Top 2 Brush Bottle Suppliers (And How to Choose)

Introduction: Navigating the Global Market for brush bottle

The global market for brush bottles is evolving rapidly, presenting significant opportunities and challenges for international B2B buyers. Sourcing high-quality brush bottles that meet diverse cleaning needs can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the complexities of the brush bottle market by exploring various types, applications, and materials, along with essential insights into supplier vetting and cost considerations.

With an increasing demand for sustainable and efficient cleaning solutions, understanding the nuances of brush bottle design—ranging from eco-friendly options to specialized brushes for different bottle shapes—is crucial. This guide equips B2B buyers with the knowledge needed to make informed purchasing decisions, ensuring they can navigate the landscape effectively. We delve into the latest trends, market dynamics, and product innovations, enabling businesses to select the right brush bottles that align with their operational needs and customer expectations.

By focusing on practical insights and actionable strategies, this guide not only addresses the common pain points faced by international buyers but also empowers them to forge successful partnerships with reliable suppliers. Whether you are looking to enhance your product offerings or streamline your procurement processes, our guide serves as a valuable resource to help you thrive in the competitive brush bottle market.

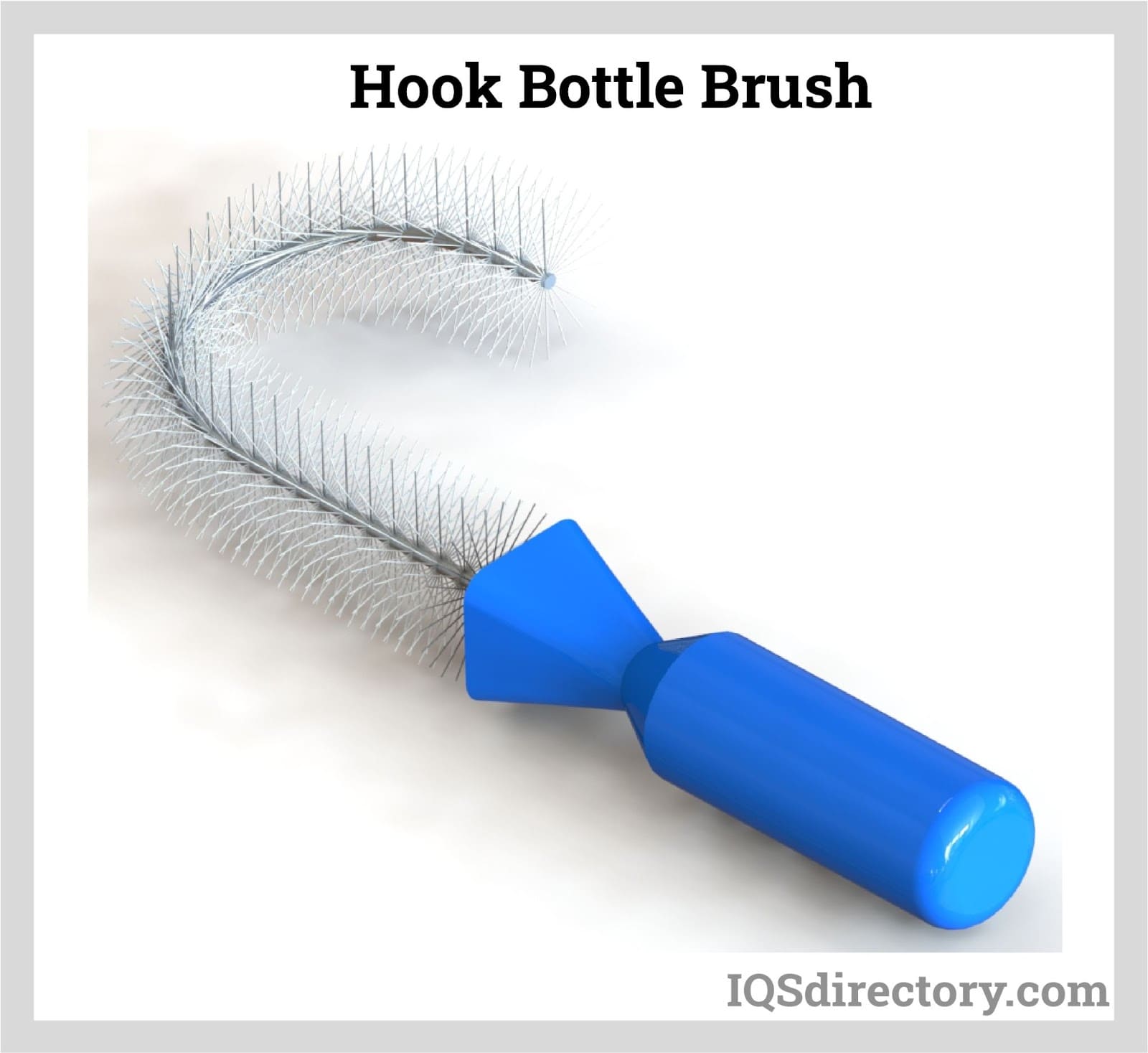

Understanding brush bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Bottle Brush | Long handle, nylon bristles, versatile for various bottle types | Food and beverage industries, cleaning services | Pros: Versatile, effective cleaning; Cons: May not reach deep or narrow bottles. |

| Eco-Friendly Brush | Natural bristles (e.g., coconut), biodegradable materials | Sustainability-focused businesses, eco-friendly product lines | Pros: Environmentally friendly; Cons: Shorter lifespan, may shed bristles. |

| Specialty Sports Bottle Brush | Ergonomic design, wavy bristles for optimal soap retention | Sports equipment retailers, health and fitness sectors | Pros: Effective for sports bottles; Cons: Limited to specific bottle types. |

| Compact Travel Brush | Foldable or collapsible design, lightweight | Travel and outdoor gear retailers | Pros: Portable; Cons: Smaller cleaning surface area. |

| Heavy-Duty Bottle Brush | Sturdy construction, extra stiff bristles | Industrial cleaning, catering services | Pros: Durable, suitable for tough cleaning jobs; Cons: Can be too abrasive for delicate surfaces. |

What Are the Characteristics of Standard Bottle Brushes?

