Top 2 Curtis Metal Finishing Suppliers (And How to Choose)

Introduction: Navigating the Global Market for curtis metal finishing

In an increasingly competitive global market, sourcing high-quality metal finishing solutions can pose significant challenges for international B2B buyers. Curtis metal finishing, known for its engineered protective coatings and advanced heat treatment services, is essential for industries ranging from automotive to construction. This guide provides an in-depth exploration of the diverse types of metal finishing services available, their applications, and critical factors to consider when vetting suppliers.

Buyers will gain insights into various finishing techniques such as coating, patching, and heat treatment, which are vital for enhancing product durability and performance. Additionally, the guide addresses cost considerations, logistical factors, and quality assurance processes, empowering decision-makers to make informed purchasing choices.

Particularly for businesses in Africa, South America, the Middle East, and Europe—regions that are rapidly industrializing and expanding—this guide serves as a strategic resource. By understanding the global landscape of Curtis metal finishing, buyers can streamline their sourcing processes, ensuring they partner with reliable suppliers who meet their quality standards and delivery timelines. Ultimately, this comprehensive guide equips B2B buyers with the knowledge necessary to navigate the complexities of the metal finishing market, driving successful procurement outcomes.

Understanding curtis metal finishing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engineered Coatings | Custom formulations for enhanced durability and corrosion resistance. | Automotive, aerospace, military, construction. | Pros: High performance, tailored solutions. Cons: Potentially higher costs for specialized formulations. |

| Heat Treatment | Processes such as hardening, tempering, and annealing to enhance material properties. | Fasteners, automotive parts, industrial machinery. | Pros: Improved strength and durability. Cons: Requires precise control and expertise. |

| Pre-Treatment | Surface preparation methods like cleaning and phosphating to enhance adhesion of coatings. | Metal fabrication, automotive components. | Pros: Increases coating effectiveness. Cons: Additional processing time and costs. |

| Surface Finishing | Techniques such as polishing or blasting to improve aesthetics and reduce friction. | Consumer goods, appliances, automotive. | Pros: Enhanced appearance and performance. Cons: May require ongoing maintenance. |

| Packaging and Sorting | Specialized services to ensure safe handling and delivery of finished products. | Manufacturing, logistics, and distribution. | Pros: Reduces damage during transport. Cons: Adds complexity to supply chain management. |

What Are Engineered Coatings and Their Benefits for B2B Buyers?

Engineered coatings are tailored formulations designed to provide superior protection against wear, corrosion, and other environmental factors. They are particularly suited for industries such as automotive, aerospace, and military, where durability is paramount. B2B buyers should consider factors such as the specific environmental conditions their products will face and the performance requirements needed for their applications. While these coatings offer significant advantages in performance, they may come with higher costs due to customization.

How Does Heat Treatment Enhance Metal Properties for Industrial Applications?

Heat treatment involves various processes like hardening and tempering, aimed at improving the mechanical properties of metals. This technique is essential for applications in fasteners and automotive parts, where strength and reliability are crucial. Buyers should evaluate the specific heat treatment processes that align with their material specifications and operational requirements. Although heat treatment enhances durability, it necessitates skilled execution to achieve optimal results, which can impact lead times and costs.

What Role Does Pre-Treatment Play in the Coating Process?

Pre-treatment involves cleaning and preparing metal surfaces to enhance the adhesion of subsequent coatings. This step is vital in industries such as metal fabrication and automotive, where surface quality directly affects coating performance. B2B buyers should consider the type of pre-treatment methods that best suit their materials and the anticipated service environment. While pre-treatment increases coating effectiveness, it also adds processing time and costs, which must be factored into project timelines.

Why is Surface Finishing Important for Aesthetic and Functional Quality?

Surface finishing techniques, including polishing and blasting, are employed to improve the visual appeal and functional characteristics of metal products. This is particularly relevant in consumer goods and automotive sectors where aesthetics and performance are closely linked. Buyers should assess how surface finishing can enhance their products and whether the benefits justify the additional costs. Although these processes can significantly elevate product quality, they may require ongoing maintenance and care.

How Does Packaging and Sorting Impact Supply Chain Efficiency?

Packaging and sorting services are crucial for ensuring that finished metal products are delivered safely and efficiently. This is particularly important in manufacturing and logistics, where damage during transport can lead to significant losses. B2B buyers should prioritize suppliers that offer robust packaging solutions to mitigate risks. While these services enhance product safety, they can also complicate supply chain management, requiring careful coordination between manufacturers and logistics providers.

Key Industrial Applications of curtis metal finishing

| Industry/Sector | Specific Application of curtis metal finishing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engineered coatings for fasteners and components | Enhanced corrosion resistance and durability | Ensure compliance with industry standards and certifications |

| Aerospace | Protective coatings for lightweight components | Weight reduction and improved performance | Focus on precision and adherence to strict aerospace regulations |

| Construction | Coating for structural steel and fasteners | Increased lifespan and reduced maintenance costs | Evaluate compatibility with local environmental regulations |

| Military & Defense | Specialized coatings for military-grade components | Enhanced reliability and performance under extreme conditions | Consider sourcing from certified suppliers with defense contracts |

| Heavy Equipment | Heat treatment and coating for machinery components | Improved wear resistance and operational efficiency | Assess lead times and capacity for large-scale orders |

How Are Engineered Coatings Applied in the Automotive Sector?

In the automotive industry, Curtis Metal Finishing specializes in applying engineered coatings to fasteners and various components. These coatings enhance the corrosion resistance and durability of parts, which is critical in vehicles that operate in diverse environments. Buyers from international markets, such as Europe and South America, should prioritize suppliers that comply with automotive industry standards to ensure quality and reliability in their supply chain. Additionally, the ability to meet volume demands quickly is essential for maintaining production schedules.

What Benefits Do Protective Coatings Provide in Aerospace Applications?

