Top 2 3 4 Cup Measuring Cup Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 3 4 cup measuring cup

In today’s competitive culinary landscape, sourcing a reliable 3/4 cup measuring cup can be a daunting challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The need for precision in ingredient measurement is paramount, as it directly impacts food quality, consistency, and cost-efficiency in professional kitchens. This guide aims to simplify the procurement process by providing a comprehensive overview of various types of 3/4 cup measuring cups, their applications in different foodservice environments, and essential supplier vetting criteria.

Throughout this guide, we will delve into the intricacies of selecting the right measuring cup, considering factors such as material durability, ease of cleaning, and ergonomic design. Additionally, we will discuss cost considerations and highlight reputable suppliers that cater to international markets, ensuring that you can make informed purchasing decisions tailored to your specific operational needs. By addressing these critical aspects, we empower international B2B buyers to streamline their sourcing processes and enhance their kitchen efficiency.

Whether you are a restaurant owner, caterer, or institutional food service provider, understanding the nuances of 3/4 cup measuring cups will equip you with the knowledge to invest wisely in tools that not only meet your culinary requirements but also uphold the standards of excellence that your business demands.

Understanding 3 4 cup measuring cup Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel | Durable, corrosion-resistant, easy to clean | Commercial kitchens, catering services | Pros: Long-lasting, precise measurements. Cons: Higher initial cost. |

| Plastic | Lightweight, often stackable, and colorful | Cafeterias, schools, and casual dining | Pros: Affordable, versatile. Cons: Less durable, may warp over time. |

| Glass | Heavy-duty, microwave-safe, can double as serving vessels | Bakeries, upscale restaurants | Pros: Non-reactive, aesthetically pleasing. Cons: Fragile, heavier to handle. |

| Collapsible Silicone | Flexible, space-saving design, available in various colors | Food trucks, pop-up restaurants | Pros: Portable, easy storage. Cons: May lack precision in measurement. |

| Measuring Spoon Set | Includes 3/4 cup among various sizes, often nesting | Home kitchens, small food businesses | Pros: Compact, multi-functional. Cons: Less robust for high-volume use. |

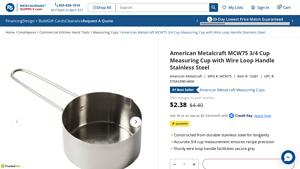

What Are the Key Characteristics of Stainless Steel 3/4 Cup Measuring Cups?

Stainless steel measuring cups, like the American Metalcraft MCW75, are known for their durability and corrosion resistance. They are ideal for high-volume foodservice environments where consistent measurement is essential. The ergonomic wire loop handle ensures a secure grip, making them easy to use even in fast-paced kitchens. When considering stainless steel options, buyers should evaluate their long-term investment, as these cups typically come at a higher initial cost but provide significant durability and precision.

How Do Plastic 3/4 Cup Measuring Cups Compare?

Plastic measuring cups are popular in casual dining and educational settings due to their lightweight nature and affordability. They often come in vibrant colors, making them visually appealing and easy to identify in a busy kitchen. However, they may not withstand high temperatures as well as metal or glass options, which could lead to warping or degradation over time. Buyers should assess the balance between cost and durability when selecting plastic measuring cups for their operations.

Why Choose Glass 3/4 Cup Measuring Cups for Your Business?

Glass measuring cups offer a heavy-duty option that is non-reactive and suitable for both measuring and serving. Their microwave-safe feature allows for versatile use in bakeries and upscale restaurants where presentation matters. However, glass cups are more fragile and can be heavier to handle, which may not be ideal for all kitchen environments. Businesses should consider their operational needs and the potential risks of breakage when investing in glass measuring cups.

What Advantages Do Collapsible Silicone 3/4 Cup Measuring Cups Offer?

Collapsible silicone measuring cups provide a flexible, space-saving solution for foodservice operations that require portability. Their ability to fold down makes them particularly useful for food trucks and pop-up restaurants where storage space is limited. While they are convenient, buyers should note that they may lack the precision of rigid measuring cups, which could impact recipe consistency. Assessing the trade-offs between portability and measurement accuracy is crucial for businesses considering this option.

How Do Measuring Spoon Sets with 3/4 Cup Options Fit into B2B Needs?

Measuring spoon sets that include a 3/4 cup option are compact and multi-functional, making them suitable for home kitchens and small food businesses. These sets are often designed to nest together for easy storage, appealing to buyers with limited kitchen space. However, they may not be robust enough for high-volume use in commercial settings. Businesses should weigh the benefits of versatility against the potential limitations in durability when choosing measuring spoon sets for their operations.

