Top 3 Airplane Cables Suppliers (And How to Choose)

Introduction: Navigating the Global Market for airplane cables

Navigating the complexities of sourcing airplane cables can present significant challenges for international B2B buyers. With the diverse applications ranging from aircraft control systems to safety equipment, understanding the various types of cables available—such as galvanized and stainless steel—is essential for making informed purchasing decisions. This comprehensive guide delves into the intricacies of airplane cables, covering critical aspects like product specifications, applications across different industries, supplier vetting processes, and cost considerations.

For businesses in Africa, South America, the Middle East, and Europe—regions characterized by rapidly evolving aviation markets—having access to reliable information on airplane cables is vital. Whether you are a procurement manager in Saudi Arabia or an aviation equipment supplier in Vietnam, this guide empowers you to navigate the global market with confidence. By equipping you with actionable insights, it aims to enhance your sourcing strategies, mitigate risks, and ultimately drive efficiency in your operations.

Additionally, we will explore best practices for selecting suppliers who meet international standards, ensuring quality and compliance in your purchases. As you progress through this guide, you will gain a clearer understanding of the nuances of airplane cables, enabling you to make choices that align with your business objectives and operational needs.

Understanding airplane cables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7×19 Galvanized Aircraft Cable | Constructed with 7 strands of 19 wires; cost-effective; high strength | General rigging, winch lines, fencing | Pros: Cost-effective, high strength. Cons: Limited corrosion resistance compared to stainless steel. |

| 7×19 Stainless Steel Type 304 | Made from corrosion-resistant stainless steel; good for moderate environments | Marine applications, outdoor structures | Pros: Excellent corrosion resistance. Cons: Higher cost than galvanized options. |

| 7×19 Stainless Steel Type 316 | Enhanced corrosion resistance due to molybdenum; ideal for harsh conditions | Chemical processing, marine environments | Pros: Superior rust resistance. Cons: Slightly lower strength compared to Type 304. |

| Vinyl-Coated Aircraft Cable | Additional vinyl layer for protection; reduces wear and tear | Indoor applications, decorative use | Pros: Added protection, easier handling. Cons: Slightly higher price point. |

| Custom Wire Rope | Tailored specifications for unique applications; various materials available | Specialized rigging, unique lifting solutions | Pros: Customizable to specific needs. Cons: Longer lead times, potentially higher costs. |

What Are the Characteristics and Suitability of 7×19 Galvanized Aircraft Cable?

The 7×19 galvanized aircraft cable is a versatile option, made from 7 strands of 19 wires, providing significant tensile strength while remaining cost-effective. It is primarily used in general rigging applications, winch lines, and fencing. However, buyers should consider its limited corrosion resistance, making it less suitable for environments with high moisture or salt exposure.

Why Choose 7×19 Stainless Steel Type 304 for Your Projects?

7×19 stainless steel Type 304 cables are ideal for moderate environmental conditions, offering good corrosion resistance, which makes them suitable for marine applications and outdoor structures. This type boasts a higher price point than galvanized options, but its longevity and reduced maintenance needs can justify the investment, especially in corrosive settings.

How Does 7×19 Stainless Steel Type 316 Stand Out?

7×19 stainless steel Type 316 cables are specifically designed for harsh conditions, incorporating molybdenum for enhanced corrosion resistance. This makes them suitable for chemical processing and marine environments where exposure to saltwater is a concern. While they offer superior rust resistance, buyers should note that they have slightly lower strength compared to Type 304 cables.

What Advantages Does Vinyl-Coated Aircraft Cable Offer?

Vinyl-coated aircraft cables provide an additional layer of protection against dirt, moisture, and abrasions. They are particularly beneficial for indoor applications and decorative uses, as they enhance the cable’s handling and reduce wear on pulleys and sheaves. However, buyers should be aware that this added protection comes at a higher price point.

Why Consider Custom Wire Rope for Specialized Needs?

Custom wire rope is tailored to meet specific application requirements, allowing for unique specifications in terms of material and construction. This flexibility is essential for specialized rigging or lifting solutions. While custom options can provide significant advantages, they often come with longer lead times and potentially higher costs, which buyers should factor into their procurement strategy.

Key Industrial Applications of airplane cables

| Industry/Sector | Specific Application of Airplane Cables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aviation | Aircraft Control Systems | Ensures safety and reliability in flight operations | Compliance with aviation standards and certifications |

| Marine & Offshore | Rigging and Lifting Equipment | Enhances operational efficiency in challenging environments | Corrosion resistance and load capacity requirements |

| Construction | Temporary Supports and Hoisting Systems | Provides strong support for construction projects | Material specifications and break strength ratings |

| Telecommunications | Cable Suspension for Antennas and Towers | Supports infrastructure stability and reduces maintenance costs | Environmental resistance and installation ease |

| Industrial Manufacturing | Conveyor Systems and Material Handling | Increases productivity and reduces downtime | Customization options and compatibility with existing systems |

How Are Airplane Cables Used in Aviation Control Systems?

In the aviation sector, airplane cables are integral to control systems, linking cockpit controls to various aircraft components. These cables must meet stringent safety standards to ensure reliability during flight operations. Buyers in this sector need to ensure that the cables are compliant with aviation regulations and capable of withstanding extreme environmental conditions, including temperature fluctuations and high levels of vibration. Sourcing from reputable manufacturers with experience in aviation applications is crucial for maintaining safety and compliance.

What Role Do Airplane Cables Play in Marine and Offshore Applications?

In marine and offshore industries, airplane cables are commonly used for rigging and lifting equipment, such as cranes and winches. These cables provide high tensile strength and resistance to corrosion, making them ideal for harsh marine environments. Businesses benefit from enhanced operational efficiency and safety when using these cables for lifting heavy loads. Buyers should prioritize sourcing cables with proven durability and corrosion resistance, especially for applications in saltwater conditions.

How Are Airplane Cables Utilized in Construction Projects?

Airplane cables serve a vital role in construction as temporary supports and hoisting systems. They provide the necessary strength and stability to support structures during the building phase, ensuring safety and efficiency. Construction companies must consider the break strength ratings of the cables and their compliance with local building codes. Sourcing durable and reliable cables can significantly reduce project delays and enhance safety on-site.

How Do Airplane Cables Support Telecommunications Infrastructure?

In telecommunications, airplane cables are used for suspending antennas and supporting towers. These cables must be able to withstand various environmental factors, such as wind and moisture, to maintain the integrity of communication systems. Businesses benefit from reduced maintenance costs and improved infrastructure stability. Buyers should focus on sourcing cables that offer environmental resistance and ease of installation to ensure long-term functionality.

What Are the Applications of Airplane Cables in Industrial Manufacturing?

In the industrial manufacturing sector, airplane cables are utilized in conveyor systems and material handling applications. These cables contribute to increased productivity by ensuring the smooth operation of machinery and reducing downtime. Buyers need to consider customization options to ensure compatibility with existing systems and the specific requirements of their manufacturing processes. Selecting high-quality cables can lead to significant operational efficiencies and cost savings over time.

3 Common User Pain Points for ‘airplane cables’ & Their Solutions

Scenario 1: Sourcing High-Quality Airplane Cables for Safety Compliance

The Problem: B2B buyers in the aviation industry often face challenges when sourcing airplane cables that meet stringent safety standards. With various manufacturers offering different materials, strengths, and finishes, it can be overwhelming to determine which options comply with industry regulations. In regions such as Africa and the Middle East, where local suppliers may not always have transparent quality assurances, buyers risk purchasing substandard cables that could jeopardize safety during operations.

