Top 2 Universal Grinding Corporation Suppliers (And How to Choose)

Introduction: Navigating the Global Market for universal grinding corporation

In the ever-evolving landscape of global manufacturing, sourcing precision grinding services from a reliable partner like Universal Grinding Corporation presents a unique challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly demand high-quality components, understanding the nuances of grinding operations—such as double disc grinding, centerless grinding, and secondary machining—becomes essential. This guide serves as a comprehensive resource, offering insights into the various types of grinding services available, their applications in diverse sectors including aerospace and automotive, and strategies for effectively vetting suppliers.

By delving into the intricacies of cost structures and quality certifications, particularly the ISO 9001:2008 standard upheld by Universal Grinding Corporation, this guide empowers international buyers to make informed purchasing decisions. Whether you are based in Germany or Saudi Arabia, the insights provided here will help you navigate the complexities of sourcing grinding services tailored to your specific needs. Understanding these factors not only mitigates risks but also enhances operational efficiency, ensuring that your supply chain remains robust and responsive in a competitive global market. Embrace the knowledge within this guide to forge lasting partnerships with trusted grinding service providers, ultimately driving your business success.

Understanding universal grinding corporation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Double Disc Grinding | Highly efficient, reduces pre-machining costs by up to 50% | Aerospace, automotive, industrial manufacturing | Pros: Cost-effective, high throughput. Cons: Limited to specific shapes. |

| Centerless Infeed Grinding | Thrufeed and profile grinding capabilities | Automotive components, medical devices | Pros: Versatile, high precision. Cons: Setup complexity for varied sizes. |

| Centerless Bar & Tube Grinding | Handles a wide range of diameters and lengths | Oil & gas, construction, manufacturing | Pros: Accommodates large batches, efficient. Cons: May require extensive tooling. |

| Blanchard Grinding | Flat surface grinding for large parts | Heavy machinery, aerospace | Pros: Fast material removal, cost-effective for large surfaces. Cons: Limited to flat surfaces. |

| Secondary Machining Operations | Includes chrome plating, heat treatment, and more | Parts finishing, aerospace, automotive | Pros: Comprehensive service offerings. Cons: Additional lead time for secondary processes. |

What Are the Characteristics of Double Disc Grinding?

Double disc grinding is a highly efficient process where two grinding wheels grind both sides of a workpiece simultaneously. This method significantly reduces pre-machining costs, making it ideal for high-volume production runs in industries like aerospace and automotive. When considering double disc grinding, buyers should evaluate the shape and material of their components, as this method is best suited for specific geometries.

How Does Centerless Infeed Grinding Benefit B2B Buyers?

Centerless infeed grinding is distinguished by its ability to grind components without the need for a central axis. This technique allows for both thrufeed and profile grinding, making it versatile for various applications, particularly in the automotive and medical sectors. B2B buyers should consider the precision requirements of their components and the complexity of setup, as this can affect lead times and costs.

Why Choose Centerless Bar & Tube Grinding?

Centerless bar and tube grinding is optimized for handling a diverse range of diameters and lengths, making it suitable for industries such as oil and gas and construction. This method is particularly efficient for large batch processing, allowing manufacturers to meet high demand with consistent quality. Buyers should assess their production volume and the specific dimensions of their materials when selecting this grinding type.

What Are the Advantages of Blanchard Grinding?

Blanchard grinding is known for its ability to quickly grind large, flat surfaces. It is commonly used in industries requiring heavy machinery components and aerospace applications. The speed of material removal makes it a cost-effective choice for large parts. However, buyers should be aware that this method is limited to flat surfaces, which may not suit all applications.

How Do Secondary Machining Operations Enhance Grinding Services?

Secondary machining operations, such as chrome plating and heat treatment, complement primary grinding processes by providing finishing touches that enhance durability and performance. This comprehensive service offering is especially beneficial for manufacturers looking to streamline their supply chain. Buyers should consider the additional lead time required for these operations and how they impact overall production schedules.

Key Industrial Applications of universal grinding corporation

| Industry/Sector | Specific Application of Universal Grinding Corporation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision grinding of aircraft components, such as turbine blades | Ensures high performance, reliability, and safety standards | Certification (e.g., ISO 9001), material specifications, lead times |

| Automotive | Centerless grinding of engine components and shafts | Enhances efficiency and precision in engine performance | Tolerance requirements, volume of parts, delivery schedules |

| Medical Devices | Grinding of surgical instruments and implants | Guarantees biocompatibility and precision for patient safety | Regulatory compliance, material certifications, quality assurance |

| Industrial Manufacturing | Double disc grinding for metal parts and assemblies | Reduces pre-machining costs and increases production speed | Equipment compatibility, batch size, and pricing |

| Electronics | Precision lapping of components for circuit boards | Improves signal quality and component reliability | Tolerance levels, material types, and delivery timelines |

How is Universal Grinding Corporation Applied in the Aerospace Sector?

In the aerospace industry, Universal Grinding Corporation specializes in precision grinding of critical components, such as turbine blades and landing gear parts. These components must meet stringent safety and performance standards to ensure aircraft reliability. By utilizing advanced grinding techniques, U.G.C. helps aerospace manufacturers achieve the necessary tolerances and finishes required for high-performance applications. International buyers, particularly from regions like Europe and the Middle East, should ensure that the supplier meets relevant aerospace certifications (e.g., AS9100) and can provide detailed documentation of quality control processes.

What Role Does Universal Grinding Corporation Play in Automotive Manufacturing?

Universal Grinding Corporation offers centerless grinding services for automotive engine components, including crankshafts and camshafts. This process is essential for producing parts with high precision and minimal runout, which directly impacts engine efficiency and durability. Automotive manufacturers, especially those in Africa and South America, should consider U.G.C.’s capabilities to handle varying batch sizes and specific tolerances, ensuring timely delivery and compliance with automotive industry standards.