Standard bottle brushes are designed with a long handle and nylon bristles, making them suitable for cleaning a wide range of bottle types, from water bottles to baby bottles. Their versatility is a significant advantage for B2B buyers in the food and beverage industries, as they can be used across multiple products. When purchasing, consider the bristle stiffness and handle length to ensure compatibility with the intended bottle types.

How Do Eco-Friendly Brushes Stand Out in the Market?

Eco-friendly bottle brushes feature natural bristles made from materials like coconut and are often biodegradable. This type appeals to businesses focused on sustainability, such as those in the eco-friendly product market. When selecting eco-friendly brushes, buyers should assess the durability and cleaning effectiveness, as these brushes may have a shorter lifespan compared to synthetic alternatives.

What Makes Specialty Sports Bottle Brushes Unique?

Specialty sports bottle brushes are ergonomically designed with wavy bristles that hold soap and water effectively, making them ideal for cleaning sports and fitness bottles. These brushes are particularly relevant for sports equipment retailers and health and fitness sectors. Buyers should evaluate the brush’s ability to fit various bottle openings and its cleaning efficiency to ensure optimal performance.

Why Choose Compact Travel Brushes for Your Business?

Compact travel brushes are designed to be lightweight and often feature a foldable or collapsible design, making them ideal for travel and outdoor gear retailers. While their portability is a significant advantage, buyers should be mindful of the smaller cleaning surface area, which may not be as effective for larger bottles. Assessing the materials used and ease of storage will be critical in the purchasing decision.

What Are the Benefits of Heavy-Duty Bottle Brushes?

Heavy-duty bottle brushes are built for durability, featuring extra stiff bristles that can tackle tough cleaning jobs, making them suitable for industrial cleaning and catering services. While they are effective for heavy use, buyers should consider the potential abrasiveness of the bristles, which may not be suitable for all bottle types. Evaluating the brush’s construction and intended use will help ensure it meets business needs.

Key Industrial Applications of brush bottle

| Industry/Sector | Specific Application of Brush Bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cleaning reusable beverage containers and equipment | Ensures hygiene and compliance with health regulations | Material safety, durability, and effectiveness in deep cleaning |

| Pharmaceuticals | Cleaning laboratory glassware and equipment | Maintains sterile environments and prevents contamination | Resistance to harsh chemicals, size compatibility, and ease of use |

| Personal Care and Cosmetics | Cleaning bottles and containers for products | Enhances brand image by ensuring product cleanliness | Eco-friendliness, bristle quality, and design for various bottle types |

| Environmental Sustainability | Promoting the use of reusable bottles | Supports sustainability initiatives and reduces plastic waste | Availability of biodegradable materials and design for recyclability |

| Hospitality | Cleaning drinkware in hotels and restaurants | Improves customer satisfaction through cleanliness | Bulk purchasing options and compatibility with various container types |

How is Brush Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, brush bottles are essential for cleaning reusable containers, such as water bottles, thermoses, and other beverage-serving equipment. These brushes help ensure that all residues are effectively removed, maintaining hygiene and compliance with health regulations. For international buyers, especially from regions like Africa and South America, sourcing durable brushes made from food-safe materials is crucial to withstand frequent use and harsh cleaning agents.

What Role Does Brush Bottle Play in Pharmaceuticals?

In pharmaceutical settings, brush bottles are vital for cleaning laboratory glassware and equipment. The thorough cleaning provided by these brushes helps maintain sterile environments, thereby preventing contamination of sensitive substances. Buyers from the Middle East and Europe must consider brushes that are resistant to harsh chemicals and can fit a variety of lab equipment sizes, ensuring versatility and effectiveness.

How Can Brush Bottle Benefit Personal Care and Cosmetics?

In the personal care and cosmetics industry, brush bottles are used to clean bottles and containers that hold various products, from lotions to serums. This ensures that products remain uncontaminated and maintain their quality, enhancing the brand’s image. B2B buyers in this sector should prioritize sourcing eco-friendly brushes that offer high-quality bristles to accommodate a range of container shapes and sizes, especially in environmentally-conscious markets like Germany and Brazil.

Why is Brush Bottle Important for Environmental Sustainability?

Brush bottles promote the use of reusable containers, aligning with sustainability initiatives aimed at reducing single-use plastic waste. By effectively cleaning these bottles, businesses can encourage consumers to adopt more sustainable habits. International buyers should focus on sourcing brushes made from biodegradable materials, ensuring that their cleaning tools not only perform well but also support environmental goals.

Illustrative image related to brush bottle

How Does Brush Bottle Improve Cleanliness in Hospitality?

In the hospitality sector, brush bottles are crucial for ensuring that drinkware in hotels and restaurants is thoroughly cleaned. This attention to cleanliness directly impacts customer satisfaction and brand loyalty. For bulk purchases, hospitality buyers need to consider brushes that can efficiently clean a wide range of drinkware types while being durable enough to withstand constant use in a busy environment.

