Top 2 Window Regulator Brushes Suppliers (And How to Choose)

Introduction: Navigating the Global Market for window regulator brushes

In the competitive landscape of the automotive industry, sourcing high-quality window regulator brushes can pose a significant challenge for international B2B buyers. As these components are crucial for the smooth operation of power window systems, understanding their various types, applications, and the nuances of supplier vetting is essential for making informed purchasing decisions. This guide delves into the intricacies of window regulator brushes, providing insights into the diverse materials and designs available, and the factors influencing their performance and longevity.

Through comprehensive analysis, this resource equips buyers from regions such as Africa, South America, the Middle East, and Europe—including Brazil and Vietnam—with the knowledge necessary to navigate the global market effectively. We explore critical aspects such as cost considerations, quality benchmarks, and supplier reliability, ensuring that businesses can procure components that meet their specific requirements.

Moreover, the guide emphasizes the importance of understanding local market dynamics and regulatory standards, which can significantly impact purchasing strategies. By empowering B2B buyers with actionable insights and a clear framework for evaluating potential suppliers, this guide aims to streamline the sourcing process, ultimately enhancing operational efficiency and reducing overhead costs in the long term.

Understanding window regulator brushes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Brushes | Made of carbon, offering good conductivity; common in many models | Automotive, industrial equipment | Pros: Cost-effective; Cons: Limited lifespan; requires regular replacement. |

| Graphite Brushes | Composed of graphite, providing excellent wear resistance; higher thermal stability | High-performance vehicles, heavy machinery | Pros: Longer lifespan; Cons: Higher initial cost. |

| Copper Brushes | Feature copper contacts for superior conductivity; often used in high-load applications | Heavy-duty vehicles, industrial motors | Pros: Excellent conductivity; Cons: Prone to corrosion if not properly maintained. |

| Composite Brushes | Made from a blend of materials for enhanced durability; often used in specialized applications | Aerospace, specialized automotive parts | Pros: Customizable; Cons: More expensive and less widely available. |

| 3D-Printed Brushes | Innovative design allows for custom shapes and sizes; use of conductive materials | Custom applications, prototyping | Pros: Tailored solutions; Cons: Still in development; material limitations. |

What Are the Characteristics of Carbon Brushes?

Carbon brushes are the most widely used type in window regulators due to their cost-effectiveness and decent electrical conductivity. They are often found in standard automotive applications and are suitable for general-purpose use. However, they have a limited lifespan and require regular maintenance to ensure optimal performance. Buyers should consider the frequency of replacement and overall cost-effectiveness when opting for carbon brushes.

How Do Graphite Brushes Differ in Performance?

Graphite brushes are known for their superior wear resistance and thermal stability, making them ideal for high-performance vehicles and heavy machinery. They can handle higher temperatures and loads, which extends their lifespan compared to carbon brushes. While the initial investment is higher, B2B buyers must weigh the long-term benefits of reduced maintenance and replacement costs against the upfront price.

Why Choose Copper Brushes for Heavy-Duty Applications?

Copper brushes are designed for high-load applications, providing excellent conductivity and performance. They are commonly used in heavy-duty vehicles and industrial motors, where reliability is crucial. However, they can be prone to corrosion if not maintained properly. Buyers in industries that demand high performance should consider the environmental conditions and maintenance capabilities before choosing copper brushes.

What Advantages Do Composite Brushes Offer?

Composite brushes combine various materials to enhance durability and performance. They are often used in specialized applications, such as aerospace or custom automotive parts, where unique specifications are required. While they can be more expensive and less readily available, they offer customizable solutions for specific needs. B2B buyers should assess the customization potential and application requirements when considering composite brushes.

Are 3D-Printed Brushes the Future of Window Regulator Solutions?

3D-printed brushes represent an innovative approach to manufacturing, allowing for customized shapes and sizes that meet specific requirements. The use of conductive materials in 3D printing is still being explored, but it opens up possibilities for tailored solutions in various applications. Buyers interested in cutting-edge technology should consider the potential benefits of 3D-printed brushes, keeping in mind that this technology is still in development and may have material limitations.

Key Industrial Applications of window regulator brushes

| Industry/Sector | Specific Application of window regulator brushes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Power window systems in passenger vehicles | Enhances durability and reliability of window mechanisms | Compatibility with various motor types and dimensions |

| Heavy Machinery | Window mechanisms in construction equipment | Reduces maintenance costs and downtime | Material quality and resistance to wear |

| Transportation | Window systems in public transport vehicles | Improves passenger safety and comfort | Compliance with safety standards and regulations |

| Aftermarket Parts | Replacement brushes for consumer vehicles | Cost-effective repair solutions for end-users | Availability of compatible models and part numbers |

| Renewable Energy | Window systems in solar panel installations | Enhances efficiency of operational mechanisms | Sustainability of materials used |

How Are Window Regulator Brushes Used in Automotive Manufacturing?

In the automotive manufacturing sector, window regulator brushes are essential components in the power window systems of passenger vehicles. They are responsible for facilitating the movement of the window up and down, ensuring smooth operation. By sourcing high-quality brushes, manufacturers can enhance the durability and reliability of their window mechanisms, reducing the frequency of repairs and replacements. For international buyers, particularly in emerging markets, it is crucial to ensure compatibility with various motor types and dimensions to avoid costly production delays.

