Top 3 Demountable Cabinet Hinges Suppliers (And How to Choose)

Introduction: Navigating the Global Market for demountable cabinet hinges

Navigating the complexities of sourcing demountable cabinet hinges can be a significant challenge for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the increasing demand for versatile and user-friendly cabinet hardware, understanding the various types of hinges, their applications, and the nuances of supplier vetting is crucial. This comprehensive guide aims to equip businesses with the knowledge necessary to make informed purchasing decisions, ensuring that they select the right demountable cabinet hinges to meet their unique operational needs.

In this guide, we will explore the diverse range of demountable cabinet hinges available on the market, including single and double demountable options, and their respective features such as soft-closing mechanisms and aesthetic finishes. We will also delve into the various applications of these hinges, from residential furniture to commercial cabinetry, highlighting how they enhance functionality and ease of maintenance. Furthermore, we will provide insights on evaluating suppliers, understanding pricing structures, and the importance of quality assurance, which are all critical for making strategic procurement decisions.

By the end of this guide, international buyers will be empowered with actionable insights that streamline their sourcing process, reduce risks, and ultimately improve their product offerings. Whether you are a manufacturer, distributor, or retailer, understanding the global market for demountable cabinet hinges will be essential for staying competitive and meeting customer expectations.

Understanding demountable cabinet hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Demountable Hinge | One-part design, easy door removal | Residential and commercial cabinetry | Pros: Cost-effective, simple installation. Cons: Limited adjustability. |

| Double Demountable Hinge | Two-part design, enhanced stability and adjustability | High-end cabinetry, custom furniture | Pros: Greater durability, versatile applications. Cons: Higher cost than single hinges. |

| Partial Wrap Demountable Hinge | Wraps partially around the door for a secure fit | Kitchen cabinets, office furniture | Pros: Stronger hold, aesthetically pleasing. Cons: More complex installation. |

| Inset Demountable Hinge | Fits flush with the cabinet frame | Modern cabinetry designs | Pros: Sleek appearance, space-efficient. Cons: Requires precise measurements for installation. |

| Soft-Close Demountable Hinge | Integrated damping mechanism for quiet closure | High-end residential and commercial spaces | Pros: Reduces noise, enhances user experience. Cons: Higher price point, potential maintenance needs. |

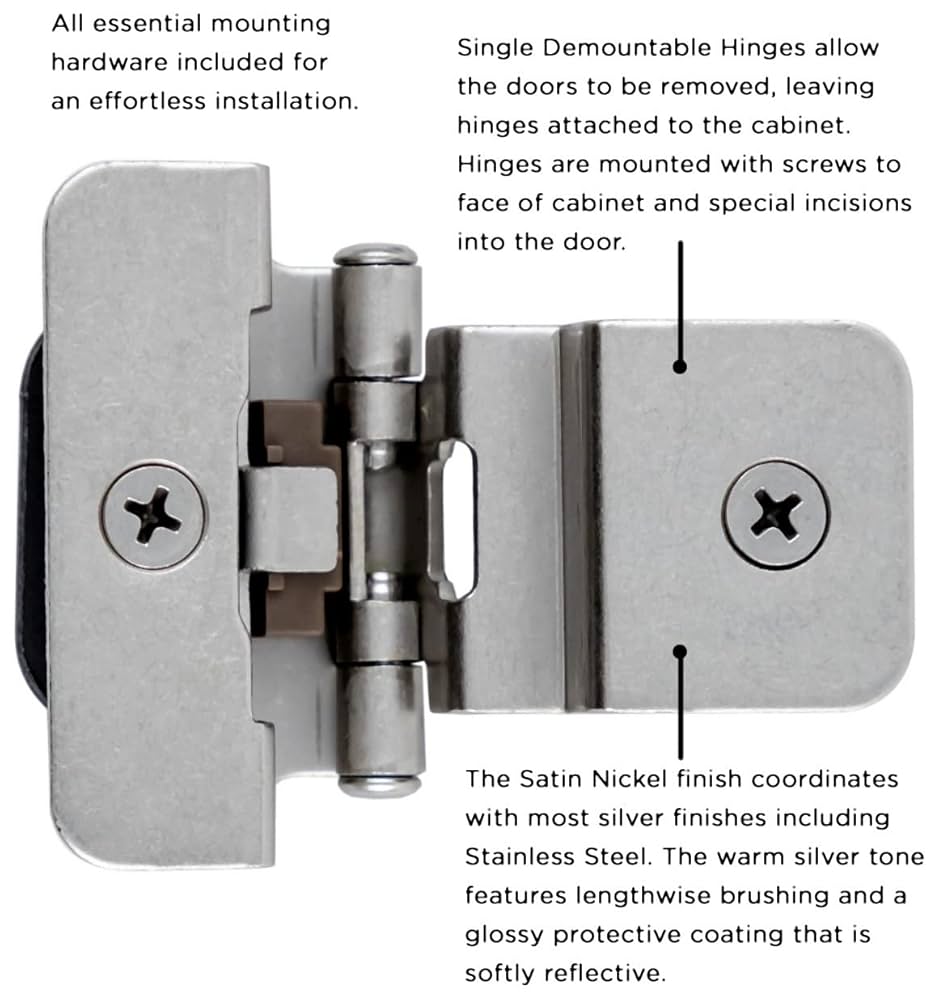

What Are the Key Characteristics of Single Demountable Hinges?

Single demountable hinges are designed with a straightforward mechanism, allowing for quick removal and reattachment of cabinet doors. This type is particularly suited for both residential and commercial cabinetry where ease of access is necessary. B2B buyers appreciate its cost-effectiveness and simplicity in installation, making it a popular choice among manufacturers and contractors. However, the limited adjustability can be a drawback for those needing precise alignment in high-traffic areas.

