Top 3 2 Prong Plug Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 2 prong plug

In today’s interconnected world, sourcing high-quality 2 prong plugs can pose significant challenges for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany. The varying regulations, standards, and supplier capabilities can complicate purchasing decisions, making it essential to navigate this complex landscape with care. This guide offers a comprehensive overview of the 2 prong plug market, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By providing detailed insights into the specifications and functionality of different 2 prong plugs, this resource empowers buyers to make informed purchasing decisions that align with their specific needs and regional requirements. From understanding the distinctions between polarized and non-polarized plugs to evaluating the durability and safety certifications of products, this guide serves as a valuable tool for businesses seeking reliable electrical components.

Moreover, it emphasizes the importance of selecting trustworthy suppliers, ensuring that your organization can maintain quality and compliance in its operations. With this knowledge, B2B buyers will be better equipped to secure optimal solutions that enhance their projects and foster successful partnerships in the global market.

Understanding 2 prong plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polarized 2 Prong Plug | Features one blade wider than the other, ensuring correct orientation | Lighting fixtures, lamps, small appliances | Pros: Increased safety, prevents incorrect connections. Cons: Limited compatibility with non-polarized outlets. |

| Non-Polarized 2 Prong Plug | Both blades are the same width, allowing insertion in either direction | General household electronics, small tools | Pros: Versatile, compatible with most outlets. Cons: Less safe, higher risk of incorrect wiring. |

| Vintage Style 2 Prong Plug | Aesthetic design mimicking antique styles, often polarized | Restoration projects, vintage lighting | Pros: Enhances aesthetic appeal, suitable for retro designs. Cons: May not meet modern safety standards. |

| Heavy-Duty 2 Prong Plug | Designed for higher gauge wires and loads, often rated for 15A | Industrial equipment, heavy machinery | Pros: Durable, suitable for demanding applications. Cons: Bulkier, may not fit in standard outlets. |

| 2 Prong Female Outlet Connector | Accepts a 2-prong male plug, designed for easy cord connection | Extension cords, custom electrical setups | Pros: Flexible use, ideal for custom applications. Cons: Requires a compatible male plug, limited to 2-prong systems. |

What Are the Characteristics of a Polarized 2 Prong Plug?

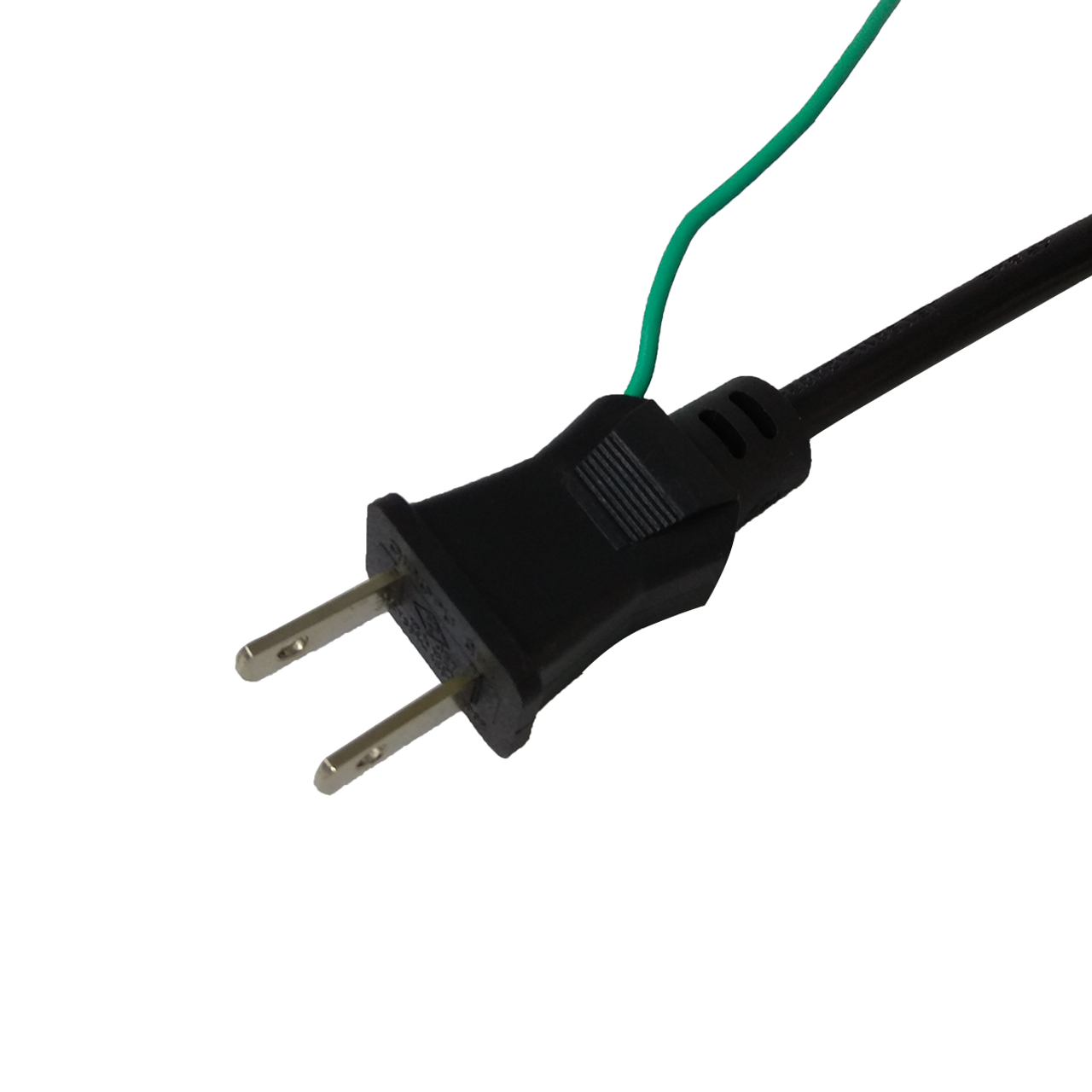

Polarized 2 prong plugs are characterized by their asymmetrical design, with one blade wider than the other. This feature ensures that the plug can only be inserted into an outlet in one orientation, enhancing safety by preventing reverse polarity connections. These plugs are commonly used in lighting fixtures, lamps, and small appliances where safety is a priority. When purchasing, buyers should consider the voltage and amperage ratings to ensure compatibility with their devices.