How Does Universal Grinding Corporation Support Medical Device Manufacturing?

In the medical sector, U.G.C. provides precision grinding services for surgical instruments and implants, where biocompatibility and precision are paramount. The grinding process enhances the surface finish and ensures the instruments meet stringent regulatory requirements. Buyers in this sector must prioritize suppliers that are familiar with medical device regulations, such as ISO 13485, and can demonstrate a robust quality assurance framework to ensure patient safety and product reliability.

What Benefits Does Double Disc Grinding Offer to Industrial Manufacturing?

Double disc grinding is a key service provided by Universal Grinding Corporation for various industrial applications, particularly in the production of metal parts and assemblies. This grinding method significantly reduces pre-machining costs—up to 50%—while enhancing production efficiency. Companies in need of high-volume parts, especially in Europe and the Middle East, should evaluate U.G.C.’s experience with diverse materials and its ability to meet specific production timelines and pricing structures.

How is Universal Grinding Corporation Involved in Electronics Manufacturing?

In the electronics sector, U.G.C. specializes in precision lapping of components used in circuit boards, ensuring optimal signal quality and component reliability. This process is critical in producing high-performance electronic devices. International buyers, particularly from South America and Europe, should assess U.G.C.’s capabilities to handle specific material types and tight tolerances, as well as its experience in meeting the unique demands of the electronics industry.

