Top 3 Door Hinge Parts Suppliers (And How to Choose)

Introduction: Navigating the Global Market for door hinge parts

In today’s interconnected world, sourcing high-quality door hinge parts poses a significant challenge for international B2B buyers. From Africa to South America, the Middle East, and Europe, businesses are increasingly seeking reliable suppliers that can meet their specific needs while ensuring compliance with regional standards. This comprehensive guide is designed to assist you in navigating the complexities of the global market for door hinge parts, providing insights into various hinge types, their applications, and the critical components that contribute to their functionality.

Throughout this guide, we will delve into essential topics such as supplier vetting processes, cost considerations, and the unique requirements of different markets. Understanding the intricacies of hinge designs—ranging from butt hinges to continuous hinges—will empower you to make informed purchasing decisions that enhance your operational efficiency. Additionally, we will highlight best practices for evaluating suppliers, ensuring you choose partners that align with your quality expectations and logistical needs.

By the end of this guide, you will be equipped with the knowledge necessary to confidently select door hinge parts that not only meet your specifications but also contribute to the durability and performance of your products. Whether you’re in Vietnam or Saudi Arabia, this resource will serve as your roadmap to successfully sourcing door hinge components in a competitive global landscape.

Understanding door hinge parts Types and Variations

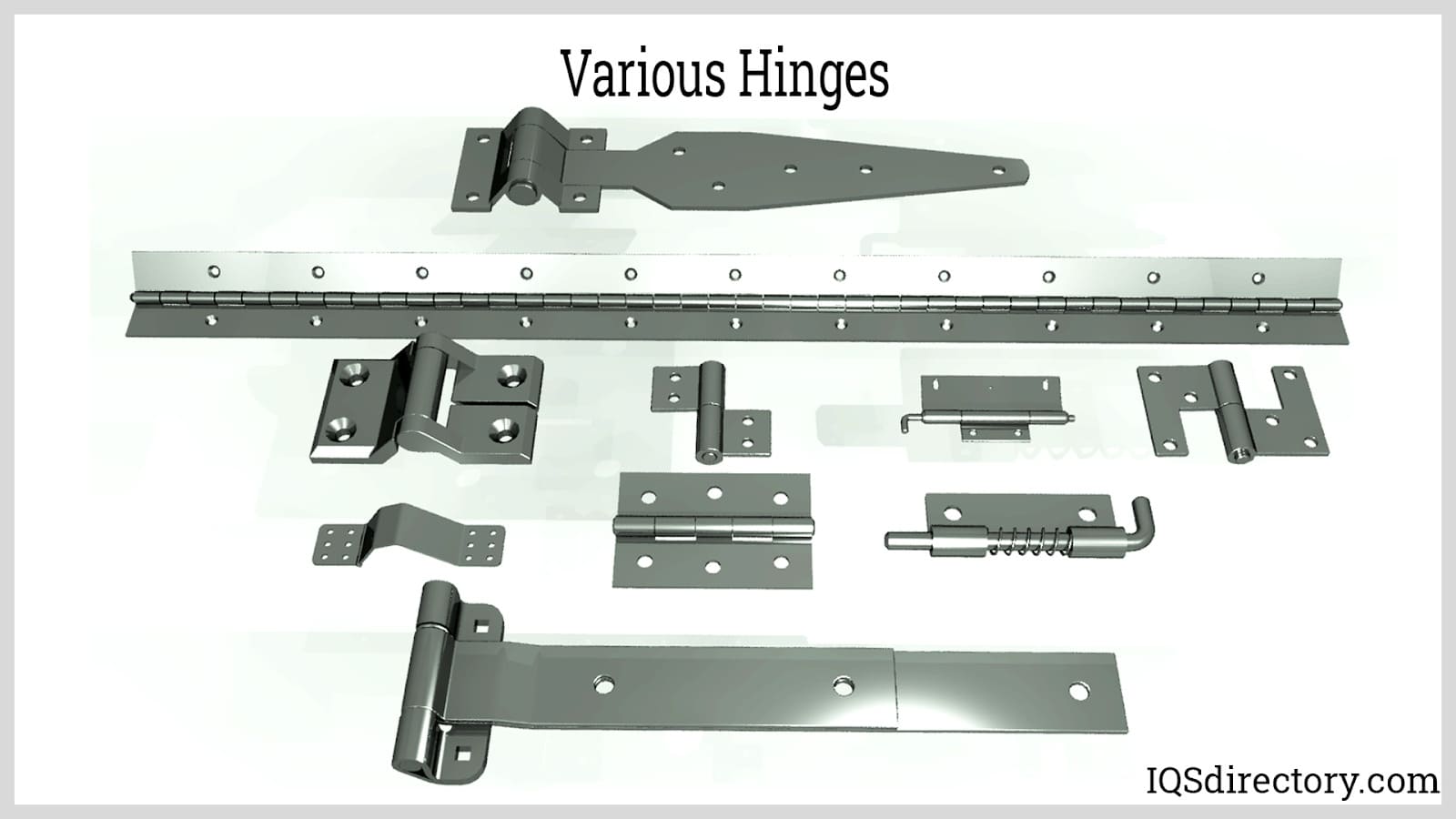

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinge | Compact design with two leaves joined by a pin | Residential and commercial doors | Pros: Easy installation; Cons: Limited weight capacity. |

| Continuous Hinge | Long, flexible design with a series of knuckles | Heavy-duty doors, gates | Pros: Even weight distribution; Cons: Requires precise installation. |

| Pivot Hinge | Allows doors to swing open with a pivot point | Commercial entryways | Pros: Space-saving design; Cons: More complex installation. |

| Spring Hinge | Incorporates a spring mechanism for automatic closing | Restroom stalls, cabinets | Pros: Self-closing feature; Cons: May wear out faster. |

| Piano Hinge | Continuous hinge with a long leaf, providing robust support | Piano lids, heavy doors | Pros: High durability; Cons: More expensive than standard hinges. |

What Are the Characteristics of Butt Hinges and Their Applications?