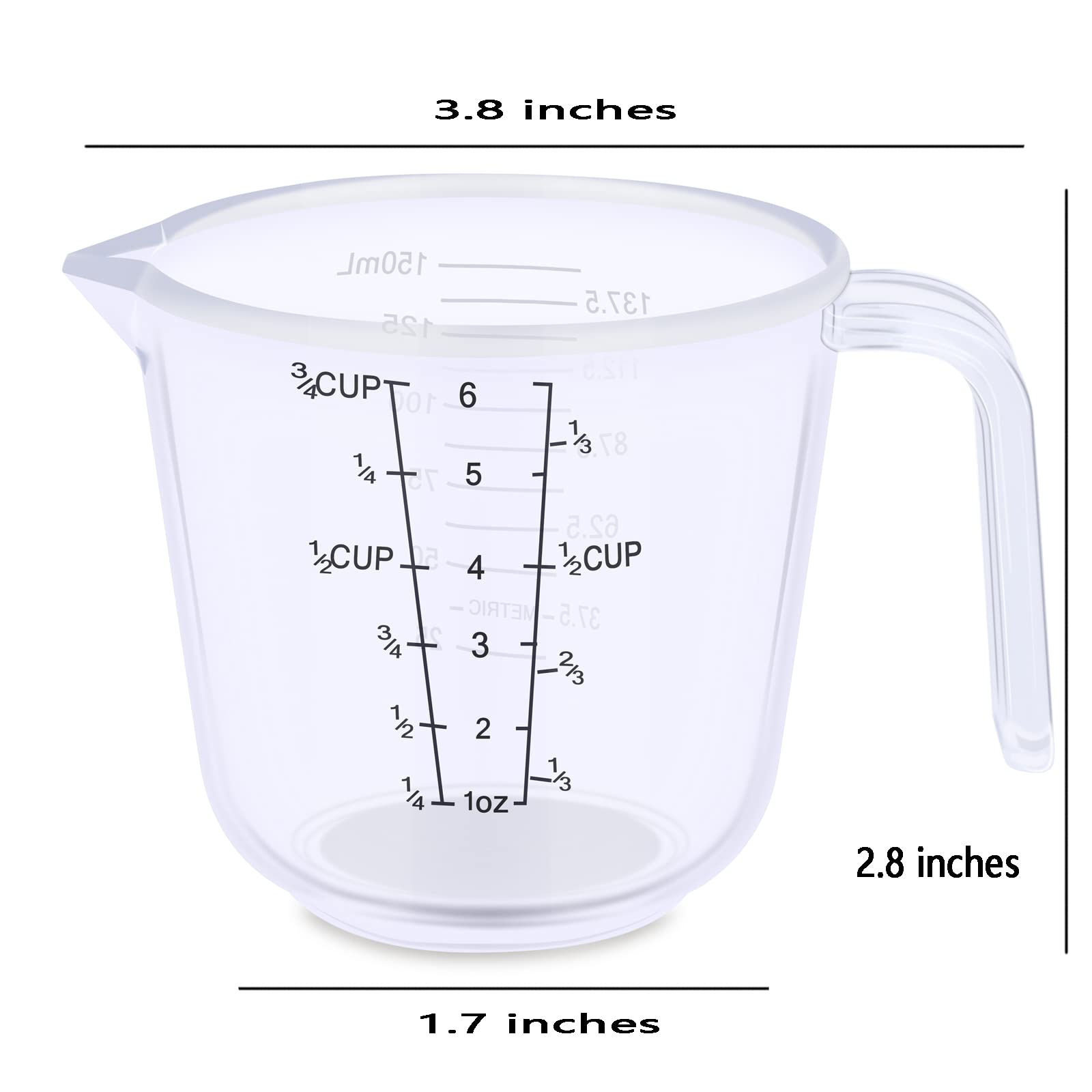

Illustrative image related to 3 4 cup measuring cup

Key Industrial Applications of 3 4 cup measuring cup

| Industry/Sector | Specific Application of 3/4 Cup Measuring Cup | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Foodservice & Catering | Ingredient portioning during meal preparation | Ensures recipe consistency and portion control | Durability, corrosion resistance, and ease of cleaning |

| Bakery Production | Accurate measurement of dry and wet ingredients | Enhances product quality and reduces waste | Material quality, precision, and compatibility with other tools |

| Pharmaceuticals | Measuring active ingredients for formulations | Guarantees precise dosages for safety and efficacy | Compliance with industry standards and material safety |

| Educational Institutions | Teaching proper measuring techniques in culinary classes | Promotes skill development and accuracy in students | Availability in bulk and cost-effectiveness |

| Hospitality Industry | Standardizing portion sizes for menu items | Increases customer satisfaction and inventory control | Versatility and ease of storage in compact kitchens |

How is the 3/4 Cup Measuring Cup Used in Foodservice & Catering?

In the foodservice and catering industry, the 3/4 cup measuring cup plays a critical role in ingredient portioning during meal preparation. Accurate measurements are essential for maintaining recipe consistency and ensuring that dishes meet quality standards. This tool helps chefs and kitchen staff quickly and efficiently measure ingredients, reducing the risk of errors that could lead to food waste or customer dissatisfaction. For international buyers, sourcing durable, corrosion-resistant measuring cups that can withstand high-volume use and frequent dishwashing is vital.

What Role Does the 3/4 Cup Measuring Cup Play in Bakery Production?

In bakery production, the 3/4 cup measuring cup is crucial for accurately measuring both dry and wet ingredients, such as flour, sugar, and liquids. Precision in these measurements significantly impacts the quality of baked goods, helping to achieve the desired texture and flavor. The use of stainless steel measuring cups ensures durability and resistance to wear, which is essential in a fast-paced environment. Buyers, particularly from emerging markets, should prioritize sourcing measuring cups that meet industry standards for accuracy and can be easily integrated into existing kitchen workflows.

How is the 3/4 Cup Measuring Cup Utilized in Pharmaceuticals?