The Solution: To mitigate this risk, it’s essential to establish relationships with reputable suppliers who provide detailed product specifications and certifications. Buyers should look for cables that meet federal specifications such as RR-W-410 and ASTM A1023 standards. Conduct thorough due diligence by requesting samples and inspecting the manufacturing processes. Additionally, consider sourcing from suppliers that offer transparent traceability in their supply chain, ensuring that materials are sourced responsibly and meet international safety standards. Leveraging online platforms and industry trade shows can help connect with trusted suppliers and gather insights from peer reviews.

Scenario 2: Managing Corrosion Resistance in Harsh Environments

The Problem: In many applications, especially in marine or high-moisture environments, airplane cables are susceptible to corrosion, leading to potential failures. B2B buyers, particularly in coastal regions of South America and the Middle East, often find that standard galvanized cables may not provide the necessary longevity and durability needed in such challenging conditions. This can lead to increased maintenance costs and operational downtime.

The Solution: To address corrosion issues, buyers should prioritize stainless steel cables, specifically Type 316, which offers superior resistance to rust and environmental degradation compared to galvanized options. It is advisable to conduct a cost-benefit analysis to compare the upfront costs of stainless steel against the long-term savings in maintenance and replacements. Furthermore, utilizing vinyl-coated cables can add an extra layer of protection against moisture and abrasives, enhancing cable longevity. It’s also recommended to implement a routine inspection and maintenance schedule to monitor cable conditions proactively, allowing for early detection of wear and tear.

Scenario 3: Customizing Cable Specifications for Unique Applications

The Problem: B2B buyers often encounter situations where standard airplane cable specifications do not meet their unique application needs. For example, a company may require specific lengths, diameters, or breaking strengths that aren’t available off-the-shelf. This can lead to project delays and increased costs if custom solutions are not sourced efficiently.

The Solution: Buyers should engage with manufacturers that offer custom wire rope solutions. When discussing requirements, be precise about the application, including load capacities, environmental conditions, and specific usage scenarios. Collaborating closely with engineering teams can help refine the specifications needed for the custom cable. Additionally, utilizing advanced online configurators offered by some manufacturers can simplify the process, allowing buyers to visualize and specify their requirements effectively. It’s also beneficial to establish a clear timeline for production and delivery to ensure that custom cables are available when needed, thus avoiding project delays.

Strategic Material Selection Guide for airplane cables

What Are the Key Properties of Common Materials Used in Airplane Cables?

When selecting materials for airplane cables, it is essential to consider their properties that directly impact performance, safety, and longevity. The most common materials include galvanized steel, stainless steel (Type 304 and Type 316), and synthetic materials. Each has unique characteristics that influence their suitability for specific applications.

How Does Galvanized Steel Perform in Airplane Cable Applications?

Galvanized steel is widely used for airplane cables due to its excellent strength-to-weight ratio and cost-effectiveness. The galvanization process provides a protective zinc coating that enhances corrosion resistance, making it suitable for various environments. However, it has limitations in high-moisture or marine applications where corrosion can accelerate.

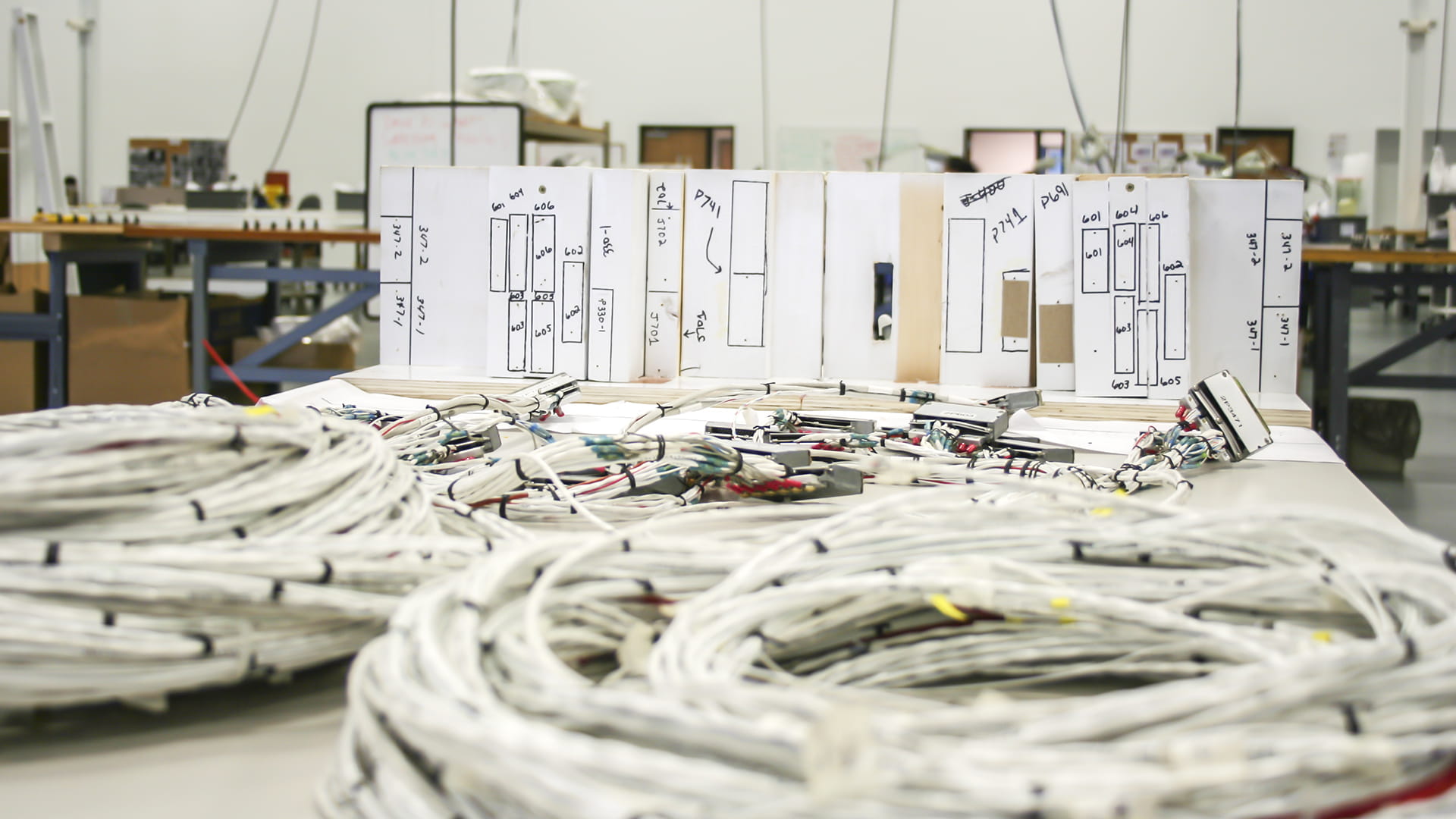

Illustrative image related to airplane cables

Pros: Cost-effective, high strength, good corrosion resistance in moderate conditions.

Cons: Limited performance in extreme environments, potential for coating wear over time.

Impact on Application: Suitable for general-use cables in dry or mildly humid environments.

