Top 3 Cattle Panels Tractor Supply Suppliers (And How to Choose)

Introduction: Navigating the Global Market for cattle panels tractor supply

In the dynamic landscape of agricultural supplies, sourcing reliable cattle panels can pose significant challenges for international B2B buyers. Whether you’re operating in the vast expanses of Africa, the diverse terrains of South America, the arid regions of the Middle East, or the agricultural hubs of Europe, finding high-quality, durable cattle panels that meet your specific needs is crucial. This comprehensive guide to cattle panels from Tractor Supply aims to streamline your purchasing process by providing in-depth insights into various types of panels, their applications, and best practices for supplier vetting.

Understanding the range of cattle panels available—from galvanized feedlot panels to versatile utility panels—will empower you to make informed decisions that enhance your livestock management and fencing solutions. Additionally, this guide will cover essential aspects such as cost considerations, shipping logistics, and compliance with local regulations, ensuring you are well-equipped to navigate the complexities of sourcing across borders.

By leveraging the information within this guide, B2B buyers can optimize their procurement strategies, minimize risks, and ultimately enhance their operational efficiency. This resource is designed to equip you with the knowledge necessary to secure the best products for your agricultural needs, fostering a more productive and sustainable farming environment.

Understanding cattle panels tractor supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Feedlot Panels | Heavy-duty, galvanized steel, typically 16 ft long | Cattle feedlots, temporary pens | Pros: Durable, easy installation; Cons: Bulkier for transport. |

| Handy Panels | Smaller size (8 ft), lighter weight | Small farms, temporary fencing | Pros: Portable, versatile; Cons: Less sturdy for large livestock. |

| Utility Panels | Various heights, suitable for mixed livestock | General livestock management, gardens | Pros: Multi-purpose, customizable; Cons: May require additional support. |

| Corral Panels | Extra heavy-duty, often reinforced | Cattle handling facilities, rodeos | Pros: High strength, secure; Cons: Higher cost. |

| Combination Panels | Mixed design for different livestock types | Versatile applications, from cattle to goats | Pros: Adaptable; Cons: Complexity in installation. |

What are the Key Features of Feedlot Panels for B2B Buyers?

Feedlot panels are typically constructed from heavy-duty galvanized steel, measuring around 16 feet in length and 50 inches in height. They are designed for robust use in environments like cattle feedlots where durability is essential. B2B buyers in livestock production will find these panels ideal for creating secure, long-term enclosures. Their strength allows them to withstand harsh weather and the pressure from larger animals, making them a reliable choice. However, their bulkiness can pose challenges during transport, especially for smaller operations.

How Do Handy Panels Serve Smaller Operations?

Handy panels, measuring 8 feet in length, are lightweight and easy to handle, making them suitable for smaller farms or temporary fencing needs. Their versatility allows for various applications, from creating temporary pens to serving as garden trellises. For B2B buyers, these panels provide a cost-effective solution for operations that require flexibility without compromising on quality. However, they may not offer the same level of durability as larger, heavier panels, which could be a consideration for those managing larger livestock.

What Are the Advantages of Utility Panels for Diverse Livestock?

Utility panels are designed to cater to a variety of livestock types, with varying heights and strengths. They are particularly useful for farms that manage mixed livestock species. B2B buyers can leverage these panels for multiple purposes, including fencing for gardens or creating temporary enclosures. Their customizable nature allows buyers to adapt the panels to specific needs. However, additional support may be necessary for larger animals, which can increase overall costs.

Why Choose Corral Panels for Cattle Handling?

Corral panels are built for high strength and security, making them suitable for cattle handling facilities and rodeos. These panels are often reinforced to withstand significant stress, providing a safe environment for both animals and handlers. B2B buyers focused on livestock management will appreciate their durability and the peace of mind they offer. However, the higher cost associated with these panels may deter smaller operations or those with limited budgets.

How Do Combination Panels Enhance Versatility in Livestock Management?

Combination panels are designed with mixed specifications to accommodate various livestock types, making them a versatile choice for diverse operations. They can be used in settings ranging from cattle to goats, allowing for greater flexibility in livestock management. B2B buyers will benefit from their adaptability, especially in environments where different species are kept. However, the complexity of installation may require additional expertise, which could present a challenge for some buyers.

Key Industrial Applications of cattle panels tractor supply

| Industry/Sector | Specific Application of cattle panels tractor supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock Containment and Management | Ensures the safety and security of livestock, reducing losses. | Durability, weather resistance, and ease of installation. |

| Horticulture | Garden Trellis and Support Structures | Provides support for climbing plants, improving yield and quality. | Material quality, size options, and adaptability to local crops. |

| Construction | Temporary Fencing for Construction Sites | Offers quick and effective site security and animal control. | Compliance with local regulations and strength for safety. |

| Event Management | Perimeter Fencing for Outdoor Events | Creates secure areas for guests and equipment, enhancing safety. | Portability, ease of setup, and aesthetic options. |

| Eco-Tourism | Wildlife Observation Areas and Enclosures | Facilitates safe and controlled wildlife viewing experiences. | Non-intrusive design, durability, and environmental impact. |

How Are Cattle Panels Used in Agriculture for Livestock Management?