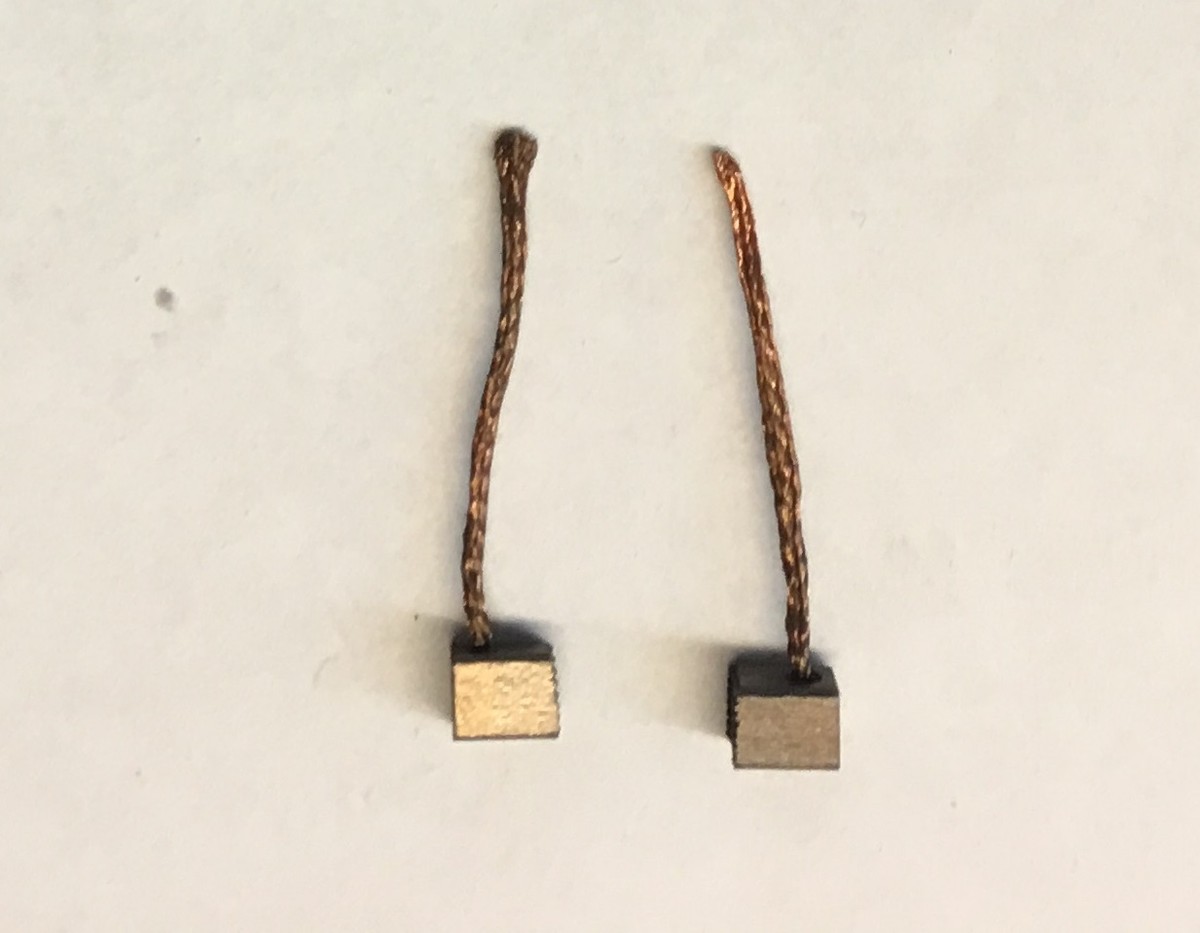

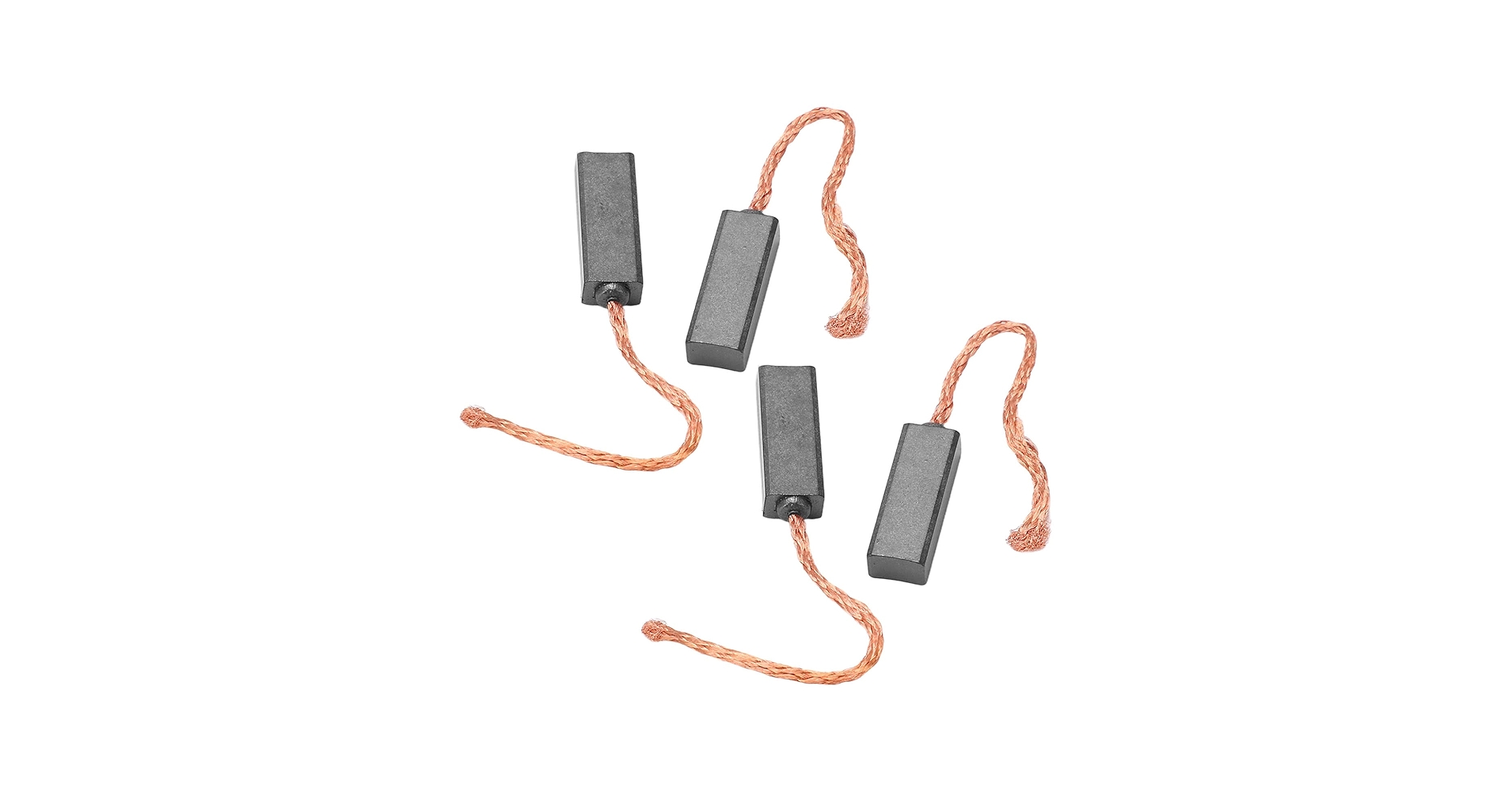

Illustrative image related to window regulator brushes

What Role Do Window Regulator Brushes Play in Heavy Machinery?

In heavy machinery, such as construction equipment, window regulator brushes are critical for operating window mechanisms that provide visibility and ventilation to operators. The use of robust brushes helps reduce maintenance costs and minimizes equipment downtime, which is vital in industries where time is money. Buyers in regions with harsh operating conditions, like the Middle East or South America, should prioritize sourcing brushes made from high-quality, wear-resistant materials to ensure longevity and reliability in demanding environments.

Why Are Window Regulator Brushes Important in Transportation?

In the transportation sector, window systems in public transport vehicles, such as buses and trains, rely on efficient window regulator brushes for safe and comfortable passenger experiences. These brushes must perform reliably to ensure that windows can be opened or closed quickly in emergencies. Compliance with safety standards and regulations is paramount for international buyers, especially in Europe, where stringent guidelines govern public transportation equipment.

How Do Aftermarket Parts Benefit from Window Regulator Brushes?

The aftermarket parts industry often relies on replacement window regulator brushes for consumer vehicles. These brushes provide a cost-effective solution for consumers looking to repair their vehicles instead of replacing entire window regulator assemblies. For buyers, ensuring the availability of compatible models and part numbers is crucial to meet diverse customer needs. This sector can thrive by offering high-quality brushes that extend the lifespan of existing window mechanisms.

What Is the Impact of Window Regulator Brushes in Renewable Energy Applications?

In renewable energy installations, such as solar panels, window regulator brushes are used in mechanisms that allow for the adjustment of solar panels to maximize sunlight exposure. High-quality brushes enhance the efficiency of these operational mechanisms, ensuring optimal performance. Buyers should consider the sustainability of the materials used in these brushes, as eco-friendly options can align with the overall goals of renewable energy initiatives, particularly in regions focusing on green technologies.

3 Common User Pain Points for ‘window regulator brushes’ & Their Solutions

Scenario 1: Sourcing Compatible Window Regulator Brushes for Diverse Models

The Problem:

B2B buyers often encounter difficulties when sourcing window regulator brushes that are compatible with a range of vehicle models. This challenge is compounded in regions with diverse vehicle populations, such as Africa and South America, where multiple brands and models might share similar components. Buyers frequently struggle to find reliable suppliers that can provide the exact specifications needed for different vehicles, leading to potential delays in repair processes and increased operational costs.

The Solution:

To effectively source compatible window regulator brushes, buyers should first compile a comprehensive list of the specific vehicle models they service, including details like the year, make, and model. Utilizing this information, they can engage with suppliers who specialize in automotive components and request detailed catalogs or databases that indicate compatibility. It is also beneficial to develop relationships with manufacturers who can provide custom solutions or modifications, ensuring that the brushes fit precisely. Additionally, investing in digital tools or platforms that aggregate parts data can streamline the sourcing process, allowing buyers to quickly verify compatibility across various models and thus minimize downtime.

Illustrative image related to window regulator brushes

Scenario 2: Managing Brush Wear and Longevity in Window Regulators

The Problem:

One of the prevalent issues faced by businesses is the premature wear of window regulator brushes, leading to frequent replacements and increased maintenance costs. In regions with extreme weather conditions, such as the Middle East, brushes may degrade faster due to temperature fluctuations. This not only affects the functionality of power windows but also impacts customer satisfaction and operational efficiency.

The Solution:

To address the challenge of brush wear, B2B buyers should consider sourcing high-quality brushes made from durable materials designed for longevity. It is essential to consult with manufacturers regarding the specific environmental conditions where the vehicles operate. Implementing a preventative maintenance schedule can also help identify wear early, allowing for timely replacements before complete failure occurs. Moreover, educating technicians on proper installation techniques can enhance the lifespan of the brushes. Investing in training or instructional materials can help ensure that all replacements are done correctly, thereby improving performance and reducing the frequency of replacements.

Scenario 3: Navigating Cost-Effective Solutions for Window Regulator Repairs

The Problem:

B2B buyers frequently encounter high costs associated with replacing entire window regulator assemblies rather than just the brushes. This financial strain can be particularly burdensome for smaller repair shops or businesses operating on tight budgets, especially in developing markets where parts can be significantly marked up. As a result, many businesses struggle to maintain profitability while providing quality service to their customers.

The Solution:

A practical approach to manage costs involves educating buyers on the feasibility of replacing only the brushes instead of entire assemblies. Buyers should seek out suppliers who offer replacement brushes specifically designed for various window regulator models at competitive prices. Establishing partnerships with manufacturers can also lead to bulk purchasing options or discounts. Furthermore, promoting awareness among customers about the cost-effectiveness of brush replacements compared to full assembly replacements can enhance service offerings and customer loyalty. Encouraging workshops or training sessions on DIY repairs for common issues can empower customers to maintain their vehicles, ultimately reducing the demand for full replacements and enhancing overall satisfaction.