How Do Double Demountable Hinges Enhance Stability and Adjustability?

Double demountable hinges feature a two-part design that provides enhanced stability and adjustability, making them ideal for high-end cabinetry and custom furniture. These hinges allow for three-way adjustments, accommodating various door sizes and weights. For B2B buyers, the durability and versatility of double demountable hinges justify the higher price point, especially in projects requiring long-lasting solutions. However, their complexity may lead to increased installation time and costs.

What Advantages Do Partial Wrap Demountable Hinges Offer?

Partial wrap demountable hinges wrap partially around the cabinet door, providing a secure fit and stronger hold. This design is commonly used in kitchen cabinets and office furniture, where aesthetics and functionality are both critical. B2B buyers find these hinges appealing due to their enhanced stability and attractive appearance. However, the installation process can be more complex compared to other hinge types, requiring skilled labor for optimal results.

Why Are Inset Demountable Hinges Preferred in Modern Designs?

Inset demountable hinges are designed to fit flush with the cabinet frame, making them a popular choice in modern cabinetry designs. Their sleek appearance and space-efficient design appeal to B2B buyers focused on aesthetics and functionality. However, precise measurements are crucial during installation, which can pose a challenge for manufacturers and contractors. This type of hinge is ideal for high-end projects where visual appeal is paramount.

What Benefits Do Soft-Close Demountable Hinges Provide?

Soft-close demountable hinges incorporate a damping mechanism that allows cabinet doors to close quietly and gently. This feature is especially desirable in high-end residential and commercial spaces, enhancing the overall user experience. B2B buyers appreciate the reduced noise and potential for increased longevity, as these hinges minimize wear and tear. However, the higher price point and possible maintenance needs may deter budget-conscious buyers from opting for this premium solution.

Key Industrial Applications of demountable cabinet hinges

| Industry/Sector | Specific Application of demountable cabinet hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Used in modular furniture designs for easy assembly and disassembly | Enhances product versatility and customer satisfaction | Durability of materials, design compatibility, cost-effectiveness |

| Retail Fixtures | Employed in display cabinets for easy access and maintenance | Facilitates quick updates to displays, improving sales | Aesthetic finishes, weight capacity, ease of installation |

| Hospitality | Incorporated in cabinetry for hotel rooms and kitchens | Streamlines maintenance and renovations, enhancing guest experience | Compliance with safety standards, corrosion resistance, design options |

| Healthcare | Utilized in medical cabinetry for easy cleaning and access | Supports hygiene and efficiency in healthcare settings | Non-toxic materials, ease of use, customization options |

| Residential Construction | Installed in kitchen and bathroom cabinets for easy removal | Simplifies renovations and repairs, adding value to properties | Style variety, load-bearing capacity, compatibility with existing designs |

How Are Demountable Cabinet Hinges Used in Furniture Manufacturing?

In the furniture manufacturing sector, demountable cabinet hinges are essential for modular furniture designs. These hinges allow for straightforward assembly and disassembly, enabling manufacturers to create versatile products that can be easily transported and reconfigured. This flexibility not only enhances customer satisfaction but also reduces shipping costs and assembly time. When sourcing, buyers should consider the durability of materials to ensure longevity and compatibility with various designs to meet market demands.

What Role Do Demountable Cabinet Hinges Play in Retail Fixtures?

In retail environments, demountable cabinet hinges are used in display cabinets, allowing for easy access and maintenance of merchandise. This accessibility facilitates quick updates to displays, which can significantly improve sales performance. Retailers often seek hinges with aesthetic finishes that complement their brand image, as well as those that can support the weight of the displayed items. Cost-effectiveness is also a critical factor, especially for large-scale retail operations.

Why Are Demountable Cabinet Hinges Important in Hospitality?

The hospitality industry utilizes demountable cabinet hinges in cabinetry for hotel rooms and kitchens, where ease of maintenance is paramount. These hinges enable quick renovations and repairs, ensuring that the facilities remain appealing to guests. Buyers in this sector must prioritize hinges that comply with safety standards and are resistant to corrosion, given the high-usage environments. A variety of design options can also enhance the overall aesthetic of the property.

How Do Demountable Cabinet Hinges Benefit Healthcare Settings?

In healthcare, demountable cabinet hinges are crucial for medical cabinetry, allowing for easy cleaning and access to supplies. This functionality supports hygiene and operational efficiency, which are vital in healthcare settings. Buyers should focus on sourcing hinges made from non-toxic materials to ensure safety, as well as those that offer customization options to fit specific cabinetry needs. Ease of use is another important consideration for healthcare professionals.

What Are the Advantages of Using Demountable Cabinet Hinges in Residential Construction?

Demountable cabinet hinges are increasingly popular in residential construction, particularly in kitchens and bathrooms, where they simplify renovations and repairs. Homeowners benefit from the ability to remove cabinet doors easily, which can add value to their properties. Buyers in this sector should look for a variety of styles to match existing designs and ensure that the hinges can bear adequate weight. Compatibility with current cabinetry is also a key factor to consider during the sourcing process.

3 Common User Pain Points for ‘demountable cabinet hinges’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Fit for Cabinet Designs

The Problem: B2B buyers often encounter challenges when trying to source demountable cabinet hinges that fit specific cabinet designs. The variety of hinge types, overlays, and finishes can be overwhelming, leading to mismatched hardware that doesn’t align with the aesthetic or functional requirements of the cabinetry. Buyers may find themselves ordering multiple samples, wasting time and resources, only to find that the hinges do not meet their needs. This frustration can hinder project timelines and increase costs.