How Does a Non-Polarized 2 Prong Plug Differ?

Non-polarized 2 prong plugs have blades of equal width, allowing them to be inserted into outlets in any direction. This versatility makes them suitable for general household electronics and small tools. However, they pose a higher risk of incorrect wiring, which can lead to safety hazards. B2B buyers should weigh the pros and cons, especially in applications where safety is paramount, and consider whether polarized options may be more suitable.

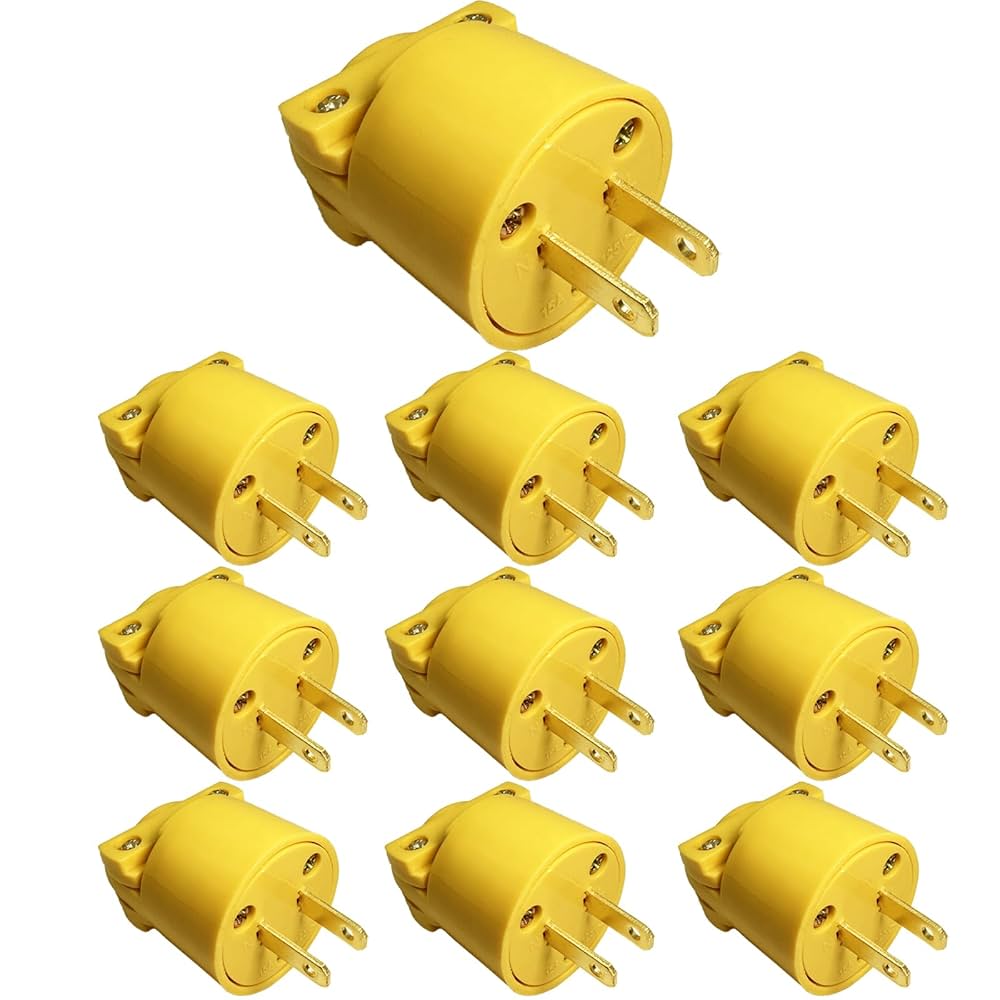

Illustrative image related to 2 prong plug

What Makes Vintage Style 2 Prong Plugs Unique?

Vintage style 2 prong plugs offer an aesthetic appeal that mimics antique designs, often incorporating polarized features for safety. These plugs are ideal for restoration projects, particularly in vintage lighting and decor applications. While they enhance the visual appeal of retro designs, buyers should be cautious about their compliance with modern safety standards, as not all vintage-style plugs are built to current electrical codes.

Why Choose a Heavy-Duty 2 Prong Plug?

Heavy-duty 2 prong plugs are specifically designed for higher gauge wires and loads, typically rated for 15 amps. They are commonly used in industrial equipment and heavy machinery applications where durability and reliability are crucial. While these plugs are robust, they can be bulkier and may not fit standard outlets. B2B buyers need to assess the specific requirements of their equipment to ensure they select a compatible plug.

What Are the Benefits of Using a 2 Prong Female Outlet Connector?

A 2 prong female outlet connector is designed to accept a 2-prong male plug, making it ideal for creating custom electrical setups or extension cords. This flexibility allows businesses to tailor their electrical solutions to specific needs. However, it is essential for buyers to ensure they have a compatible male plug and to be aware that these connectors are limited to 2-prong systems, which may not support all devices.

Key Industrial Applications of 2 prong plug

| Industry/Sector | Specific Application of 2 prong plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Lighting & Fixtures | Wiring for lamps and pendant lights | Ensures reliable power supply for lighting solutions | Quality certification (UL listed), material durability, and aesthetic design compatibility |

| Consumer Electronics | Power cords for small appliances | Provides safe and efficient power connections | Compliance with local electrical standards, voltage rating, and ease of assembly |

| Automotive Aftermarket | Electrical connections for vintage car restorations | Enables integration of modern electrical components | Historical accuracy in design, safety certifications, and compatibility with existing systems |

| Home Renovation | Installation in DIY projects for home improvement | Facilitates safe and stylish electrical installations | Availability of various styles, ease of installation, and cost-effectiveness |

| Antique Restoration | Replacement for old electrical components in antiques | Preserves the integrity and functionality of vintage items | Authenticity in design, quality of materials, and compatibility with antique wiring standards |

How Are 2 Prong Plugs Used in the Lighting & Fixtures Industry?