In the pharmaceutical sector, the 3/4 cup measuring cup is utilized for measuring active ingredients when preparing formulations. Accuracy in dosage is paramount in this industry, as it directly affects the safety and efficacy of medications. Sourcing measuring cups that comply with industry regulations regarding material safety and precision is critical for pharmaceutical companies. International buyers must consider suppliers that offer high-quality, food-grade materials that ensure compliance with safety standards while also providing the necessary durability for repeated use.

Illustrative image related to 3 4 cup measuring cup

Why is the 3/4 Cup Measuring Cup Important for Educational Institutions?

Educational institutions offering culinary programs benefit from using the 3/4 cup measuring cup as a teaching tool for proper measuring techniques. This measuring cup helps students learn the importance of accuracy in food preparation, which is a fundamental skill in the culinary arts. It is essential for educational buyers to source measuring cups that are affordable and available in bulk, allowing for consistent training experiences across multiple classes. The durability and ease of cleaning of stainless steel measuring cups also make them ideal for classroom environments.

How Does the 3/4 Cup Measuring Cup Enhance Operations in the Hospitality Industry?

In the hospitality industry, the 3/4 cup measuring cup is crucial for standardizing portion sizes in menu items, contributing to customer satisfaction and efficient inventory control. By ensuring that portion sizes are consistent, establishments can manage food costs better and maintain quality across various locations. Buyers in this sector should look for versatile measuring cups that can easily fit into compact kitchen spaces while offering durability for frequent use. The ability to stack and store these cups efficiently is an added advantage for busy kitchens.

3 Common User Pain Points for ‘3 4 cup measuring cup’ & Their Solutions

Scenario 1: Inconsistent Measurement Accuracy in High-Volume Kitchens

The Problem: B2B buyers, especially those in the foodservice industry, often face challenges with measuring tools that do not provide consistent accuracy, particularly under high-volume conditions. For instance, a restaurant kitchen may require the precise measurement of ingredients for large batch recipes. Inconsistent measurements can lead to variations in food quality, affecting customer satisfaction and potentially leading to waste of both ingredients and time.

The Solution: To ensure measurement accuracy, buyers should prioritize sourcing high-quality 3/4 cup measuring cups made from durable materials such as stainless steel, which resist corrosion and maintain their shape over time. It is advisable to look for products with clear measurement markings that are easy to read. Additionally, investing in measuring cups that are designed for commercial use can enhance durability and reliability. Regular training of kitchen staff on proper measuring techniques, such as leveling off dry ingredients and using the measuring cup at eye level, can further improve accuracy and consistency in ingredient preparation.

Scenario 2: Difficulty in Handling and Pouring Ingredients

The Problem: In busy kitchen environments, handling measuring cups can be cumbersome, especially when pouring ingredients into mixing bowls or pots. A measuring cup that is too heavy or has an awkward handle can lead to spills, resulting in both waste and messy workstations. This challenge is particularly prevalent in establishments that prioritize efficiency and speed, such as catering services and high-volume restaurants.

The Solution: To mitigate this issue, B2B buyers should seek 3/4 cup measuring cups that feature ergonomic designs, such as wire loop handles, which provide a secure grip and enhance control while pouring. A lightweight yet sturdy construction is also essential to minimize fatigue during prolonged use. Additionally, choosing measuring cups with spouts can facilitate smoother pouring and reduce the likelihood of spills. Buyers can also consider implementing standard operating procedures (SOPs) that encourage staff to use both hands when pouring to ensure stability and control.

Scenario 3: Time-Consuming Cleaning and Maintenance

The Problem: In the fast-paced environment of a commercial kitchen, time is of the essence. Many B2B buyers encounter the frustration of measuring tools that are difficult to clean or maintain, leading to longer downtime between uses. Measuring cups that are not dishwasher safe or that retain stains can create inefficiencies and may require additional labor to keep them in good condition.

The Solution: When sourcing 3/4 cup measuring cups, B2B buyers should prioritize options that are specifically labeled as dishwasher-safe and resistant to staining and tarnishing. Stainless steel measuring cups, like the American Metalcraft MCW75, are an excellent choice due to their durability and ease of cleaning. Incorporating a routine where measuring cups are promptly cleaned after use, either by hand or in a dishwasher, can help maintain hygiene and readiness for the next use. Additionally, establishing a regular inventory check can ensure that enough measuring cups are available, minimizing the need for washing while maintaining workflow efficiency.

By addressing these pain points with actionable solutions, B2B buyers can enhance their operations, improve staff efficiency, and ultimately contribute to a higher quality of service in their foodservice establishments.

Illustrative image related to 3 4 cup measuring cup

Strategic Material Selection Guide for 3 4 cup measuring cup

What are the Key Materials for a 3/4 Cup Measuring Cup?

When selecting a material for a 3/4 cup measuring cup, it’s essential to consider various factors that affect performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of measuring cups: stainless steel, plastic, glass, and aluminum.

How Does Stainless Steel Perform in Measuring Cups?

Stainless steel is a popular choice for measuring cups due to its excellent durability and resistance to corrosion. It can withstand high temperatures, making it suitable for both hot and cold ingredients. The material is also non-reactive, which means it won’t impart any flavors or odors to the food.

Pros: Stainless steel measuring cups are highly durable, resistant to rust and staining, and can endure repeated washing in commercial dishwashers. They are also easy to clean and maintain.

Cons: The initial cost of stainless steel can be higher than plastic or aluminum options. Additionally, while they are generally lightweight, they can be heavier than plastic counterparts, which may be a consideration for some users.