Considerations for Buyers: Compliance with ASTM A1023 standards is essential, and buyers should be aware of local corrosion risks, especially in humid regions like parts of Africa and South America.

What Are the Advantages of Using Stainless Steel in Airplane Cables?

Stainless steel, particularly Type 304 and Type 316, is favored for its superior corrosion resistance and durability. Type 304 is commonly used for general applications, while Type 316, which contains molybdenum, offers enhanced resistance to rust and is ideal for marine environments. This material can withstand higher temperatures and pressures, making it versatile for various applications.

Pros: Excellent corrosion resistance, high strength, suitable for extreme conditions.

Cons: Higher cost compared to galvanized steel, slightly lower strength in Type 316.

Impact on Application: Ideal for applications in coastal or high-humidity environments where corrosion is a concern.

Considerations for Buyers: Ensure compliance with international standards like ASTM and DIN, particularly in regions with stringent aviation regulations.

How Do Synthetic Materials Compare to Traditional Metals in Airplane Cables?

Synthetic materials, such as high-strength polymers, offer unique benefits, including lightweight properties and resistance to corrosion and chemicals. While they may not match the tensile strength of steel, they excel in applications where weight savings are critical, such as in aerospace design.

Pros: Lightweight, excellent corrosion resistance, flexible.

Cons: Lower tensile strength than metals, potential UV degradation.

Impact on Application: Suitable for non-load-bearing applications or where weight reduction is critical.

Considerations for Buyers: Check for compliance with aviation standards and performance under specific environmental conditions, especially in regions with high UV exposure.

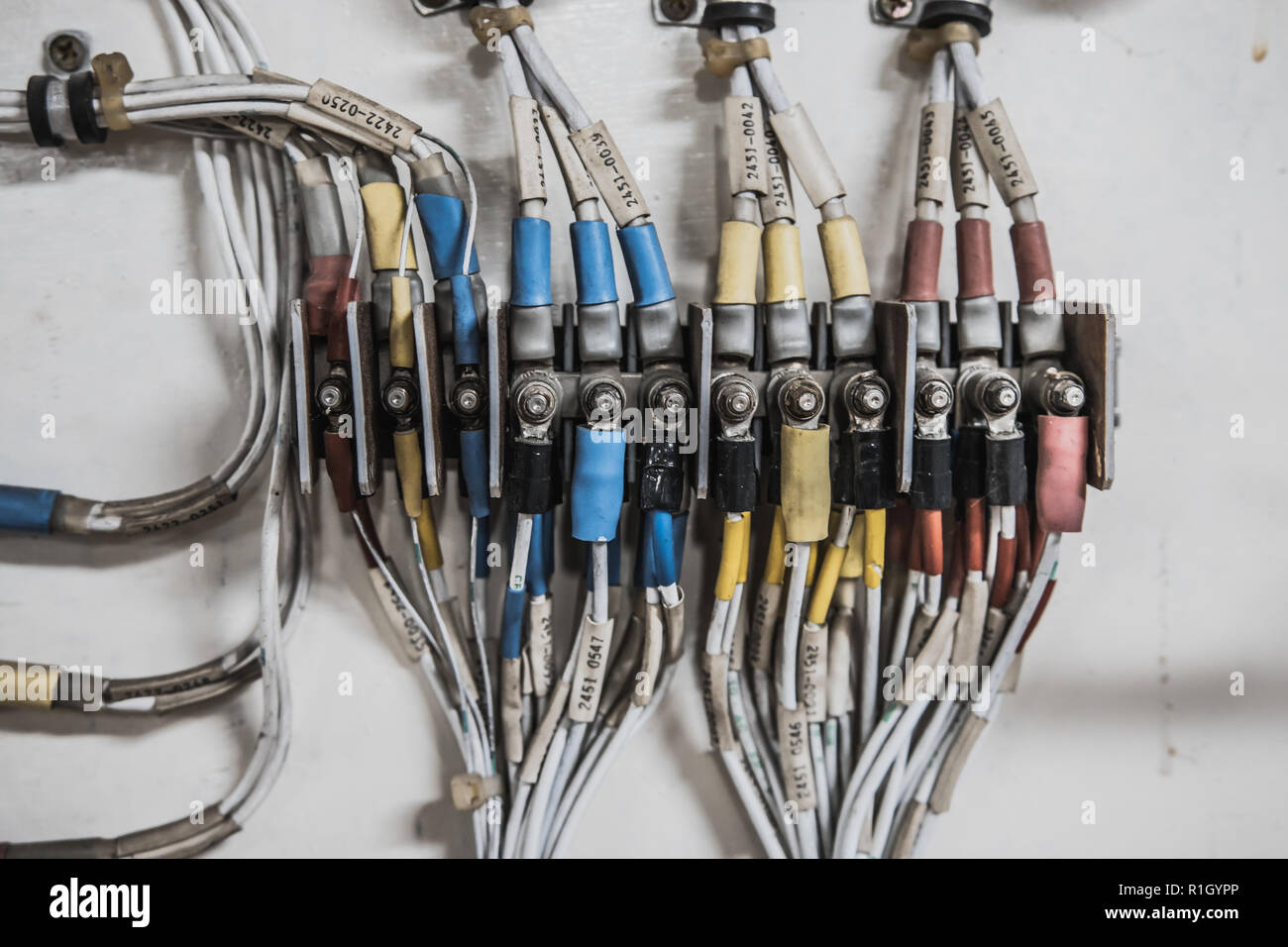

Illustrative image related to airplane cables

Summary Table of Material Selection for Airplane Cables

| Material | Typical Use Case for Airplane Cables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | General-purpose applications | Cost-effective and strong | Limited corrosion resistance | Low |

| Stainless Steel | Marine and high-humidity environments | Excellent corrosion resistance | Higher cost than galvanized steel | High |

| Type 304 Stainless Steel | General aviation applications | Good strength and corrosion resistance | Less effective in extreme conditions | Medium |

| Type 316 Stainless Steel | Marine and coastal applications | Superior corrosion resistance | Slightly lower strength | High |

| Synthetic Materials | Lightweight applications | Very lightweight and flexible | Lower tensile strength | Medium |

This guide provides a comprehensive overview of material options for airplane cables, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for airplane cables

What Are the Key Stages in the Manufacturing Process of Airplane Cables?

The manufacturing process for airplane cables involves several critical stages that ensure the final product meets stringent safety and performance standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

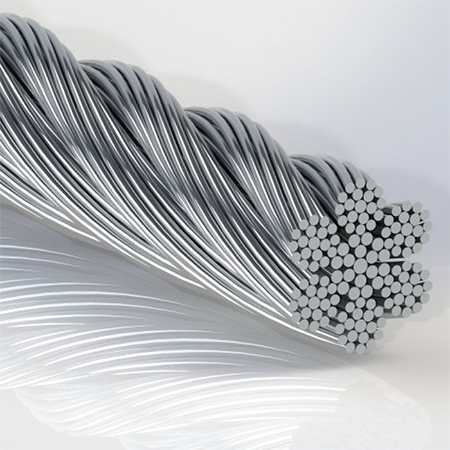

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing airplane cables is material preparation, which typically involves the selection of high-strength steel or stainless steel. Common grades include Type 304 and Type 316 stainless steel, known for their corrosion resistance and tensile strength.