In the lighting and fixtures sector, 2 prong plugs are crucial for wiring lamps and pendant lights. These plugs provide a safe and efficient power connection, essential for both residential and commercial lighting solutions. Businesses benefit from using high-quality, UL-listed plugs that ensure durability and reliability. When sourcing, it’s vital to consider the aesthetic compatibility of the plugs with various lighting designs, as well as their ability to handle the required voltage and current ratings.

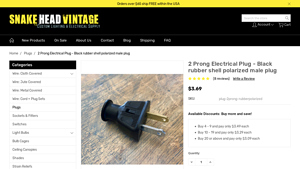

Illustrative image related to 2 prong plug

What Role Do 2 Prong Plugs Play in Consumer Electronics?

In the consumer electronics industry, 2 prong plugs are commonly used for small appliances like radios, fans, and kitchen gadgets. They provide a secure and efficient electrical connection, crucial for the safe operation of these devices. International buyers must ensure that the plugs comply with local electrical standards and are rated for the appropriate voltage. Additionally, ease of assembly and robust construction are essential factors that can impact the longevity and performance of the appliances.

How Are 2 Prong Plugs Utilized in the Automotive Aftermarket?

The automotive aftermarket sector often employs 2 prong plugs for electrical connections in vintage car restorations. These plugs allow for the integration of modern electrical components while maintaining the vehicle’s historical integrity. Businesses in this sector must focus on sourcing plugs that are both aesthetically accurate and compliant with safety standards. Compatibility with existing electrical systems is also a critical consideration for ensuring seamless integration into restored vehicles.

How Do 2 Prong Plugs Facilitate Home Renovation Projects?

In home renovation projects, 2 prong plugs are frequently used in DIY applications, providing a reliable connection for various electrical installations. They enable homeowners and contractors to implement safe and stylish electrical solutions that enhance living spaces. When sourcing these plugs, it’s important to consider their availability in different styles and materials to match the home’s design. Cost-effectiveness and ease of installation are also significant factors for businesses targeting the home improvement market.

Illustrative image related to 2 prong plug

Why Are 2 Prong Plugs Important in Antique Restoration?

For antique restoration, 2 prong plugs are essential for replacing outdated electrical components while preserving the functionality of vintage items. These plugs ensure that restored antiques can be safely used without compromising their historical value. Businesses should prioritize sourcing plugs that reflect authentic designs and high-quality materials to maintain the integrity of the antiques. Additionally, compatibility with antique wiring standards is crucial for successful restoration projects.

3 Common User Pain Points for ‘2 prong plug’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality 2 Prong Plugs

The Problem: B2B buyers often struggle to find reliable suppliers that provide high-quality 2 prong plugs. This issue is particularly pronounced in regions such as Africa and South America, where access to reputable electrical components can be limited. Poor quality plugs can lead to safety hazards, equipment malfunctions, and ultimately, dissatisfied customers. The challenge is further compounded by the varying standards and certifications across different countries, making it difficult to ensure compliance and safety.

The Solution: To effectively source quality 2 prong plugs, B2B buyers should prioritize suppliers with established reputations and strong customer feedback. Conduct thorough research, looking for manufacturers that are UL-listed or meet similar international safety standards. Consider attending industry trade shows or utilizing B2B platforms that specialize in electrical components to connect with reputable suppliers. Additionally, establishing relationships with local distributors who understand the market’s needs can help ensure consistent quality and availability of products. Buyers should also request samples before placing bulk orders to assess the quality firsthand, and consider forming partnerships with suppliers that offer robust warranties or guarantees to mitigate risks.

Illustrative image related to 2 prong plug

Scenario 2: Installation Challenges with 2 Prong Plugs

The Problem: Many B2B buyers face installation challenges when dealing with 2 prong plugs, particularly when retrofitting them into existing systems. This is common in sectors such as lighting or appliance manufacturing, where integrating new components into established designs can lead to compatibility issues. Improper installation not only risks equipment failure but can also pose safety hazards, leading to potential liability concerns.