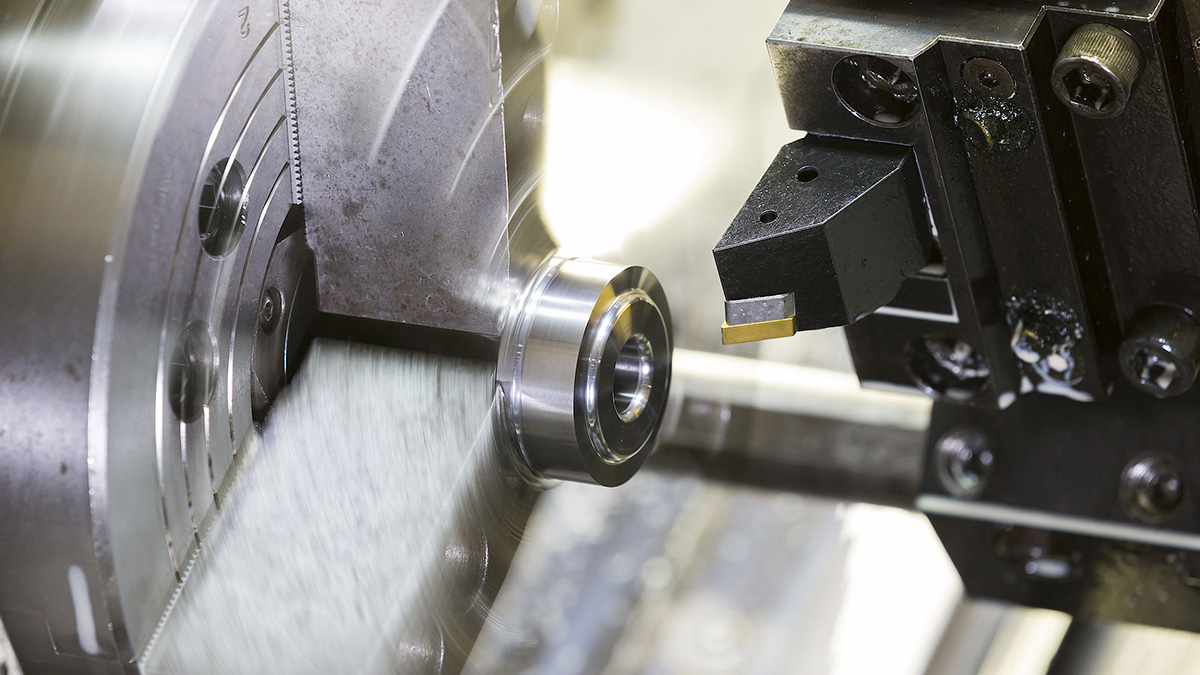

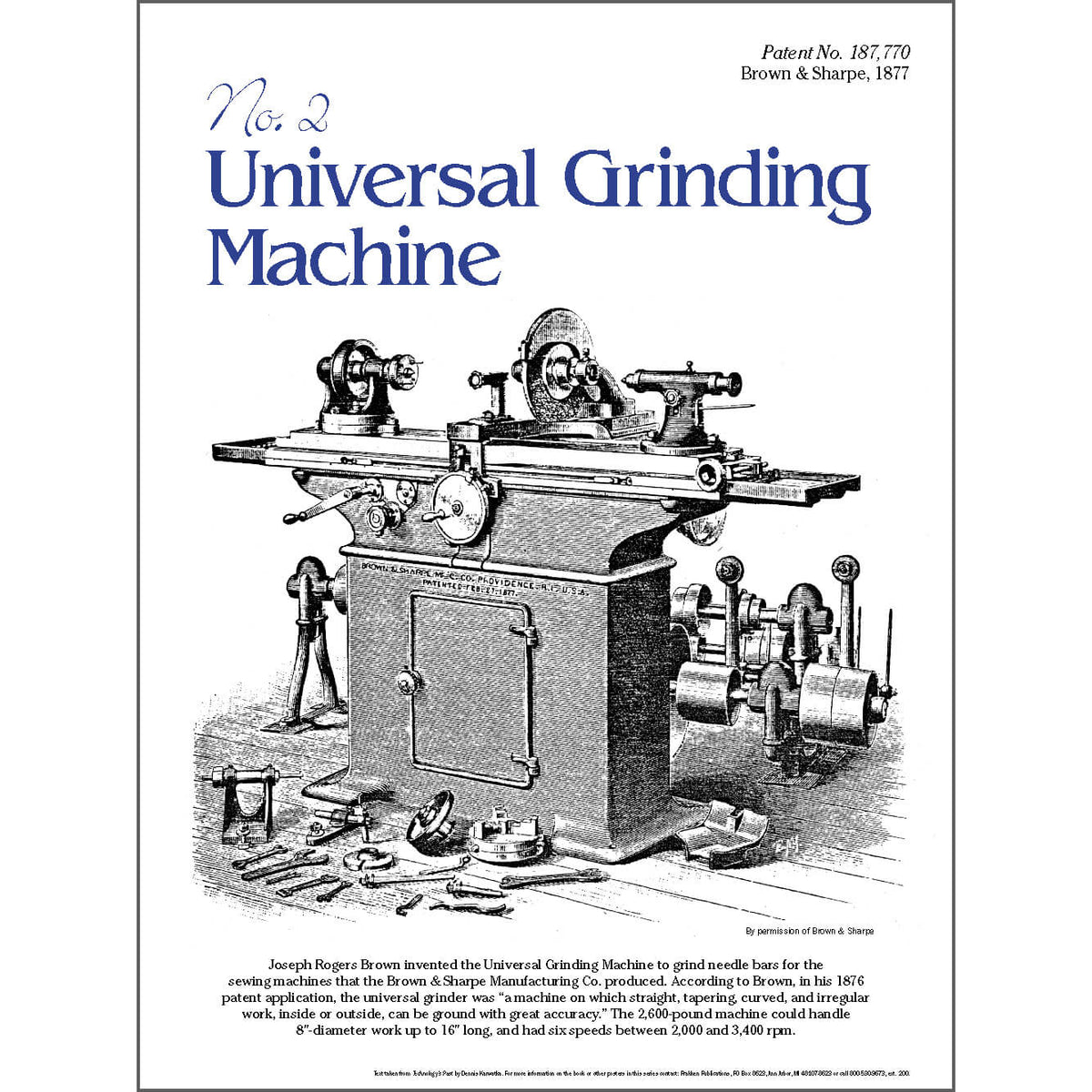

Illustrative image related to universal grinding corporation

3 Common User Pain Points for ‘universal grinding corporation’ & Their Solutions

Scenario 1: Navigating Complex Specifications for Precision Grinding Services

The Problem: B2B buyers often struggle with the intricacies of specifying the right grinding services for their specific applications. For instance, a manufacturer in the aerospace sector may require precise tolerances and finishes on components made from exotic materials, yet they may not fully understand the capabilities of Universal Grinding Corporation (UGC). This lack of clarity can lead to selecting the wrong grinding method, resulting in increased costs, project delays, and compromised product quality.

The Solution: To effectively navigate these complexities, buyers should engage directly with UGC’s technical support team early in the project planning phase. Providing detailed information about the materials, dimensions, and desired tolerances will help the team recommend the most suitable grinding service, whether it be double disc grinding for efficiency or centerless grinding for high precision. Additionally, buyers should request samples or trial runs to ensure that UGC’s capabilities align with their project requirements. Establishing a clear line of communication will not only streamline the process but also foster a partnership that enhances product quality and reduces lead times.

Scenario 2: Overcoming Production Bottlenecks Due to Equipment Limitations

The Problem: Companies may face production bottlenecks when their in-house grinding equipment fails to meet the demands of larger or more complex projects. For example, a medical device manufacturer may require a large batch of precision-ground parts but find that their current setup is inefficient or incapable of handling the volume or specific tolerances required. This scenario can lead to delays in production schedules and increased operational costs.

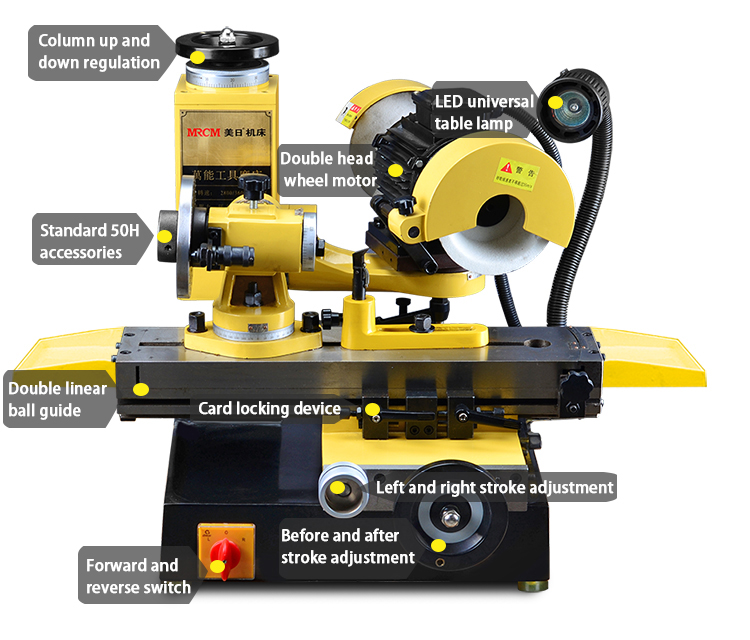

Illustrative image related to universal grinding corporation

The Solution: Partnering with UGC can be a strategic move to alleviate these bottlenecks. Buyers should assess their current grinding workload and identify projects that exceed their in-house capabilities. By outsourcing these specific grinding operations to UGC, which offers a wide range of services—including centerless and double disc grinding—they can ensure timely delivery without compromising quality. Moreover, negotiating long-term contracts or establishing a recurring service agreement can provide predictable turnaround times and pricing, helping buyers better manage their production schedules and costs.