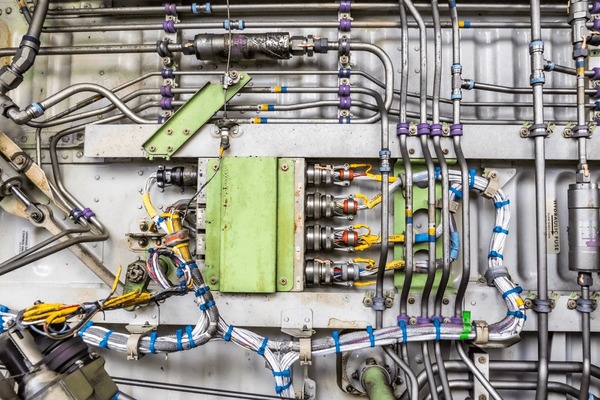

Illustrative image related to airplane cables

The raw materials undergo a thorough inspection to assess their quality. They are then cut to specified lengths based on the requirements of the final product. This preparation stage is crucial because the choice of material directly influences the cable’s performance, particularly in environments with high moisture or corrosive elements.

How Are Airplane Cables Formed?

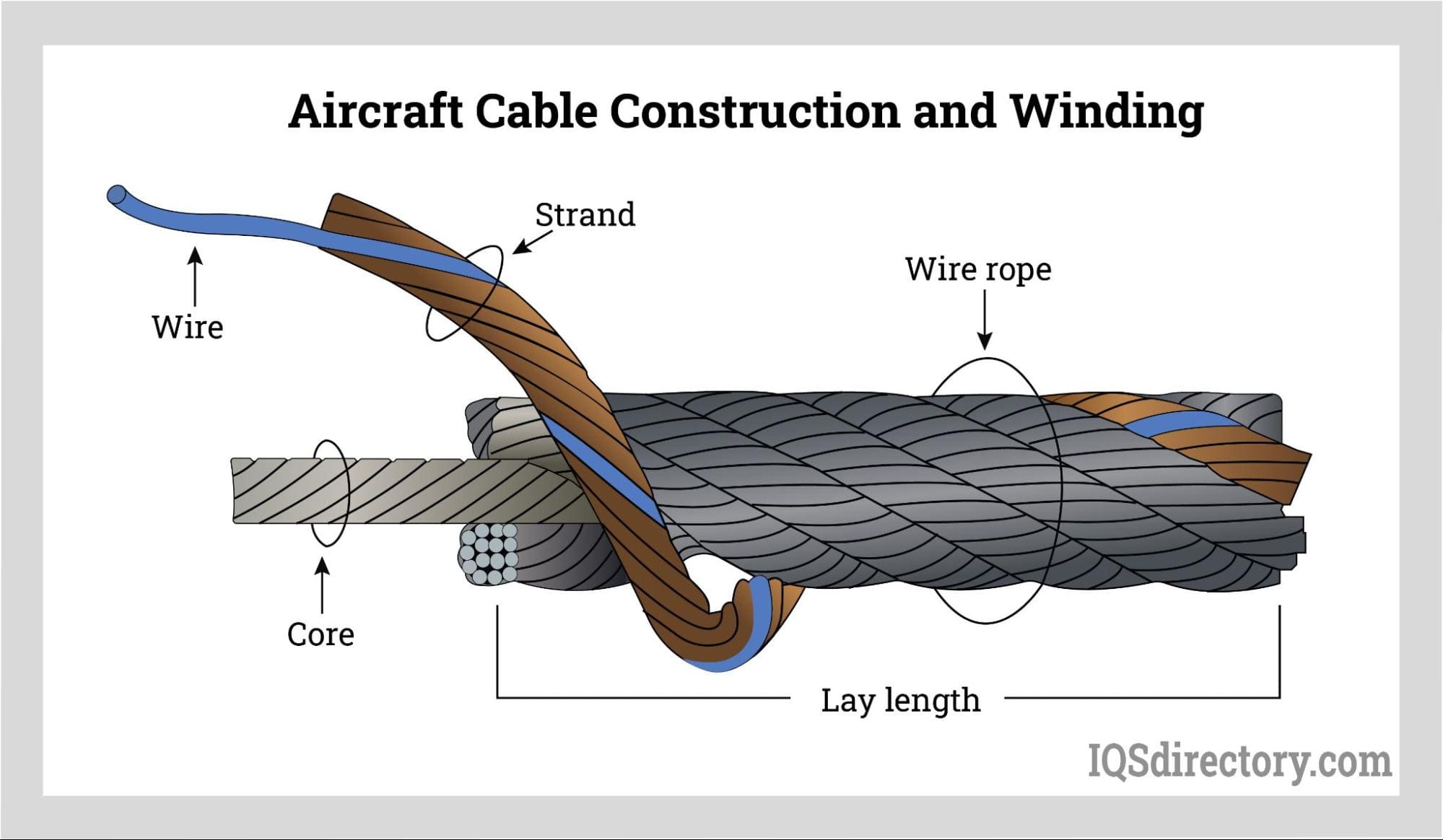

Following material preparation, the next step is forming. This involves the creation of strands and wires that will be twisted together to form the cable. Typically, a 7×19 configuration is used, meaning that each cable consists of 7 outer strands, each containing 19 wires.

Key techniques in this stage include strand twisting and compacting, which enhance the cable’s strength and flexibility. The application of heat treatment may also be employed to improve material properties, such as tensile strength and ductility.