In aerospace, Curtis Metal Finishing provides protective coatings for lightweight components, which are crucial for improving fuel efficiency and overall performance. The coatings help reduce weight while ensuring that parts can withstand harsh environmental conditions. International B2B buyers in this sector need to ensure that their suppliers adhere to strict aerospace regulations and quality standards. This includes certifications like AS9100, which guarantee that the coatings meet the rigorous requirements of the aerospace industry.

How Does Coating Improve Construction Materials?

Curtis Metal Finishing’s services extend to the construction industry, where coatings are applied to structural steel and fasteners. These coatings significantly increase the lifespan of materials by providing a barrier against corrosion and wear, which is vital for infrastructure longevity. Buyers, particularly from regions with challenging climates, should consider sourcing from companies that offer coatings tailored to local environmental conditions. Additionally, understanding local regulations on construction materials is crucial for compliance.

Why Are Specialized Coatings Important for Military Applications?

In the military and defense sectors, Curtis Metal Finishing offers specialized coatings for military-grade components. These coatings enhance the reliability and performance of parts under extreme conditions, which is essential for mission-critical applications. International buyers must ensure that their suppliers have the necessary certifications and experience in military contracts. This guarantees that the coatings will meet stringent quality and performance standards required for defense applications.

What Role Does Heat Treatment Play in Heavy Equipment Manufacturing?

Curtis Metal Finishing also provides heat treatment and coating services for heavy machinery components. This process improves wear resistance and operational efficiency, making it essential for industries reliant on heavy equipment. Buyers should assess the supplier’s capacity to handle large-scale orders and their lead times, as downtime in heavy machinery can lead to significant losses. Additionally, understanding the specific heat treatment processes employed can help buyers ensure they receive the right specifications for their applications.

3 Common User Pain Points for ‘curtis metal finishing’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Metal Finishing

The Problem: As a B2B buyer in industries like automotive or aerospace, ensuring that metal components meet stringent quality standards is crucial. Buyers often face challenges in sourcing metal finishing services that can guarantee consistent quality across large volumes. Variability in coatings or treatments can lead to product failures, recalls, or safety issues, which can severely damage a company’s reputation and financial standing. Moreover, suppliers may provide insufficient documentation or fail to meet compliance standards, adding to the buyer’s anxiety.

Illustrative image related to curtis metal finishing

The Solution: To mitigate these quality assurance issues, B2B buyers should prioritize partnerships with metal finishing providers like Curtis Metal Finishing that emphasize a robust quality management system. Buyers should request detailed documentation of the company’s quality certifications (such as ISO 9001) and inquire about their testing procedures. Establishing clear communication channels is also vital; setting up regular quality reviews and audits can help buyers monitor the consistency of the finishes. Additionally, specifying the exact requirements for coatings, such as thickness, adhesion tests, and environmental resistance, ensures that the supplier is on the same page, ultimately leading to higher quality outcomes.

Scenario 2: Managing Lead Times for Urgent Projects

The Problem: In fast-paced industries, unexpected delays in metal finishing can derail production schedules and affect project timelines. Buyers often struggle with lead times that can extend unpredictably, especially when dealing with international suppliers. This uncertainty can lead to significant operational disruptions, increased costs, and missed market opportunities, making it critical for buyers to understand how to effectively manage timelines.

The Solution: To address lead time challenges, B2B buyers should engage with Curtis Metal Finishing to establish a reliable supply chain strategy. One effective approach is to use a “Just-in-Time” (JIT) inventory model, which aligns closely with the supplier’s production capabilities. Buyers should communicate their production schedules and any potential changes promptly to Curtis, allowing them to adjust their operations accordingly. Additionally, leveraging local production facilities can reduce transit times and improve responsiveness. Establishing a long-term partnership can also lead to prioritized service during peak times, ensuring that urgent projects are not sidelined.

Scenario 3: Understanding the Full Range of Finishing Options

The Problem: Buyers often find themselves overwhelmed by the multitude of metal finishing options available, such as galvanization, anodizing, and various coatings. Without a clear understanding of how each process impacts performance and durability, making informed decisions can be challenging. This confusion can lead to selecting inappropriate finishes that do not meet the specific demands of their applications, resulting in product failures and increased costs.

The Solution: To navigate the complexities of metal finishing options, B2B buyers should consult with experts at Curtis Metal Finishing to gain insights into the best solutions for their specific needs. Engaging in a thorough needs assessment, where buyers can discuss their application requirements, environmental considerations, and performance expectations, is crucial. Curtis can provide tailored recommendations based on their extensive portfolio of services, including engineered coatings and heat treatments. Buyers should also consider requesting samples or pilot runs to test the proposed finishes in real-world conditions. This proactive approach not only enhances understanding but also fosters a collaborative relationship with the supplier, ultimately leading to better outcomes.

Illustrative image related to curtis metal finishing

Strategic Material Selection Guide for curtis metal finishing

When selecting materials for metal finishing, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. This guide analyzes four common materials used in Curtis Metal Finishing’s operations, providing insights that can help international buyers make informed decisions.

What Are the Key Properties of Steel in Metal Finishing?

Steel is one of the most widely used materials in metal finishing due to its strength and versatility. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures. Steel is also available in various grades, such as carbon steel and stainless steel, each offering different levels of corrosion resistance.

Pros: Steel is durable and can be treated to enhance its properties, making it suitable for a wide range of applications, including automotive and construction. It is also relatively cost-effective compared to other materials.

Illustrative image related to curtis metal finishing

Cons: The primary drawback of steel is its susceptibility to corrosion, particularly in harsh environments. This can necessitate additional coatings or treatments, which may increase manufacturing complexity and costs.

Impact on Application: Steel’s compatibility with various coatings, such as galvanization and powder coating, enhances its performance in diverse environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local regulations regarding steel quality standards, such as ASTM and ISO certifications. In Europe, compliance with DIN standards is essential.

How Do Aluminum Alloys Perform in Metal Finishing?