3 Common User Pain Points for ‘brush bottle’ & Their Solutions

Scenario 1: Struggling with Ineffective Cleaning for Diverse Bottle Types

The Problem: B2B buyers, especially those in the food and beverage sector, often face challenges when trying to maintain hygiene across a variety of bottle types. Many cleaning brushes are designed for specific bottle shapes or sizes, leaving users frustrated when they can’t effectively clean sports bottles, baby bottles, or specialty containers. This issue can lead to unsanitary conditions and potential product recalls, impacting brand reputation and customer trust.

The Solution: To address this issue, buyers should seek versatile brush bottles that can accommodate various shapes and sizes. Opt for brushes with flexible bristles and ergonomic handles that allow for deep cleaning in narrow openings. Sourcing from suppliers that offer customizable options can also be beneficial; for example, inquire about brushes with interchangeable heads or adjustable lengths. Additionally, consider investing in brushes that are dishwasher safe and made from durable materials resistant to wear, ensuring longevity and efficiency in cleaning operations.

Illustrative image related to brush bottle

Scenario 2: Difficulty in Sourcing Sustainable Cleaning Solutions

The Problem: As businesses increasingly prioritize sustainability, many B2B buyers struggle to find environmentally friendly cleaning tools that align with their corporate responsibility goals. Traditional plastic brushes contribute to environmental waste, and buyers may feel overwhelmed by the options available, unsure which products are genuinely sustainable and effective.

The Solution: To navigate this challenge, buyers should focus on suppliers that specialize in eco-friendly products. Look for brush bottles made from natural materials such as coconut husk bristles or bamboo handles, which not only clean effectively but also decompose at the end of their lifecycle. Request certifications or documentation from suppliers that verify their sustainability claims. Additionally, consider bulk purchasing options to minimize packaging waste and improve cost-efficiency. Establishing long-term partnerships with eco-conscious suppliers can also streamline the sourcing process, ensuring consistent availability of sustainable cleaning solutions.

Scenario 3: Managing Costs While Maintaining Quality

The Problem: Many B2B buyers are caught between the need for high-quality cleaning tools and the pressure to manage operational costs. Low-cost brushes may lead to poor cleaning results, while high-quality options can strain budgets. This balancing act can create tension, particularly for businesses that rely on maintaining stringent hygiene standards.

The Solution: To manage this financial dilemma, buyers should conduct a total cost of ownership analysis for brush bottles. Evaluate not just the initial purchase price, but also the durability, lifespan, and effectiveness of different options. Investing in higher-quality brushes may lead to lower replacement rates and reduced labor costs over time. Additionally, consider implementing a trial program where employees can test various brush options before making bulk purchases. This approach allows for informed decision-making based on actual performance and user feedback, ultimately leading to better quality assurance while keeping costs manageable. Partnering with suppliers who offer loyalty discounts or flexible payment terms can also help in aligning quality with budget constraints.

Illustrative image related to brush bottle

Strategic Material Selection Guide for brush bottle

When selecting materials for brush bottles, it is essential to consider various factors that impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of brush bottles, tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Nylon in Brush Bottles?

Nylon is a popular choice for bristles in brush bottles due to its excellent flexibility and resilience. It can withstand temperatures up to 120°C (248°F) and is resistant to many chemicals, making it suitable for cleaning various types of bottles. However, nylon can absorb moisture, which may lead to microbial growth if not dried properly.

Pros & Cons: Nylon bristles are durable and maintain their shape over time, providing effective scrubbing power. However, they can be more expensive than other materials and may require more complex manufacturing processes. For international buyers, compliance with regulations regarding plastic materials is crucial, especially in regions with stringent environmental laws.