The Solution: To effectively source the right demountable cabinet hinges, buyers should begin by conducting a thorough assessment of their cabinet specifications, including overlay measurements, weight capacity, and desired aesthetic. Utilizing a standardized measurement guide can ensure that the selected hinges align with the cabinet dimensions. Collaborating with manufacturers or suppliers who offer customization options can also be beneficial. This approach allows buyers to specify their needs directly, ensuring that the hinges will fit seamlessly. Additionally, leveraging digital tools such as 3D modeling or CAD software can help visualize how the hinges will integrate with the overall design, reducing the likelihood of errors in ordering.

Scenario 2: Challenges with Installation and Maintenance

The Problem: Another common pain point arises during the installation and maintenance of demountable cabinet hinges. Buyers may struggle with ensuring proper alignment during installation, leading to functional issues such as doors not closing properly or being misaligned. Furthermore, lack of proper maintenance can lead to wear and tear, causing hinges to become loose or malfunction over time. This not only affects the functionality of the cabinets but can also result in costly repairs or replacements.

The Solution: To mitigate installation challenges, it is crucial to provide comprehensive installation guides and video tutorials along with the hinges. Suppliers should offer resources that outline step-by-step procedures, including tips on how to achieve accurate alignment. Additionally, investing in tools that aid in the installation process, such as hinge jigs or alignment fixtures, can significantly enhance accuracy. For maintenance, establishing a routine inspection schedule can help identify issues before they escalate. Encouraging buyers to use lubricants specifically designed for metal hinges can prolong the lifespan of the hardware and ensure smooth operation.

Scenario 3: Misunderstanding of Hinge Types and Features

The Problem: B2B buyers frequently face confusion regarding the different types of demountable cabinet hinges available in the market. The terminology can be complex, and features such as self-closing, soft-closing, and weight ratings may not be clearly understood. This lack of clarity can lead to poor purchasing decisions, resulting in hinges that do not meet the operational requirements of the cabinets, causing inefficiencies and dissatisfaction.

The Solution: To address this knowledge gap, suppliers should invest in educational content that clearly explains the various types of demountable cabinet hinges and their specific features. This could include detailed comparison charts, webinars, or FAQ sections on their websites. Buyers should be encouraged to engage directly with sales representatives who can provide tailored advice based on their specific applications. Additionally, creating product bundles that include hinges with compatible features can simplify the decision-making process, ensuring that buyers select the right hardware for their needs without second-guessing their choices. Providing real-world examples or case studies can also illustrate the benefits of different hinge types, aiding buyers in making informed decisions.

Strategic Material Selection Guide for demountable cabinet hinges

What Are the Key Materials Used for Demountable Cabinet Hinges?

When selecting demountable cabinet hinges, the choice of material significantly affects performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of these hinges, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform as a Material for Demountable Cabinet Hinges?

Key Properties: Steel hinges are known for their high strength and durability. They typically exhibit excellent load-bearing capabilities and can withstand significant stress. Steel also has a good temperature rating, making it suitable for various environments.

Pros & Cons: The primary advantage of steel is its robustness, which contributes to a longer lifespan. However, steel is prone to corrosion if not properly treated, which can limit its use in humid or coastal environments. The cost of steel is generally moderate, but the manufacturing process can be complex due to the need for protective coatings.

Impact on Application: Steel hinges are ideal for heavy-duty applications, such as in commercial cabinetry or outdoor settings, provided they are treated for corrosion resistance.

Considerations for International Buyers: Buyers in regions like the Middle East and coastal areas of South America should prioritize corrosion-resistant finishes, such as galvanization or powder coating. Compliance with international standards like ASTM for steel quality can also be a deciding factor.

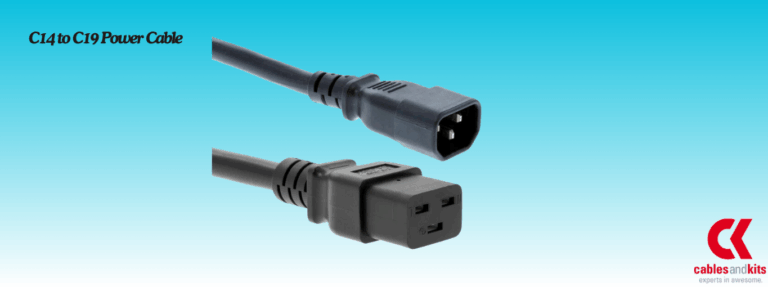

Illustrative image related to demountable cabinet hinges

What Role Does Stainless Steel Play in Demountable Cabinet Hinges?

Key Properties: Stainless steel is renowned for its corrosion resistance and aesthetic appeal. It maintains its integrity in various environmental conditions, including high humidity and exposure to moisture.

Pros & Cons: The primary advantage of stainless steel hinges is their longevity and low maintenance requirements. They are more expensive than regular steel hinges, which can be a consideration for budget-conscious buyers. Manufacturing stainless steel hinges is generally straightforward, though it may require specialized equipment.

Impact on Application: Stainless steel hinges are particularly suitable for environments where hygiene is critical, such as kitchens and laboratories. Their resistance to rust makes them ideal for applications in humid regions.

Considerations for International Buyers: Buyers from Europe and Africa should ensure that the stainless steel used meets specific standards, such as DIN or JIS, for quality assurance. Additionally, the higher cost may require justification in terms of long-term value.

How Do Plastic and Composite Materials Compare for Demountable Cabinet Hinges?

Key Properties: Plastic and composite materials are lightweight and resistant to corrosion. They can also be molded into various shapes and sizes, offering design flexibility.

Pros & Cons: The main advantage of plastic hinges is their low cost and ease of installation. However, they may not offer the same strength and durability as metal options, making them less suitable for heavy-duty applications. They are also less resistant to high temperatures.