Aluminum alloys are favored for their lightweight properties and resistance to corrosion. They exhibit good thermal and electrical conductivity, making them ideal for applications in the aerospace and automotive industries.

Illustrative image related to curtis metal finishing

Pros: The lightweight nature of aluminum alloys reduces overall product weight, contributing to fuel efficiency in vehicles. They also have excellent corrosion resistance, which is beneficial for outdoor applications.

Cons: Aluminum can be more expensive than steel and may require specialized finishing processes, such as anodizing, to enhance surface durability.

Impact on Application: Aluminum’s compatibility with various coatings allows for enhanced aesthetics and performance, particularly in consumer products and automotive parts.

Considerations for International Buyers: Buyers should consider the availability of specific aluminum grades and their compliance with international standards, such as JIS in Japan and EN in Europe.

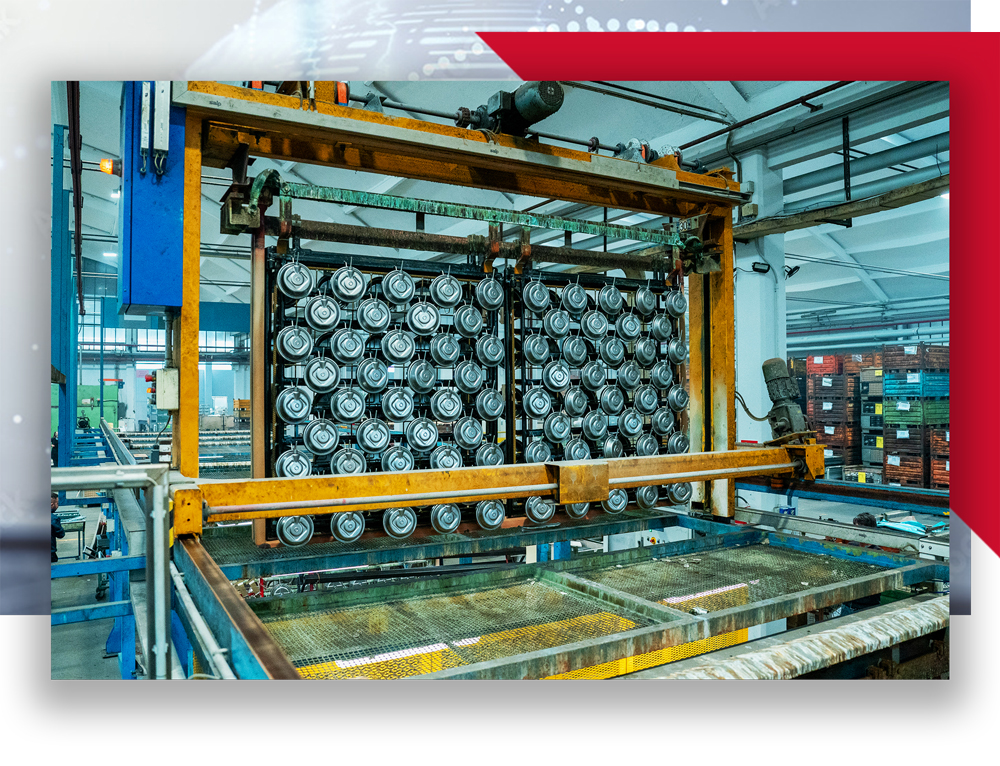

What Role Does Zinc Play in Metal Finishing?

Zinc is primarily used as a coating material to provide corrosion resistance to steel and iron products. It is often applied through galvanization processes, which involve coating the base metal with a layer of zinc.

Illustrative image related to curtis metal finishing

Pros: Zinc coatings are highly effective in preventing rust and corrosion, significantly extending the lifespan of metal components. They are also relatively inexpensive and easy to apply.

Cons: The main limitation of zinc is its lower mechanical strength compared to other metals, which may not be suitable for high-stress applications. Additionally, zinc coatings can degrade over time if exposed to harsh environments.

Impact on Application: Zinc’s compatibility with other materials makes it a popular choice for outdoor applications, particularly in construction and automotive sectors.

Illustrative image related to curtis metal finishing

Considerations for International Buyers: Buyers should verify that zinc coatings meet local and international corrosion resistance standards. Compliance with ASTM standards is crucial for ensuring quality.

How Does Plastic Coating Enhance Metal Finishing?

Plastic coatings, such as polyvinyl chloride (PVC) and polyurethane, are used to enhance the surface properties of metal components. They provide excellent corrosion resistance and can improve the aesthetic appeal of products.

Pros: Plastic coatings are highly customizable, allowing for various colors and finishes. They also provide a barrier against moisture and chemicals, enhancing durability.

Cons: The primary drawback is that plastic coatings may not withstand high temperatures as effectively as metal coatings. They can also be more expensive due to the additional processing involved.

Illustrative image related to curtis metal finishing

Impact on Application: Plastic coatings are particularly effective in applications where aesthetics and corrosion resistance are paramount, such as in consumer goods and automotive parts.

Considerations for International Buyers: Buyers should ensure that plastic coatings comply with relevant environmental regulations, particularly in Europe, where REACH compliance is essential.

| Material | Typical Use Case for curtis metal finishing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive components, construction | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum Alloys | Aerospace parts, automotive applications | Lightweight and corrosion-resistant | Higher cost and requires specialized finishing | High |

| Zinc | Coating for steel products | Excellent corrosion resistance | Lower mechanical strength | Low |

| Plastic Coating | Consumer goods, automotive parts | Customizable aesthetics and durability | Limited high-temperature resistance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to choose the right materials for their specific applications while considering compliance and performance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for curtis metal finishing