Scenario 3: Addressing Quality Assurance Concerns in Outsourced Grinding Services

The Problem: Quality assurance is a critical concern for B2B buyers, particularly when outsourcing grinding services. A company may worry about the consistency and reliability of the finished products, especially when dealing with high-stakes industries such as aerospace or automotive. If the grinding process is not executed to the necessary standards, it can lead to defects, recalls, and significant financial losses.

The Solution: To mitigate quality assurance concerns, buyers should leverage UGC’s ISO 9001:2008 certification as a benchmark for quality. It’s essential to initiate a thorough vetting process that includes reviewing UGC’s quality control protocols and production processes. Buyers can also request documentation of past projects and customer testimonials to assess UGC’s track record. Establishing clear quality metrics and conducting periodic audits during the production process can further enhance confidence. Collaborating on quality assurance agreements that outline specific tolerances and performance expectations will create a framework for accountability, ensuring that the grinding services meet or exceed the required standards for every batch produced.

Strategic Material Selection Guide for universal grinding corporation

What Are the Key Properties of Common Materials Used in Grinding Operations?

When selecting materials for grinding operations at Universal Grinding Corporation, it’s essential to consider the specific properties that will influence performance and application suitability. Below, we analyze four common materials used in grinding processes, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel Alloys

Key Properties: Steel alloys, particularly tool steels, exhibit high hardness and wear resistance, making them suitable for grinding applications requiring durability. They typically have a temperature rating of up to 600°C and can withstand moderate pressure.

Pros & Cons: Steel alloys are durable and can be machined to tight tolerances, making them ideal for precision parts. However, they can be more expensive than other materials and may require complex manufacturing processes, such as heat treatment, to achieve the desired properties.

Impact on Application: Steel alloys are compatible with various media and are often used in aerospace and automotive applications due to their strength and reliability.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A681 for tool steels. Additionally, understanding local sourcing options for high-quality steel can impact overall costs.

2. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, corrosion-resistant, and have good thermal conductivity. They can operate effectively at temperatures up to 300°C, making them suitable for many industrial applications.

Pros & Cons: The primary advantage of aluminum alloys is their low weight, which can reduce overall product weight and improve efficiency in applications. However, they are less durable than steel alloys and may not withstand high-pressure applications as effectively.

Impact on Application: Aluminum’s compatibility with various media makes it a popular choice in industries like automotive and aerospace, where weight savings are critical.

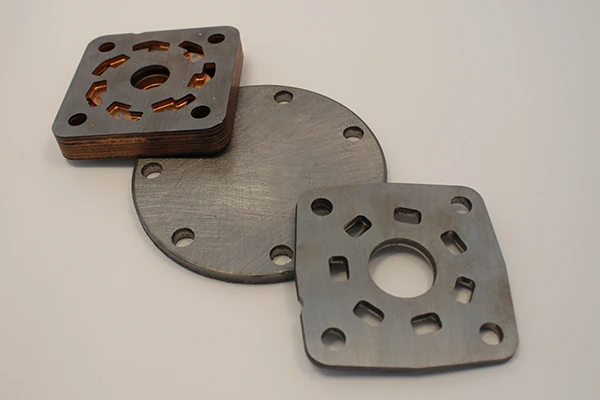

Illustrative image related to universal grinding corporation

Considerations for International Buyers: Buyers should be aware of the specific alloy grades, such as 6061 or 7075, and their compliance with standards like DIN EN 573. Understanding local availability can help mitigate costs.

3. Titanium Alloys

Key Properties: Titanium alloys are known for their high strength-to-weight ratio and excellent corrosion resistance, functioning effectively at temperatures up to 400°C. They are particularly advantageous in high-stress applications.

Pros & Cons: The key advantage of titanium is its exceptional strength and resistance to corrosion, making it ideal for demanding environments. However, titanium alloys are more expensive and can be challenging to machine due to their toughness.

Impact on Application: Titanium is often used in aerospace and medical applications where performance and reliability are paramount.

Considerations for International Buyers: Buyers should ensure compliance with ASTM F136 for titanium alloys, particularly in medical applications. Understanding the local market for titanium can also affect pricing and availability.

4. Composite Materials

Key Properties: Composites, such as fiberglass and carbon fiber, offer unique properties like lightweight, high strength, and excellent corrosion resistance. They can operate effectively at moderate temperatures but are sensitive to extreme conditions.

Pros & Cons: Composites are advantageous for applications requiring lightweight materials with high strength. However, they can be more expensive to manufacture and may require specialized machining techniques.

Impact on Application: Composites are commonly used in industries like aerospace and automotive, where weight reduction is critical without sacrificing strength.

Considerations for International Buyers: Buyers should be aware of compliance with standards like ASTM D3039 for composite materials. Additionally, understanding the local supply chain for composite materials can influence project timelines and costs.

Summary Table of Material Selection for Universal Grinding Corporation

| Material | Typical Use Case for Universal Grinding Corporation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Precision components in aerospace and automotive | High durability and wear resistance | Higher cost and complex manufacturing | High |

| Aluminum Alloys | Lightweight parts in automotive and aerospace | Low weight and good corrosion resistance | Less durable under high pressure | Medium |

| Titanium Alloys | High-stress applications in aerospace and medical | Excellent strength-to-weight ratio | Expensive and challenging to machine | High |

| Composite Materials | Lightweight structures in aerospace and automotive | High strength with low weight | Expensive and requires specialized machining | Medium to High |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing grinding materials from Universal Grinding Corporation. Understanding the properties and implications of each material will ensure that buyers select the right options for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for universal grinding corporation

What Are the Key Stages in the Manufacturing Processes at Universal Grinding Corporation?