In agriculture, cattle panels are primarily utilized for livestock containment. They create secure enclosures for cattle, goats, and other livestock, preventing escapes and protecting animals from predators. This application is crucial for farmers aiming to minimize losses due to straying animals. International buyers, particularly from regions like Africa and South America, should consider the durability of the panels against harsh weather conditions, as well as the ease of installation, which can significantly reduce labor costs.

What Role Do Cattle Panels Play in Horticulture?

In horticulture, cattle panels serve as effective trellises for climbing plants such as beans, cucumbers, and tomatoes. By providing vertical support, they maximize space usage and improve crop yield. Buyers in Europe and the Middle East may find this application particularly valuable as they look to enhance urban farming practices. When sourcing, it is important to assess the material quality and size options to ensure compatibility with specific plant varieties and local growing conditions.

How Are Cattle Panels Used in Construction?

Construction sites often require temporary fencing to secure the area and control access. Cattle panels are ideal for this purpose due to their strength and ease of setup. They can quickly establish boundaries, ensuring safety for workers and equipment. For buyers in regions like Saudi Arabia, where construction projects are booming, sourcing panels that comply with local regulations and offer robust safety features is essential to avoid potential liabilities.

What Benefits Do Cattle Panels Provide for Event Management?

In the event management sector, cattle panels can be employed as perimeter fencing for outdoor events such as festivals and concerts. They help create secure areas for attendees and protect equipment from theft or damage. Buyers should focus on the portability and ease of setup of these panels, especially in areas across Africa where logistics can be challenging. Additionally, aesthetic options may be considered to enhance the visual appeal of the event space.

How Are Cattle Panels Beneficial for Eco-Tourism?

Cattle panels are increasingly used in eco-tourism to create observation areas and enclosures for wildlife. They allow tourists to safely view animals in their natural habitats without disturbing them. For international buyers in eco-tourism, sourcing panels that are durable yet non-intrusive is crucial to minimize environmental impact while ensuring visitor safety. Understanding local wildlife regulations and environmental standards will also guide effective sourcing decisions.

3 Common User Pain Points for ‘cattle panels tractor supply’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Cattle Panels for Extreme Weather Conditions

The Problem: B2B buyers, particularly those operating in regions with extreme weather conditions, often face challenges in sourcing cattle panels that can withstand high winds, heavy rain, or snow. Traditional panels may bend, rust, or become unstable, leading to costly repairs and the potential loss of livestock. This issue is exacerbated in areas where suppliers may not stock weather-resistant options, leaving buyers scrambling for solutions that may not be readily available.

The Solution: To address this problem, buyers should focus on sourcing galvanized cattle panels specifically designed for durability in harsh environments. When evaluating suppliers like Tractor Supply, inquire about the specifications of the panels, such as gauge thickness and the type of galvanization used. Opt for panels with a higher gauge number (e.g., 6 or 8 gauge) as they offer better strength and resistance against bending and rusting. Additionally, consider ordering panels with reinforced welds and smooth edges to enhance safety and longevity. Establishing a long-term relationship with a reliable supplier can also ensure that you have access to replacement panels and parts when needed.

Scenario 2: Challenges in Installing Cattle Panels for Large Operations

The Problem: In large agricultural operations, the installation of cattle panels can become a daunting task. Buyers often struggle with coordinating the logistics of panel placement, ensuring structural integrity, and managing labor costs. This is particularly true in extensive grazing areas where uneven terrain complicates the installation process, leading to delays and increased expenses.

The Solution: To streamline the installation process, B2B buyers should consider modular panel systems that are easier to handle and set up. Look for panels that are lightweight yet robust, allowing for single-person installation if necessary. Additionally, utilize equipment such as post drivers or augers to facilitate quick and precise placement of posts. Prior to installation, conduct a site assessment to map out panel placements, considering factors such as livestock behavior and terrain. This proactive planning can help avoid potential issues and ensure a secure setup. Collaborating with experienced local contractors who specialize in livestock fencing can also provide valuable insights and efficiency during installation.

Scenario 3: Cost Management When Purchasing Cattle Panels in Bulk

The Problem: B2B buyers often encounter challenges when purchasing cattle panels in bulk, particularly regarding budgeting and cost management. Fluctuating prices, shipping fees, and unexpected tariffs can lead to significant discrepancies between initial estimates and final costs. This uncertainty can strain financial resources and impact overall project viability.

The Solution: To effectively manage costs, buyers should engage in thorough market research to understand pricing trends in their region. Establishing relationships with multiple suppliers can provide leverage when negotiating bulk purchase discounts. Furthermore, buyers should explore options such as direct shipping or local pickup to minimize transportation costs. Consider joining cooperative buying groups with other local farmers or ranchers to increase purchasing power and secure better rates. Additionally, always factor in total cost of ownership by evaluating the lifespan and maintenance needs of the cattle panels to ensure long-term value aligns with initial expenditures.

Strategic Material Selection Guide for cattle panels tractor supply

What Are the Key Materials Used in Cattle Panels for Tractor Supply?