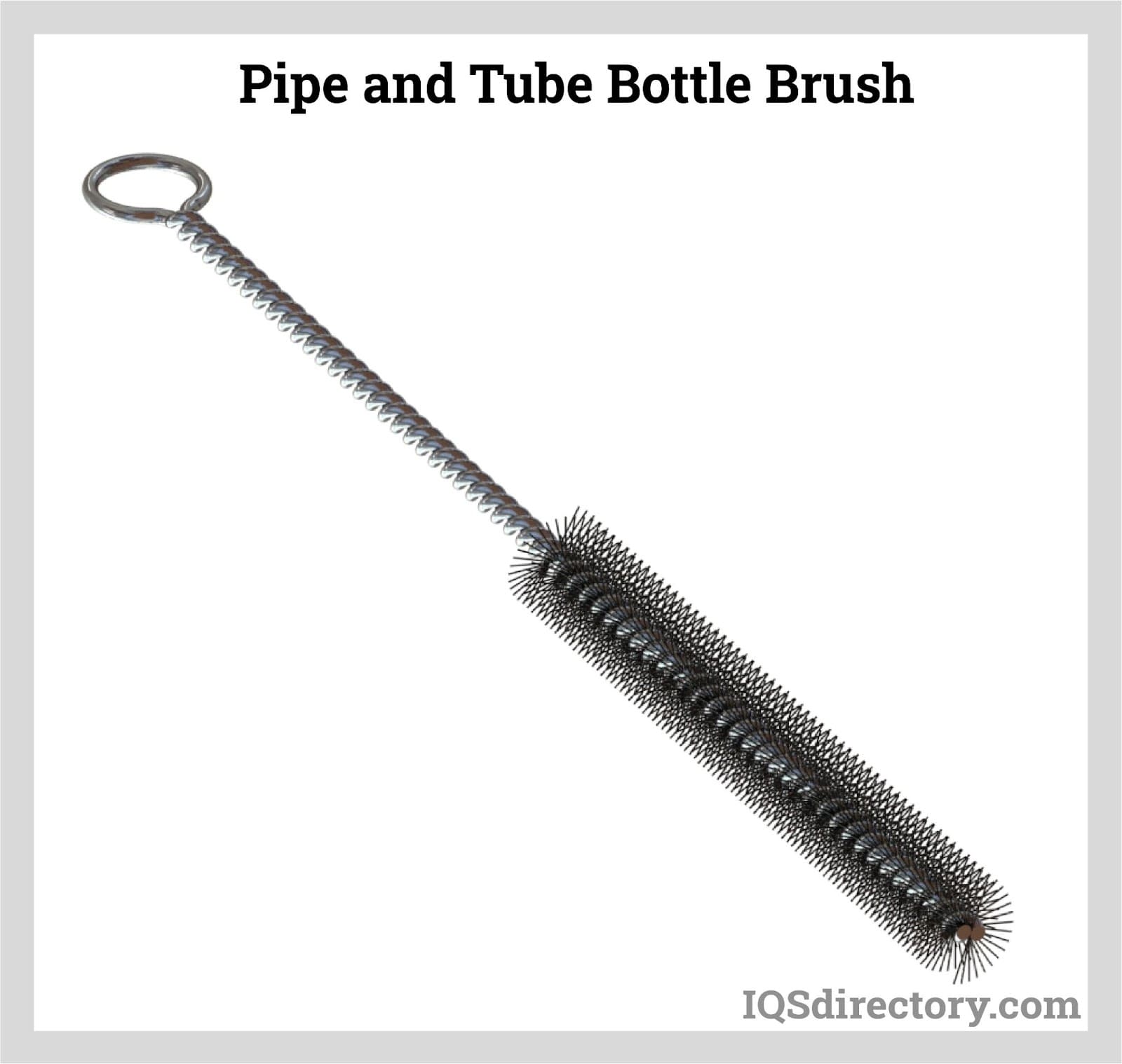

How Does Stainless Steel Enhance Brush Bottle Durability?

Stainless steel is often used for the handle and wire components of brush bottles due to its corrosion resistance and strength. It can withstand high temperatures and is not prone to rust, making it ideal for long-term use in various environments.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, which can justify a higher upfront cost. However, the manufacturing process can be complex, and it may not be suitable for all bottle designs due to weight considerations. Buyers should be aware of compliance with food safety standards, particularly in Europe, where regulations like the EU’s REACH may apply.

What Role Does Wood Play in Eco-Friendly Brush Bottles?

Wood, particularly bamboo, is gaining traction in the brush bottle market as a sustainable option. It is naturally antimicrobial and biodegradable, appealing to environmentally conscious consumers. Wood can withstand moderate temperatures but is less durable than synthetic materials.

Pros & Cons: The eco-friendliness of wood is a significant advantage, making it attractive to buyers in regions with a growing emphasis on sustainability. However, wood can be more susceptible to wear and tear, and its longevity may be a concern for B2B buyers looking for durable solutions. Compliance with sustainability certifications can also enhance marketability in Europe and other regions.

Why Choose Natural Fiber for Brush Bottles?

Natural fibers, such as coconut husks, are increasingly being used for bristles in brush bottles. These materials are biodegradable and provide a unique cleaning capability without scratching surfaces.

Pros & Cons: Natural fibers offer an eco-friendly alternative and are generally cost-effective. However, they may not provide the same level of durability as synthetic options and can shed during use. Buyers should consider market trends favoring sustainable products, especially in regions like Europe, where consumer preferences are shifting towards greener options.

Illustrative image related to brush bottle

Summary Table of Material Selection for Brush Bottles

| Material | Typical Use Case for brush bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Bristles for general cleaning | Durable and flexible | Absorbs moisture, can harbor bacteria | Medium |

| Stainless Steel | Handles and wire components | Corrosion-resistant and strong | Higher manufacturing complexity | High |

| Wood | Eco-friendly brush handles | Sustainable and biodegradable | Less durable, may wear out quickly | Medium |

| Natural Fiber | Bristles for gentle cleaning | Eco-friendly and cost-effective | Less durable, potential shedding | Low |

In conclusion, the selection of materials for brush bottles should align with product performance requirements, cost considerations, and compliance with international standards. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that meet their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for brush bottle

What Are the Key Stages in the Manufacturing Process of Brush Bottles?

The manufacturing process of brush bottles involves several critical stages, each designed to ensure the final product meets quality standards and customer expectations. Here’s a breakdown of the main stages:

Material Preparation

The first step in manufacturing brush bottles is material selection and preparation. Common materials include durable plastics for the brush handles, stainless steel or other rust-resistant metals for the wire, and various types of bristles, which may be synthetic or natural. Suppliers often conduct rigorous tests on raw materials to ensure they meet specific mechanical and chemical properties. For example, nylon bristles are popular for their flexibility and resistance to wear, while natural fibers like coconut husks are favored for eco-friendly products.

Illustrative image related to brush bottle

Forming Processes

Once materials are prepared, the next phase is forming the individual components of the brush bottle. This can involve several techniques:

- Injection Molding: Commonly used for producing plastic handles, this method ensures precision and allows for complex designs.

- Wire Forming: Involves bending and shaping the metal wire that holds the bristles, ensuring it is durable and flexible enough for effective cleaning.

- Bristle Attachment: This process involves securely attaching the bristles to the wire, which may include techniques such as crimping or heat sealing to ensure they remain in place during use.

Assembly

After individual components are formed, they are assembled into the final product. This stage often requires skilled labor or automated systems to ensure proper alignment and secure attachment of parts. Quality control measures should be in place to monitor this process, as improper assembly can lead to product failure.