Strategic Material Selection Guide for window regulator brushes

What Materials Are Commonly Used for Window Regulator Brushes?

When selecting materials for window regulator brushes, several options are prevalent in the industry, each with distinct properties that affect their performance, durability, and cost. Understanding these materials is critical for international B2B buyers looking to make informed purchasing decisions.

How Do Carbon Brushes Perform in Window Regulators?

Carbon brushes are the most widely used material for window regulator applications. They exhibit excellent electrical conductivity and are capable of withstanding high temperatures, making them suitable for the varying conditions found in automotive environments.

Illustrative image related to window regulator brushes

Pros: Carbon brushes are cost-effective and widely available, which makes them an attractive option for manufacturers. They also have good wear resistance, ensuring a longer lifespan under normal operating conditions.

Cons: However, they can wear out quickly under extreme pressure or temperature fluctuations, which may necessitate more frequent replacements. Additionally, carbon brushes may not perform well in highly humid or corrosive environments, which can be a concern in certain regions.

Impact on Application: Carbon brushes are compatible with most motor types used in window regulators, but buyers in humid climates should consider potential degradation over time.

What Advantages Do Copper Brushes Offer?

Copper brushes are another alternative, known for their superior conductivity and durability. They are often used in high-performance applications where efficiency is paramount.

Pros: The primary advantage of copper brushes is their excellent electrical conductivity, which can enhance the overall performance of the window regulator. They are also more resistant to wear compared to carbon brushes, leading to a longer operational life.

Cons: On the downside, copper brushes are generally more expensive and can be heavier, which may affect the overall weight of the window regulator assembly. Additionally, they can corrode if not properly treated, making them less suitable for environments with high moisture levels.

Impact on Application: Buyers in regions with high humidity or salt exposure should consider protective coatings to prevent corrosion, which could otherwise lead to premature failure.

How Do Graphite Brushes Compare?

Graphite brushes are a hybrid option that combines the properties of carbon and copper, offering a balance between conductivity and wear resistance.

Pros: Graphite brushes are lightweight and provide good electrical conductivity, making them suitable for a variety of applications. They also have a lower friction coefficient, which can enhance the efficiency of the window regulator.

Cons: However, graphite brushes can be more prone to wear under heavy loads, which may reduce their lifespan compared to copper brushes. They also tend to be more expensive than traditional carbon brushes.

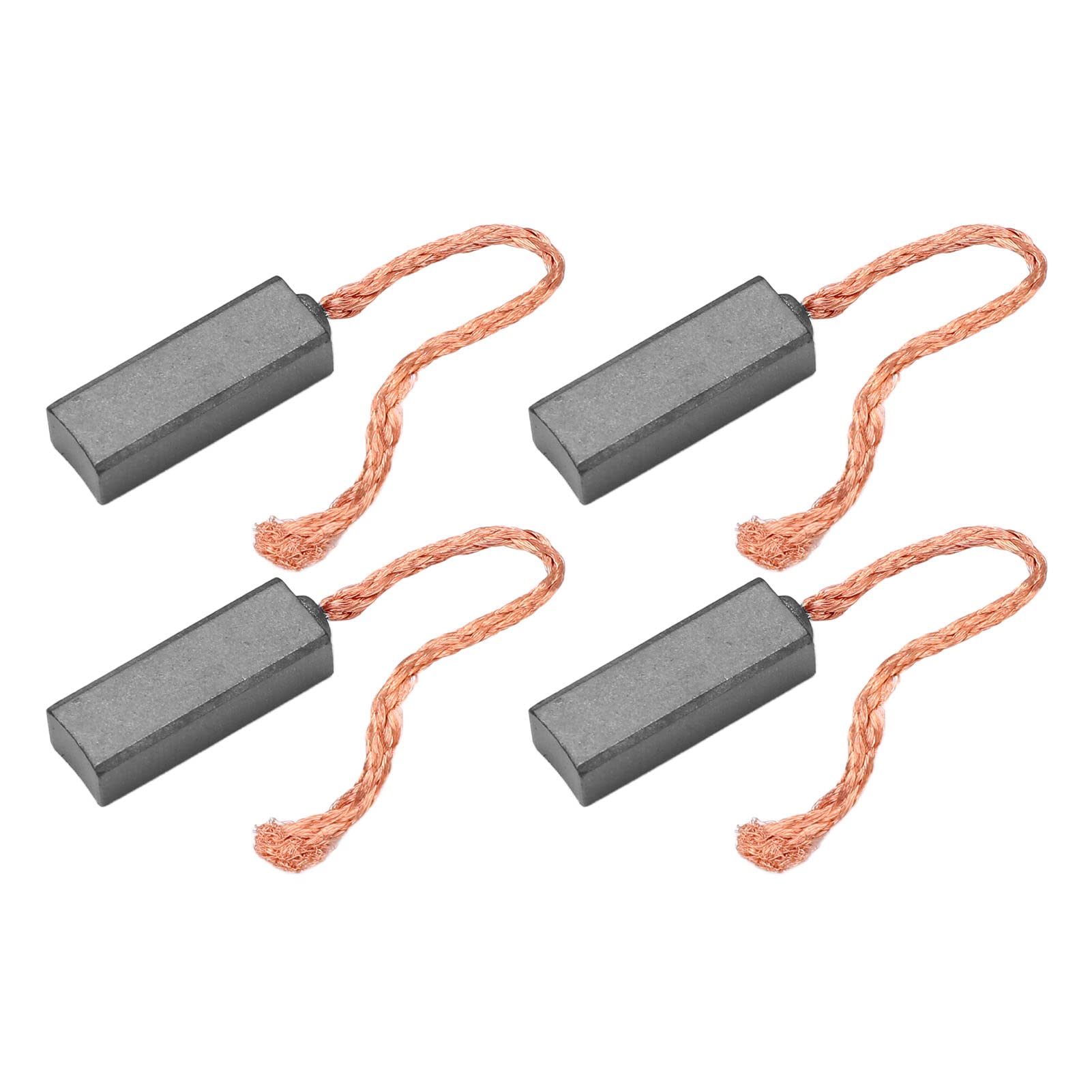

Illustrative image related to window regulator brushes

Impact on Application: For international buyers, graphite brushes may be particularly appealing in markets that prioritize lightweight components, though they should ensure compatibility with the specific motor design.