Impact on Application: These materials are suitable for lightweight cabinetry and applications where aesthetics are prioritized over strength. They are often used in residential settings.

Considerations for International Buyers: Buyers should be aware of the specific environmental conditions in their regions, as extreme temperatures can affect the performance of plastic hinges. Compliance with local regulations regarding material safety may also be necessary.

What Are the Benefits of Using Brass for Demountable Cabinet Hinges?

Key Properties: Brass hinges are known for their excellent corrosion resistance and aesthetic appeal. They have a good strength-to-weight ratio and can withstand moderate loads.

Pros & Cons: The key advantage of brass is its attractive finish, which can enhance the overall look of cabinetry. However, brass can be more expensive than steel and may require more maintenance to prevent tarnishing.

Impact on Application: Brass is often used in decorative applications where aesthetics are crucial, such as in luxury cabinetry or furniture.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer brass for its aesthetic qualities, but they should also consider the cost implications. Ensuring compliance with material standards is essential for maintaining quality.

Summary Table of Material Selection for Demountable Cabinet Hinges

| Material | Typical Use Case for demountable cabinet hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Humid environments, kitchens | Corrosion-resistant | Higher cost | High |

| Plastic | Lightweight cabinetry, residential settings | Low cost and easy installation | Less durable | Low |

| Brass | Decorative cabinetry | Aesthetic appeal | Higher maintenance required | High |

This strategic material selection guide aims to provide B2B buyers with essential insights to make informed decisions regarding demountable cabinet hinges, ensuring compatibility with their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for demountable cabinet hinges

Demountable cabinet hinges are essential components in the furniture and cabinetry industry, particularly for their ease of installation and maintenance. Understanding their manufacturing processes and quality assurance measures is crucial for international B2B buyers looking to ensure that they source high-quality products. This section provides an in-depth look at the typical manufacturing processes and quality control protocols involved in producing demountable cabinet hinges.

What Are the Main Stages in the Manufacturing Process of Demountable Cabinet Hinges?

The manufacturing of demountable cabinet hinges involves several key stages, each critical to ensuring the final product meets both functionality and aesthetic standards.

Material Preparation: How Are Materials Selected and Prepared?

The first step in the manufacturing process is the selection and preparation of materials. Most demountable cabinet hinges are made from durable materials such as steel or zinc alloy, chosen for their strength and resistance to wear. The raw materials undergo a rigorous inspection to ensure they meet specified standards.

Once selected, materials are cut to size using techniques such as laser cutting or stamping, which provide precision and reduce waste. This step is crucial for maintaining the integrity of the hinge’s design and ensuring uniformity across production batches.

Forming: What Techniques Are Used to Shape the Hinges?

After material preparation, the next stage is forming. This involves shaping the cut materials into the desired hinge components. Techniques used in this stage include:

- Stamping: This method uses a die to shape the metal under high pressure, creating precise forms for the hinge parts.

- Bending: Bending machines are employed to create the necessary angles and shapes required for the hinge functionality.

- Machining: Some components may require additional machining processes to achieve specific tolerances or surface finishes.

These forming techniques are essential for producing high-quality hinges that function smoothly and last over time.

Assembly: How Are Hinges Assembled for Functionality?

Once the individual components are formed, the assembly process begins. This typically involves:

- Joining Components: The hinge leaf is attached to the hinge plate using screws or rivets, ensuring a secure connection.

- Incorporating Mechanisms: For self-closing or soft-closing hinges, additional mechanisms are integrated during assembly. These components require precise alignment to function correctly.

- Final Adjustments: The assembly line may include stations for adjusting the tension or alignment of the hinges, ensuring that they operate flawlessly.

Quality control checkpoints during assembly are vital to catch any defects before the hinges move to the finishing stage.

Finishing: What Are the Common Finishing Techniques?

The finishing stage enhances the aesthetic appeal and durability of the hinges. Common finishing techniques include:

- Electroplating: This process involves applying a thin layer of metal to the hinge surface, improving corrosion resistance and providing a decorative finish.

- Powder Coating: A method where a dry powder is applied and then cured under heat, resulting in a tough, durable coating that can be colored to match various design themes.

- Polishing: This technique is used to achieve a smooth and shiny surface, enhancing the visual appeal of the hinge.

These finishing processes not only add to the product’s longevity but also ensure that the hinges meet the aesthetic requirements of various markets.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance is critical in the production of demountable cabinet hinges, ensuring that every product meets international standards and buyer expectations.

What Are the Relevant International Standards for Quality Assurance?

Demountable cabinet hinges often need to comply with several international quality standards. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization that aims to improve customer satisfaction and ensure quality in its products.

- CE Marking: For products sold in the European Union, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Specifications: For hinges used in specific industrial applications, adherence to American Petroleum Institute standards may be required.

These certifications are important for B2B buyers, as they provide assurance of the product’s quality and reliability.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Ongoing inspections occur during the manufacturing stages, including checks for dimensions, finishes, and assembly quality.

- Final Quality Control (FQC): Once the hinges are fully assembled, a final inspection is conducted to assess functionality, aesthetic quality, and compliance with relevant standards.

These QC checkpoints help to minimize defects and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used to Ensure Product Quality?

To ensure the reliability and durability of demountable cabinet hinges, various testing methods are employed, including:

- Load Testing: Hinges are subjected to weight loads to ensure they can support the intended weight of cabinet doors without failure.

- Cycle Testing: This involves opening and closing the hinges repeatedly to assess their durability and performance over time.

- Corrosion Testing: Hinges may be exposed to saline environments to evaluate their resistance to rust and corrosion.