When selecting cattle panels for agricultural needs, understanding the material composition is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in cattle panels: galvanized steel, high-tensile steel, aluminum, and polymer composites. Each material has distinct properties that influence its suitability for various applications, especially in diverse international markets.

How Does Galvanized Steel Perform in Cattle Panels?

Galvanized steel is a popular choice for cattle panels due to its excellent corrosion resistance and durability. The galvanization process involves coating the steel with a layer of zinc, which protects it from rust and environmental wear. This material can withstand significant pressure and is rated for high-temperature applications, making it suitable for various climates.

Pros: Galvanized steel panels are robust and can last for many years with minimal maintenance. They are relatively cost-effective compared to other materials, making them a preferred choice for large-scale operations.

Cons: While galvanized steel is durable, it can be prone to scratches that may expose the underlying steel to corrosion if not properly maintained. Additionally, it can be heavier than other materials, complicating transportation and installation.

Impact on Application: Galvanized steel panels are compatible with various livestock and are effective in creating secure boundaries. They are particularly well-suited for regions with high humidity or rainfall, such as parts of Africa and South America.

What Advantages Does High-Tensile Steel Offer for Cattle Panels?

High-tensile steel is engineered to provide superior strength and flexibility, making it an excellent choice for cattle panels that require resilience against impact and stress. This material is designed to handle high-pressure situations without bending or breaking, making it ideal for active livestock environments.

Pros: The primary advantage of high-tensile steel is its strength-to-weight ratio, allowing for lighter panels that are easier to handle and install. They also have a longer lifespan compared to traditional steel panels.

Cons: High-tensile steel panels can be more expensive than galvanized options, which may deter budget-conscious buyers. Moreover, they require specialized tools for cutting and installation, adding complexity to the manufacturing process.

Impact on Application: These panels are particularly suitable for regions with extreme weather conditions, as they can withstand high winds and heavy loads. International buyers in Europe, especially in areas with stringent agricultural standards, may prefer high-tensile steel for its durability.

How Do Aluminum Cattle Panels Compare?

Aluminum panels are lightweight and resistant to corrosion, making them an appealing option for temporary fencing solutions. They are easier to transport and install, which is advantageous for farmers who need to set up and dismantle pens frequently.

Pros: The main advantage of aluminum panels is their lightweight nature, which simplifies handling and reduces transportation costs. They are also resistant to rust, ensuring longevity in various environmental conditions.

Cons: However, aluminum is not as strong as steel, making it less suitable for high-stress applications. It can also be more expensive than galvanized steel, which may not align with the cost-effectiveness sought by some international buyers.

Impact on Application: Aluminum panels are ideal for regions with mild climates and are often used for temporary applications, such as at livestock shows or during transport. Buyers in the Middle East may find aluminum panels particularly useful due to their resistance to corrosion in arid environments.

What Role Do Polymer Composites Play in Cattle Panels?

Polymer composites are emerging as a modern alternative for cattle panels. These materials combine plastic with other components to create a lightweight, durable product that is resistant to weathering and corrosion.

Pros: The key advantage of polymer composites is their versatility and low maintenance requirements. They are resistant to chemicals and do not rust, making them suitable for various agricultural applications.

Cons: On the downside, polymer composites may not offer the same structural strength as metal panels, which can limit their use in high-stress environments. Additionally, they may not be as widely available in certain international markets.

Impact on Application: These panels are particularly beneficial for regions with high humidity or chemical exposure, such as agricultural areas in South America. Buyers should consider compatibility with local agricultural practices and standards.

Summary of Material Selection for Cattle Panels

| Material | Typical Use Case for cattle panels tractor supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Permanent fencing for cattle and livestock | Excellent corrosion resistance | Prone to scratches and heavier | Medium |

| High-Tensile Steel | High-impact environments for active livestock | Superior strength-to-weight ratio | Higher cost and requires specialized tools | High |

| Aluminum | Temporary fencing solutions | Lightweight and easy to transport | Less strength compared to steel | Medium to High |

| Polymer Composites | Chemical-resistant and low-maintenance fencing | Versatile and resistant to weathering | Limited structural strength | Medium |

This strategic material selection guide provides insights into the various materials available for cattle panels, helping international B2B buyers make informed decisions based on their specific requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cattle panels tractor supply

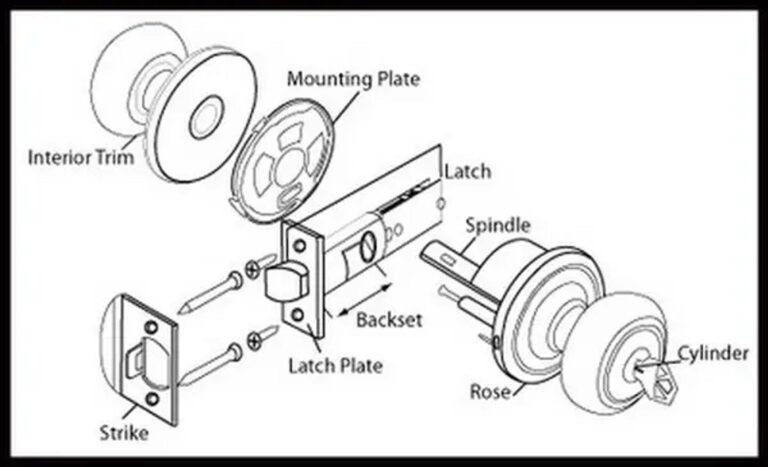

What Are the Key Stages in the Manufacturing Process of Cattle Panels?