Universal Grinding Corporation (UGC) employs a comprehensive manufacturing process that ensures the delivery of high-quality grinding services. The process consists of several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves sourcing raw materials that meet stringent quality standards. UGC utilizes a variety of materials, including ferrous and non-ferrous metals, plastics, and exotic materials like fiberglass. Each material is carefully inspected upon receipt to ensure it meets the specified requirements before moving to the next stage.

-

Forming: This stage encompasses various grinding techniques tailored to the specific needs of clients. UGC specializes in double disc grinding, centerless infeed grinding, and jig grinding, among others. Each technique is selected based on factors such as part geometry, size, and material type. For instance, double disc grinding is renowned for its efficiency, significantly reducing pre-machining costs by up to 50%.

-

Assembly: Although grinding operations are primarily focused on surface preparation and finishing, UGC also offers secondary machining operations. This includes services such as chrome plating, heat treatment, and laser marking, which can be integrated into the assembly process to enhance the functionality and durability of the components.

-

Finishing: The final stage of manufacturing involves achieving the required surface finish and tolerances. UGC employs advanced finishing techniques to ensure that products meet the exact specifications demanded by clients. This may include surface grinding, lapping, and polishing, which are essential for industries such as aerospace and medical manufacturing where precision is paramount.

How Does Universal Grinding Corporation Ensure Quality Assurance?

Quality assurance is a cornerstone of UGC’s operations, with a commitment to maintaining high standards throughout the manufacturing process. The company adheres to internationally recognized quality management systems, particularly ISO 9001:2008 certification, which underscores its dedication to continuous improvement and customer satisfaction.

-

International Standards and Industry-Specific Certifications: UGC’s ISO certification ensures that its processes are systematically monitored and continuously improved. Additionally, depending on client requirements, UGC may also comply with industry-specific standards such as CE marking for European markets or API specifications for the oil and gas industry. This adherence to various standards helps in ensuring product reliability and safety.

-

Quality Control Checkpoints: UGC implements a robust quality control framework that includes several critical checkpoints:

– Incoming Quality Control (IQC): Raw materials undergo rigorous inspection upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor equipment performance and product dimensions, ensuring they remain within tolerances.

– Final Quality Control (FQC): Before products are shipped, a final inspection is carried out to verify that all quality standards have been met and that the products are ready for delivery. -

Common Testing Methods: UGC utilizes a range of testing methods to ensure quality, including dimensional checks, surface finish measurements, and material composition analysis. These tests help to confirm that the finished products meet the required specifications and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several approaches to ensure confidence in UGC’s quality assurance processes:

-

Supplier Audits: Prospective buyers can conduct audits of UGC’s facilities to observe manufacturing processes and quality control measures firsthand. This can provide insight into operational capabilities and adherence to quality standards.

-

Quality Assurance Reports: UGC can provide detailed quality assurance reports that outline their processes, certifications, and compliance with international standards. These documents serve as valuable resources for buyers to assess the company’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can help validate UGC’s quality practices. These agencies can conduct independent assessments of the manufacturing processes and quality control measures, ensuring that buyers receive unbiased evaluations.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances when working with suppliers like UGC. Understanding these can enhance the buyer-supplier relationship and ensure compliance with local regulations and standards.

Illustrative image related to universal grinding corporation

-

Cultural and Regulatory Differences: Buyers should be aware of cultural differences that may affect communication and expectations regarding quality. Furthermore, they must understand the regulatory landscape in their respective countries to ensure that products meet local standards.

-

Documentation and Traceability: International buyers should emphasize the importance of documentation and traceability in quality control. UGC should maintain detailed records of inspections, testing results, and certifications, which can help in compliance with international trade regulations.

-

Flexibility in Quality Standards: As different regions may have varying quality expectations, UGC must demonstrate flexibility in adapting its quality standards to meet the specific requirements of international clients. This may involve tailoring processes to align with the buyer’s industry standards and preferences.

In conclusion, Universal Grinding Corporation’s meticulous manufacturing processes and robust quality assurance practices make it a reliable partner for international B2B buyers. By understanding the intricacies of UGC’s operations and quality control measures, buyers can ensure they are making informed decisions that align with their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘universal grinding corporation’

In the competitive landscape of precision grinding, sourcing the right partner is crucial for achieving high-quality results while maintaining efficiency and cost-effectiveness. This guide provides a systematic approach for B2B buyers looking to procure services from Universal Grinding Corporation (U.G.C.), ensuring that all critical factors are considered in the decision-making process.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements. This includes the materials you need processed (ferrous, non-ferrous, plastics, etc.), the specific grinding methods (double disc, centerless, etc.), and tolerances required. Defining these specifications helps in effectively communicating your needs and ensuring the supplier can meet them.

Step 2: ✅ Verify Supplier Certifications

Ensure that the supplier holds relevant industry certifications, such as ISO 9001. Certification indicates a commitment to quality management and operational excellence. For international buyers, this is particularly important as it ensures compliance with global standards.

Step 3: Evaluate the Range of Services Offered

Investigate the variety of grinding services provided by U.G.C. Beyond basic grinding, look for secondary operations such as chrome plating, heat treating, and laser marking. A comprehensive service offering can reduce the need for multiple suppliers, streamlining your procurement process and potentially lowering costs.

Step 4: Assess Production Capabilities and Equipment

Review U.G.C.’s production capabilities, including the types of equipment they utilize. Advanced machinery can significantly impact the quality and efficiency of grinding operations. Inquire about their capacity to handle your specific volume requirements and the range of dimensions they can accommodate.

Step 5: ✅ Request Samples or Case Studies

Before finalizing your decision, request samples of previous work or case studies related to your industry. This will provide insight into the supplier’s quality and reliability. Pay attention to how their work has met similar specifications and the feedback from past clients.