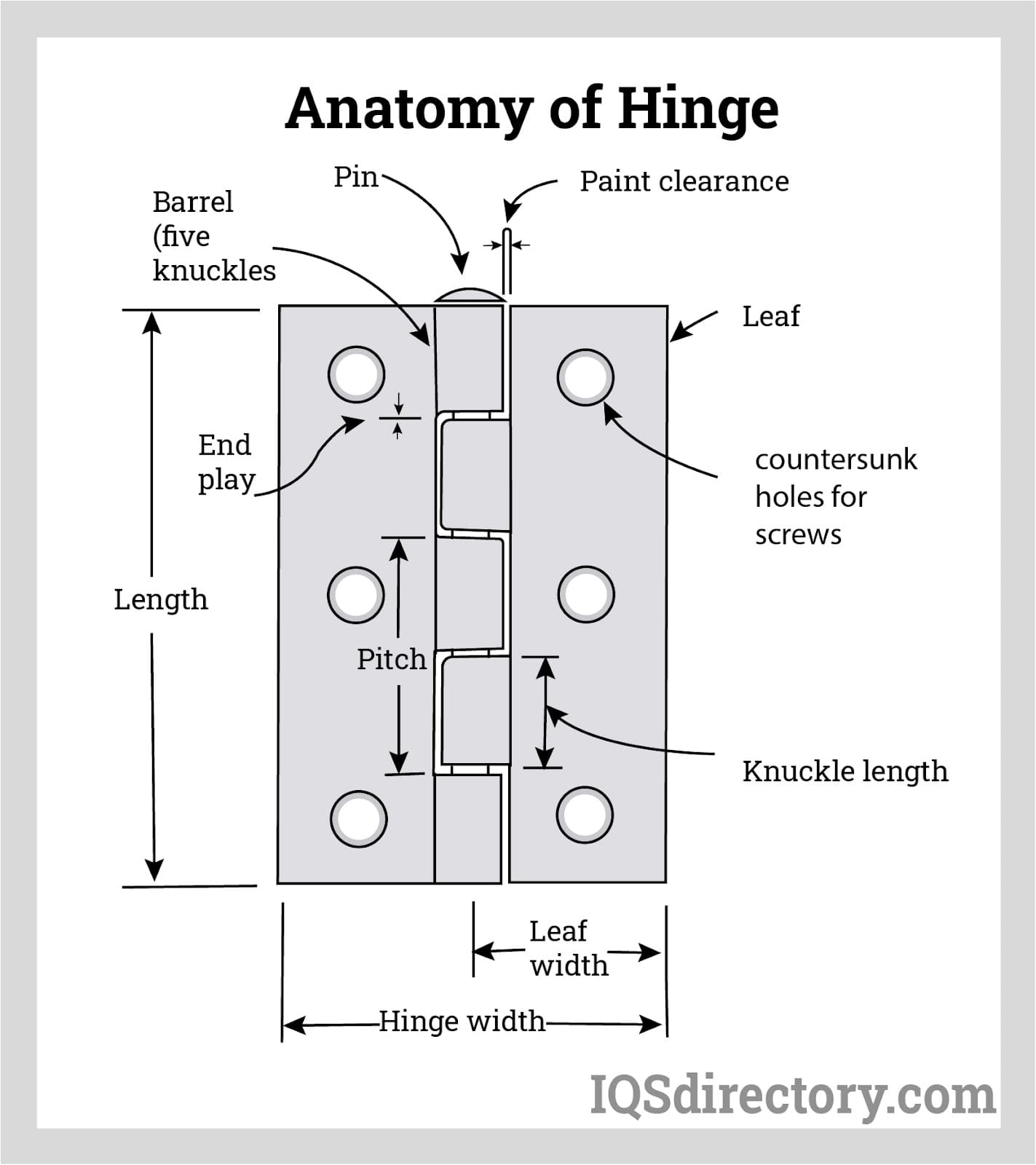

Butt hinges are the most common type used in residential and commercial settings. They consist of two flat plates (leaves) that are joined by a pin, allowing for a simple pivoting motion. Their compact size makes them ideal for standard doors, but they may not be suitable for heavier applications due to their limited weight capacity. When purchasing butt hinges, consider the material (steel, stainless steel, or brass) to match the door’s requirements and ensure durability.

Why Choose Continuous Hinges for Heavy-Duty Applications?

Continuous hinges, also known as piano hinges, feature a long design with multiple knuckles, providing superior strength and stability. They are particularly useful in heavy-duty applications such as gates and large doors, where even weight distribution is crucial. While they can be more complex to install due to their length, the durability they offer makes them a worthwhile investment for businesses requiring reliable performance over time.

How Do Pivot Hinges Enhance Space Efficiency?

Pivot hinges allow doors to swing open around a pivot point rather than the traditional side. This design is particularly advantageous in commercial entryways, where space is limited. When considering pivot hinges, businesses should evaluate the installation requirements, as they may require more precise alignment compared to standard hinges. Additionally, the aesthetic appeal of pivot hinges can enhance the overall design of modern commercial spaces.

What Are the Advantages of Spring Hinges in Commercial Settings?

Spring hinges are designed to automatically close doors after opening, making them ideal for applications like restroom stalls and cabinets. The self-closing feature can improve hygiene and security in commercial settings. However, buyers should be aware that the spring mechanism may wear out faster than traditional hinges, necessitating regular maintenance or replacement. Choosing high-quality materials can mitigate this issue and extend the lifespan of the spring hinge.

When Should Businesses Consider Piano Hinges?

Piano hinges are notable for their continuous design, which provides robust support for heavy applications like piano lids and large doors. Their durability and resistance to wear make them suitable for environments that require frequent use. While they may come at a higher price point, the investment can be justified by the longevity and stability they offer. Businesses should assess their specific application needs and consider the benefits of piano hinges when making purchasing decisions.

Key Industrial Applications of door hinge parts

| Industry/Sector | Specific Application of door hinge parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Architecture | Installation of commercial doors and partitions | Ensures durability and functionality of entry points | Material quality, load capacity, and corrosion resistance |

| Manufacturing and Industrial | Heavy machinery access and maintenance | Facilitates easy access for repairs, enhancing productivity | Strength specifications, compatibility with equipment design |

| Hospitality and Retail | Restroom stalls and service area doors | Enhances customer experience through reliable functionality | Aesthetic design, ease of installation, and maintenance needs |

| Transportation and Logistics | Cargo doors for shipping containers and trucks | Supports efficient loading and unloading operations | Weight tolerance, weather resistance, and security features |

| Healthcare | Hospital room doors and cabinets | Ensures hygiene and ease of access in critical environments | Compliance with health regulations, material safety, and ease of cleaning |

How are Door Hinge Parts Used in Construction and Architecture?

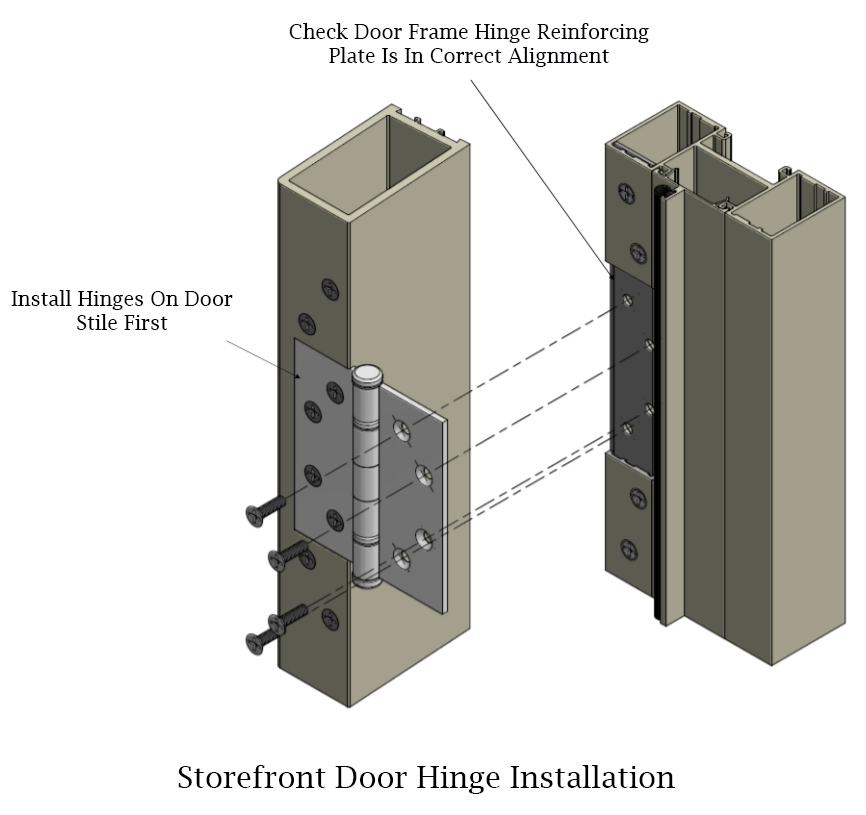

In the construction and architecture sector, door hinge parts are vital for the installation of commercial doors and partitions. These components need to withstand heavy usage and various environmental conditions. Buyers must prioritize the material quality, ensuring hinges are made from corrosion-resistant metals like stainless steel to enhance durability. Additionally, load capacity is crucial, especially for high-traffic areas, as it directly impacts the door’s functionality and lifespan.