Finishing Touches

The final manufacturing stage includes finishing processes such as polishing, coating, or packaging. Depending on the product, additional treatments might be applied to enhance durability or aesthetics, such as applying a non-slip grip to handles or ensuring that all components are free of sharp edges. This stage is crucial for the overall functionality and marketability of the brush bottle.

How Is Quality Assurance Implemented in Brush Bottle Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet international standards and customer expectations. Here’s how it’s typically structured:

What Are the Relevant International Standards for Brush Bottle Manufacturing?

B2B buyers should be aware of several international quality standards relevant to brush bottle manufacturing:

- ISO 9001: This standard outlines criteria for a quality management system and is applicable to any organization, regardless of size or industry. Compliance indicates that a supplier maintains consistent quality in their manufacturing processes.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For suppliers dealing with specific industries, such as pharmaceuticals or food, adherence to American Petroleum Institute (API) standards may be necessary.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product integrity:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production line. It includes testing for physical properties, chemical composition, and compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, IPQC involves regular checks at various stages of production to identify any deviations from quality standards. This can include monitoring machine calibration, observing assembly techniques, and conducting spot checks on components.

- Final Quality Control (FQC): Once the brush bottles are fully assembled, FQC ensures that each product meets the required specifications before packaging. This includes functional testing, visual inspections, and packaging checks.

What Common Testing Methods Are Used to Ensure Quality?

To verify product quality, various testing methods may be employed, including:

- Durability Testing: Simulating prolonged use to assess the lifespan of the brush and its components.

- Chemical Resistance Testing: Evaluating how materials react to various cleaning agents and substances to ensure safety and longevity.

- Microbial Testing: Particularly for products used in food and beverage applications, ensuring that materials do not harbor harmful bacteria.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial. Here are actionable steps:

Supplier Audits

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This may involve on-site visits to assess facilities, review documentation, and interview key personnel responsible for quality control.

Illustrative image related to brush bottle

Requesting Quality Reports

Buyers should request detailed quality reports that outline the supplier’s adherence to international standards and internal QC processes. These reports can provide valuable information about the supplier’s reliability and commitment to quality.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspections can be conducted at various stages of the manufacturing process, ensuring that standards are met before products reach the buyer.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control that can differ by region:

- Cultural Differences: Understanding local manufacturing practices and quality expectations is essential. For instance, European buyers may have stricter environmental standards compared to those in other regions.

- Logistical Challenges: International shipping can introduce risks such as damage or contamination. Buyers should ensure that suppliers have robust packaging and transport protocols in place.

- Regulatory Compliance: Different regions have distinct regulations regarding product safety and quality. B2B buyers must ensure that their suppliers comply with local laws to avoid legal complications.

By understanding the manufacturing processes and quality assurance practices of brush bottles, B2B buyers can make informed decisions and establish strong partnerships with suppliers that prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brush bottle’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure brush bottles, essential tools for maintaining cleanliness in various applications, from personal use to industrial settings. By following this step-by-step approach, buyers can ensure they select the right products that meet their specifications, quality standards, and budget constraints.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the brush bottles you need. Consider factors such as size, bristle material, handle design, and intended use.

– Bristle Material: Choose between natural fibers (like coconut husks) for sustainability or synthetic options for durability.

– Size and Shape: Ensure the brush fits the bottle openings you intend to clean, focusing on length and flexibility.

Step 2: Identify Your Target Market

Understanding the demographics and preferences of your target market will guide your sourcing decisions.

– Regional Preferences: Different regions may have distinct preferences for materials and designs. For instance, eco-friendly options may be more appealing in Europe.

– End-User Needs: Consider whether the brushes will be used for personal, commercial, or industrial applications, as this will influence the specifications.

Step 3: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who can meet your technical specifications and market needs.

– Supplier Background: Look into their history, product range, and reputation in the industry.

– Certifications: Verify that suppliers hold relevant certifications for quality and sustainability, which can be crucial for compliance in your target markets.

Step 4: Request Samples

Before making a bulk purchase, request samples to evaluate the quality and functionality of the brush bottles.

– Quality Assessment: Check for durability, bristle effectiveness, and overall design. Ensure the samples meet your specifications before proceeding with a larger order.

– User Testing: If possible, conduct user testing within your target market to gather feedback on performance and satisfaction.

Illustrative image related to brush bottle

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers, engage in negotiations to secure favorable terms.

– Pricing Structure: Discuss bulk pricing options and any potential discounts for larger orders.

– Delivery Timelines: Clarify lead times and shipping arrangements to ensure they align with your project deadlines.

Step 6: Evaluate After-Sales Support

Assess the level of customer service and support provided by the supplier post-purchase.

– Warranty and Returns: Understand their policies on product defects and returns, which can protect your investment.

– Customer Support: Ensure they offer reliable support channels for any inquiries or issues that may arise after the sale.

Step 7: Monitor Industry Trends

Stay informed about emerging trends in the brush bottle market to adapt your sourcing strategy accordingly.

– Sustainability Trends: As consumers increasingly favor eco-friendly products, consider how you can align your offerings with these preferences.

– Technological Advances: Keep an eye on innovations that could enhance the functionality or appeal of brush bottles, such as antimicrobial materials or ergonomic designs.

By following this checklist, B2B buyers can make informed decisions when sourcing brush bottles, ensuring they meet both quality and market demands.

Comprehensive Cost and Pricing Analysis for brush bottle Sourcing

In the highly competitive market for brush bottles, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. This section delves into the various cost components that influence pricing and offers actionable insights to optimize sourcing strategies.