Step 6: Discuss Lead Times and Flexibility

Establish clear expectations regarding lead times for orders and the supplier’s flexibility to accommodate changes. Understanding these factors is vital for planning your production schedules and maintaining supply chain efficiency.

Illustrative image related to universal grinding corporation

Step 7: ✅ Negotiate Terms and Conditions

Once you’ve evaluated your options, engage in discussions about pricing, payment terms, and warranty policies. Clear communication on these aspects will help build a mutually beneficial relationship and prevent misunderstandings in the future.

By following this checklist, B2B buyers can ensure a thorough and informed sourcing process when partnering with Universal Grinding Corporation, ultimately leading to enhanced operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for universal grinding corporation Sourcing

What Are the Key Cost Components in Universal Grinding Corporation’s Pricing Structure?

When considering sourcing from Universal Grinding Corporation, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to universal grinding corporation

-

Materials: The selection of materials directly influences pricing. Universal Grinding handles a wide range of materials, including ferrous and non-ferrous metals, plastics, and even exotic materials like glass and rubber. The cost will vary significantly based on the material type, availability, and market fluctuations.

-

Labor: Skilled labor is a critical component in the grinding process. Universal Grinding’s experienced technicians ensure precision and quality, which can impact labor costs. The complexity of the grinding operation and the expertise required also factor into labor pricing.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Given the advanced technology used by Universal Grinding, overhead can be significant but is necessary to maintain high-quality standards.

-

Tooling: Specialized tooling for grinding operations adds to the costs. Custom tooling may be required for specific projects, which can lead to higher expenses initially but can enhance efficiency and precision in the long run.

-

Quality Control (QC): Rigorous quality assurance processes ensure that products meet industry standards. The costs associated with QC are integral to maintaining ISO 9001 certification and can affect overall pricing.

-

Logistics: Shipping and handling charges, especially for international transactions, can add to the final cost. Factors like distance, freight methods, and customs duties play a significant role in logistics expenses.

-

Margin: Finally, the profit margin applied by Universal Grinding will be influenced by the above components, market conditions, and competition.

How Do Price Influencers Affect Sourcing Decisions for B2B Buyers?

Several key factors influence the pricing of grinding services, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Buyers should consider their needs and negotiate volume discounts.

-

Specifications and Customization: Customized grinding specifications can increase costs. Clearly defining requirements upfront can help avoid unexpected expenses.

-

Material Selection: The choice of material affects both price and availability. Buyers should evaluate the cost-benefit of different materials based on their application.

-

Quality and Certifications: Higher quality and certified products may come at a premium but can reduce long-term costs associated with failures or rework.

-

Supplier Factors: The supplier’s reputation, reliability, and financial stability can influence pricing. Established suppliers like Universal Grinding may command higher prices due to their proven track record.

-

Incoterms: Understanding the terms of trade, such as FOB or CIF, is crucial for managing total costs. Incoterms affect who is responsible for shipping costs and risks, impacting overall pricing.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, here are some negotiation tips:

-

Establish Clear Communication: Be explicit about your requirements and expectations. Miscommunication can lead to costly mistakes.

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term savings rather than just the initial price. Consider factors like durability, maintenance, and logistics.

-

Research Market Prices: Understand the competitive landscape and gather intelligence on pricing from various suppliers. This knowledge can empower negotiations.

-

Negotiate Payment Terms: Flexibility in payment terms can enhance cash flow. Discuss options such as payment on delivery or extended payment terms.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms in the long run.

Are There Pricing Nuances for International B2B Buyers to Consider?

International buyers should be aware of specific pricing nuances, including:

-

Currency Fluctuations: Exchange rates can significantly impact costs. Consider negotiating prices in a stable currency to mitigate risks.

-

Import Duties and Taxes: Understand the local regulations regarding import duties and taxes that may apply to your purchases.

-

Shipping Costs: International logistics can be complex and expensive. Factor in shipping times and costs when planning your procurement strategy.

In summary, buyers should approach sourcing from Universal Grinding Corporation with a comprehensive understanding of cost components, price influencers, and negotiation strategies to ensure a successful partnership.

Alternatives Analysis: Comparing universal grinding corporation With Other Solutions

Understanding Alternatives in Grinding Solutions

In the competitive landscape of precision machining, businesses often seek various grinding solutions that cater to specific operational needs. Universal Grinding Corporation (UGC) is a notable player, but it’s essential to evaluate its offerings against other viable alternatives in the market. This analysis will focus on two alternatives: Trinel, Inc. and Alternative Surface Grinding, both of which provide specialized grinding services.

Comparison Table

| Comparison Aspect | Universal Grinding Corporation | Trinel, Inc. | Alternative Surface Grinding |

|---|---|---|---|

| Performance | High precision across diverse materials | Exceptional microfinishing capabilities | Focus on critical components and tight tolerances |

| Cost | Competitive pricing with potential savings on pre-machining | Moderate pricing, higher for specialized services | Generally higher due to precision focus |

| Ease of Implementation | Established processes, easy to integrate | Requires initial assessment for specific needs | Simple onboarding for common projects |

| Maintenance | Regular maintenance schedules in place | Ongoing improvements, equipment upgrades | High maintenance standards for precision tools |

| Best Use Case | Aerospace, automotive, and industrial manufacturing | Bar grinding and specialized tight tolerance jobs | Aerospace, transportation, and agriculture sectors |

In-Depth Analysis of Alternatives

What Sets Trinel, Inc. Apart?

Trinel, Inc., established in 1986, specializes in bar grinding with a strong emphasis on quality and customer satisfaction. The company’s capabilities include centerless grinding and polishing, achieving tight tolerances that are crucial for applications such as pump and boat shafts. While Trinel’s performance is commendable, its pricing can be moderate, particularly for specialized jobs. Buyers should consider Trinel when their projects demand high precision and can accommodate a slightly higher cost.