The manufacturing of cattle panels involves several critical stages, each designed to ensure the final product meets the rigorous demands of livestock management. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically galvanized steel, which is known for its corrosion resistance and strength. The steel is cut into specified lengths and widths, ensuring that it meets design specifications. Quality checks on the raw materials are performed to verify that they meet international standards, such as ISO 9001.

-

Forming: Once the materials are prepared, they undergo forming, where the steel is shaped into the desired panel structure. This is usually achieved through techniques such as welding, bending, and stamping. Advanced machinery is employed to ensure precision in the formation of the panels, which results in a consistent product that can withstand the rigors of farm life.

-

Assembly: After forming, the panels are assembled. This involves welding the horizontal and vertical bars to create the panel framework. In this stage, quality assurance measures are critical; manufacturers often utilize automated welding processes to ensure uniformity and strength across all panels.

-

Finishing: The final stage involves surface treatment to enhance durability. Panels are typically coated with a layer of galvanized zinc to protect against rust and corrosion. Additional finishing processes may include powder coating or painting, which not only adds aesthetic value but also provides an extra layer of protection.

How Is Quality Assurance Integrated into Cattle Panel Manufacturing?

Quality assurance (QA) is a pivotal aspect of cattle panel production, ensuring that products are safe, durable, and reliable. Manufacturers adhere to several international standards and industry-specific certifications to maintain high-quality outputs.

Illustrative image related to cattle panels tractor supply

-

International Standards: Many manufacturers seek certification under ISO 9001, which outlines criteria for a quality management system. This certification ensures that organizations consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Standards: In addition to ISO standards, compliance with industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards may be applicable, particularly for heavy-duty applications.

-

Quality Control Checkpoints: Quality control is enforced at multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, random samples of panels are tested for dimensional accuracy and weld strength.

– Final Quality Control (FQC): Finished products undergo rigorous testing to verify that they meet all design specifications and quality standards before shipment.

What Common Testing Methods Are Used to Ensure Cattle Panel Quality?

To guarantee the quality and durability of cattle panels, manufacturers implement a variety of testing methods, including:

- Tensile Testing: This assesses the strength of the steel used in the panels by determining how much force the material can withstand before breaking.

- Corrosion Resistance Testing: Panels are subjected to accelerated weathering tests to evaluate their resistance to rust and degradation over time.

- Dimensional Testing: This ensures that the panels conform to specified dimensions and tolerances, which is crucial for ease of installation and functionality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational efficiency. This firsthand observation can help identify potential issues before placing large orders.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QA processes, testing results, and compliance with international standards. Regular updates on quality metrics can also demonstrate a commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These services can offer certifications that validate the quality of the panels and the integrity of the manufacturing process.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers must navigate additional complexities regarding quality control, particularly in regions like Africa, South America, the Middle East, and Europe.

-

Regulatory Compliance: Different regions may have varying regulations regarding livestock management and fencing products. Buyers should ensure that products comply with local regulations, which may include specific material standards or certifications.

-

Cultural and Environmental Factors: Understanding local environmental conditions (e.g., humidity, temperature) can influence the choice of materials and finishes. Buyers should discuss these factors with suppliers to select the most suitable cattle panel products for their specific climates.

-

Supply Chain Reliability: International buyers should assess the supplier’s supply chain resilience, including logistics capabilities and inventory management. A reliable supplier can provide timely delivery and consistent product availability, which is crucial for ongoing livestock management operations.

Conclusion

In summary, the manufacturing processes and quality assurance practices for cattle panels are integral to ensuring that these products meet the demanding needs of livestock management. By understanding the key stages of production, the importance of quality control, and the verification methods available, B2B buyers can make informed decisions when sourcing cattle panels for their operations. Adopting a thorough approach to evaluating suppliers will help mitigate risks and enhance the reliability of livestock management solutions across diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cattle panels tractor supply’

This practical sourcing guide aims to provide international B2B buyers with a systematic checklist for procuring cattle panels from suppliers, particularly focusing on offerings similar to those found at Tractor Supply. Following these steps will help ensure that buyers make informed decisions while securing high-quality products that meet their operational needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the cattle panels you intend to purchase. Consider factors such as dimensions, material type, and load-bearing capacity.

- Dimensions: Determine whether you need standard sizes (e.g., 8 ft x 50 in or 16 ft x 50 in) or custom dimensions based on your specific application.

- Material: Galvanized steel is a popular choice for durability and resistance to corrosion, making it ideal for outdoor use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in cattle panels. Use online directories, trade shows, and industry publications to compile a list.