What Are the Key Cost Components in Brush Bottle Manufacturing?

The cost structure of brush bottles typically encompasses several critical components:

-

Materials: The choice of materials significantly impacts costs. Common materials include durable plastics, stainless steel, and natural fibers (e.g., coconut husks for bristles). Sustainable materials often come at a premium but can enhance brand value and appeal to eco-conscious consumers.

-

Labor: Labor costs vary by region. Countries with lower labor costs can offer more competitive pricing, but this can be balanced by the quality of craftsmanship. Skilled labor is essential for ensuring the functionality and durability of the brush bottles.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production processes can help reduce overhead and improve margins.

-

Tooling: Initial tooling costs for molds and specialized equipment can be significant, particularly for custom designs. These costs are typically amortized over the production volume, meaning higher volumes can lead to lower per-unit costs.

-

Quality Control (QC): Implementing rigorous quality control measures is vital, especially for products intended for food or beverage use. QC costs can vary based on the complexity of the inspection processes and regulatory compliance.

-

Logistics: Shipping and handling costs are crucial for international transactions. Factors such as the distance from the manufacturer, shipping method, and customs duties can greatly influence total logistics costs.

-

Margin: Suppliers often build a margin into their pricing to ensure profitability. This margin can vary based on market demand and competitive pressures.

How Do Pricing Influencers Affect Brush Bottle Costs?

Several factors influence the final pricing of brush bottles:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders often lead to bulk discounts, making it essential for buyers to assess their purchasing strategies to optimize costs.

-

Specifications/Customization: Custom designs or specialized features (such as ergonomic handles or unique bristle types) can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Material Quality/Certifications: Higher quality materials and certifications (e.g., BPA-free or eco-friendly labels) can command higher prices but may be necessary for market differentiation.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer premium pricing for their proven quality and service.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears responsibility for shipping costs and risks, impacting the total cost of ownership.

What Are Effective Buyer Tips for Cost-Efficiency?

B2B buyers should consider the following strategies to enhance cost efficiency when sourcing brush bottles:

-

Negotiation: Engage in negotiations to explore bulk purchase discounts or favorable payment terms. Building strong relationships with suppliers can lead to better pricing and service.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire lifecycle cost, including maintenance and disposal. Sustainable products may have higher upfront costs but lower long-term environmental impact.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and regional market dynamics that can affect pricing. Buyers from regions like Africa or South America should also consider local market preferences and regulatory requirements.

In summary, understanding the cost components and pricing influencers of brush bottles is essential for effective sourcing. By applying strategic insights and best practices, international B2B buyers can optimize their purchasing decisions and enhance their competitive edge in the market.

Alternatives Analysis: Comparing brush bottle With Other Solutions

Exploring Alternatives to Brush Bottles in Cleaning Solutions

In the realm of cleaning solutions for bottles, the brush bottle is a popular choice due to its effectiveness in reaching tight spaces and thoroughly removing residue. However, there are alternative methods and tools that may offer unique benefits depending on the specific needs of a business. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational goals.

| Comparison Aspect | Brush Bottle | Eco-Friendly Scrub Brush | Ultrasonic Cleaner |

|---|---|---|---|

| Performance | Excellent for manual scrubbing | Good for general cleaning | Outstanding for deep cleaning |

| Cost | $10 – $25 per unit | $7 – $15 per unit | $200 – $500 per unit |

| Ease of Implementation | Simple to use with no setup required | Immediate use, requires no setup | Requires initial setup and training |

| Maintenance | Low; occasional replacement needed | Moderate; replace every 6-12 months | Moderate; requires regular cleaning and upkeep |

| Best Use Case | Versatile for various bottle types | Great for eco-conscious brands | Ideal for high-volume cleaning needs |

What Are the Benefits and Drawbacks of Eco-Friendly Scrub Brushes?

Eco-friendly scrub brushes serve as a sustainable alternative to traditional brush bottles. Made from natural materials like coconut husks and wood, these brushes are designed to be biodegradable and reduce plastic waste. They perform well for general cleaning tasks but may not reach deep into narrow bottles as effectively as a brush bottle. Additionally, they tend to have a lower price point, making them an attractive option for companies focused on sustainability. However, they typically require replacement every six to twelve months, which can add to long-term costs.

How Do Ultrasonic Cleaners Compare to Brush Bottles?

Ultrasonic cleaners utilize high-frequency sound waves to create microscopic bubbles in a cleaning solution, which implode and effectively remove dirt and contaminants from surfaces. This method offers an outstanding level of cleanliness, making it ideal for high-volume operations such as manufacturing or laboratories where sanitation is critical. However, the initial investment is significantly higher than that of brush bottles or eco-friendly scrub brushes, and they require a certain level of training to operate efficiently. Regular maintenance and cleaning of the ultrasonic unit are also necessary to ensure optimal performance.

Making the Right Choice for Your Business Needs

When evaluating cleaning solutions, B2B buyers should consider their specific requirements, including the volume of cleaning needed, the types of bottles or containers involved, and the importance of sustainability. For businesses focusing on eco-friendly practices, the eco-friendly scrub brush may be the best fit. Conversely, companies that require rigorous cleaning standards and can justify the investment may find ultrasonic cleaners to be a valuable asset. Ultimately, the choice between brush bottles and their alternatives will hinge on balancing performance, cost, and operational ease to meet the unique demands of each business environment.

Essential Technical Properties and Trade Terminology for brush bottle

What Are the Key Technical Properties of Brush Bottles That Buyers Should Consider?