What Role Do Door Hinge Parts Play in Manufacturing and Industrial Settings?

Within manufacturing and industrial environments, door hinge parts facilitate access to heavy machinery for maintenance and repairs. The correct hinge ensures that doors can support significant weight and withstand frequent opening and closing. International buyers should focus on strength specifications and compatibility with existing equipment designs to avoid operational disruptions. Proper hinge selection can lead to increased productivity by minimizing downtime during maintenance.

How Do Door Hinge Parts Enhance Hospitality and Retail Experiences?

In the hospitality and retail industry, door hinge parts are essential for restroom stalls and service area doors, contributing to a positive customer experience. Reliable hinges allow for smooth operation, which is critical in high-traffic areas. Buyers should consider aesthetic design alongside functionality, as hinges should complement the overall decor. Additionally, ease of installation and maintenance is important to reduce operational interruptions in busy settings.

Why Are Door Hinge Parts Critical in Transportation and Logistics?

Door hinge parts are crucial for cargo doors on shipping containers and trucks, enabling efficient loading and unloading processes. The right hinge can significantly enhance operational efficiency by providing reliable access to goods. When sourcing, businesses must consider weight tolerance and weather resistance, particularly in regions with extreme climates. Security features are also essential to protect valuable cargo during transit.

How Do Door Hinge Parts Contribute to Healthcare Facilities?

In healthcare settings, door hinge parts are used in hospital room doors and cabinets, ensuring both hygiene and ease of access in critical environments. These hinges must comply with health regulations, emphasizing the importance of material safety and ease of cleaning. Buyers should prioritize features that facilitate quick access for medical staff while maintaining a sterile environment, as this directly impacts patient care and operational efficiency.

3 Common User Pain Points for ‘door hinge parts’ & Their Solutions

Scenario 1: Inconsistent Quality of Door Hinge Parts

The Problem: B2B buyers often face the challenge of sourcing door hinge parts with consistent quality. This inconsistency can lead to frequent replacements, resulting in increased operational costs and project delays. For instance, a manufacturer may receive a shipment of hinges that appear robust but fail to perform under stress, causing doors to misalign or jam. Such scenarios not only affect the functionality of the doors but also compromise the overall integrity of the installations, impacting client satisfaction and potentially damaging the buyer’s reputation in the market.

The Solution: To mitigate the risk of inconsistent quality, buyers should establish strong relationships with reputable suppliers who prioritize quality control. This means selecting suppliers with certifications such as ISO 9001, which indicates adherence to international quality management standards. Furthermore, buyers should request detailed product specifications and material certifications for each batch. Conducting on-site visits to suppliers or utilizing third-party inspection services can also provide assurance of quality. Finally, implementing a robust testing protocol upon receiving goods—such as load testing and durability assessments—will ensure that only high-quality parts are used in projects.

Scenario 2: Compatibility Issues with Existing Infrastructure

The Problem: Another common pain point for B2B buyers is the compatibility of new door hinge parts with existing door systems. When upgrading or replacing hinges, mismatches can occur, leading to installation delays and additional costs. For example, a buyer may order a new type of hinge only to discover it does not fit the pre-drilled holes or that its weight-bearing capacity is insufficient for the doors in use. This not only results in wasted resources but can also disrupt project timelines, affecting customer relationships.