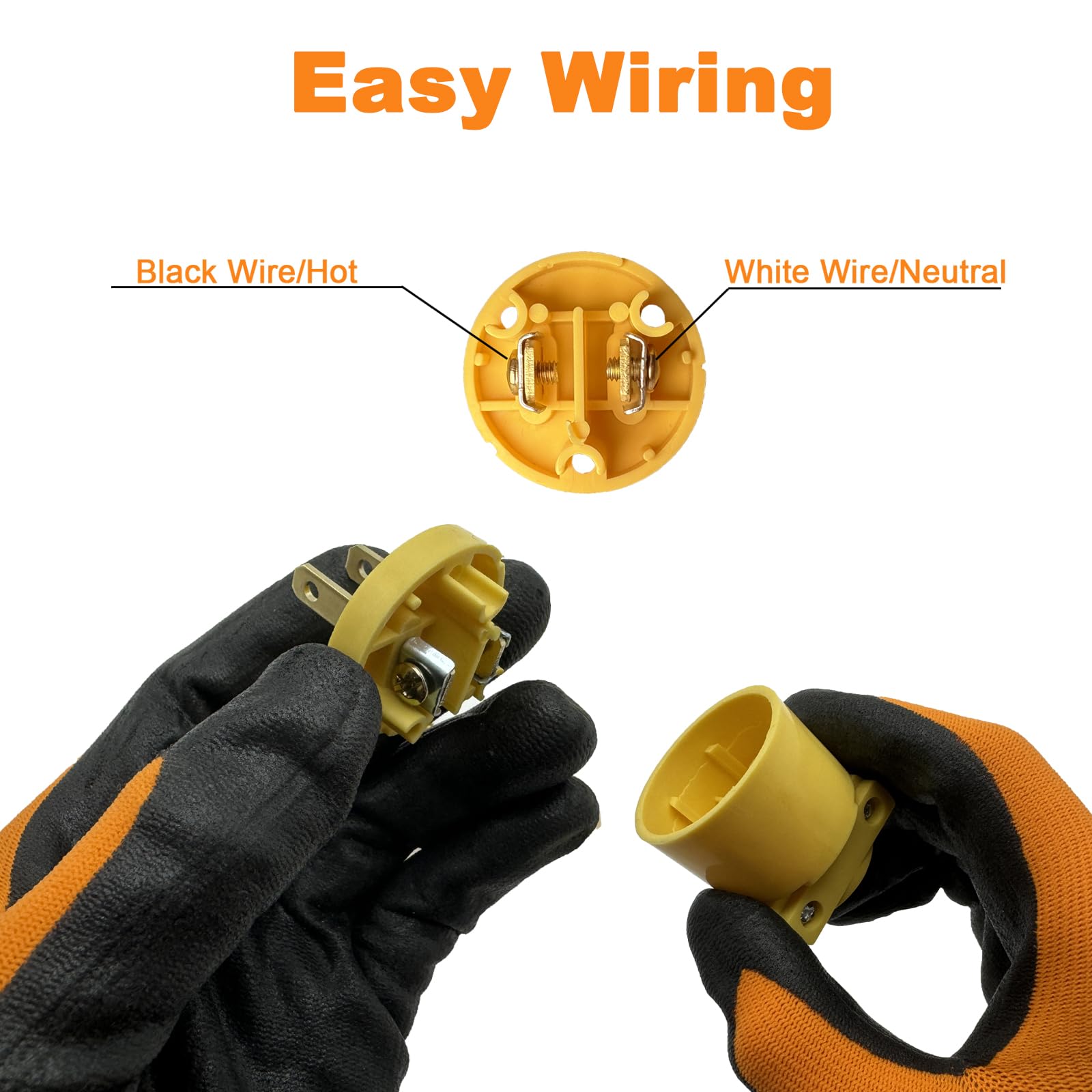

The Solution: To overcome installation challenges, B2B buyers should invest in comprehensive training for their technical teams. This training should cover the specific wiring and installation processes for 2 prong plugs, including the importance of correct polarity and secure connections. Providing detailed installation manuals or video tutorials can enhance understanding and ensure proper procedures are followed. Additionally, buyers should consider sourcing plugs designed for easy disassembly and assembly, which can streamline the installation process. Engaging with manufacturers who offer technical support can also be beneficial, allowing teams to troubleshoot issues in real time. This proactive approach will not only reduce installation errors but also enhance overall operational efficiency.

Scenario 3: Regulatory Compliance and Safety Concerns

The Problem: Navigating the regulatory landscape for electrical components, including 2 prong plugs, can be a daunting task for B2B buyers, especially in regions with strict safety standards. Failure to comply with local regulations can result in fines, product recalls, and damage to a company’s reputation. Buyers may find it challenging to understand the specific requirements for electrical components in different markets, leading to uncertainty and risk.

The Solution: To ensure compliance with regulatory standards, B2B buyers should familiarize themselves with the specific electrical codes and regulations applicable in their target markets. This may involve consulting with local electrical authorities or industry associations that provide guidelines for product compliance. Collaborating with suppliers who are well-versed in these regulations can also provide valuable insights. Buyers should prioritize products that come with proper certifications, such as CE marking in Europe or similar certifications in other regions. Regular audits of suppliers and products can help maintain compliance, while keeping abreast of changes in regulations ensures that buyers remain informed. Establishing a compliance checklist can serve as a practical tool to streamline the verification process and safeguard against potential legal issues.

Strategic Material Selection Guide for 2 prong plug

What Are the Key Materials Used in 2 Prong Plugs?

When selecting materials for 2 prong plugs, several factors come into play, including electrical performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of 2 prong plugs, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Plastic Impact the Performance of 2 Prong Plugs?

Key Properties: Plastic is lightweight and offers good electrical insulation properties. Common types include thermoplastics like polyvinyl chloride (PVC) and nylon, which can withstand temperatures up to 85°C (185°F) and have decent resistance to moisture and chemicals.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing. However, it may not be as durable as other materials, particularly under high temperatures or mechanical stress. Additionally, some plastics may degrade over time when exposed to UV light.

Impact on Application: Plastic plugs are suitable for general household appliances but may not be ideal for heavy-duty industrial applications where higher durability is required.

Considerations for International Buyers: Compliance with international standards such as IEC 60884-1 is essential. Buyers should ensure that the plastic used is flame-retardant and meets local regulations in their respective regions.

What Role Does Metal Play in the Durability of 2 Prong Plugs?

Key Properties: Metals, particularly brass and copper, are commonly used for the prongs due to their excellent electrical conductivity. Brass can handle temperatures up to 200°C (392°F) and offers good corrosion resistance.

Pros & Cons: Metal prongs provide superior durability and conductivity, essential for high-performance applications. However, they are more expensive than plastic and can be prone to corrosion if not properly coated.

Illustrative image related to 2 prong plug

Impact on Application: Metal components are crucial for plugs used in industrial settings where high current loads are common. Their robustness ensures reliable connections even in demanding environments.

Considerations for International Buyers: Buyers should verify that the metals used comply with standards such as ASTM B16 for brass or EN 12164 for copper. Corrosion resistance is particularly important in humid climates like those found in parts of Africa and South America.

How Do Rubber and Elastomers Enhance Safety in 2 Prong Plugs?

Key Properties: Rubber and elastomers provide excellent insulation and flexibility. They can withstand temperatures between -40°C (-40°F) and 90°C (194°F) and are resistant to moisture and abrasion.

Pros & Cons: The main advantage of rubber is its safety features, including shock resistance. However, it may not be as durable as plastics or metals when exposed to extreme conditions, and its manufacturing process can be more complex and costly.

Impact on Application: Rubber is ideal for plugs used in outdoor or industrial settings where exposure to moisture is a concern. Its flexibility also allows for easier handling during installation.

Illustrative image related to 2 prong plug

Considerations for International Buyers: Compliance with safety standards such as UL 498 is critical. Buyers in regions with high humidity should prioritize rubber components to ensure longevity and safety.

What Are the Benefits of Bakelite in Vintage 2 Prong Plugs?

Key Properties: Bakelite is a thermosetting plastic known for its high electrical insulation properties and heat resistance, withstanding temperatures up to 150°C (302°F).