These tests help identify potential weaknesses and ensure that the hinges perform well under normal use conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential for ensuring product reliability. Here are several methods to conduct due diligence:

- Audits: Conducting factory audits can provide insights into the supplier’s manufacturing processes, quality control measures, and overall operational standards.

- Quality Assurance Reports: Requesting reports from suppliers detailing their quality control processes, inspection results, and any certifications can help verify compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product reliability.

These verification methods help mitigate risks and ensure that buyers are sourcing from reputable manufacturers.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must consider specific nuances related to quality control:

- Cultural Differences: Understanding the manufacturing culture and practices of suppliers in different regions can influence the effectiveness of quality control measures.

- Regulatory Compliance: Buyers must be aware of local regulations and standards that may differ from international ones, affecting product certification and compliance.

- Logistics and Supply Chain: Quality control can also be impacted by logistical challenges, such as shipping delays or customs regulations, which may affect product condition upon arrival.

By being aware of these nuances, buyers can better navigate the complexities of international sourcing and ensure high-quality product procurement.

In conclusion, understanding the manufacturing processes and quality assurance measures for demountable cabinet hinges is vital for B2B buyers. By focusing on these aspects, buyers can make informed purchasing decisions, ensuring that they source reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘demountable cabinet hinges’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure demountable cabinet hinges. With a variety of options available in the market, it’s crucial to ensure you make informed decisions that align with your specific needs, budget, and quality standards. Following this step-by-step checklist will help streamline your sourcing process and enhance your purchasing strategy.

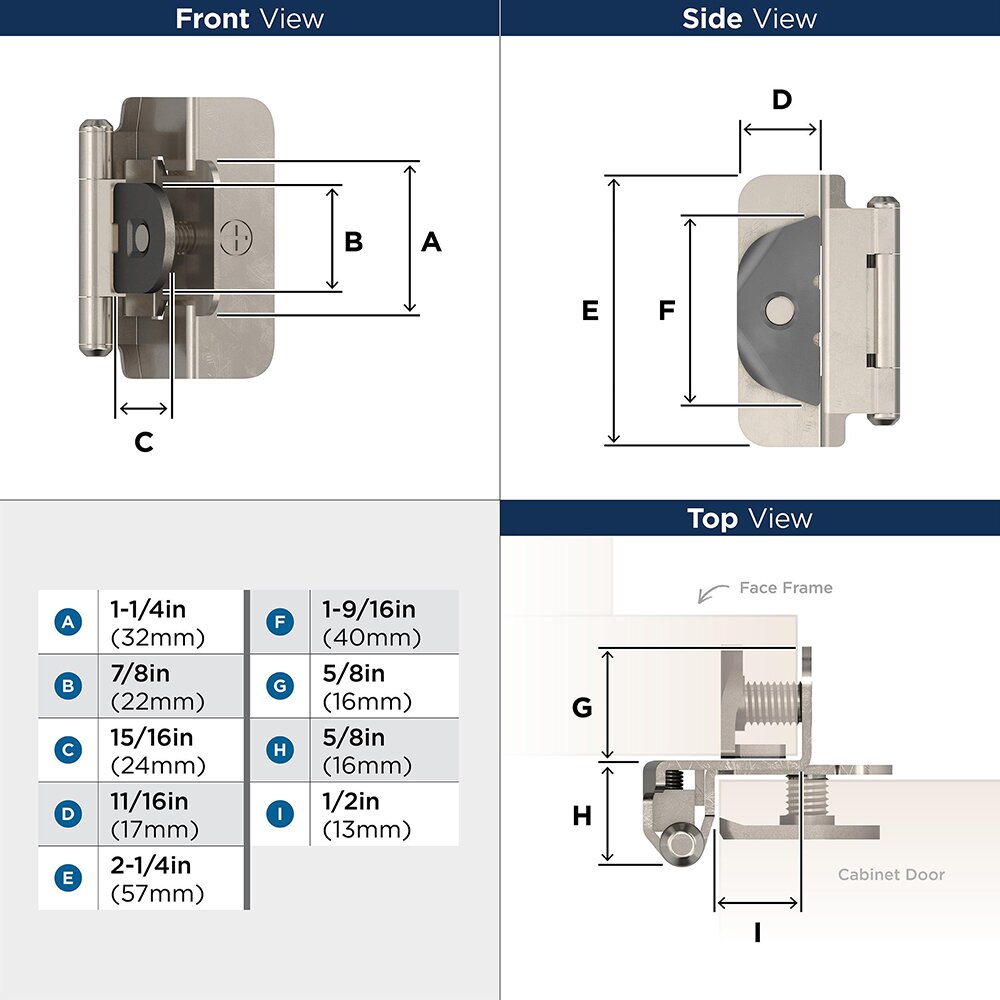

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as the size, weight capacity, and type of cabinet you are working with. Knowing whether you need single or double demountable hinges, as well as the required overlay size, will guide your supplier search and ensure compatibility with your cabinetry.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers in the market. Look for manufacturers and distributors specializing in cabinet hardware, particularly demountable hinges. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential vendors, paying attention to their reputation and product offerings.

Step 3: Evaluate Supplier Certifications and Standards

Before proceeding with any supplier, verify their certifications and compliance with relevant quality standards. This includes checking for ISO certifications, adherence to regional safety regulations, and any industry-specific credentials. Ensuring that suppliers meet these standards will help guarantee the reliability and safety of the products you source.

Step 4: Request Product Samples

Always request samples of demountable cabinet hinges from shortlisted suppliers. This allows you to assess the quality, finish, and functionality of the hinges firsthand. Pay attention to aspects such as material durability, ease of installation, and overall design to determine if they meet your specifications.