Illustrative image related to 3 4 cup measuring cup

Impact on Application: Stainless steel measuring cups are ideal for professional kitchens where hygiene and durability are paramount. They comply with international food safety standards, making them suitable for export to regions such as Africa and Europe.

What are the Benefits of Plastic Measuring Cups?

Plastic measuring cups are lightweight and typically less expensive than their metal counterparts. They are available in various colors and designs, which can be appealing for branding and aesthetic purposes.

Pros: Plastic measuring cups are affordable and often come in a variety of sizes and colors. They are lightweight and easy to handle, making them suitable for home kitchens and casual cooking environments.

Cons: They are less durable than stainless steel and can warp or stain over time, especially when exposed to high temperatures or certain food substances. Additionally, not all plastics are food-safe, so compliance with safety standards is crucial.

Illustrative image related to 3 4 cup measuring cup

Impact on Application: Plastic measuring cups may be more suitable for informal settings or regions where cost is a significant factor. However, buyers should ensure that the plastic used complies with international safety standards such as ASTM D6400.

How Does Glass Compare as a Material for Measuring Cups?

Glass measuring cups are known for their aesthetic appeal and precise measurement markings. They are non-reactive and easy to clean, making them a popular choice for home cooks.

Pros: Glass measuring cups do not stain or retain odors, ensuring that the ingredients maintain their purity. They are also dishwasher safe and can be used in microwaves.

Cons: While glass is durable, it is also fragile and can break easily if dropped. This fragility can be a concern in busy commercial kitchens.

Impact on Application: Glass measuring cups are suitable for environments where precision is crucial, but their fragility limits their use in high-volume commercial settings. International buyers should consider the shipping and handling implications due to breakage risks.

What Role Does Aluminum Play in Measuring Cup Manufacturing?

Aluminum measuring cups are lightweight and often less expensive than stainless steel. They are typically coated to prevent reactions with acidic foods.

Pros: Aluminum is lightweight and generally more affordable than stainless steel. It heats quickly, which can be advantageous in certain cooking scenarios.

Cons: Aluminum can corrode over time, especially if not properly coated. It is also less durable than stainless steel and may not withstand the rigors of a commercial kitchen.

Illustrative image related to 3 4 cup measuring cup

Impact on Application: Aluminum measuring cups may be suitable for casual cooking environments or for specific applications where weight is a concern. However, international buyers should ensure that the aluminum used meets safety standards to avoid any health risks.

Summary of Material Selection for 3/4 Cup Measuring Cups

| Material | Typical Use Case for 3/4 Cup Measuring Cup | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Professional kitchens, high-volume use | Durable, corrosion-resistant | Higher initial cost | High |

| Plastic | Home kitchens, casual cooking | Lightweight, affordable | Less durable, potential safety concerns | Low |

| Glass | Home kitchens, precise measurements | Non-reactive, aesthetic appeal | Fragile, risk of breakage | Medium |

| Aluminum | Casual cooking, lightweight applications | Lightweight, cost-effective | Corrosion risk, less durable | Low |

This material selection guide provides valuable insights for B2B buyers looking to source 3/4 cup measuring cups. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 4 cup measuring cup

What Are the Key Stages in the Manufacturing Process of a 3/4 Cup Measuring Cup?

Manufacturing a 3/4 cup measuring cup involves several critical stages, each designed to ensure the final product meets the rigorous demands of commercial foodservice environments. The primary stages of production include material preparation, forming, assembly, and finishing.

How Is Material Prepared for a 3/4 Cup Measuring Cup?

The process begins with the selection of high-quality materials, typically stainless steel, known for its durability, corrosion resistance, and ease of cleaning. Suppliers often source stainless steel sheets that comply with food safety standards, ensuring they are food-grade and safe for kitchen use. The material is then cut into precise dimensions using advanced laser cutting or stamping techniques. This accuracy is vital to achieving the exact capacity of 3/4 cup.

What Forming Techniques Are Used in Manufacturing?

Once the material is prepared, it undergoes forming. This step may involve processes like deep drawing or hydroforming, where the cut metal is shaped into the desired cup form under high pressure. These techniques allow for the creation of uniform and consistent shapes, critical for maintaining measurement accuracy. Additionally, this stage may incorporate methods to create features such as the wire loop handle, enhancing the cup’s ergonomics and usability in busy kitchens.

Illustrative image related to 3 4 cup measuring cup

How Is Assembly Conducted for Measuring Cups?

Following the forming stage, assembly occurs. For measuring cups that feature handles, this step involves welding or securely attaching the wire loop handle to the cup. Quality during assembly is crucial; any misalignment or improper attachment can lead to functional issues, especially in a high-use environment. Each cup is then inspected for visual defects, ensuring that only products meeting aesthetic and functional standards proceed to the next stage.

What Finishing Processes Are Applied to the Measuring Cups?

The final manufacturing stage is finishing, which may include polishing, coating, and cleaning processes. Polishing enhances the cup’s surface, providing a smooth finish that is not only visually appealing but also prevents food particles from adhering. A thorough cleaning process ensures that no contaminants remain from manufacturing. Additionally, some manufacturers may apply a protective coating to further enhance corrosion resistance, which is especially important for products used in humid kitchen environments.

What Quality Assurance Practices Are Essential for 3/4 Cup Measuring Cups?