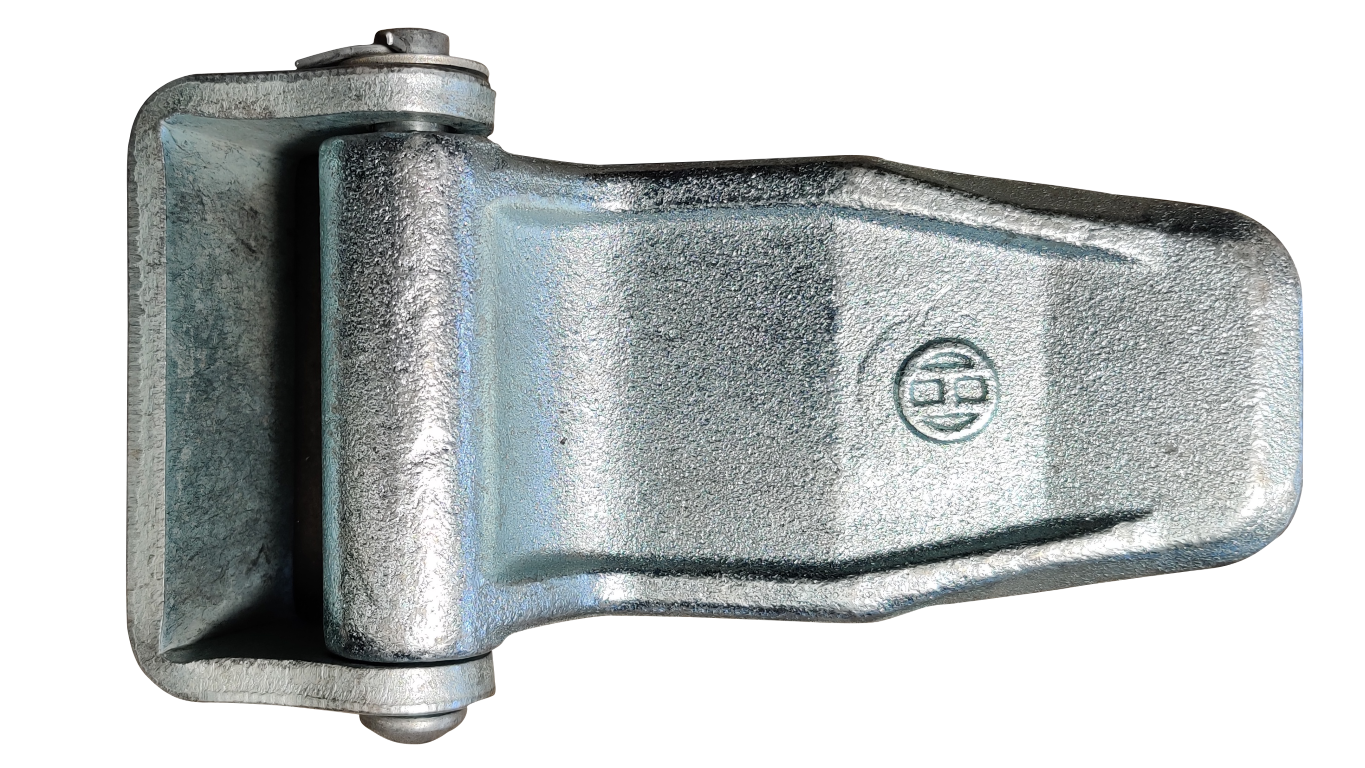

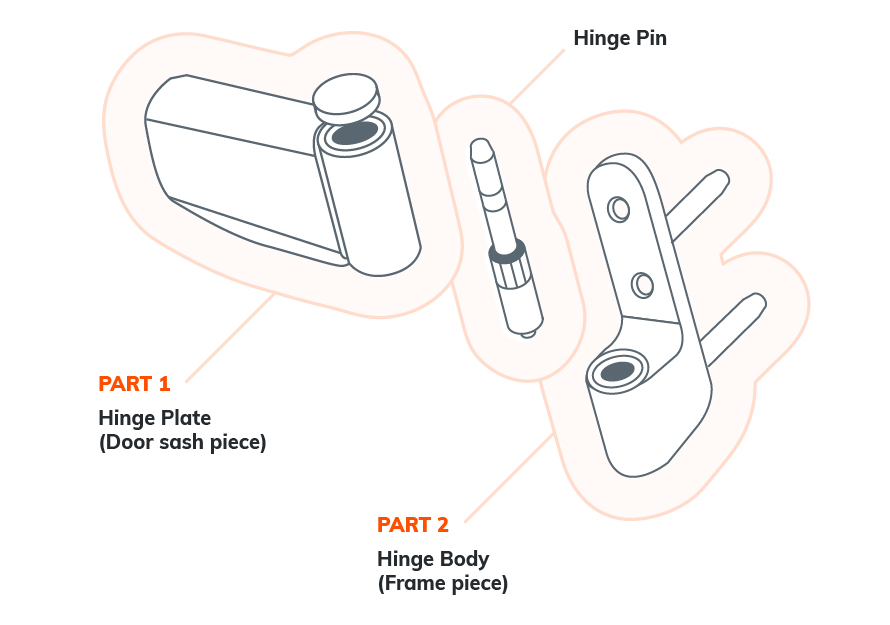

Illustrative image related to door hinge parts

The Solution: To avoid compatibility issues, buyers should conduct thorough assessments of their current door systems before placing orders. This includes measuring existing hinge sizes, types, and load requirements. Creating a comprehensive inventory of current hardware can facilitate better decision-making when sourcing new parts. Additionally, engaging with suppliers who offer customization options can provide solutions tailored to specific needs. Buyers should also utilize digital tools such as CAD software to visualize how new hinges will integrate with existing systems. Finally, maintaining open communication with suppliers about specific requirements can help ensure that the right products are sourced, reducing the likelihood of incompatibility.

Scenario 3: High Costs of Replacement and Maintenance

The Problem: Cost management is a significant concern for B2B buyers, particularly regarding the long-term expenses associated with door hinge parts. Many buyers may initially opt for cheaper hinges to cut costs, only to face higher expenses later due to frequent replacements or maintenance. For instance, low-quality hinges can wear out quickly, leading to increased labor costs for repairs and replacements, as well as potential downtime for businesses that rely on functionality and access.

The Solution: Buyers should adopt a value-based purchasing approach rather than solely focusing on upfront costs. Investing in high-quality hinges, even at a higher initial price, can lead to substantial long-term savings through reduced replacement frequency and maintenance needs. Conducting a total cost of ownership (TCO) analysis can help buyers evaluate the true cost of hinge options over their lifespan. Additionally, sourcing hinges with extended warranties or guarantees can provide financial protection against premature failure. Collaborating with suppliers who offer maintenance and repair services can also ensure that the hinges are properly installed and maintained, further extending their lifespan and reducing overall costs.

Strategic Material Selection Guide for door hinge parts

What Are the Key Materials for Door Hinge Parts?

When selecting materials for door hinge parts, several factors must be considered, including performance properties, cost, and suitability for specific applications. Below, we analyze four common materials used in manufacturing door hinges: stainless steel, brass, zinc alloy, and plastic. Each material presents unique advantages and challenges that can significantly influence the choice for international B2B buyers.

How Does Stainless Steel Perform in Door Hinge Applications?

Stainless steel is renowned for its exceptional corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, making it suitable for various environments, including humid or coastal areas. The most common grades used in hinge manufacturing are 304 and 316, with 316 offering superior resistance to chlorides.

Pros: Stainless steel hinges are highly durable and require minimal maintenance. They can support heavy doors and are often compliant with international standards such as ASTM A240.

Cons: The primary drawback is the higher cost compared to other materials. Additionally, manufacturing complexity can increase due to the need for specialized tooling.

Impact on Application: Stainless steel hinges are ideal for heavy-duty applications, such as commercial buildings and industrial settings, where longevity and reliability are paramount.

Illustrative image related to door hinge parts

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local building codes and standards, which may reference ASTM or DIN specifications.

What Are the Benefits of Brass for Door Hinges?

Brass is a popular choice for decorative hinges due to its aesthetic appeal and corrosion resistance. It is less prone to tarnishing than other metals and offers good strength-to-weight ratios.

Pros: Brass hinges provide a classic look, making them suitable for residential applications and historical restorations. They are also relatively easy to machine, which can reduce manufacturing costs.

Cons: While brass is durable, it is softer than stainless steel and may not be suitable for heavy-duty applications. Additionally, it can be more expensive than zinc alloys.

Impact on Application: Brass hinges are often used in interior doors, cabinets, and furniture, where appearance is as important as functionality.

Illustrative image related to door hinge parts

Considerations for International Buyers: Buyers should verify that the brass used meets international standards such as JIS H 3250 for brass products, especially in regions with strict quality regulations.

How Does Zinc Alloy Compare for Door Hinge Parts?

Zinc alloy is frequently used for cost-effective hinge solutions. It offers good corrosion resistance and is lightweight, making it suitable for various applications.

Pros: The primary advantage of zinc alloy hinges is their affordability and ease of manufacturing. They can be cast into complex shapes, allowing for versatility in design.

Cons: However, zinc alloys are generally less durable than stainless steel and brass. They may not perform well in high-stress applications or extreme environments.

Impact on Application: Zinc alloy hinges are suitable for lightweight doors and applications where cost is a significant factor, such as in residential construction.

Considerations for International Buyers: Buyers should be aware of the potential for lower durability and ensure that the products meet relevant standards, such as ASTM B86 for zinc die castings.

In What Situations Is Plastic Used for Door Hinges?

Plastic hinges are gaining popularity due to their lightweight, non-corrosive nature, and cost-effectiveness. They are often used in environments where moisture is a concern.

Illustrative image related to door hinge parts

Pros: Plastic hinges are resistant to rust and corrosion, making them ideal for outdoor applications. They are also easy to install and can be manufactured in various colors.

Cons: The major limitation is their lower strength compared to metal hinges, which may restrict their use to lighter doors.

Impact on Application: Plastic hinges are commonly found in residential settings, such as bathroom doors, and in environments where aesthetic appeal is less critical.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and performance standards, particularly in regions with stringent regulations.

Illustrative image related to door hinge parts

Summary Table of Material Selection for Door Hinges

| Material | Typical Use Case for Door Hinge Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty commercial and industrial doors | Exceptional durability and corrosion resistance | Higher cost, complex manufacturing | High |

| Brass | Decorative residential and historical applications | Aesthetic appeal, good corrosion resistance | Softer than steel, higher cost | Medium |

| Zinc Alloy | Lightweight doors and cost-sensitive applications | Cost-effective, versatile design | Lower durability in high-stress environments | Low |

| Plastic | Moisture-prone areas, lightweight doors | Rust-resistant, lightweight | Lower strength, limited use cases | Low |

This strategic material selection guide provides valuable insights for international B2B buyers looking to make informed decisions regarding door hinge parts. Understanding the properties, advantages, and limitations of each material will facilitate better procurement strategies tailored to specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for door hinge parts

What Are the Key Stages in the Manufacturing Process of Door Hinge Parts?