Illustrative image related to demountable cabinet hinges

Step 5: Review Pricing and Terms of Sale

Analyze the pricing structures provided by your potential suppliers. Compare not only the unit prices but also any bulk purchase discounts, shipping costs, and payment terms. Understanding the total cost of ownership will enable you to make an informed decision that aligns with your budget constraints.

Step 6: Assess Lead Times and Delivery Options

Inquire about the lead times for delivery and any shipping options available. Timely delivery is crucial in maintaining your project timelines, so ensure that your chosen supplier can meet your deadlines. Consider suppliers that offer expedited shipping or have a local presence to minimize delays.

Step 7: Establish Communication and Support Channels

Ensure that your chosen supplier has effective communication channels in place. This includes responsive customer service, technical support, and clear processes for addressing any issues that may arise post-purchase. A supplier that prioritizes communication will enhance your overall sourcing experience and facilitate a smoother transaction process.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing demountable cabinet hinges effectively, ensuring they select the best products for their needs while building strong relationships with trustworthy suppliers.

Comprehensive Cost and Pricing Analysis for demountable cabinet hinges Sourcing

What Are the Key Cost Components in Demountable Cabinet Hinges Sourcing?

When sourcing demountable cabinet hinges, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common options are steel and brass, with variations in finishes such as oil-rubbed bronze or satin nickel. Higher-quality materials typically lead to increased durability and corrosion resistance but may also elevate costs.

-

Labor: Labor costs encompass both the manufacturing process and assembly of the hinges. Regions with lower labor costs may offer more competitive pricing, but this can also affect the quality and craftsmanship of the product.

-

Manufacturing Overhead: This includes utilities, rent, and equipment costs associated with production. Manufacturers operating in regions with lower operational expenses may pass those savings onto buyers.

-

Tooling: The initial investment in tooling for production molds and machinery can be substantial. Custom designs or specifications will require additional tooling, impacting the overall cost.

-

Quality Control (QC): Stringent QC processes can raise costs, but they ensure product reliability and compliance with international standards. Certifications for quality can influence buyer decisions, particularly in markets with strict regulations.

-

Logistics: Shipping costs vary based on distance, freight methods, and the volume of orders. Understanding the logistics involved is essential for calculating the total cost.

-

Margin: Suppliers will add a margin to cover their expenses and profit. This margin can differ based on the supplier’s market position and the level of service provided.

How Do Price Influencers Affect Demountable Cabinet Hinges Pricing?

Several factors influence the pricing of demountable cabinet hinges, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Establishing a long-term relationship with suppliers can also improve negotiating power on pricing.

-

Specifications and Customization: Customized hinges or those with specific dimensions or features will typically cost more. Buyers should weigh the necessity of customization against available stock options.

-

Materials and Quality Certifications: Higher-grade materials and certifications (e.g., ISO, CE) increase production costs but may be essential for compliance in certain markets, influencing purchase decisions.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge a premium due to their quality assurance and service levels.

-

Incoterms: Understanding shipping terms is crucial for cost management. Different Incoterms (like FOB, CIF) can significantly impact the total landed cost of the product.

What Are Effective Buyer Tips for Sourcing Demountable Cabinet Hinges?

To navigate the complexities of sourcing demountable cabinet hinges, consider the following strategies:

-

Negotiate Effectively: Leverage volume commitments and long-term relationships to negotiate better pricing. Understanding market prices can provide leverage in discussions.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, installation, and maintenance costs. Selecting high-quality hinges may reduce long-term replacement and repair costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and taxes that may affect pricing when sourcing from different regions. Additionally, consider the impact of regional market conditions on pricing strategies.

-

Conduct Supplier Audits: Regularly assess suppliers for quality, compliance, and service delivery. This can help ensure that you are getting the best value for your investment.

In conclusion, understanding the cost structure, price influencers, and effective negotiation strategies can empower B2B buyers to make informed decisions when sourcing demountable cabinet hinges. It is essential to consider both immediate costs and long-term implications to maximize value in your procurement process.

Alternatives Analysis: Comparing demountable cabinet hinges With Other Solutions

When considering the best solutions for cabinet door functionality, it is essential to evaluate the available options. Demountable cabinet hinges are a popular choice due to their ease of use and versatility. However, various alternatives may also meet specific needs depending on the application, budget, and operational requirements. Below, we compare demountable cabinet hinges with two viable alternatives: traditional butt hinges and concealed hinges.

Illustrative image related to demountable cabinet hinges

| Comparison Aspect | Demountable Cabinet Hinges | Traditional Butt Hinges | Concealed Hinges |

|---|---|---|---|

| Performance | High, allows easy removal | Moderate, fixed position | High, seamless appearance |

| Cost | Moderate | Low to moderate | Higher initial cost |

| Ease of Implementation | Simple installation | Easy installation | Requires precise alignment |

| Maintenance | Low, durable materials | Moderate, lubrication needed | Low, minimal upkeep |

| Best Use Case | Modular setups, frequent access | General cabinetry | Modern cabinetry designs |

What are the Advantages and Disadvantages of Traditional Butt Hinges?

Traditional butt hinges are widely used due to their simplicity and cost-effectiveness. They consist of two plates that are fixed to the cabinet and door, allowing for straightforward opening and closing. One significant advantage of butt hinges is their lower cost, making them an economical choice for large projects. However, they lack the flexibility of demountable hinges, as removing the door requires detaching the hinge entirely, which can be cumbersome for maintenance or cleaning.

How Do Concealed Hinges Compare to Demountable Cabinet Hinges?