Pros & Cons: Bakelite offers a vintage aesthetic, making it popular for decorative applications. However, it is more expensive and can be brittle, making it less suitable for high-stress environments.

Impact on Application: Ideal for antique or decorative lighting fixtures, Bakelite plugs provide both functionality and aesthetic appeal.

Considerations for International Buyers: Buyers should ensure that Bakelite plugs meet relevant safety standards and are suitable for the voltage and current ratings in their regions.

Illustrative image related to 2 prong plug

Summary Table of Material Selection for 2 Prong Plugs

| Material | Typical Use Case for 2 Prong Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General household appliances | Low cost and lightweight | Less durable under high stress | Low |

| Metal (Brass/Copper) | Industrial applications | Superior durability and conductivity | Higher cost and potential for corrosion | Med |

| Rubber/Elastomers | Outdoor and industrial settings | Excellent insulation and shock resistance | Less durable in extreme conditions | Med |

| Bakelite | Vintage and decorative applications | High insulation and aesthetic appeal | Brittle and higher cost | High |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific applications and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 prong plug

What Are the Main Stages of Manufacturing 2 Prong Plugs?

Manufacturing 2 prong plugs involves several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality materials, typically including thermoplastic or rubber for the casing and brass for the internal contacts. These materials are tested for electrical insulation properties and durability to ensure they can withstand varying environmental conditions. Suppliers often conduct material tests to certify compliance with international standards, which is crucial for B2B buyers who prioritize quality.

Forming

Once materials are prepared, the next stage is forming. This involves molding the thermoplastic or rubber into the desired shape for the plug casing. Advanced techniques such as injection molding are frequently employed to ensure precision and consistency in the dimensions of the plug. The use of molds that conform to international safety standards is essential, as it impacts both the plug’s functionality and its marketability in different regions.

Assembly

The assembly process involves integrating the internal components, such as the brass contacts and screws, into the molded casing. This stage is crucial for ensuring that the electrical connections are secure and that the plug is polarized correctly, which enhances safety. Automated assembly lines are commonly used to maintain high production rates while minimizing human error. Manual assembly may still be utilized for specialized or vintage-style plugs, where craftsmanship is valued.

Finishing

Finishing processes include quality checks, polishing, and applying protective coatings. The plugs are often tested for electrical conductivity and insulation integrity. This stage may also involve packaging and labeling, ensuring that products are ready for shipping and comply with international regulations. B2B buyers should inquire about the specific finishing techniques used, as they can affect the longevity and safety of the plugs.

How Is Quality Assurance Implemented in the Production of 2 Prong Plugs?

Quality assurance (QA) is critical in the manufacturing of 2 prong plugs, ensuring that products meet both safety standards and customer expectations.

International Standards and Industry-Specific Certifications

Manufacturers often adhere to international standards like ISO 9001, which emphasizes a quality management system that ensures consistent product quality. Additionally, certifications such as CE for European markets and UL for North American markets are essential. These certifications indicate that the plugs meet specific safety and performance criteria, which is particularly important for B2B buyers operating in regions with stringent regulatory requirements.

Illustrative image related to 2 prong plug

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically implemented throughout the manufacturing process. Incoming Quality Control (IQC) involves inspecting raw materials before they enter production. In-Process Quality Control (IPQC) checks are performed during the manufacturing stages to catch any defects early. Finally, Final Quality Control (FQC) occurs after production, ensuring that each plug meets the established standards before it is packaged and shipped.

Common Testing Methods for Electrical Safety

Testing methods for 2 prong plugs include dielectric strength tests, insulation resistance tests, and temperature rise tests. These methods verify that the plugs can handle their rated voltage and current without failure, ensuring safety and reliability. For B2B buyers, understanding these testing methods is crucial for evaluating supplier capabilities and product safety.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must conduct due diligence to ensure their suppliers maintain rigorous quality control standards. Here are several actionable methods to verify QC measures:

Supplier Audits

Conducting on-site audits can provide insight into a manufacturer’s quality control processes. During these audits, buyers can assess the production environment, review quality management documentation, and observe operational practices. This firsthand examination helps build trust and ensures that the supplier adheres to the expected quality standards.

Requesting Quality Reports

Buyers should request detailed quality reports that outline testing results, defect rates, and compliance with international standards. These reports can provide transparency about the supplier’s commitment to quality and help buyers make informed decisions.

Illustrative image related to 2 prong plug

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process. These services can perform random sampling of finished products, conduct tests, and provide detailed reports on compliance with safety standards. Third-party inspections are particularly beneficial for international buyers who may not have the capability to conduct audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control in different regions is vital. Here are several factors to consider:

Regulatory Variations

Different regions have distinct regulatory requirements for electrical products. For example, European buyers must ensure compliance with CE marking, while buyers in the U.S. may prioritize UL certification. Buyers should familiarize themselves with the specific regulations in their target markets to ensure compliance and avoid potential legal issues.

Cultural Considerations

Cultural differences may influence manufacturing practices and quality perceptions. For instance, in some regions, there may be a greater emphasis on craftsmanship, while in others, efficiency may take precedence. Buyers should consider these cultural nuances when assessing suppliers and their quality assurance processes.

Language Barriers

Language differences can complicate communication regarding quality standards and expectations. Buyers should ensure that they can effectively communicate with suppliers or utilize translation services to avoid misunderstandings that could impact product quality.

Illustrative image related to 2 prong plug

By understanding the manufacturing processes, quality assurance measures, and international nuances, B2B buyers can make informed decisions when sourcing 2 prong plugs, ensuring they select suppliers that uphold the highest standards of quality and safety.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 prong plug’

This practical sourcing guide aims to assist international B2B buyers in procuring high-quality 2-prong plugs. By following this step-by-step checklist, you can ensure that your purchasing decisions meet both technical requirements and market expectations.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your technical requirements. Consider factors such as voltage ratings, amperage, and materials.

– Voltage and Amperage: Ensure the plugs you are considering can handle the necessary voltage (typically 125V) and amperage (often 15A).

– Material Quality: Look for plugs made from durable materials like rubber or high-grade plastics that can withstand wear and tear.

