B2B buyers. Familiarity with these terms can streamline communication and purchasing processes.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of drift tires, purchasing OEM products can ensure compatibility and performance standards. Buyers should consider OEM options for reliability and warranty support.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier requires for an order. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs that align with their purchasing capacity and market demand to avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products or services. For drift tires, sending an RFQ can help buyers compare prices and terms from various manufacturers. This process is vital for making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks in international transactions, particularly when sourcing drift tires from different regions.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each product variant, used for inventory management. In the drift tire industry, SKUs can help buyers keep track of specific tire models, sizes, and specifications, facilitating efficient order processing and inventory control.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their drift tire purchasing strategies, ensuring optimal performance and value in their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the drift tires Sector

Understanding the Current Market Dynamics in the Drift Tires Sector

The global drift tires market is experiencing significant growth, driven by the rising popularity of motorsports, particularly in regions such as Africa, South America, the Middle East, and Europe. This growth is fueled by increasing disposable incomes and the desire for unique automotive experiences among consumers. As drifting becomes more mainstream, international B2B buyers are presented with opportunities to source specialized tires that enhance vehicle performance while ensuring safety and control.

Emerging technologies are reshaping the way drift tires are manufactured and marketed. Innovations such as advanced rubber compounds and tire design software are enabling manufacturers to create products that offer superior grip, durability, and performance. Additionally, the adoption of e-commerce platforms facilitates easier access to a wider variety of drift tire options, allowing buyers to compare prices and specifications from multiple suppliers efficiently. Bulk purchasing options are also becoming a norm, providing cost savings for businesses looking to stock up on tires for their customers or events.

Furthermore, there is a notable trend toward customization in the drift tires sector. Buyers are increasingly seeking tires that cater to specific driving styles and conditions, leading manufacturers to offer more tailored solutions. This trend highlights the importance of having a robust supply chain that can respond quickly to changing customer demands while maintaining quality.

How Are Sustainability and Ethical Sourcing Shaping the Drift Tires Market?

As sustainability becomes a pressing concern globally, B2B buyers in the drift tires sector are increasingly prioritizing ethical sourcing and environmentally friendly materials. The production of traditional tires often involves harmful chemicals and processes that can have adverse environmental impacts. In response, manufacturers are exploring eco-friendly alternatives, such as bio-based rubber compounds and sustainable manufacturing practices.

Buyers are encouraged to look for suppliers that possess ‘green’ certifications, which indicate adherence to environmental standards. These certifications not only assure the quality and sustainability of the tires but also enhance the buyer’s brand reputation in an increasingly eco-conscious market. Furthermore, implementing transparent supply chains is becoming essential, as buyers want to ensure that their suppliers uphold ethical labor practices and environmental stewardship.

By prioritizing sustainability, businesses can not only mitigate their environmental impact but also align with consumer preferences, as many customers are now considering the ecological footprint of the products they purchase. This shift is particularly relevant in regions like Europe and North America, where regulatory frameworks are increasingly favoring sustainable practices.

What is the Evolution of Drift Tires and Their Impact on B2B Buying?

The evolution of drift tires can be traced back to the emergence of drifting as a motorsport discipline in the late 20th century. Originally, standard tires were adapted for drifting; however, as the sport gained popularity, the need for specialized tires became evident. Manufacturers began developing drift-specific tires designed to optimize grip and control during high-speed maneuvers, leading to the creation of unique tread patterns and rubber compounds.

Over the years, the technology behind drift tires has advanced significantly. Modern drift tires offer enhanced performance attributes, including better heat resistance and improved durability, which are crucial for competitive racing. This evolution has not only shaped the way enthusiasts approach drifting but also influenced B2B buying behavior. Buyers are now more informed and selective, seeking high-performance options that meet the rigorous demands of professional drifting. As such, suppliers must stay ahead of technological advancements and market preferences to remain competitive in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of drift tires

-

How do I select the right drift tires for my business?

Choosing the right drift tires involves understanding your target market’s needs, the types of vehicles they use, and the specific conditions they will face. Consider factors like tire compound, tread design, and size. Different tires excel in different scenarios—some offer better grip for high-powered applications, while others may be designed for durability in grassroots drifting. Request samples or trial options from suppliers to assess performance before committing to bulk orders. -

What are the most popular drift tire brands among international buyers?