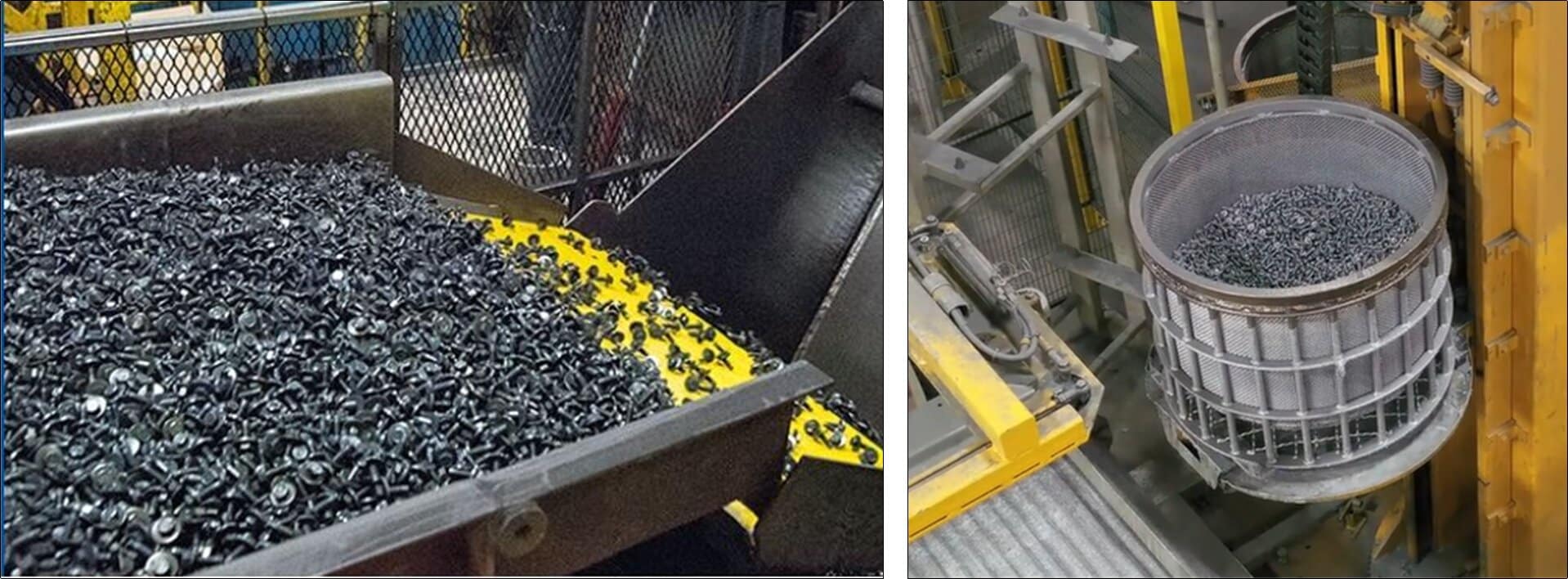

What Are the Key Manufacturing Processes at Curtis Metal Finishing?

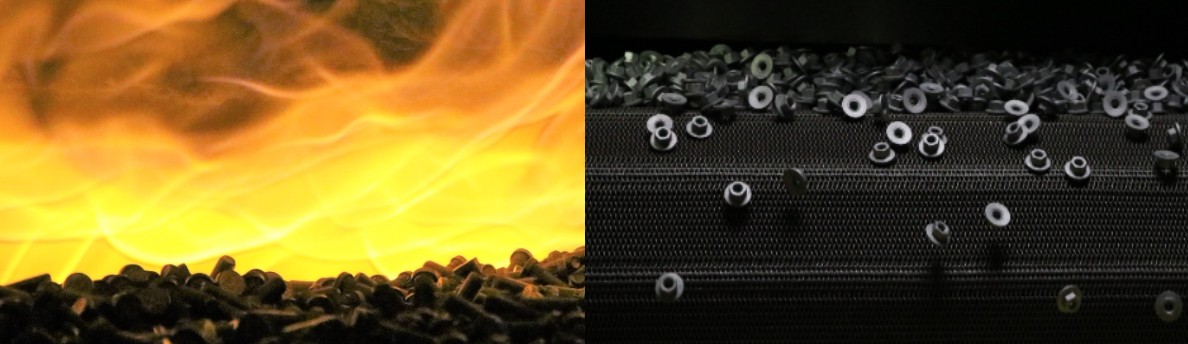

Curtis Metal Finishing employs a comprehensive manufacturing process tailored to meet the specific needs of various industries, including automotive, military, and construction. The main stages of their manufacturing process encompass material preparation, forming, assembly, and finishing.

How Does Material Preparation Work?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, typically metal fasteners and small stampings. Curtis Metal Finishing emphasizes the importance of selecting materials that meet industry standards and customer specifications. Quality checks are conducted on incoming materials to ensure they are free of defects and suitable for the intended application.

Illustrative image related to curtis metal finishing

Once the materials are verified, they undergo surface treatment processes such as cleaning and degreasing. This step is crucial for ensuring that the subsequent coatings adhere properly to the metal surfaces. Advanced cleaning techniques, including ultrasonic cleaning and chemical baths, are often employed to remove contaminants effectively.

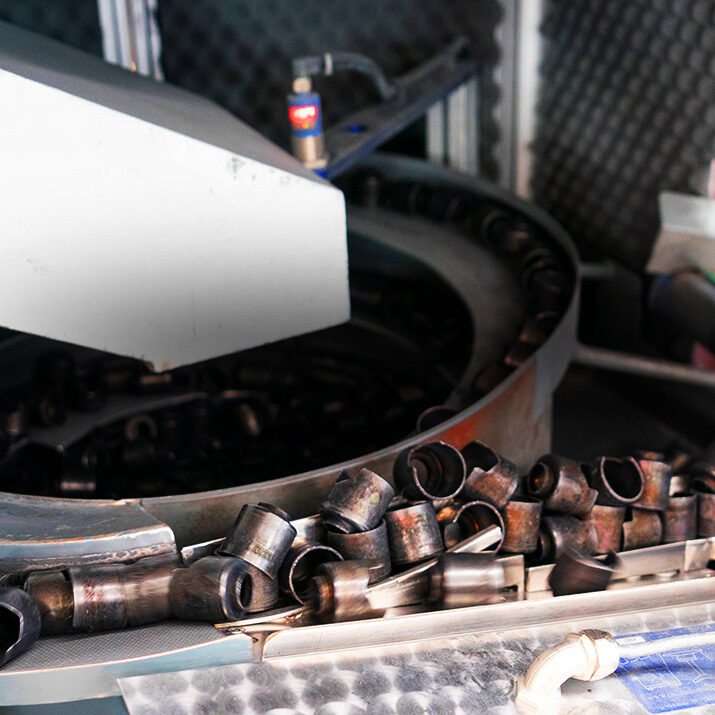

What Techniques Are Used in Forming and Assembly?