Step 2: Identify Regulatory Compliance

Verify that the 2-prong plugs comply with the relevant safety and quality standards in your target markets.

– Certification: Check for certifications such as UL (Underwriters Laboratories) or CE (Conformité Européenne) that indicate adherence to safety standards.

– Local Regulations: Be aware of specific regulations in regions like the Middle East or Europe, as these can vary significantly.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure reliability and product quality.

– Company Profile: Request detailed company profiles, including their manufacturing capabilities and experience in the electrical components market.

– References and Reviews: Seek references from other B2B clients in similar sectors to gauge supplier performance and product reliability.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, request samples to assess the quality of the 2-prong plugs firsthand.

– Sample Testing: Evaluate the plugs for durability, ease of installation, and overall build quality.

– Compatibility Checks: Ensure the samples fit well with your existing products or systems to avoid compatibility issues.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers, engage in price negotiations to secure the best deal.

– Bulk Discounts: Discuss potential discounts for larger orders, which can significantly reduce your overall procurement costs.

– Payment Terms: Clarify payment terms and conditions, including options for credit or installment payments.

Step 6: Establish Logistics and Delivery Schedule

Plan the logistics of your order to ensure timely delivery.

– Shipping Options: Discuss shipping methods and costs with your supplier to choose the most efficient route.

– Lead Times: Confirm lead times for production and delivery to align with your project timelines.

Step 7: Implement Quality Control Measures

After receiving your order, implement a quality control process to verify that the plugs meet your specifications.

– Inspection Protocols: Establish inspection protocols to check for defects or inconsistencies in the products.

– Feedback Loop: Maintain communication with your supplier regarding any issues encountered to foster a long-term partnership.

By following this checklist, you can streamline your procurement process for 2-prong plugs, ensuring that you secure quality products that meet your specific business needs.

Illustrative image related to 2 prong plug

Comprehensive Cost and Pricing Analysis for 2 prong plug Sourcing

What Are the Key Cost Components in Sourcing 2 Prong Plugs?

When sourcing 2 prong plugs, understanding the cost structure is essential for effective budgeting and price negotiations. The primary cost components include:

-

Materials: The cost of raw materials such as rubber, metals for terminals, and any insulating components can vary significantly based on quality and sourcing location. For example, high-quality rubber and brass for terminals will increase the overall cost but enhance durability and safety.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and testing the plugs. Regions with lower labor costs might offer competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, maintenance, and utilities. These costs can be distributed over production volume, so higher production runs may lower the per-unit overhead.

-

Tooling: Initial setup costs for molds and manufacturing tools can be substantial, especially for custom designs. These costs are typically amortized over the production run, influencing pricing significantly.

-

Quality Control (QC): Ensuring that plugs meet safety and quality standards incurs additional costs. Certifications such as UL listings are crucial for international compliance, particularly in markets like Europe and North America.

-

Logistics: Transportation and warehousing costs can vary widely based on the sourcing location and delivery terms. These costs can dramatically affect the final price, especially for international shipments.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks, which can vary based on market demand and competition.

How Do Price Influencers Affect Sourcing Decisions for 2 Prong Plugs?

Several factors influence the pricing of 2 prong plugs, which international B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to price breaks, making it beneficial to consolidate purchases. Buyers should assess their needs carefully to optimize order sizes.

-

Specifications and Customization: Custom specifications, such as color or design, can significantly increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., UL, CE) command higher prices but offer long-term reliability and safety, which can be critical in regulated markets.

-

Supplier Factors: The reliability, reputation, and geographic location of suppliers can impact pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is crucial for calculating total costs. Different Incoterms (e.g., FOB, CIF) can affect shipping costs, insurance, and responsibilities, influencing the overall price.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of 2 Prong Plugs?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should employ the following strategies to optimize their sourcing:

-

Negotiate Wisely: Always engage in negotiations with suppliers. Understanding market rates and being prepared to discuss volume discounts can lead to better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. Cheaper plugs may lead to higher TCO if they fail prematurely.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and local taxes that can impact the final price. Establishing relationships with local agents can help navigate these complexities.

-

Request Samples: Before committing to large orders, request samples to assess quality. This step can prevent costly mistakes and ensure that the products meet your specifications.

Disclaimer on Indicative Prices

While the above analysis provides a comprehensive overview of cost components and pricing factors, prices can vary significantly based on market conditions, supplier relationships, and specific buyer needs. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing 2 prong plug With Other Solutions

Exploring Alternatives to the 2 Prong Plug

When evaluating electrical connectivity solutions, the 2 prong plug often serves as a standard option. However, businesses may benefit from considering alternative technologies that may provide enhanced performance, safety, or adaptability to specific operational needs. Below is a comparative analysis of the 2 prong plug against two viable alternatives: the 3 prong plug and the USB power connector.

| Comparison Aspect | 2 Prong Plug | 3 Prong Plug | USB Power Connector |

|---|---|---|---|

| Performance | Suitable for low-power devices | Supports higher power and grounding | Ideal for low to moderate power |

| Cost | Generally low cost | Slightly higher due to additional components | Varies widely based on type |

| Ease of Implementation | Simple to install and use | Requires proper grounding installation | Easy plug-and-play functionality |

| Maintenance | Minimal maintenance required | Low maintenance, but grounding checks needed | Generally no maintenance required |

| Best Use Case | Lamps, small appliances | Heavy-duty appliances, electronics | Mobile devices, computers |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Using a 3 Prong Plug?

The 3 prong plug is designed for higher power applications and provides a grounding connection, which enhances safety by reducing the risk of electrical shock. This makes it ideal for heavy-duty appliances such as refrigerators and industrial equipment. However, the installation process can be more complex, requiring proper grounding, which may not be feasible in all environments. Additionally, the cost is slightly higher than a 2 prong plug, which may be a consideration for budget-conscious buyers.

How Does the USB Power Connector Compare?

The USB power connector has become increasingly prevalent in both consumer and industrial applications. Its primary advantage lies in its versatility and ease of use; devices can be charged or powered with minimal effort. USB connectors are also standardized, which simplifies compatibility across devices. However, they are generally limited to low to moderate power applications, making them unsuitable for heavier equipment. Furthermore, the cost can vary significantly depending on the type and quality of the USB connector, which may impact procurement decisions.