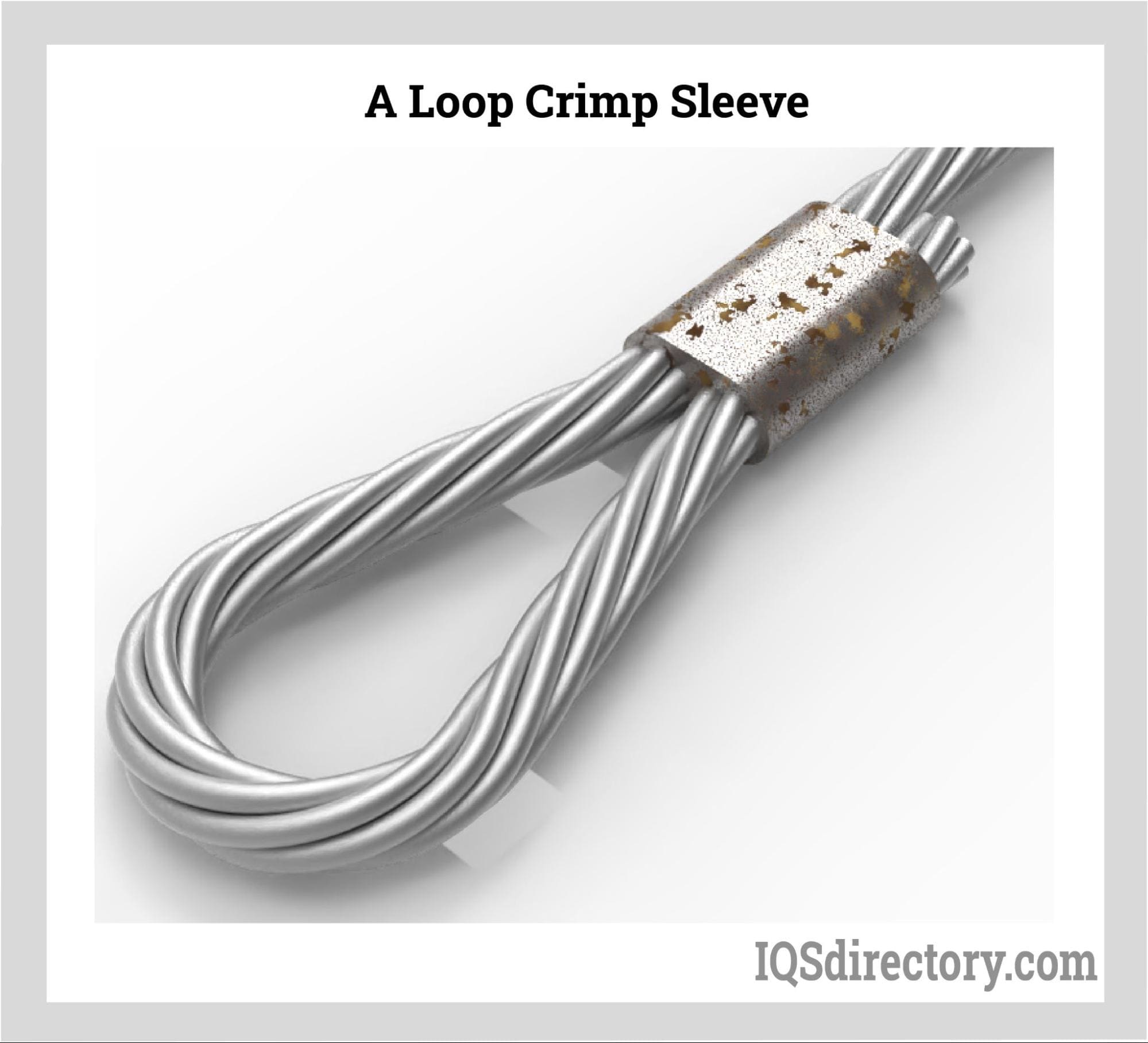

What Is Involved in the Assembly of Airplane Cables?

After forming, the next stage is assembly, where the twisted strands are combined and terminated with fittings. Depending on the application, these fittings may be made from materials like zinc, aluminum, or copper.

It’s essential that the assembly process adheres to specific guidelines to ensure the cable’s integrity. For instance, manufacturers may utilize swaging techniques to secure terminals to the cable, which enhances the overall strength and reliability of the assembly.

What Finishing Techniques Are Commonly Used?

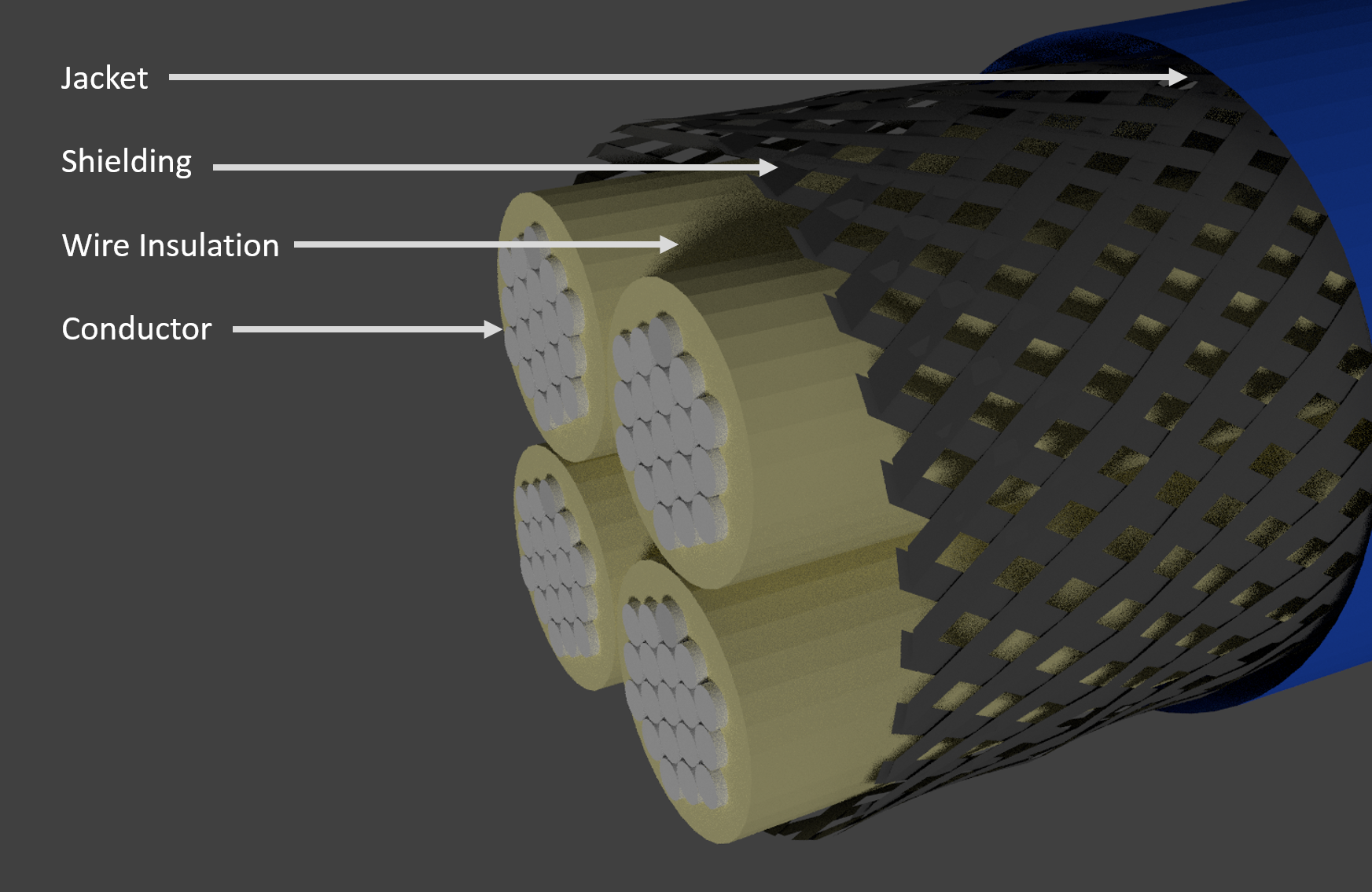

The finishing stage involves applying coatings or additional treatments to the cable. Options include vinyl coatings that offer extra protection against environmental factors and galvanized finishes that enhance corrosion resistance.

This stage also includes quality checks to confirm that the cable meets specifications for diameter, weight, and break strength. An effective finishing process not only improves the cable’s durability but also its aesthetic appeal.

What Quality Assurance Measures Are Implemented in the Manufacturing of Airplane Cables?

Quality assurance (QA) is a critical component in the manufacturing of airplane cables, ensuring that they meet both international and industry-specific standards.

Illustrative image related to airplane cables

Which International Standards Are Relevant for Airplane Cable Manufacturing?

International standards such as ISO 9001 play a significant role in guiding the quality management systems of manufacturers. These standards focus on continuous improvement and customer satisfaction, which are vital for B2B buyers who prioritize reliability.

In addition, industry-specific certifications such as CE marking and API (American Petroleum Institute) standards may also apply, particularly for cables used in specialized applications. Compliance with these standards reassures buyers that the products have undergone rigorous testing and evaluation.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials before they enter the production line, ensuring they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, real-time checks are conducted to monitor processes and identify any deviations from standards.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive evaluation is performed to verify that the finished product meets all specifications.