- Reviews and Ratings: Look for suppliers with high ratings and positive reviews from previous clients, especially in your region.

- Experience: Evaluate how long the supplier has been in business and their experience in fulfilling orders similar to yours.

Step 3: Evaluate Supplier Certifications

Before finalizing any deals, verify that potential suppliers hold the necessary certifications and comply with international standards.

- Quality Assurance: Check for certifications such as ISO 9001, which indicate a commitment to quality management systems.

- Safety Standards: Ensure that their products meet local agricultural and safety regulations, particularly if you are operating in different countries.

Step 4: Request Samples and Specifications

Request samples of the cattle panels to assess their quality firsthand. Additionally, ask for detailed specifications and installation guidelines.

- Material Quality: Examine the finish and gauge of the panels to ensure they meet your durability requirements.

- Installation Instructions: Clear installation guidelines will help minimize labor costs and reduce installation time.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers, initiate negotiations regarding pricing, bulk discounts, and payment terms.

- Volume Discounts: Inquire about discounts for larger orders, which can significantly reduce overall costs.

- Payment Flexibility: Discuss payment terms that align with your cash flow needs, including options for deposits or extended payment periods.

Step 6: Check Delivery and Logistics

Confirm the logistics of delivery, including timelines, shipping methods, and associated costs.

- Shipping Options: Determine whether the supplier offers local delivery or if you need to arrange transportation.

- Lead Times: Be aware of lead times to ensure that the panels arrive when needed, especially if you are working on a tight schedule.

Step 7: Finalize Your Order and Confirm After-Sales Support

After agreeing on terms, finalize your order and ensure that the supplier provides after-sales support for any issues that may arise post-purchase.

- Warranty Information: Confirm warranty details to protect your investment in case of defects.

- Customer Support: Ensure that the supplier has a responsive customer service team to assist with any inquiries or issues that may occur after installation.

By following this checklist, B2B buyers can navigate the procurement process for cattle panels with confidence, ensuring they select the best products for their agricultural needs.

Comprehensive Cost and Pricing Analysis for cattle panels tractor supply Sourcing

What Are the Key Cost Components in Sourcing Cattle Panels?

When analyzing the cost structure for sourcing cattle panels, several critical components must be considered:

-

Materials: The primary cost driver is the raw materials used in manufacturing cattle panels, which typically include galvanized steel or other durable metals. The quality of the material directly affects the price and longevity of the panels.

-

Labor: Labor costs encompass wages for workers involved in production, assembly, and quality control. In regions with higher labor costs, such as parts of Europe, this can significantly impact the overall pricing.

-

Manufacturing Overhead: This includes costs associated with the factory’s operational expenses, such as utilities, equipment maintenance, and facility rent. Efficient overhead management can help lower prices.

-

Tooling: Initial tooling costs for specialized equipment can be substantial, particularly for customized panels. These costs may be amortized over large production runs, reducing the cost per unit.

-

Quality Control (QC): Ensuring that each panel meets specified standards incurs additional costs. Investments in QC processes can prevent defects and improve the product’s reliability, which is crucial for international buyers.

-

Logistics: Transportation costs from the manufacturing facility to the buyer’s location are essential to consider. This includes shipping methods, insurance, and handling fees, which can vary significantly based on distance and mode of transport.

-

Margin: Suppliers add their profit margins to the cost of production, which can vary widely depending on market conditions and competition.

How Do Price Influencers Impact Cattle Panel Costs?

Several factors can influence the pricing of cattle panels significantly:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk pricing discounts. Understanding the supplier’s MOQ can help negotiate better rates.

-

Specifications and Customization: Custom panels designed for specific applications may incur higher costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials and Quality Certifications: Panels made from higher-grade materials or those that meet specific certifications (like ISO or ASTM) may come at a premium but offer greater durability and safety.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier play a crucial role in pricing. Established suppliers may offer better service and warranties, justifying higher prices.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for cost management. Buyers should clarify responsibilities for shipping costs, duties, and insurance to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost Efficiency in International B2B Transactions?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost efficiency:

-

Negotiate Wisely: Leverage your buying power, especially for large orders. Be prepared to discuss pricing based on competitor offers and market conditions.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, replacement, and operational efficiency. Investing in higher-quality panels may reduce TCO.

-

Understand Pricing Nuances: Different regions may have varying costs due to tariffs, transportation, and local economic factors. Conduct market research to benchmark prices effectively.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, improved service, and priority during supply chain disruptions.

-

Stay Informed About Market Trends: Regularly monitor industry trends, material costs, and supply chain dynamics to make informed purchasing decisions and anticipate price changes.

Disclaimer on Indicative Prices

The prices mentioned in various sources can fluctuate based on market conditions, supplier pricing strategies, and local economic factors. Buyers should conduct thorough due diligence and seek quotes from multiple suppliers to ensure competitive pricing and value.