Following material preparation, the forming stage begins. This involves shaping the metal into the desired configurations through processes such as stamping, machining, or forging. Curtis Metal Finishing utilizes state-of-the-art machinery and automated systems to maintain precision and efficiency during this phase.

Once the components are formed, assembly takes place. This stage may involve the integration of multiple parts into a single assembly, requiring meticulous attention to detail. Workers are trained to follow strict guidelines to ensure that every assembly meets the quality standards expected by customers.

How Is the Finishing Process Conducted?

The finishing stage is where Curtis Metal Finishing truly shines. They specialize in various coating techniques, including engineered protective coatings, heat treatment, and surface treatments. The company’s capabilities include processes such as Magni, Geomet, and PPG cathodic ecoat, which are essential for enhancing the durability and corrosion resistance of metal components.

Illustrative image related to curtis metal finishing

Heat treatment processes such as hardening, solution treating, and gas nitriding are also integral to the finishing stage. These techniques not only improve the mechanical properties of the metal but also ensure that the finished products meet rigorous performance requirements. The finishing processes are critical, especially for industries where component reliability is non-negotiable, such as automotive and military applications.

What Quality Assurance Measures Are in Place?

Quality assurance is a cornerstone of Curtis Metal Finishing’s operations. The company adheres to international standards, including ISO 9001, which ensures a systematic approach to quality management. This certification demonstrates Curtis Metal Finishing’s commitment to maintaining high-quality processes across all stages of manufacturing.

How Are International Standards and Industry-Specific Certifications Applied?

In addition to ISO 9001, Curtis Metal Finishing also complies with industry-specific certifications relevant to their clients, such as CE marking for products sold within the European Economic Area and API standards for oil and gas applications. These certifications ensure that products not only meet quality expectations but also comply with safety regulations and industry best practices.

What Are the Key Quality Control Checkpoints?

Curtis Metal Finishing implements a robust quality control (QC) framework that includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial check assesses raw materials as they arrive at the facility. Any non-conforming materials are rejected and documented.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to specifications. This includes checks on dimensional accuracy, surface quality, and adherence to processing parameters.

-

Final Quality Control (FQC): Before products are shipped, a final inspection is performed to ensure that all items meet customer specifications and quality standards. This may involve functional testing, visual inspections, and packaging evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to partner with Curtis Metal Finishing can take several steps to verify the quality control measures in place:

Illustrative image related to curtis metal finishing

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational standards. This provides valuable insights into the supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports, including statistical process control (SPC) data and defect rates, can help buyers understand the supplier’s performance history and adherence to quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These inspections can verify compliance with both international and industry-specific standards.

What Nuances Should International Buyers Consider?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance in metal finishing is crucial. Different regions may have varying regulatory requirements and quality expectations. Therefore, buyers should ensure that their suppliers are familiar with the specific standards applicable to their markets.

Additionally, language barriers and cultural differences may affect communication regarding quality expectations. It is advisable for buyers to establish clear guidelines and maintain open lines of communication with their suppliers to mitigate any potential misunderstandings.

In summary, Curtis Metal Finishing employs a comprehensive manufacturing process, backed by rigorous quality assurance measures that align with international standards. B2B buyers can confidently engage with Curtis Metal Finishing by leveraging audits, quality reports, and third-party inspections to ensure that they receive products that meet their high standards for quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘curtis metal finishing’

This practical sourcing guide is designed to assist B2B buyers in effectively procuring services from Curtis Metal Finishing, a leading provider in engineered protective coatings and metal finishing solutions. By following these steps, you can ensure that your sourcing process is thorough, strategic, and aligned with your specific requirements.

Step 1: Define Your Technical Specifications

Before initiating contact with potential suppliers, clearly outline your technical requirements for metal finishing. Consider factors such as material types, coating specifications, and performance standards. This clarity will help suppliers understand your needs and provide accurate solutions.

Illustrative image related to curtis metal finishing

Step 2: Research Supplier Capabilities

Investigate the capabilities of Curtis Metal Finishing and its competitors. Look for details regarding their service offerings, such as coating types (e.g., Magni, Geomet), heat treatment processes, and their ability to handle large volumes. Understanding their strengths will help you assess their suitability for your projects.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This assessment can reveal insights into their operational efficiency and customer satisfaction, helping you make informed decisions.

- Check Certifications: Ensure that the supplier holds relevant industry certifications, which can be indicative of their adherence to quality and safety standards.

- Assess Experience: Look for their experience in sectors that align with your business, such as automotive or aerospace, to ensure they understand the specific challenges and requirements.

Step 4: Request Samples and Prototypes

Once you have shortlisted suppliers, request samples or prototypes of their work. This hands-on evaluation allows you to assess the quality of their finishes and coatings firsthand. Pay attention to the consistency, durability, and aesthetic quality of the samples provided.

Illustrative image related to curtis metal finishing

Step 5: Discuss Lead Times and Flexibility

Engage in discussions regarding lead times and the supplier’s capacity to accommodate fluctuations in demand. Understanding their logistics capabilities, including delivery timelines and order fulfillment processes, is crucial for maintaining your production schedules without delays.

Step 6: Negotiate Terms and Pricing

Once you have gathered all necessary information, initiate negotiations on pricing and terms. Be clear about your budget constraints while also discussing volume discounts or long-term partnership opportunities. A well-negotiated agreement can lead to better pricing and service terms.