What Testing Methods Are Commonly Used to Ensure Cable Quality?

Common testing methods for airplane cables include tensile tests, which measure the break strength, and fatigue tests, assessing how well the cable withstands repeated loads. Other tests may include corrosion resistance assessments and dimensional checks to ensure compliance with specified tolerances.

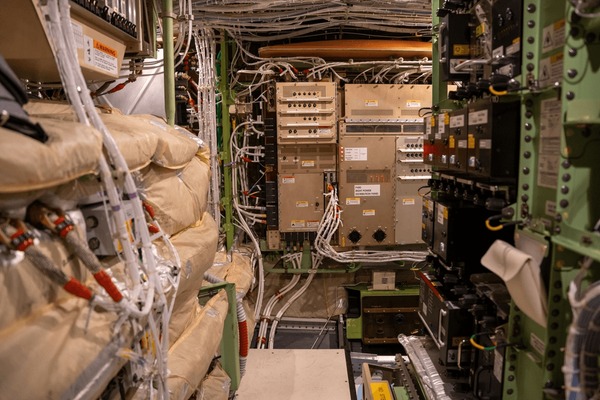

Illustrative image related to airplane cables

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of potential suppliers.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one effective method for verifying quality assurance practices. Buyers should request access to the supplier’s quality management documentation, including certifications, test reports, and process descriptions.

Additionally, on-site visits can provide valuable insights into the manufacturing environment, equipment, and practices employed by the supplier. This hands-on approach allows buyers to assess the supplier’s commitment to quality and compliance with international standards.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can add another layer of assurance for B2B buyers. These independent entities can conduct detailed inspections and testing, verifying that the products meet specified standards before they are shipped.

Buyers should inquire about the qualifications of the third-party inspectors and request reports that detail their findings. This transparency can significantly reduce the risk of product failure and enhance trust in the supply chain.

What Nuances Should International Buyers Consider Regarding QC and Certifications?

For international buyers, understanding the nuances of quality control and certification requirements is essential. Different regions may have varying standards, and compliance with local regulations can be complex.

Buyers should familiarize themselves with specific certifications that may be required in their markets. For example, cables used in the aviation sector may need to comply with stringent safety and performance standards that differ from those applicable to general industrial use.

Conclusion

Understanding the manufacturing processes and quality assurance measures for airplane cables is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on material selection, manufacturing techniques, and rigorous quality control practices, buyers can ensure they are sourcing high-quality, reliable products that meet their specific needs.

Illustrative image related to airplane cables

Practical Sourcing Guide: A Step-by-Step Checklist for ‘airplane cables’

Introduction

This practical sourcing guide is designed to assist B2B buyers in effectively procuring airplane cables. Whether you’re operating in Africa, South America, the Middle East, or Europe, understanding the nuances of sourcing these essential components will help ensure you make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of a successful procurement process. Consider factors such as the type of aircraft cable (galvanized or stainless steel), diameter, length, and breaking strength required for your application. This will help you narrow down your options and ensure you select a product that meets your performance criteria.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of airplane cables. Look for manufacturers and distributors with a proven track record in the industry. Utilize online platforms, industry directories, and trade shows to gather a comprehensive list of suppliers. Pay attention to their product range and specializations to ensure they can meet your specific needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet your shortlisted suppliers thoroughly. Request company profiles, product specifications, and references from other buyers in your region. Look for reviews and testimonials that speak to their reliability, quality, and customer service, as these factors are vital for long-term partnerships.

Illustrative image related to airplane cables

Step 4: Verify Compliance with Standards

Ensure that the airplane cables you are considering comply with relevant industry standards and regulations. Check for certifications such as ASTM A1023 and federal specification RR-W-410, which indicate quality and safety. Compliance not only assures product reliability but also mitigates potential legal and operational risks.

Step 5: Request Samples for Testing

Before finalizing your purchase, request samples of the airplane cables to conduct your own quality testing. This step allows you to assess the materials, construction, and performance characteristics firsthand. Evaluate aspects like corrosion resistance and tensile strength to ensure they align with your operational requirements.

Step 6: Assess Pricing and Payment Terms

Engage in discussions with suppliers regarding pricing structures and payment terms. Compare quotes from multiple suppliers to identify the best value for your investment. Ensure that you understand any additional costs, such as shipping and handling, and consider the payment terms that align with your cash flow strategy.

Illustrative image related to airplane cables

Step 7: Establish a Clear Communication Plan

Effective communication is essential throughout the sourcing process. Establish a clear line of communication with your chosen supplier to discuss timelines, order specifications, and delivery expectations. This proactive approach will help prevent misunderstandings and ensure a smooth procurement experience.

By following these steps, B2B buyers can navigate the complexities of sourcing airplane cables, ensuring they make informed choices that enhance their operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for airplane cables Sourcing

What Are the Key Cost Components in Airplane Cable Manufacturing?

When sourcing airplane cables, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to airplane cables

Materials represent a significant portion of the cost, with variations depending on the type of cable—galvanized or stainless steel. Stainless steel cables, especially those made from Type 316, are typically more expensive due to their superior corrosion resistance and durability. Labor costs can vary significantly based on geographic location and labor availability, with regions that offer skilled labor often commanding higher wages. Manufacturing overhead encompasses indirect costs such as utilities, rent, and administrative expenses, which can fluctuate based on the production scale and efficiency of the facility.

Tooling costs, which include the machinery and equipment necessary for production, can also impact pricing, especially for customized orders. Investing in advanced manufacturing technologies may lead to higher initial costs but can offer efficiencies that lower overall expenses in the long run. Quality Control processes are essential in maintaining standards, particularly in industries like aviation where safety is paramount. This can add to the cost but is necessary for compliance with industry regulations.

What Influences Pricing for Airplane Cables?

Several factors influence the pricing of airplane cables. Volume and Minimum Order Quantity (MOQ) are significant; larger orders often lead to economies of scale, reducing per-unit costs. Customization requests, such as specific lengths or coatings, can also affect pricing. The choice of materials plays a critical role—while galvanized cables are typically more affordable, the selection of high-grade stainless steel can drive costs up.

Quality certifications such as ISO or FAA approvals can further influence pricing, as suppliers may incur additional costs to meet these standards. Supplier reputation and reliability are also essential; established suppliers with a history of quality and timely deliveries may charge a premium. Lastly, Incoterms determine the responsibilities of buyers and sellers regarding shipping and logistics, which can impact the overall cost structure.

What Negotiation Strategies Can International Buyers Employ?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving favorable pricing. Understanding the Total Cost of Ownership (TCO) is vital; consider not just the purchase price but also shipping costs, import duties, and potential tariffs. This holistic view can inform negotiations and help identify the best overall value.

Buyers should also leverage their purchasing volume to negotiate better pricing or discounts. Establishing long-term relationships with suppliers may lead to more favorable terms and conditions. Additionally, being aware of the pricing nuances in different markets can give buyers an edge; for instance, suppliers in emerging markets might be more flexible in negotiations compared to those in developed regions.

How Can Buyers Optimize Cost Efficiency When Sourcing Airplane Cables?

To optimize cost efficiency, buyers should consider bulk purchasing or consolidating orders to meet MOQs that allow for better pricing. Exploring alternative materials or specifications that still meet performance requirements can also yield cost savings.