What Role Do Composite Materials Play?

Composite brushes, which often blend various materials, are becoming increasingly popular due to their tailored properties. These brushes can be engineered to meet specific performance criteria.

Pros: The primary advantage of composite brushes is their versatility; they can be designed to optimize conductivity, wear resistance, and thermal stability according to application needs. This customization can lead to better performance in specific environments.

Cons: The complexity of manufacturing composite brushes can lead to higher costs. Additionally, their performance can vary significantly based on the specific materials used, which may complicate sourcing.

Impact on Application: Buyers should verify compliance with international standards such as ASTM or DIN to ensure that composite brushes meet their specific requirements.

Summary Table of Material Selection for Window Regulator Brushes

| Material | Typical Use Case for window regulator brushes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon | Standard automotive window regulators | Cost-effective and widely available | Wears out quickly under extreme conditions | Low |

| Copper | High-performance applications | Superior conductivity and durability | Higher cost and potential for corrosion | High |

| Graphite | Lightweight applications | Good conductivity with lower friction | Prone to wear under heavy loads | Medium |

| Composite | Custom applications | Tailored properties for specific needs | Higher manufacturing complexity and cost | Medium to High |

This guide provides a comprehensive overview of the materials used in window regulator brushes, enabling B2B buyers to make informed choices based on their specific regional and application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for window regulator brushes

What Are the Key Stages in the Manufacturing Process of Window Regulator Brushes?

The manufacturing of window regulator brushes involves several critical stages, each designed to ensure that the final product meets the necessary performance and durability standards.

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Most window regulator brushes are made from conductive materials such as copper and carbon composites. High-quality carbon is essential for ensuring longevity and optimal performance. Suppliers often source raw materials that comply with international standards, ensuring they have the necessary properties for effective conductivity and wear resistance.

Once the materials are acquired, they undergo a series of tests to check for purity and consistency. This step is crucial as impurities can significantly affect the performance of the brushes. Advanced equipment like spectrometers may be used for material analysis, ensuring that only the best materials proceed to the next stage.

Forming Techniques

The forming stage involves shaping the prepared materials into the desired brush configuration. This can include processes such as molding, cutting, and machining.

-

Molding: In this method, carbon materials are mixed with binders and then molded into specific shapes. This is particularly useful for producing brushes with complex geometries.

-

Cutting and Machining: For brushes that require precise dimensions, cutting techniques such as CNC machining are employed. This allows for high precision and consistency in the final product.

Techniques like die-casting may also be utilized for forming the metallic components that hold the brushes in place. The choice of technique often depends on the required volume and specifications of the brushes.

Assembly and Finishing

After forming, the brushes are assembled with their respective components, such as spring clips and copper connectors. This assembly is critical as it determines how well the brushes will fit and function within the window regulator motor.

Finishing processes, including surface treatments, are then applied to enhance durability and performance. These treatments can help reduce friction and wear during operation, extending the lifespan of the brushes. Processes may include polishing, coating with anti-corrosive materials, or applying lubricants.

What Quality Assurance Measures Are Essential for Window Regulator Brushes?

Quality assurance (QA) is a vital part of the manufacturing process, especially for components like window regulator brushes, which must meet stringent performance standards.

What International Standards Should Manufacturers Adhere To?

Manufacturers should comply with international quality standards such as ISO 9001, which emphasizes quality management systems. This certification ensures that the manufacturing process is consistently monitored and improved. Additionally, compliance with industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) can provide further assurance of quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control involves several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production line. Each batch should be tested for quality and specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that production aligns with quality standards. This may involve monitoring dimensions, material properties, and performance metrics.

-

Final Quality Control (FQC): The final inspection occurs before the products are packaged and shipped. This stage includes functional tests, performance evaluations, and visual inspections to ensure that each brush meets the required specifications.

What Common Testing Methods Are Used for Quality Assurance?

Common testing methods for window regulator brushes include:

-

Electrical Conductivity Tests: Assessing the electrical properties of the brushes to ensure they meet conductivity standards.

-

Wear and Tear Tests: Simulating operational conditions to evaluate how the brushes perform under stress and over time.

-

Dimensional Checks: Using precision instruments to measure the dimensions of the brushes to ensure they fit properly in the window regulator assembly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is crucial. Here are several strategies to ensure that suppliers adhere to stringent quality standards:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. During an audit, buyers can assess whether suppliers comply with international quality standards and check their QA documentation.

Reviewing Quality Reports and Certifications

Buyers should request and review quality reports and certifications from suppliers. These documents can provide evidence of compliance with industry standards and demonstrate the effectiveness of their quality control systems.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. These services can conduct inspections and testing, providing an additional layer of assurance regarding product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

-

Cultural Differences: Different regions may have varying expectations regarding quality standards. Understanding these cultural nuances can facilitate better communication and collaboration with suppliers.

-

Regulatory Compliance: Buyers must ensure that suppliers comply with local regulations and standards. This may require additional documentation or certifications, particularly when importing products across borders.

-

Supply Chain Transparency: Given the complexity of international supply chains, buyers should seek suppliers who provide transparency in their sourcing and manufacturing processes. This can help mitigate risks related to quality and compliance.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for window regulator brushes can empower B2B buyers to make informed decisions. By prioritizing quality and compliance, buyers can ensure the durability and performance of their products, ultimately leading to better customer satisfaction and loyalty.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘window regulator brushes’

To assist international B2B buyers in sourcing window regulator brushes effectively, this guide provides a step-by-step checklist. Each step is designed to ensure you make informed decisions while navigating the procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline the technical specifications of the window regulator brushes you need. This includes dimensions, material composition (such as carbon content), and electrical conductivity requirements. Having clear specifications helps you avoid compatibility issues and ensures that the brushes will function efficiently within the window regulator systems.