Alternatives Analysis: Comparing cattle panels tractor supply With Other Solutions

Exploring Alternatives for Cattle Panels: A Comparative Analysis

In the realm of livestock management and fencing solutions, cattle panels from Tractor Supply are a popular choice due to their durability and versatility. However, businesses looking to optimize their operations should consider alternative solutions that may better fit their specific needs. This analysis compares the performance, cost, ease of implementation, maintenance, and best use cases of cattle panels from Tractor Supply against other viable options.

| Comparison Aspect | Cattle Panels Tractor Supply | Welded Wire Fencing | Electric Fencing |

|---|---|---|---|

| Performance | High durability and strength; effective for containment. | Strong and long-lasting; can handle various livestock. | Quick to set up; effective for perimeter control. |

| Cost | Moderate cost ($27.99 – $59.99 per panel). | Generally higher upfront costs but long-term savings on maintenance. | Initial costs can vary widely; may require ongoing electricity costs. |

| Ease of Implementation | Simple installation; requires minimal tools. | Moderate difficulty; needs more tools and planning. | Requires electrical setup and knowledge of safety protocols. |

| Maintenance | Low maintenance; occasional inspections needed. | Moderate; rust-proof options available but may need replacement over time. | Low maintenance, but checks for power supply and functionality are essential. |

| Best Use Case | Ideal for temporary pens, garden trellises, and durable fencing solutions. | Best for permanent fencing solutions on larger properties. | Suitable for controlling movement across large areas or for temporary fencing needs. |

Analyzing Welded Wire Fencing as an Alternative

Welded wire fencing is a robust alternative to cattle panels, especially for businesses seeking a more permanent solution. These fences consist of vertical and horizontal wires welded together, providing excellent strength and durability. The primary advantage of welded wire fencing is its longevity; once installed, it can last for many years with minimal maintenance. However, its installation can be labor-intensive and may require more planning and tools compared to cattle panels. Additionally, welded wire fencing tends to have a higher initial cost but can lead to savings in the long run due to its durability.

Understanding Electric Fencing as a Different Approach

Electric fencing offers a modern approach to livestock management, particularly for businesses that require flexibility and quick setup. This system uses electric currents to create a psychological barrier, which can be particularly effective for containing livestock within a designated area. The primary benefits of electric fencing include its ease of installation and the ability to quickly modify or expand the layout as needed. However, it does require access to a power source and regular checks to ensure the system is functioning properly. The ongoing electricity costs can also add up, making it a less favorable option for some businesses.

Making the Right Choice for Your Livestock Management Needs

When evaluating alternatives to cattle panels from Tractor Supply, B2B buyers should carefully consider their specific operational needs, budget constraints, and the type of livestock they manage. Cattle panels are a strong choice for those needing a reliable and straightforward fencing solution, while welded wire fencing may be more suitable for permanent installations. Electric fencing can be ideal for those requiring flexibility and quick adjustments. Ultimately, the right solution depends on the unique circumstances of each business, including land size, livestock type, and long-term management goals.

Essential Technical Properties and Trade Terminology for cattle panels tractor supply

What are the Essential Technical Properties of Cattle Panels?

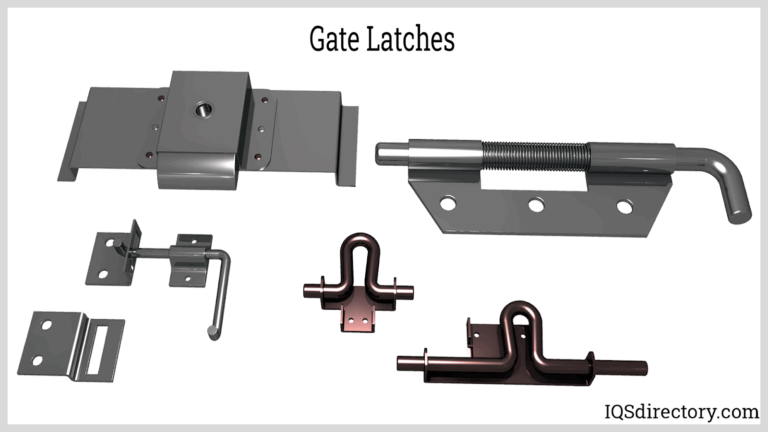

When selecting cattle panels for livestock management, understanding the technical properties is crucial for ensuring safety, durability, and operational efficiency. Here are some key specifications to consider:

-

Material Grade:

– Cattle panels are typically made from galvanized steel, which is resistant to rust and corrosion. The quality of the steel is often measured in gauge, with lower numbers indicating thicker and stronger materials. For example, a 6-gauge panel is sturdier than an 11-gauge panel, making it more suitable for heavy-duty use in harsher environments. -

Height and Length:

– Common sizes include 16 ft x 50 in and 8 ft x 50 in panels. The height is essential for containing larger animals like cattle, while the length allows for flexibility in fencing designs. Buyers should assess the specific needs of their operations to choose appropriately sized panels that minimize the number of joints and potential weak points. -

Weld Quality:

– The integrity of the welds used in cattle panels impacts their overall strength and longevity. High-quality panels feature continuous welding, which provides a robust structure that can withstand the stress of daily use and the impact of livestock. Inspecting the weld quality is vital for ensuring the panel can endure harsh conditions. -

Line Spacing:

– Panels often come with varying line spacing, which affects their suitability for different types of livestock. For example, tighter spacing is essential for smaller animals like goats or sheep, while wider spacing may suffice for larger cattle. Understanding the line spacing helps prevent escapes and injuries, making it a critical consideration for buyers. -

Weight Capacity:

– The weight capacity of a cattle panel is an important property that indicates how much pressure it can withstand without bending or breaking. This specification is particularly relevant for operations with larger herds or those that may put additional strain on fencing due to environmental factors. -

Finish Type:

– Cattle panels can have various finishes, such as galvanized or powder-coated. Galvanization offers corrosion resistance, while powder coating provides additional protection against the elements. The choice of finish impacts the panel’s lifespan and maintenance requirements, making it a critical factor in the buying decision.