Conducting thorough market research to compare supplier offerings and prices can reveal opportunities for negotiation. It is also advisable to request quotes from multiple suppliers to understand the competitive landscape and gain leverage in negotiations.

Illustrative image related to airplane cables

Finally, considering the logistics aspect early in the sourcing process can help mitigate unexpected costs. Understanding shipping routes, potential delays, and customs clearance can provide a clearer picture of the overall cost and timeline, ensuring a smoother procurement process.

Disclaimer: The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for current pricing and terms.

Alternatives Analysis: Comparing airplane cables With Other Solutions

Exploring Alternatives to Airplane Cables in Industrial Applications

In the quest for effective solutions in various industrial applications, airplane cables, known for their versatility and strength, often stand at the forefront. However, it’s crucial for B2B buyers to consider alternative options that may better suit specific operational needs, environmental conditions, or budget constraints. This analysis will compare airplane cables with other viable solutions such as synthetic rope and chain assemblies, providing a comprehensive overview to aid decision-making.

Comparison Table

| Comparison Aspect | Airplane Cables | Synthetic Rope | Chain Assemblies |

|---|---|---|---|

| Performance | High tensile strength; limited diameter | Lightweight; good tensile strength, but lower than steel | Extremely strong; heavy; can handle heavy loads |

| Cost | Moderate to high depending on material | Generally lower than steel cables | Higher initial cost, but durable over time |

| Ease of Implementation | Requires specific fittings and expertise | Easy to handle and cut; minimal tooling needed | Installation can be complex; requires proper fittings |

| Maintenance | Low maintenance; corrosion resistance varies | Minimal maintenance; susceptible to UV degradation | Requires regular inspection for wear and tear |

| Best Use Case | General rigging, marine applications | Lightweight applications, temporary setups | Heavy lifting, permanent installations |

Detailed Breakdown of Alternatives

Synthetic Rope

Synthetic ropes, often made from materials like nylon or polyester, offer several advantages. They are lightweight, making them easier to handle and transport compared to traditional steel cables. Their flexibility allows for easier knotting and rigging, and they are less susceptible to rust and corrosion, which is beneficial in marine environments. However, synthetic ropes generally have a lower tensile strength compared to airplane cables and can degrade under UV exposure, necessitating more frequent replacements in outdoor applications.

Chain Assemblies

Chain assemblies are another alternative that excels in heavy-duty applications. Chains provide exceptional strength and durability, making them ideal for lifting and securing heavy loads. They are less likely to snap under extreme stress compared to cables, providing a sense of safety in critical operations. However, chains are considerably heavier and can be cumbersome to work with. Installation often requires specialized fittings and tools, which can complicate the implementation process. Additionally, while chains require low maintenance, they do need regular inspections to ensure there are no signs of wear or failure.

Illustrative image related to airplane cables

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for your industrial application, consider the specific requirements of your project, including load capacity, environmental factors, and budget. Airplane cables are robust and versatile, suitable for a range of applications, while synthetic ropes may offer advantages in weight and ease of handling for lighter tasks. On the other hand, chain assemblies provide unparalleled strength for heavy lifting but come with added weight and installation complexity. By assessing these factors, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for airplane cables

When navigating the complexities of sourcing airplane cables, understanding their technical properties and relevant trade terminology is essential. This knowledge not only aids in making informed purchasing decisions but also enhances communication with suppliers and manufacturers.

What Are the Key Technical Properties of Airplane Cables?

1. Material Grade

Airplane cables are typically made from high-strength steel, available in various grades such as stainless steel (Type 304 or 316) and galvanized steel. Type 316 stainless steel offers superior corrosion resistance, making it ideal for marine or high-moisture environments. Understanding material grades helps buyers select cables that meet specific environmental and operational demands, ensuring longevity and reliability.

2. Construction Type

The most common construction types for airplane cables are 7×19 and 7×7 configurations. The “7×19” construction consists of seven strands, each containing 19 wires, providing enhanced flexibility and strength. This specification is crucial for applications requiring dynamic movement, as it affects both performance and safety.

Illustrative image related to airplane cables

3. Break Strength

Break strength, measured in pounds, indicates the maximum load a cable can withstand before failing. For example, a 3/8″ 7×19 galvanized aircraft cable can have a break strength of 14,400 lbs. Knowing the break strength is vital for ensuring that the chosen cable can safely handle the intended load, thus preventing potential accidents and liability issues.

4. Diameter

The diameter of airplane cables typically ranges from 3/32″ to 3/8″. This specification not only affects the cable’s strength but also its suitability for specific applications, such as rigging or suspension. Buyers must consider the diameter to ensure compatibility with existing systems and components.

5. Coating Options

Cables may come with a vinyl coating, which adds an extra layer of protection against dirt, moisture, and abrasion. This coating can prolong the cable’s lifespan and enhance its performance in challenging environments. Understanding coating options can help buyers choose cables that meet their operational needs while also reducing maintenance costs.

6. Length Variability

Airplane cables are available in various lengths, from 1 foot to several thousand feet. This flexibility allows buyers to procure the exact amount needed for their projects, minimizing waste and optimizing inventory management. Knowing the length options can aid in planning and budgeting for large-scale projects.

What Are Common Trade Terms Used in the Airplane Cable Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of airplane cables, understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQs is crucial for buyers, especially when budgeting and planning inventory levels. It can also influence decisions on sourcing from multiple suppliers to meet project requirements without overcommitting.

Illustrative image related to airplane cables

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific products or services. Issuing an RFQ for airplane cables allows buyers to compare costs, specifications, and delivery timelines, ensuring they secure the best deal.

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help buyers navigate shipping and delivery logistics, ensuring clarity on costs and risks associated with transporting airplane cables.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning, particularly in industries where timelines are tight and delays can impact operations.

By equipping themselves with knowledge of these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right airplane cables for their specific needs while also optimizing communication with suppliers.

Navigating Market Dynamics and Sourcing Trends in the airplane cables Sector

What are the Current Market Dynamics and Key Trends in the Airplane Cables Sector?

The airplane cables sector is experiencing significant growth, driven by increasing demand for air travel and advancements in aerospace technology. Key market drivers include the expansion of the global aviation market, rising investments in aircraft manufacturing, and a growing emphasis on safety and efficiency. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate these dynamics carefully.

Illustrative image related to airplane cables

Emerging technologies such as lightweight materials and advanced manufacturing processes are reshaping sourcing trends. For instance, companies are increasingly integrating composite materials into airplane cable production to enhance performance while reducing weight. Additionally, the adoption of automation and digital tools in supply chain management is streamlining procurement processes and improving inventory management.

B2B buyers should also be aware of the fluctuating prices of raw materials, which can impact overall costs. The shift towards just-in-time inventory systems is becoming prevalent, allowing companies to minimize storage costs and respond quickly to market demands. However, this approach requires robust supplier relationships and reliable logistics to ensure timely deliveries.

How is Sustainability Influencing Sourcing Decisions in the Airplane Cables Sector?

Sustainability is becoming a critical factor in the sourcing of airplane cables. As environmental concerns grow, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmentally-friendly practices. The production of airplane cables can have significant environmental impacts, particularly related to material sourcing and waste generation.

Buyers should seek suppliers who adhere to sustainability certifications, such as ISO 14001, which outlines effective environmental management systems. Additionally, the use of recyclable materials and eco-friendly manufacturing processes is gaining traction, enabling companies to reduce their carbon footprints. For instance, opting for cables made from recycled metals or those that meet stringent environmental regulations can enhance a company’s sustainability profile.