Understanding the essential technical properties of brush bottles is critical for B2B buyers looking to make informed purchasing decisions. Here are some of the most important specifications to keep in mind:

-

Material Composition

– Brush bottles are typically made from materials such as stainless steel, plastic, or natural fibers. Stainless steel is preferred for its durability and resistance to rust, while plastic options may be lighter and more cost-effective. Buyers should consider how the material affects the product’s longevity and cleaning efficiency. -

Bristle Type and Density

– The bristles of a bottle brush can vary in type (e.g., nylon, natural fibers) and density. Nylon bristles are often more durable and effective at scrubbing, while natural fibers may be more eco-friendly. A higher density of bristles typically offers better cleaning capabilities. Understanding bristle characteristics is crucial for ensuring the brush meets specific cleaning requirements. -

Length and Flexibility

– The length of the brush is significant for reaching deep into bottles. Longer brushes can clean larger containers, while flexible designs can adapt to various bottle shapes. Buyers should evaluate the intended use of the brush and select a model that can accommodate different sizes effectively. -

Heat Resistance

– Many brush bottles are designed to withstand high temperatures, making them suitable for cleaning hot liquids. Heat resistance is particularly important for industrial applications where sanitization is critical. Buyers should confirm the temperature limits to ensure compliance with cleaning protocols. -

Ergonomic Design

– A brush bottle with an ergonomic handle will improve user comfort and efficiency. Features like a non-slip grip can reduce hand fatigue during prolonged use. For businesses that prioritize employee safety and comfort, investing in ergonomically designed tools can lead to higher productivity. -

Dishwasher Safety

– Many brush bottles are marketed as dishwasher safe, which simplifies maintenance and enhances hygiene. This property is essential for businesses that require thorough cleaning of their tools. Confirming dishwasher compatibility can save time and labor costs in the long run.

What Are the Common Trade Terms Associated with Brush Bottles?

Familiarity with industry terminology can enhance communication and streamline transactions. Here are several critical terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of brush bottles, buyers may work with OEMs to obtain customized designs tailored to their specific needs. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure that they are not overcommitting to stock that may not sell. It also affects pricing, as larger orders often come with discounts. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. Buyers can use RFQs to compare offers from different suppliers, ensuring they receive the best value for their purchase. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and reduces the risk of disputes. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory planning, especially for businesses that operate on tight schedules. -

Certification Standards

– Certification standards, such as ISO or FDA approvals, indicate that a product meets specific safety and quality benchmarks. Buyers should consider these certifications when sourcing brush bottles to ensure they comply with industry regulations and quality expectations.

By grasping these essential properties and terminologies, B2B buyers can make more informed decisions when sourcing brush bottles, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the brush bottle Sector

What Are the Key Trends Shaping the Global Brush Bottle Market?

The brush bottle sector is experiencing dynamic shifts influenced by several global drivers. Rising health consciousness and sustainability trends are compelling consumers to seek cleaner, reusable alternatives, thus increasing demand for effective cleaning tools like bottle brushes. In regions such as Africa, South America, the Middle East, and Europe, the market is witnessing a surge in interest for products that facilitate the maintenance of reusable bottles, especially among eco-conscious consumers.

Emerging technologies are also reshaping sourcing strategies. E-commerce platforms and digital supply chain management tools are becoming crucial for B2B buyers, allowing them to source high-quality products more efficiently. The integration of data analytics is enabling companies to better understand consumer preferences and optimize their inventory, leading to more targeted marketing strategies. Additionally, the ongoing trend towards customization is prompting manufacturers to offer bespoke solutions, addressing the specific needs of diverse markets.

International buyers should also be aware of fluctuating raw material costs, particularly for sustainable materials like bamboo or recycled plastics. These fluctuations can affect pricing strategies and product availability. As manufacturers increasingly focus on product durability and functionality, buyers are encouraged to look for suppliers that offer comprehensive warranties and quality assurances.

How Is Sustainability Influencing Sourcing Decisions in the Brush Bottle Sector?

Sustainability has become a cornerstone of modern sourcing strategies within the brush bottle sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmentally friendly practices. The environmental impact of production processes, particularly concerning plastic waste and carbon emissions, is under scrutiny, pushing businesses to adopt more sustainable methods.

The demand for ‘green’ certifications is on the rise, with buyers looking for products that are certified by recognized environmental standards. Materials such as biodegradable plastics, natural fibers, and recycled components are gaining traction. For instance, brushes made from coconut husks or bamboo not only appeal to eco-conscious consumers but also reduce the reliance on non-renewable resources.

Furthermore, ethical supply chains are integral to brand reputation. Buyers are encouraged to conduct thorough due diligence on their suppliers to ensure compliance with labor and environmental standards. This includes evaluating the supply chain for transparency and social responsibility, which can enhance brand loyalty and customer trust.

Illustrative image related to brush bottle

How Has the Brush Bottle Market Evolved Over Time?

The brush bottle market has undergone significant evolution in response to changing consumer preferences and technological advancements. Initially, bottle brushes were simple tools made from basic materials, primarily aimed at functionality. However, as environmental awareness grew, so did the demand for more sustainable options, leading to innovations in materials and design.

In recent years, the introduction of ergonomic designs and multi-functional brushes has transformed the market, making these products not only practical but also appealing to a broader consumer base. The rise of social media and influencer marketing has further propelled trends, as consumers share their experiences with various products, shaping market dynamics in real-time.