The manufacturing of door hinge parts involves several critical stages, each requiring specific techniques and materials to ensure high-quality output. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Door Hinge Production?

Material preparation is the first step in the manufacturing process. High-quality materials, typically stainless steel, brass, or zinc alloys, are selected based on the specific requirements of the hinge application. The materials undergo processes such as cutting, machining, and surface treatment to ensure they meet the necessary specifications. For instance, stainless steel is often chosen for its durability and corrosion resistance, making it ideal for hinges used in outdoor environments or humid conditions.

What Techniques Are Used in the Forming Process of Hinge Parts?

Once the materials are prepared, the forming process begins. This stage often employs techniques such as stamping, forging, or die-casting, depending on the design and functionality of the hinge. Stamping is particularly common for producing flat hinge leaves, while forging is used for creating more complex shapes that require enhanced strength. Advanced CNC (Computer Numerical Control) machining may also be utilized for precise shaping and detailing, ensuring that each component fits perfectly during assembly.

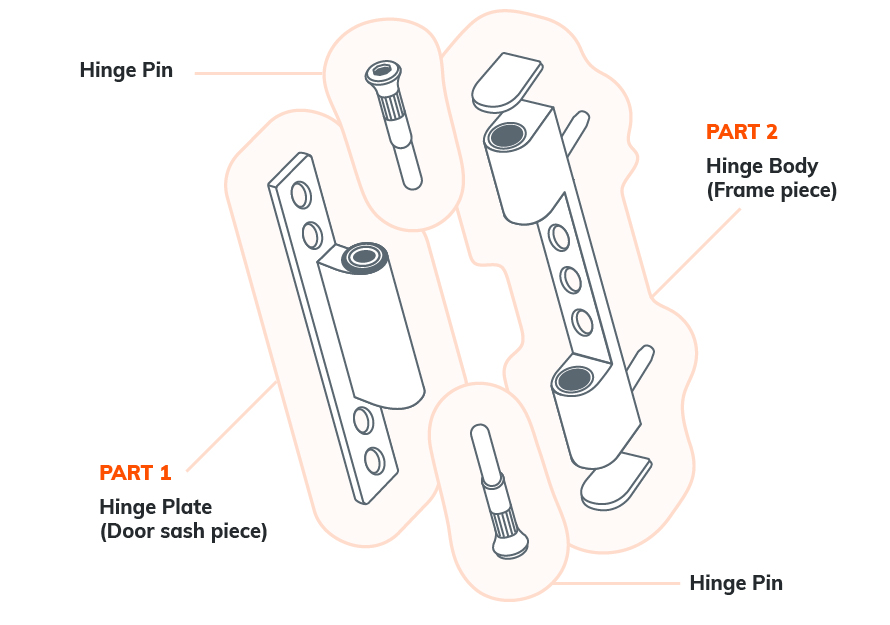

How Are Door Hinge Parts Assembled?

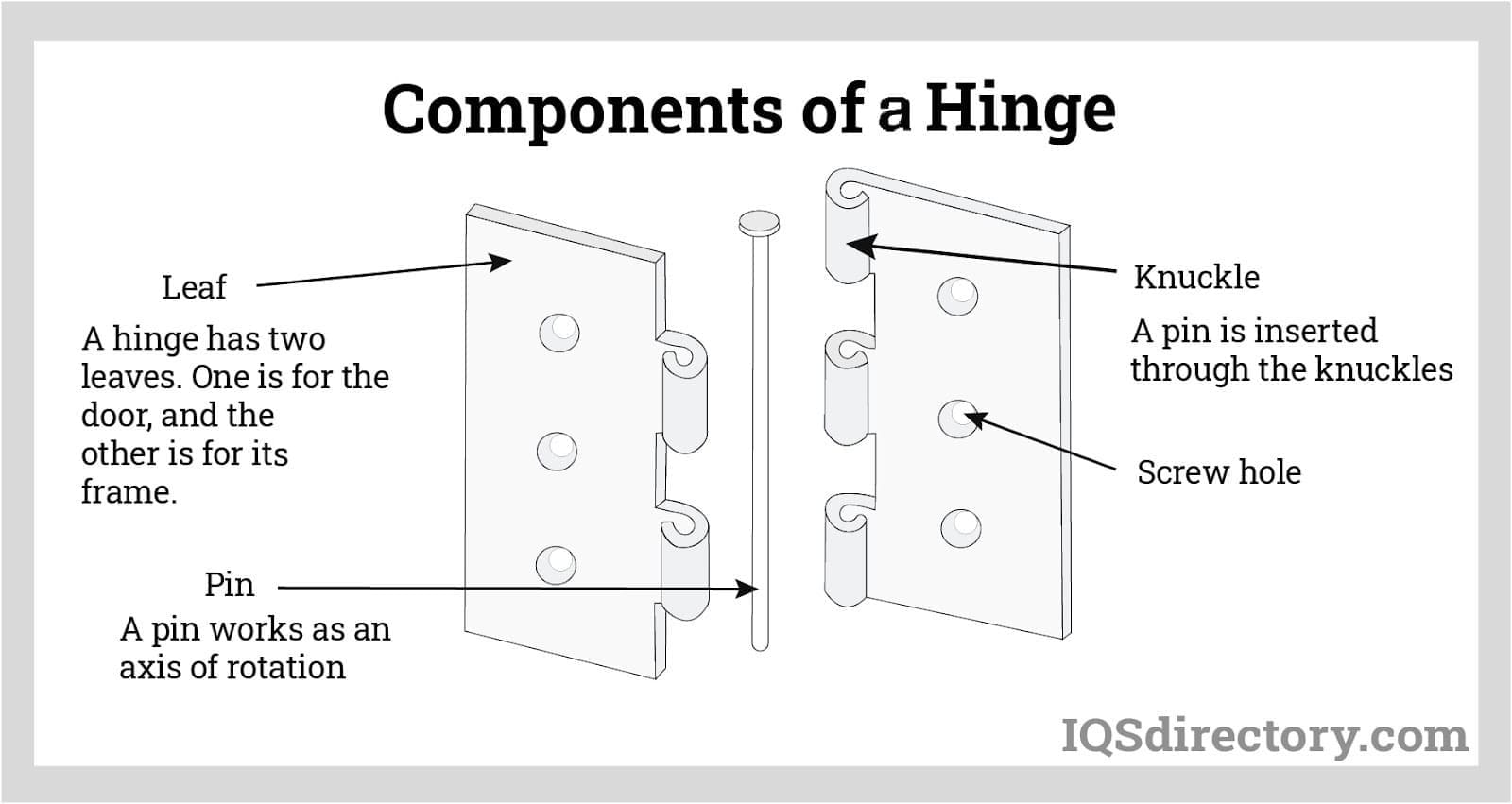

The assembly stage brings together the individual components—leaves, knuckles, and pins—into a complete hinge. This process can involve manual assembly or automated systems, depending on the production scale. Quality control checks are essential at this stage to ensure that each hinge operates smoothly and meets design specifications. For instance, the fit between the leaves and the pin must be precise to facilitate seamless movement without friction.

What Finishing Techniques Enhance the Quality of Door Hinges?