What are Common Trade Terms in the Cattle Panel Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to cattle panels:

-

OEM (Original Equipment Manufacturer):

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of cattle panels, buyers may work directly with OEMs to obtain customized panels tailored to specific needs. -

MOQ (Minimum Order Quantity):

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for buyers, especially when planning inventory and cost management for larger operations. -

RFQ (Request for Quotation):

– An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is often used in B2B transactions to ensure competitive pricing and terms before making a purchase decision. -

Incoterms:

– Short for International Commercial Terms, these are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They are essential for defining the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. -

Lead Time:

– This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management, especially in industries that require timely deliveries for operational efficiency. -

Warranty:

– A warranty is a guarantee provided by the manufacturer regarding the quality and durability of the product. Buyers should pay close attention to warranty terms to understand the level of protection and recourse available in the event of product failure.

By familiarizing themselves with these essential properties and terminology, B2B buyers can make informed decisions when sourcing cattle panels, ultimately enhancing their operational efficiency and livestock management practices.

Navigating Market Dynamics and Sourcing Trends in the cattle panels tractor supply Sector

What are the Current Market Dynamics and Key Trends in the Cattle Panels Sector?

The cattle panels market is experiencing notable growth driven by several global factors. Increasing demand for livestock farming, particularly in regions like Africa and South America, is pushing the need for reliable fencing solutions. The rise of sustainable agricultural practices is also reshaping the market, as farmers seek durable and eco-friendly materials. Technological advancements in manufacturing processes are yielding more robust and versatile cattle panels, which are essential for various applications, from livestock containment to temporary fencing solutions.

B2B buyers are increasingly leveraging digital platforms for sourcing, enabling them to compare products, prices, and supplier reputations easily. The adoption of e-commerce solutions in regions like the Middle East and Europe has streamlined procurement processes, allowing for bulk purchasing and improved inventory management. Furthermore, the integration of data analytics is enhancing demand forecasting, helping buyers make informed decisions that align with market trends. As a result, suppliers are focusing on customization options to cater to diverse needs, including specific panel sizes and materials that can withstand regional weather conditions.

How is Sustainability and Ethical Sourcing Influencing Cattle Panel Purchases?

Environmental sustainability is becoming a critical factor in the sourcing of cattle panels. The cattle farming industry faces scrutiny regarding its ecological footprint, prompting buyers to prioritize products that minimize environmental impact. This includes seeking panels made from recycled materials or sustainably sourced steel, which not only reduces waste but also supports circular economy practices.

Ethical sourcing is equally important, as B2B buyers are increasingly aware of the social implications of their purchases. Suppliers who adhere to fair labor practices and have transparent supply chains are becoming preferred partners. Certifications such as ISO 14001 for environmental management systems or LEED for green building materials are influencing buyer decisions, as they signify a commitment to sustainability. By aligning purchasing strategies with ethical standards, businesses can enhance their brand reputation and meet the growing consumer demand for responsible sourcing.

What is the Evolution of Cattle Panels in the Agricultural Sector?

The history of cattle panels can be traced back to early agricultural practices when farmers used rudimentary fencing methods to contain livestock. Over the years, advancements in materials and design have transformed cattle panels into essential tools for modern farming. Initially made from wood or basic wire, the introduction of galvanized steel in the mid-20th century marked a significant shift, offering enhanced durability and resistance to weather conditions.

As livestock farming evolved into a more commercialized sector, so did the requirements for fencing solutions. Today’s cattle panels are engineered for strength, versatility, and ease of installation, accommodating a range of farming needs from small-scale operations to large feedlots. This evolution reflects the broader trends in agriculture towards increased efficiency, sustainability, and the use of technology, shaping the future of cattle management practices worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of cattle panels tractor supply

-

How do I choose the right cattle panels for my livestock needs?

Selecting the appropriate cattle panels involves assessing your specific requirements, such as the type of livestock, the size of your operation, and the intended use of the panels. For example, heavier-duty panels are ideal for larger cattle herds, while lighter panels may suffice for smaller animals like goats or sheep. It’s also essential to consider panel height, gauge, and material; galvanized steel is often recommended for durability. Consulting with local suppliers or agricultural experts can provide additional insights tailored to your region’s climate and animal behavior. -

What is the best way to source cattle panels for international shipping?