Conclusion: How Should B2B Buyers Choose the Right Solution?

In selecting the appropriate plug or connector, B2B buyers should assess their specific operational requirements, including the power demands of their devices, safety standards, and budget constraints. While the 2 prong plug remains a reliable choice for lower power applications, alternatives like the 3 prong plug and USB connectors provide unique benefits that may better serve particular needs. By carefully analyzing the performance, cost, ease of implementation, maintenance, and best use cases of each option, businesses can make informed decisions that align with their operational goals and enhance overall safety and efficiency.

Essential Technical Properties and Trade Terminology for 2 prong plug

What Are the Key Technical Properties of a 2 Prong Plug?

When sourcing 2 prong plugs for electrical applications, it’s crucial to understand the essential technical properties that ensure safety, reliability, and compatibility. Below are some key specifications that buyers should consider:

-

Material Composition

The most common materials used for 2 prong plugs include thermoplastic and rubber. Thermoplastic provides durability and resistance to heat, while rubber offers flexibility and insulation. Choosing the right material is vital for ensuring longevity and safety in various environments, especially for international buyers who may face differing climate conditions. -

Current Rating (Amperage)

A 2 prong plug typically comes with a current rating of 15 amps. This specification indicates the maximum current the plug can safely carry without overheating. Understanding current ratings is essential for B2B buyers to ensure that the plug can handle the intended load of the equipment it will be used with, preventing electrical failures or hazards. -

Voltage Rating

Most 2 prong plugs are rated for 125 volts. This voltage rating indicates the maximum voltage the plug can safely accommodate. Buyers must ensure that the voltage rating aligns with the electrical systems in their regions to avoid compatibility issues that could lead to equipment damage or safety risks. -

Wire Gauge Compatibility

Plugs are designed to work with specific wire gauges, typically between 18 and 16 AWG (American Wire Gauge). Using the correct wire gauge is crucial for maintaining safe electrical connections and preventing overheating. B2B buyers should verify that the plugs match the wire gauge of their cords to ensure optimal performance. -

Polarization

Polarized plugs have one prong wider than the other, ensuring that the hot and neutral wires are connected correctly. This feature enhances safety by reducing the risk of electrical shock. For businesses in regions with strict electrical standards, choosing polarized plugs can be a requirement for compliance. -

Certification and Standards Compliance

Look for certifications such as UL (Underwriters Laboratories) or CE (Conformité Européenne) markings, which indicate that the plug meets specific safety and performance standards. Compliance with international standards is crucial for B2B buyers, especially when importing products across borders, to ensure that they meet local regulations.

Which Trade Terminology Should B2B Buyers Understand for 2 Prong Plugs?

Understanding industry jargon can facilitate smoother transactions and clearer communication. Here are some key terms relevant to B2B buyers:

Illustrative image related to 2 prong plug

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. When sourcing 2 prong plugs, identifying reputable OEMs can ensure quality and reliability in the components you purchase. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to make bulk purchases of 2 prong plugs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products, including pricing and terms. For B2B buyers, utilizing RFQs can streamline the procurement process, making it easier to compare offers from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, risk management, and cost allocation when importing 2 prong plugs. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time for 2 prong plugs can help businesses plan their projects more effectively and avoid delays in operations. -

Certification

This term refers to the process of verifying that a product meets specific standards set by regulatory bodies. For B2B buyers, ensuring that 2 prong plugs are certified can mitigate risks associated with product safety and compliance.

By understanding these technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 2 prong plug Sector

What Are the Key Market Drivers and Trends Influencing the 2 Prong Plug Sector?

The global market for 2 prong plugs is driven by several factors, including the growing demand for electrical appliances, increased urbanization, and the expansion of the DIY culture, particularly in emerging economies across Africa, South America, and the Middle East. International B2B buyers are increasingly seeking high-quality, versatile, and aesthetically pleasing electrical components, such as polarized 2 prong plugs, which are favored for their safety features in residential and commercial applications.

Current trends indicate a shift towards smart and energy-efficient devices, which often require specialized electrical components. For instance, the integration of technology in home automation systems has created a demand for plugs that can seamlessly connect with smart home devices. Additionally, the rise of e-commerce platforms has simplified the sourcing process for international buyers, allowing them to access a broader range of products and suppliers.

Sourcing dynamics are also evolving, with a focus on just-in-time (JIT) inventory systems to reduce holding costs and increase responsiveness to market changes. B2B buyers must navigate complexities such as varying regional standards and regulations, especially when sourcing from diverse markets like Germany, Saudi Arabia, and South Africa. Understanding local compliance requirements and engaging with reliable suppliers is crucial for successful procurement in this sector.

How Can Sustainability and Ethical Sourcing Impact the 2 Prong Plug Market?

Sustainability is becoming a critical consideration for B2B buyers in the 2 prong plug sector. The environmental impact of manufacturing processes and the lifecycle of electrical components is under scrutiny, leading to an increased demand for ‘green’ certifications and materials. Suppliers that prioritize sustainable practices, such as using recyclable materials and minimizing waste, are gaining traction in the market.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their supply chains. Ensuring that suppliers adhere to fair labor practices and environmental regulations is essential not only for compliance but also for brand reputation. Companies that can demonstrate a commitment to ethical sourcing are more likely to foster trust and loyalty among their customers.

As the market evolves, buyers should look for suppliers that offer transparency in their sourcing processes. This includes certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous materials, which can enhance product credibility and appeal to environmentally conscious consumers.

Illustrative image related to 2 prong plug

What Is the Evolution of the 2 Prong Plug and Its Relevance to Today’s B2B Landscape?

The 2 prong plug has evolved significantly since its inception in the early 20th century. Originally designed for basic electrical connections, these plugs have undergone numerous redesigns to enhance safety, usability, and aesthetic appeal. The introduction of polarized designs, which ensure that the live and neutral wires are connected correctly, marked a significant advancement in electrical safety.