Step 7: Establish Communication Protocols

Finally, set up effective communication channels with your chosen supplier. Define points of contact, regular update schedules, and feedback mechanisms to ensure smooth collaboration. Clear communication is vital to address any issues promptly and to maintain a productive working relationship.

Illustrative image related to curtis metal finishing

By following this checklist, B2B buyers can ensure a strategic and efficient sourcing process for Curtis Metal Finishing services, ultimately leading to successful partnerships and high-quality outcomes in their projects.

Comprehensive Cost and Pricing Analysis for curtis metal finishing Sourcing

What Are the Key Cost Components in Curtis Metal Finishing Sourcing?

When considering sourcing from Curtis Metal Finishing, understanding the cost structure is crucial for B2B buyers. The main components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts pricing. Curtis specializes in engineered coatings and treatments for metal fasteners, meaning costs can vary based on the specific metal types and coatings selected. Higher-grade materials or specialized coatings will naturally drive up the cost.

-

Labor: Skilled labor is essential for the precision required in metal finishing processes. Labor costs can fluctuate based on the complexity of the tasks, the level of expertise required, and regional wage differences, particularly relevant for international buyers.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. With Curtis’s multiple production facilities across North America and Europe, overhead costs can vary based on location and operational efficiencies.

-

Tooling: Custom tooling may be necessary for specific projects, adding to the initial costs. This is particularly relevant for specialized or high-volume orders where unique tooling is required to meet specifications.

-

Quality Control: Ensuring high-quality output requires investment in QC processes. This includes testing and certification, which are essential, especially for industries like automotive and aerospace that demand stringent quality standards.

-

Logistics: Transportation and warehousing costs can affect overall pricing. Given Curtis’s global reach, logistics can vary significantly based on the buyer’s location and the agreed Incoterms.

-

Margin: Finally, the profit margin is added to cover operational costs and ensure company profitability. This margin can vary based on the competitive landscape and the specific terms negotiated between the buyer and Curtis.

How Do Pricing Influencers Impact Costs for International Buyers?

Several factors influence the pricing structure that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, need to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from bulk pricing, allowing buyers to negotiate better rates. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom requests for specific coatings or treatments can lead to increased costs. Buyers should be clear on their specifications to receive accurate quotes.

-

Material Quality and Certifications: The level of certification required (e.g., ISO standards) can influence pricing. Industries such as automotive and aerospace often require higher-quality certifications, which may come at a premium.

-

Supplier Factors: The reputation and reliability of Curtis as a supplier can impact pricing. Established suppliers often command higher prices due to perceived quality and service levels.

-

Incoterms: The choice of Incoterms determines who bears the cost of shipping, insurance, and tariffs. Buyers should choose terms that align with their logistics capabilities and budget.

What Tips Can Help Buyers Optimize Costs in Curtis Metal Finishing Sourcing?

To maximize cost-efficiency when sourcing from Curtis Metal Finishing, international buyers should consider the following strategies:

-

Negotiation: Engage in thorough negotiations to understand pricing breakdowns and explore options for discounts based on volume or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not only the initial purchase price but also logistics, maintenance, and potential quality issues. This holistic view can help identify the best overall value.

-

Pricing Nuances: Be aware of seasonal fluctuations in pricing and availability, especially for materials. Understanding these nuances can help buyers time their purchases for maximum savings.

-

Research and Network: Connect with industry peers and conduct market research to gather insights on competitive pricing and supplier performance. Networking can reveal valuable information that aids in decision-making.

-

Establish Clear Specifications: Provide detailed specifications to avoid misunderstandings that could lead to costly reworks or delays. Clear communication with Curtis will ensure that both parties are aligned.

In conclusion, navigating the cost and pricing landscape for Curtis Metal Finishing requires a comprehensive understanding of the various components and influencing factors. By leveraging this knowledge, international B2B buyers can make informed decisions that align with their business objectives.

Alternatives Analysis: Comparing curtis metal finishing With Other Solutions

In the competitive landscape of metal finishing solutions, various alternatives exist alongside Curtis Metal Finishing. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific needs, budget, and operational capabilities. The following analysis compares Curtis Metal Finishing with two viable alternatives: traditional electroplating and powder coating.

Illustrative image related to curtis metal finishing

| Comparison Aspect | Curtis Metal Finishing | Traditional Electroplating | Powder Coating |

|---|---|---|---|

| Performance | High-quality engineered coatings; specialized in fasteners and small stampings | Good for achieving a uniform finish; offers corrosion resistance | Excellent durability and resistance to chipping and scratching |

| Cost | Moderate to high; depends on volume and complexity | Generally lower upfront costs, but can have higher maintenance costs | Moderate; initial investment can be offset by long-term durability |

| Ease of Implementation | Requires specialized equipment and expertise | Relatively straightforward; however, hazardous materials may complicate | Requires specialized equipment, but less hazardous than electroplating |

| Maintenance | Regular maintenance needed for equipment; consistency in quality | Requires careful monitoring of chemical baths; potential for waste management issues | Low maintenance; equipment needs periodic checks but is generally less demanding |

| Best Use Case | Automotive, military, and construction sectors needing precision coatings | General applications where cost is critical, but quality can vary | Industries requiring high durability and aesthetic appeal, such as appliances and outdoor products |

What Are the Key Pros and Cons of Traditional Electroplating as an Alternative?

Traditional electroplating is a well-established method for applying metallic coatings to substrates. It excels in achieving a uniform finish and provides good corrosion resistance. However, it often relies on hazardous chemicals, which necessitate stringent safety measures and can lead to environmental concerns. The initial investment is relatively low, but ongoing maintenance and compliance costs can accumulate, impacting long-term viability for some businesses.

How Does Powder Coating Compare to Curtis Metal Finishing?