Step 2: Research Market Demand and Trends

Understanding the market landscape is crucial for successful sourcing. Investigate current trends in the automotive parts sector, particularly focusing on window regulators. Monitor demand fluctuations, as they may influence pricing and availability. This knowledge will help you anticipate market shifts and position your procurement strategy accordingly.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in automotive components, particularly window regulator brushes. Look for manufacturers with a robust reputation in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize industry-specific platforms and trade shows to discover suppliers and gather initial information about their product offerings.

Step 4: Evaluate Supplier Certifications and Compliance

Before finalizing any agreements, verify that suppliers comply with relevant industry standards and certifications. This may include ISO certifications or adherence to local regulations. Ensuring compliance not only guarantees product quality but also mitigates risks associated with substandard components.

Step 5: Request Samples and Conduct Quality Tests

Once you narrow down your supplier options, request samples of the window regulator brushes. Conduct thorough quality assessments to test for durability, performance, and compatibility with your existing systems. This step is vital to ensure that the products meet your specifications and can withstand operational demands.

Step 6: Negotiate Pricing and Terms of Service

Engage in negotiations with your selected suppliers to secure favorable pricing and terms. Consider bulk order discounts, payment terms, and delivery timelines. A well-negotiated contract can lead to long-term partnerships that benefit both parties, so ensure clarity on all terms before finalizing any agreements.

Step 7: Establish a Logistics and Supply Chain Plan

Finally, develop a logistics strategy for the procurement and distribution of the window regulator brushes. Assess shipping options, lead times, and potential customs regulations for international shipments. A well-structured logistics plan ensures timely delivery and helps maintain your inventory levels efficiently.

By following this checklist, B2B buyers can navigate the complexities of sourcing window regulator brushes, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for window regulator brushes Sourcing

What Are the Key Cost Components in Sourcing Window Regulator Brushes?

When analyzing the cost structure for sourcing window regulator brushes, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials typically involve the cost of raw materials such as carbon or graphite, which are essential for producing brushes. These materials should meet specific electrical conductivity standards to ensure optimal performance. Labor costs encompass the wages of skilled workers required for manufacturing and assembling the brushes, which can vary significantly depending on the region and skill level of the workforce.

Manufacturing overhead includes expenses related to factory operations, including utilities, maintenance, and administrative costs. Tooling costs are associated with the equipment and molds needed for production, which can be substantial for custom or specialized brushes. Quality control measures are vital in ensuring that the brushes meet industry standards, adding another layer of cost. Finally, logistics costs cover transportation and warehousing, which can fluctuate based on location and shipping methods.

How Do Price Influencers Affect the Cost of Window Regulator Brushes?

Several factors can influence the pricing of window regulator brushes, significantly impacting the overall cost for buyers. Volume and Minimum Order Quantity (MOQ) are crucial; larger orders often lead to discounted pricing due to economies of scale. Customization requirements also play a role; specialized brushes may require unique materials or designs, which can drive up costs.

Quality and certification are other important aspects. Brushes that meet international quality standards or have specific certifications will typically command higher prices. Supplier factors, such as reliability and reputation, can also affect pricing; established suppliers may charge a premium for their products due to perceived quality and service levels.

Additionally, Incoterms can greatly influence the final cost. Understanding the terms of shipping, insurance, and risk transfer is essential for international buyers to ensure they are not overpaying due to misunderstandings.

What Buyer Tips Can Help Optimize Costs When Sourcing Window Regulator Brushes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize sourcing costs. First, negotiation is key; being prepared to discuss terms and quantities can lead to better pricing. Buyers should also consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, replacement, and operational costs over the brush’s lifecycle.

Illustrative image related to window regulator brushes

Understanding pricing nuances specific to different markets is essential. For example, prices may vary significantly between suppliers in Brazil and Vietnam, influenced by local economic conditions, tariffs, and shipping costs. Buyers should also be aware of potential fluctuations in raw material prices, which can affect overall costs.

Lastly, establishing strong relationships with suppliers can lead to better deals and increased flexibility in terms and conditions. This is especially important for ongoing projects where consistent quality and supply are critical.

Disclaimer on Pricing

While this analysis provides a comprehensive view of the cost and pricing structure for window regulator brushes, it is important to note that prices can vary widely based on specific requirements, supplier capabilities, and market conditions. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing in their sourcing decisions.

Alternatives Analysis: Comparing window regulator brushes With Other Solutions

Introduction

In the automotive industry, particularly in the realm of power window systems, finding the right solution for window regulator issues is paramount. While window regulator brushes are a common fix for malfunctioning motors, alternative solutions exist that may offer varying benefits. This analysis explores these alternatives, enabling B2B buyers to make informed decisions based on performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | Window Regulator Brushes | Replacement Motor Assembly | DIY Repair with Aftermarket Parts |

|---|---|---|---|

| Performance | High if properly fitted | Excellent, new components | Moderate, depends on parts quality |

| Cost | Low ($8-$40) | High ($300-$500) | Moderate ($50-$150) |

| Ease of Implementation | Moderate (requires skill) | Easy (plug-and-play) | Variable (depends on compatibility) |

| Maintenance | Requires periodic checks | Low (new part) | Variable (depends on quality) |

| Best Use Case | Cost-sensitive repairs | Comprehensive replacements | Custom solutions or upgrades |

Detailed Breakdown

Window Regulator Brushes

Using window regulator brushes offers a cost-effective solution for repairing worn-out motors. Typically priced between $8 to $40, they allow for a targeted repair rather than a complete assembly replacement. However, the installation process can be labor-intensive and requires technical knowledge to ensure proper fitting. While they can restore functionality if installed correctly, they may require periodic maintenance checks to ensure longevity.