How Does Alternative Surface Grinding Excel?

Alternative Surface Grinding, located in Brunswick, Ohio, focuses on precision surface grinding services for critical components. With a reputation for meticulous craftsmanship, this company excels in microfinishing and ancillary services like heat treating and tumbling. Their commitment to maintaining tight tolerances makes them an ideal choice for industries like aerospace and transportation. However, this high level of precision often comes with a higher price tag, which may not be suitable for all budgets. Businesses looking for exceptional quality in critical components should consider this option.

Making the Right Choice for Your Grinding Needs

Choosing the right grinding solution depends on several factors, including the specific requirements of your projects, budget constraints, and the level of precision needed. Universal Grinding Corporation offers a broad range of services that may suit various industries, while alternatives like Trinel, Inc. and Alternative Surface Grinding provide specialized capabilities that could be beneficial for niche applications. B2B buyers should carefully assess their operational needs and the performance characteristics of each option to ensure they select a solution that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for universal grinding corporation

What Are the Critical Technical Properties for Grinding Services?

Understanding the essential technical properties associated with grinding services is crucial for B2B buyers, particularly in industries like aerospace, automotive, and medical manufacturing. Here are some key specifications that buyers should consider:

1. Material Grade

Material grade refers to the specific classification of the raw materials being processed, such as ferrous metals, non-ferrous metals, plastics, and ceramics. The material grade affects the grinding process and the final product’s performance. For example, aerospace components often require high-strength alloys, necessitating precise grinding techniques to maintain structural integrity.

Illustrative image related to universal grinding corporation

2. Tolerance

Tolerance indicates the allowable deviation from a specified dimension. In grinding operations, tight tolerances (often within ±0.0001 inches) are critical for components that must fit together with high precision. Industries with stringent quality standards, such as aerospace and medical, rely heavily on precise tolerances to ensure safety and functionality.

3. Surface Finish

Surface finish measures the texture of the ground surface, typically expressed in microinches (μin) or micrometers (μm). A smoother surface finish can enhance product performance, reduce friction, and improve aesthetic appeal. For instance, components used in precision instruments often require a fine finish to ensure optimal performance.

4. Diameter and Length Capacity

The diameter and length capacity of the grinding equipment dictate the size of the components that can be processed. Universal Grinding Corporation specializes in grinding bars with diameters from .015″ to 9″ and lengths up to 60′. This flexibility enables manufacturers to meet diverse project requirements.

5. Grinding Method

Different grinding methods, such as double disc grinding, centerless grinding, and Blanchard grinding, have unique advantages depending on the application. For example, double disc grinding is known for its efficiency in reducing pre-machining costs, which is particularly beneficial for high-volume production runs.

What Are Common Trade Terms in the Grinding Industry?

Familiarity with industry jargon can facilitate smoother transactions and communications between buyers and suppliers. Here are several essential terms:

Illustrative image related to universal grinding corporation

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to procure components that need to meet specific quality and compatibility standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and production planning. Suppliers like Universal Grinding Corporation may have different MOQs based on the complexity of the grinding operations required.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. It enables buyers to compare costs and services effectively. In grinding operations, an RFQ should detail the material specifications, tolerances, and quantities required.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is essential for buyers looking to import grinding services or components from overseas.

5. Secondary Operations

Secondary operations refer to additional processes that may be needed after the primary grinding service, such as chrome plating, deburring, or heat treatment. Understanding the range of secondary operations can help buyers streamline their supply chains by consolidating services with a single provider.

Conclusion

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, grasping these technical properties and trade terms is vital. This knowledge not only aids in selecting the right grinding service provider but also enhances negotiation capabilities and overall project efficiency.

Navigating Market Dynamics and Sourcing Trends in the universal grinding corporation Sector

What Are the Current Market Dynamics and Key Trends in the Universal Grinding Sector?

The universal grinding sector is experiencing significant transformation driven by globalization, technological advancements, and evolving buyer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking grinding solutions that enhance efficiency and reduce costs. The adoption of advanced grinding technologies, such as double disc and centerless grinding, has become a focal point for manufacturers aiming to optimize production processes. These methods not only minimize pre-machining costs but also improve precision, which is critical in sectors like aerospace, automotive, and medical manufacturing.

Emerging trends in digitalization, such as the integration of IoT and AI in manufacturing, are reshaping sourcing strategies. B2B buyers are increasingly valuing suppliers that can provide real-time data on production capabilities, lead times, and quality control. Furthermore, the emphasis on just-in-time manufacturing is leading companies to seek grinding partners with flexible production capabilities and robust supply chains. As international trade barriers continue to lower, buyers are encouraged to explore diverse sourcing options, enabling them to tap into competitive pricing and specialized services across different regions.

How Is Sustainability and Ethical Sourcing Impacting the Universal Grinding Sector?

Sustainability has become a pivotal concern for B2B buyers in the universal grinding sector, particularly as environmental regulations tighten globally. Companies are increasingly pressured to adopt practices that mitigate their environmental impact. This includes sourcing materials and services that adhere to green certifications, such as ISO 14001, which demonstrate a commitment to environmental management.

Ethical sourcing is gaining traction as buyers prioritize suppliers that maintain transparent supply chains and fair labor practices. For the universal grinding corporation, this means adopting sustainable practices in grinding operations, such as minimizing waste through efficient resource use and implementing recycling programs for metal shavings and other byproducts. Additionally, investing in energy-efficient machinery not only reduces operational costs but also aligns with the growing demand for eco-friendly manufacturing processes. As buyers from regions like Germany and Saudi Arabia become more environmentally conscious, the ability to showcase sustainable practices will become a critical differentiator for suppliers in the universal grinding sector.