Quality assurance (QA) in the manufacturing of measuring cups is paramount to ensure they meet international standards and customer expectations. The QA process typically adheres to both international standards, such as ISO 9001, and industry-specific certifications, like CE marking for products sold in Europe.

Illustrative image related to 3 4 cup measuring cup

Which International Standards Are Relevant for Measuring Cups?

ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. It ensures that manufacturers maintain consistent quality in their processes and products. Additionally, for measuring cups, compliance with food safety standards is critical. This includes certifications that demonstrate the materials used are safe for food contact, such as FDA approval in the U.S. or LFGB certification in Germany.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integral to the manufacturing process, often segmented into several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications before manufacturing begins. For stainless steel, this includes checking for material grades and surface quality.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs at various stages, particularly during forming and assembly. Random sampling and checks ensure that dimensions and shapes remain consistent and that the assembly is correctly executed.

-

Final Quality Control (FQC): After finishing, each measuring cup undergoes a final inspection, focusing on functionality, aesthetics, and compliance with specifications. This may include pressure tests for structural integrity and measurement accuracy tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are some actionable steps buyers can take:

What Audit Processes Should B2B Buyers Consider?

Conducting supplier audits is a proactive approach to assess a manufacturer’s capabilities and quality assurance processes. Buyers should request to see the supplier’s quality management certifications and audit reports. An on-site audit can provide insights into the supplier’s manufacturing environment, processes, and adherence to quality standards.

Illustrative image related to 3 4 cup measuring cup

How Important Are Third-Party Inspections?

Engaging third-party inspection agencies can add an additional layer of assurance. These organizations can conduct independent assessments of the manufacturing process, ensuring compliance with international standards and verifying the quality of the final product. Buyers should seek suppliers who are open to third-party inspections and can provide documentation of past inspections.

What Documentation Should Buyers Request from Suppliers?

Buyers should request comprehensive quality documentation, including:

– Certificates of Compliance for materials used.

– Detailed QC reports outlining the results of inspections at various checkpoints.

– Records of any testing conducted, such as measurement accuracy and corrosion resistance tests.

What Unique Quality Control Challenges Do International Buyers Face?

International buyers often encounter specific nuances in quality control that can impact their purchasing decisions. These include:

-

Regulatory Variations: Different countries have varying food safety regulations, which may affect the certification process for measuring cups. Buyers should be aware of the specific regulations in their markets and ensure that suppliers comply.

-

Cultural Differences in Quality Expectations: Understanding regional preferences and standards can aid in establishing clearer communication with suppliers regarding quality expectations.

-

Logistical Challenges: Importing goods from different regions may introduce risks related to product handling and storage. Buyers should ensure that their suppliers have robust logistics and handling procedures to maintain product integrity during transit.

By understanding the manufacturing processes and quality assurance practices for 3/4 cup measuring cups, B2B buyers can make informed decisions that align with their operational needs and quality standards. This knowledge not only aids in selecting reliable suppliers but also enhances overall supply chain efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 4 cup measuring cup’

In the competitive landscape of B2B procurement, sourcing the right tools is essential for operational efficiency and product quality. This guide provides a step-by-step checklist for international buyers seeking to procure 3/4 cup measuring cups, ensuring that you make informed decisions tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a 3/4 cup measuring cup. Consider factors such as material (stainless steel vs. plastic), design features (like a wire loop handle), and capacity accuracy. These specifications will help you narrow down your options and ensure that the measuring cups meet your operational requirements.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is crucial for a successful procurement process. Look for suppliers with a proven track record in the foodservice industry, and check for online reviews and testimonials. Additionally, assess their market presence in your region—this can indicate reliability and their understanding of local needs.

Step 3: Evaluate Product Quality

Before making a purchase, it’s essential to assess the quality of the measuring cups. Request samples to evaluate the construction and durability, particularly the corrosion resistance of stainless steel options. Pay attention to the weight and handling comfort, as these factors can significantly impact efficiency in high-volume kitchen settings.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant certifications, such as food safety standards and ISO certifications. These certifications can serve as a guarantee of product quality and compliance with health regulations. Inquire about their manufacturing processes to confirm that they adhere to industry best practices.

Step 5: Assess Pricing and Payment Terms

Pricing can vary significantly between suppliers, so it’s important to compare quotes while considering total cost implications. Look for competitive pricing but be wary of unusually low costs, which might indicate inferior quality. Additionally, clarify payment terms, including bulk order discounts and shipping costs, to ensure they align with your budget.

Step 6: Confirm Shipping and Delivery Options

Understanding shipping and delivery logistics is vital for timely procurement. Confirm the estimated delivery timeframes and shipping methods offered by the supplier. Ensure that they have the capacity to meet your required timelines, especially if you are operating in regions with longer lead times, such as Africa or South America.

Step 7: Establish a Communication Plan

Effective communication with your supplier is key to a smooth procurement process. Set up regular check-ins to discuss order status, any potential delays, or quality issues. Clear communication will help build a strong relationship with the supplier and can facilitate smoother transactions in the future.

By following this checklist, B2B buyers can confidently navigate the procurement process for 3/4 cup measuring cups, ensuring that they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for 3 4 cup measuring cup Sourcing

Analyzing the cost structure and pricing of the 3/4 cup measuring cup is essential for international B2B buyers, especially those in emerging markets such as Africa, South America, the Middle East, and Europe. This analysis encompasses various cost components, price influencers, and provides actionable tips for buyers.