Brands like Accelera, Vitour, and DS Racing are frequently sought after by international buyers for their balance of performance, durability, and affordability. Each brand has its unique strengths; for instance, Accelera tires are known for their versatility, while Vitour offers competitive performance at a lower price point. Researching regional preferences can also help you align your inventory with market demands. -

What customization options are available for drift tires?

Many manufacturers offer customization options, including specific tread patterns, rubber compounds, and tire sizes tailored to meet unique performance requirements. Discuss your specifications with suppliers to ensure they can accommodate your needs. Additionally, inquire about branding opportunities, such as custom logos or colors that can enhance your product’s appeal in your market. -

What is the minimum order quantity (MOQ) for drift tires?

MOQs for drift tires can vary significantly by supplier and brand, typically ranging from 12 to 50 tires. Some manufacturers may offer lower MOQs for initial orders or custom arrangements. It’s advisable to communicate your needs upfront when contacting suppliers to find options that fit your purchasing strategy, especially if you are testing a new market. -

How can I ensure the quality of the drift tires I am purchasing?

To ensure quality, verify that the manufacturer adheres to international quality standards and has relevant certifications. Request detailed product specifications and performance tests, and consider ordering samples for hands-on evaluation. Establishing a good relationship with suppliers and conducting regular quality audits can also help maintain high standards. -

What payment terms should I expect when sourcing drift tires internationally?

Payment terms can vary widely among suppliers. Common practices include upfront payments, net 30 or 60 days, and letters of credit for larger orders. It’s essential to negotiate terms that align with your cash flow needs while ensuring security in the transaction. Be sure to clarify the accepted payment methods, including wire transfers and online payment platforms. -

What are the shipping and logistics considerations for importing drift tires?

Importing drift tires involves careful consideration of shipping methods, costs, and customs regulations. Sea freight is often cost-effective for bulk orders, while air freight may be necessary for urgent needs. Familiarize yourself with the import duties and taxes applicable in your country, and work with logistics partners who have experience handling automotive products to ensure smooth delivery. -

How do I identify reliable suppliers for drift tires?

To identify reliable suppliers, conduct thorough research by checking online reviews, industry forums, and trade directories. Attend trade shows and networking events to meet potential partners in person. Request references from other clients and verify their business credentials. Establishing a clear line of communication and understanding their production capabilities will also help you gauge their reliability and commitment to quality.

Top 3 Drift Tires Manufacturers & Suppliers List

1. Accelera – Drift Tires Collection

Domain: tirestreets.com

Registered: 2015 (10 years)

Introduction: Drift Tires: Accelera 351 Sport GD, Accelera 651 Sport, Accelera 651 Sport XTRA, Vitour Tempesta Enzo, GT Radial Champiro SX2 RS.

2. Race Treads – Drift Tires

Domain: racetreads.com

Registered: 2023 (2 years)

Introduction: Race Treads offers drift tires with bulk discounts: 5% off for 12+ tires, 10% off for 24+ tires, and 15% off for 50+ tires. Custom quotes available for orders of 100+ tires. Free shipping and payment plans are available at checkout. Returns and warranty claims are not accepted for tires used for drifting.

3. Linglong – Crosswinds Tires

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Linglong Crosswinds tires are mentioned positively for drifting, particularly for daily use and affordability.

Strategic Sourcing Conclusion and Outlook for drift tires

In the rapidly evolving market for drift tires, strategic sourcing plays a pivotal role in ensuring that businesses remain competitive and responsive to the needs of their customers. By leveraging bulk purchasing options and exploring diverse tire offerings, international B2B buyers can optimize their supply chain while maximizing cost efficiencies. Brands that offer risk-free trial periods, such as the 30-day satisfaction guarantee, create opportunities for buyers to test products before committing, thereby enhancing customer satisfaction and loyalty.

As demand for drifting continues to surge across regions like Africa, South America, the Middle East, and Europe, the importance of aligning sourcing strategies with market trends cannot be overstated. Buyers should focus on suppliers that provide comprehensive support, including tailored pricing for large orders and loyalty programs that reward repeat purchases.

Looking ahead, businesses are encouraged to embrace innovation and stay informed about the latest developments in tire technology. By fostering strong relationships with reliable suppliers and continuously evaluating product performance, B2B buyers can secure a competitive edge in the drifting sector. Now is the time to take action—explore your options, optimize your sourcing strategies, and ensure your business is well-positioned for future success in this exhilarating market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to drift tires

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.