Today, the relevance of the 2 prong plug in the B2B landscape is underscored by its versatility across various applications, from lighting fixtures to appliances. As industries increasingly prioritize safety and efficiency, the demand for high-quality, reliable plugs continues to grow. This evolution highlights the importance of staying updated on industry standards and technological advancements, enabling B2B buyers to make informed purchasing decisions that align with contemporary market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 prong plug

-

How do I solve compatibility issues with 2 prong plugs in different countries?

To address compatibility issues with 2 prong plugs across different regions, it’s essential to understand the local electrical standards and plug types. For instance, European countries often use different voltage levels and plug configurations compared to those in Africa or South America. Research the specific requirements for each target market and consider sourcing adapters or investing in universal plugs that can accommodate varying voltages and plug styles. Partnering with local suppliers can also provide insights into compliance with regional electrical codes. -

What is the best material for durable 2 prong plugs?

When sourcing 2 prong plugs, look for materials that ensure durability and safety. High-quality plastics like polycarbonate and nylon are often used for the casing, while copper is recommended for the internal conductors due to its excellent conductivity. Rubber or thermoplastic elastomers are ideal for insulation and protection against environmental factors. Always check for certifications such as UL or CE, which indicate compliance with safety standards, ensuring the plugs can withstand repeated use and environmental stresses. -

How do I vet suppliers for 2 prong plugs?

To effectively vet suppliers for 2 prong plugs, start by assessing their manufacturing capabilities and quality control processes. Request samples to evaluate product quality firsthand and ask for references or case studies from previous clients. Verify their certifications and compliance with international standards relevant to your market. Additionally, consider suppliers with experience in your specific region, as they may be more familiar with local regulations and customer preferences, which can enhance your supply chain reliability. -

What are the minimum order quantities (MOQ) for 2 prong plugs?

Minimum order quantities (MOQ) for 2 prong plugs can vary significantly among manufacturers. Generally, MOQs can range from as low as 100 to several thousand units, depending on the supplier’s production capabilities and your specific needs. For customized designs or specific materials, MOQs may be higher due to the additional setup costs involved. When negotiating, discuss flexibility with your supplier, especially if you are a new buyer or are testing the market for specific products. -

What payment terms should I expect when sourcing 2 prong plugs?

Payment terms for sourcing 2 prong plugs typically vary by supplier and may include options such as upfront payment, partial payment upon order confirmation, and the remainder upon delivery. Common methods include bank transfers, credit terms, or payment through secure platforms like PayPal. It’s advisable to establish clear terms in the contract to protect both parties, especially regarding timelines and penalties for late payments. Always consider using escrow services for large transactions to ensure security. -

What quality assurance practices should I require from suppliers?

When sourcing 2 prong plugs, insist on stringent quality assurance (QA) practices from your suppliers. This includes regular product testing for electrical safety, compliance with international standards, and thorough inspections during production. Request documentation of quality control processes, including the frequency of tests and the criteria used. Additionally, consider implementing third-party inspections or audits to verify that your supplier maintains high-quality standards consistently, which can help mitigate risks related to defective products. -

How do I handle logistics and shipping for international orders of 2 prong plugs?

Managing logistics for international orders of 2 prong plugs involves careful planning and coordination with shipping companies. Start by choosing reliable freight forwarders experienced in handling electrical components. Understand the shipping regulations, customs duties, and tariffs for your target countries to avoid unexpected costs. Opt for incoterms that best suit your business model, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to clarify responsibilities. Tracking shipments and ensuring proper documentation will also facilitate smoother customs clearance. -

What customization options are available for 2 prong plugs?

Customization options for 2 prong plugs can include variations in color, materials, shape, and branding. Many manufacturers offer the ability to design plugs that meet specific aesthetic or functional requirements, such as incorporating logos or specific electrical ratings. Discuss your needs with potential suppliers and inquire about their capabilities for custom designs. Remember that customizations may affect MOQs and lead times, so it’s essential to plan accordingly to align with your business objectives.

Top 3 2 Prong Plug Manufacturers & Suppliers List

1. Snakehead Vintage – 2 Prong Electrical Plug

Domain: snakeheadvintage.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “2 Prong Electrical Plug – Black Rubber Shell Polarized Male Plug”, “price”: “$3.69”, “SKU”: “plug-2prong-rubberpolarized”, “current_stock”: 2824, “discounts”: [{“quantity_range”: “4 – 9”, “price_each”: “$3.49”}, {“quantity_range”: “10 – 19”, “price_each”: “$3.29”}, {“quantity_range”: “20 or above”, “price_each”: “$3.09”}], “description”: “Top Quality Electrical Supplies For Your …

2. Reddit – Two-Prong Plug Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Replacing a two-prong plug; no ground; wires not color-coded; no wider prong indicating polarity.

3. Target – Two Prong Adapter Solutions

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Two Prong Adapter Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 2 prong plug

What Are the Key Considerations for Sourcing 2 Prong Plugs?

In summary, strategic sourcing of 2 prong plugs is essential for ensuring quality, safety, and compliance with international standards. B2B buyers should prioritize suppliers that offer high-quality materials, such as rubber shells and UL-listed products, which enhance safety and durability. Additionally, understanding the specific regional requirements and preferences—like plug aesthetics and functionality—can inform better purchasing decisions, especially in diverse markets across Africa, South America, the Middle East, and Europe.

How Can International Buyers Leverage Strategic Sourcing?

Emphasizing a proactive sourcing strategy allows buyers to foster long-term partnerships with reliable manufacturers and suppliers. This not only mitigates risks associated with product quality but also enhances supply chain efficiency. Engaging with suppliers who are adept at meeting local regulations and who can provide customization options will yield a significant competitive advantage.

What Is the Future Outlook for the 2 Prong Plug Market?

Looking ahead, the demand for 2 prong plugs is expected to grow, driven by trends in vintage aesthetics and the need for reliable electrical connections. As international markets evolve, buyers are encouraged to stay informed about emerging technologies and design preferences. By aligning sourcing strategies with market trends, buyers can better position themselves to capitalize on future opportunities. Now is the time to refine your sourcing approach and explore innovative partnerships that will elevate your product offerings and satisfy your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.