What Are the Key Cost Components in Sourcing 3/4 Cup Measuring Cups?

-

Materials: The primary cost driver for measuring cups is the material used. Stainless steel is a popular choice due to its durability and corrosion resistance. The price of stainless steel can fluctuate based on market conditions, which will directly impact the final cost of the measuring cup.

-

Labor: Labor costs vary by region and can significantly affect pricing. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality. Understanding the labor market in the supplier’s region is crucial for assessing overall costs.

-

Manufacturing Overhead: This includes the costs associated with the production facilities, utilities, and indirect labor. In regions with higher operational costs, such as Europe, overhead can significantly influence the pricing structure.

-

Tooling: Tooling costs are incurred in the initial setup for production. Custom designs or modifications to standard measuring cups can increase these costs, making it important for buyers to consider their specific needs when evaluating suppliers.

-

Quality Control (QC): Implementing strict QC measures ensures product consistency and quality, which can add to costs. However, this investment can save buyers money in the long run by reducing returns and ensuring customer satisfaction.

-

Logistics: Shipping costs, including freight and handling, are essential to factor in, especially for international buyers. The chosen Incoterms will dictate who bears these costs and can significantly affect the overall pricing.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary widely based on the supplier’s market position and competitive landscape.

What Influences Pricing for 3/4 Cup Measuring Cups?

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding a supplier’s MOQ can help in negotiating better terms and achieving cost efficiencies.

-

Specifications and Customization: Custom features, such as unique designs or branding, can increase costs. Buyers should weigh the necessity of these customizations against the potential benefits.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., food safety standards) often lead to increased costs. Buyers should assess their target market’s requirements to determine the necessary level of quality.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a track record of quality may command higher prices but can offer better service and reliability.

-

Incoterms: The choice of Incoterms impacts logistics and pricing. For example, Ex Works (EXW) may offer lower upfront costs, but the buyer assumes more risk and responsibility for shipping.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiate with Multiple Suppliers: Engaging multiple suppliers can create competitive tension and help secure better pricing. Don’t hesitate to ask for quotes and compare them carefully.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, evaluate ongoing costs such as shipping, maintenance, and potential replacements. A lower upfront cost may not always mean better value.

-

Understand Pricing Nuances for International Markets: Be aware of currency fluctuations, local tariffs, and taxes that may impact the total cost. Engaging a local expert can help navigate these complexities.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing over time, as trust and reliability are fostered.

Disclaimer for Indicative Prices

The prices provided in this analysis are indicative and may vary based on the supplier, market conditions, and specific buyer requirements. It is essential to conduct thorough due diligence and obtain updated quotes from suppliers to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing 3 4 cup measuring cup With Other Solutions

Exploring Alternatives to the 3/4 Cup Measuring Cup: What Are Your Options?

When it comes to precise ingredient measurement in commercial kitchens, the 3/4 cup measuring cup is a staple tool. However, there are alternative solutions that can also serve the purpose of accurate measurement in foodservice operations. Understanding these alternatives can help B2B buyers make informed decisions based on their specific operational needs and constraints.

| Comparison Aspect | 3/4 Cup Measuring Cup | Digital Kitchen Scale | Portion Control Dispenser |

|---|---|---|---|

| Performance | Accurate for liquid and dry ingredients | Highly precise, often to the gram | Consistent portioning for bulk ingredients |

| Cost | Typically low-cost (around $2.38) | Moderate investment ($20-$100) | Higher initial cost ($50-$200) |

| Ease of Implementation | Simple, ready-to-use tool | Requires calibration and setup | Requires training for optimal use |

| Maintenance | Dishwasher-safe, easy to clean | Needs battery replacement, occasional calibration | Requires regular cleaning and maintenance |

| Best Use Case | Ideal for small-batch cooking | Best for precise measurements in bulk | Suitable for high-volume dispensing in busy kitchens |

What Are the Pros and Cons of Each Alternative?

Digital Kitchen Scale

Digital kitchen scales offer a high level of precision, making them ideal for recipes that require exact measurements. They can measure both liquid and dry ingredients, often down to the gram. However, they come with a moderate cost and may require initial setup and calibration. Maintenance involves battery changes and occasional recalibration to ensure accuracy. This tool is best suited for operations where precision is critical, such as baking or ingredient formulation.

Illustrative image related to 3 4 cup measuring cup

Portion Control Dispenser

Portion control dispensers are designed for high-volume foodservice operations, providing consistent and accurate portioning of bulk ingredients. They are particularly useful in environments where speed and efficiency are paramount, such as busy restaurants or catering services. However, they tend to have a higher initial investment and may require training for staff to use effectively. Regular cleaning and maintenance are necessary to ensure hygiene and operational efficiency. This solution is best for kitchens that prioritize speed and portion consistency over the flexibility of measuring various ingredient types.

How Can B2B Buyers Choose the Right Solution?

When selecting the right measuring solution, B2B buyers should consider their specific operational needs, including the types of ingredients they commonly use, the volume of food prepared, and the level of precision required. The 3/4 cup measuring cup remains an excellent choice for straightforward tasks and small-batch cooking due to its low cost and ease of use. For operations that demand higher precision, digital kitchen scales may be the preferred option, while portion control dispensers are ideal for environments that prioritize speed and consistency in ingredient dispensing. Ultimately, understanding the unique requirements of the kitchen environment will guide buyers toward the most suitable measuring solution.