After assembly, hinges undergo finishing processes that enhance their aesthetic and functional qualities. Common techniques include plating (e.g., chrome or nickel plating), powder coating, and anodizing. These finishes not only improve the appearance of the hinges but also provide additional protection against corrosion and wear. Quality assurance during this stage is crucial, as any imperfections can compromise the hinge’s performance and lifespan.

What Quality Assurance Standards Are Relevant for Door Hinge Parts?

Quality assurance (QA) is a vital aspect of hinge manufacturing, ensuring that products meet international and industry-specific standards. One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system that can enhance customer satisfaction and operational efficiency.

How Do International Standards Impact Manufacturing Quality?

In addition to ISO 9001, specific industries may have additional requirements. For instance, CE marking is essential for products sold in the European market, indicating compliance with EU safety, health, and environmental protection standards. For hinges used in industrial applications, compliance with API (American Petroleum Institute) standards may also be necessary, particularly for products used in harsh environments.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints throughout the manufacturing process help identify defects early, reducing waste and ensuring that only high-quality products reach the market. The main QC checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and ensure adherence to specifications.

-

Final Quality Control (FQC): Finished products undergo rigorous testing to verify that they meet all functional and aesthetic criteria before shipping.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to assess the quality of door hinge parts. Common techniques include:

-

Dimensional Inspection: This involves measuring the dimensions of hinge components to ensure they conform to design specifications.

-

Functional Testing: Hinge performance is evaluated under simulated operating conditions to ensure smooth operation and durability.

-

Corrosion Resistance Testing: Particularly important for hinges used in outdoor applications, this test assesses how well the hinge withstands environmental factors over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

Illustrative image related to door hinge parts

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. This includes examining their adherence to international standards like ISO 9001.

-

Request Quality Assurance Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC results. These reports can help assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. This can be particularly useful for buyers unfamiliar with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control. These include varying regulatory standards across countries and potential language barriers that may affect communication. Buyers should be aware of:

-

Local Regulations: Understanding the specific quality standards and regulations in the buyer’s country is crucial for compliance and market acceptance.

-

Cultural Considerations: Building relationships with suppliers may require understanding cultural differences in business practices and communication styles.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain can help mitigate risks associated with quality control. This involves clear communication about expectations and regular updates on production status.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting suppliers for door hinge parts, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door hinge parts’

In this practical sourcing guide, we aim to equip international B2B buyers with essential steps to procure door hinge parts efficiently. The procurement process can be complex, especially when catering to diverse markets across Africa, South America, the Middle East, and Europe. By following this checklist, you can ensure a seamless purchasing experience that meets your technical and logistical requirements.

Illustrative image related to door hinge parts

Step 1: Define Your Technical Specifications

Start by detailing the specific requirements for the door hinge parts you need. This includes dimensions, materials (e.g., stainless steel, zinc alloy), and any particular features like load-bearing capacity or corrosion resistance. Clear specifications will help you communicate effectively with suppliers and avoid misunderstandings that can lead to costly errors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in door hinge parts. Utilize online directories, trade platforms, and industry-specific websites to compile a list of potential candidates. Consider their market reputation, customer reviews, and product range to ensure they align with your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international quality standards. Look for ISO certifications or similar industry-specific certifications that indicate a commitment to quality and safety. This step is crucial in ensuring that the products you receive will meet regulatory requirements in your target markets.

Step 4: Request Samples

Obtaining samples is a vital part of the sourcing process. Request samples of the door hinge parts to assess their quality, durability, and functionality firsthand. This allows you to make informed decisions and ensures that the products will meet your operational requirements before placing a bulk order.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare pricing, payment terms, and delivery schedules. Ensure that you take into account not just the unit price but also shipping costs, potential tariffs, and lead times. A comprehensive comparison will help you identify the best overall value rather than simply the lowest price.

Step 6: Negotiate Contracts Carefully

Once you’ve selected a supplier, engage in contract negotiations to establish clear terms regarding pricing, delivery, and quality assurance. Specify penalties for late deliveries or subpar quality to safeguard your interests. A well-structured contract can prevent disputes and foster a positive long-term relationship.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your chosen supplier. Regular updates on order status, potential delays, or changes in requirements are essential for a smooth procurement process. Establishing clear lines of communication will help you address any issues promptly and maintain a strong working relationship.

By adhering to this checklist, B2B buyers can navigate the complexities of sourcing door hinge parts effectively, ensuring they acquire the right products for their operational needs while fostering reliable supplier relationships.

Illustrative image related to door hinge parts

Comprehensive Cost and Pricing Analysis for door hinge parts Sourcing

What Are the Key Cost Components in Sourcing Door Hinge Parts?

When sourcing door hinge parts, understanding the cost structure is critical for B2B buyers. The primary components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of material used significantly impacts costs. Stainless steel, for instance, is generally more expensive than plastic or zinc alloys due to its durability and corrosion resistance. High-quality materials can enhance the longevity of the hinges, thus affecting the Total Cost of Ownership (TCO).

-

Labor: Labor costs vary based on geographical location and the complexity of the hinge design. Regions with lower labor costs may offer more competitive pricing, but it’s essential to consider the trade-offs in quality and expertise.

-

Manufacturing Overhead: This encompasses all the indirect costs associated with production, including utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help minimize overhead and reduce overall costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Buyers should factor in these costs when requesting bespoke products, as they can significantly influence the unit price.

-

Quality Control (QC): Ensuring that hinge parts meet specific quality standards incurs additional costs. High-quality hinges may require more rigorous testing and certification processes, which can raise the price but ultimately lead to fewer failures and lower maintenance costs.

-

Logistics: Shipping and handling costs vary widely depending on the supplier’s location and the buyer’s destination. Understanding Incoterms is crucial, as they dictate who is responsible for shipping costs, insurance, and risk during transit.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Door Hinge Parts Costs?

Several factors influence the pricing of door hinge parts, and B2B buyers should be aware of these when negotiating.

-

Volume/MOQ: The minimum order quantity (MOQ) often affects pricing. Suppliers may offer discounts for bulk orders, allowing buyers to negotiate better rates. Higher volumes can lead to lower per-unit costs.

-

Specifications and Customization: Custom hinges tailored to specific applications can be more expensive due to the additional design and tooling requirements. Standardized products typically offer better pricing and shorter lead times.

-

Materials: The choice of materials not only affects the initial cost but also the long-term performance and maintenance expenses. Higher-quality materials may come at a premium but can result in lower TCO.

-

Quality and Certifications: Products that meet specific industry standards or certifications may command higher prices. However, these certifications can assure buyers of the product’s reliability and performance.

-

Supplier Factors: The supplier’s reputation, experience, and geographic location can influence pricing. Established suppliers with a proven track record may charge higher prices but offer better service and reliability.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

B2B buyers can employ several strategies to enhance cost-efficiency when sourcing door hinge parts.

-

Negotiate Terms: Engage in discussions about payment terms, lead times, and delivery schedules. Flexibility on these fronts can lead to better pricing arrangements.

-

Consider the Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. Investing in higher-quality hinges may yield savings over time.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of additional costs, including tariffs, import duties, and currency fluctuations. These factors can significantly affect the final price.