Moreover, ethical supply chains are vital for building brand reputation and ensuring compliance with international standards. Transparent sourcing practices not only mitigate risks associated with unethical labor practices but also attract environmentally-conscious customers. As such, fostering relationships with suppliers who align with these values is essential for long-term success in the airplane cables market.

What is the Historical Context of Airplane Cables in the B2B Sector?

The airplane cables industry has evolved significantly since its inception. Initially, cables were primarily made from traditional materials like iron and steel, which limited their weight and flexibility. However, as aviation technology advanced, the demand for more durable and lightweight materials led to the adoption of high-strength steel and composite materials in cable manufacturing.

Over the decades, innovations such as improved cable construction techniques and corrosion-resistant coatings have enhanced the performance and longevity of airplane cables. Today, manufacturers are not only focused on meeting safety standards but also on incorporating sustainable practices into their production processes. This evolution reflects a broader trend within the aerospace sector, where efficiency, safety, and environmental responsibility are paramount. B2B buyers today benefit from a diverse range of products that cater to the increasing demands of modern aviation, ensuring they can source high-quality airplane cables that meet both operational and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of airplane cables

-

How do I choose the right type of airplane cable for my application?

Selecting the right airplane cable depends on several factors, including the specific application, environmental conditions, and required strength. For general-purpose use, galvanized cables offer cost-effectiveness and decent corrosion resistance. However, if your application involves exposure to moisture or harsh conditions, stainless steel cables, particularly Type 316, provide superior corrosion resistance. Consider the break strength needed for your application and whether additional features, such as vinyl coating for added protection, are beneficial. -

What are the key differences between galvanized and stainless steel airplane cables?

Galvanized airplane cables are coated with zinc, providing a cost-effective solution with good corrosion resistance for many applications. They are generally stronger than stainless steel cables but may not withstand extreme conditions as effectively. Stainless steel cables, especially Type 316, offer excellent rust resistance and are ideal for marine or high-moisture environments. The choice between these materials should be based on the specific environmental conditions and mechanical requirements of your application. -

What minimum order quantities (MOQ) should I expect when sourcing airplane cables?

Minimum order quantities for airplane cables can vary significantly between suppliers. Some manufacturers may have an MOQ as low as 100 meters, while others might require orders of 1,000 meters or more. When sourcing internationally, it’s essential to discuss MOQs upfront to ensure they align with your purchasing needs. Additionally, consider the supplier’s ability to accommodate smaller orders or custom lengths, which may be beneficial for your specific application. -

How can I vet potential suppliers for airplane cables?

Vetting suppliers involves assessing their reputation, certifications, and quality control processes. Look for suppliers with industry certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to evaluate product quality and inquire about their production capabilities and lead times. Additionally, consider their experience in international trade, particularly in your target regions, as this can impact logistics and compliance with local regulations. -

What payment terms are commonly offered by airplane cable suppliers?

Payment terms can vary widely, but many suppliers offer options such as upfront payment, net 30, or even letters of credit for larger orders. For international transactions, it’s crucial to negotiate terms that minimize financial risk while ensuring timely delivery. Consider using secure payment methods that offer buyer protection. Always clarify terms related to currency exchange rates and any additional fees that may apply, especially when dealing with suppliers in different countries. -

What quality assurance measures should I look for in airplane cables?

Quality assurance measures can include compliance with industry standards such as ASTM A1023 and federal specifications. Ensure that the supplier conducts regular testing for strength, durability, and corrosion resistance. Request documentation of quality tests, such as break strength tests and material certifications. A reliable supplier will also have a robust return policy and customer support to address any quality concerns post-purchase. -

How do logistics and shipping impact the sourcing of airplane cables?

Logistics play a crucial role in the timely delivery of airplane cables, especially when sourcing from international suppliers. Consider the shipping methods offered (air freight vs. sea freight), lead times, and costs associated with each option. It’s essential to understand customs regulations in your country and the supplier’s location, as these can affect delivery times and additional fees. Collaborating with a logistics partner experienced in international trade can help streamline the process. -

Can I customize airplane cables to meet specific requirements?

Many suppliers offer customization options for airplane cables, including variations in length, diameter, material, and additional features such as coatings. When seeking customization, provide clear specifications and discuss your application needs with the supplier. Custom orders may have longer lead times and potentially higher costs, so it’s important to balance these factors with the benefits of tailored solutions for your specific applications.

Top 3 Airplane Cables Manufacturers & Suppliers List

1. Rigging Warehouse – Key Products

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Key product details include: 1. Types of products: Aircraft Cable, General Purpose Wire Rope, Rotation-Resistant Wire Rope, Strand, Swaged & Compacted Wire Rope, Cable Laid Wire Rope, Wire Rope Winch Lines, Wire Rope Lubricants. 2. Sizes and constructions: Aircraft Cable is typically 3/8 inch and smaller in 7×7 and 7×19 constructions; Wire Rope is larger than 3/8 inch with common constructions lik…

2. Murphy Lift – Stainless Steel Aircraft Cables

Domain: murphylift.com

Registered: 2021 (4 years)

Introduction: Stainless Steel Aircraft Cables, Wires, Cords. Free FedEx/UPS ground shipping to the 48 contiguous U.S. on all online orders of $50 or more. Various types of cables available including galvanized, vinyl coated, and stainless steel options. Includes accessories such as cable sleeves, wire rope clips, thimbles, and installation tools. Product categories include industrial cable, wire rope, and vario…

3. Loosco – Aircraft Cable Solutions

Domain: loosco.com

Registered: 1997 (28 years)

Introduction: Aircraft Cable products are manufactured and stocked to commercial and military specifications in stainless steel, galvanized carbon steel, and various other alloys. The cable supports flight control, landing gear, emergency systems, and other critical applications. Available constructions include 1×19, 1×7, 3×19, 6×19, 6×25, 6×36, 6×37, 6×42, 7×19, 7×7, 7x7x19, 7x7x7, 3×7, and 19×7. Materials inc…

Strategic Sourcing Conclusion and Outlook for airplane cables

What Are the Key Insights for Strategic Sourcing of Airplane Cables?

In the dynamic landscape of aviation, strategic sourcing for airplane cables is essential for optimizing performance and ensuring safety. Understanding the differences between galvanized and stainless steel cables is crucial, as each material offers distinct advantages depending on environmental conditions. For instance, stainless steel cables excel in high-moisture environments, while galvanized options provide cost-effective solutions for general applications.

B2B buyers should prioritize suppliers that offer a wide range of customizable cable assemblies, catering to specific needs and compliance with industry standards. The ability to source cables with various break strengths and coatings can significantly enhance operational efficiency and safety.

How Can International Buyers Stay Ahead in Sourcing Airplane Cables?

As the aviation industry continues to evolve, international buyers, especially from Africa, South America, the Middle East, and Europe, must remain proactive in their sourcing strategies. Engaging with reliable suppliers who can provide timely delivery and competitive pricing will be vital in maintaining a competitive edge.

In conclusion, a well-informed approach to sourcing airplane cables will not only ensure compliance and safety but also foster long-term partnerships that drive innovation. Take the next step in your sourcing journey by connecting with leading manufacturers and suppliers to secure the best solutions for your aviation needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.