Essential Technical Properties and Trade Terminology for 3 4 cup measuring cup

What Are the Key Technical Properties of a 3/4 Cup Measuring Cup?

Understanding the critical specifications of a 3/4 cup measuring cup can greatly influence purchasing decisions for B2B buyers, especially in the foodservice industry. Here are several essential properties to consider:

1. Material Grade

The most common material for measuring cups is stainless steel due to its durability and resistance to corrosion. High-grade stainless steel (such as 304 or 316) is often preferred in commercial kitchens for its longevity and ability to withstand high temperatures and frequent washing. Choosing the right material ensures that the measuring cup can endure the rigors of daily use in a professional kitchen setting.

Illustrative image related to 3 4 cup measuring cup

2. Capacity and Tolerance

The capacity of the measuring cup is a fundamental specification; in this case, it accurately measures 3/4 cup. Tolerance refers to the allowable variation in measurement, which is critical for maintaining recipe accuracy. A high-precision measuring cup should have a tolerance of ±1% to ensure consistency in portion control, which is vital for food quality and cost management.

3. Handle Design

The handle design, often a wire loop in commercial-grade measuring cups, is essential for ergonomic handling. A sturdy, well-designed handle allows for a secure grip, reducing the risk of spills and enhancing user efficiency. This feature is particularly important in high-volume kitchens where speed and safety are paramount.

4. Weight

The weight of the measuring cup can affect its usability. A lightweight design (typically around 0.22 lbs for a 3/4 cup measuring cup) is easier to handle and facilitates faster workflow. However, it should still be substantial enough to prevent tipping when filled with ingredients. Balancing weight and stability is crucial for operational efficiency.

Illustrative image related to 3 4 cup measuring cup

5. Cleaning and Maintenance

A measuring cup that is dishwasher-safe and resistant to staining and tarnishing simplifies maintenance. Foodservice environments require strict sanitation standards, and easy-to-clean materials contribute to compliance and efficiency. This property directly impacts the time and labor costs associated with kitchen operations.

What Are Common Trade Terms Related to Measuring Cups?

Familiarity with industry terminology is crucial for B2B buyers to navigate purchasing processes effectively. Here are several common terms relevant to measuring cups:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For measuring cups, this term may apply when sourcing products from manufacturers who specialize in kitchen tools. Understanding OEM relationships can help buyers identify reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest order size a supplier will accept. For businesses, knowing the MOQ is essential for budgeting and inventory management. In the context of measuring cups, suppliers may set MOQs to ensure production efficiency and cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. When purchasing measuring cups, an RFQ can help businesses compare pricing, terms, and specifications from multiple vendors, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers, especially when importing measuring cups from overseas, as they clarify who bears the costs and risks during shipping.

5. Lead Time

Lead time is the period from placing an order to receiving the product. For businesses, knowing the lead time for measuring cups is critical for planning inventory and ensuring that kitchen operations run smoothly without interruptions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 3/4 cup measuring cups, ensuring that they select the most suitable products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 3 4 cup measuring cup Sector

What Are the Current Market Dynamics for 3/4 Cup Measuring Cups?

The global market for 3/4 cup measuring cups is witnessing significant growth driven by the increasing demand for precision in food preparation across various sectors, including restaurants, catering services, and home kitchens. This trend is particularly notable in emerging markets in Africa, South America, the Middle East, and Europe, where the culinary industry is expanding rapidly. B2B buyers in these regions are increasingly seeking durable and reliable measuring tools that can withstand high-volume usage.

Key trends influencing this market include the integration of technology in sourcing and procurement processes. Suppliers are adopting e-commerce platforms and digital supply chain management tools, allowing international buyers to access a wider range of products and negotiate better prices. Moreover, the demand for stainless steel measuring cups, like the American Metalcraft MCW75, is on the rise due to their durability and ease of cleaning, which are essential for maintaining hygiene in busy kitchen environments.

Additionally, sustainability is becoming a central theme in sourcing decisions. Buyers are now more focused on procuring products from suppliers who prioritize eco-friendly practices, thereby influencing their purchasing decisions. As the market evolves, understanding these dynamics will be crucial for B2B buyers looking to make informed sourcing choices.

How Important Is Sustainability and Ethical Sourcing for 3/4 Cup Measuring Cups?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the 3/4 cup measuring cup sector. The environmental impact of kitchen tools is under scrutiny, with a growing demand for products that are both durable and made from sustainable materials. Stainless steel measuring cups, for instance, offer a longer lifespan compared to plastic alternatives, reducing waste and promoting a more sustainable approach to kitchenware.

Moreover, ethical supply chains are essential for building brand trust and loyalty among consumers. Buyers are encouraged to partner with manufacturers that adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 (Environmental Management) and the use of recycled materials can serve as indicators of a supplier’s commitment to sustainability.

B2B buyers should actively seek out suppliers who are transparent about their sourcing practices and can provide documentation on the sustainability of their products. This not only aligns with the growing consumer demand for ethical products but also helps businesses comply with increasingly stringent regulations on environmental impact.

What Is the Historical Context of 3/4 Cup Measuring Cups in B2B Markets?

The evolution of measuring cups, particularly the 3/4 cup variant, reflects broader changes in culinary practices and food service efficiency. Historically, measuring cups have been essential tools in both domestic and professional kitchens, enabling chefs to maintain consistency in recipes. As the food service industry has grown, so too has the demand for measuring tools that can withstand the rigors of commercial use.