Replacement Motor Assembly

Opting for a complete replacement motor assembly is the most straightforward solution. This method guarantees that all components are new and functioning optimally, reducing the risk of future failures. However, this option comes at a significantly higher cost, typically ranging from $300 to $500, which may not be feasible for all buyers. Replacement assemblies are ideal for businesses that prioritize reliability over budget constraints and prefer a straightforward, plug-and-play installation.

DIY Repair with Aftermarket Parts

A middle-ground approach involves using aftermarket parts for DIY repairs. This method can be cost-effective, with parts generally costing between $50 and $150. The DIY aspect allows for customization and potential upgrades, making it attractive for businesses looking to innovate or adapt their window systems. However, the success of this method heavily relies on the quality of the aftermarket parts and the user’s technical skills. Compatibility issues can also arise, complicating the repair process.

Conclusion

Choosing the right solution for window regulator issues involves weighing performance, cost, and implementation ease. For businesses operating on tight budgets, window regulator brushes provide a viable option, while those seeking reliability may prefer a complete motor assembly. DIY repairs using aftermarket parts can offer a balance of cost and customization but require careful consideration of part quality and compatibility. Ultimately, B2B buyers should assess their specific needs and operational capabilities to select the most suitable solution for their window regulator challenges.

Essential Technical Properties and Trade Terminology for window regulator brushes

What Are the Key Technical Properties of Window Regulator Brushes?

Understanding the technical specifications of window regulator brushes is essential for B2B buyers looking to ensure product quality and compatibility. Here are the critical properties to consider:

1. Material Composition

The most common material for window regulator brushes is carbon or graphite. Carbon brushes are preferred due to their excellent conductivity and wear resistance. The choice of material directly affects the brush’s lifespan and performance, making it crucial for buyers to select high-grade materials that align with their operational demands.

2. Brush Dimensions and Tolerances

Brush dimensions, including length, width, and height, are vital for compatibility with the motor’s commutator. Tolerances, or the acceptable deviations from specified dimensions, are critical as they ensure a proper fit within the motor assembly. Inaccurate dimensions can lead to inefficient operation or premature wear, which can be costly for businesses.

Illustrative image related to window regulator brushes

3. Hardness Rating

The hardness of window regulator brushes, measured on the Shore scale, influences their durability and performance. Softer brushes may wear out quickly, while harder brushes can lead to increased wear on the commutator. Buyers should consider their application environment and choose a hardness rating that balances durability with performance.

4. Electrical Conductivity

The electrical conductivity of the brush material is essential for efficient power transfer to the motor. Higher conductivity results in improved performance and reduced energy loss. B2B buyers should inquire about the conductivity specifications to ensure that the brushes meet the electrical demands of their specific applications.

5. Operating Temperature Range

Understanding the operating temperature range is crucial, as brushes that exceed their temperature limits can fail prematurely. Buyers should verify that the brushes can withstand the temperatures typical in their operating environments, ensuring reliability and longevity.

What Are Common Trade Terms Related to Window Regulator Brushes?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original vehicle or equipment. When sourcing window regulator brushes, opting for OEM parts can ensure compatibility and reliability, providing peace of mind for buyers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cost-efficiency. Buyers should negotiate MOQs that align with their purchasing capabilities to avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. For window regulator brushes, issuing an RFQ allows buyers to compare offers, ensuring they obtain the best value while meeting their technical specifications.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is essential for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thereby reducing potential disputes.

5. Aftermarket Parts

Aftermarket parts refer to components made by manufacturers other than the original equipment manufacturer. While often less expensive, these parts may vary in quality and compatibility. Buyers should carefully assess aftermarket options for window regulator brushes to ensure they meet required specifications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing window regulator brushes, ultimately leading to enhanced operational efficiency and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the window regulator brushes Sector

What Are the Key Drivers Shaping the Global Window Regulator Brushes Market?

The global window regulator brushes market is experiencing significant shifts driven by various factors. As automotive manufacturers increasingly prioritize cost-efficiency and durability, the demand for high-quality brushes that can withstand wear and tear is rising. This trend is particularly pertinent for international B2B buyers in Africa, South America, the Middle East, and Europe, where varying climatic conditions can affect the longevity of window regulators. Additionally, the growing trend towards electric vehicles (EVs) is influencing sourcing strategies, as these vehicles often require specialized components, including window regulator brushes designed for enhanced performance.

Moreover, technological advancements in manufacturing processes, such as automation and precision engineering, are enabling suppliers to produce brushes with improved specifications, reducing lead times and costs. In markets like Brazil and Vietnam, where local manufacturing is on the rise, buyers are increasingly looking for suppliers that can deliver customized solutions tailored to specific automotive models. This shift is driving a competitive landscape where innovation and flexibility are paramount.

How Are Sustainability and Ethical Sourcing Influencing the Window Regulator Brushes Market?

Sustainability is becoming a central theme in the window regulator brushes sector, reflecting a broader industry shift towards environmentally responsible practices. Buyers are increasingly aware of the environmental impact of their sourcing decisions, prompting them to seek suppliers who adhere to sustainable manufacturing practices. This includes the use of eco-friendly materials, such as recycled plastics and sustainably sourced carbon, in the production of window regulator brushes.

Ethical supply chains are also gaining prominence, with an emphasis on transparency and fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade certification are becoming essential criteria for B2B buyers. Suppliers that can demonstrate their commitment to sustainability not only enhance their market appeal but also build long-term relationships with buyers who prioritize ethical considerations.

The integration of ‘green’ certifications into the sourcing process can significantly influence purchasing decisions, particularly in regions like Europe, where regulatory frameworks are increasingly stringent. By aligning with suppliers who prioritize sustainability, B2B buyers can contribute to a more sustainable automotive industry while also meeting consumer demand for environmentally friendly products.

What Is the Historical Context of Window Regulator Brushes and Their Evolution?