Powder coating is another popular alternative that offers excellent durability and resistance to wear and tear. This method is particularly advantageous for products exposed to harsh environments, making it ideal for applications in outdoor furniture and appliances. While the initial setup cost can be moderate, powder coating typically requires less maintenance over time compared to electroplating. However, it may not provide the same level of precision for small components as Curtis Metal Finishing does.

How Can B2B Buyers Choose the Right Metal Finishing Solution?

Selecting the most suitable metal finishing solution hinges on various factors, including the specific application requirements, budget constraints, and desired performance characteristics. B2B buyers should assess their product needs against the strengths and weaknesses of each alternative. For instance, if precision and tailored coatings are critical, Curtis Metal Finishing may be the preferred choice. Conversely, businesses focused on cost-efficiency and general applications may find traditional electroplating more appealing. Ultimately, evaluating the long-term benefits, environmental impact, and maintenance requirements will guide buyers in making an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for curtis metal finishing

What Are the Key Technical Properties in Curtis Metal Finishing?

In the context of Curtis Metal Finishing, understanding the essential technical properties is vital for making informed purchasing decisions. Here are some critical specifications relevant to the industry:

-

Material Grade: This refers to the classification of metal materials based on their chemical composition and mechanical properties. Common grades include carbon steel, stainless steel, and aluminum. Selecting the right material grade is crucial as it impacts the durability, corrosion resistance, and overall performance of the finished product, especially in demanding applications like automotive and aerospace.

-

Coating Thickness: The measurement of the layer of protective coating applied to metal surfaces. Coating thickness is typically measured in microns and is essential for ensuring adequate protection against corrosion and wear. For B2B buyers, specifying the correct thickness is vital to meet regulatory requirements and performance standards in various industries.

-

Tolerance: This term refers to the permissible limit of variation in a physical dimension. In metal finishing, tight tolerances are often required to ensure parts fit and function correctly. For manufacturers, understanding tolerance levels is key to maintaining quality control and minimizing waste during production.

-

Heat Treatment Process: This encompasses various processes used to alter the physical and sometimes chemical properties of a material. Techniques such as hardening, annealing, and tempering are common. Heat treatment enhances the strength and durability of metal components, making it a critical specification in industries where performance is paramount.

-

Surface Finish: This describes the texture and smoothness of a metal surface after finishing processes. Surface finish affects not only aesthetic qualities but also functionality, such as friction and wear resistance. Buyers must consider the required surface finish for applications ranging from automotive to industrial machinery.

-

Corrosion Resistance: This property measures a material’s ability to withstand deterioration due to chemical or electrochemical reactions. In sectors like automotive and construction, corrosion resistance is critical for ensuring longevity and reliability. Understanding the level of corrosion resistance needed helps buyers select appropriate coatings and materials.

What Are the Common Trade Terms in Curtis Metal Finishing?

Familiarity with industry jargon is essential for effective communication and negotiation in the metal finishing sector. Here are several key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers looking to source components that meet specific performance standards required by original manufacturers.

-

MOQ (Minimum Order Quantity): This is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is important for B2B buyers as it affects purchasing decisions, especially for startups or companies with limited budgets.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price bids for specific products or services. For buyers, crafting an effective RFQ can lead to competitive pricing and favorable terms, making it an essential tool in procurement processes.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, crucial for international transactions.

-

Lead Time: This term refers to the amount of time between placing an order and receiving it. Understanding lead times is essential for supply chain management, particularly for industries that require just-in-time manufacturing.

-

Batch Processing: This refers to the production of goods in groups or batches rather than continuous flow. For buyers, knowing whether a supplier utilizes batch processing can impact timelines and pricing, especially in industries with fluctuating demand.

By grasping these technical properties and trade terms, B2B buyers can navigate the Curtis Metal Finishing landscape more effectively, ensuring they make informed decisions that align with their operational needs and strategic objectives.

Navigating Market Dynamics and Sourcing Trends in the curtis metal finishing Sector

What Are the Current Market Dynamics and Key Trends in the Curtis Metal Finishing Sector?

The global metal finishing market is witnessing transformative shifts driven by technological advancements, increased demand for high-quality coatings, and a focus on sustainability. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is critical for making informed sourcing decisions. The rise of automation and smart manufacturing technologies has allowed companies like Curtis Metal Finishing to enhance their operational efficiency, reduce lead times, and improve product quality. This trend aligns with the increasing demand for just-in-time manufacturing, especially in industries such as automotive and aerospace, where precision and reliability are paramount.

Emerging B2B sourcing trends also highlight the importance of integrated supply chains. Companies are seeking partnerships that offer a comprehensive suite of services, from coating to heat treatment, enabling them to streamline their operations and reduce costs. The acquisition of Curtis by the Primat Group exemplifies this trend, as it combines resources and expertise across continents, creating a robust platform for serving global clients. Furthermore, with the ongoing digital transformation, businesses are leveraging data analytics and AI-driven solutions to optimize their sourcing strategies and predict market demands more accurately.

How Is Sustainability and Ethical Sourcing Reshaping the Curtis Metal Finishing Sector?

Sustainability is no longer a mere buzzword but a fundamental aspect of the metal finishing industry. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally responsible practices. In the Curtis metal finishing sector, this includes minimizing waste, reducing energy consumption, and utilizing eco-friendly materials. Suppliers are adopting ‘green’ certifications such as ISO 14001, which signifies a robust environmental management system, and are investing in technologies that lower their carbon footprint.

Illustrative image related to curtis metal finishing

Ethical sourcing is equally crucial, especially for buyers concerned about the social and environmental impacts of their supply chains. Companies like Curtis are focusing on transparency and traceability, ensuring that the materials they use are sourced responsibly. This not only helps in complying with regulatory requirements but also builds trust with customers who are increasingly aware of the ethical implications of their purchasing decisions. The integration of sustainable practices and ethical sourcing not only enhances brand reputation but also opens up new market opportunities, particularly in regions where regulatory frameworks are becoming stricter.

What Is the Evolution of the Curtis Metal Finishing Sector?