To source cattle panels for international shipping, start by identifying reputable suppliers that offer export services. Look for manufacturers with experience in international trade, as they will be familiar with customs regulations, tariffs, and shipping logistics. It’s also advisable to request samples before placing large orders, ensuring the panels meet your quality standards. Engage with suppliers who can provide detailed product specifications and shipping timelines to facilitate smooth transactions. -

What are the minimum order quantities (MOQ) for cattle panels?

Minimum order quantities (MOQ) for cattle panels can vary significantly among suppliers. Some manufacturers may have a MOQ of as few as 10 panels, while others may require orders of 50 or more. When negotiating with suppliers, consider your budget and storage capacity, as well as potential shipping costs, which can escalate with larger orders. It’s often beneficial to inquire about discounts for bulk purchases, which can help reduce overall costs. -

What payment terms should I expect when purchasing cattle panels internationally?

Payment terms for international purchases can differ widely by supplier and region. Common options include upfront payments, letters of credit, or payment upon delivery. It’s essential to discuss these terms upfront to avoid any misunderstandings. Additionally, consider using secure payment methods that provide buyer protection. Establishing a clear agreement on payment terms will facilitate a smoother transaction and build trust between you and the supplier. -

How can I ensure the quality of cattle panels before purchasing?

To ensure the quality of cattle panels, request certifications or quality assurance documents from suppliers. You can also ask for references or case studies from other buyers who have used their products. If possible, visit the manufacturing facility or use third-party inspection services to assess the panels’ durability and construction. Additionally, look for panels made from high-quality materials like galvanized steel, which can withstand weather conditions and heavy use. -

What customization options are available for cattle panels?

Many manufacturers offer customization options for cattle panels, such as varying heights, widths, and designs tailored to specific livestock needs. Some suppliers may also provide additional features like gates or connectors for easier setup and flexibility. When discussing customization, be clear about your requirements and any specific features you need for your operation. This will help the supplier provide the best solution for your unique situation. -

What logistics considerations should I keep in mind when importing cattle panels?

When importing cattle panels, logistics considerations include shipping methods, customs clearance, and transportation from the port to your location. Choose a reliable freight forwarder experienced in agricultural equipment to help navigate these complexities. Understand the import regulations in your country, including any tariffs or duties that may apply. Additionally, plan for potential delays in shipping, especially during peak seasons, to ensure timely delivery. -

How can I build a long-term relationship with cattle panel suppliers?

Building a long-term relationship with cattle panel suppliers involves clear communication and mutual respect. Start by establishing trust through transparent negotiations and timely payments. Regularly provide feedback on product quality and service to help suppliers improve. Additionally, consider placing repeat orders or exploring other products they offer, which can strengthen your partnership. Attending industry events or trade shows can also facilitate personal connections and foster collaboration.

Top 3 Cattle Panels Tractor Supply Manufacturers & Suppliers List

1. Max 50 – 16 ft. x 50 in. Galvanized Cattle Fence Panel

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 16 ft. x 50 in. Max 50 Feedlot 10-Line Galvanized Cattle Fence Panel

2. College of EMS – Cattle Panels

Domain: collegeofems.com

Registered: 2015 (10 years)

Introduction: Hot Sale Cattle Panels, also known as Cow Panels, designed for livestock containment and fencing. These panels are durable, made from high-quality materials, and are suitable for various agricultural applications. They provide a secure environment for cattle while allowing for easy installation and mobility.

3. Coastal Country – Outdoor Gear & Accessories

Domain: coastalcountry.com

Registered: 2009 (16 years)

Introduction: Best Price Guarantee & Free Shipping Over $99* Categories include: Outdoor (Grills, Cookware, Camping & Hiking gear), Hunting (Accessories, Calls, Scopes), Mini Bikes, ATVs & Go-Karts, Fishing, Watersports, Shooting, Farm & Ranch (Fencing, Irrigation, Ag Spraying), Men’s Clothing & Footwear, Women’s Clothing & Footwear, Lawn & Garden (Tools, Power Equipment), Outdoor Living (Firepits, Furniture), …

Strategic Sourcing Conclusion and Outlook for cattle panels tractor supply

Why is Strategic Sourcing Crucial for Cattle Panels in Global Markets?

In conclusion, the strategic sourcing of cattle panels is essential for international B2B buyers seeking reliable, durable, and cost-effective fencing solutions. Sourcing from reputable suppliers, such as Tractor Supply, ensures access to high-quality products designed for the rigorous demands of livestock management. By leveraging bulk purchasing and establishing long-term partnerships, buyers can optimize their supply chains and reduce costs while maintaining the integrity of their operations.

Moreover, understanding regional needs and preferences is vital for successfully entering diverse markets across Africa, South America, the Middle East, and Europe. Adaptability in product specifications and pricing strategies can significantly enhance competitive advantage.

As the global demand for efficient livestock management solutions continues to grow, now is the time for B2B buyers to act. Explore the extensive range of cattle panels available and consider the long-term benefits of strategic partnerships with trusted suppliers. Embrace the opportunity to elevate your operational efficiency and ensure the safety and productivity of your livestock. The future of your agricultural endeavors starts with the right choices today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.