The history of window regulator brushes dates back to the early days of automotive manufacturing when manual window cranks were commonplace. As vehicles evolved towards electric windows in the late 20th century, the need for efficient and reliable window regulator brushes became apparent. Initially, these components were made from basic materials, often resulting in frequent replacements and repairs.

Over the years, advancements in materials science and manufacturing technologies have led to the development of brushes that offer superior performance, longevity, and resistance to wear. Today, the focus is not only on functionality but also on sustainability and ethical sourcing. The evolution of window regulator brushes reflects broader industry trends towards innovation and responsibility, making it essential for B2B buyers to understand the historical context as they navigate modern sourcing dynamics.

This historical insight provides buyers with a deeper appreciation of the product’s development, enabling them to make informed decisions when selecting suppliers in the contemporary market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of window regulator brushes

-

How do I identify the right window regulator brushes for my application?

To identify the correct window regulator brushes, first check the specifications of the motor you are working with, including dimensions and material type. Cross-reference these details with manufacturer part numbers or consult with your supplier for compatibility. If exact replacements aren’t available, consider sourcing brushes that can be customized or modified. It’s also beneficial to look for brushes used in similar models or brands to ensure a proper fit, as many automotive parts are standardized across different vehicle models. -

What is the best material for window regulator brushes?

The best materials for window regulator brushes typically include high-grade carbon or graphite composites. These materials provide excellent conductivity and durability, ensuring consistent performance under varying temperature and pressure conditions. When sourcing, prioritize brushes that have been tested for longevity and performance in automotive applications. Always verify that the material used meets industry standards, particularly for the specific automotive sectors you are targeting. -

How can I ensure quality assurance when sourcing window regulator brushes internationally?

To ensure quality assurance, establish clear quality control (QC) measures with your suppliers. This may include requesting samples for testing, conducting factory audits, and reviewing certifications such as ISO. Additionally, consider implementing a robust inspection process upon receipt of goods, which can include dimensional checks and performance testing. Maintaining open communication with suppliers regarding expectations and standards is crucial to mitigate risks associated with international sourcing. -

What are the common payment terms for international purchases of window regulator brushes?

Common payment terms for international purchases can vary but often include options like Letter of Credit (LC), advance payment, or payment on delivery. It’s essential to negotiate terms that protect both parties, ensuring that you receive quality products while providing your supplier with assurance of payment. Additionally, consider using escrow services for higher-value transactions to further secure your investment until you confirm satisfactory delivery and quality. -

What are typical minimum order quantities (MOQ) for window regulator brushes?

Minimum order quantities (MOQ) for window regulator brushes can differ significantly based on the supplier and the specific brush type. Typically, MOQs range from 100 to 1,000 pieces, depending on manufacturing capabilities and inventory levels. When negotiating with suppliers, consider discussing your needs and potential flexibility in order sizes, especially if you are testing new products or markets. Some suppliers may offer lower MOQs for established relationships or first-time orders. -

How do I vet suppliers for window regulator brushes effectively?

Effective supplier vetting involves researching the supplier’s reputation, financial stability, and previous customer reviews. Request references and check their track record for delivering quality products on time. Additionally, assess their manufacturing capabilities and certifications to ensure they meet industry standards. If possible, visit their facilities or engage third-party inspection services to verify quality processes and operational efficiency. -

What logistics considerations should I keep in mind when importing window regulator brushes?

Logistics considerations include understanding shipping options, transit times, and customs regulations specific to your country. Evaluate freight forwarders who can handle the complexities of international shipping and customs clearance. Additionally, consider the implications of tariffs and duties on your import costs. Ensure you have a reliable supply chain strategy that includes contingency plans for delays or disruptions in logistics. -

Can I customize window regulator brushes for specific applications?

Yes, many manufacturers offer customization options for window regulator brushes, allowing you to tailor specifications such as size, shape, and material to fit unique applications. When pursuing customization, provide detailed specifications and performance requirements to your supplier. Be prepared for potential lead times that may be longer than standard products, and consider the implications of higher costs associated with bespoke manufacturing.

Top 2 Window Regulator Brushes Manufacturers & Suppliers List

1. Insight Central – Honda Insight Window Regulator Motor Brushes Repair

Domain: insightcentral.net

Registered: 2000 (25 years)

Introduction: Repair Window Regulator Motor Brushes for Honda Insight (2000 model). Replacement options include purchasing similar brushes for $8 (2 pairs for Dremel 3000 tool) or finding an identical part from a 2002-2005 Honda Civic for $40. A new window regulator assembly from Majestic costs $392.31. The repair involves replacing worn commutator brushes, which are known to wear out over time.

2. Reddit – E30 Window Motor Issues

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The window motor for the E30 can experience several issues: 1. The brass bushing on the bottom of the motor shaft can rust onto the shaft, which should be a slip fit and well greased. 2. Carbon brushes can wear out, and lack of lubricant on the shaft surface can cause failure. 3. Windings should be checked for integrity, and brushes must be intact and long enough to contact the armature. 4. Cleani…

Strategic Sourcing Conclusion and Outlook for window regulator brushes

In the ever-evolving automotive industry, understanding the intricacies of window regulator brushes is essential for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. Strategic sourcing of these components can significantly reduce costs and enhance product reliability. As demonstrated in various discussions, opting for repairable parts or compatible substitutes can provide substantial savings over complete window regulator assemblies, which can be prohibitively expensive.

Moreover, identifying commonalities across different vehicle models can streamline sourcing efforts, allowing buyers to leverage bulk purchasing and potentially negotiate better pricing. As the market continues to advance towards innovative solutions, such as 3D printing for component fabrication, staying informed about emerging technologies can further enhance procurement strategies.

Looking ahead, B2B buyers should prioritize building relationships with reliable suppliers who understand local market dynamics and can provide tailored solutions. By embracing strategic sourcing practices, companies can not only improve their bottom line but also contribute to a more sustainable supply chain. Engage with industry experts and explore collaborative opportunities to ensure your business remains competitive in this vital sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.