The Curtis Metal Finishing sector has a rich history that significantly shapes its current market position. Established in 1927, Curtis began as a heat treatment company primarily serving the automotive industry. Over the decades, it evolved into one of the largest bulk metal finishing operations in North America, expanding its capabilities to include engineered coatings and a variety of finishing processes. The acquisition by the Primat Group in 2023 marked a pivotal moment, enhancing its global footprint and integrating innovative technologies to meet the demands of modern manufacturing.

This evolution reflects broader industry trends, where companies are adapting to technological advancements and shifting market needs. As a result, Curtis has positioned itself as a leader in providing comprehensive solutions for sectors ranging from automotive to aerospace, ensuring that it remains relevant in a rapidly changing landscape. The emphasis on quality, efficiency, and sustainability has enabled Curtis to build long-lasting relationships with clients across the globe, making it a valuable partner for international B2B buyers seeking reliable metal finishing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of curtis metal finishing

1. How do I ensure the quality of coatings from Curtis Metal Finishing?

To ensure the quality of coatings from Curtis Metal Finishing, it’s essential to review their certifications and quality assurance processes. The company employs advanced technologies and adheres to strict industry standards. Request documentation such as ISO certifications and quality control reports. Engaging in a dialogue with their technical team can also provide insights into their processes and the specific coatings suitable for your application, ensuring that you receive a product that meets your specifications.

2. What are the customization options available for coatings?

Curtis Metal Finishing offers a range of customization options tailored to your specific requirements. This includes various coating types, thicknesses, and finishes. You can discuss your project needs directly with their team to explore options such as engineered coatings for specific applications in automotive, military, or construction sectors. Customization can also extend to batch sizes, allowing you to obtain precisely what you need for your project, enhancing both efficiency and performance.

Illustrative image related to curtis metal finishing

3. What is the minimum order quantity (MOQ) for custom coatings?

The minimum order quantity (MOQ) for custom coatings at Curtis Metal Finishing varies depending on the specific service and coating type required. Generally, they cater to large volume orders, but smaller batch sizes may be negotiable, especially for trial runs or specialized projects. It’s advisable to contact their sales team for detailed information on MOQs, as they can provide flexibility based on your business needs and volume forecasts.

4. How does Curtis Metal Finishing handle international shipping and logistics?

Curtis Metal Finishing is well-equipped to manage international shipping and logistics, leveraging their established global network. They work closely with logistics partners to ensure timely delivery while adhering to international trade regulations. Buyers are encouraged to discuss shipping options, including freight terms and delivery timelines, during the ordering process. Additionally, they can provide assistance with customs documentation to facilitate smooth cross-border transactions.

5. What payment terms does Curtis Metal Finishing offer for international buyers?

For international buyers, Curtis Metal Finishing typically offers flexible payment terms tailored to the nature of the transaction. Common options include letters of credit, wire transfers, and payment upon delivery, depending on the buyer’s creditworthiness and relationship with the company. It’s crucial to establish clear payment terms upfront to ensure transparency and mutual understanding, helping to avoid any potential delays in order fulfillment.

6. What types of industries does Curtis Metal Finishing serve?

Curtis Metal Finishing serves a diverse range of industries, including automotive, military, construction, aerospace, and appliance manufacturing. Their expertise in engineered coatings and heat treatment processes makes them a valuable partner across these sectors. When sourcing, it’s beneficial to inquire about their specific experiences within your industry to ensure they can meet your unique needs and standards.

7. How can I vet Curtis Metal Finishing as a supplier?

To vet Curtis Metal Finishing as a supplier, begin by assessing their industry reputation and client testimonials. Request references from current customers and review their case studies that demonstrate successful partnerships. Additionally, evaluate their certifications, quality control processes, and compliance with international standards. Engaging in direct communication with their team can also provide insights into their operational capabilities and commitment to customer satisfaction.

8. What is the lead time for orders with Curtis Metal Finishing?

The lead time for orders with Curtis Metal Finishing can vary based on the complexity of the project and the current production schedule. Typically, standard orders may have a lead time ranging from a few days to several weeks. For custom projects, discussing your timeline needs with their sales team can help establish a more precise delivery schedule. Prompt communication about your requirements will ensure that Curtis can meet your deadlines effectively.

Top 2 Curtis Metal Finishing Manufacturers & Suppliers List

1. Curtis Metal Finishing – Employee Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Curtis Metal Finishing – Employee Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Curtis Metal Finishing Group – Engineered Protective Coatings

Domain: finishingandcoating.com

Introduction: Curtis Metal Finishing Group provides engineered protective coating, pre-treatment, heat treatment, and technical intermediation services for metal fasteners. They serve various sectors including automotive, construction, military, appliance, and aerospace. Services include continuous and batch hardening, solution treating, age hardening, gas nitriding, and induction hardening. Coating application…

Strategic Sourcing Conclusion and Outlook for curtis metal finishing

Strategic sourcing with Curtis Metal Finishing presents an invaluable opportunity for international buyers, particularly in Africa, South America, the Middle East, and Europe. With a robust portfolio that includes engineered protective coatings and heat treatment services, Curtis stands out as a leader in the metal finishing industry. Their recent merger under the Primat Group has further strengthened their global presence, enabling them to deliver high-quality solutions with enhanced efficiency.

By leveraging Curtis’s fully integrated service model, businesses can expect not only superior product quality but also significant reductions in lead times and costs. This strategic sourcing approach is vital for companies aiming to remain competitive in rapidly evolving markets. The ability to access advanced technologies and diversified services from a single provider allows for streamlined operations and improved supply chain resilience.

Illustrative image related to curtis metal finishing

As the global demand for metal finishing services continues to rise, now is the opportune moment for B2B buyers to engage with Curtis Metal Finishing. Take advantage of their extensive capabilities to elevate your business operations. Connect with Curtis today to explore how their innovative solutions can meet your unique needs and drive your success in the international marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to curtis metal finishing