Overall, the brush bottle sector is poised for continued growth, driven by a combination of sustainability initiatives, technological advancements, and shifting consumer behaviors. B2B buyers should remain vigilant in adapting to these trends, ensuring they source products that align with both market demands and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of brush bottle

-

How do I choose the right brush bottle for my business needs?

Selecting the right brush bottle requires evaluating your specific cleaning needs, bottle types, and target markets. Consider factors such as the size and shape of the bottles you plan to clean, as well as the materials that your brushes will be made from. Look for durable bristles that can handle various contaminants, and ensure that the brush fits well into your bottles for effective cleaning. Additionally, assess whether eco-friendly options are important to your clientele, as sustainability is increasingly valued in many markets. -

What is the best material for brush bottles?

The best materials for brush bottles often include nylon, natural fibers, and stainless steel. Nylon bristles are durable and effective for general cleaning, while natural fibers, such as coconut husks, offer a sustainable alternative. Stainless steel handles provide strength and rust resistance, ensuring longevity. Evaluate the preferences of your target market, as some may prioritize sustainability, while others might focus on durability and performance. Customization options can also enhance the appeal of your product line. -

What are the minimum order quantities (MOQ) for brush bottles?

Minimum order quantities for brush bottles can vary significantly by supplier and product type. Generally, MOQs can range from 100 to 1,000 units, depending on the manufacturer’s capacity and the complexity of the product. When negotiating with suppliers, consider your initial market demand and storage capabilities. It’s often beneficial to discuss flexible MOQs, especially if you’re testing new markets or launching a new product line. -

How can I vet suppliers for brush bottles?

Vetting suppliers involves a multi-faceted approach. Start by researching their reputation through online reviews and industry references. Request samples to assess product quality firsthand. Evaluate their production capabilities and compliance with international standards, especially if you are importing goods. Engage in direct communication to gauge responsiveness and reliability. Additionally, consider visiting the supplier’s facility if feasible, or leveraging third-party inspection services to ensure quality and compliance with your specifications. -

What customization options are available for brush bottles?

Many suppliers offer customization options for brush bottles, including branding, size, color, and packaging. You can request custom bristle stiffness or handle design to suit specific cleaning needs. Some manufacturers might also provide eco-friendly materials for branding alignment. When discussing customization, ensure that the supplier can meet your quality standards and timelines, and be prepared to share detailed specifications and design concepts to facilitate the process. -

What payment terms should I expect when sourcing brush bottles?

Payment terms can vary widely among suppliers but typically include options like a deposit followed by balance payment upon shipment or delivery. Common practices involve a 30% upfront deposit with the remainder due before shipment. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing contracts to avoid misunderstandings and ensure smooth transactions. -

What quality assurance processes should I expect from suppliers?

Quality assurance processes may include raw material inspections, in-process checks, and final product testing. Reputable suppliers should provide documentation of their quality control measures, such as ISO certifications or compliance with safety standards. It’s advisable to request third-party inspections or audits to verify quality practices. Establish clear quality expectations in your agreements, including acceptable defect rates and return policies, to safeguard your interests. -

How can I manage logistics for importing brush bottles?

Managing logistics involves coordinating shipping, customs clearance, and warehousing. Work with logistics partners experienced in international trade, especially those familiar with your target markets in Africa, South America, the Middle East, and Europe. Ensure that you understand the import regulations and tariffs specific to your region. Develop a clear logistics plan that includes timelines for shipping and delivery, and consider using freight forwarders to simplify the process and mitigate risks associated with international shipping.

Top 2 Brush Bottle Manufacturers & Suppliers List

1. Fuller – Pretty & Pink Sports Bottle Brush

Domain: fuller.com

Registered: 1991 (34 years)

Introduction: Pretty & Pink Sports Bottle Brush

– SKU: 336-FB

– Regular price: $19.99

– Perfect for cleaning sports and baby bottles, jars, long wide neck bottles, vases, and drinking glasses.

– Extra durable polyester bristles for tough cleaning jobs.

– Wavy bristle shape holds soap and water better than other brushes.

– Unique twist of wire at the tip allows for scrubbing in all directions.

– Made with sturdy…

2. Memento Earth – Bottle Scrub Brush

Domain: memotherearthbrand.com

Registered: 2019 (6 years)

Introduction: Product Name: Bottle Scrub Brush

Price: $9.99 (currently on sale for $7.99)

Size: 11.5″ length, 2″ tip width

Material: Bristles made from natural coconut husks, wooden handle, natural cotton or twine loop for hanging

Features: Medium stiffness bristles for deep cleaning without abrasion, bendable wire tip for fitting different openings, naturally antimicrobial wood

Care Instructions: Hang to dry, …

Strategic Sourcing Conclusion and Outlook for brush bottle

In navigating the dynamic market for brush bottles, international B2B buyers must prioritize strategic sourcing to maximize value and efficiency. Key takeaways include the importance of selecting suppliers that offer a diverse range of products, from eco-friendly options made of natural materials to high-quality synthetic alternatives. Understanding local market demands and preferences is crucial, as buyers from Africa, South America, the Middle East, and Europe may have different criteria for quality, pricing, and sustainability.

Moreover, fostering strong supplier relationships can lead to better negotiation outcomes and access to innovative products. Buyers should also consider the potential of integrating technology into their sourcing strategies to streamline operations and enhance product tracking.

Illustrative image related to brush bottle

As we look ahead, the brush bottle market is poised for growth, driven by increasing consumer awareness of hygiene and sustainability. Now is the time for B2B buyers to leverage these trends by sourcing products that meet both quality standards and environmental expectations. Engage with suppliers who share your commitment to sustainability and innovation, and take proactive steps to secure your place in this evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to brush bottle