Concealed hinges, also known as European hinges, provide a sleek, modern appearance as they are hidden when the door is closed. They offer excellent performance with a seamless design that enhances the aesthetic of the cabinetry. The downside is that they tend to be more expensive and require precise installation to function correctly. While they do not provide the same ease of door removal as demountable hinges, they can often be adjusted for alignment, which can be beneficial in high-traffic environments.

Conclusion: Which Cabinet Hinge Solution is Right for Your Business Needs?

Choosing the right hinge solution depends on various factors including the specific application, budget constraints, and aesthetic preferences. For modular setups or environments requiring frequent access, demountable cabinet hinges stand out due to their functionality and ease of use. Traditional butt hinges may be better suited for budget-conscious projects where aesthetics are less of a concern. Conversely, concealed hinges are ideal for modern designs where appearance is paramount, despite their higher cost. B2B buyers should assess their specific requirements and weigh the pros and cons of each option to make an informed decision that aligns with their operational needs and design aspirations.

Essential Technical Properties and Trade Terminology for demountable cabinet hinges

What Are the Key Technical Properties of Demountable Cabinet Hinges?

Understanding the technical specifications of demountable cabinet hinges is essential for B2B buyers, especially when making decisions that impact product performance and longevity. Here are the critical properties to consider:

1. Material Grade

Demountable cabinet hinges are typically made from various materials, including steel, stainless steel, and brass. The material grade directly influences the hinge’s durability, corrosion resistance, and aesthetic appeal. For instance, stainless steel hinges are ideal for environments that may be exposed to moisture, while brass offers a classic look. Selecting the right material can enhance the longevity of your cabinetry, reducing replacement costs over time.

2. Load Capacity

The load capacity indicates the maximum weight a hinge can support without compromising its integrity. This specification is crucial for ensuring that cabinet doors function smoothly and remain securely attached. Buyers should assess the intended use of the cabinets—whether for residential, commercial, or industrial applications—and choose hinges that can accommodate the expected weight of the doors and contents.

3. Overlay and Inset Dimensions

Overlay and inset dimensions refer to how much of the cabinet door overlaps the frame. Demountable hinges can be categorized as overlay (where the door covers part of the frame) or inset (where the door is flush with the frame). Understanding these dimensions is vital for ensuring that the hinges fit properly and function as intended, providing seamless operation and a polished look.

4. Closing Mechanism

Demountable cabinet hinges may feature various closing mechanisms, such as self-closing or soft-closing options. Self-closing hinges automatically pull the door closed when it is within a certain range, while soft-closing hinges gently close the door without slamming. These features enhance user experience and can be a significant selling point for high-end cabinetry.

5. Finish Options

The finish of the hinges affects both aesthetics and functionality. Common finishes include oil-rubbed bronze, polished chrome, and satin nickel. The choice of finish can enhance the overall design of the cabinetry and should align with other hardware in the space. Additionally, certain finishes offer better resistance to tarnishing and wear, which is an important consideration for long-term use.

What Are Common Trade Terminology and Jargon in the Demountable Cabinet Hinge Industry?

Familiarity with industry terminology can streamline the purchasing process and improve communication between buyers and suppliers. Here are essential terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of demountable cabinet hinges, buyers may engage with OEMs to source specific hinge designs tailored to their product lines, ensuring compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstock or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal request for pricing from suppliers. When seeking demountable cabinet hinges, buyers should prepare detailed RFQs that include specifications, quantities, and delivery timelines to receive accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs, risk, and delivery obligations, which is particularly important for international purchases.

5. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In the case of hinges, precise tolerances ensure that components fit together correctly, which is vital for functionality and safety. Buyers should specify tolerances in their orders to avoid compatibility issues.

By understanding these technical properties and trade terms, B2B buyers can make informed purchasing decisions that enhance their cabinet offerings while ensuring quality and reliability.

Navigating Market Dynamics and Sourcing Trends in the demountable cabinet hinges Sector

What Are the Key Market Dynamics and Trends Influencing Demountable Cabinet Hinges?

The global market for demountable cabinet hinges is influenced by several key drivers, including the growing demand for modular and adaptable furniture solutions. As urbanization increases, particularly in regions like Africa and South America, there is a rising trend toward flexible living spaces that require easy-to-install and removable hardware. This trend is complemented by a surge in home improvement projects, driven by consumers seeking to personalize their living environments. In Europe and the Middle East, the shift toward sustainable design is also impacting purchasing decisions, with buyers increasingly favoring products that align with eco-friendly practices.

In terms of technology, advancements in materials science are leading to the development of lighter, more durable hinges that offer improved functionality. The integration of smart technology into furniture is another emerging trend, where hinges can now be designed to accommodate smart cabinets that are electronically controlled. For international B2B buyers, understanding these trends is critical for sourcing decisions, as they reflect broader consumer preferences that can dictate market success.

How Is Sustainability and Ethical Sourcing Reshaping the Demountable Cabinet Hinges Market?

Sustainability is becoming a cornerstone of the demountable cabinet hinges sector, as environmental impact is at the forefront of business operations. B2B buyers are increasingly scrutinizing the entire supply chain, seeking suppliers that prioritize ethical sourcing and minimal ecological footprints. The use of recycled materials, non-toxic finishes, and manufacturing processes that reduce waste are becoming standard expectations.

Certifications such as FSC (Forest Stewardship Council) for wood products and ISO 14001 for environmental management systems are gaining traction among suppliers. Buyers are encouraged to prioritize partnerships with manufacturers who can demonstrate compliance with these standards, thereby enhancing their own brand reputation. Moreover, transparency in sourcing practices not only fosters trust but also aligns with the growing consumer demand for socially responsible products. By prioritizing sustainability, B2B buyers can meet regulatory requirements and cater to a market increasingly driven by eco-conscious consumers.