-

Leverage Relationships: Building a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in loyalty discounts and improved service levels.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned in various sources can fluctuate based on market conditions, supplier negotiations, and specific order requirements. Buyers should always request updated quotes and confirm pricing before finalizing any transactions to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing door hinge parts With Other Solutions

Exploring Alternative Solutions to Door Hinge Parts

When considering door hinge parts for your business needs, it’s essential to explore alternatives that can offer similar functionalities. By comparing these alternatives, you can make an informed decision that aligns with your operational requirements, budget, and installation preferences. Below, we analyze door hinge parts against two viable alternatives: pivot hinges and sliding door systems.

| Comparison Aspect | Door Hinge Parts | Pivot Hinges | Sliding Door Systems |

|---|---|---|---|

| Performance | Reliable for standard door usage | Offers a smooth, 180-degree rotation | Space-saving and easy access |

| Cost | Moderate price range | Typically higher than standard hinges | Higher initial cost but saves space |

| Ease of Implementation | Straightforward installation | Requires precise alignment | Installation can be complex |

| Maintenance | Low maintenance requirements | Moderate; may require occasional lubrication | Low, but tracks need cleaning |

| Best Use Case | Standard doors in various settings | Heavy doors or gates needing full rotation | Areas with limited space or high traffic |

What Are the Advantages and Disadvantages of Pivot Hinges?

Pivot hinges allow doors to swing open and closed around a central pivot point rather than relying on traditional side-mounted hinges. This design can provide a full 180-degree rotation, making them ideal for heavy doors or situations where a standard hinge may be insufficient. However, the installation requires precise alignment, which can complicate the process. Additionally, pivot hinges are generally more expensive than standard door hinge parts, which may be a consideration for budget-conscious buyers.

How Do Sliding Door Systems Compare?

Sliding door systems operate on a track, allowing doors to glide open and closed rather than swinging outward. This feature is particularly advantageous in environments where space is limited, such as small offices or retail spaces. While they do come with a higher initial cost, they can ultimately save space and improve traffic flow in busy areas. However, the installation process can be more complex, requiring careful planning and construction to ensure the tracks are properly aligned. Maintenance is generally low, but the tracks may require occasional cleaning to prevent debris buildup.

How Should B2B Buyers Choose the Right Solution?

When selecting the right solution for your door access needs, consider the specific requirements of your environment. If you need a reliable, straightforward option for standard doors, traditional door hinge parts may be the best fit. For heavy doors requiring greater rotation, pivot hinges could be advantageous despite their higher cost and installation complexity. Conversely, if your space is limited and you prioritize ease of access, sliding door systems may provide the best long-term value despite their initial investment. Assessing these factors will guide you to the optimal choice for your business.

Essential Technical Properties and Trade Terminology for door hinge parts

What Are the Key Technical Properties of Door Hinge Parts That B2B Buyers Should Know?

When selecting door hinge parts, understanding their technical properties is crucial for ensuring product reliability and performance. Here are some essential specifications that buyers should consider:

1. Material Grade

The material used in hinge manufacturing significantly affects durability and corrosion resistance. Common materials include stainless steel, brass, and zinc alloys. For instance, stainless steel (often graded 304 or 316) is preferred for its strength and resistance to rust, making it ideal for outdoor or humid environments. B2B buyers should specify material grades to ensure longevity and compliance with industry standards.

Illustrative image related to door hinge parts

2. Load Capacity

This specification indicates the maximum weight a hinge can support. Load capacity is critical for applications like heavy doors or industrial settings. Manufacturers typically provide load ratings based on testing conditions. Buyers must assess the intended use and choose hinges that can handle the expected weight to prevent premature failure.

3. Tolerance

Tolerance refers to the permissible variation in hinge dimensions, crucial for ensuring proper fit and function. Tight tolerances are essential for precision applications where misalignment can lead to operational issues. Buyers should consider tolerance levels during procurement to avoid compatibility problems with door frames or hardware.

4. Finish Type

The finish of a hinge affects both aesthetics and functionality. Common finishes include powder coating, polished chrome, and satin nickel. Each finish offers different levels of resistance to wear, tarnishing, and environmental factors. Buyers should select finishes that align with their project’s design requirements and environmental conditions.

5. Pin Material and Design

The pin is the pivot point of a hinge and can be made from various materials, including steel and nylon. The design of the pin, such as whether it is removable or fixed, also affects maintenance and functionality. For example, removable pins facilitate easy door removal for repairs or replacements. Buyers should consider the pin design based on their operational needs.

Illustrative image related to door hinge parts

What Are Common Trade Terms Related to Door Hinge Parts in B2B Transactions?

Familiarity with industry terminology can streamline communication and negotiation processes. Here are some essential trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s product. In the context of door hinges, buyers might seek OEM parts to ensure compatibility and quality. Understanding OEM relationships can help buyers secure reliable products that meet their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget planning and inventory management. Buyers should inquire about MOQs to avoid overcommitting to quantities that may not align with their needs.

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to request price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Crafting a detailed RFQ can lead to more accurate quotes and better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for international transactions, as they clarify who bears the risk and cost during transportation. Buyers should ensure clarity on Incoterms to avoid disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. It is an essential factor in supply chain management. Buyers must factor in lead times when planning projects to avoid delays in installation or product launch.

In summary, grasping the critical technical properties and trade terminology of door hinge parts can empower B2B buyers to make informed decisions, enhance procurement processes, and improve overall project success.

Navigating Market Dynamics and Sourcing Trends in the door hinge parts Sector

What Are the Current Market Dynamics and Key Trends in the Door Hinge Parts Sector?

The global door hinge parts market is witnessing significant growth driven by several key factors. The increasing demand for construction and renovation projects in emerging markets, particularly in Africa, South America, and the Middle East, is a primary driver. These regions are experiencing urbanization and infrastructure development, leading to a rising need for durable and efficient door hardware. Additionally, advancements in manufacturing technologies, including automation and digitalization, are reshaping sourcing practices. International B2B buyers are increasingly leveraging online platforms to streamline procurement processes, enabling easier access to a wider range of suppliers.

Emerging trends also highlight the importance of customization and adaptability in hinge designs to meet specific architectural requirements. For instance, heavy-duty hinges are gaining popularity in commercial applications, while lightweight options are favored for residential projects. Furthermore, the integration of smart technology into door hardware is becoming more prevalent, providing enhanced security and convenience. This trend is particularly relevant in developed markets in Europe and North America, where smart homes are on the rise.

International buyers must also navigate fluctuations in material costs and supply chain disruptions, which have been exacerbated by global events. Establishing strong relationships with reliable suppliers and investing in local sourcing can mitigate these challenges and enhance resilience in the supply chain.

How Can Sustainability and Ethical Sourcing Impact Your Business in the Door Hinge Parts Sector?

Sustainability and ethical sourcing are increasingly influencing purchasing decisions in the door hinge parts sector. The environmental impact of production processes, such as emissions and waste generation, has prompted buyers to seek suppliers committed to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and adherence to environmental regulations.

Moreover, ethical supply chains are becoming a priority for B2B buyers, particularly those operating in regions with stringent regulations or consumer expectations regarding corporate responsibility. Suppliers that can demonstrate compliance with recognized sustainability certifications—such as ISO 14001 or LEED—are more likely to attract business from conscientious buyers.

In terms of product offerings, the demand for “green” materials, such as eco-friendly coatings and recyclable components, is rising. Buyers should look for suppliers who not only provide high-quality door hinge parts but also prioritize sustainability in their manufacturing and sourcing strategies. By aligning with sustainable practices, businesses can enhance their brand reputation, reduce operational risks, and potentially lower costs associated with waste management and energy use.

How Has the Door Hinge Parts Sector Evolved Over Time?