The introduction of stainless steel as a primary material for measuring cups marked a significant advancement in durability and hygiene. Over the years, manufacturers have focused on enhancing the design and functionality of these tools, leading to the development of ergonomic features like wire loop handles that facilitate easier pouring and cleaning. This historical context underscores the importance of innovation in meeting the needs of modern culinary professionals while ensuring that products remain compliant with safety and quality standards.

Understanding this evolution can provide B2B buyers with insights into the reliability and performance of measuring cups available today, guiding them in making informed purchasing decisions that align with their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 4 cup measuring cup

-

How do I ensure accurate measurements with a 3/4 cup measuring cup?

To ensure accurate measurements, always use the measuring cup on a flat, level surface. Fill the cup to the brim without packing or pressing the ingredients down. For liquid measurements, check the meniscus (the curve at the liquid’s surface) at eye level to avoid parallax errors. Regularly calibrate your measuring tools against known standards to maintain precision, especially in professional kitchens where consistency is key. -

What is the best material for a 3/4 cup measuring cup in a commercial kitchen?

Stainless steel is the best material for a 3/4 cup measuring cup in commercial kitchens due to its durability, corrosion resistance, and ease of cleaning. Stainless steel can withstand high temperatures and frequent dishwasher cycles, making it ideal for busy environments. Additionally, it does not absorb odors or flavors, ensuring that your measurements remain accurate over time. -

What customization options are available for 3/4 cup measuring cups?

Many suppliers offer customization options for 3/4 cup measuring cups, including branding, color choices, and specific measurement markings. You can request unique designs tailored to your kitchen’s needs or your brand’s identity. It’s advisable to discuss these options with potential suppliers during the initial sourcing phase to ensure they can meet your specific requirements. -

What are the minimum order quantities (MOQs) for 3/4 cup measuring cups?

Minimum order quantities (MOQs) for 3/4 cup measuring cups can vary significantly depending on the supplier and the level of customization required. Typically, MOQs can range from 100 to 1,000 units. It’s essential to communicate your needs clearly to suppliers and negotiate MOQs that align with your purchasing strategy while ensuring you can maintain adequate stock levels. -

What payment terms should I expect when sourcing measuring cups internationally?

Payment terms for international orders can vary based on supplier policies and your negotiation outcomes. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon shipping. Some suppliers may accept letters of credit or payment through secure platforms like PayPal. Always ensure that you have a clear agreement on payment terms before finalizing orders to avoid any misunderstandings. -

How can I vet suppliers for 3/4 cup measuring cups?

To vet suppliers, start by checking their reputation through reviews and testimonials from previous clients. Request samples to evaluate product quality and ensure they meet your specifications. Investigate their production capabilities, compliance with international standards, and shipping reliability. Engaging in direct communication and asking for references can also provide insights into their reliability and professionalism. -

What quality assurance measures should I consider for measuring cups?

Quality assurance measures for measuring cups should include checking for consistent measurement accuracy, durability under frequent use, and compliance with food safety standards. Request certifications that demonstrate adherence to international quality standards. It’s also beneficial to establish a quality control process during production and before shipment to ensure that all products meet your expectations. -

What logistics considerations should I keep in mind when importing measuring cups?

When importing measuring cups, consider shipping costs, lead times, and customs regulations in your country. Work with logistics providers experienced in international trade to navigate potential challenges. Ensure that you have the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in storage solutions upon arrival, especially if dealing with bulk orders.

Top 2 3 4 Cup Measuring Cup Manufacturers & Suppliers List

1. American Metalcraft – MCW75 3/4 Cup Measuring Cup

Domain: restaurantsupply.com

Registered: 1998 (27 years)

Introduction: American Metalcraft MCW75 3/4 Cup Measuring Cup with Wire Loop Handle, made of stainless steel.

2. WikiHow – Measuring ¾ Cup

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: To measure ¾ cup, you can use the following methods: 1. Measure out 12 tablespoons or 36 teaspoons if only measuring spoons are available. 2. Use household containers that hold 6 fl oz (180 mL), such as small mason jars, food canisters, or leftover cans. 3. For dry ingredients, use 1/4 and 1/2 measuring cups to combine for the total. 4. A kitchen scale can provide precise weights for ingredients, …

Strategic Sourcing Conclusion and Outlook for 3 4 cup measuring cup

In conclusion, the strategic sourcing of 3/4 cup measuring cups, particularly the robust American Metalcraft MCW75 model, presents significant advantages for B2B buyers in foodservice sectors across Africa, South America, the Middle East, and Europe. These measuring cups are not merely tools; they embody precision, durability, and efficiency in high-volume kitchen environments. The stainless steel construction ensures longevity and sanitation, while the ergonomic design enhances operational workflows, making them essential for consistent recipe execution and portion control.

B2B buyers should prioritize sourcing products that not only meet their immediate needs but also align with their long-term operational goals. Investing in high-quality measuring cups like the MCW75 can lead to improved kitchen efficiency, reduced waste, and ultimately, enhanced customer satisfaction.

As the global foodservice industry continues to evolve, now is the opportune moment to evaluate and upgrade your kitchen tools. By aligning with suppliers who offer durable and reliable measuring solutions, businesses can position themselves for success in an increasingly competitive market. Take action today and ensure your operations are equipped with the best tools to thrive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.