What Is the Historical Evolution of Demountable Cabinet Hinges and Its Relevance Today?

The concept of demountable cabinet hinges has evolved significantly since its inception. Originally designed for ease of installation and removal, these hinges were primarily used in industrial applications. However, as the furniture industry transformed, so too did the design and functionality of these hinges. Innovations in materials and manufacturing processes have resulted in highly aesthetic options that cater to a wide range of consumer preferences.

Illustrative image related to demountable cabinet hinges

Today, demountable cabinet hinges are not only functional but also serve as a design element that complements modern cabinetry. This evolution is crucial for B2B buyers, as it highlights the importance of selecting hinges that not only meet functional requirements but also align with current design trends. Understanding this historical context can provide valuable insights into product selection, ensuring that buyers are equipped to meet the demands of a diverse and evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of demountable cabinet hinges

1. How do I choose the right demountable cabinet hinges for my projects?

Selecting the right demountable cabinet hinges involves considering several factors including the weight and size of the cabinet doors, the intended use, and the desired aesthetics. Look for hinges that match your door overlay (e.g., 1/4″, 1/2″) and material type (e.g., steel, brass). Additionally, consider the hinge’s closing mechanism—options like self-closing or soft-closing can enhance usability. Supplier catalogs typically provide detailed specifications, allowing you to ensure compatibility with your cabinets.

2. What is the best way to evaluate suppliers of demountable cabinet hinges?

Evaluating suppliers requires thorough research. Start by checking their experience in the industry and their reputation among previous clients. Request samples to assess the quality of their hinges firsthand. Additionally, inquire about their production capabilities, lead times, and adherence to international quality standards. Reviews and testimonials from other B2B buyers can provide insights into their reliability and customer service.

3. What are the common minimum order quantities (MOQ) for demountable cabinet hinges?

Minimum order quantities can vary significantly depending on the supplier and the hinge type. Typically, MOQs range from 100 to 1,000 pieces. Larger orders may lead to discounted pricing, while smaller orders might incur higher costs per unit. Always clarify MOQs with your supplier upfront to avoid unexpected costs and ensure that your order meets their requirements.

4. Can I customize demountable cabinet hinges to fit specific design requirements?

Yes, many manufacturers offer customization options for demountable cabinet hinges, including size, finish, and functionality. Custom orders can help you match the hinges with your cabinets’ aesthetics or specific operational needs. When discussing customization, provide detailed specifications and quantities to receive accurate quotes and production timelines.

5. What payment terms should I expect when sourcing demountable cabinet hinges internationally?

Payment terms can vary by supplier, but common practices include upfront deposits (typically 30-50%) with the balance due prior to shipment. Some suppliers may offer payment via letters of credit or escrow services to protect both parties. It’s essential to negotiate clear payment terms and ensure they align with your cash flow requirements before finalizing any agreements.

6. How do I ensure quality assurance (QA) for demountable cabinet hinges?

To ensure quality assurance, establish clear QA standards with your supplier before production begins. Request certificates of compliance or test reports, especially if you are importing hinges to meet specific regulations. Consider conducting factory visits or hiring third-party inspection services to verify product quality before shipment. Regular communication throughout the production process can also help address any potential issues early.

7. What are the logistics considerations for importing demountable cabinet hinges?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who understands the requirements for your destination country. Be aware of lead times and plan for potential delays in customs clearance. Ensure that your shipping terms (like Incoterms) are clearly defined to avoid miscommunication regarding responsibilities and costs.

8. What trends should I be aware of in the demountable cabinet hinge market?

Current trends include a growing demand for eco-friendly materials and finishes, as well as the integration of advanced features such as soft-close mechanisms. Innovations in design are also emerging, with a focus on aesthetics that complement modern cabinetry. Staying updated on these trends can help you meet consumer preferences and differentiate your offerings in competitive markets.

Top 3 Demountable Cabinet Hinges Manufacturers & Suppliers List

1. Hardwaresource – Demountable Cabinet Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Demountable Cabinet Hinges: 1/2″ Overlay Double Demountable Hinge – From $13.10 Per Pair, Available Finishes: Oil Rubbed Bronze, Antique Brass, Black Iron, Satin Nickel; 1/2″ Overlay Single Demountable Hinge – From $12.49 Per Pair, Available Finishes: Antique Brass, Nickel, Oil Rubbed Bronze, Satin Nickel; 3/8″ Inset Double Demountable Hinge – From $12.49 Per Pair, Available Finishes: Satin Nickel…

2. Hardware Hut – Demountable Hinges

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: Demountable Hinges – 19 items available

3. Rockler – Self-Closing Hinges for Face-Frame Cabinets

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – Self-Closing Hinges for Face-Frame Cabinets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for demountable cabinet hinges

As the demand for demountable cabinet hinges continues to rise, strategic sourcing remains paramount for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. These hinges offer not only convenience and ease of use but also significant cost savings in the long run, as they facilitate quick access for maintenance and upgrades.

By focusing on quality, durability, and design, buyers can enhance their product offerings while meeting the specific needs of diverse markets. Understanding the various styles, finishes, and functionality of demountable hinges allows businesses to tailor their inventory to suit customer preferences, ultimately improving customer satisfaction and loyalty.

Looking ahead, it is crucial for B2B buyers to establish strong relationships with suppliers to navigate the complexities of global sourcing effectively. Engaging with reliable manufacturers will ensure access to innovative products and competitive pricing. As the market evolves, leveraging insights from industry trends will empower businesses to remain ahead of the curve.

Take action now—evaluate your sourcing strategies, explore new partnerships, and invest in high-quality demountable cabinet hinges to drive growth and enhance your competitive edge in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.