The evolution of the door hinge parts sector is marked by significant advancements in materials and technology. Historically, hinges were predominantly made from wood and simple metal designs, limiting their durability and application. The industrial revolution ushered in the use of cast iron and steel, allowing for stronger and more reliable hinges suitable for a variety of environments.

In recent decades, innovations in manufacturing techniques, including precision machining and the introduction of composite materials, have expanded the functional capabilities of door hinges. Today, manufacturers offer a diverse range of products, including specialized hinges designed for specific applications such as hospital doors, industrial settings, and residential use. This evolution has been driven by a growing emphasis on safety, durability, and aesthetic appeal, responding to the evolving needs of consumers and industries alike.

As the market continues to grow, the focus on technology integration, sustainability, and customization will likely shape the future landscape of the door hinge parts sector, providing B2B buyers with an array of opportunities to enhance their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of door hinge parts

-

1. How do I solve issues with hinge compatibility for my doors?

To address compatibility issues, start by identifying the specific type of door and hinge you have, including dimensions, weight capacity, and material. Consult technical specifications from your hinge supplier to ensure they match the door requirements. If customization is needed, communicate with the supplier about your needs. Many manufacturers offer bespoke solutions based on your specifications, which can help avoid future issues. Additionally, consider working with a local expert or installer who can provide insights into the best hinge options for your application. -

2. What is the best type of hinge for heavy doors in commercial applications?

For heavy doors, especially in commercial settings, look for heavy-duty butt hinges or continuous hinges (piano hinges). These types provide robust support and durability, allowing for smooth operation under significant weight. Stainless steel options are ideal due to their strength and corrosion resistance, particularly in humid environments. Always verify the hinge’s weight rating against the door’s specifications to ensure optimal performance and longevity. -

3. How can I ensure the quality of door hinge parts before purchasing?

To ensure quality, request samples from potential suppliers to evaluate the materials and craftsmanship firsthand. Look for certifications that indicate adherence to international quality standards, such as ISO 9001. Additionally, review customer feedback and case studies to assess the reliability and performance of their products in similar applications. Establishing a quality assurance process with the supplier can also help maintain standards throughout your procurement. -

4. What are the typical payment terms for international orders of door hinge parts?

Payment terms can vary by supplier and region, but common practices include a deposit (usually 30-50%) upfront, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or payment after inspection. It’s essential to clarify these terms during negotiations and consider using secure payment methods to mitigate risk. Always review the supplier’s payment policies and discuss any concerns to reach a mutually beneficial agreement. -

5. How do I vet suppliers for door hinge parts in international markets?

Vetting suppliers involves researching their business history, reputation, and production capabilities. Start by checking their certifications and compliance with international standards. Request references or case studies from previous clients, particularly those within your industry. Additionally, consider visiting their facilities if possible or conducting a virtual audit to assess their operations. Utilizing third-party verification services can also provide insights into the supplier’s reliability and production practices. -

6. What are the minimum order quantities (MOQ) for door hinge parts?

Minimum order quantities (MOQ) can vary significantly between suppliers and are often influenced by the type of hinge and customization requirements. Standard products may have lower MOQs, while custom designs typically require larger orders to offset production costs. Always inquire about MOQs upfront and explore options for smaller trial orders if you’re testing a new supplier. Negotiating flexible MOQs can also be beneficial, especially for first-time orders or long-term partnerships. -

7. How should I approach logistics and shipping for international orders of door hinge parts?

When managing logistics for international orders, work closely with your supplier to understand shipping options, costs, and timelines. Consider factors such as delivery terms (e.g., FOB, CIF) and customs regulations in your region. Collaborating with a reliable freight forwarder can streamline the process and help navigate any logistical challenges. Ensure that all shipping documents are accurate and complete to avoid delays at customs. Additionally, plan for potential tariffs or duties that may apply upon importation. -

8. Can I customize door hinge parts for specific applications?

Yes, many manufacturers offer customization options for door hinge parts to meet specific application needs. Customizations can include dimensions, materials, finishes, and functional features like load ratings or corrosion resistance. When requesting custom hinges, provide detailed specifications and application context to ensure the final product meets your requirements. Discuss lead times and any additional costs associated with custom orders to align your expectations with the supplier’s capabilities.

Top 3 Door Hinge Parts Manufacturers & Suppliers List

1. TPH Supply – Hinges and Hinge Parts

Domain: tphsupply.com

Registered: 2008 (17 years)

Introduction: Hinges and Hinge Parts include various types of door hinges that fasten partition doors to pilasters, allowing them to swing open while keeping the pilaster in place. Key components include cams and pintles that enable the door to rise when opened and self-close by gravity. The product range features parts from manufacturers such as Accurate, All American, Flush Metal, Hadrian, Knickerbocker, and …

2. Component Hardware – Walk-In Door Hinges and Parts

Domain: walkincoolerparts.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘COMPONENT HARDWARE/KEIL MALE/FEMALE CAM SET FOR W60/W61 SERIES WALK-IN DOOR HINGES’, ‘price’: ‘$23.00’}, {‘name’: ‘COMPONENT HARDWARE/KEIL W60 SATIN CHROME REVERSIBLE LIFT OFF HINGE, 1 CT, WITH HARDWARE KIT’, ‘price’: ‘$69.00’}, {‘name’: ‘COMPONENT HARDWARE/KEIL W60 SATIN CHROME REVERSIBLE LIFT OFF HINGE, 2 CT, AND HARDWARE KIT’, ‘price’: ‘$132.00’}, {‘name’: ‘COMPONENT HARDWARE/KEIL W6…

3. Andersen – Hinges and Hinge Kits

Domain: parts.andersenwindows.com

Registered: 1996 (29 years)

Introduction: {“Hinges and Hinge Kits”: {“Total Products”: 7, “Handing”: {“Left”: 2, “Right”: 3}, “Color or Finish”: {“Black”: 2, “Brushed Chrome”: 2, “Polished Chrome”: 1}, “Product Line”: “400 Series Frenchwood Hinged Patio Door”, “Products”: [{“Part Number”: “2579045”, “Description”: “Hex Wrench with Adjustment Instructions”, “Price”: “$2.90”}, {“Part Number”: “9007599”, “Description”: “Left Hand Hinge with …

Strategic Sourcing Conclusion and Outlook for door hinge parts

In the rapidly evolving landscape of door hinge parts, strategic sourcing emerges as a pivotal strategy for international B2B buyers. Understanding the diverse range of hinge components—including leaves, knuckles, and pins—enables companies to select products that meet their specific operational requirements while ensuring longevity and reliability. By prioritizing quality and compatibility in sourcing decisions, buyers can mitigate risks associated with product failure, reduce maintenance costs, and enhance overall efficiency.

As markets in Africa, South America, the Middle East, and Europe become increasingly interconnected, the ability to source high-quality hinge parts from reputable manufacturers will drive competitive advantage. Buyers are encouraged to leverage supplier relationships and explore innovative solutions that can adapt to their unique needs, such as customized hinge designs or environmentally sustainable materials.

Looking ahead, the demand for durable and versatile door hinge parts will only grow. Now is the time for international buyers to seize opportunities in this dynamic market. By investing in strategic sourcing practices, companies can secure a robust supply chain that not only meets current demands but also prepares them for future challenges. Engage with trusted suppliers today to enhance your operational capabilities and ensure your business thrives in the global marketplace.

Illustrative image related to door hinge parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.