What Is the Historical Context of the Universal Grinding Corporation?

Established in 1944, Universal Grinding Corporation has built a reputation as a leader in precision grinding services. Over the decades, the company has evolved its capabilities to meet the changing demands of various industries, including aerospace, automotive, and medical manufacturing. The introduction of ISO 9001 certification in 2006 underscored its commitment to quality and customer satisfaction, enhancing its competitive edge in the global market.

Throughout its history, Universal Grinding has adapted to technological advancements, expanding its service offerings to include sophisticated grinding techniques like double disc and centerless grinding. This evolution has enabled the company to cater to a diverse clientele, ensuring it remains a trusted partner for international B2B buyers seeking high-quality grinding solutions. As it continues to innovate and align with market trends, Universal Grinding Corporation is well-positioned to meet the future needs of the grinding industry.

Frequently Asked Questions (FAQs) for B2B Buyers of universal grinding corporation

-

How do I ensure quality when sourcing grinding services internationally?

To ensure quality when sourcing grinding services, start by verifying the supplier’s certifications, such as ISO 9001:2008, which indicates a commitment to quality management standards. Request samples of their work to assess precision and consistency. Additionally, consider reviewing customer testimonials and case studies to gauge their reliability and service quality. Establishing a communication channel for ongoing quality checks can also help maintain standards throughout your partnership. -

What factors should I consider when selecting a grinding service provider?

When selecting a grinding service provider, consider their specialization in the materials and processes relevant to your needs. Evaluate their experience in your industry, whether it’s aerospace, automotive, or medical, as this can influence their understanding of your requirements. Additionally, assess their equipment capabilities, turnaround times, and flexibility in handling custom orders. Finally, ensure their pricing aligns with your budget while still offering high-quality service. -

What is the minimum order quantity (MOQ) for grinding services?

The minimum order quantity (MOQ) for grinding services can vary based on the specific service and materials required. Many providers, including Universal Grinding Corporation, may have flexible MOQs depending on the complexity of the project and the type of grinding service requested. It’s advisable to discuss your specific needs with the supplier to determine their MOQ and explore options for smaller orders if necessary. -

How can I customize my grinding service needs with Universal Grinding Corporation?

Customization is a key feature of Universal Grinding Corporation’s services. You can initiate customization by providing detailed specifications for your grinding requirements, including dimensions, tolerances, and material types. Engaging in a dialogue with their engineering team can help refine your project needs and ensure that the final product meets your expectations. They can also offer recommendations based on their extensive experience across various industries. -

What payment terms are typically offered for international orders?

Payment terms for international orders can vary widely among suppliers. Typically, options may include upfront payment, partial payment upon order confirmation, or net terms after delivery. Universal Grinding Corporation may offer flexible arrangements based on your business relationship and order size. It’s crucial to clarify payment conditions upfront to ensure smooth transactions and avoid misunderstandings. -

How does Universal Grinding Corporation handle logistics for international shipping?

Universal Grinding Corporation collaborates with reliable logistics partners to ensure timely and safe delivery of products internationally. They can assist in arranging shipping and customs clearance, providing you with tracking information throughout the process. It’s essential to communicate your preferred shipping method and any specific requirements you may have regarding delivery timelines or packaging to ensure a seamless experience. -

What are the secondary operations available after grinding?

In addition to grinding, Universal Grinding Corporation offers various secondary operations to enhance your components. These services include chrome plating, heat treating, deburring, and laser marking. Utilizing these secondary processes can streamline your supply chain by providing a one-stop-shop for multiple manufacturing needs, ensuring that your parts are ready for immediate use upon delivery. -

How can I verify the reputation of Universal Grinding Corporation before placing an order?

Verifying the reputation of Universal Grinding Corporation can be done through several methods. Start by reviewing their website for case studies and testimonials from previous clients. Additionally, consider reaching out to industry contacts or checking online forums and review platforms for feedback. Attending trade shows or industry conferences where they participate can also provide insights into their operations and customer interactions.

Top 2 Universal Grinding Corporation Manufacturers & Suppliers List

1. Universal Grinding Corporation – Precision Grinding Services

Domain: universalgrinding.com

Registered: 1996 (29 years)

Introduction: Universal Grinding Corporation offers a variety of grinding services including Double Disc Grinding, Centerless Infeed Grinding, Centerless Bar & Tube Grinding, ID/OD Grinding, Hypro Lapping, Blanchard Grinding, Surface Grinding, and Laser Marking. They handle ferrous, non-ferrous, and exotic materials such as glass, rubber, plastic, and fiberglass. Their Centerless Bar & Tube Grinding can accommo…

2. Precision Grinding – Grinding Services

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Precision Grinding – Grinding Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for universal grinding corporation

In conclusion, Universal Grinding Corporation (UGC) stands out as a premier provider of precision grinding services, offering a comprehensive suite of capabilities that cater to diverse industries such as aerospace, automotive, and medical manufacturing. The company’s commitment to quality is underscored by its ISO 9001-2008 certification, which assures international buyers of UGC’s adherence to high standards. With specialized services like double disc grinding and centerless grinding, UGC effectively reduces pre-machining costs while ensuring tight tolerances and superior finishes.

For B2B buyers across Africa, South America, the Middle East, and Europe, strategic sourcing from UGC presents a unique opportunity to optimize supply chains and enhance product quality. Engaging with UGC not only provides access to advanced grinding technologies but also fosters long-term partnerships that can lead to innovation and efficiency gains.

As industries continue to evolve, embracing strategic sourcing with Universal Grinding Corporation positions businesses to meet future demands with agility and precision. We encourage international buyers to reach out for tailored solutions that align with their manufacturing needs, ensuring a competitive edge in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to universal grinding corporation

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.